battery capacity DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 39 of 1502

0

- 21

LUBRICATION

AND

MAINTENANCE

• SERVICE INFORMATION

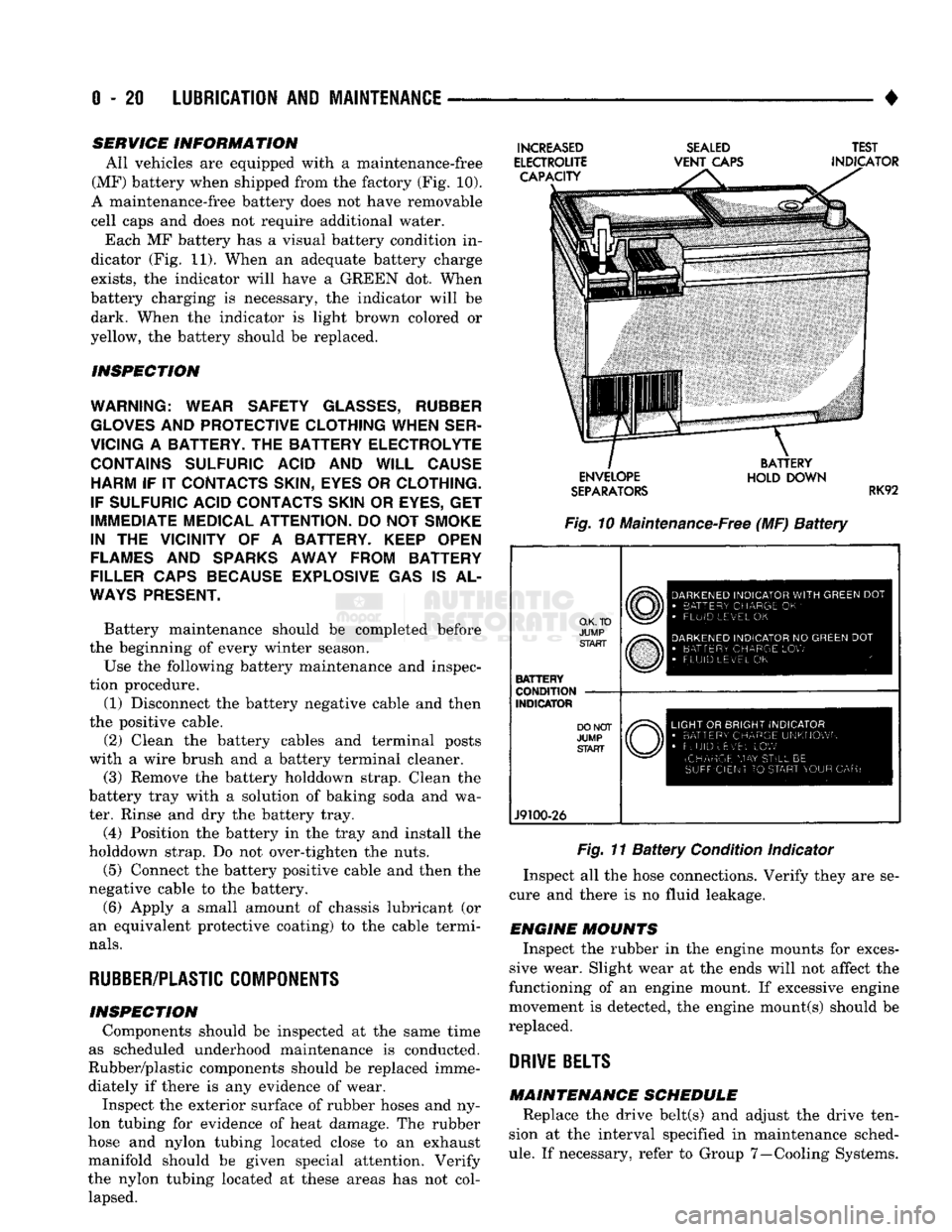

All vehicles are equipped with a maintenance-free

(MF) battery when shipped from the factory (Fig. 10).

A maintenance-free battery does not have removable

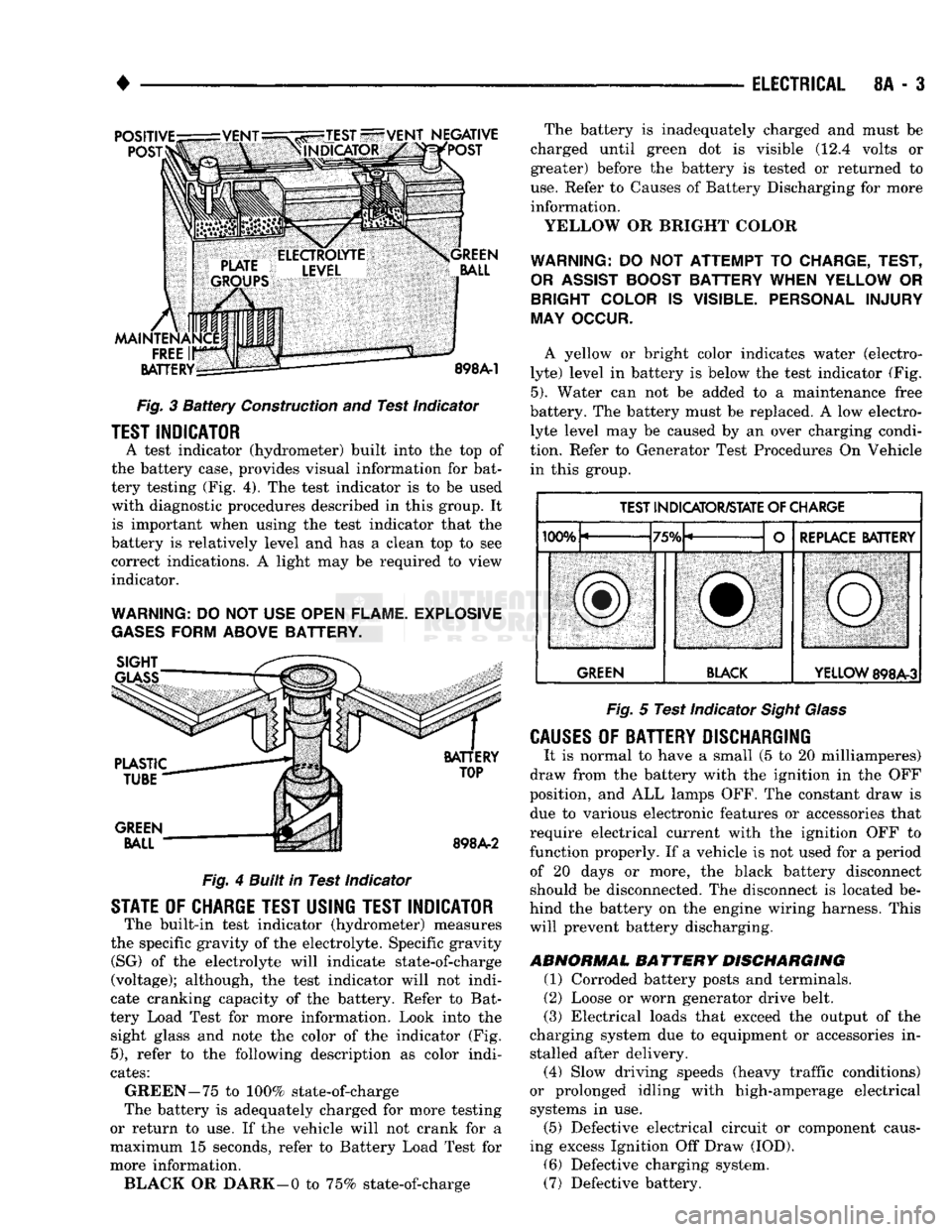

cell caps and does not require additional water. Each MF battery has a visual battery condition in

dicator (Fig. 11). When an adequate battery charge

exists,

the indicator will have a GREEN dot. When

battery charging is necessary, the indicator will be dark. When the indicator is light brown colored or

yellow, the battery should be replaced.

INSPECTION

WARNING; WEAR SAFETY

GLASSES,

RUBBER

GLOVES

AND

PROTECTIVE CLOTHING WHEN SER

VICING

A

BATTERY.

THE

BATTERY ELECTROLYTE CONTAINS SULFURIC ACID

AND

WILL CAUSE HARM

IF IT

CONTACTS SKIN, EYES

OR

CLOTHING.

IF SULFURIC ACID CONTACTS SKIN

OR

EYES,

GET

IMMEDIATE MEDICAL ATTENTION.

DO

NOT

SMOKE

IN

THE

VICINITY

OF A

BATTERY. KEEP OPEN

FLAMES

AND

SPARKS AWAY FROM BATTERY

FILLER CAPS BECAUSE EXPLOSIVE

GAS IS AL

WAYS

PRESENT.

Battery maintenance should be completed before

the beginning of every winter season.

Use the following battery maintenance and inspec

tion procedure. (1) Disconnect the battery negative cable and then

the positive cable.

(2) Clean the battery cables and terminal posts

with a wire brush and a battery terminal cleaner. (3) Remove the battery holddown strap. Clean the

battery tray with a solution of baking soda and wa

ter. Rinse and dry the battery tray.

(4) Position the battery in the tray and install the

holddown strap. Do not over-tighten the nuts.

(5) Connect the battery positive cable and then the

negative cable to the battery.

(6) Apply a small amount of chassis lubricant (or

an equivalent protective coating) to the cable termi

nals.

RUBBER/PLASTIC

COMPONENTS

INSPECTION Components should be inspected at the same time

as scheduled underhood maintenance is conducted.

Rubber/plastic components should be replaced imme diately if there is any evidence of wear. Inspect the exterior surface of rubber hoses and ny

lon tubing for evidence of heat damage. The rubber

hose and nylon tubing located close to an exhaust

manifold should be given special attention. Verify

the nylon tubing located at these areas has not col lapsed.

INCREASED

ELECTROUTE CAPACITY

SEALED

VENT

CAPS TEST

INDICATOR ENVELOPE

SEPARATORS

BATTERY

HOLD DOWN

RK92

Fig. 10 Maintenance-Free (MF)

Battery

O.K. TO

JUMP START

BATTERY

CONDITION

INDICATOR

J9100-26

DARKENED

INDICATOR

WITH

GREEN

DOT

•

BATTERY CHARGE

OK '

•

FLUID LEVEL

OK

DARKENED

INDICATOR

NO

GREEN

DOT

•

BATTERY CHARGE

LOW

FLUID LEVEL

OK

LIGHT

OR

BRIGHT INDICATOR

•

BATTERY CHARGE UNKNOWN

•

FLUID uEv'EL

LOW

(CHARGE

MAY

STILL

BE

SUFFICIENT

TO

START YOUR

CAR)

Fig. 11

Battery

Condition Indicator

Inspect all the hose connections. Verify they are se

cure and there is no fluid leakage.

ENGINE MOUNTS Inspect the rubber in the engine mounts for exces

sive wear. Slight wear at the ends will not affect the

functioning of an engine mount. If excessive engine

movement is detected, the engine mount(s) should be

replaced.

DRIVE

BELTS

MAINTENANCE SCHEDULE Replace the drive belt(s) and adjust the drive ten

sion at the interval specified in maintenance sched

ule.

If necessary, refer to Group 7—Cooling Systems.

Page 324 of 1502

•

ELECTRICAL

8A - 3

Fig.

3

Battery

Construction

and

Test Indicator

TEST INDICATOR

A test indicator (hydrometer) built into

the top of

the battery case, provides visual information

for

bat

tery testing (Fig.

4). The

test indicator

is to be

used with diagnostic procedures described

in

this group.

It

is important when using

the

test indicator that

the

battery

is

relatively level

and has a

clean

top to see

correct indications.

A

light

may be

required

to

view

indicator.

WARNING:

DO

NOT USE

OPEN FLAME. EXPLOSIVE

GASES

FORM ABOVE BATTERY.

Fig.

4

Built in Test Indicator

STATE

OF

CHARGE TEST USING TEST INDICATOR

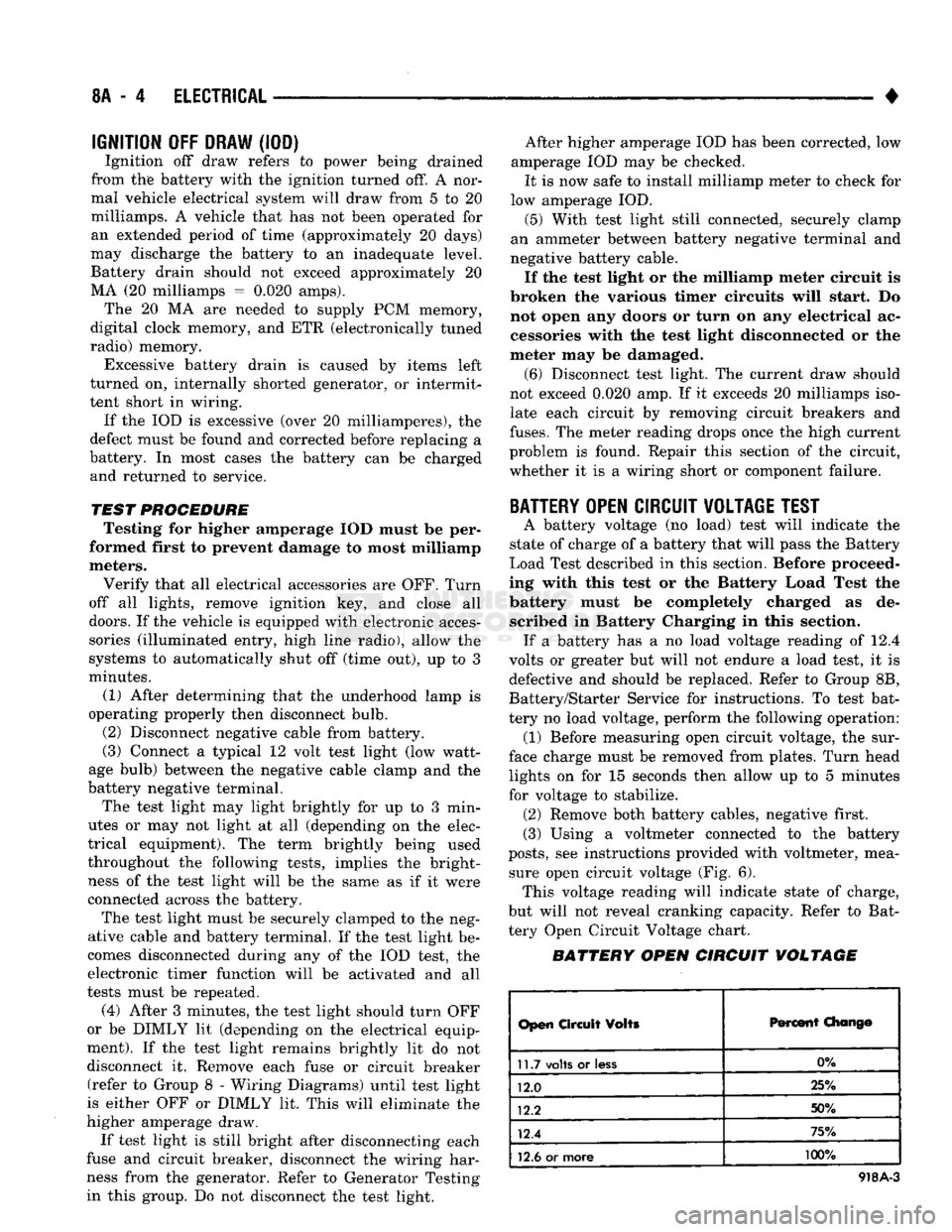

The built-in test indicator (hydrometer) measures

the specific gravity

of

the electrolyte. Specific gravity (SG)

of the

electrolyte will indicate state-of-charge

(voltage); although,

the

test indicator will

not

indi

cate cranking capacity

of the

battery. Refer

to

Bat

tery Load Test

for

more information. Look into

the

sight glass

and

note

the

color

of the

indicator

(Fig.

5),

refer

to the

following description

as

color indi

cates:

GREEN-75

to

100% state-of-charge

The battery

is

adequately charged

for

more testing

or return

to use. If the

vehicle will

not

crank

for a

maximum

15

seconds, refer

to

Battery Load Test

for

more information. BLACK

OR

DARK—0

to

75% state-of-charge The battery

is

inadequately charged

and

must

be

charged until green

dot is

visible

(12.4

volts

or

greater) before

the

battery

is

tested

or

returned

to

use.

Refer

to

Causes

of

Battery Discharging

for

more information.

YELLOW

OR

BRIGHT COLOR

WARNING:

DO NOT

ATTEMPT

TO

CHARGE, TEST,

OR

ASSIST

BOOST BATTERY WHEN YELLOW

OR

BRIGHT COLOR

IS

VISIBLE. PERSONAL INJURY

MAY OCCUR.

A yellow

or

bright color indicates water (electro

lyte) level

in

battery

is

below

the

test indicator

(Fig.

5).

Water

can not be

added

to a

maintenance free

battery.

The

battery must

be

replaced.

A low

electro lyte level

may be

caused

by an

over charging condi

tion. Refer

to

Generator Test Procedures

On

Vehicle in this group.

TEST INDICATOR/STATE

OF

CHARGE

IfVW,

"TCfV

REPLACE BATTERY

lUUTu

/Otu L

f

REPLACE BATTERY

SBl

ill,

iMMiMMMMSMM^MM

GREEN BLACK

YELLOW

898A-3

Fig.

5

Test Indicator

Sight Glass

CAUSES

OF

BATTERY DISCHARGING

It

is

normal

to

have

a

small

(5 to 20

milliamperes)

draw from

the

battery with

the

ignition

in the OFF

position,

and ALL

lamps OFF.

The

constant draw

is

due

to

various electronic features

or

accessories that

require electrical current with

the

ignition

OFF to

function properly.

If a

vehicle

is not

used

for a

period of

20

days

or

more,

the

black battery disconnect

should

be

disconnected.

The

disconnect

is

located

be

hind

the

battery

on the

engine wiring harness. This will prevent battery discharging.

ABNORMAL

BATTERY

DISCHARGING

(1) Corroded battery posts

and

terminals.

(2) Loose

or

worn generator drive belt.

(3) Electrical loads that exceed

the

output

of the

charging system

due to

equipment

or

accessories

in

stalled after delivery. (4) Slow driving speeds (heavy traffic conditions)

or prolonged idling with high-amperage electrical systems

in use.

(5) Defective electrical circuit

or

component caus

ing excess Ignition

Off

Draw (IOD).

(6) Defective charging system.

(7) Defective battery.

Page 325 of 1502

8A

- 4

ELECTRICAL

•

IGNITION

OFF

DRAW

(IOD)

Ignition off draw refers to power being drained

from the battery with the ignition turned off. A nor

mal vehicle electrical system will draw from 5 to 20

milliamps. A vehicle that has not been operated for

an extended period of time (approximately 20 days)

may discharge the battery to an inadequate level.

Battery drain should not exceed approximately 20

MA (20 milliamps = 0.020 amps). The 20 MA are needed to supply PCM memory,

digital clock memory, and ETR (electronically tuned

radio) memory. Excessive battery drain is caused by items left

turned on, internally shorted generator, or intermit

tent short in wiring.

If the IOD is excessive (over 20 milliamperes), the

defect must be found and corrected before replacing a

battery. In most cases the battery can be charged and returned to service.

TEST PROCEDURE Testing for higher amperage IOD must be per

formed first to prevent damage to most milliamp

meters.

Verify that all electrical accessories are OFF. Turn

off all lights, remove ignition key, and close all

doors.

If the vehicle is equipped with electronic acces

sories (illuminated entry, high line radio), allow the

systems to automatically shut off (time out), up to 3

minutes.

(1) After determining that the underhood lamp is

operating properly then disconnect bulb. (2) Disconnect negative cable from battery.

(3) Connect a typical 12 volt test light (low watt

age bulb) between the negative cable clamp and the

battery negative terminal. The test light may light brightly for up to 3 min

utes or may not light at all (depending on the elec

trical equipment). The term brightly being used

throughout the following tests, implies the bright ness of the test light will be the same as if it were

connected across the battery.

The test light must be securely clamped to the neg

ative cable and battery terminal. If the test light be

comes disconnected during any of the IOD test, the electronic timer function will be activated and all

tests must be repeated.

(4) After 3 minutes, the test light should turn OFF

or be DIMLY lit (depending on the electrical equip

ment).

If the test light remains brightly lit do not

disconnect it. Remove each fuse or circuit breaker (refer to Group 8 - Wiring Diagrams) until test light

is either OFF or DIMLY lit. This will eliminate the

higher amperage draw.

If test light is still bright after disconnecting each

fuse and circuit breaker, disconnect the wiring har ness from the generator. Refer to Generator Testing

in this group. Do not disconnect the test light. After higher amperage IOD has been corrected, low

amperage IOD may be checked.

It is now safe to install milliamp meter to check for

low amperage IOD.

(5) With test light still connected, securely clamp

an ammeter between battery negative terminal and

negative battery cable.

If the test light or the milliamp meter circuit is

broken the various timer circuits will start. Do

not open any doors or turn on any electrical ac cessories with the test light disconnected or the

meter may be damaged.

(6) Disconnect test light. The current draw should

not exceed 0.020 amp. If it exceeds 20 milliamps iso

late each circuit by removing circuit breakers and

fuses.

The meter reading drops once the high current

problem is found. Repair this section of the circuit,

whether it is a wiring short or component failure.

BATTERY

OPEN CIRCUIT VOLTAGE TEST

A battery voltage (no load) test will indicate the

state of charge of a battery that will pass the Battery

Load Test described in this section. Before proceed

ing with this test or the Battery Load Test the

battery must be completely charged as de scribed in Battery Charging in this section. If a battery has a no load voltage reading of 12.4

volts or greater but will not endure a load test, it is

defective and should be replaced. Refer to Group 8B,

Battery/Starter Service for instructions. To test bat

tery no load voltage, perform the following operation: (1) Before measuring open circuit voltage, the sur

face charge must be removed from plates. Turn head lights on for 15 seconds then allow up to 5 minutes

for voltage to stabilize. (2) Remove both battery cables, negative first.

(3) Using a voltmeter connected to the battery

posts,

see instructions provided with voltmeter, mea sure open circuit voltage (Fig. 6). This voltage reading will indicate state of charge,

but will not reveal cranking capacity. Refer to Bat

tery Open Circuit Voltage chart.

BATTERY OPEN CIRCUIT VOLTAGE

Open

Circuit

Volts

Percent

Chang©

11.7

volts

or

less

0%

12.0 25%

12.2 50%

12.4 75%

12.6

or more 100%

918A-3

Page 327 of 1502

8A

- 6

ELECTRICAL

•

Fig.

10

Load

50%

Cold

Crank

Rating Note Voltage

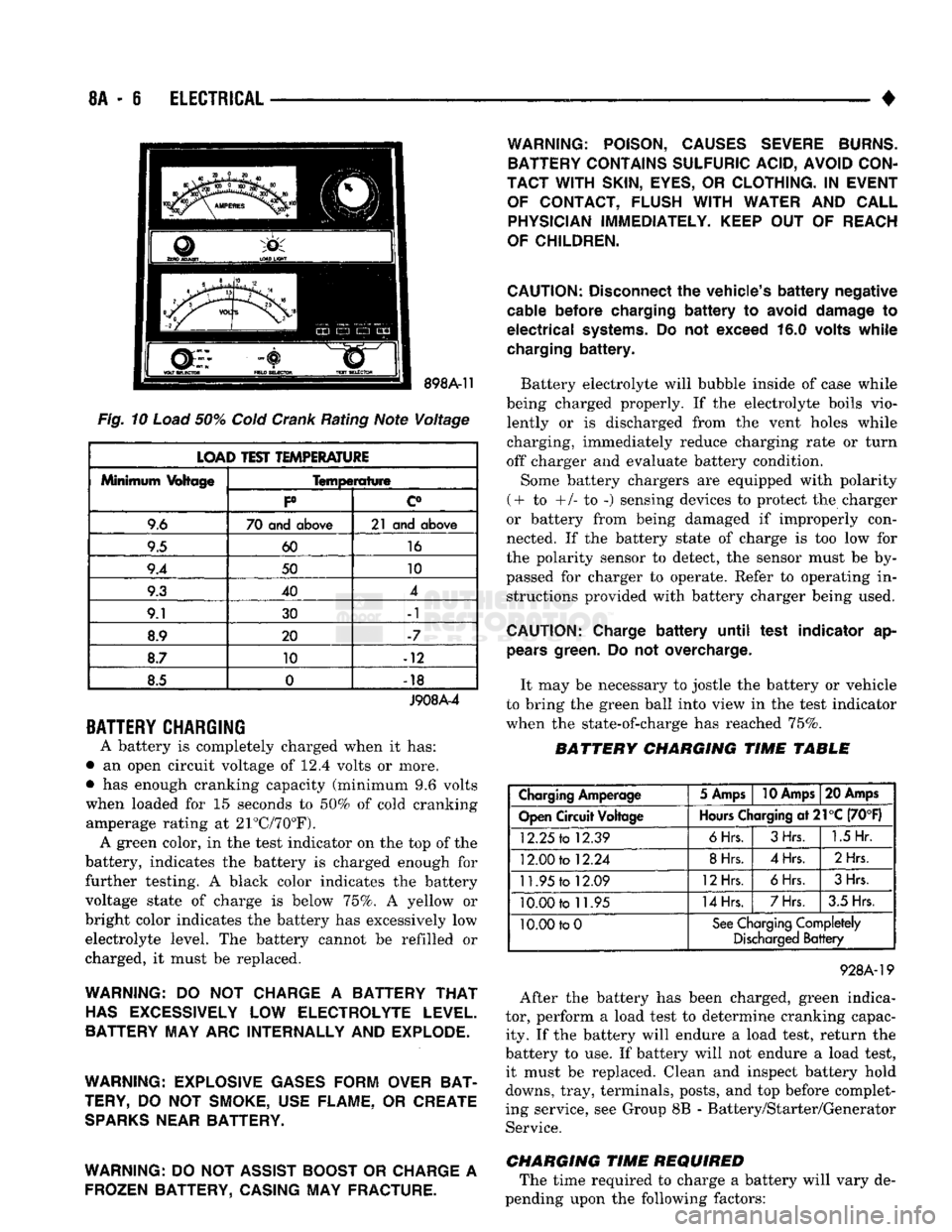

LOAD TEST TEMPERATURE

Minimum

Voltage

Temperature

Minimum

Voltage

P c°

9.6 70 and

above

21 and

above

9.5 60

16

9.4 50 10

9.3 40 4

9.1 30 -1

8.9 20 -7

8.7 10 -12

8.5 0

•

18

J908A-4

BATTERY

CHARGING

A battery is completely charged when it has:

• an open circuit voltage of 12.4 volts or more.

• has enough cranking capacity (minimum 9.6 volts

when loaded for 15 seconds to 50% of cold cranking amperage rating at 21°C/70°F). A green color, in the test indicator on the top of the

battery, indicates the battery is charged enough for

further testing. A black color indicates the battery

voltage state of charge is below 75%. A yellow or

bright color indicates the battery has excessively low electrolyte level. The battery cannot be refilled or

charged, it must be replaced.

WARNING:

DO NOT

CHARGE

A

BATTERY

THAT

HAS

EXCESSIVELY

LOW

ELECTROLYTE LEVEL.

BATTERY MAY ARC INTERNALLY AND EXPLODE.

WARNING: EXPLOSIVE GASES FORM OVER BAT

TERY,

DO NOT

SMOKE, USE FLAME,

OR

CREATE

SPARKS

NEAR BATTERY.

WARNING:

DO

NOT ASSIST BOOST

OR

CHARGE

A

FROZEN BATTERY, CASING MAY FRACTURE. WARNING: POISON, CAUSES SEVERE BURNS.

BATTERY CONTAINS SULFURIC ACID, AVOID CON

TACT WITH

SKIN,

EYES,

OR

CLOTHING.

IN

EVENT OF CONTACT, FLUSH

WITH

WATER

AND

CALL PHYSICIAN IMMEDIATELY. KEEP

OUT OF

REACH

OF CHILDREN.

CAUTION:

Disconnect

the

vehicle's

battery

negative

cable

before

charging

battery to

avoid

damage

to

electrical

systems.

Do not

exceed

16.0

volts

while

charging

battery.

Battery electrolyte will bubble inside of case while

being charged properly. If the electrolyte boils vio lently or is discharged from the vent holes while

charging, immediately reduce charging rate or turn

off charger and evaluate battery condition.

Some battery chargers are equipped with polarity

(+ to +/- to -) sensing devices to protect the charger

or battery from being damaged if improperly con

nected. If the battery state of charge is too low for

the polarity sensor to detect, the sensor must be by

passed for charger to operate. Refer to operating in structions provided with battery charger being used.

CAUTION:

Charge

battery

until

test

indicator

ap

pears

green.

Do not

overcharge.

It may be necessary to jostle the battery or vehicle

to bring the green ball into view in the test indicator

when the state-of-charge has reached 75%.

BATTERY CHARGING TIME TABLE

Charging

Amperage

5 Amps

10 Amps

20 Amps

Open

Circuit

Voltage

Hours

Charging

at21°C

(70°F)

12.25

to

12.39

6Hrs.

3Hrs.

1.5

Hr.

12.00

to

12.24

8Hrs.

4Hrs.

2Hrs

11.95

to

12.09

12Hrs.

6Hrs.

3Hrs.

10.00

to

11.95

14Hrs.

7Hrs.

3.5 Hrs.

10.00 to

0

See

Charging

Completely

Discharged

Battery

928A-19

After the battery has been charged, green indica

tor, perform a load test to determine cranking capac ity. If the battery will endure a load test, return the

battery to use. If battery will not endure a load test, it must be replaced. Clean and inspect battery hold

downs, tray, terminals, posts, and top before complet

ing service, see Group 8B - Battery/Starter/Generator Service.

CHARGING TIME REQUIRED The time required to charge a battery will vary de

pending upon the following factors:

Page 328 of 1502

•

ELECTRICAL

8A - 7

(1) Size

of

Battery—

A

completely discharged

large heavy-duty battery requires more than twice

the recharging time

as a

completely discharged small capacity battery.

WARNING: NEVER EXCEED

20

AMPS

WHEN

CHARGING

A

COLD

(-1°C/30°F)

BATTERY,

PER

SONAL

INJURY

MAY RESULT.

(2) Temperature—

A

longer time will

be

needed

to charge

a

battery

at -18°C (0°F)

than

at

27°C

(80°F).

When

a

fast charger

is

connected

to a

cold

battery, current accepted

by

battery will

be

very

low

at first. Then,

in

time,

the

battery will accept

a

higher rate

as

battery warms.

(3) Charger Capacity—

A

charger that supplies

only

5

amperes requires

a

much longer charging

time than

a

charger that supplies

20

amperes.

(4) State

Of

Charge—

A

completely discharged

battery requires more charging time than

a

partially charged battery. Electrolyte

is

nearly pure water

in a

completely discharged battery.

At

first

the

charging

current amperage will

be low. As

acid

is

forced from

the plates, inside

the

battery,

the

current amperate

will rise. Also,

the

specific gravity

of the

electrolyte will rise, bringing

the

green

dot

into view.

CHARGING

COMPLETELY

DISCHARGED

BATTERY

The following procedure should

be

used

to

recharge

a completely discharged battery. Unless procedure

is

properly followed,

a

good battery

may be

needlessly replaced.

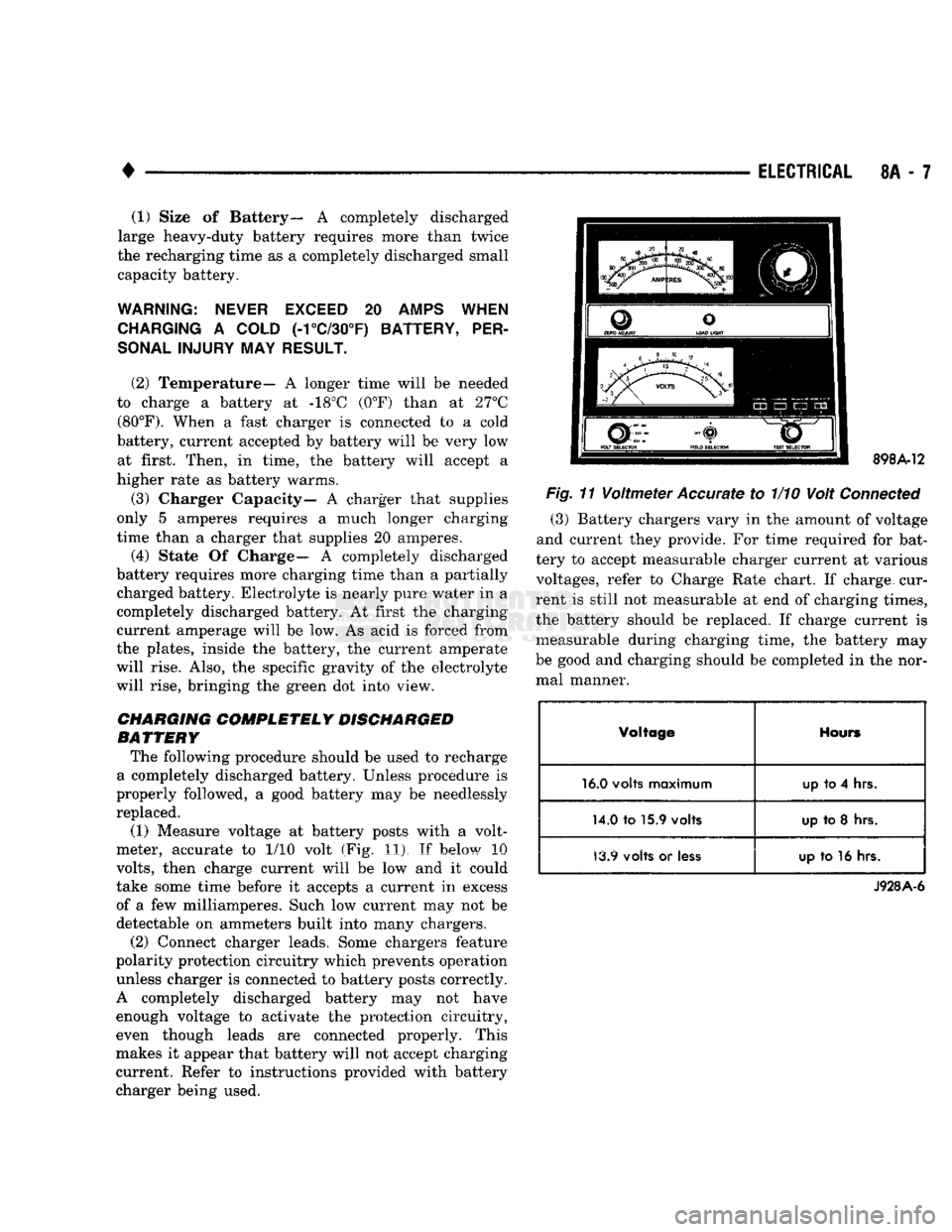

(1) Measure voltage

at

battery posts with

a

volt

meter, accurate

to 1/10

volt

(Fig, 11). If

below

10

volts,

then charge current will

be low and it

could

take some time before

it

accepts

a

current

in

excess of

a few

milliamperes. Such

low

current

may not be

detectable

on

ammeters built into many chargers.

(2) Connect charger leads. Some chargers feature

polarity protection circuitry which prevents operation

unless charger

is

connected

to

battery posts correctly.

A completely discharged battery

may not

have enough voltage

to

activate

the

protection circuitry,

even though leads

are

connected properly. This

makes

it

appear that battery will

not

accept charging

current. Refer

to

instructions provided with battery

charger being used.

VOLT

SELECTOR

FIELD

SELECTOR

TEST

SELECTOR

898A-12

Fig.

11

Voltmeter

Accurate

to 1/10

Volt

Connected

(3) Battery chargers vary

in the

amount

of

voltage

and current they provide.

For

time required

for

bat

tery

to

accept measurable charger current

at

various voltages, refer

to

Charge Rate chart.

If

charge, cur

rent

is

still

not

measurable

at end of

charging times,

the battery should

be

replaced.

If

charge current

is

measurable during charging time,

the

battery

may

be good

and

charging should

be

completed

in the

nor mal manner.

Voltage

Hours

16.0

volts

maximum

up

to

4

hrs.

14.0

to

15.9

volts

up

to 8 hrs

13.9

volts

or

less up

to 16

hrs.

J928A-6

Page 331 of 1502

8A

- 10

ELECTRICAL

•

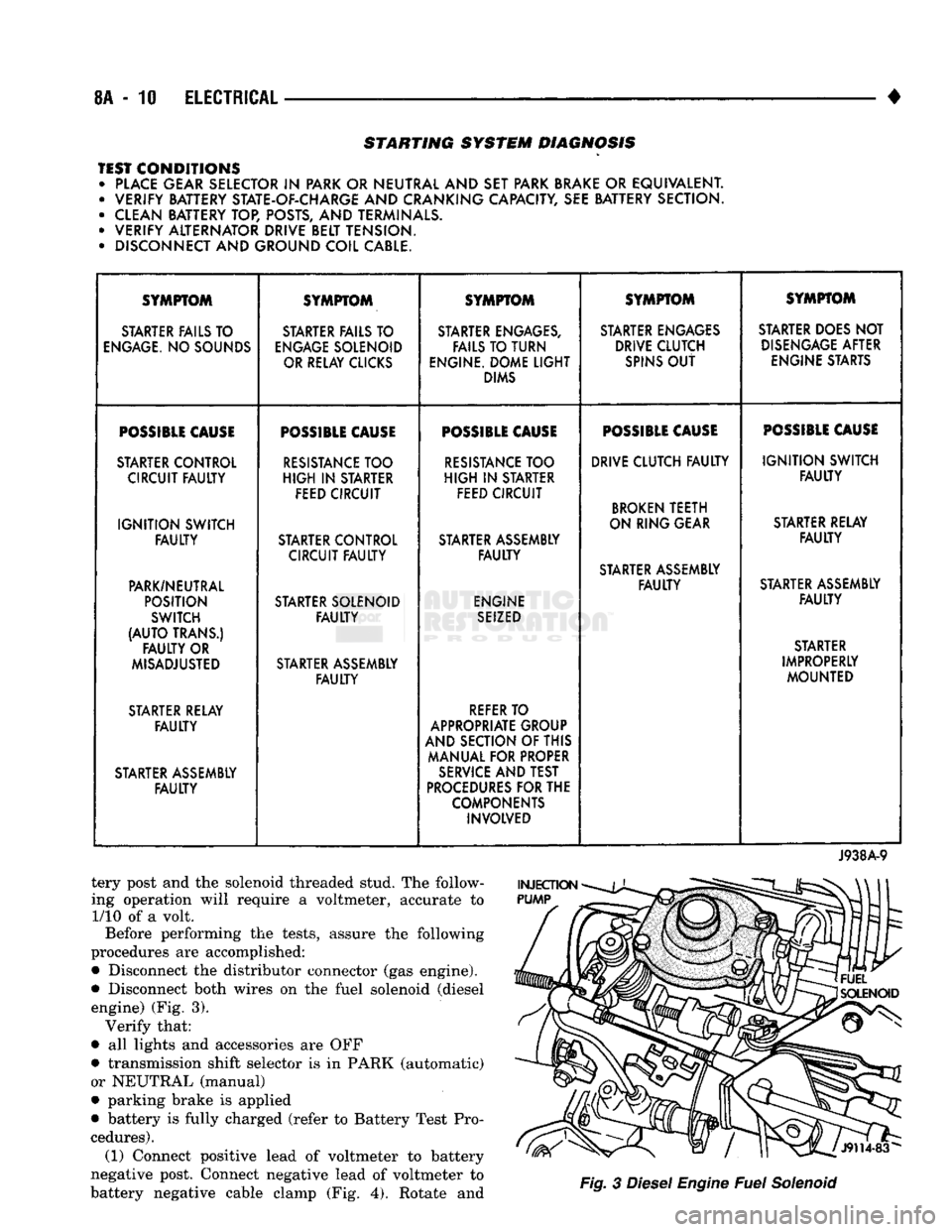

STARTING SYSTEM DIAGNOSIS

TEST CONDITIONS • PLACE GEAR SELECTOR

IN

PARK OR NEUTRAL AND SET PARK BRAKE

OR

EQUIVALENT. • VERIFY BATTERY STATE-OF-CHARGE AND CRANKING CAPACITY, SEE BATTERY SECTION.

• CLEAN BATTERY TOP, POSTS, AND TERMINALS.

• VERIFY ALTERNATOR DRIVE BELT TENSION.

• DISCONNECT AND GROUND COIL CABLE. SYMPTOM

SYMPTOM SYMPTOM SYMPTOM SYMPTOM

STARTER FAILS TO STARTER FAILS TO STARTER ENGAGES, STARTER ENGAGES STARTER DOES NOT

ENGAGE.

NO SOUNDS

ENGAGE

SOLENOID FAILS TO TURN DRIVE CLUTCH

DISENGAGE

AFTER

OR RELAY CLICKS ENGINE. DOME

LIGHT

SPINS

OUT

ENGINE STARTS

DIMS

POSSIBLE

CAUSE

POSSIBLE

CAUSE

POSSIBLE

CAUSE

POSSIBLE

CAUSE

POSSIBLE

CAUSE

STARTER CONTROL

RESISTANCE

TOO

RESISTANCE

TOO DRIVE CLUTCH

FAULTY

IGNITION

SWITCH

CIRCUIT

FAULTY

HIGH

IN

STARTER

HIGH

IN

STARTER

FAULTY

FEED CIRCUIT FEED CIRCUIT

BROKEN

TEETH

IGNITION

SWITCH ON RING GEAR

STARTER RELAY

FAULTY

STARTER CONTROL STARTER ASSEMBLY

FAULTY

CIRCUIT

FAULTY FAULTY

STARTER ASSEMBLY

PARK/NEUTRAL

FAULTY

STARTER ASSEMBLY

POSITION STARTER SOLENOID ENGINE

FAULTY

SWITCH

FAULTY

SEIZED

(AUTO

TRANS.) STARTER

FAULTY

OR STARTER

MISADJUSTED STARTER ASSEMBLY IMPROPERLY

FAULTY

MOUNTED

STARTER RELAY

REFER

TO

FAULTY

APPROPRIATE GROUP

AND SECTION OF THIS

MANUAL FOR PROPER

STARTER ASSEMBLY

SERVICE

AND TEST

FAULTY

PROCEDURES

FOR THE

COMPONENTS INVOLVED

J938A-9

tery post and the solenoid threaded stud. The follow

ing operation will require a voltmeter, accurate to 1/10 of a volt.

Before performing the tests, assure the following

procedures are accomplished:

•

Disconnect the distributor connector (gas engine).

•

Disconnect both wires on the fuel solenoid (diesel engine) (Fig. 3). Verify that:

•

all lights and accessories are OFF

•

transmission shift selector is in PARK (automatic)

or NEUTRAL (manual)

•

parking brake is applied

•

battery is fully charged (refer to Battery Test Pro

cedures). (1) Connect positive lead of voltmeter to battery

negative post. Connect negative lead of voltmeter to

battery negative cable clamp (Fig. 4). Rotate and

Fig.

3

Diesel

Engine

Fuel

Solenoid

Page 339 of 1502

8A

- 18

ELECTRICAL

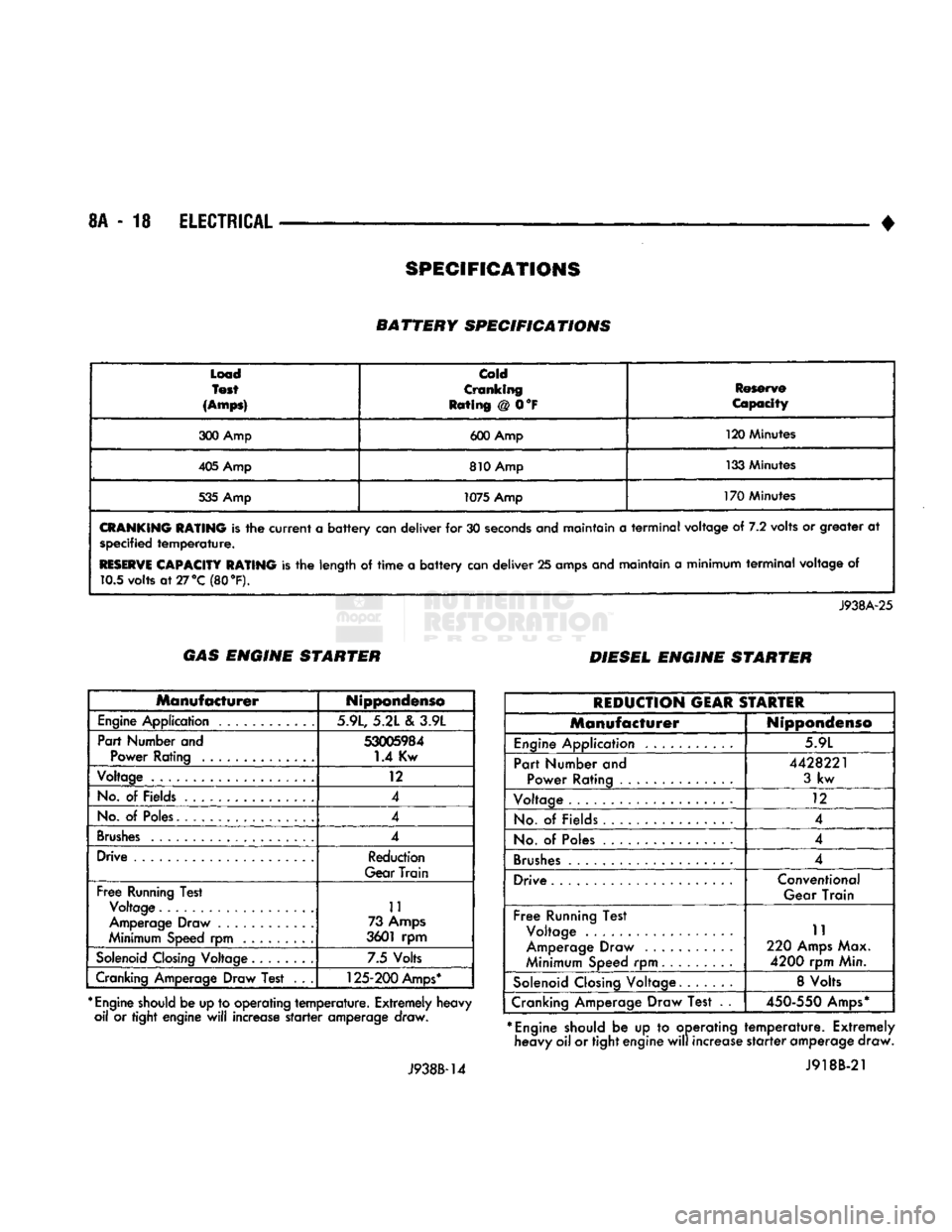

• BATTERY SPECIFICATIONS

Load

Test

(Amps)

Cold

Cranking

Rating @ 0°F Reserve

Capacity

300 Amp 600 Amp 120 Minutes

405 Amp 810 Amp 133 Minutes

535 Amp 1075 Amp 170 Minutes

CRANKING

RATING

is the

current

a

battery

can deliver for 30

seconds

and maintain a

terminal

voltage of 7.2 volts or greater at specified

temperature.

RESERVE

CAPACITY RATING

is the length of

time

a

battery

can deliver 25 amps and maintain a minimum

terminal

voltage of 10.5 volts

at27°C

(80 °F).

J938A-25 GAS ENGINE STARTER

DIESEL ENGINE STARTER

Manufacturer

Nippondenso

Engine

Application 5.9L, 5.21 e\ 3.9L

Part Number and

53005984

Power Rating 1.4 Kw

Voltage 12

No.

of Fields 4

No.

of

Poles.

4

Brushes

4

Drive Reduction

Gear Train

Free

Running Test Voltage 11

Amperage Draw ............ 73

Amps

Minimum Speed rpm 3601 rpm

Solenoid

Closing

Voltage 7.5 Volts

Cranking Amperage Draw Test . . .

125-200

Amps*

*

Engine

should

be up to operating

temperature.

Extremely heavy oil or tight engine

will

increase

starter

amperage draw.

J938B-14

REDUCTION

GEAR

STARTER

Manufacturer

Nippondenso

Engine

Application 5.9L

Part Number and Power Rating ..............

4428221

3

kw

Voltage 12

No.

of Fields 4

No.

of

Poles

4

Brushes

.................... 4

Drive Conventional

Gear Train

Free

Running Test Voltage .

Amperage Draw

Minimum Speed rpm 11

220

Amps

Max.

4200

rpm Min.

Solenoid

Closing

Voltage. 8 Volts

Cranking Amperage Draw Test . .

450-550

Amps*

*

Engine

should be up to operating heavy oil or tight engine

will

increase

temperature.

Extremely

starter

amperage draw. J918B-21

SPECIFICATIONS

Page 350 of 1502

•

BATTERY/STARTER/GENERATOR

SERVICE

8B - 9

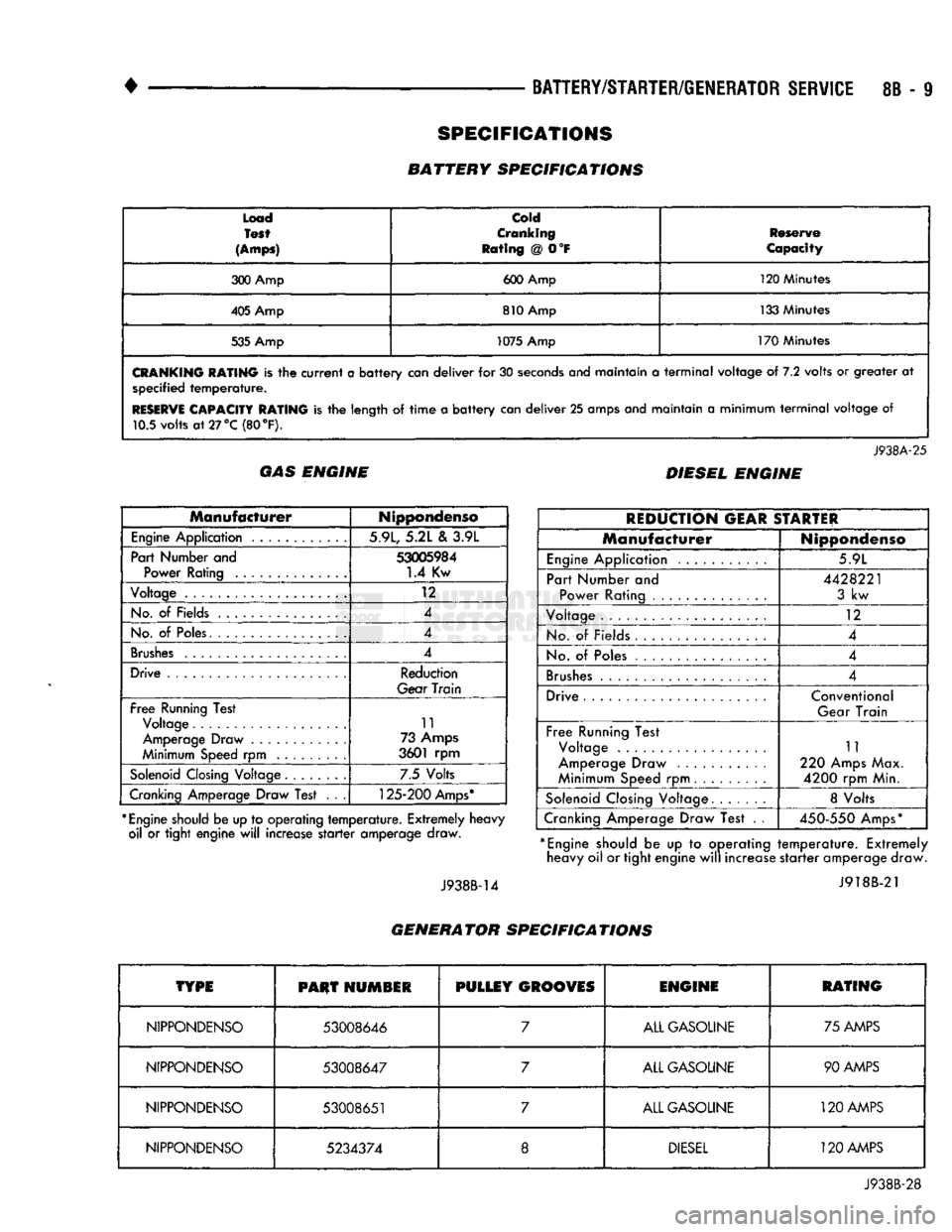

Load

Test

(Amps)

cold

Cranking

Rating

@ 0°F

Reserve

Capacity

300 Amp 600 Amp 120 Minutes

405 Amp 810 Amp 133 Minutes

535 Amp 1075 Amp

170 Minutes

CRANKING

RATING

is the

current

a

battery

can

deliver

for 30

seconds

anej

maintain

a

terminal

voltage

of 7.2

volts

or

greater

at

specified

temperature.

RESERVE

CAPACITY RATING

is the

length

of

time

a

battery

can

deliver

25

amps and maintain

a

minimum

terminal

voltage

of

10.5 volts

at

27 °C (80

°F).

J938A-25

GAS ENGINE DIESEL ENGINE

Manufacturer

Nippondenso

Engine

Application 5.9L, 5.2L

&

3.9L

Part Number and

53005984

Power Rating

1.4

Kw

Voltage

12

No.

of

Fields 4

No.

of

Poles. 4

Brushes

4

Drive Reduction

Gear

Train

Free

Running Test Voltage 11

Amperage Draw 73 Amps

Minimum Speed

rpm

3601

rpm

Solenoid

Closing Voltage 7.5 Volts

Cranking Amperage Draw Test

. . .

125-200

Amps*

*

Engine

should be up to operating

temperature.

Extremely heavy oil

or

tight engine

will

increase

starter

amperage draw.

J938B-14

REDUCTION

GEAR

STARTER

Manufacturer

Nippondenso

Engine

Application 5.9L

Part Number

and

Power Rating

4428221

3

kw

Voltage

12

No.

of

Fields

4

No.

of

Poles 4

Brushes

4

Drive Conventional

Gear Train

Free

Running Test Voltage

Amperage Draw

Minimum Speed

rpm

11

220 Amps Max.

4200

rpm Min.

Solenoid

Closing Voltage 8 Volts

Cranking Amperage Draw Test

. .

450-550

Amps*

*

Engine

should

be up to

operating

temperature.

Extremely heavy oil or tight engine

will

increase

starter

amperage draw.

J918B-21

GENERATOR SPECIFICATIONS

TYPE

PHUT

HUMSIR

PULLEY

GROOVES

ENGINE

RATING

NIPPONDENSO

53008646

7

ALL GASOLINE 75 AMPS

NIPPONDENSO

53008647

7

ALL GASOLINE 90 AMPS

NIPPONDENSO

53008651

7

ALL GASOLINE

120

AMPS

NIPPONDENSO

5234374

8

DIESEL

120 AMPS

J938B-28

SPECIFICATIONS

BATTERY SPECIFICATIONS

Page 622 of 1502

•

3.9L ENGINE

9 - 17

3.9L

ENGINE SERVICE PROCEDURES

INDEX

page

Camshaft

31

Crankshaft

38

Crankshaft Main Bearings

39

Crankshaft Rear

Oil

Seals

. 40

Cylinder Block

41

Cylinder Head Cover

. , 21

Cylinder Heads

. 22

Distributor

33

Engine

Assembly .........................

20

Engine

Front Mounts

17

Engine

Rear Mount

18

Front Crankshaft

Oil

Seal Replacement ........

31

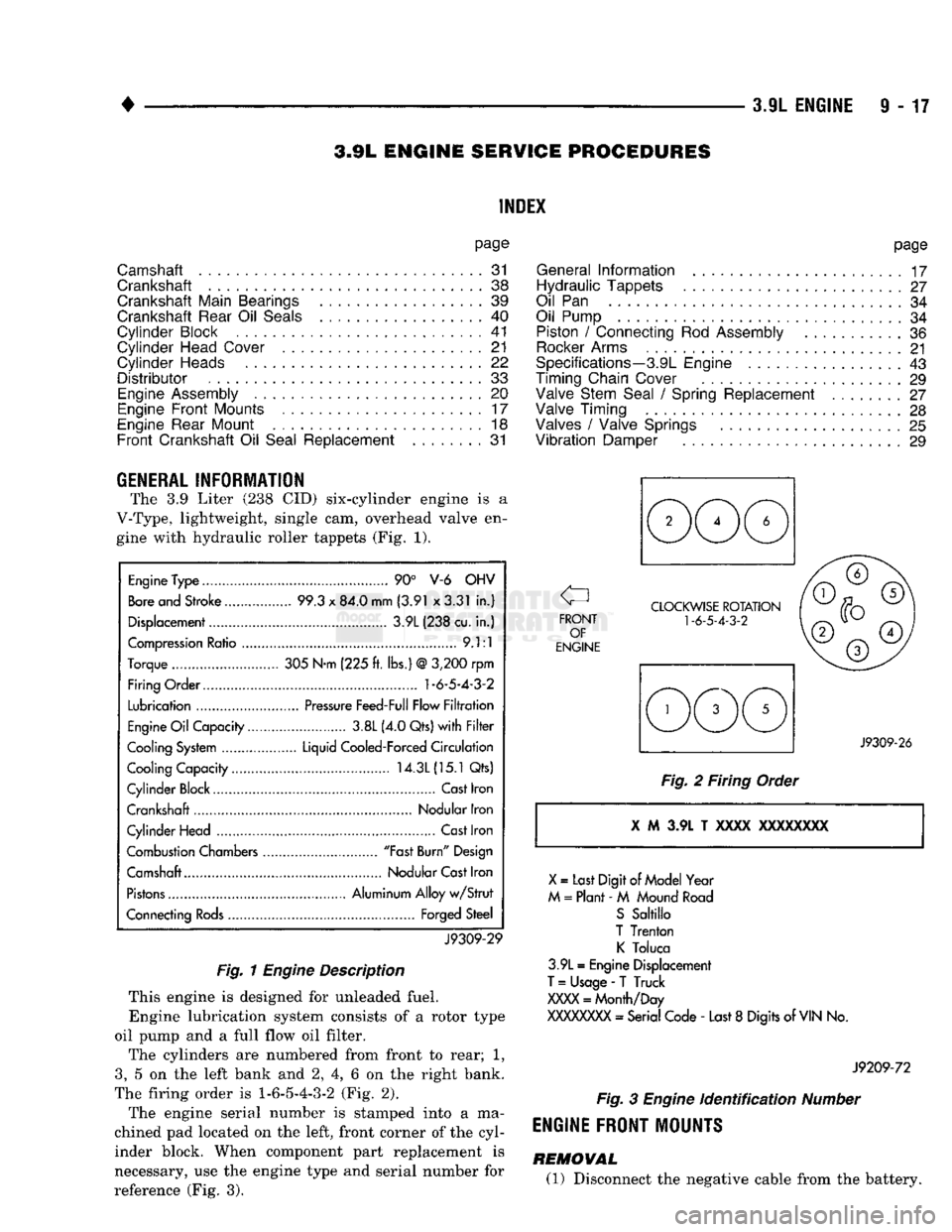

GENERAL INFORMATION

The 3.9 Liter (238 CID) six-cylinder engine is a

V-Type, lightweight, single cam, overhead valve en gine with hydraulic roller tappets (Fig. 1).

Engine

Type

90° V-6 OHV

Bore

and Stroke 99.3

x

84.0 mm (3.91 x3.31

in.)

Displacement 3.9L (238 cu.

in.)

Compression

Ratio

9.1:1

Torque 305 N-m (225

ft.

lbs.)

@

3,200

rpm

Firing Order.... 1-6-5-4-3-2

Lubrication

Pressure

Feed-Full Flow

Filtration

Engine

Oil

Capacity 3.8L (4.0 Qts)

with Filter

Cooling

System

Liquid Cooled-Forced

Circulation

Cooling Capacity 14.3L

(15.1

Qts)

Cylinder Block Cast Iron

Crankshaft Nodular Iron

Cylinder Head

Cast

Iron

Combustion Chambers "Fast

Burn"

Design

Camshaft Nodular

Cast

Iron

Pistons

Aluminum Alloy

w/Strut

Connecting

Rods

Forged Steel

J9309-29

Fig.

1

Engine

Description

This engine is designed for unleaded fuel. Engine lubrication system consists of a rotor type

oil pump and a full flow oil filter.

The cylinders are numbered from front to rear; 1,

3,

5 on the left bank and 2, 4, 6 on the right bank.

The firing order is

1-6-5-4-3-2

(Fig. 2).

The engine serial number is stamped into a ma

chined pad located on the left, front corner of the cyl

inder block. When component part replacement is

necessary, use the engine type and serial number for

reference (Fig. 3).

page

General

Information

17

Hydraulic Tappets

27

Oil

Pan 34

Oil Pump

34

Piston

/

Connecting

Rod

Assembly

36

Rocker

Arms

21

Specifications—3.9L Engine

43

Timing Chain Cover

29

Valve Stem Seal

/

Spring Replacement ........

27

Valve Timing

28

Valves

/

Valve Springs

25

Vibration

Damper

29

J9309-26

Fig.

2 Firing Order i M 3.9L T xxxx

XXXXXXXX

X

=

Last Digit

of

Model Year

M

=

Plant -

M

Mound

Road

S

Sabillo

T Trenton

K

Toluca

3.9L

=

Engine Displacement

T

=

Usage

-

T Truck

XXXX

=

Month/Day

XXXXXXXX

- Serial Code -

Last

8

Digits of

VIN

No.

J9209-72

Fig.

3

Engine

identification

Number

ENGINE FRONT MOUNTS

REMOVAL (1) Disconnect the negative cable from the battery.