set clock DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 257 of 1502

e - 4

CLUTCH

•

7/16 - 20

THREAD

NUT

10 INCHES LONG J9006-25

CLUTCH

HOUSING

BORE

J9006-26

Fig.

2 Checking Clutch Housing Bore Runout

.000

CLUTCH

HOUSING

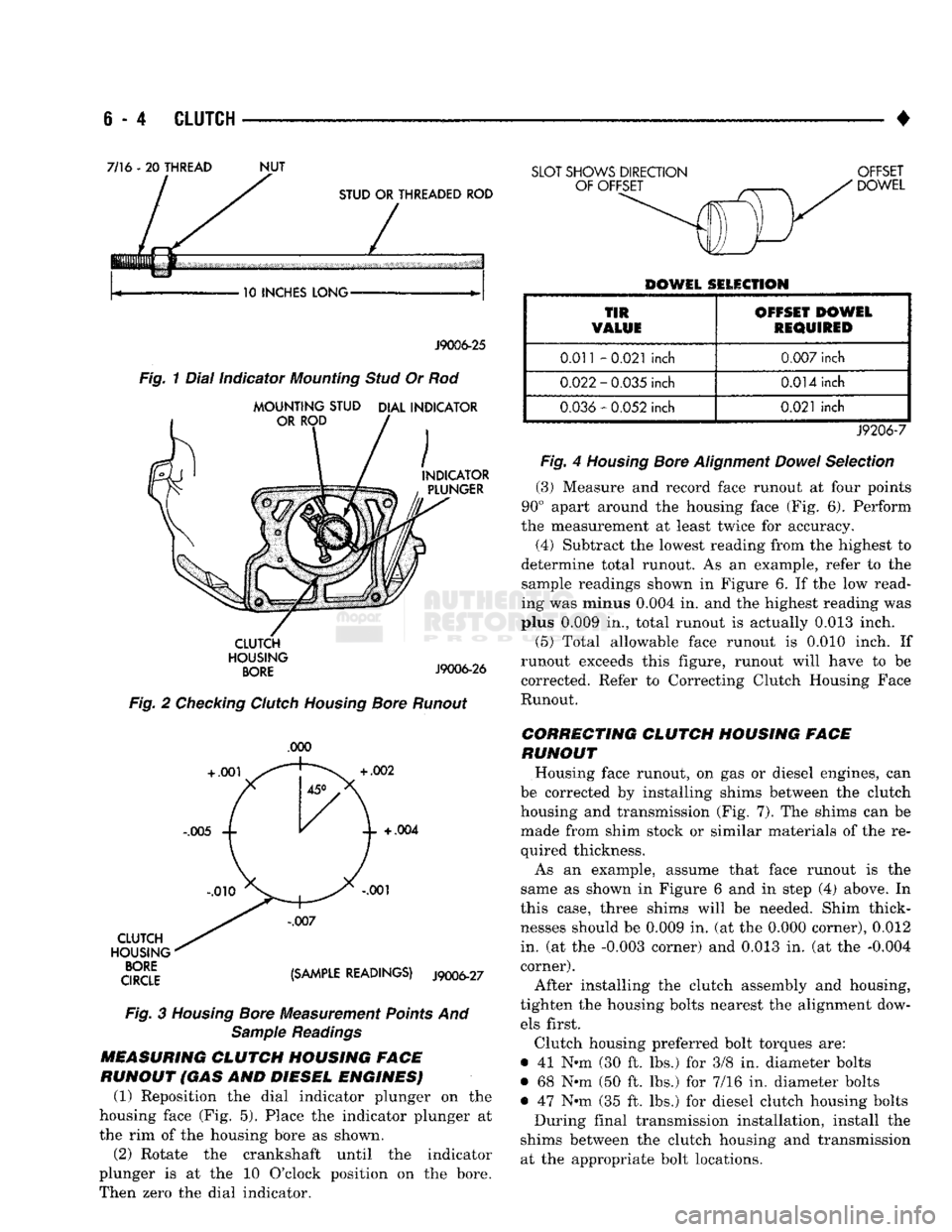

qroe {Smm READINGS) J9006-27

Fig.

3

Housing

Bore Measurement Points And Sample Readings

MEASURING

CLUTCH

HOUSING FACE

RUNOUT (GAS AND DIESEL ENGINES) (1) Reposition the dial indicator plunger on the

housing face (Fig. 5). Place the indicator plunger at

the rim of the housing bore as shown.

(2) Rotate the crankshaft until the indicator

plunger is at the 10 O'clock position on the bore.

Then zero the dial indicator.

SLOT SHOWS DIRECTION OFFSET

DOWEL

DOWEL SELECTION

TIR

VALUE OFFSET DOWEL

REQUIRED

0.011

-0.021

inch

0.007

inch

0.022

-

0.035

inch

0.014

inch

0.036

-

0.052

inch

0.021

inch

J9206-7

Fig.

4

Housing

Bore

Alignment

Dowel

Selection

(3)

Measure and record face runout at four points

90° apart around the housing face (Fig. 6). Perform

the measurement at least twice for accuracy.

(4)

Subtract the lowest reading from the highest to

determine total runout. As an example, refer to the

sample readings shown in Figure 6. If the low read

ing was minus

0.004

in. and the highest reading was

plus

0.009

in., total runout is actually

0.013

inch.

(5)

Total allowable face runout is 0.010 inch. If

runout exceeds this figure, runout will have to be

corrected. Refer to Correcting Clutch Housing Face

Runout.

CORRECTING CLUTCH HOUSING FACE

RUNOUT

Housing face runout, on gas or diesel engines, can

be corrected by installing shims between the clutch

housing and transmission (Fig. 7). The shims can be made from shim stock or similar materials of the re

quired thickness.

As an example, assume that face runout is the

same as shown in Figure 6 and in step (4) above. In

this case, three shims will be needed. Shim thick

nesses should be

0.009

in. (at the

0.000

corner),

0.012

in. (at the

-0.003

corner) and

0.013

in. (at the

-0.004

corner).

After installing the clutch assembly and housing,

tighten the housing bolts nearest the alignment dow els first.

Clutch housing preferred bolt torques are:

• 41 N-m (30 ft. lbs.) for 3/8 in. diameter bolts

• 68 Nnn (50 ft. lbs.) for 7/16 in. diameter bolts

• 47 Nth (35 ft. lbs.) for diesel clutch housing bolts During final transmission installation, install the

shims between the clutch housing and transmission at the appropriate bolt locations.

Page 286 of 1502

•

COOLING SYSTEM

7 - 15

SERVICE

PROCEDURES

INDEX

page

Coolant

26

Coolant Reserve/Overflow System

30

Cooling System Cleaning/Reverse Flushing

28

Cooling System Fan—Diesel Engine

. 37

Cooling System

Fan—Gas

Engines

36

Cooling System

Hoses

34

Draining Cooling System

27

Pressure

Testing

Radiator

Caps

............. 32

Radiator Pressure

Cap 31

Radiators

32

Refilling

the

Cooling System

28

WATER PUMPS—EXCEPT DIESEL

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a drive belt. The water pump impeller is pressed onto the rear

of a shaft that rotates in a bearing pressed into the

water pump body. The body has a small hole for ven

tilation. The water pump seals are lubricated by an

tifreeze in the coolant mixture. Additional lubrication is not necessary. A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core. The water pump on all models can be removed

without discharging the air conditioning system (if equipped).

REMOVAL The water pump on all gas powered engines is

bolted directly to the engine timing chain case/cover.

A gasket is used as a seal between the water pump

and timing chain case/cover.

If water pump is replaced because of bearing/shaft

damage or leaking shaft seal, the mechanical cooling

fan assembly should also be inspected. Inspect for fa tigue cracks, loose blades or loose rivets that could

have resulted from excessive vibration. Replace fan if any of these conditions are found. Also check condi

tion of the thermal viscous fan drive. Refer to Vis

cous Fan Drive in this group. (1) Disconnect negative battery cable from battery.

(2) Drain cooling system. Refer to Draining Cool

ing System in this group. Do not waste reusable coolant. If solution is clean,

drain coolant into a clean container for reuse.

(3)

Disconnect throttle cable from clip at top of fan

shroud.

page

Testing

Cooling System

for

Leaks

. 29

Thermostat

22

Transmission

Oil

Cooler—Diesel

35

Transmission

Oil

Cooler—Except Diesel

35

Transmission Oil-To-Air Cooler

36

Viscous

Fan

Drive

38

Water

Pump

Bypass

Hose—All

Gas

Powered

Engines

.............................. 19

Water

Pumps—5.9L Diesel

18

Water

Pumps—Except Diesel

15

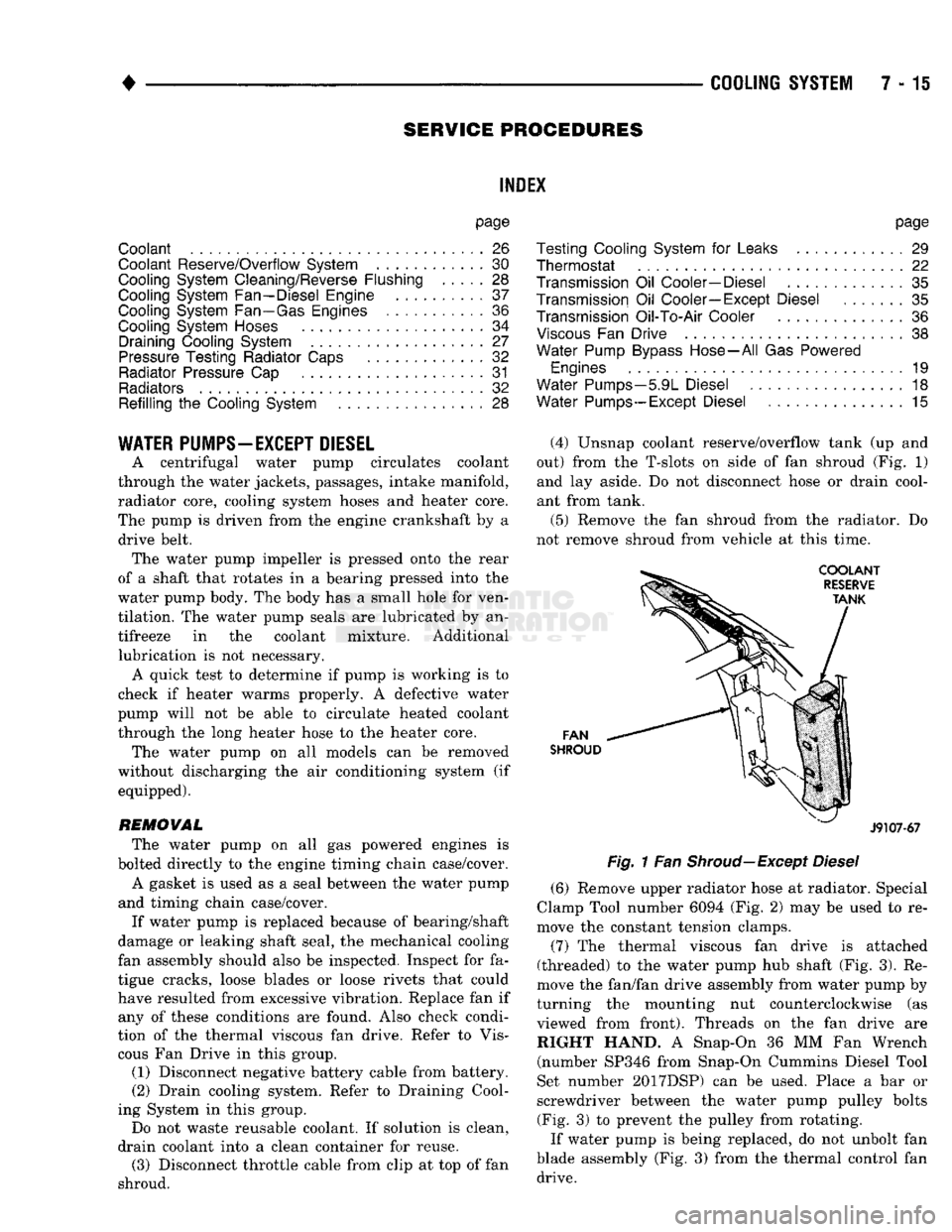

(4) Unsnap coolant reserve/overflow tank (up and

out) from the T-slots on side of fan shroud (Fig. 1) and lay aside. Do not disconnect hose or drain cool

ant from tank.

(5) Remove the fan shroud from the radiator. Do

not remove shroud from vehicle at this time.

FAN

SHROUD

J9107-67

Fig.

1 Fan

Shroud—Except

Diesel

(6) Remove upper radiator hose at radiator. Special

Clamp Tool number 6094 (Fig. 2) may be used to re

move the constant tension clamps.

(7) The thermal viscous fan drive is attached

(threaded) to the water pump hub shaft (Fig. 3). Re

move the fan/fan drive assembly from water pump by

turning the mounting nut counterclockwise (as viewed from front). Threads on the fan drive are RIGHT HAND. A Snap-On 36 MM Fan Wrench (number SP346 from Snap-On Cummins Diesel Tool

Set number 2017DSP) can be used. Place a bar or

screwdriver between the water pump pulley bolts (Fig. 3) to prevent the pulley from rotating.

If water pump is being replaced, do not unbolt fan

blade assembly (Fig. 3) from the thermal control fan drive.

Page 307 of 1502

7 - 36

COOLING

SYSTEM

• (4) Connect coolant hoses to cooler.

(5)

Connect battery cable to battery.

(6)

Fill cooling system. Refer to Refilling Cooling

System in this section. (7) Check transmission oil level and fill as neces

sary.

TRANSMISSION

OIL/TO-AIR

COOLER

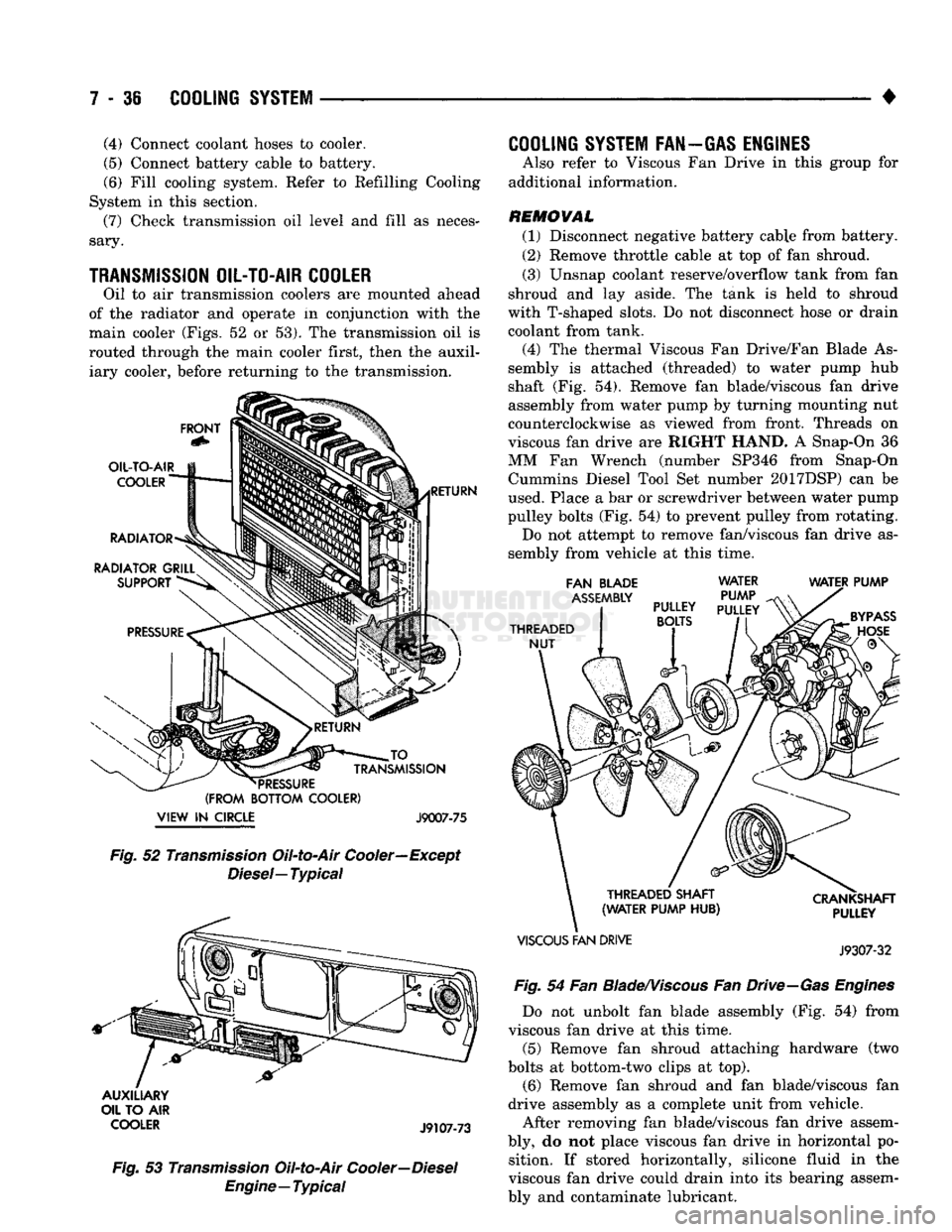

Oil to air transmission coolers are mounted ahead

of the radiator and operate in conjunction with the

main cooler (Figs, 52 or 53). The transmission oil is

routed through the main cooler first, then the auxil iary cooler, before returning to the transmission.

FRONT

OIL-TO-AIR

COOLER

RADIATOR

RADIATOR GRILL SUPPORT RETURN JO

_

TRANSMISSION

*

PRESSURE

(FROM BOTTOM COOLER)

VIEW

IN

CIRCLE J9007-75 Fig.

52

Transmission

Oil-to-Air Cooler—Except

Diesel—

Typical

AUXILIARY

OIL TO AIR

COOLER

J9107-73

Fig.

53

Transmission

Oil-to-Air

Cooler—Diesel

Engine—Typical

COOLING

SYSTEM FAN—GAS ENGINES

Also refer to Viscous Fan Drive in this group for

additional information.

REMOVAL (1) Disconnect negative battery cable from battery.

(2) Remove throttle cable at top of fan shroud.

(3) Unsnap coolant reserve/overflow tank from fan

shroud and lay aside. The tank is held to shroud

with T-shaped slots. Do not disconnect hose or drain

coolant from tank.

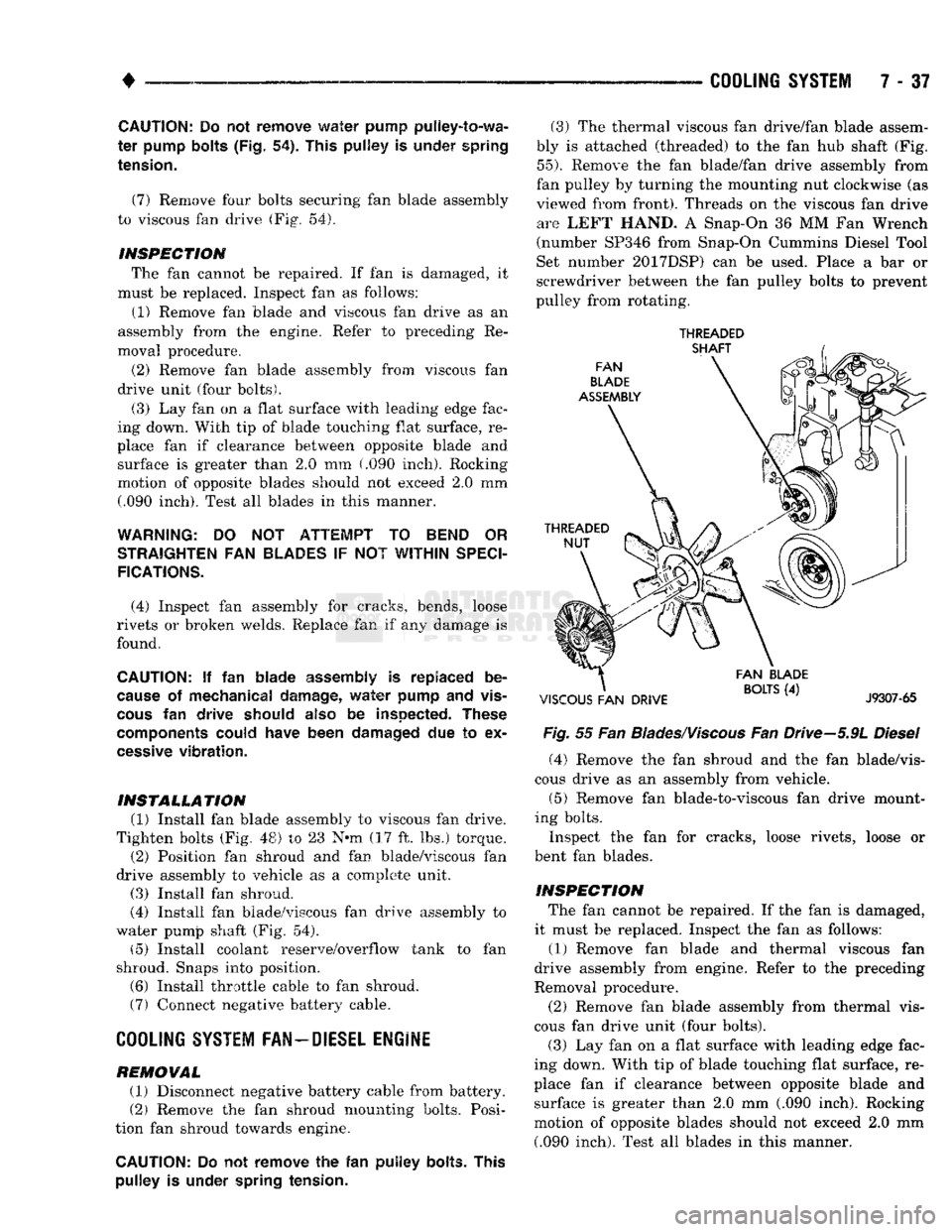

(4) The thermal Viscous Fan Drive/Fan Blade As

sembly is attached (threaded) to water pump hub

shaft (Fig. 54). Remove fan blade/viscous fan drive

assembly from water pump by turning mounting nut

counterclockwise as viewed from front. Threads on

viscous fan drive are RIGHT HAND. A Snap-On 36

MM Fan Wrench (number SP346 from Snap-On Cummins Diesel Tool Set number 2017DSP) can be

used. Place a bar or screwdriver between water pump

pulley bolts (Fig. 54) to prevent pulley from rotating. Do not attempt to remove fan/viscous fan drive as

sembly from vehicle at this time.

FAN BLADE

ASSEMBLY

THREADED NUT WATER

PUMP

PULLEY

PULLEY

BOLTS

WATER PUMP

THREADED SHAFT

(WATER PUMP HUB)

VISCOUS

FAN DRIVE CRANKSHAFT

PULLEY

J9307-32

Fig.

54 Fan

Blade/Viscous

Fan

Drive—Gas

Engines

Do not unbolt fan blade assembly (Fig. 54) from

viscous fan drive at this time.

(5) Remove fan shroud attaching hardware (two

bolts at bottom-two clips at top). (6) Remove fan shroud and fan blade/viscous fan

drive assembly as a complete unit from vehicle.

After removing fan blade/viscous fan drive assem

bly, do not place viscous fan drive in horizontal po sition. If stored horizontally, silicone fluid in the

viscous fan drive could drain into its bearing assem

bly and contaminate lubricant.

Page 308 of 1502

•

COOLING

SYSTEM

7 - 37

CAUTION:

Do not

remove

water

pump pulley-to-wa

ter

pump

bolts

(Fig. 54), This

pulley

is

under spring

tension.

(7) Remove four bolts securing fan blade assembly

to viscous fan drive (Fig. 54).

INSPECTION The fan cannot be repaired. If fan is damaged, it

must be replaced. Inspect fan as follows:

(1) Remove fan blade and viscous fan drive as an

assembly from the engine. Refer to preceding Re

moval procedure.

(2) Remove fan blade assembly from viscous fan

drive unit (four bolts).

(3) Lay fan on a flat surface with leading edge fac

ing down. With tip of blade touching flat surface, re

place fan if clearance between opposite blade and surface is greater than 2.0 mm (.090 inch). Rocking

motion of opposite blades should not exceed 2.0 mm (.090 inch). Test all blades in this manner.

WARNING:

DO NOT

ATTEMPT

TO

BEND

OR

STRAIGHTEN

FAN

BLADES

IF NOT

WITHIN

SPECI

FICATIONS.

(4) Inspect fan assembly for cracks, bends, loose

rivets or broken welds. Replace fan if any damage is

found,

CAUTION:

If fan

blade assembly

is

replaced

be

cause

of

mechanical damage,

water

pump

and

vis

cous

fan

drive should

also

be

inspected. These

components

could have been damaged

due to ex

cessive

vibration.

INSTALLATION (1) Install fan blade assembly to viscous fan drive.

Tighten bolts (Fig. 48) to 23 N*m (17 ft. lbs.) torque. (2) Position fan shroud and fan blade/viscous fan

drive assembly to vehicle as a complete unit.

(3) Install fan shroud.

(4) Install fan blade/viscous fan drive assembly to

water pump shaft (Fig. 54). (5) Install coolant reserve/overflow tank to fan

shroud. Snaps into position.

(6) Install throttle cable to fan shroud.

(7) Connect negative battery cable.

COOLING

SYSTEM

FAN-DIESEL ENGINE

REMOVAL (1) Disconnect negative battery cable from battery.

(2) Remove the fan shroud mounting bolts. Posi

tion fan shroud towards engine.

CAUTION:

Do not

remove

the fan

puHey bolts. This pulley

is

under spring tension.

(3) The thermal viscous fan drive/fan blade assem

bly is attached (threaded) to the fan hub shaft (Fig.

55).

Remove the fan blade/fan drive assembly from

fan pulley by turning the mounting nut clockwise (as

viewed from front). Threads on the viscous fan drive are LEFT HAND. A Snap-On 36 MM Fan Wrench

(number SP346 from Snap-On Cummins Diesel Tool

Set number 2017DSP) can be used. Place a bar or

screwdriver between the fan pulley bolts to prevent

pulley from rotating.

THREADED

Fig.

55 Fan

Blades/Viscous

Fan Drive-5.9L

Diesel

(4) Remove the fan shroud and the fan blade/vis

cous drive as an assembly from vehicle.

(5) Remove fan blade-to-viscous fan drive mount

ing bolts.

Inspect the fan for cracks, loose rivets, loose or

bent fan blades.

INSPECTION The fan cannot be repaired. If the fan is damaged,

it must be replaced. Inspect the fan as follows:

(1) Remove fan blade and thermal viscous fan

drive assembly from engine. Refer to the preceding

Removal procedure.

(2) Remove fan blade assembly from thermal vis

cous fan drive unit (four bolts). (3) Lay fan on a flat surface with leading edge fac

ing down. With tip of blade touching flat surface, re

place fan if clearance between opposite blade and surface is greater than 2.0 mm (.090 inch). Rocking

motion of opposite blades should not exceed 2.0 mm (.090 inch). Test all blades in this manner.

Page 375 of 1502

8D

- 24

IGNITION

SYSTEMS

•

.040

GAUGE

SPARK

"PLUG

J908D-10

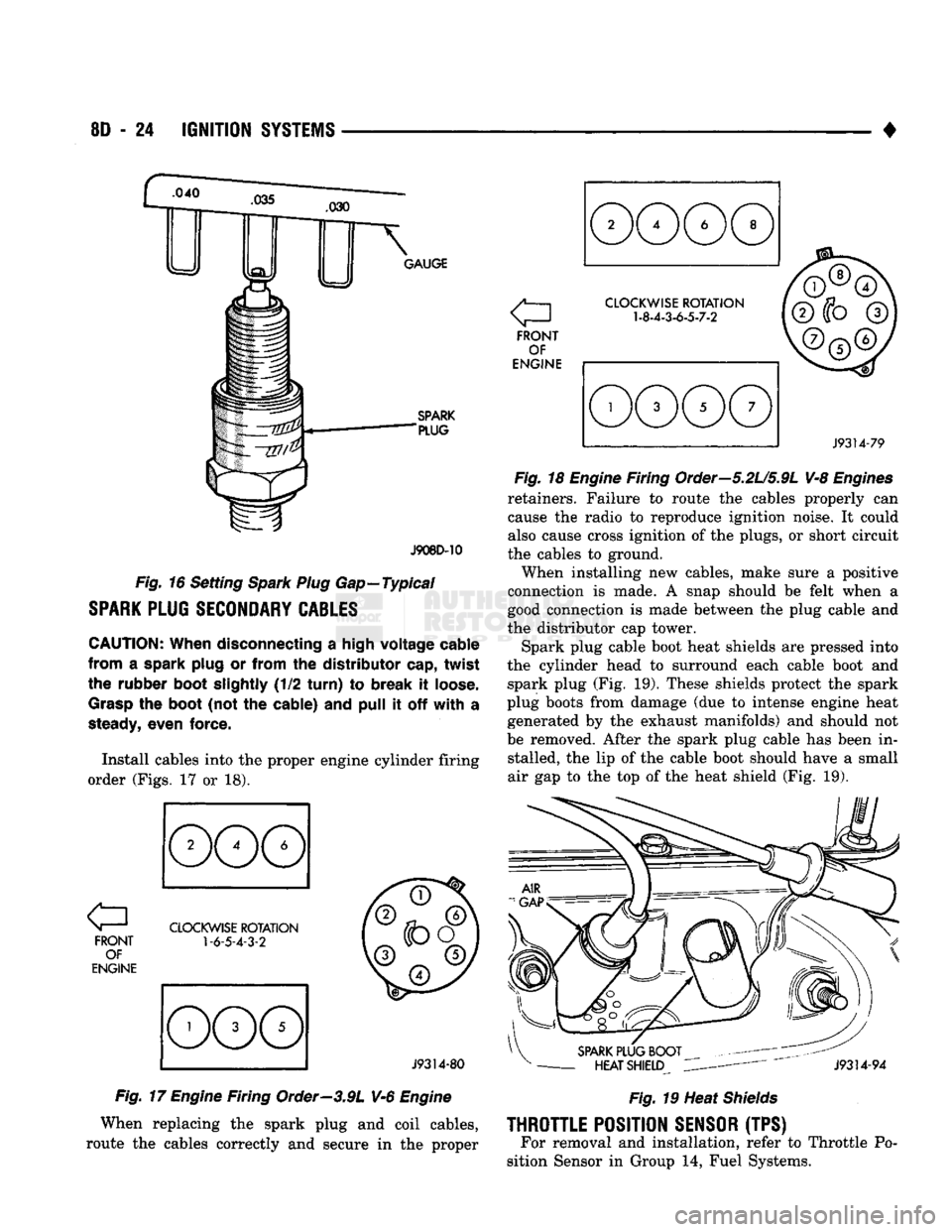

Fig.

16 Setting

Spark Plug

Gap—Typical

SPARK

PLUG

SECONDARY

CABLES

CAUTION:

When disconnecting

a

high voltage cable

from

a

spark plug

or

from

the

distributor cap, twist

the rubber boot slightly

(1/2

turn)

to

break

it

loose.

Grasp

the

boot

(not

the

cable)

and

pull

it off

with

a

steady,

even force.

Install cables into

the

proper engine cylinder firing

order (Figs.

17 or 18).

FRONT OF

ENGINE

CLOCKWISE

ROTATION

1-6-5-4-3-2

J9314-80

Fig.

17

Engine

Firing Order—3.9L V-6

Engine

When replacing

the

spark plug

and

coil cables,

route

the

cables correctly

and

secure

in the

proper a

FRONT OF

ENGINE

CLOCKWISE

ROTATION

1-8-4-3-6-5-7-2

J9314-79

Fig.

18

Engine

Firing Order—5.2U5.9L V-8

Engines

retainers. Failure

to

route

the

cables properly

can

cause

the

radio

to

reproduce ignition noise.

It

could

also cause cross ignition

of the

plugs,

or

short circuit

the cables

to

ground.

When installing

new

cables, make sure

a

positive

connection

is

made.

A

snap should

be

felt when

a

good connection

is

made between

the

plug cable

and

the distributor

cap

tower.

Spark plug cable boot heat shields

are

pressed into

the cylinder head

to

surround each cable boot

and

spark plug

(Fig. 19).

These shields protect

the

spark

plug boots from damage

(due to

intense engine heat generated

by the

exhaust manifolds)

and

should

not

be removed. After

the

spark plug cable

has

been

in

stalled,

the lip of the

cable boot should have

a

small

air

gap to the top of the

heat shield

(Fig. 19).

SPARK

PLUG BOOT

-

HEAT SHIELD

J9314-94

Fig.

19 Heat

Shields

THROTTLE

POSITION

SENSOR

(TPS) For removal

and

installation, refer

to

Throttle

Po

sition Sensor

in

Group

14,

Fuel Systems.

Page 384 of 1502

•

INSTRUMENT PANEL

AND

GAUGES

8E - 3

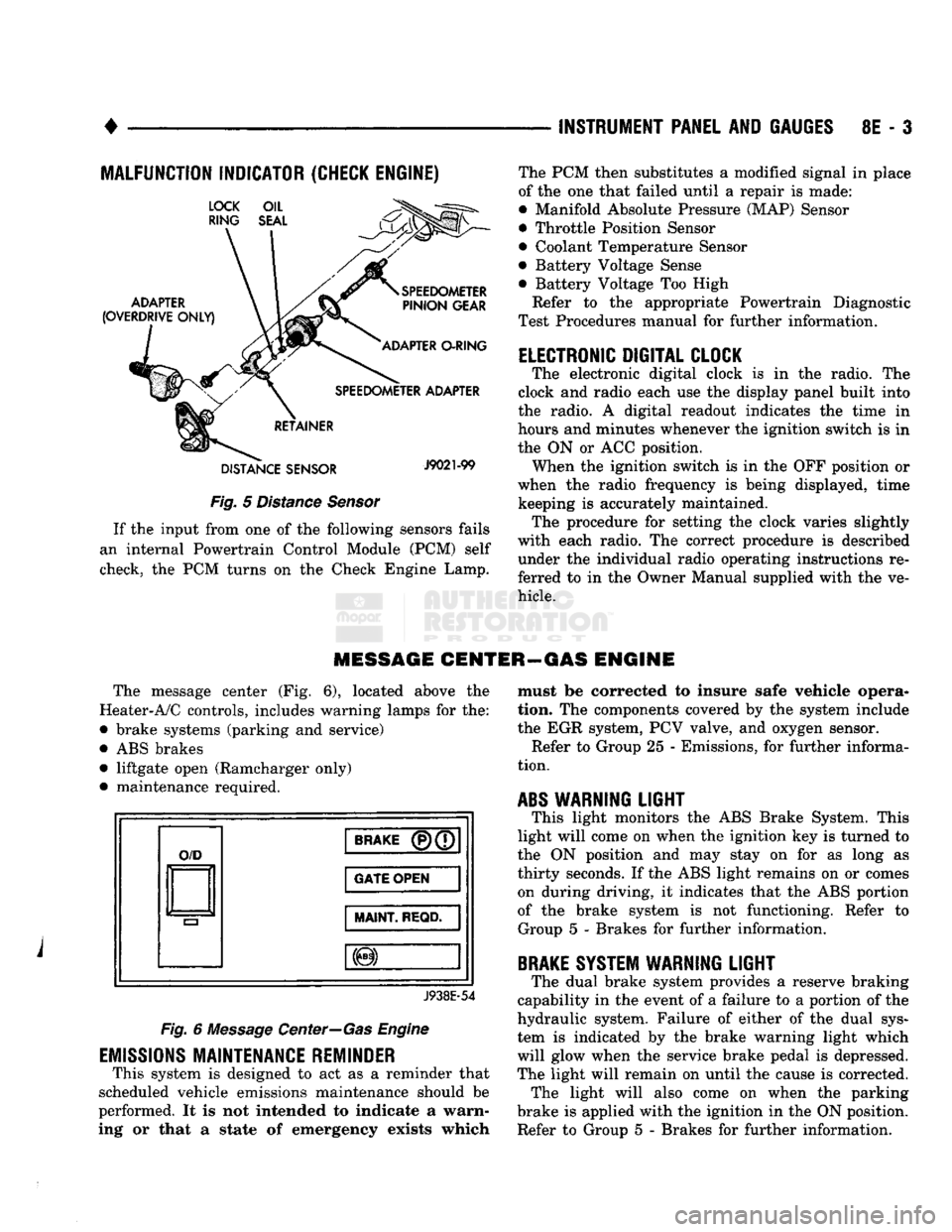

MALFUNCTION INDICATOR (CHECK ENGINE)

Fig.

5

Distance Sensor

If

the

input from

one of the

following sensors fails

an internal Powertrain Control Module

(PCM)

self

check,

the PCM

turns

on the

Check Engine Lamp. The

PCM

then substitutes

a

modified signal

in

place

of

the one

that failed until

a

repair

is

made:

• Manifold Absolute Pressure (MAP) Sensor

• Throttle Position Sensor

• Coolant Temperature Sensor

• Battery Voltage Sense

• Battery Voltage

Too

High

Refer

to the

appropriate Powertrain Diagnostic

Test Procedures manual

for

further information.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock

is in the

radio.

The

clock

and

radio each

use the

display panel built into

the radio.

A

digital readout indicates

the

time

in

hours

and

minutes whenever

the

ignition switch

is in

the

ON or ACC

position. When

the

ignition switch

is in the OFF

position

or

when

the

radio frequency

is

being displayed, time keeping

is

accurately maintained. The procedure

for

setting

the

clock varies slightly

with each radio.

The

correct procedure

is

described under

the

individual radio operating instructions

re

ferred

to in the

Owner Manual supplied with

the ve

hicle.

MESSAGE CENTER—GAS ENGINE

The message center

(Fig. 6),

located above

the

Heater-A/C controls, includes warning lamps

for the:

• brake systems (parking

and

service)

•

ABS

brakes • liftgate open (Ramcharger only)

• maintenance required.

O/D

BRAKE

(P)(7

GATE OPEN

MAINT

REQD.

J938E-54

Fig.

6

Message Center—Gas Engine

EMISSIONS

MAINTENANCE REMINDER

This system

is

designed

to act as a

reminder that

scheduled vehicle emissions maintenance should

be

performed.

It is not

intended

to

indicate

a

warn

ing

or

that

a

state

of

emergency exists which must

be

corrected

to

insure safe vehicle opera

tion.

The

components covered

by the

system include

the

EGR

system,

PCV

valve,

and

oxygen sensor. Refer

to

Group

25 -

Emissions,

for

further informa

tion.

ABS

WARNING

LIGHT

This light monitors

the ABS

Brake System. This

light will come

on

when

the

ignition

key is

turned

to

the

ON

position

and may

stay

on for as

long

as

thirty seconds.

If the ABS

light remains

on or

comes on during driving,

it

indicates that

the ABS

portion

of

the

brake system

is not

functioning. Refer

to

Group

5 -

Brakes

for

further information.

BRAKE

SYSTEM WARNING

LIGHT

The dual brake system provides

a

reserve braking

capability

in the

event

of a

failure

to a

portion

of the

hydraulic system. Failure

of

either

of the

dual sys

tem

is

indicated

by the

brake warning light which

will glow when

the

service brake pedal

is

depressed.

The light will remain

on

until

the

cause

is

corrected. The light will also come

on

when

the

parking

brake

is

applied with

the

ignition

in the ON

position.

Refer

to

Group

5 -

Brakes

for

further information.

Page 437 of 1502

8K

- 6

WINDSHIELD WIPER

AND

WASHER SYSTEMS

• INTERMITTENT WINDSHIELD WIPER FUNCTION

AND

SWITCH TESTING

PROCEDURES

INTERMITTENT

WIPER

FUNCTION

TESTING

PROCEDURES

The intermittent wipe and standard two speed mo

tors are identical. Refer to previous sections for diag

nosis of system problems which do not involve the

DELAY function. If problem occurs only in the DE LAY mode, the following tests are to be performed.

These tests involve disconnecting the intermittent wipe control unit which can be found on the steering column support bracket (Fig. 2).

CONDITION Excessive delay (more than 30 seconds) or in

adequate variation in delay.

PROCEDURE Variations in delay should be as follows: (1) Minimum delay (delay control to extreme coun

terclockwise position before first detent) 1/2 to 2 sec

onds.

(2) Maximum delay (delay control to extreme

clockwise position before off detent) 10 to 30 seconds.

(3) If there is excessive delay or no variations in

delay proceed to intermittent wipe switch test.

CONDITION In DELAY mode wipers run continually when

wash is operated but do not provide an extra

wipe when the wash control is released.

PROCEDURE Replace the control unit.

CONDITION ' Wipers start erratically during DELAY mode.

PROCEDURE (1) Verify that the ground connection at the in

strument panel is making good connection (free from

paint) and is tight.

(2) Verify that the motor ground strap is making

good contact and that the motor mounting bolts are

tight.

(3) Verify that the wiring ground connections for

the intermittent wipe control unit and the wiper switch are tight.

(4) If condition is not corrected, replace control

unit.

MULTIFUNCTION (INTERMITTENT WIPER) SWITCH

TESTING

PROCEDURES

Refer to Multifunction (Two Speed Wiper) Switch

Testing Procedures using the following continuity chart.

i

24 23 22

21 20 19

17 16 15 14

/V~\M3

12 11 10 9 8

7

6 V5^4 3

.

2 1

EZJ

CZ3 CZ3 C3 Jr

L

JT

MULTIFUNCTION

SWITCH

PINS

SWITCH

POSITION

CONTINUITY

BETWEEN

OFF

PIN

6 AND PIN 7

DELAY

PIN 8 AND PIN 9

PIN 2 AND PIN 4

PIN

1

AND PIN 2

PIN

1

AND PIN 4

LOW PIN 4 AND PIN 6

HIGH

PIN 4 AND PIN 5

WASH

PIN 3 AND PIN 4

*

RESISTANCE

AT

AAAXIMUM

DELAY

POSITION

SHOULD

BE

BETWEEN

270,000

OHMS

AND

330,000

OHMS.

•RESISTANCE

AT

MINIMUM

DELAY

POSITION

SHOULD

BE

ZERO

WITH

OHMMETER

SET ON

HIGH

OHM

SCALE.

918J-4

Fig.

11ntermittent

Wipe

Switch

Continuity Chart

INTERMITTENT WIPE MODULE LOCATION

The intermittent wipe module is located to the

right of the steering column on the back side of the instrument panel (Fig. 2).

BUZZER

MODULE

INTERMITTENT

WIPE

MODULE

Fig.

2

Intermittent

Wipe

Module

Location

Page 642 of 1502

(5) Be sure the connecting rod and connecting rod

cap are identified with the cylinder number. Remove

connecting rod cap. Install connecting rod bolt guide

set on connecting rod bolts.

(6) Pistons and connecting rods must be removed

from top of cylinder block. When removing piston and connecting rod assemblies from the engine, ro

tate crankshaft so that the connecting rod is centered in cylinder bore and at BDC. Be careful not to nick

crankshaft journals.

(7) After removal, install bearing cap on the mat

ing rod.

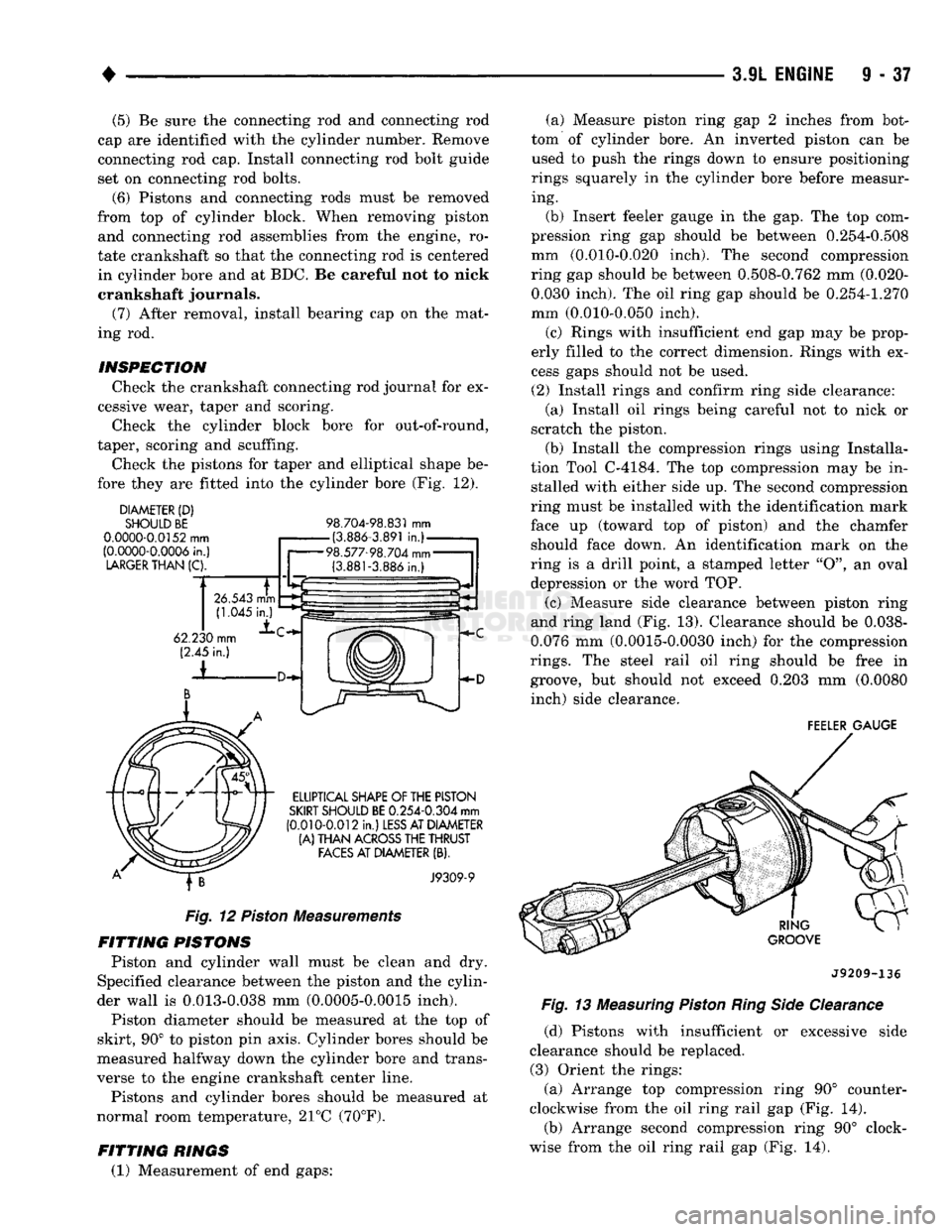

INSPECTION

Check the crankshaft connecting rod journal for ex

cessive wear, taper and scoring. Check the cylinder block bore for out-of-round,

taper, scoring and scuffing.

Check the pistons for taper and elliptical shape be

fore they are fitted into the cylinder bore (Fig. 12).

DIAMETER

(D)

SHOULD BE

0.0000-0.0152

mm

(0.0000-0.0006

in.)

LARGER

THAN

(C).

98.704-98.831

mm

-(3.886-3.891

in.)-

98.577-98.704

mm-

(3.881-3.886

in.) (a) Measure piston ring gap 2 inches from bot

tom of cylinder bore. An inverted piston can be used to push the rings down to ensure positioning

rings squarely in the cylinder bore before measur ing.

(b) Insert feeler gauge in the gap. The top com

pression ring gap should be between 0.254-0.508

mm (0.010-0.020 inch). The second compression

ring gap should be between 0.508-0.762 mm (0.020- 0.030 inch). The oil ring gap should be 0.254-1.270

mm (0.010-0.050 inch).

(c) Rings with insufficient end gap may be prop

erly filled to the correct dimension. Rings with ex

cess gaps should not be used.

(2) Install rings and confirm ring side clearance: (a) Install oil rings being careful not to nick or

scratch the piston.

(b) Install the compression rings using Installa

tion Tool C-4184. The top compression may be in stalled with either side up. The second compression

ring must be installed with the identification mark

face up (toward top of piston) and the chamfer should face down. An identification mark on the

ring is a drill point, a stamped letter "O", an oval

depression or the word TOP.

(c) Measure side clearance between piston ring

and ring land (Fig. 13). Clearance should be 0.038-

0.076 mm (0.0015-0.0030 inch) for the compression

rings.

The steel rail oil ring should be free in groove, but should not exceed 0.203 mm (0.0080 inch) side clearance.

FEELER

GAUGE

ELLIPTICAL SHAPE

OF

THE PISTON

SKIRT

SHOULD

BE

0.254-0.304

mm

(0.010-0.012

in.)

LESS

AT DIAMETER

(A)

THAN

ACROSS

THE THRUST

FACES

AT DIAMETER

(B).

J9309-9

Fig.

12

Piston

Measurements

FITTING

PISTONS

Piston and cylinder wall must be clean and dry.

Specified clearance between the piston and the cylin

der wall is 0.013-0.038 mm (0.0005-0.0015 inch). Piston diameter should be measured at the top of

skirt, 90° to piston pin axis. Cylinder bores should be

measured halfway down the cylinder bore and trans

verse to the engine crankshaft center line.

Pistons and cylinder bores should be measured at

normal room temperature, 21°C (70°F).

FITTING

RINGS

(1) Measurement of end gaps: J9209-136

Fig.

13

Measuring

Piston

Ring Side

Clearance (d) Pistons with insufficient or excessive side

clearance should be replaced. (3) Orient the rings:

(a) Arrange top compression ring 90° counter

clockwise from the oil ring rail gap (Fig. 14). (b) Arrange second compression ring 90° clock

wise from the oil ring rail gap (Fig. 14).

Page 663 of 1502

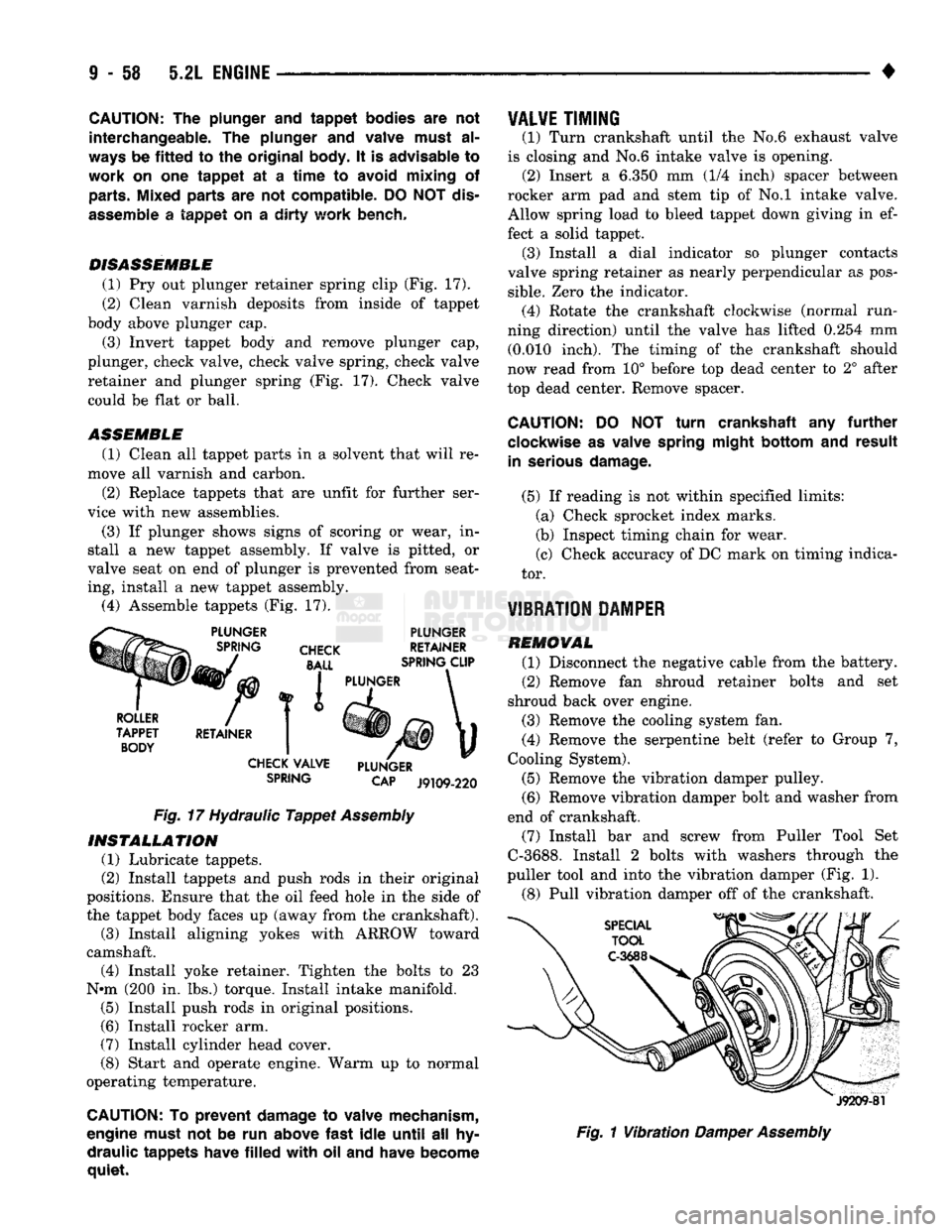

CAUTION:

Th© plunger and

tappet

bodies are not

interchangeable. The plunger and valve must al

ways

be

fitted

to the

original

body. It is advisable to

work

on one

tappet

at a

time

to avoid

mixing

of parts. Mixed

parts

are not

compatible.

DO NOT

dis

assemble

a

tappet

on a

dirty

work

bench,

DISASSEMBLE

(1) Pry out plunger retainer spring clip (Fig. 17).

(2) Clean varnish deposits from inside of tappet

body above plunger cap.

(3) Invert tappet body and remove plunger cap,

plunger, check valve, check valve spring, check valve

retainer and plunger spring (Fig. 17). Check valve could be flat or ball.

ASSEMBLE

(1) Clean all tappet parts in a solvent that will re

move all varnish and carbon.

(2) Replace tappets that are unfit for further ser

vice with new assemblies.

(3) If plunger shows signs of scoring or wear, in

stall a new tappet assembly. If valve is pitted, or

valve seat on end of plunger is prevented from seat

ing, install a new tappet assembly. (4) Assemble tappets (Fig. 17).

PLUNGER

CHECK

BALL

PLUNGER

RETAINER

SPRING CLIP

ROLLER

TAPPET BODY RETAINER I PLUNGER

CHECK VALVE

SPRING PLUNGER

CAP

J9109-220

Fig.

17 Hydraulic

Tappet

Assembly

INSTALLATION

(1) Lubricate tappets.

(2) Install tappets and push rods in their original

positions. Ensure that the oil feed hole in the side of

the tappet body faces up (away from the crankshaft). (3) Install aligning yokes with ARROW toward

camshaft. (4) Install yoke retainer. Tighten the bolts to 23

N»m (200 in. lbs.) torque. Install intake manifold. (5) Install push rods in original positions.

(6) Install rocker arm.

(7) Install cylinder head cover.

(8) Start and operate engine. Warm up to normal

operating temperature.

CAUTION: To

prevent

damage to valve mechanism,

engine must not be run above

fast

idle

until

all hy

draulic

tappets

have

filled

with

oil and have become

quiet.

VALVE

TIMING

(1) Turn crankshaft until the No.6 exhaust valve

is closing and No.6 intake valve is opening. (2) Insert a 6.350 mm (1/4 inch) spacer between

rocker arm pad and stem tip of No.l intake valve. Allow spring load to bleed tappet down giving in ef

fect a solid tappet. (3) Install a dial indicator so plunger contacts

valve spring retainer as nearly perpendicular as pos

sible.

Zero the indicator. (4) Rotate the crankshaft clockwise (normal run

ning direction) until the valve has lifted 0.254 mm (0.010 inch). The timing of the crankshaft should

now read from 10° before top dead center to 2° after

top dead center. Remove spacer.

CAUTION:

DO NOT

turn

crankshaft any

further

clockwise as valve spring

might

bottom

and

result

in serious

damage.

(5) If reading is not within specified limits: (a) Check sprocket index marks.

(b) Inspect timing chain for wear.

(c) Check accuracy of DC mark on timing indica

tor.

VIBRATION DAMPER

REMOVAL (1) Disconnect the negative cable from the battery.

(2) Remove fan shroud retainer bolts and set

shroud back over engine.

(3) Remove the cooling system fan.

(4) Remove the serpentine belt (refer to Group 7,

Cooling System).

(5) Remove the vibration damper pulley. (6) Remove vibration damper bolt and washer from

end of crankshaft. (7) Install bar and screw from Puller Tool Set

C-3688. Install 2 bolts with washers through the

puller tool and into the vibration damper (Fig. 1).

(8) Pull vibration damper off of the crankshaft.

J9209-81

Fig.

1

Vibration

Damper

Assembly

Page 693 of 1502

9

- 88 5.9L

ENGINE

•

CAUTION:

The

plunger

and

tappet

bodies

are not

interchangeable,.

The

plunger

and

valve must

al

ways

be

fitted

to the

original

body,

It is

advisable

to

work

on one

tappet

at a time to

avoid mixing

of

parts. Mixed parts

are not

compatible.

DO

NOT dis

assemble

a

tappet

on a dirty

work bench.

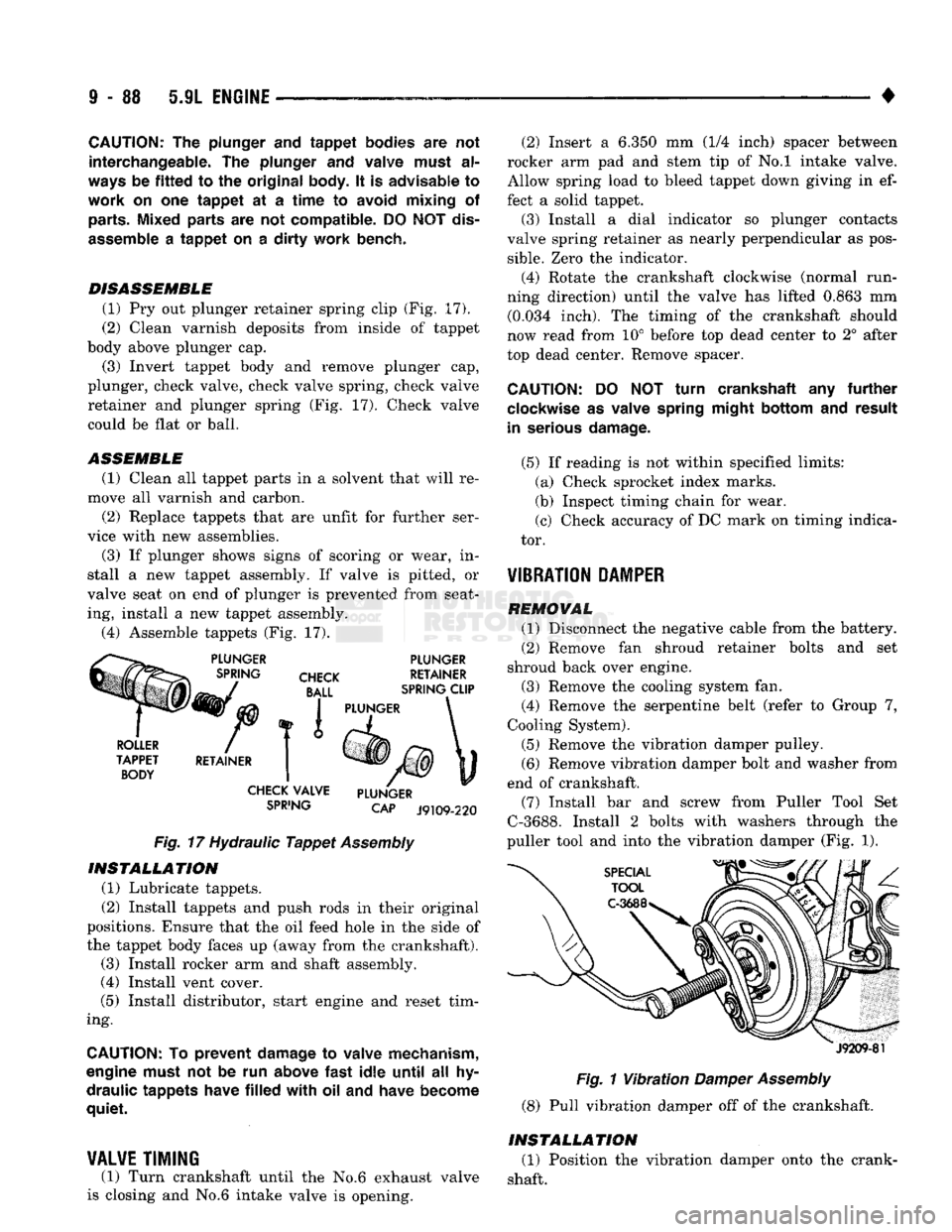

DISASSEMBLE (1) Pry out plunger retainer spring clip (Fig. 17).

(2) Clean varnish deposits from inside of tappet

body above plunger cap.

(3) Invert tappet body and remove plunger cap,

plunger, check valve, check valve spring, check valve

retainer and plunger spring (Fig, 17). Check valve

could be flat or ball.

ASSEMBLE

(1) Clean all tappet parts in a solvent that will re

move all varnish and carbon. (2) Replace tappets that are unfit for further ser

vice with new assemblies.

(3) If plunger shows signs of scoring or wear, in

stall a new tappet assembly. If valve is pitted, or

valve seat on end of plunger is prevented from seat ing, install a new tappet assembly.

(4) Assemble tappets (Fig. 17).

SPiING

CAP J9109-220

Fig.

17 Hydraulic

Tappet

Assembly INSTALLATION

(1) Lubricate tappets.

(2) Install tappets and push rods in their original

positions. Ensure that the oil feed hole In the side of

the tappet body faces up (away from the crankshaft). (3) Install rocker arm and shaft assembly.

(4) Install vent cover.

(5) Install distributor, start engine and reset tim

ing.

CAUTION:

To

prevent damage

to

valve mechanism,

engine must

not be run

above

fast

idle

until

all hy

draulic tappets have

filled

with oil and

have become

quiet.

¥AL¥E

TIMING

(1) Turn crankshaft until the No.6 exhaust valve

is closing and No.6 intake valve Is opening. (2) Insert a 6.350 mm (1/4 inch) spacer between

rocker arm pad and stem tip of No.l intake valve.

Allow spring load to bleed tappet down giving in ef

fect a solid tappet. (3) Install a dial indicator so plunger contacts

valve spring retainer as nearly perpendicular as pos

sible.

Zero the Indicator.

(4) Rotate the crankshaft clockwise (normal run

ning direction) until the valve has lifted 0.863 mm (0.034 inch). The timing of the crankshaft should

now read from 10° before top dead center to 2° after

top dead center. Remove spacer.

CAUTION:

DO NOT

turn crankshaft

any

further

clockwise

as

valve spring might bottom

and

result

in serious damage.

(5) If reading is not within specified limits: (a) Check sprocket index marks.

(b) Inspect timing chain for wear.

(c) Check accuracy of DC mark on timing indica

tor. -

¥IBRATI0N

PAMPER

REMOVAL (1) Disconnect the negative cable from the battery.

(2) Remove fan shroud retainer bolts and set

shroud back over engine. (3) Remove the cooling system fan.

(4) Remove the serpentine belt (refer to Group 7,

Cooling System). (5) Remove the vibration damper pulley. (6) Remove vibration damper bolt and washer from

end of crankshaft. (7) Install bar and screw from Puller Tool Set

C-3688. Install 2 bolts with washers through the

puller tool and into the vibration damper (Fig. 1).

J9209-81

Fig.

1

Vibration

Damper

Assembly

(8) Pull vibration damper off of the crankshaft.

INSTALLATION (1) Position the vibration damper onto the crank

shaft.