gas tank size DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 719 of 1502

9

- 114 5.9L

(DIESEL) ENGINE

—

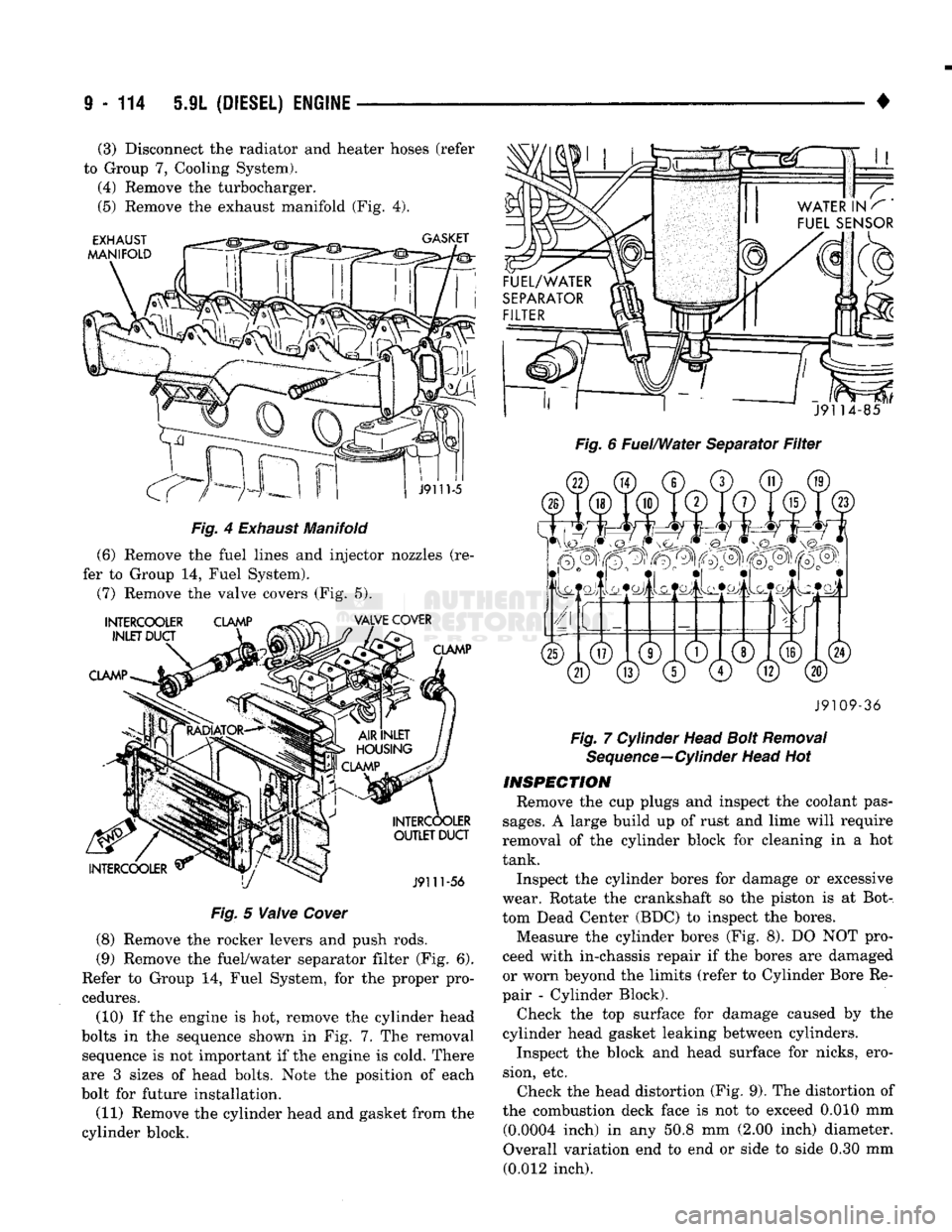

Fig.

4

Exhaust

Manifold

(6) Remove the fuel lines and injector nozzles (re

fer to Group 14, Fuel System).

(7) Remove the valve covers (Fig. 5).

Fig.

5

Valve

Cover

(8) Remove the rocker levers and push rods.

(9) Remove the fuel/water separator filter (Fig. 6).

Refer to Group 14, Fuel System, for the proper pro

cedures.

(10) If the engine is hot, remove the cylinder head

bolts in the sequence shown in Fig. 7..The removal sequence is not important if the engine is cold. There

are 3 sizes of head bolts. Note the position of each

bolt for future installation.

(11) Remove the cylinder head and gasket from the

cylinder block.

•

Fig. 6 Fuel/Water Separator Filter J9109-36

Fig. 7 Cylinder Head Bolt Removal Sequence—Cylinder Head Hot

INSPECTION

Remove the cup plugs and inspect the coolant pas

sages.

A large build up of rust and lime will require

removal of the cylinder block for cleaning in a hot

tank.

Inspect the cylinder bores for damage or excessive

wear. Rotate the crankshaft so the piston is at Bot

tom Dead Center (BDC) to inspect the bores. Measure the cylinder bores (Fig. 8). DO NOT pro

ceed with in-chassis repair if the bores are damaged

or worn beyond the limits (refer to Cylinder Bore Re

pair - Cylinder Block).

Check the top surface for damage caused by the

cylinder head gasket leaking between cylinders.

Inspect the block and head surface for nicks, ero

sion, etc. Check the head distortion (Fig. 9). The distortion of

the combustion deck face is not to exceed 0.010 mm (0.0004 inch) in any 50.8 mm (2.00 inch) diameter.

Overall variation end to end or side to side 0.30 mm (0.012 inch).

(3) Disconnect the radiator and heater hoses (refer

to Group 7, Cooling System). (4) Remove the turbocharger.

(5) Remove the exhaust manifold (Fig. 4).

Page 1159 of 1502

21 - 158

TRANSMISSION

OVERHAUL—32RH

•

OVERHAUL SERVICE

INFORMATION

Inspect all the transmission bushings during over

haul. Bushing condition is important as worn, scored

bushings contribute to low pressures, clutch slip and accelerated wear of other components. Do not replace

bushings as a matter of course. Replace bushings

only when actually worn or scored. Use recommended tools to replace bushings. The

tools are sized and designed to remove, install and seat bushings correctly, The bushing replacement

tools are included in Bushing Tool Set C-3887-B. The

tool set is manufactured by the Miller Tool Co. and is available through the dealer tool program. Pre-sized service bushings are available for re

placement purposes. Only the sun gear bushings are

not serviced. Low cost of the sun gear assembly

makes it easier to simply replace the gear and bush

ings as an assembly. Heli-Coil inserts are recommended for repairing

damaged, stripped or worn threads in aluminum

parts.

These inserts are available from most automo

tive jobbers. Stainless steel inserts are preferred. The use of crocus cloth is permissible where neces

sary, providing it is used carefully. When used on

valves, use extreme care to avoid rounding off sharp

edges.

Sharp edges are vital as they prevent foreign

matter from getting between the valve and valve

bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or

E-clips that are bent or distorted. Replace these parts as well.

Lubricate transmission parts with Mopar ATF

Plus,

Type 7176, or Dexron II™ transmission fluid during overhaul and assembly.

Use Ru-Glyde or Door Eze to lubricate clutch pis

ton seals. Use petroleum jelly to lubricate O-rings and thrust washers. Petroleum jelly can also be used

to hold parts in place during reassembly.

TRANSMISSION

CASE

CLEAN1N8

AND

INSPECTION

Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent. Dry the case and all fluid passages with compressed

air. Be sure all solvent is removed from the case and

that all fluid passages are clear. Do not use shop towels or rags to dry the case

(or any other transmission component) unless

they are made from lint-free materials. Lint will

readily adhere to case surfaces and transmission

components and will circulate throughout the

transmission after assembly. A sufficient quan

tity of lint can block fluid passages and interfere

with valve body operation. Inspect the case for cracks, porous spots, worn

bores,

or damaged threads. Damaged threads can be repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

Lubricate the front band adjusting screw threads

with petroleum jelly and thread the screw part-way into the case. Be sure the screw turns freely.

Remount the case in Repair Stand C-3750-B after

cleaning and inspection.

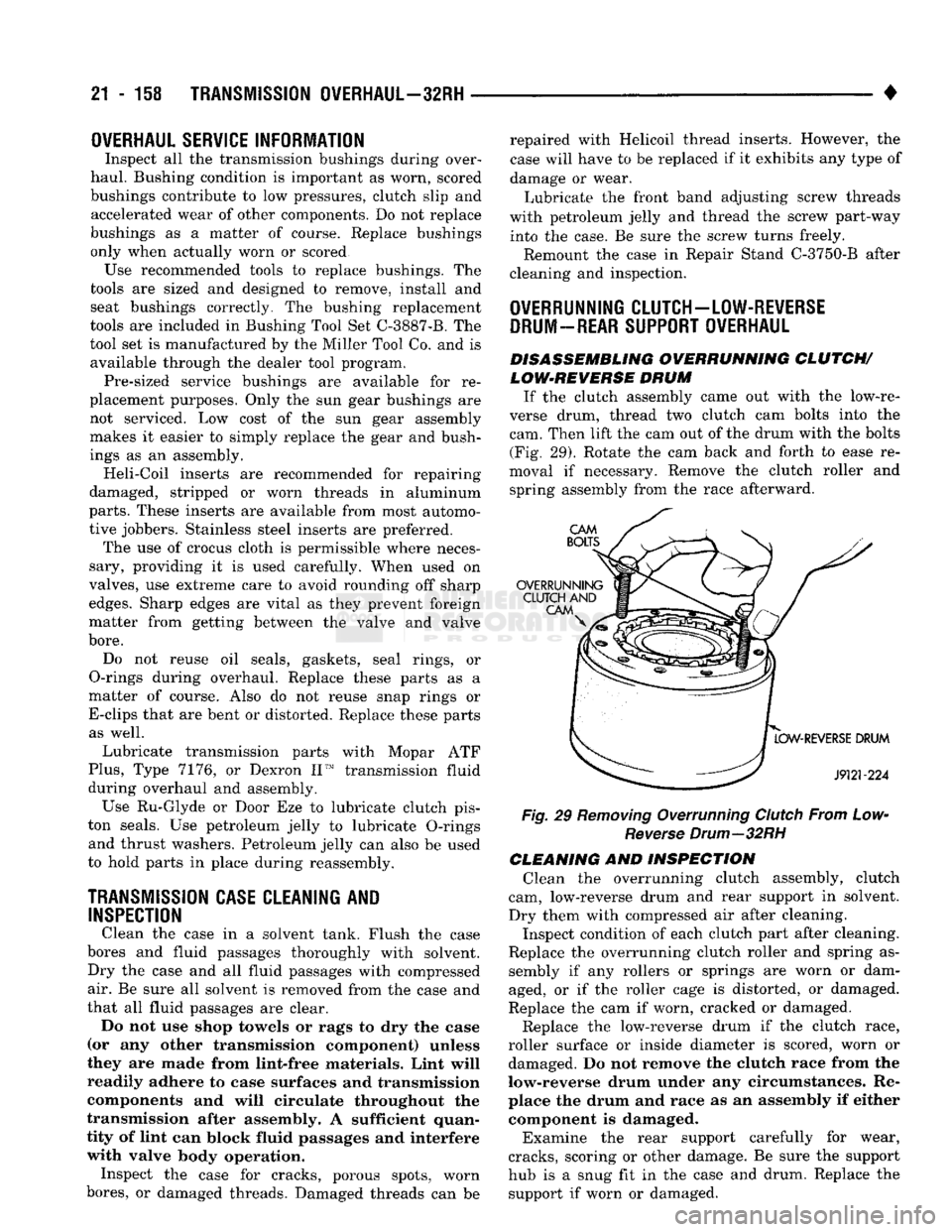

OVERRUNNING CLUTCH-LOW-REVERSE

DRUM-REAR

SUPPORT OVERHAUL

DISASSEMBLING OVERRUNNING CLUTCH/ LOW-REVERSE DRUM

If the clutch assembly came out with the low-re

verse drum, thread two clutch cam bolts into the cam. Then lift the cam out of the drum with the bolts (Fig. 29). Rotate the cam back and forth to ease re

moval if necessary. Remove the clutch roller and spring assembly from the race afterward.

Fig, 29 Removing Overrunning Clutch From Low- Reverse Drum—32RH

CLEANING AND INSPECTION Clean the overrunning clutch assembly, clutch

cam, low-reverse drum and rear support in solvent.

Dry them with compressed air after cleaning. Inspect condition of each clutch part after cleaning.

Replace the overrunning clutch roller and spring as sembly if any rollers or springs are worn or dam

aged, or if the roller cage is distorted, or damaged.

Replace the cam if worn, cracked or damaged.

Replace the low-reverse drum if the clutch race,

roller surface or inside diameter is scored, worn or damaged. Do not remove the clutch race from the

low-reverse drum under any circumstances. Re place the drum and race as an assembly if either component is damaged.

Examine the rear support carefully for wear,

cracks, scoring or other damage. Be sure the support

hub is a snug fit in the case and drum. Replace the support if worn or damaged.

Page 1203 of 1502

21

- 202

TRANSMISSION

OVERHAUL—36RH/37RH

•

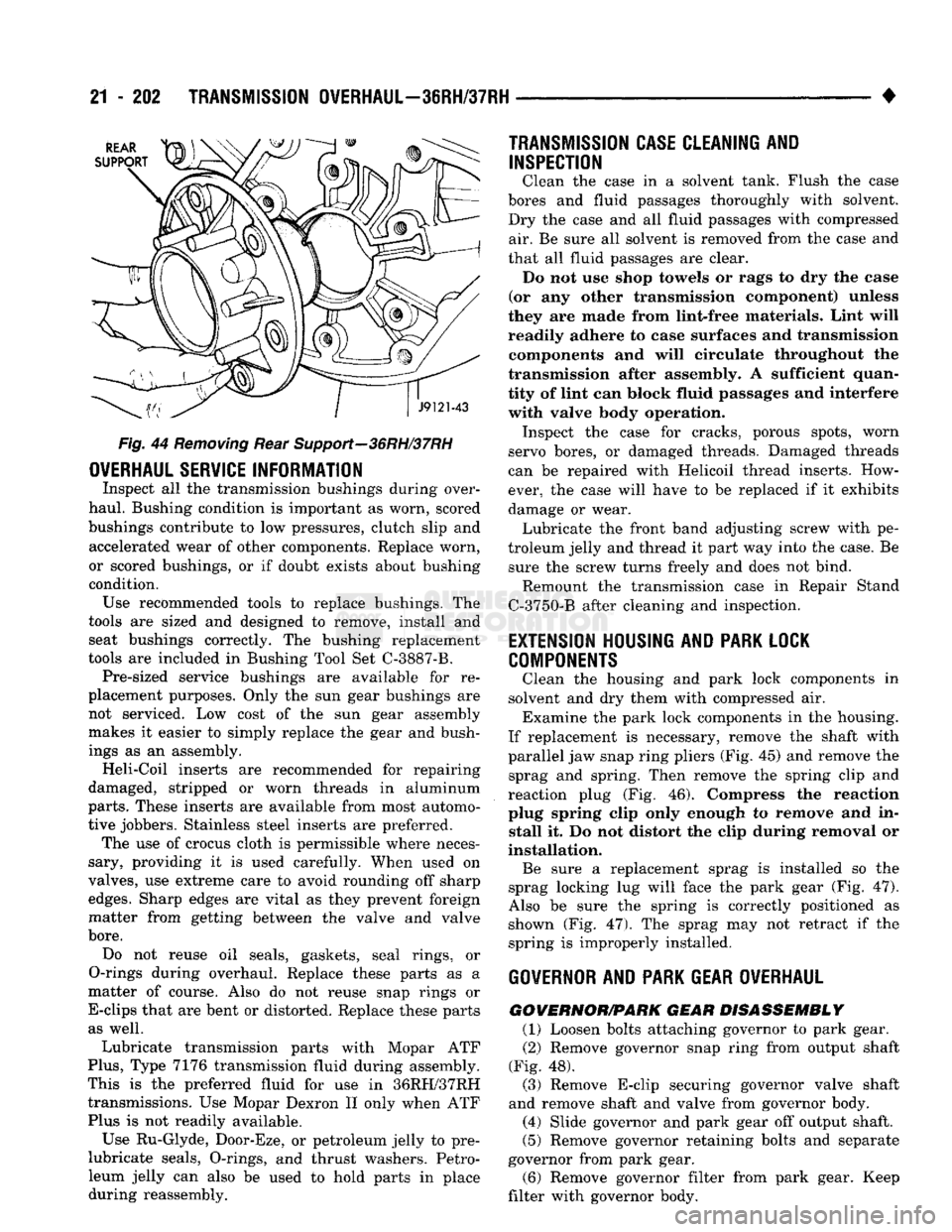

Fig.

44

Removing

Rear Support—36RH/37RH

OVERHAUL

SERVICE

INFORMATION

Inspect

all the

transmission bushings during over

haul. Bushing condition

is

important

as

worn, scored

bushings contribute

to low

pressures, clutch slip

and

accelerated wear

of

other components. Replace worn,

or scored bushings,

or if

doubt exists about bushing

condition. Use recommended tools

to

replace bushings.

The

tools

are

sized

and

designed

to

remove, install

and

seat bushings correctly.

The

bushing replacement

tools

are

included

in

Bushing Tool

Set

C-3887-B. Pre-sized service bushings

are

available

for re

placement purposes. Only

the sun

gear bushings

are

not serviced.

Low

cost

of the sun

gear assembly

makes

it

easier

to

simply replace

the

gear

and

bush

ings

as an

assembly. Heli-Coil inserts

are

recommended

for

repairing

damaged, stripped

or

worn threads

in

aluminum

parts.

These inserts

are

available from most automo

tive jobbers. Stainless steel inserts

are

preferred. The

use of

crocus cloth

is

permissible where neces

sary, providing

it is

used carefully. When used

on

valves,

use

extreme care

to

avoid rounding

off

sharp

edges.

Sharp edges

are

vital

as

they prevent foreign

matter from getting between

the

valve

and

valve

bore.

Do

not

reuse

oil

seals, gaskets, seal rings,

or

O-rings during overhaul. Replace these parts

as a

matter

of

course. Also

do not

reuse snap rings

or

E-clips that

are

bent

or

distorted. Replace these parts as well.

Lubricate transmission parts with Mopar

ATF

Plus,

Type

7176

transmission fluid during assembly.

This

is the

preferred fluid

for use in

36RH/37RH transmissions.

Use

Mopar Dexron

II

only when

ATF

Plus

is not

readily available.

Use Ru-Glyde, Door-Eze,

or

petroleum jelly

to pre-

lubricate seals, O-rings,

and

thrust washers. Petro

leum jelly

can

also

be

used

to

hold parts

in

place during reassembly.

TRANSMISSION CASE

CLEAN1NI

AND

INSPECTION

Clean

the

case

in a

solvent tank. Flush

the

case

bores

and

fluid passages thoroughly with solvent.

Dry

the

case

and all

fluid passages with compressed air.

Be

sure

all

solvent

is

removed from

the

case

and

that

all

fluid passages

are

clear. Do

not use

shop towels

or

rags

to dry the

ease

(or

any

other transmission component) unless

they

are

made from lint-free materials. Lint will

readily adhere

to

case surfaces

and

transmission components

and

will circulate throughout

the

transmission after assembly.

A

sufficient quan

tity

of

lint

can

block fluid passages

and

interfere with valve body operation. Inspect

the

case

for

cracks, porous spots, worn

servo bores,

or

damaged threads. Damaged threads

can

be

repaired with Helicoil thread inserts. How

ever,

the

case will have

to be

replaced

if it

exhibits

damage

or

wear. Lubricate

the

front band adjusting screw with

pe

troleum jelly

and

thread

it

part

way

into

the

case.

Be

sure

the

screw turns freely

and

does

not

bind. Remount

the

transmission case

in

Repair Stand

C-3750-B after cleaning

and

inspection.

EXTENSION

HOUSING

AND PARK

LOCK

COMPONENTS

Clean

the

housing

and

park lock components

in

solvent

and dry

them with compressed

air.

Examine

the

park lock components

in the

housing.

If replacement

is

necessary, remove

the

shaft with

parallel

jaw

snap ring pliers

(Fig. 45) and

remove

the

sprag

and

spring. Then remove

the

spring clip

and

reaction plug

(Fig. 46).

Compress

the

reaction

plug spring clip only enough

to

remove

and in

stall

it. Do not

distort

the

clip during removal

or

installation. Be sure

a

replacement sprag

is

installed

so the

sprag locking

lug

will face

the

park gear

(Fig. 47).

Also

be

sure

the

spring

is

correctly positioned

as

shown

(Fig. 47). The

sprag

may not

retract

if the

spring

is

improperly installed.

GOVERNOR

AND PARK

GEAR OVERHAUL

GOWERNOR/PARK

GEAR DISASSEMBLY

(1) Loosen bolts attaching governor

to

park gear.

(2) Remove governor snap ring from output shaft

(Fig.

48).

(3) Remove E-clip securing governor valve shaft

and remove shaft

and

valve from governor body. (4) Slide governor

and

park gear

off

output shaft.

(5) Remove governor retaining bolts

and

separate

governor from park gear.

(6) Remove governor filter from park gear. Keep

filter with governor body.

Page 1286 of 1502

•

TRANSMISSION

OVERHAUL-46RH

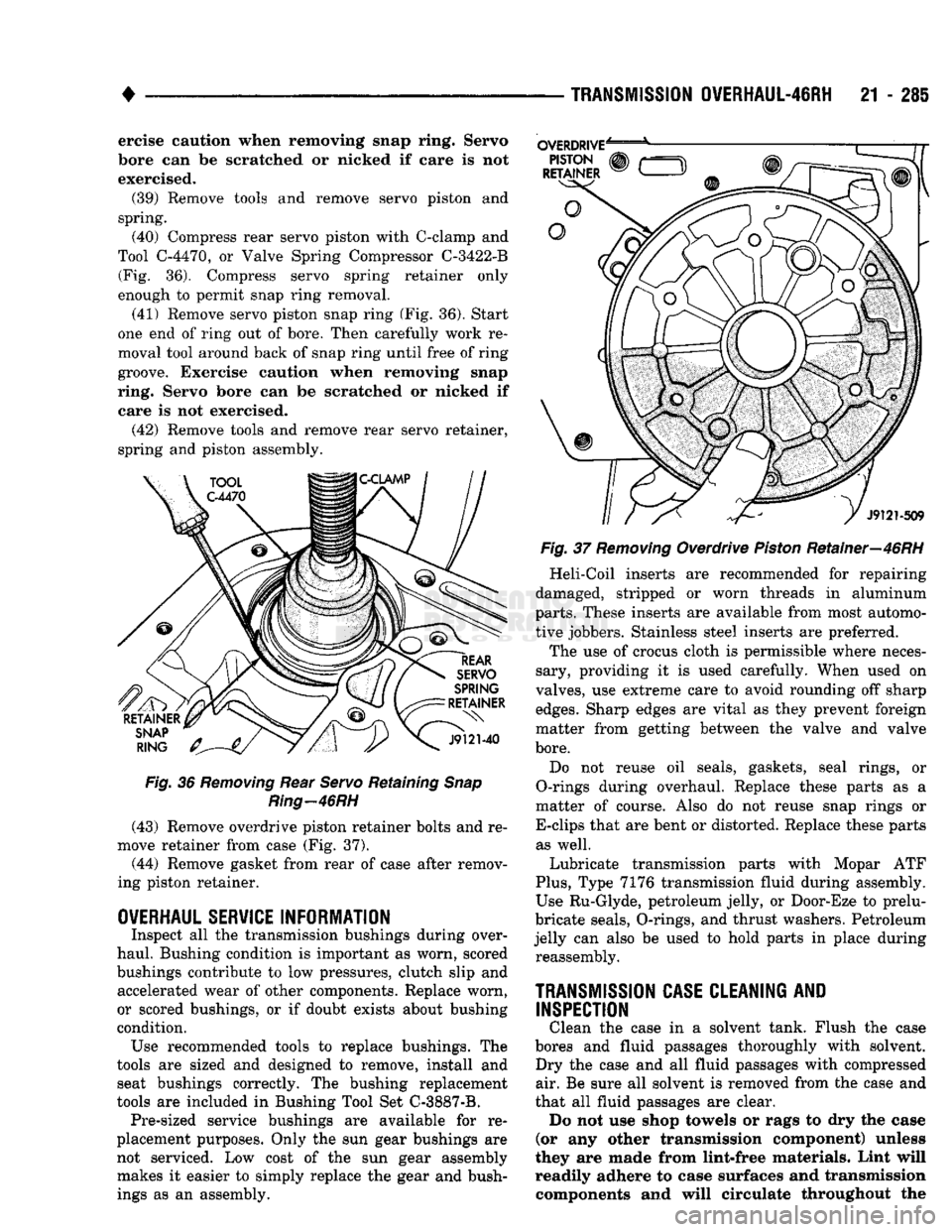

21 - 285 ercise caution when removing snap ring. Servo

bore can be scratched or nicked if care is not

exercised.

(39)

Remove tools and remove servo piston and

spring.

(40)

Compress rear servo piston with C-clamp and

Tool C-4470, or Valve Spring Compressor C-3422-B (Fig. 36). Compress servo spring retainer only

enough to permit snap ring removal.

(41) Remove servo piston snap ring (Fig. 36). Start

one end of ring out of bore. Then carefully work re

moval tool around back of snap ring until free of ring

groove. Exercise caution when removing snap

ring. Servo bore can be scratched or nicked if care is not exercised.

(42) Remove tools and remove rear servo retainer,

spring and piston assembly.

Fig.

36

Removing

Rear

Servo

Retaining

Snap

Ring—46RH

(43) Remove overdrive piston retainer bolts and re

move retainer from case (Fig. 37).

(44) Remove gasket from rear of case after remov

ing piston retainer.

OVERHAUL SERVICE

INFORMATION

Inspect all the transmission bushings during over

haul. Bushing condition is important as worn, scored

bushings contribute to low pressures, clutch slip and accelerated wear of other components. Replace worn,

or scored bushings, or if doubt exists about bushing

condition. Use recommended tools to replace bushings. The

tools are sized and designed to remove, install and seat bushings correctly. The bushing replacement

tools are included in Bushing Tool Set C-3887-B. Pre-sized service bushings are available for re

placement purposes. Only the sun gear bushings are not serviced. Low cost of the sun gear assembly makes it easier to simply replace the gear and bushings as an assembly.

Fig.

37

Removing

Overdrive

Piston

Retainer—46RH

Heli-Coil inserts are recommended for repairing

damaged, stripped or worn threads in aluminum

parts.

These inserts are available from most automo

tive jobbers. Stainless steel inserts are preferred.

The use of crocus cloth is permissible where neces

sary, providing it is used carefully. When used on

valves, use extreme care to avoid rounding off sharp

edges.

Sharp edges are vital as they prevent foreign

matter from getting between the valve and valve

bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or

E-clips that are bent or distorted. Replace these parts as well.

Lubricate transmission parts with Mopar ATF

Plus,

Type 7176 transmission fluid during assembly.

Use Ru-Glyde, petroleum jelly, or Door-Eze to prelu-

bricate seals, O-rings, and thrust washers. Petroleum

jelly can also be used to hold parts in place during reassembly.

TRANSMISSION

CASE

CLEANING

AND

INSPECTION

Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent. Dry the case and all fluid passages with compressed air. Be sure all solvent is removed from the case and

that all fluid passages are clear. Do not use shop towels or rags to dry the case

(or any other transmission component) unless

they are made from lint-free materials. Lint will readily adhere to case surfaces and transmission components and will circulate throughout the