headlamp DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 47 of 1502

0

- 28

LUBRICATION

AND

MAINTENANCE

•

CHASSIS AND BODY

page

Body

Component Mechanisms

32

Front

Suspension

Ball

Joints

28

Front

Wheel Bearings

29

Headlamps

32

Lower

and

Upper Suspension

Arm

Bushings

.... 30

Manual

Steering Gear

28

STEERING

LINKAGE

INSPECTION When

a

vehicle

is

raised

for

maintenance under

the vehicle,

all

steering components should

be

checked.

LUBRICATION SCHEDULE The steering linkage

is

lubricated with

a

chassis

lubricant. However,

it is

recommended that

the

link

age

be

inspected

and

lubricated after each:

•

24 000 km

(15,000 miles) interval

or

every

6

months,

for 2WD

vehicles subject

to the

LIGHT

DUTY CYCLE Maintenance Schedule

•

9 600 km

(6,000 miles) interval

or

every

6

months,

for

2WD

vehicles subject

to the

HEAVY DUTY

CY

CLE Maintenance Schedule

•

12 000 km

(7,500 miles) interval

or

every

6

months,

for 4WD

vehicles subject

to the

LIGHT DUTY CYCLE Maintenance Schedule

•

9 600 km

(6,000 miles) interval

or

every

6

months,

for

4WD

vehicles subject

to the

HEAVY DUTY

CY

CLE Maintenance Schedule.

LUBRICATION (1) Inspect

the

steering linkage

for

looseness

and

excessive wear. (2) Replace,

all

ruptured seals

and

damaged steer

ing linkage components. Damaged seals should

be re

placed

to

prevent leakage

and

contamination

of the

lubricant.

CAUTION:

Use

care

to

prevent lubricant from

con

tacting

the

brake rotors.

(3) Lubricate

the

steering linkage:

• Clean

the

Zerk type lubrication fittings

on the tie-

rod

and

center link ball-stud ends

• Lubricate

the

ball studs with MOPAR®Multi-Mile- age Lubricant

• Wipe

the

excess lubricant from

the

exterior sur

faces

of the

ball joints

page

Power

Brake System

30

Power

Steering System

. . 29

Rear

Wheel Bearings

30

Speedometer Cable

33

Steering Linkage

28

Tires

32

FRONT

SUSPENSION

BALL JOINTS

INSPECTION When

a

vehicle

is

raised

for

lubrication/general

maintenance,

the

ball joints should

be

inspected.

LUBRICATION SCHEDULE The front suspension ball joints

are

lubricated dur

ing manufacture with

a

long-life chassis lubricant.

However,

it is

recommended that

the

ball joints

be

inspected

and the

studs lubricated:

•

At

each

36 000 km

(22,500 miles) interval

or

every

2 years,

for

vehicles subject

to the

LIGHT DUTY

CY

CLE Maintenance Schedule

•

At

each

9 600 km

(6,000 miles) interval

or

every

2

years,

for

vehicles subject

to the

HEAVY DUTY

CY

CLE Maintenance Schedule.

4WD vehicles that

are

frequently driven

off-

road should

be

lubricated

at

every engine

oil

change.

LUBRICATION (1) Inspect

the

front suspension. Examine

the

ball

studs

for

looseness

and

excessive wear. (2) Replace

all

torn ball-stud seals

and

damaged

ball joints. Damaged seals should

be

replaced

to

pre vent leakage

and

contamination.

CAUTION:

Use

care

to

prevent lubricant from

con

tacting

the

brake rotors.

(3) Lubricate

the

ball studs:

• Clean

the

Zerk type lubrication fittings

on the

ball-stud ends

• Lubricate

the

ball studs with MOPAR®Multi-Mile-age Lubricant

• Wipe

the

excess lubricant from

the

exterior sur

faces

of the

ball joints

MANUAL

STEERING

GEAR

LUBRICATION Manual steering gears

are

permanently lubricated

during manufacture. Periodic lubrication

is not

nec

essary.

Page 51 of 1502

0

- 32

LUBRICATION

AND

MAINTENANCE

•

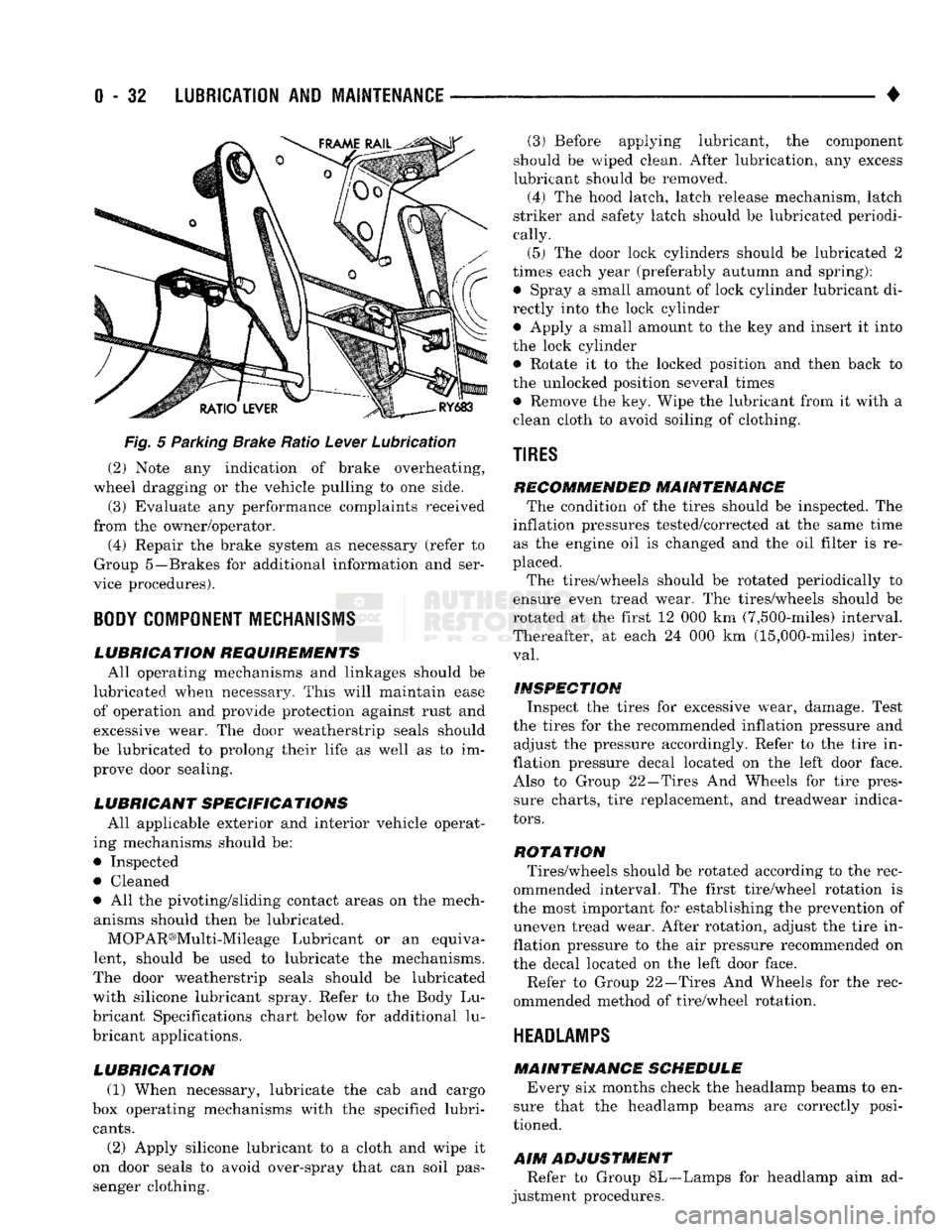

Fig.

5 Parking Brake Ratio Lever Lubrication (2) Note any indication of brake overheating,

wheel dragging or the vehicle pulling to one side.

(3) Evaluate any performance complaints received

from the owner/operator. (4) Repair the brake system as necessary (refer to

Group 5—Brakes for additional information and ser

vice procedures).

BODY

COMPONENT

MECHANISMS

LUBRICATION REQUIREMENTS

All operating mechanisms and linkages should be

lubricated when necessary. This will maintain ease of operation and provide protection against rust and

excessive wear. The door weatherstrip seals should

be lubricated to prolong their life as well as to im prove door sealing.

LUBRICANT SPECIFICATIONS

All applicable exterior and interior vehicle operat

ing mechanisms should be:

• Inspected • Cleaned

• All the pivoting/sliding contact areas on the mech anisms should then be lubricated.

MOPAR®Multi-Mileage Lubricant or an equiva

lent, should be used to lubricate the mechanisms.

The door weatherstrip seals should be lubricated

with silicone lubricant spray. Refer to the Body Lu

bricant Specifications chart below for additional lu

bricant applications.

LUBRICATION

(1) When necessary, lubricate the cab and cargo

box operating mechanisms with the specified lubri

cants.

(2) Apply silicone lubricant to a cloth and wipe it

on door seals to avoid over-spray that can soil pas

senger clothing. (3) Before applying lubricant, the component

should be wiped clean. After lubrication, any excess

lubricant should be removed.

(4) The hood latch, latch release mechanism, latch

striker and safety latch should be lubricated periodi

cally.

(5) The door lock cylinders should be lubricated 2

times each year (preferably autumn and spring): • Spray a small amount of lock cylinder lubricant di

rectly into the lock cylinder

• Apply a small amount to the key and insert it into

the lock cylinder • Rotate it to the locked position and then back to

the unlocked position several times

• Remove the key. Wipe the lubricant from it with a

clean cloth to avoid soiling of clothing.

TIRES

RECOMMENDED MAINTENANCE

The condition of the tires should be inspected. The

inflation pressures tested/corrected at the same time as the engine oil is changed and the oil filter is re

placed.

The tires/wheels should be rotated periodically to

ensure even tread wear. The tires/wheels should be

rotated at the first 12 000 km (7,500-miles) interval.

Thereafter, at each 24 000 km (15,000-miles) inter

val.

INSPECTION

Inspect the tires for excessive wear, damage. Test

the tires for the recommended inflation pressure and adjust the pressure accordingly. Refer to the tire in

flation pressure decal located on the left door face. Also to Group 22—Tires And Wheels for tire pressure charts, tire replacement, and treadwear indica

tors.

ROTATION

Tires/wheels should be rotated according to the rec

ommended interval. The first tire/wheel rotation is

the most important for establishing the prevention of uneven tread wear. After rotation, adjust the tire in

flation pressure to the air pressure recommended on

the decal located on the left door face.

Refer to Group 22—Tires And Wheels for the rec

ommended method of tire/wheel rotation.

HEADLAMPS

MAINTENANCE SCHEDULE

Every six months check the headlamp beams to en

sure that the headlamp beams are correctly posi

tioned.

AIM

ADJUSTMENT

Refer to Group 8L—Lamps for headlamp aim ad

justment procedures.

Page 329 of 1502

8A

- 8

ELECTRICAL

BATTERY

DIAGNOSTICS

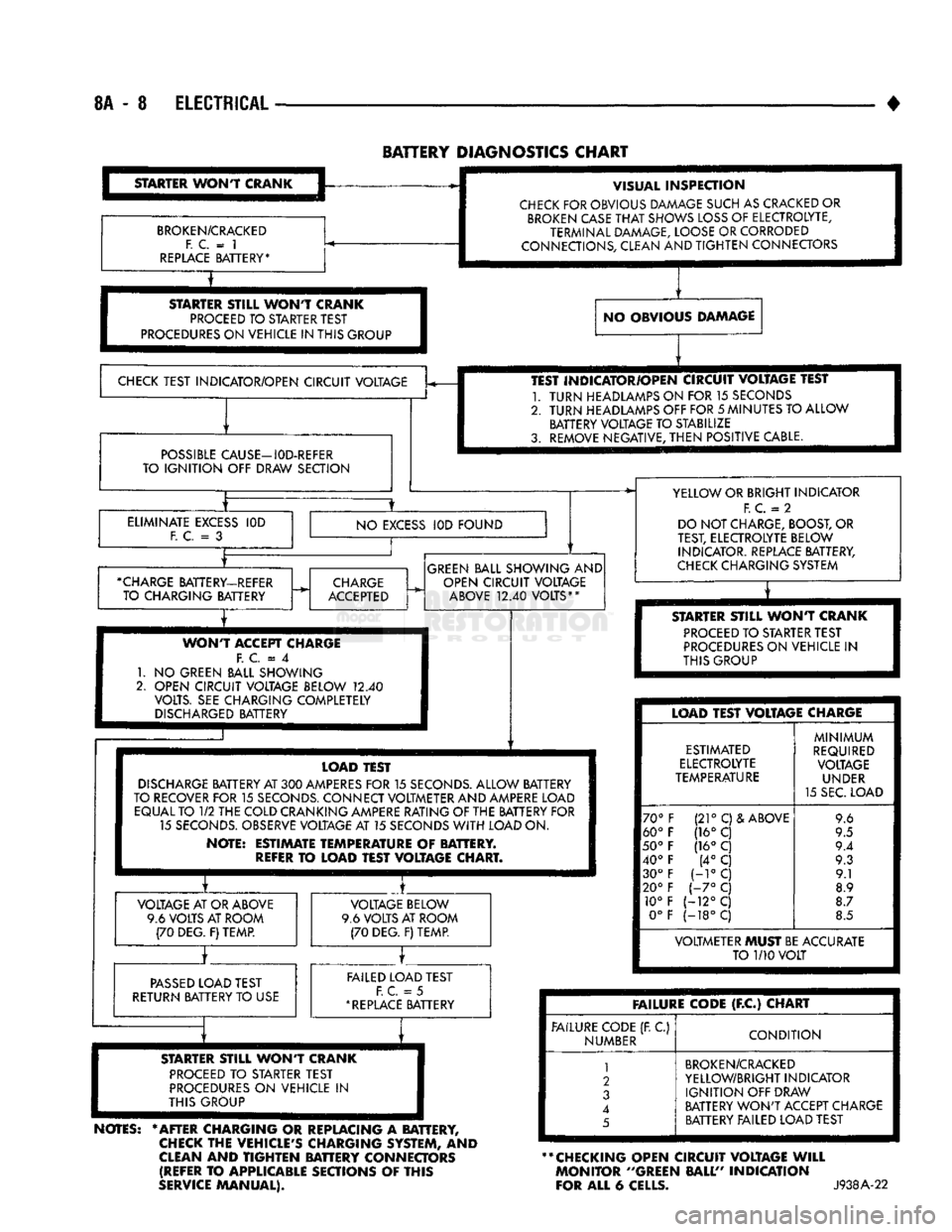

CHART

STARTER

WONT

CRANK

BROKEN/CRACKED

F. C.

= 1

REPLACE

BATTERY* VISUAL

INSPECTION

CHECK

FOR OBVIOUS DAMAGE SUCH AS CRACKED OR

BROKEN

CASE

THAT

SHOWS

LOSS

OF ELECTROLYTE,

TERMINAL DAMAGE, LOOSE OR CORRODED

CONNECTIONS, CLEAN AND

TIGHTEN

CONNECTORS

STARTER

STILL

WONT

CRANK

PROCEED

TO STARTER TEST

PROCEDURES

ON VEHICLE IN THIS GROUP NO OBVIOUS DAMAGE

CHECK

TEST INDICATOR/OPEN CIRCUIT VOLTAGE

POSSIBLE

CAUSE—I0D-REFER

TO

IGNITION

OFF DRAW SECTION TEST INDICATOR/OPEN CIRCUIT VOLTAGE TEST

1.

TURN

HEADLAMPS ON FOR 15 SECONDS

2.

TURN

HEADLAMPS OFF FOR

5

MINUTES TO ALLOW BATTERY VOLTAGE TO STABILIZE

3. REMOVE NEGATIVE,

THEN

POSITIVE CABLE.

ELIMINATE

EXCESS

F. C.

= 3

IOD

NO

EXCESS

IOD FOUND

•CHARGE

BATTERY-REFER TO CHARGING BATTERY

CHARGE

ACCEPTED

GREEN

BALL SHOWING AND

OPEN CIRCUIT VOLTAGE

ABOVE

12.40

VOLTS**

WONT

ACCEPT CHARGE F.

C = 4

1.

NO

GREEN BALL SHOWING

2. OPEN CIRCUIT VOLTAGE BELOW

12.40

VOLTS. SEE CHARGING COMPLETELY

DISCHARGED

BATTERY YELLOW OR BRIGHT INDICATOR

F.

C.

= 2

DO NOT CHARGE, BOOST, OR

TEST, ELECTROLYTE BELOW INDICATOR. REPLACE BATTERY,

CHECK

CHARGING SYSTEM

T

STARTER

STILL

WONT

CRANK

PROCEED

TO STARTER TEST

PROCEDURES

ON VEHICLE

IN

THIS GROUP LOAD TEST

DISCHARGE

BATTERY AT

300

AMPERES

FOR

15

SECONDS.

ALLOW BATTERY

TO RECOVER FOR

15

SECONDS.

CONNECT VOLTMETER AND AMPERE LOAD EQUAL TO

1/2

THE COLD CRANKING AMPERE RATING OF THE BATTERY FOR 15

SECONDS.

OBSERVE VOLTAGE AT 15 SECONDS

WITH

LOAD ON.

NOTE: ESTIMATE TEMPERATURE

OF

BATTERY.

REFER

TO

LOAD TEST VOLTAGE CHART. VOLTAGE AT OR ABOVE

9.6 VOLTS AT ROOM (70 DEG. F) TEMP. VOLTAGE BELOW

9.6 VOLTS AT ROOM (70 DEG. F) TEMP.

PASSED

LOAD TEST

RETURN BATTERY TO USE FAILED LOAD TEST

F. C.

= 5

*

REPLACE

BATTERY LOAD TEST VOLTAGE CHARGE

ESTIMATED

ELECTROLYTE

TEMPERATURE

70°

60°

50°

40° 30°

20° 10° 0° (21°

C)& ABOVE

(16° C

(16°

C (4°

C

H°C

1-7°

C

(-12°C

(-18°C

MINIMUM

REQUIRED VOLTAGE UNDER

15 SEC. LOAD 9.6

9.5

9.4 9.3 9.1

8.9

8.7

8.5 VOLTMETER MUST BE ACCURATE

TO

1/10

VOLT

STARTER

ST8LL

WONT

CRANK

PROCEED

TO

STARTER TEST

PROCEDURES

ON

VEHICLE

IN

THIS GROUP

NOTES:

* AFTER CHARGING

OR

REPLACING

A

BATTERY,

CHECK

THE VEHICLE'S CHARGING SYSTEM,

AND

CLEAN

AND

TIGHTEN

BATTERY CONNECTORS (REFER

TO

APPLICABLE SECTIONS

OF

THIS

SERVICE

MANUAL). FAILURE CODE

(F.C)

CHART

FAILURE CODE (R

C)

NUMBER

CONDITION

1

2

3

4

5

BROKEN/CRACKED

YELLOW/BRIGHT INDICATOR

IGNITION

OFF DRAW

BATTERY

WON'T

ACCEPT CHARGE BATTERY FAILED LOAD TEST

** CHECKING OPEN CIRCUIT VOLTAGE

WILL

MONITOR ''GREEN BALL" INDICATION

FOR ALL

6

CELLS.

J938A-22

Page 394 of 1502

INSTRUMENT PANEL

AND

GAUGES

8E - 13

INSTRUMENT

PANEL MAP LAMP

BRACKET

HEADLAMP

SWITCH

CLUSTER

ASSEMBLY

HEADLAMP

SWITCH

MOUNTING

NUT CARGO LAMP

SWITCH

BEZEL

AND

APPLIQUE

HEADLAMP

KNOB

AND

STEM

BRACKET-AAAP LAMP

MOUNTING

Fig.

2 Instrument

Panel

(6) Position lower steering cover and install 4

screws.

(7)

Install bezel.

(8)

Remove protective cover from steering column.

(9) Connect negative cable to battery. (10) Check to see that all instruments are func

tioning properly.

PRINTED CIRCUIT BOARD

A visual inspection of the conductors should be

made for cracks or damaged circuits. If no visual

damage is evident, each circuit should be tested for continuity with an ohmmeter or a test light. Should an open circuit be detected, the printed circuit board

should be replaced.

REMOVAL (FIG. 3J (1) Remove instrument cluster. See cluster re

moval.

(2)

Remove lamp socket assemblies.

(3) Remove gauge mounting screws and remove

gauges.

(4) Remove printed circuit board mounting screws.

(5)

Remove printed circuit board from cluster hous

ing.

HEADLAMP

SWITCH

BEZEL

CLUSTER MASK AND LENS

J928E-46

Cluster

and

Switches

INSTALLATION

CAUTION:

Do not overtighten mounting

screws

or

damage

to circuit

board

and/or

cluster

housing

will

occur.

(1) Position printed circuit board on cluster hous

ing, install mounting screws and tighten.

(2)

Install gauges.

(3) Install lamp socket assemblies. Be sure illumi

nation lamp diffusers are installed. (4) Install instrument cluster.

FUEL GAUGE

TEMPERATURE

GAUGE VOLTAGE GAUGE

OIL

PRESSURE

GAUGE

It is not necessary to remove instrument clus

ter from vehicle for gauge replacement. When removing gauge assemblies (Fig. 4) from

cluster, gauge must be pulled straight out, not

twisted, or damage to gauge pin and/or printed cir cuit board may result. (1) Disconnect negative cable from battery.

(2)

Remove bezel. Refer to Cluster Bezel Removal. (3) Remove cluster mask and lens. Refer to Cluster

Mask and Lens Removal.

Page 398 of 1502

INSTRUMENT

PANEL

AND

GAUGES

8E - 17

HEATER

A/C

CONTROL

REMOVAL

(1) Remove map lamp.

(2) Remove cluster bezel (refer to Cluster Bezel Re

moval).

(3) Remove 2 control attaching screws.

(4) Pull control rearward.

(5) Disconnect blower switch wiring.

(6) Disconnect wires to pushbutton switch (three

connectors). (7) Disconnect illumination lamp.

(8) Disconnect vacuum harness.

(9) Disconnect temperature cable.

(10) Remove control.

INSTALLATION

(1) Position control near panel.

(2) Connect temperature cable (see Group 24 -

Heating and Air Conditioning).

(3) Connect vacuum harness. (4) Connect illumination lamp.

(5) Attach 3 wire connectors to pushbutton switch.

(6) Connect wires to blower motor switch.

(7) Push control into panel.

(8) Install 2 control mounting screws.

(9) Install cluster bezel.

(10) Install map lamp.

INSTRUMENT

PANEL SWITCHES

HEADLAMP

SWITCH

(FIG. 2)

REMOVAL

(1) Remove cluster bezel (refer to Cluster Bezel Re

moval).

(2) Reaching under instrument panel, depress knob

and stem release button located on bottom of switch

housing. At the same time pull knob and stem as sembly out of switch housing located on front of

panel.

(3) Remove power mirror switch knob by pulling

straight off.

(4) Remove bezel.

(5) From front of panel remove spanner nut,

mounting switch to panel. (6) Reaching under instrument panel, lower switch

down far enough to disconnect electrical leads. (7) Remove switch.

INSTALLATION

(1) Connect all electrical leads to switch.

(2) Guide switch into position in panel, install

spanner nut and tighten securely.

(3) Install bezel.

(4) Install power mirror switch knob.

(5) Insert knob and stem assembly into switch.

AAAP LAMP

BRACKET

HEADLAMP SWITCH

CLUSTER

ASSEMBLY

HEADLAMP

SWITCH MOUNTING NUT

CARGO

LAMP SWITCH

BEZEL

AND APPLIQUE

HEADLAMP

KNOB AND STEM

BRACKET-MAP LAMP MOUNTING HEADLAMP

SWITCH BEZEL

CLUSTER AAASK AND LENS

J928E-46

Fig.

2 Instrument

Panel

Switches

Page 429 of 1502

8J

- 2

TURN SIGNALS AND HAZARD WARNING FLASHER

•

FUSE

BLOCK

INSTRUMENT

PANEL

REAR

VIEW

HAZARD

WARNING

FLASHER

VIEW

IN DIRECTION OF

ARROW

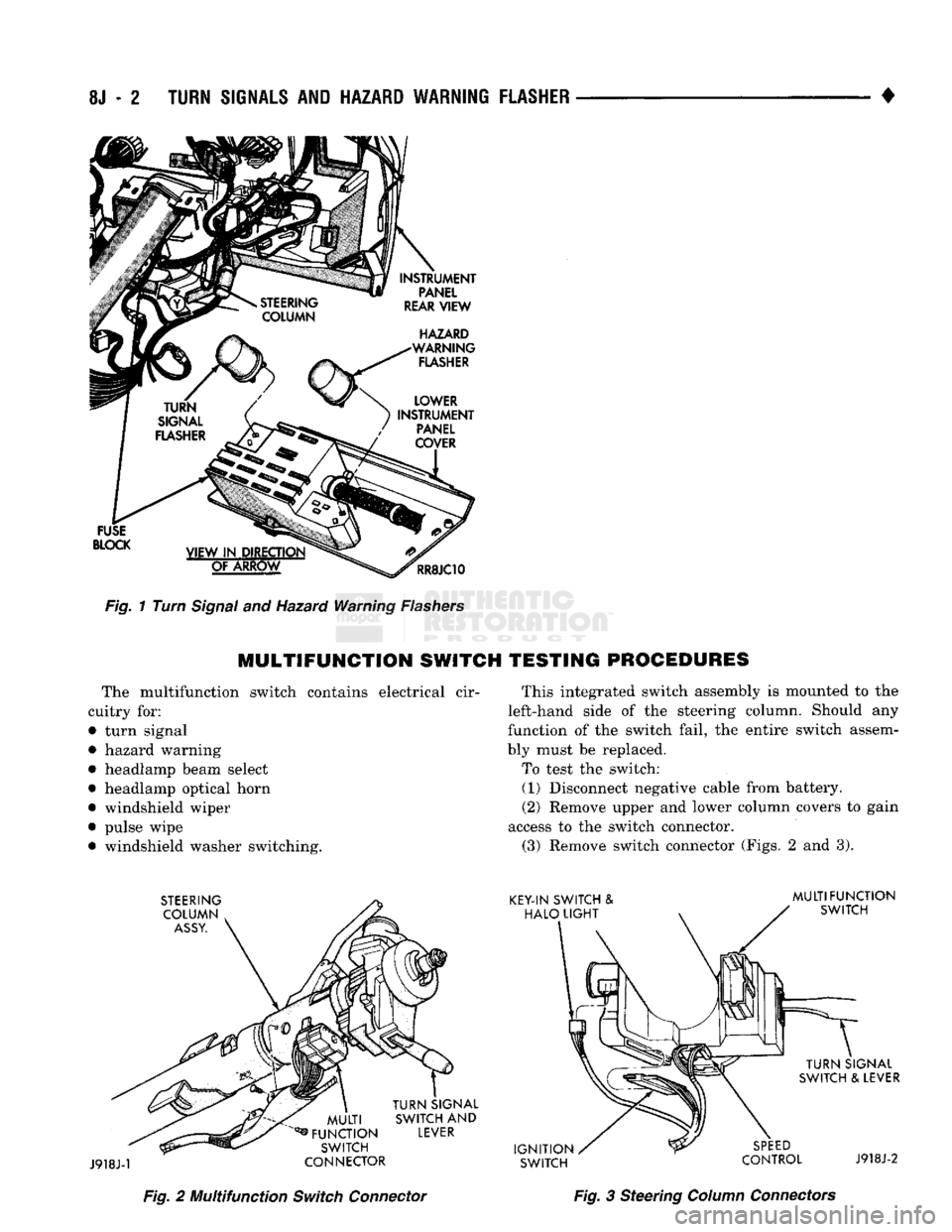

RR8JC10

Fig.

1 Turn

Signal

and Hazard Warning

Flashers

MULTIFUNCTION

SWITCH TESTING PROCEDURES

The multifunction switch contains electrical cir

cuitry for:

• turn signal

• hazard warning

• headlamp beam select

• headlamp optical horn

• windshield wiper

• pulse wipe • windshield washer switching. This integrated switch assembly is mounted to the

left-hand side of the steering column. Should any

function of the switch fail, the entire switch assem

bly must be replaced.

To test the switch: (1) Disconnect negative cable from battery.

(2) Remove upper and lower column covers to gain

access to the switch connector. (3) Remove switch connector (Figs. 2 and 3).

Fig.

2 Multifunction

Switch

Connector

Fig.

3 Steering

Column

Connectors

Page 435 of 1502

8K - 4

WINDSHIELD WIPER

AND

WASHER

SYSTEMS

•

PROCEDURE (1) Remove wiring harness. Connect jumper from

Terminal P2 to terminal "L" of wiper motor (Fig, 4).

TERMINALS

Fig. 4 Om Jumper Wire Between Terminal "P2" and

"L".

One Jumper Wire Between Terminal "P1" and "B+" (2) Connect second jumper from terminal "PI" to

battery. If motor runs to PARK position and stops,

wiper switch is faulty. If motor keeps running and

does not park, replace motor assembly.

CONDITION Motor will stop wherever it is, when column

switch is put in OFF position. (Wipers do not

continue running to PARK position).

PROCEDURE

(1) Remove motor wiring connector and clean ter

minals. Reconnect connector and test motor. If prob lem persists, proceed to step No. 2.

(2) Put wiper switch to OFF and ignition switch to

ACC position. Disconnect motor wiring connector. Connect a voltmeter or test lamp to the motor

ground strap. Connect the other lead to terminal

"PI"

of wiring connector.

(a) If voltage is not present, check for an open

circuit in the wiring harness or wiper control

switch or fuse. (b) If voltage is present, proceed to step (3).

(3) Remove wiper motor from vehicle and connect

an ohmmeter or continuity tester between terminals

"L"

and "P2" (Fig. 5).

(a) If there is continuity between these termi

nals,

the problem is a defective motor. Fig. 5 Ohmmeter Between Terminal "L" and "P2"

(b) If there is no continuity, the problem is an

open circuit in the wiper control switch or wiring

harness.

MULTIFUNCTION

(TWO

SPEED WIPER) SWITCH

TESTING PROCEDURES

The multifunction switch contains circuitry for:

• turn signal

• hazard warning

• headlamp beam select

• headlamp optical horn

• windshield wiper

• pulse wipe

• and windshield washer switching. This integrated switch assembly is mounted to the

left-hand side of the steering column. Should any

function of the switch fail, the entire switch assem

bly must be replaced. To test the switch: (1) Disconnect negative cable from battery.

(2) Remove tilt lever (Tilt column only).

(3)

Remove upper and lower column covers to gain

access to the switch connector (Fig. 6). (4) Remove lower fixed column cover.

(5) Loosen steering column upper bracket nuts. Do

Not remove nuts.

(6)

Move upper fixed column cover to gain access

to rear of multifunction switch.

(7)

Remove switch connector (Figs. 7 and 8).

(8)

Using an ohmmeter, test for continuity (no re

sistance) between the terminals of the switch as

shown in the following continuity chart (Fig. 9).

(9)

Refer to Service Procedures for assembly.

Page 444 of 1502

•

LAMPS

LAMPS

8L - 1

CONTENTS

page page

BULB

APPLICATION 11 EXTERIOR

LAMPS

SERVICE

PROCEDURES

... 3

EXTERIOR

LAMPS

1 INTERIOR

LAMPS

10

EXTERIOR LAMPS

GENERAL

INFORMATION Each vehicle is equipped with various lamp assem

blies.

A good ground is necessary for proper lighting operation. When changing lamp bulbs check the socket for

corrosion. Clean corrosion with a wire brush. Coat

the inside of the socket lightly with Mopar® Multi- Purpose Grease or equivalent.

DIAGNOSTIC

PROCEDURES

Always begin any diagnosis by testing all of the

fuses and circuit breakers in the system. Refer to Group 8W, Wiring Diagrams. Conventional and halogen headlamps are inter

changeable. It is recommended that they not be in

termixed on a given vehicle.

MULTI-FUNCTION

SWITCH TESTING

PROCEDURES

The multi-function switch contains electrical cir

cuitry for:

• Headlamp Dimmer Switch

• Passing Lights

• Turn Signals

• Hazard Warning • Windshield Wiper

• Pulse Wiper

• Windshield Washer

HEADLAMPS

HIM

ENGINE

IDLING

OR

IGNITION

OFF

TEST CHARGING

SYSTEM

HEADLAMP

DIAGNOSIS

SEALED

BEAM

OR

BULB

BURNS

OUT

FREQUENTLY

][

TEST CHARGING SYSTEM

HEADLAMPS

DIM

ENGINE

RUNNING

ABOVE

IDLE

][

TEST CHARGING SYSTEM

HEADLAMPS

RANDOM

FLASH

[

HEADLAMPS

WILL

NOT

LIGHT

POORLY GROUNDED HEADLAMP CIRCUIT

LOOSE

CONNECTION

IN HEADLAMP CIRCUIT

HIGH RESISTANCE IN HEADLAMP CIRCUIT

LOOSE

CONNECTION

IN HEADLAMP CIRCUIT HIGH RESISTANCE

IN HEADLAMP CIRCUIT

LOOSE

CONNECTION

IN HEADLAMP CIRCUIT OPEN OR CORRODED

CONTACT

IN

HEADLAMP SWITCH

CRACKED

LENS ON HALOGEN SEALED BEAM ONLY

FAULTY

SEALED

BEAMS

OR BULBS OPEN OR CORRODED

CONTACT IN DIMMER SWITCH

FAULTY

SEALED

BEAMS

OR BULBS

FAULTY

SEALED

BEAMS

OR BULBS

RR8LD21

Page 446 of 1502

•

LAMPS

8L - 3

EXTERIOR

LAMPS

SERWICE PROCEDURES

INDEX

page

Cargo

Lamp

7

Clearance Lamps

for

Dual Wheel Model

........

5

Daytime Running

Light

Module (Canada Only)

... 8

Front

Park

and

Turn Signal Lamp Bulb

4

Headlamp

Adjustment

Using

Alignment

Screen

... 3

Headlamp

Alignment

3

Headlamp

Alignment

Preparation

3

page

Headlamp Switch

4

License

Lamp

............................

7

Sealed

Beam Replacement

4

Side

Marker Lamp

and

Bulb

. 5

Tail,

Stop, Turn Signal, Rear Side Marker

and

Back-Up

Lamps

5

Underhood Lamp

8

HEADLAMP

ALIGNMENT

Headlamps

can be

aligned using

the

screen method

provided

in

this section. Alignment Tool C4466-A

or

equivalent

can

also

be

used. Refer

to

instructions

provided with

the

tool

for

proper procedures.

The

preferred headlamp alignment setting

is 0 for

the left/right adjustment

and

1" down

for the up/

down adjustment.

HEADLAMP

ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch

and

high beam

indicator operation. (2) Correct defective components that could hinder

proper headlamp alignment. (3) Verify proper tire inflation. (4) Clean headlamp lenses.

(5) Verify that luggage area

is not

heavily loaded.

(6) Fuel tank should

be

FULL.

Add 2.94 kg (6.5

lbs.)

of

weight over

the

fuel tank

for

each estimated

gallon

of

missing fuel.

HEADLAMP

ADJUSTMENT USING ALIGNMENT

SCREEN

ALIGNMENT SCREEN PREPARATION (1) Position vehicle

on a

level surface perpendicu

lar

to a

flat wall

7.62

meters

(25 ft)

away from front

of headlamp lens.

(2)

If

necessary, tape

a

line

on the

floor

7.62

meters

(25 ft)

away from

and

parallel

to the

wall.

CENTER

OF

VEHICLE

TO

CENTER

OF

HEADLAMP

LENS

VEHICLE

CENTERLINE" LOW BEAM

HOT

SPOT AREA FLOOR

TO

CENTER

OF

HEADLAMP

LENS

PREFERRED

HOT SPOT

LOCATION

7.62

METERS

(25

FEET)

FRONT

OF

HEADLAMP

938L-25X

Fig.

1 Headlamp

Alignment

Screen

—Typical

Page 447 of 1502

8L

- 4

LAMPS

• (3) Up 1.27 meters (5 feet) from the floor, tape a

line on the wall at the centerline of the vehicle.

Sight along the centerline of the vehicle (from rear of

vehicle forward) to verify accuracy of the line place

ment.

(4) Rock vehicle side-to-side three times to allow

suspension to stabilize. (5) Jounce front suspension three times by pushing

downward on front bumper and releasing. (6) Measure the distance from the center of head

lamp lens to the floor. Transfer measurement to the alignment screen (with tape). Use this line for up/

down adjustment reference.

(7) Measure distance from the centerline of the ve

hicle to the center of each headlamp being aligned. Transfer measurements to screen (with tape) to each side of vehicle centerline. Use these lines for left/

right adjustment reference.

HEADLAMP

ADJUSTMENT

A properly aimed low beam headlamp will project

top edge of high intensity pattern on screen from 50 mm (2 in.) above to 50 mm (2 in.) below headlamp

centerline. The side-to-side outboard edge of high in

tensity pattern should be from 50 mm (2 in.) left to 50 mm (2 in.) right of headlamp centerline (Fig. 1).

The preferred headlamp alignment is 0 for the

up/down adjustment and 1" down for the left/

right adjustment. The high beam pattern should be correct when the iow beams are aligned properly (Fig. 2).

To adjust headlamp aim, rotate alignment screws

to achieve the specified high intensity pattern.

1.

HORIZONTAL

ADJ. SCREW

- RH

2.

VERTICAL

ADJ. SCREW

3.

HORIZONTAL

ADJ. SCREW

- LH

J908L-24

Fig.

2

Sealed

Beam

Headlamp

Alignment

SEALED

BEAM REPLACEMENT

(1) Remove the headlamp bezel (Fig. 3).

(2) Remove four screws from retaining ring (Fig.

4).

(3) Separate sealed beam from seat and disconnect

from the socket. To install, reverse the removal procedures.

HEADLAMP

BEZEL

: ') J918L-29

Fig.

3 Headlamp

Bezel

RETAINING

RING

SCREWS

J918L-28

Fig.

4

Sealed

Beam

Replacement

HEADLAMP SWITCH

To remove or replace the headlamp switch see in

structions in Group 8E - Instrument Panel and

Gauges.

FRONT

PARK AND

TURN

SIGNAL LAMP BULB

(1) Remove 2 screws securing the Park/Turn signal

lamp (Fig. 5) (2) Twist out lamp socket from back of lamp hous

ing. (3) Replace bulb.

To install, reverse removal procedures.