lug pattern DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 239 of 1502

5

- 52

BRAKES

•

BRAKE

DRUM

REMOVAL

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove axle shaft nuts, washers and cones.

Strike axle shaft in center with copper or dead blow

hammer to loosen retaining cones.

(4) Remove axle shaft.

(5) Remove outer hub nut.

(6)

Straighten and remove lock washer.

(7) Remove inner nut and bearing.

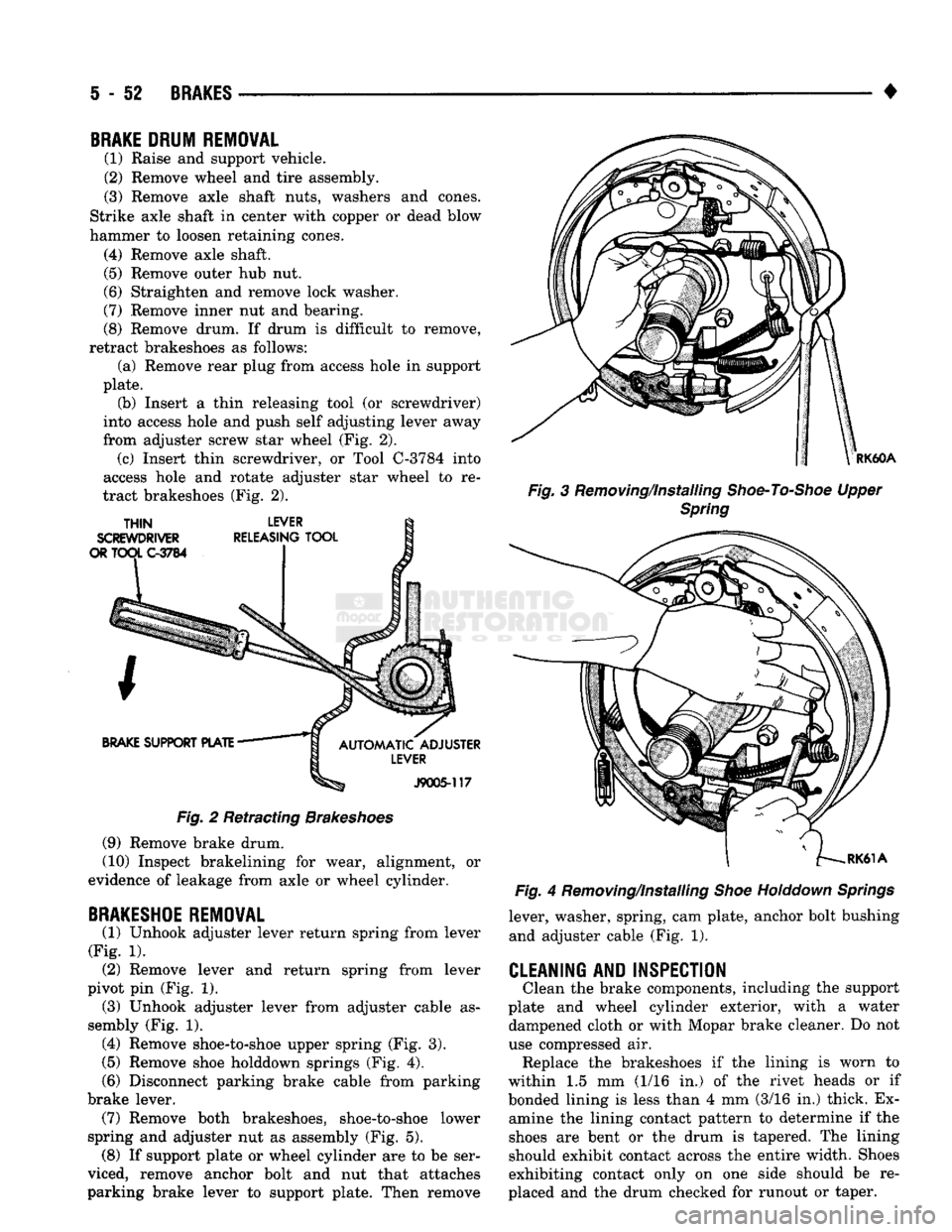

(8) Remove drum. If drum is difficult to remove,

retract brakeshoes as follows: (a) Remove rear plug from access hole in support

plate. (b) Insert a thin releasing tool (or screwdriver)

into access hole and push self adjusting lever away

from adjuster screw star wheel (Fig. 2). (c) Insert thin screwdriver, or Tool C-3784 into

access hole and rotate adjuster star wheel to re

tract brakeshoes (Fig. 2).

Fig.

2 Retracting

Brakeshoes

(9) Remove brake drum.

(10) Inspect brakelining for wear, alignment, or

evidence of leakage from axle or wheel cylinder.

BRAKESHOE

REMOVAL

(1) Unhook adjuster lever return spring from lever

(Fig. 1). (2) Remove lever and return spring from lever

pivot pin (Fig. 1). (3) Unhook adjuster lever from adjuster cable as

sembly (Fig. 1). (4) Remove shoe-to-shoe upper spring (Fig. 3).

(5)

Remove shoe holddown springs (Fig. 4).

(6)

Disconnect parking brake cable from parking

brake lever. (7) Remove both brakeshoes, shoe-to-shoe lower

spring and adjuster nut as assembly (Fig. 5). (8) If support plate or wheel cylinder are to be ser

viced, remove anchor bolt and nut that attaches

parking brake lever to support plate. Then remove

RK60A

Fig.

3 Removing/Installing

Shoe-To-Shoe

Upper

Spring

Fig.

4 Removing/Installing

Shoe

Holddown

Springs

lever, washer, spring, cam plate, anchor bolt bushing and adjuster cable (Fig. 1).

CLEANING AND INSPECTION

Clean the brake components, including the support

plate and wheel cylinder exterior, with a water dampened cloth or with Mopar brake cleaner. Do not

use compressed air. Replace the brakeshoes if the lining is worn to

within 1.5 mm (1/16 in.) of the rivet heads or if

bonded lining is less than 4 mm (3/16 in.) thick. Ex amine the lining contact pattern to determine if the

shoes are bent or the drum is tapered. The lining

should exhibit contact across the entire width. Shoes

exhibiting contact only on one side should be re

placed and the drum checked for runout or taper.

Page 1002 of 1502

•

TRANSMISSION

AND

TRANSFER

CASE

21 - 1

CONTENTS

page

AUTOMATIC

TRANSMISSI0N-32RH/36RH/

37RH/42RH/46RH

73

G360

MANUAL

TRANSMISSION

46

6360

TRANSMISSION

OVERHAUL

..........

53

NP2Q5

TRANSFER

CASE

................

342

page

NP241

TRANSFER

CASE

350

NV4500 MANUAL

TRANSMISSION

1

NV4500

TRANSMISSION

OVERHAUL

.........

6

TRANSMISSION/TRANSFER

CASE

SPECIFICATIONS

.....................

364

NV4300

MANUAL TRANSMISSION

INDEX

page

Gear Ratios

1

General

Information

1

Recommended

Lubricant—Capacity—Fill

Level

... 1

Shift

Pattern

1

Transmission Diagnosis

2

page

Transmission

Identification

1

Transmission

Installation—2-Wheel

Drive

4

Transmission

Installation—4-Wheel

Drive

........

5

Transmission

Removal—2-Wheel

Drive

3

Transmission

Removal—4-Wheel

Drive

4

GENERAL

INFORMATION The NV4500

is a

five-speed, constant mesh manual

transmission (Fig.

1). All

gear ranges including

re

verse

are

synchronized. Fifth gear

is an

overdrive

range with

a

ratio

of

0.74:1.

The transmission has

a

cast iron gear case and aluminum shift cover. The NV4500

is a

top loader style transmission. The

shift lever

is

located

in the

shift cover and operates

the shift forks and rails directly. The shift forks and

rails

are all

located within

the

aluminum cover

which

is

bolted

to

the top

of

the gear case.

A reverse gear inhibitor mechanism prevents

re

verse gear engagement when shifting into forward

gear ranges. The inhibitor mechanism

is

located

in

the shift cover.

Tapered roller bearings support

the

drive gear,

mainshaft

and

countershaft

in the

gear case. Pilot

roller bearings

in

the drive gear hub support the for

ward end

of

the mainshaft. The mainshaft gears

are

all supported

on

caged type roller bearings. Drive

gear thrust reaction

is

controlled

by a

needle type

thrust bearing. The bearing

is

located

at

the forward

end

of

the mainshaft.

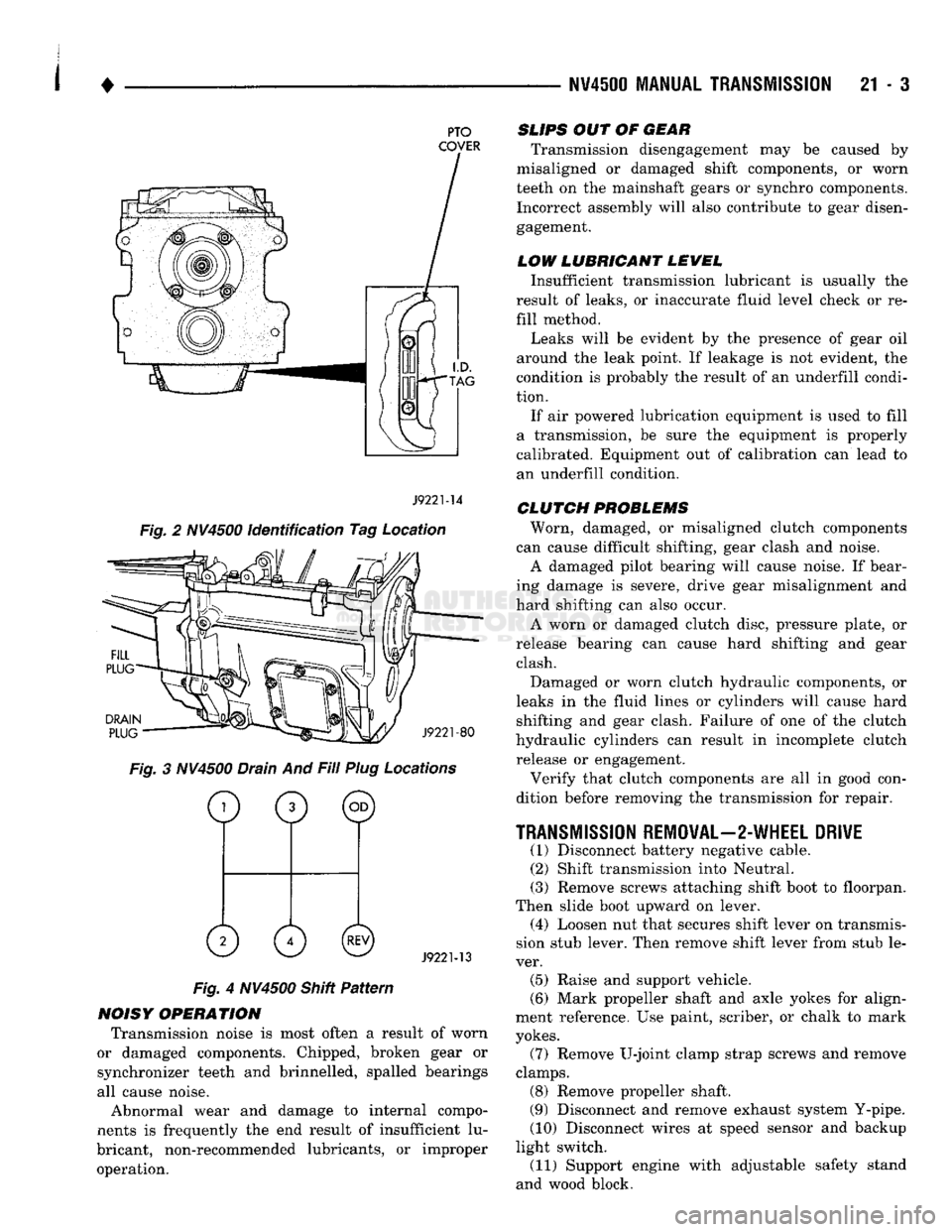

TRANSMISSION

IDENTIFICATION The NV4500 transmission identification

tag is at

tached

to

the driver side PTO cover (Fig.

2).

The

tag

provides

the

transmission model number,

build date and part number.

Be

sure

to

reinstall

the

I.D.

tag if

removed during service. The information

on the tag

is

essential

to

correct parts ordering.

RECOMMENDED

LUBRICANT-CAPACITY-FILL

LEVEL

Recommended lubricant

for

the NV4500

is

Castrol

Syntorq. This

is a

SAE 75W-90 synthetic gear lubri

cant with

an

API grade rating

of

GL

4.

Syntorq

is

the only lubricant recommended

for

use

in

NV4500 transmissions. Dry fill lubricant capacity

is

approximately 3.78

li

ters

(8

pints). Correct lubricant fill level

is to

the bottom edge

of

the fill plug hole (Fig. 3). Check fill level only when

the transmission

is

level.

GEAR

RATIOS

NV4500 gear ratios are:

First gear:

5.61:1

Second gear: 3.04:1

Third gear:

1.67:1

Fourth gear:

1.00:1

Fifth gear: 0.74:1

Reverse gear:

5.61:1

SHIFT

PATTERN

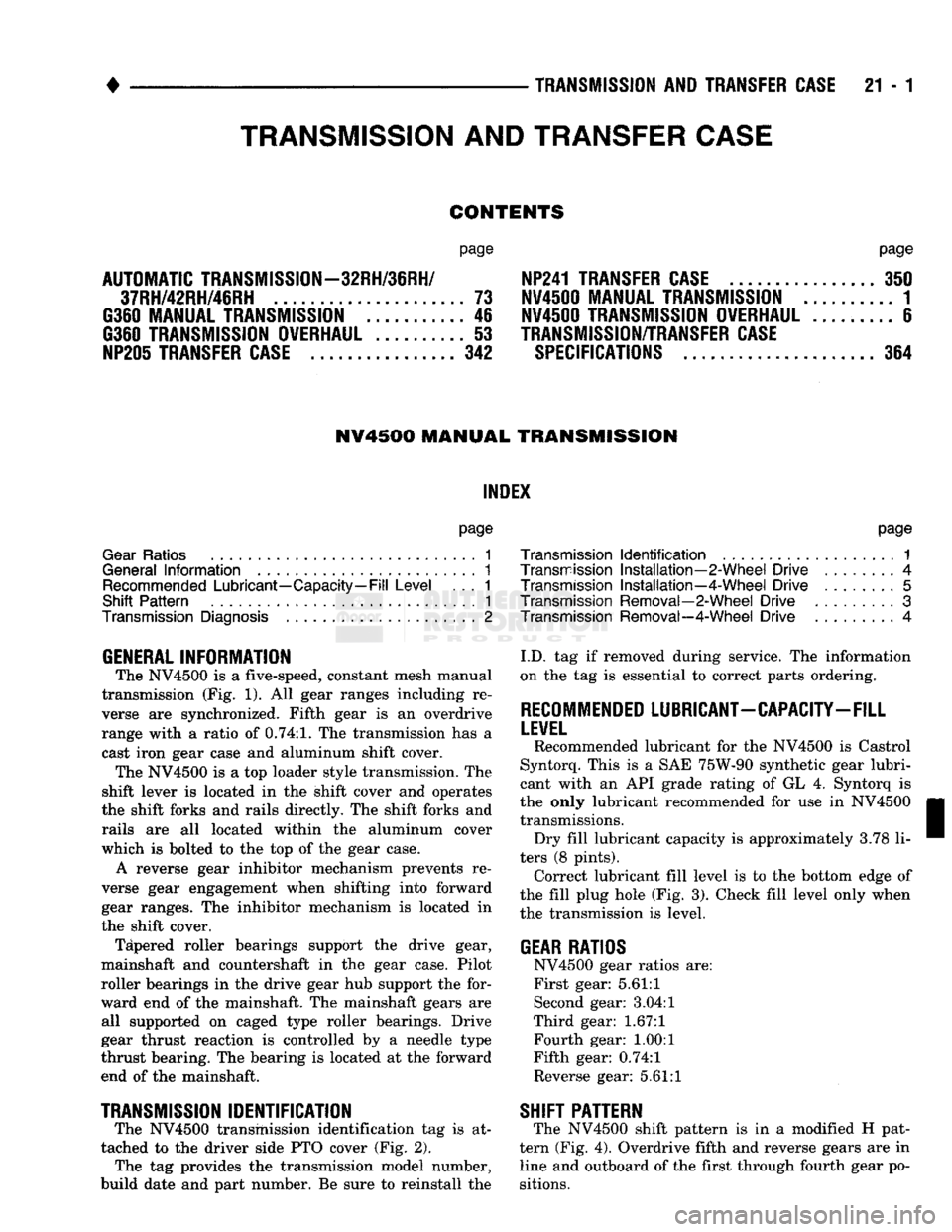

The NV4500 shift pattern

is in a

modified

H

pat

tern (Fig. 4). Overdrive fifth and reverse gears are

in

line and outboard of the first through fourth gear po

sitions.

TRANSMISSION

AND

TRANSFER

CASE

Page 1004 of 1502

•

NV4500 MANUAL

TRANSMISSION

21 - 3

PTO

COVER

J9221-14

Fig. 2 NV4500 identification Tag Location

DRAIN

PLUG

J9221-80

Fig. 3 NV4500 Drain And Fill Plug Locations

o

0 ©

0 0©

J9221-13

Fig. 4 NV4500 Shitt Pattern

NOISY OPERATION Transmission noise is most often a result of worn

or damaged components. Chipped, broken gear or

synchronizer teeth and brinnelled, spalled bearings

all cause noise.

Abnormal wear and damage to internal compo

nents is frequently the end result of insufficient lu

bricant, non-recommended lubricants, or improper operation.

SLIPS

OUT OF

GEAR

Transmission disengagement may be caused by

misaligned or damaged shift components, or worn

teeth on the mainshaft gears or synchro components. Incorrect assembly will also contribute to gear disengagement.

LOW LUBRICANT LEWEL

Insufficient transmission lubricant is usually the

result of leaks, or inaccurate fluid level check or re

fill method.

Leaks will be evident by the presence of gear oil

around the leak point. If leakage is not evident, the

condition is probably the result of an underfill condi

tion.

If air powered lubrication equipment is used to fill

a transmission, be sure the equipment is properly

calibrated. Equipment out of calibration can lead to

an underfill condition.

CLUTCH

PROBLEMS

Worn, damaged, or misaligned clutch components

can cause difficult shifting, gear clash and noise.

A damaged pilot bearing will cause noise. If bear

ing damage is severe, drive gear misalignment and

hard shifting can also occur.

A worn or damaged clutch disc, pressure plate, or

release bearing can cause hard shifting and gear clash.

Damaged or worn clutch hydraulic components, or

leaks in the fluid lines or cylinders will cause hard shifting and gear clash. Failure of one of the clutch

hydraulic cylinders can result in incomplete clutch release or engagement.

Verify that clutch components are all in good con

dition before removing the transmission for repair.

TRANSMISSION

REMOVAL—2-WHEEL DRIVE

(1) Disconnect battery negative cable. (2) Shift transmission into Neutral.

(3) Remove screws attaching shift boot to floorpan.

Then slide boot upward on lever. (4) Loosen nut that secures shift lever on transmis

sion stub lever. Then remove shift lever from stub le

ver. (5) Raise and support vehicle.

(6) Mark propeller shaft and axle yokes for align

ment reference. Use paint, scriber, or chalk to mark

yokes.

(7) Remove U-joint clamp strap screws and remove

clamps. (8) Remove propeller shaft.

(9) Disconnect and remove exhaust system Y-pipe.

(10) Disconnect wires at speed sensor and backup

light switch. (11) Support engine with adjustable safety stand

and wood block.

Page 1152 of 1502

•

AUTOMATIC

TRANSMISSION

REMOVAL

AND

INSTALLATION

21 - 151

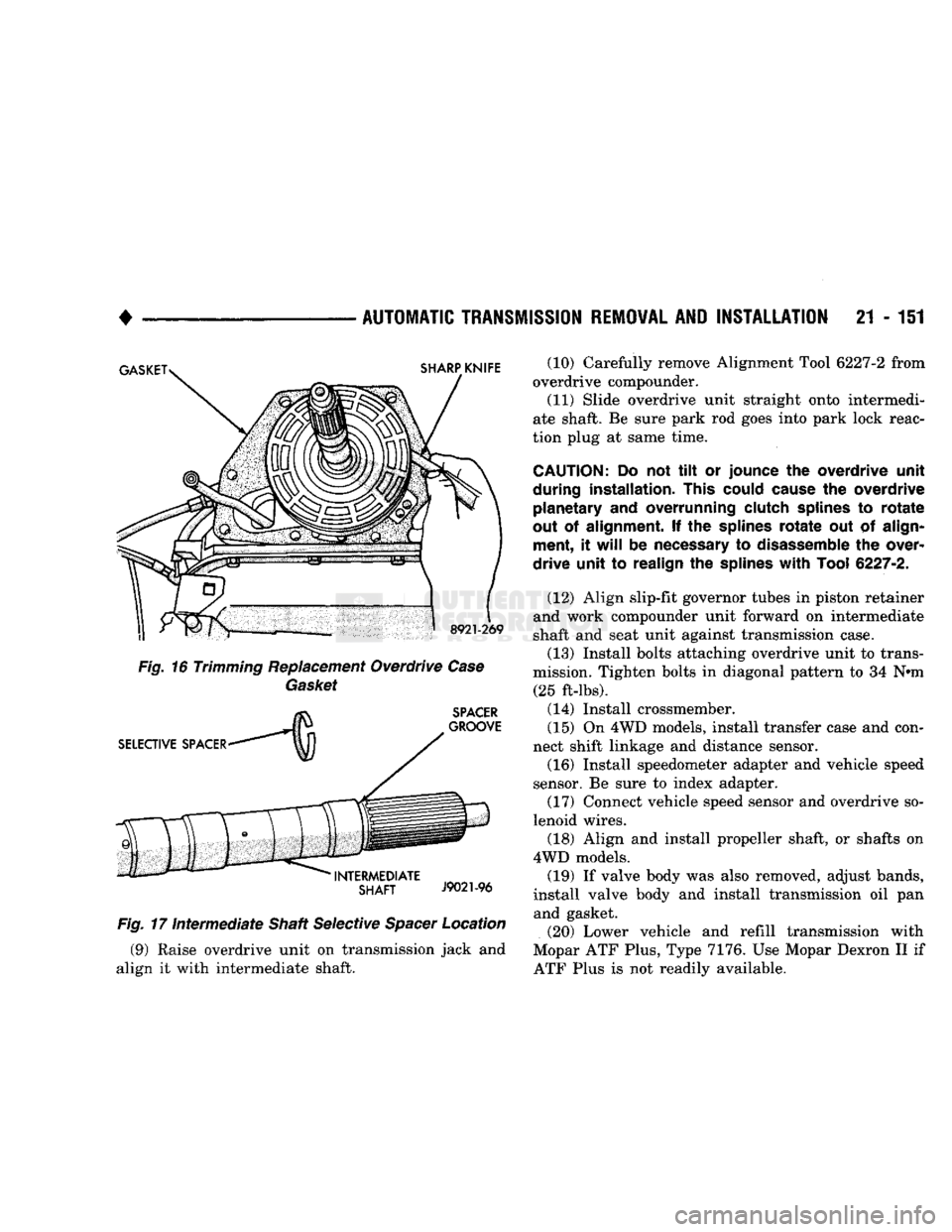

Fig.

17

Intermediate

Shaft Selective

Spacer

Location (9) Raise overdrive unit on transmission jack and

align it with intermediate shaft. (10) Carefully remove Alignment Tool 6227-2 from

overdrive compounder.

(11) Slide overdrive unit straight onto intermedi

ate shaft. Be sure park rod goes into park lock reac

tion plug at same time.

CAUTION:

Do not tilt or

jounce

the

overdrive unit

during installation. This could cause

the

overdrive planetary

and

overrunning clutch splines

to

rotate

out

of

alignment.

If the

splines

rotate

out of

align ment,

it

will

be

necessary

to

disassemble

the

over

drive unit

to

realign

the

splines

with

Tool

6227-2.

(12) Align slip-fit governor tubes in piston retainer

and work compounder unit forward on intermediate

shaft and seat unit against transmission case.

(13) Install bolts attaching overdrive unit to trans

mission. Tighten bolts in diagonal pattern to 34 N»m (25 ft-lbs).

(14) Install crossmember.

(15) On 4WD models, install transfer case and con

nect shift linkage and distance sensor. (16) Install speedometer adapter and vehicle speed

sensor. Be sure to index adapter.

(17) Connect vehicle speed sensor and overdrive so

lenoid wires.

(18) Align and install propeller shaft, or shafts on

4WD models. (19) If valve body was also removed, adjust bands,

install valve body and install transmission oil pan and gasket.

(20) Lower vehicle and refill transmission with

Mopar ATF Plus, Type 7176. Use Mopar Dexron II if

ATF Plus is not readily available.

Page 1183 of 1502

21

- 182

TRANSMISSION OVERHAUL—32RH

• VAL VE

BODY

ASSEMBL

Y

CAUTION:

Do not

force

the valves or plugs

into

place

during

reassembly. If the valve body

bores,

valves

and plugs are

free

of

distortion

or burrs, the

valve body components should all slide

into

place

easily. In

addition,

do not

overtighten

the

transfer

plate

and valve body

screws

during

reassembly.

Overtightening

can

distort

the valve body

resulting

in valve sticking,

cross

leakage and

unsatisfactory

operation. Tighten valve body

screws

to recom mended

torque

only.

(1) Lubricate valve body bores, valves and plugs

with transmission fluid.

(2) Insert rear clutch and rear servo check balls in

transfer plate (Fig. 100).

(3) Install filter screen in separator plate (Fig.

100).

(4) Align and install separator plate on transfer

plate. Verify check ball position before installing sep arator plate on transfer plate.

(5) Install new O-ring on converter clutch solenoid

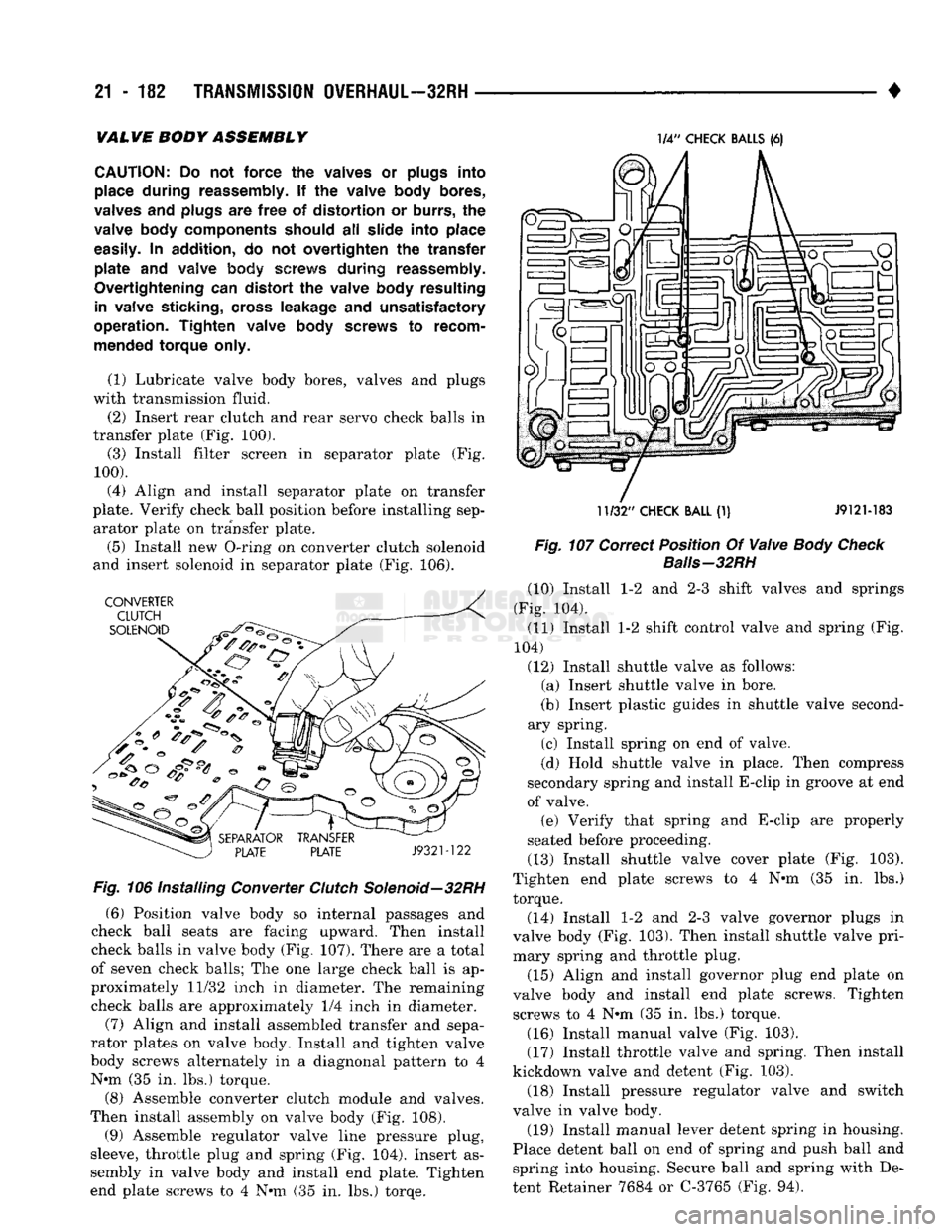

and insert solenoid in separator plate (Fig. 106). Fig. 106

Installing

Converter

Clutch

Solenoid—32RH

(6) Position valve body so internal passages and

check ball seats are facing upward. Then install

check balls in valve body (Fig. 107). There are a total

of seven check balls; The one large check ball is ap

proximately 11/32 inch in diameter. The remaining

check balls are approximately 1/4 inch in diameter.

(7) Align and install assembled transfer and sepa

rator plates on valve body. Install and tighten valve

body screws alternately in a diagnonal pattern to 4 N»m (35 in. lbs.) torque.

(8) Assemble converter clutch module and valves.

Then install assembly on valve body (Fig. 108).

(9) Assemble regulator valve line pressure plug,

sleeve, throttle plug and spring (Fig. 104). Insert as

sembly in valve body and install end plate. Tighten

end plate screws to 4 N»m (35 in. lbs.) torqe. 1/4"

CHECK

BALLS

(6)

11/32"

CHECK

BALL

(1) J912M83

Fig. 107

Correct

Position

Of

Valve

Body Check

Baiis-32RH

(10) Install 1-2 and 2-3 shift valves and springs

(Fig. 104).

(11) Install 1-2 shift control valve and spring (Fig.

104)

(12) Install shuttle valve as follows: (a) Insert shuttle valve in bore.

(b) Insert plastic guides in shuttle valve second

ary spring.

(c) Install spring on end of valve.

(d) Hold shuttle valve in place. Then compress

secondary spring and install E-clip in groove at end

of valve. (e) Verify that spring and E-clip are properly

seated before proceeding.

(13) Install shuttle valve cover plate (Fig. 103).

Tighten end plate screws to 4 N»m (35 in. lbs.)

torque.

(14) Install 1-2 and 2-3 valve governor plugs in

valve body (Fig. 103). Then install shuttle valve pri

mary spring and throttle plug.

(15) Align and install governor plug end plate on

valve body and install end plate screws. Tighten screws to 4 N*m (35 in. lbs.) torque.

(16) Install manual valve (Fig. 103).

(17) Install throttle valve and spring. Then install

kickdown valve and detent (Fig. 103).

(18) Install pressure regulator valve and switch

valve in valve body.

(19) Install manual lever detent spring in housing.

Place detent ball on end of spring and push ball and spring into housing. Secure ball and spring with De

tent Retainer 7684 or C-3765 (Fig. 94).

Page 1222 of 1502

•

TRANSMISSION

OVERHAUL—36RH/37RH

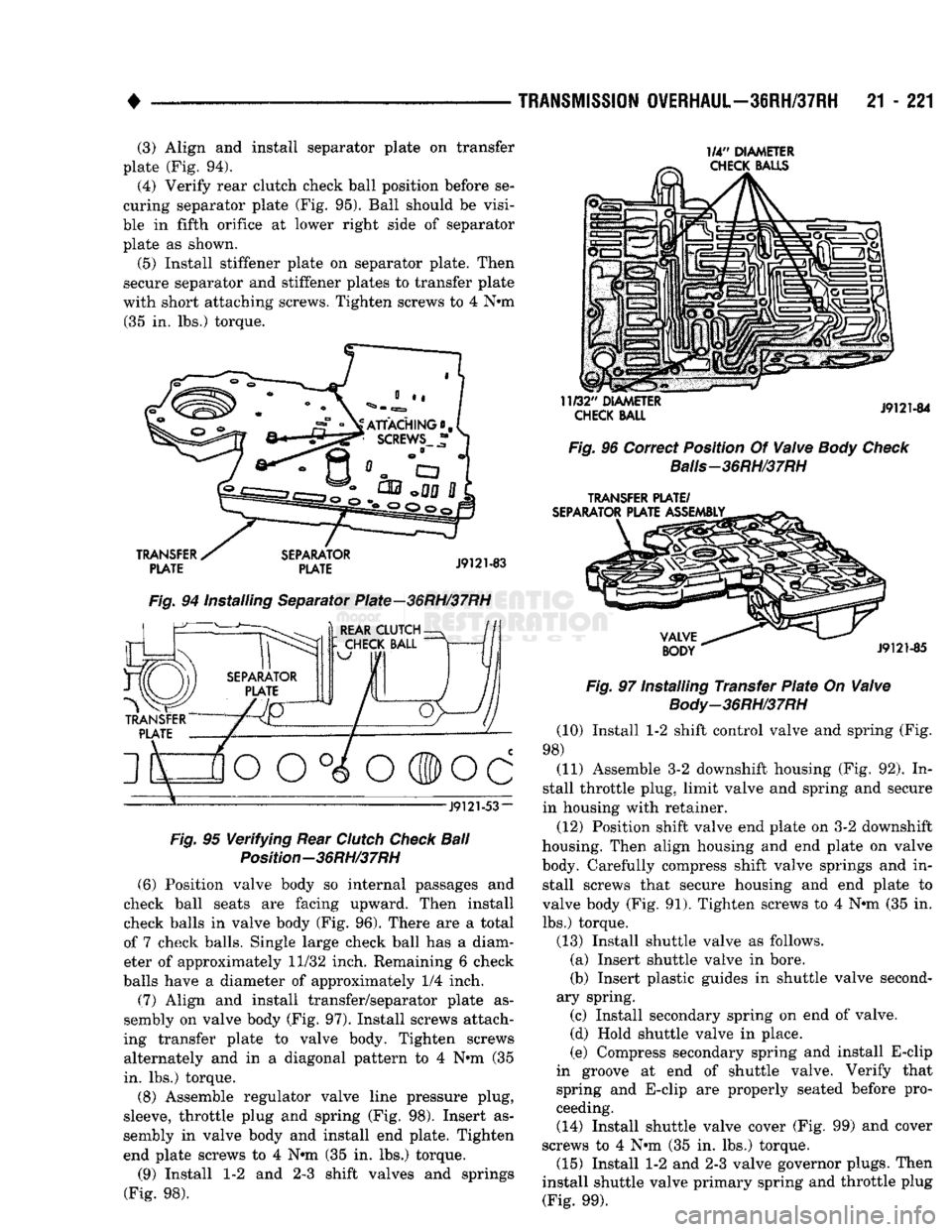

21 - 221 (3) Align and install separator plate on transfer

plate (Fig. 94). (4) Verify rear clutch check ball position before se

curing separator plate (Fig. 95). Ball should be visi

ble in fifth orifice at lower right side of separator plate as shown.

(5) Install stiffener plate on separator plate. Then

secure separator and stiffener plates to transfer plate

with short attaching screws. Tighten screws to 4 Nnn (35 in. lbs.) torque. 1/4"

DIAMETER

CHECK

BALLS

TRANSFER

PLATE

SEPARATOR

PLATE

J9121-83

Fig.

94 Installing Separator Plate—36RH/37RH f^-^. )

REAR CLUTCH-

J9121-53-

Fig.

95

Verifying

Rear

Clutch

Check

Ball

Position-36RH/37RH (6) Position valve body so internal passages and

check ball seats are facing upward. Then install

check balls in valve body (Fig. 96). There are a total

of 7 check balls. Single large check ball has a diam eter of approximately 11/32 inch. Remaining 6 check

balls have a diameter of approximately 1/4 inch.

(7) Align and install transfer/separator plate as

sembly on valve body (Fig. 97). Install screws attach

ing transfer plate to valve body. Tighten screws alternately and in a diagonal pattern to 4 Nnn (35

in. lbs.) torque.

(8) Assemble regulator valve line pressure plug,

sleeve, throttle plug and spring (Fig. 98). Insert as

sembly in valve body and install end plate. Tighten

end plate screws to 4 Nnn (35 in. lbs.) torque.

(9) Install 1-2 and 2-3 shift valves and springs

(Fig. 98).

11/32"

DIAMETER

CHECK

BALL

J9121-84

Fig.

96 Correct Position Of

Valve

Body Check

Balis-36RH/37RH

TRANSFER

PLATE/

SEPARATOR

PLATE ASSEMBLY

VALVE

BODY

J9121-85

Fig.

97 Installing Transfer

Plate

On

Valve

Body-36RH/37RH

(10) Install 1-2 shift control valve and spring (Fig.

98) (11) Assemble 3-2 downshift housing (Fig. 92). In

stall throttle plug, limit valve and spring and secure

in housing with retainer.

(12) Position shift valve end plate on 3-2 downshift

housing. Then align housing and end plate on valve

body. Carefully compress shift valve springs and in stall screws that secure housing and end plate to

valve body (Fig. 91). Tighten screws to 4 Nnn (35 in.

lbs.) torque.

(13) Install shuttle valve as follows. (a) Insert shuttle valve in bore.

(b) Insert plastic guides in shuttle valve second

ary spring. (c) Install secondary spring on end of valve.

(d) Hold shuttle valve in place.

(e) Compress secondary spring and install E-clip

in groove at end of shuttle valve. Verify that

spring and E-clip are properly seated before pro

ceeding. (14) Install shuttle valve cover (Fig. 99) and cover

screws to 4 Nnn (35 in. lbs.) torque. (15) Install 1-2 and 2-3 valve governor plugs. Then

install shuttle valve primary spring and throttle plug (Fig. 99).

Page 1276 of 1502

•

BAND BAND

Fig.

152 Front

Band

Linkage

Installation—42RH

SEAL

RINGS

J9121-194

Fig.

153 Reaction Shaft

Support

Seal

Rings

And Front

Clutch

Thrust

Washer

Position—42RH

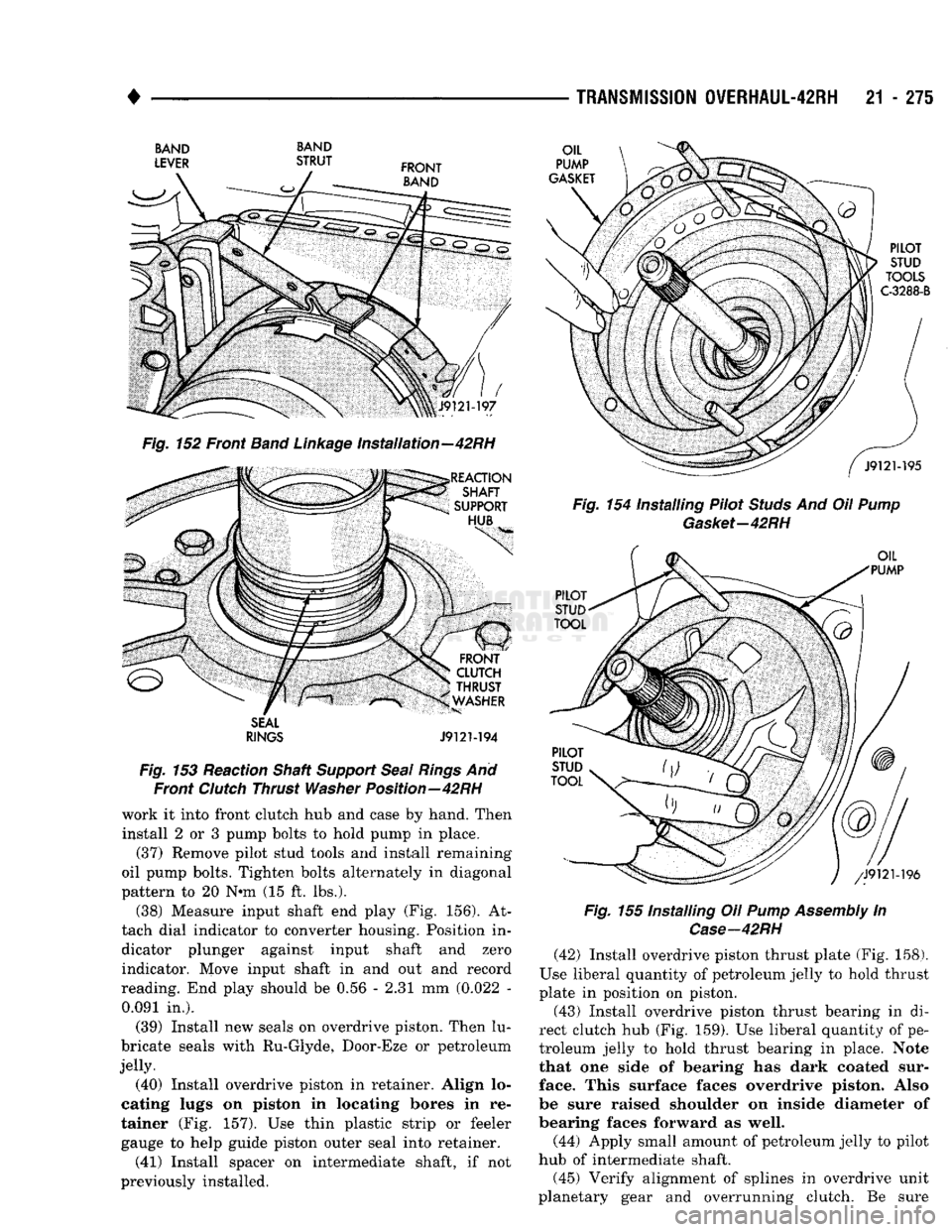

work it into front clutch hub and case by hand. Then

install 2 or 3 pump bolts to hold pump in place. (37) Remove pilot stud tools arid install remaining

oil pump bolts. Tighten bolts alternately in diagonal

pattern to 20 N*m (15 ft. lbs.).

(38) Measure input shaft end play (Fig. 156). At

tach dial indicator to converter housing. Position in dicator plunger against input shaft and zero indicator. Move input shaft in and out and record

reading. End play should be 0.56 - 2.31 mm (0.022 - 0.091 in.).

(39) Install new seals on overdrive piston. Then lu

bricate seals with Ru-Glyde, Door-Eze or petroleum

jelly. (40) Install overdrive piston in retainer. Align lo

cating lugs on piston in locating bores in re

tainer (Fig. 157). Use thin plastic strip or feeler gauge to help guide piston outer seal into retainer. (41) Install spacer on intermediate shaft, if not

previously installed.

TRANSMISSION

0VERHAUL-42RH

21 - 275

Fig.

154 Installing Pilot

Studs

And Oil

Pump

Gasket-42RH

Fig.

155 Installing Oil

Pump

Assembly

In

Case—42RH

(42) Install overdrive piston thrust plate (Fig. 158).

Use liberal quantity of petroleum jelly to hold thrust

plate in position on piston. (43) Install overdrive piston thrust bearing in di

rect clutch hub (Fig. 159). Use liberal quantity of pe

troleum jelly to hold thrust bearing in place. Note

that one side of bearing has dark coated sur

face. This surface faces overdrive piston. Also

be sure raised shoulder on inside diameter of

bearing faces forward as well.

(44) Apply small amount of petroleum jelly to pilot

hub of intermediate shaft.

(45) Verify alignment of splines in overdrive unit

planetary gear and overrunning clutch. Be sure

Page 1375 of 1502

22 - e

WHEELS

AND

TIRES

• WHEELS

GENERAL

INFORMATION

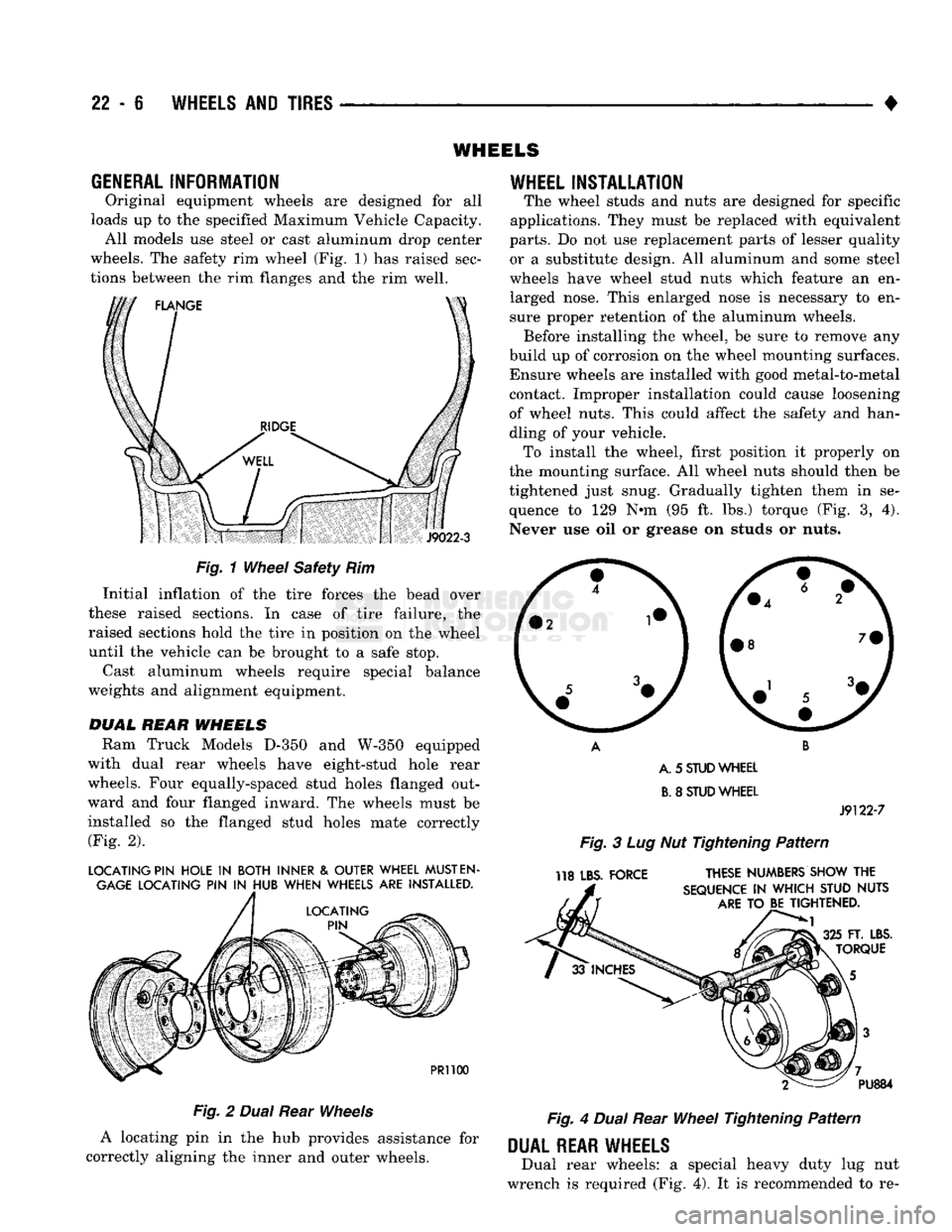

Original equipment wheels are designed for all

loads up to the specified Maximum Vehicle Capacity. All models use steel or cast aluminum drop center

wheels. The safety rim wheel (Fig. 1) has raised sec

tions between the rim flanges and the rim well.

S

J9022-3

Fig.

1

Wheel

Safety Rim Initial inflation of the tire forces the bead over

these raised sections. In case of tire failure, the

raised sections hold the tire in position on the wheel

until the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights and alignment equipment.

DUAL

REAR

WHEELS

Ram Truck Models

D-350

and

W-350

equipped

with dual rear wheels have eight-stud hole rear

wheels. Four equally-spaced stud holes flanged out

ward and four flanged inward. The wheels must be

installed so the flanged stud holes mate correctly (Fig. 2).

LOCATING PIN HOLE

IN

BOTH INNER

&

OUTER WHEEL

MUST

EN

GAGE

LOCATING PIN

IN

HUB WHEN WHEELS ARE INSTALLED.

PR1100

Fig.

2

Dual

Rear

Wheels

A locating pin in the hub provides assistance for

correctly aligning the inner and outer wheels.

WHEEL

INSTALLATION

The wheel studs and nuts are designed for specific

applications. They must be replaced with equivalent

parts.

Do not use replacement parts of lesser quality or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an en larged nose. This enlarged nose is necessary to en

sure proper retention of the aluminum wheels. Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces. Ensure wheels are installed with good metal-to-metal contact. Improper installation could cause loosening

of wheel nuts. This could affect the safety and han

dling of your vehicle. To install the wheel, first position it properly on

the mounting surface. All wheel nuts should then be

tightened just snug. Gradually tighten them in se

quence to 129 N-m (95 ft. lbs.) torque (Fig. 3, 4).

Never use oil or grease on studs or nuts.

A. 5

STUD

WHEEL

B.

8

STUD

WHEEL

J9122-7

Fig.

3 Lug Nut Tightening

Pattern

118 LBS. FORCE THESE NUMBERS SHOW THE

SEQUENCE

IN

WHICH STUD NUTS

ARE

TO BE TIGHTENED.

FT. LBS.

TORQUE PU884

Fig.

4

Dual

Rear

Wheel

Tightening

Pattern

DUAL

REAR WHEELS

Dual rear wheels: a special heavy duty lug nut

wrench is required (Fig. 4). It is recommended to re-

Page 1376 of 1502

•

WHEELS

AND

TIRES

22 - 7 move and install dual rear wheels only when the

proper wrench is available.

INSTALLATION

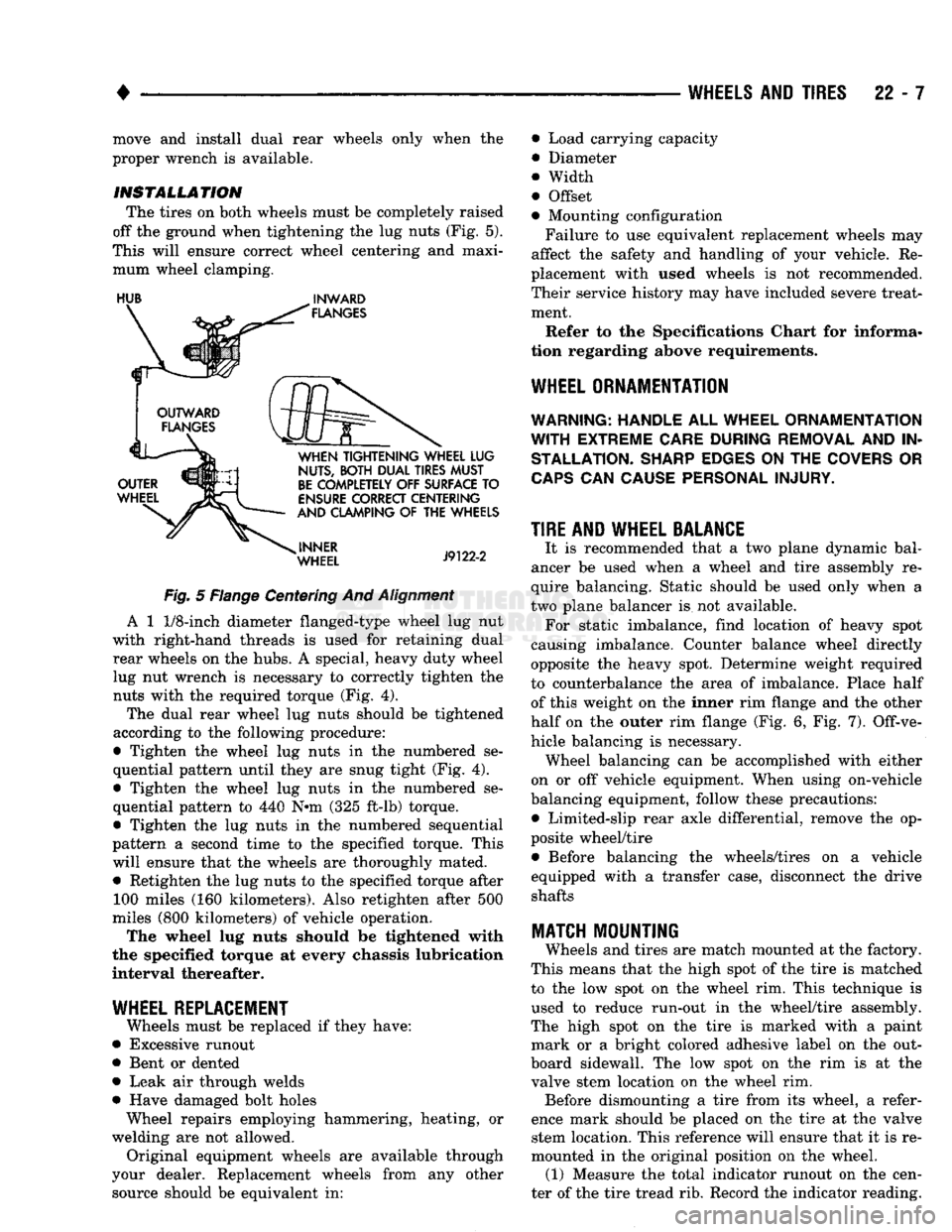

The tires on both wheels must be completely raised

off the ground when tightening the lug nuts (Fig. 5).

This will ensure correct wheel centering and maxi mum wheel clamping.

HUB

^

INWARD

Fig.

5 Flange Centering And

Alignment

A 1

1/8-inch

diameter flanged-type wheel lug nut

with right-hand threads is used for retaining dual rear wheels on the hubs. A special, heavy duty wheel lug nut wrench is necessary to correctly tighten the nuts with the required torque (Fig. 4).

The dual rear wheel lug nuts should be tightened

according to the following procedure:

• Tighten the wheel lug nuts in the numbered se

quential pattern until they are snug tight (Fig. 4).

• Tighten the wheel lug nuts in the numbered se

quential pattern to 440 N#m (325 ft-lb) torque.

• Tighten the lug nuts in the numbered sequential

pattern a second time to the specified torque. This will ensure that the wheels are thoroughly mated. • Retighten the lug nuts to the specified torque after 100 miles (160 kilometers). Also retighten after 500

miles (800 kilometers) of vehicle operation.

The wheel lug nuts should be tightened with

the specified torque at every chassis lubrication

interval thereafter.

WHEEL REPLACEMENT

Wheels must be replaced if they have:

• Excessive runout

• Bent or dented

• Leak air through welds

• Have damaged bolt holes Wheel repairs employing hammering, heating, or

welding are not allowed. Original equipment wheels are available through

your dealer. Replacement wheels from any other source should be equivalent in: • Load carrying capacity

• Diameter

® Width

• Offset

• Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle. Re

placement with used wheels is not recommended.

Their service history may have included severe treat ment.

Refer to the Specifications Chart for informa

tion regarding above requirements.

WHEEL ORNAMENTATION

WARNING; HANDLE

ALL

WHEEL ORNAMENTATION

WITH

EXTREME CARE DURING REMOVAL

AND IN

STALLATION. SHARP EDGES

ON THE

COVERS

OR

CAPS

CAN

CAUSE PERSONAL INJURY.

TIRE AND WHEEL BALANCE

It is recommended that a two plane dynamic bal

ancer be used when a wheel and tire assembly re

quire balancing. Static should be used only when a

two plane balancer is not available. For static imbalance, find location of heavy spot

causing imbalance. Counter balance wheel directly

opposite the heavy spot. Determine weight required

to counterbalance the area of imbalance. Place half of this weight on the inner rim flange and the other

half on the outer rim flange (Fig. 6, Fig. 7). Off-ve

hicle balancing is necessary. Wheel balancing can be accomplished with either

on or off vehicle equipment. When using on-vehicle

balancing equipment, follow these precautions: • Limited-slip rear axle differential, remove the op

posite wheel/tire • Before balancing the wheels/tires on a vehicle

equipped with a transfer case, disconnect the drive shafts

MATCH

MOUNTING

Wheels and tires are match mounted at the factory.

This means that the high spot of the tire is matched

to the low spot on the wheel rim. This technique is used to reduce run-out in the wheel/tire assembly.

The high spot on the tire is marked with a paint mark or a bright colored adhesive label on the out

board sidewall. The low spot on the rim is at the

valve stem location on the wheel rim. Before dismounting a tire from its wheel, a refer

ence mark should be placed on the tire at the valve stem location. This reference will ensure that it is re

mounted in the original position on the wheel. (1) Measure the total indicator runout on the cen

ter of the tire tread rib. Record the indicator reading.