heating DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 4 of 1502

GROUP TAB LOCATOR

Introduction

0

Lubrication

and

Maintenance

2

Front Suspension

and

Axle

3

Rear Suspension

and

Axles

5

Brakes

6

Clutch

7

Cooling System

8

Electrical

9

Engines

11

Exhaust System

and

Intake

Manifold

13

Frame

and Bumpers

14

Fuel

System

16

Propeller Shafts

19

Steering

21

Transmission

and

Transfer Case

22

Wheels and Tires

23

Body Components

24

Heating

and Air

Conditioning

25

Emission Control Systems Component and System Index

Service Manual Comment Forms (Rear

of

Manual)

Page 51 of 1502

0

- 32

LUBRICATION

AND

MAINTENANCE

•

Fig.

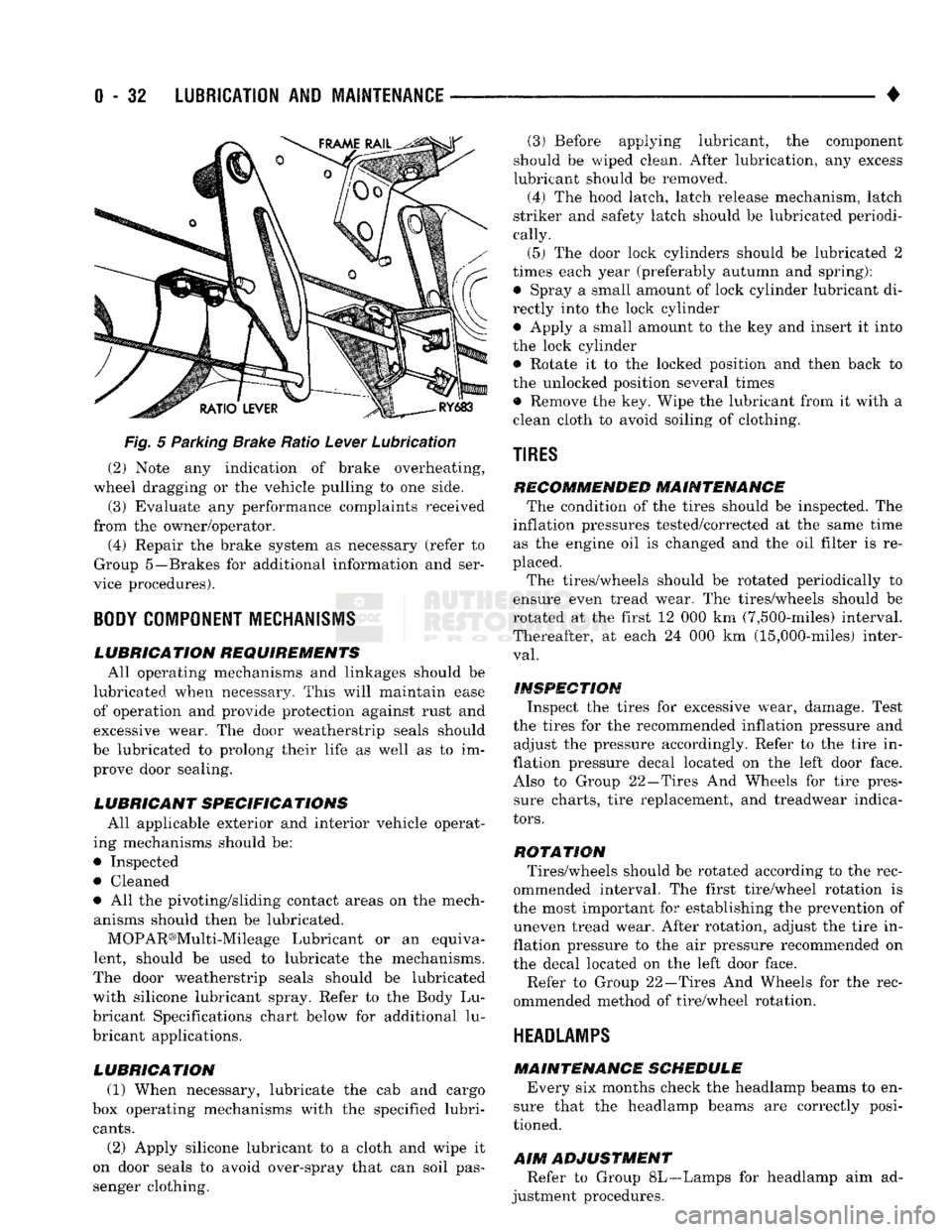

5 Parking Brake Ratio Lever Lubrication (2) Note any indication of brake overheating,

wheel dragging or the vehicle pulling to one side.

(3) Evaluate any performance complaints received

from the owner/operator. (4) Repair the brake system as necessary (refer to

Group 5—Brakes for additional information and ser

vice procedures).

BODY

COMPONENT

MECHANISMS

LUBRICATION REQUIREMENTS

All operating mechanisms and linkages should be

lubricated when necessary. This will maintain ease of operation and provide protection against rust and

excessive wear. The door weatherstrip seals should

be lubricated to prolong their life as well as to im prove door sealing.

LUBRICANT SPECIFICATIONS

All applicable exterior and interior vehicle operat

ing mechanisms should be:

• Inspected • Cleaned

• All the pivoting/sliding contact areas on the mech anisms should then be lubricated.

MOPAR®Multi-Mileage Lubricant or an equiva

lent, should be used to lubricate the mechanisms.

The door weatherstrip seals should be lubricated

with silicone lubricant spray. Refer to the Body Lu

bricant Specifications chart below for additional lu

bricant applications.

LUBRICATION

(1) When necessary, lubricate the cab and cargo

box operating mechanisms with the specified lubri

cants.

(2) Apply silicone lubricant to a cloth and wipe it

on door seals to avoid over-spray that can soil pas

senger clothing. (3) Before applying lubricant, the component

should be wiped clean. After lubrication, any excess

lubricant should be removed.

(4) The hood latch, latch release mechanism, latch

striker and safety latch should be lubricated periodi

cally.

(5) The door lock cylinders should be lubricated 2

times each year (preferably autumn and spring): • Spray a small amount of lock cylinder lubricant di

rectly into the lock cylinder

• Apply a small amount to the key and insert it into

the lock cylinder • Rotate it to the locked position and then back to

the unlocked position several times

• Remove the key. Wipe the lubricant from it with a

clean cloth to avoid soiling of clothing.

TIRES

RECOMMENDED MAINTENANCE

The condition of the tires should be inspected. The

inflation pressures tested/corrected at the same time as the engine oil is changed and the oil filter is re

placed.

The tires/wheels should be rotated periodically to

ensure even tread wear. The tires/wheels should be

rotated at the first 12 000 km (7,500-miles) interval.

Thereafter, at each 24 000 km (15,000-miles) inter

val.

INSPECTION

Inspect the tires for excessive wear, damage. Test

the tires for the recommended inflation pressure and adjust the pressure accordingly. Refer to the tire in

flation pressure decal located on the left door face. Also to Group 22—Tires And Wheels for tire pressure charts, tire replacement, and treadwear indica

tors.

ROTATION

Tires/wheels should be rotated according to the rec

ommended interval. The first tire/wheel rotation is

the most important for establishing the prevention of uneven tread wear. After rotation, adjust the tire in

flation pressure to the air pressure recommended on

the decal located on the left door face.

Refer to Group 22—Tires And Wheels for the rec

ommended method of tire/wheel rotation.

HEADLAMPS

MAINTENANCE SCHEDULE

Every six months check the headlamp beams to en

sure that the headlamp beams are correctly posi

tioned.

AIM

ADJUSTMENT

Refer to Group 8L—Lamps for headlamp aim ad

justment procedures.

Page 56 of 1502

FRONT SUSPENSION

AND

AXLE

2 - 3

FRONT

WHEEL

ALIGNMENT

GENERAL

INFORMATION

Front wheel alignment involves

the

correct posi

tioning

of the

tire contact patch

in

relation

to the

pavement.

The

positioning

is

accomplished through

the suspension

and

steering linkage adjustments.

An

alignment

is

essential

for

efficient steering

and

direc

tional stability.

The

most important factors

of

front

end alignment

are

camber, caster

and toe

position. Routine inspection

of

the front

suspension

and

steering components

is a

good

preventative

maintenance practice.

Inspection

also

helps

to

ensure

safe operation

of the

vehicle.

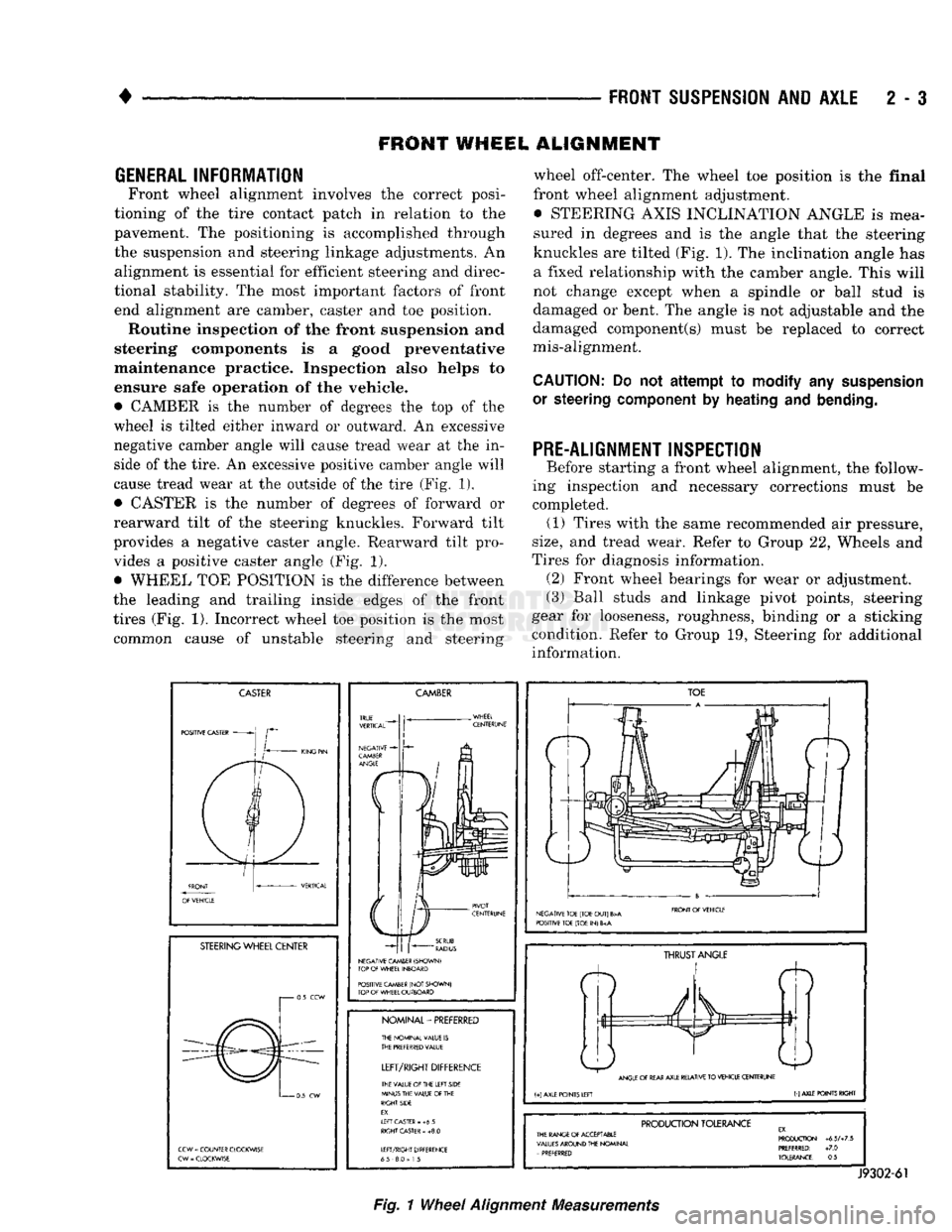

• CAMBER

is the

number

of

degrees

the top of the

wheel

is

tilted either inward

or

outward.

An

excessive

negative camber angle will cause tread wear

at the in

side

of

the tire.

An

excessive positive camber angle will

cause tread wear

at the

outside

of

the tire (Fig.

1),

• CASTER

is the

number

of

degrees

of

forward

or

rearward tilt

of the

steering knuckles. Forward tilt

provides

a

negative caster angle. Rearward tilt pro vides

a

positive caster angle

(Fig. 1).

• WHEEL

TOE

POSITION

is the

difference between

the leading

and

trailing inside edges

of the

front

tires (Fig.

1).

Incorrect wheel

toe

position

is the

most common cause

of

unstable steering

and

steering wheel off-center.

The

wheel

toe

position

is the

final

front wheel alignment adjustment. • STEERING AXIS INCLINATION ANGLE

is

mea

sured

in

degrees

and is the

angle that

the

steering

knuckles

are

tilted (Fig. 1).

The

inclination angle

has

a fixed relationship with

the

camber angle. This will

not change except when

a

spindle

or

ball stud

is

damaged

or

bent.

The

angle

is not

adjustable

and the

damaged component(s) must

be

replaced

to

correct

mis-alignment.

CAUTION:

Do not

attempt to modify

any

suspension

or steering

component

by

heating

and

bending.

PRE-ALIGNMENT INSPECTION

Before starting

a

front wheel alignment,

the

follow

ing inspection

and

necessary corrections must

be

completed.

(1)

Tires with

the

same recommended

air

pressure,

size,

and

tread wear. Refer

to

Group

22,

Wheels

and

Tires

for

diagnosis information. (2) Front wheel bearings

for

wear

or

adjustment.

(3) Ball studs

and

linkage pivot points, steering

gear

for

looseness, roughness, binding

or a

sticking

condition. Refer

to

Group

19,

Steering

for

additional information.

CASTER

POSITIVE CASTER

STEERING

WHEEL CENTER

i 0.5

CCW

0

5

CW

CCW

=

COUNTER CLOCKWISE

CW

-

CLOCKWISE

CAMBER

NEGATIVE CAMBER (SHOWN)

TOP

OF

WHEEL INBOARD

POSITIVE CAMBER

(NOT

SHOWN)

TOP

OF

WHEEL OUTBOARD

NOMINAL-PREFERRED

THE NOMINAL VALUE

IS

THE

PREFERRED

VALUE

LEFT/RIGHT

DIFFERENCE

THE VALUE

Of

THE LEFT SIDE

MINUS THE VALUE

OF

THE

RIGHT SIDE

EX.

If

FT CASTER

- +6 5

RIGHT

CASTER

»

+8.0

LEFT/RIGHT DIFFERENCE

65 8.0

=

1

5

TOE

NEGATIVE TOE (TOE

OUT)

B>A

POSITIVE TOE (TOE

IN) 6

FRONT

Of

VEHICLE

ft

THRUST

ANGLE

ANGLE

OF

REAR

AXLE RELATIVE

TO

VEHICLE CENTERUNE

(+)

AXLE POINTS LEFT

(-)

AXLE POINTS RIGHT

PRODUCTION

TOLERANCE

THE RANGE

Of

ACCEPTABLE

VALUES

AROUND THE NOMINAL

-

PREFERRED PRODUCTION

+6.5A7.5

PREFERRED:

+7.0

TOLERANCE:

0.5

J9302-61

Fig.

1

Wheel

Alignment

Measurements

Page 58 of 1502

•

FRONT

SUSPENSION

AND

AXLE

2 - 5 (4) Front wheels for excessive radial, lateral

runout and unbalance. Refer to Group 22, Wheels and Tires for diagnosis information.

(5) Suspension components for wear and noise. Check

components for correct torque. Refer to Groups 2 and 3, Suspension and Axle for additional information.

WHEEL

ALIGNMENT

MEASUREMENTS/ADJUSTMENTS

The front wheel alignment positions must be set to

the specified limits. This will prevent abnormal tire

tread wear. The equipment manufacturer's recommenda

tions for use of their

equipment

should always

be followed. All

damaged

front suspension sys

tem components

should

be replaced. Do not at tempt to straighten any

bent

component.

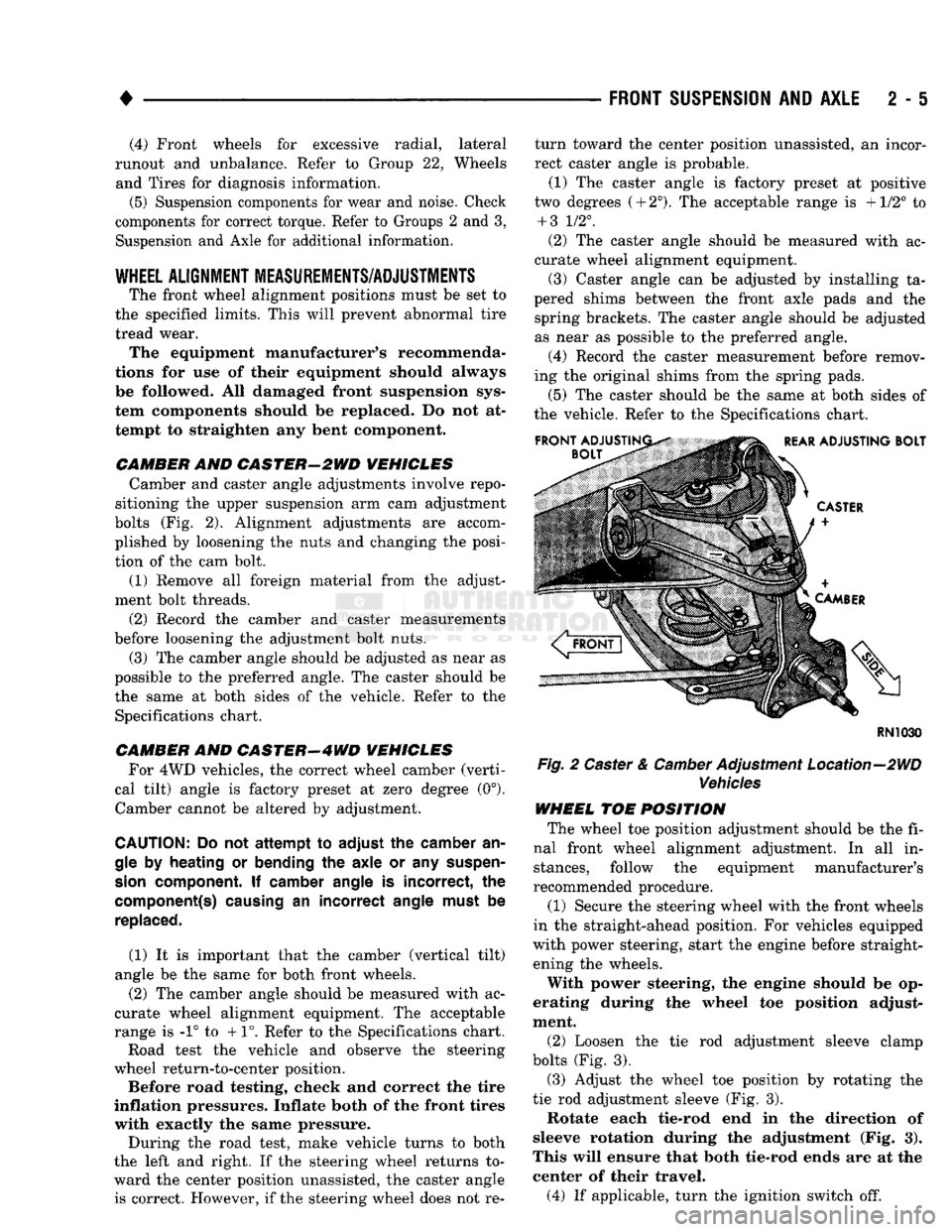

CAMBER AND CASTER-2WD VEHICLES Camber and caster angle adjustments involve repo

sitioning the upper suspension arm cam adjustment

bolts (Fig. 2). Alignment adjustments are accom

plished by loosening the nuts and changing the posi

tion of the cam bolt.

(1) Remove all foreign material from the adjust

ment bolt threads.

(2) Record the camber and caster measurements

before loosening the adjustment bolt nuts.

(3) The camber angle should be adjusted as near as

possible to the preferred angle. The caster should be

the same at both sides of the vehicle. Refer to the Specifications chart.

CAMBER AND CASTER—4WD VEHICLES For 4WD vehicles, the correct wheel camber (verti

cal tilt) angle is factory preset at zero degree (0°).

Camber cannot be altered by adjustment.

CAUTION: Do not attempt to

adjust

the

camber

an

gle by

heating

or bending the axle or any

suspen

sion

component. If camber angle is

incorrect,

the

component(s)

causing

an

incorrect

angle must be replaced.

(1) It is important that the camber (vertical tilt)

angle be the same for both front wheels.

(2) The camber angle should be measured with ac

curate wheel alignment equipment. The acceptable

range is -1° to +1°. Refer to the Specifications chart.

Road test the vehicle and observe the steering

wheel return-to-center position. Before road testing,

check

and

correct

the tire

inflation pressures. Inflate

both

of the front tires

with exactly the

same

pressure.

During the road test, make vehicle turns to both

the left and right. If the steering wheel returns to

ward the center position unassisted, the caster angle is correct. However, if the steering wheel does not re turn toward the center position unassisted, an incor

rect caster angle is probable.

(1) The caster angle is factory preset at positive

two degrees

(

+

2°).

The acceptable range is +1/2° to +

3

1/2°.

(2) The caster angle should be measured with ac

curate wheel alignment equipment.

(3) Caster angle can be adjusted by installing ta

pered shims between the front axle pads and the spring brackets. The caster angle should be adjusted

as near as possible to the preferred angle.

(4) Record the caster measurement before remov

ing the original shims from the spring pads.

(5) The caster should be the same at both sides of

the vehicle. Refer to the Specifications chart.

RN1030

Fig.

2 Caster &

Camber

Adjustment Location—2WD

Vehicles

WHEEL TOE POSITION The wheel toe position adjustment should be the fi

nal front wheel alignment adjustment. In all in stances, follow the equipment manufacturer's

recommended procedure.

(1) Secure the steering wheel with the front wheels

in the straight-ahead position. For vehicles equipped

with power steering, start the engine before straight ening the wheels.

With power steering, the engine should be op

erating during the wheel toe position adjust

ment.

(2) Loosen the tie rod adjustment sleeve clamp

bolts (Fig. 3).

(3) Adjust the wheel toe position by rotating the

tie rod adjustment sleeve (Fig. 3). Rotate each tie-rod end in the direction of

sleeve rotation during the adjustment (Fig. 3).

This will ensure that both tie-rod ends are at the center of their travel.

(4) If applicable, turn the ignition switch off.

Page 72 of 1502

FRONT

SUSPENSION

AND

AXLE

2 - 19

DRAIN

AND

REFILL

(1) Drive the vehicle until the gear lubricant

reaches normal operating temperature. (2) Raise and support the vehicle.

(3) Remove the lubricant fill hole plug from the

differential housing cover.

(4) Remove the differential housing cover. Allow

the original lubricant to completely drain from the

housing and axle shaft tubes.

(5) With standard differential, clean the differen

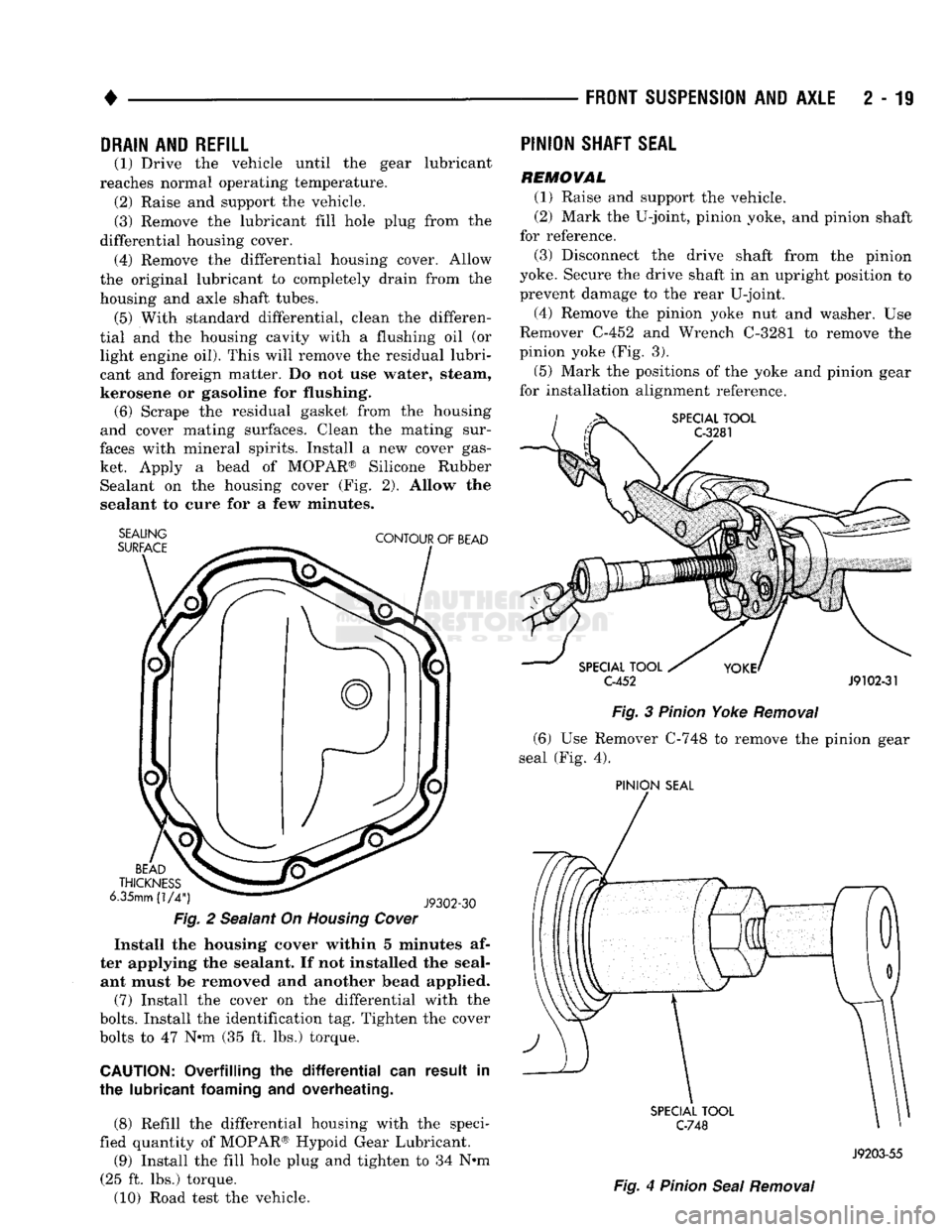

tial and the housing cavity with a flushing oil (or light engine oil). This will remove the residual lubricant and foreign matter. Do not use water, steam,

kerosene or gasoline for flushing. (6) Scrape the residual gasket from the housing

and cover mating surfaces. Clean the mating sur

faces with mineral spirits. Install a new cover gas ket. Apply a bead of MOPAR® Silicone Rubber Sealant on the housing cover (Fig. 2). Allow the

sealant to cure for a few minutes.

SEALING

SURFACE

CONTOUR

OF

BEAD

BEAD

THICKNESS

6.35mm

(1/4")

J9302-30

Fig.

2 Sealant On

Housing

Cover

Install the housing cover within 5 minutes af

ter applying the sealant. If not installed the seal ant must be removed and another bead applied.

(7) Install the cover on the differential with the

bolts.

Install the identification tag. Tighten the cover

bolts to 47 Nnn (35 ft. lbs.) torque.

CAUTION:

Overfilling the

differential

can result in

the lubricant

foaming

and overheating.

(8) Refill the differential housing with the speci

fied quantity of MOPAR® Hypoid Gear Lubricant.

(9) Install the fill hole plug and tighten to 34 N#m

(25 ft. lbs.) torque.

(10) Road test the vehicle.

PINION

SHAFT

SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Mark the U-joint, pinion yoke, and pinion shaft

for reference.

(3) Disconnect the drive shaft from the pinion

yoke. Secure the drive shaft in an upright position to prevent damage to the rear U-joint.

(4) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 3).

(5) Mark the positions of the yoke and pinion gear

for installation alignment reference.

SPECIAL

TOOL

C-3281

SPECIAL

TOOL

C-452

J9102-31

Fig.

3

Pinion

Yoke

Removal

(6) Use Remover C-748 to remove the pinion gear

seal (Fig. 4).

PINION

SEAL

SPECIAL

TOOL

C-748

Fig.

4

Pinion

Seal

Removal

J9203-55

Page 104 of 1502

FRONT

SUSPENSION

AND

AXLE

2 - 51

LUBRICANT

Multi-purpose API GL 5 quality hypoid gear lubri

cant should be used for Model 60 axles. MOPAR Hy

poid Gear Lubricant conforms to these specifications and is recommended.

CAUTION:

If a front axle is

submerged

in

water,

the

axle lubricant

must

be replaced immediately.

DRAIN AND REFILL

(1) Drive the vehicle until the gear lubricant

reaches normal operating temperature. (2) Raise and support the vehicle.

(3) Remove the lubricant fill hole plug from the

differential housing cover. (4) Remove the differential housing cover. Allow

the original lubricant to completely drain from the

housing and axle shaft tubes. (5) With standard differential, clean the differen

tial and the housing cavity with a flushing oil (or light engine oil). This will remove the residual lubricant and foreign matter. Do not use water, steam,

kerosene or gasoline for flushing. (6) Scrape the residual gasket from the housing

and cover mating surfaces. Clean the mating sur

faces with mineral spirits. Install a new cover gas

ket. Apply a bead of MOPAR® Silicone Rubber Sealant on the housing cover (Fig. 2). Allow the

sealant to cure for a few minutes.

SEALING

SURFACE

CONTOUR

OF

BEAD

BEAD

THICKNESS

6.35mm (1/4

J9302-30

Fig.

2 Sealant On

Housing

Cover

Install the housing cover within 5 minutes af

ter applying the sealant. If not installed the seal ant must be removed and another bead applied. (7) Install the cover on the differential with the

bolts.

Install the identification tag. Tighten the cover

bolts to 47 Nnn (35 ft. lbs.) torque.

CAUTION:

Overfilling the

differential

can result in

the lubricant

foaming

and overheating.

(8) Refill the differential housing with the speci

fied quantity of MOPAR® Hypoid Gear Lubricant. (9) Install the fill hole plug and tighten to 34 N«m

(25 ft. lbs.) torque. (10) Road test the vehicle.

PINION

SHAFT

SEAL

REMOVAL (1) Raise and support the vehicle.

(2) Mark the drive shaft yoke and pinion yoke for

installation alignment reference.

(3) Remove the drive shaft from the yoke.

(4) Rotate the pinion gear three or four times.

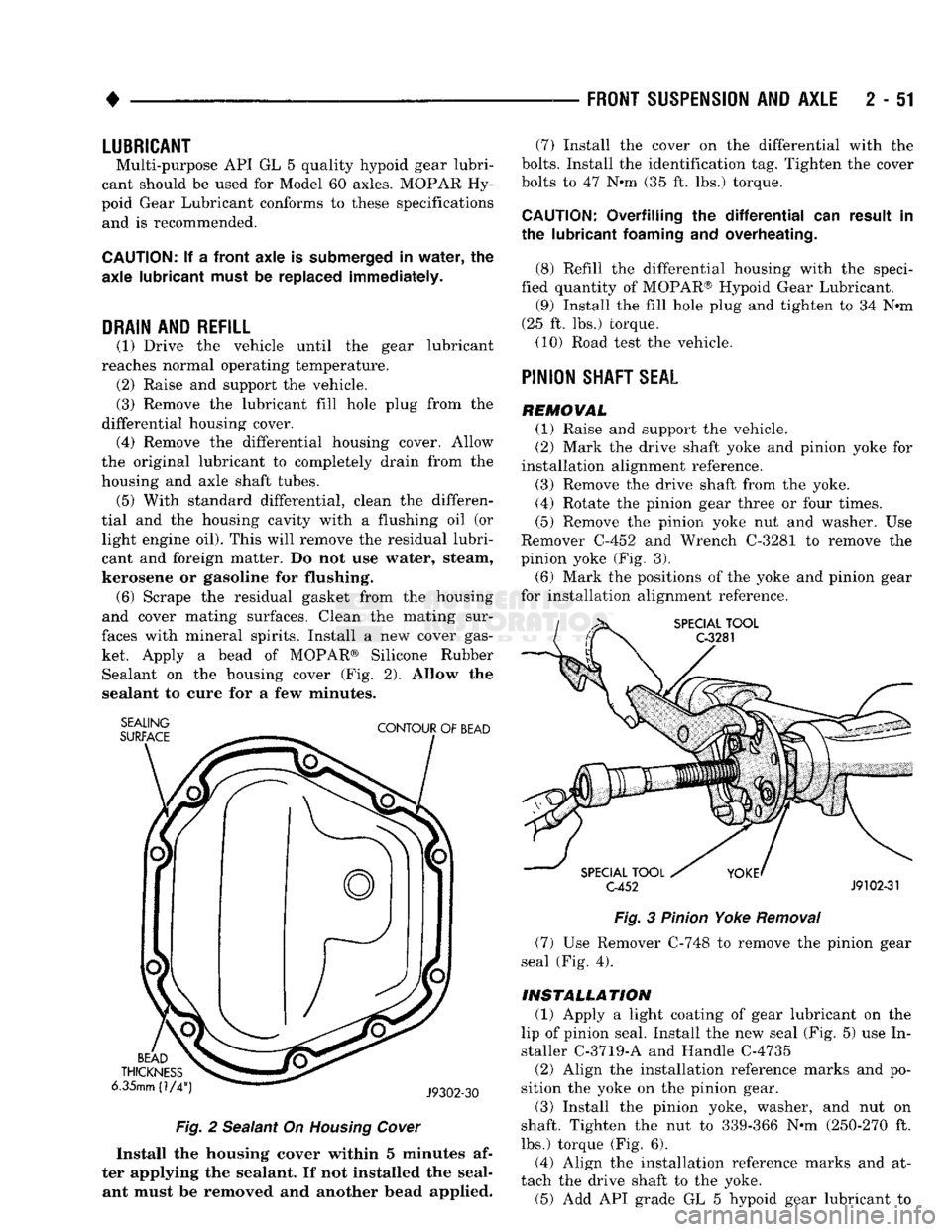

(5) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 3).

(6) Mark the positions of the yoke and pinion gear

for installation alignment reference.

SPECIAL

TOOL

C-3281

SPECIAL

TOOL

C-452

J9102-31

Fig.

3

Pinion

Yoke

Removal

(7) Use Remover C-748 to remove the pinion gear

seal (Fig. 4).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install the new seal (Fig. 5) use In

staller C-3719-A and Handle C-4735

(2) Align the installation reference marks and po

sition the yoke on the pinion gear.

(3) Install the pinion yoke, washer, and nut on

shaft. Tighten the nut to 339-366 N-m (250-270 ft.

lbs.) torque (Fig. 6).

(4) Align the installation reference marks and at

tach the drive shaft to the yoke. (5) Add API grade GL 5 hypoid gear lubricant to

Page 135 of 1502

3

- 6

REAR SUSPENSION

AND

AXLE

•

NUT PIPE

SOCKET

WRENCH

(DRIVER)

FLAT

THREADED

WASHER

ROD

J8917-20

Fig.

6

Spring

Eye

Bushing

Removal

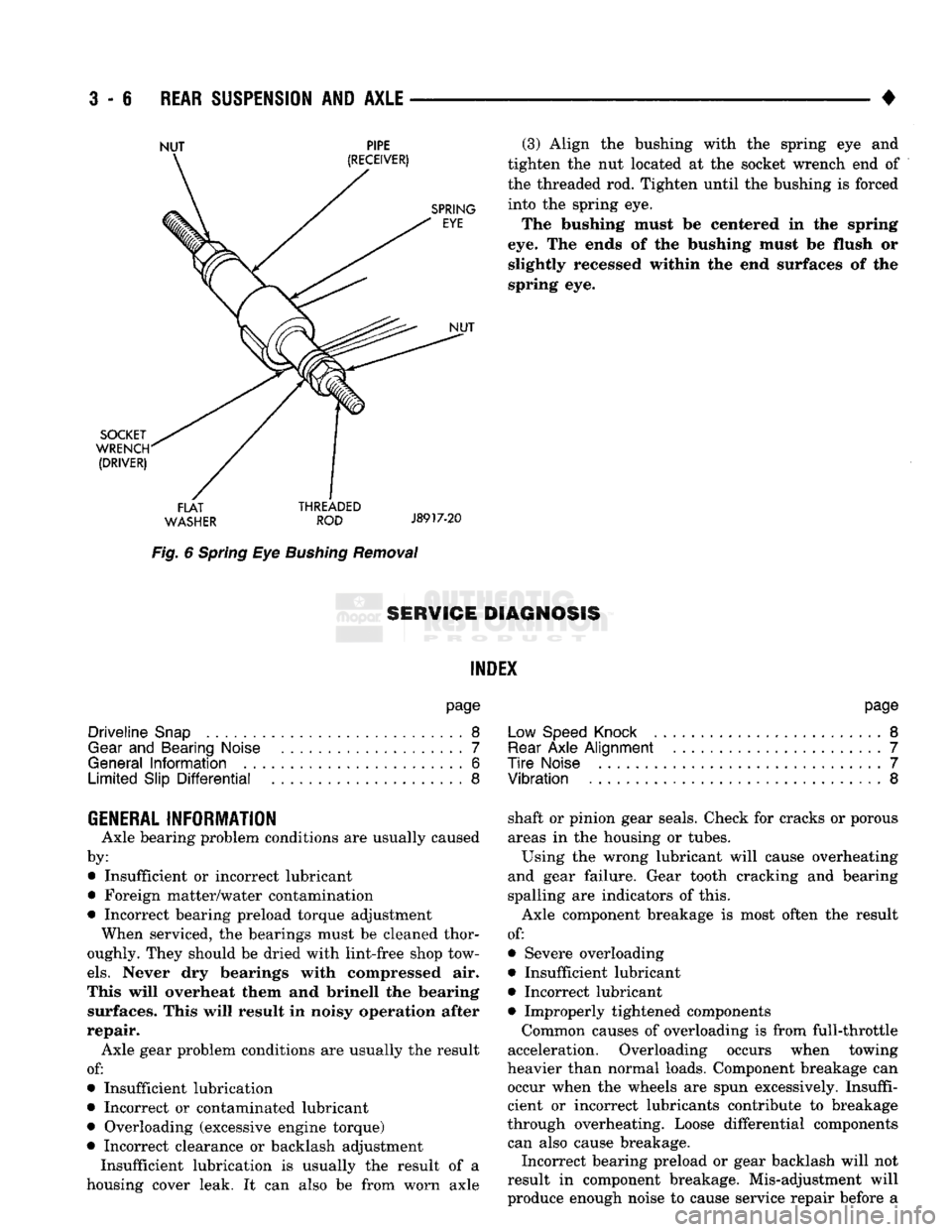

(3) Align

the

bushing with

the

spring

eye and

tighten

the nut

located

at the

socket wrench

end of

the threaded

rod.

Tighten until

the

bushing

is

forced into

the

spring

eye.

The bushing must

be

centered

in the

spring

eye.

The

ends

of the

bushing must

be

flush

or

slightly recessed within

the end

surfaces

of the

spring

eye.

8ERW1GE DIAGNOSIS

INDEX

page

Driveline

Snap

8

Gear

and

Bearing Noise

7

General

Information

6

Limited

Slip

Differential

8

page

Low Speed Knock

.........................

8

Rear

Axle

Alignment

.......................

7

Tire

Noise

7

Vibration

8

GENERAL INFORMATION

Axle bearing problem conditions

are

usually caused

by: • Insufficient

or

incorrect lubricant

• Foreign matter/water contamination

• Incorrect bearing preload torque adjustment When serviced,

the

bearings must

be

cleaned thor

oughly. They should

be

dried with lint-free shop tow

els.

Never

dry

bearings with compressed

air.

This will overheat them

and

brinell

the

bearing surfaces. This will result

in

noisy operation after

repair. Axle gear problem conditions

are

usually

the

result

of:

• Insufficient lubrication

• Incorrect

or

contaminated lubricant

• Overloading (excessive engine torque)

• Incorrect clearance

or

backlash adjustment Insufficient lubrication

is

usually

the

result

of a

housing cover leak.

It can

also

be

from worn axle shaft

or

pinion gear seals. Check

for

cracks

or

porous

areas

in the

housing

or

tubes.

Using

the

wrong lubricant will cause overheating

and gear failure. Gear tooth cracking

and

bearing

spalling

are

indicators

of

this.

Axle component breakage

is

most often

the

result

of:

• Severe overloading

• Insufficient lubricant

• Incorrect lubricant • Improperly tightened components

Common causes

of

overloading

is

from full-throttle

acceleration. Overloading occurs when towing

heavier than normal loads. Component breakage

can

occur when

the

wheels

are

spun excessively. Insuffi

cient

or

incorrect lubricants contribute

to

breakage

through overheating. Loose differential components can also cause breakage. Incorrect bearing preload

or

gear backlash will

not

result

in

component breakage. Mis-adjustment will

produce enough noise

to

cause service repair before

a

Page 139 of 1502

3-10

REAR SUSPENSION

AND

AXLE

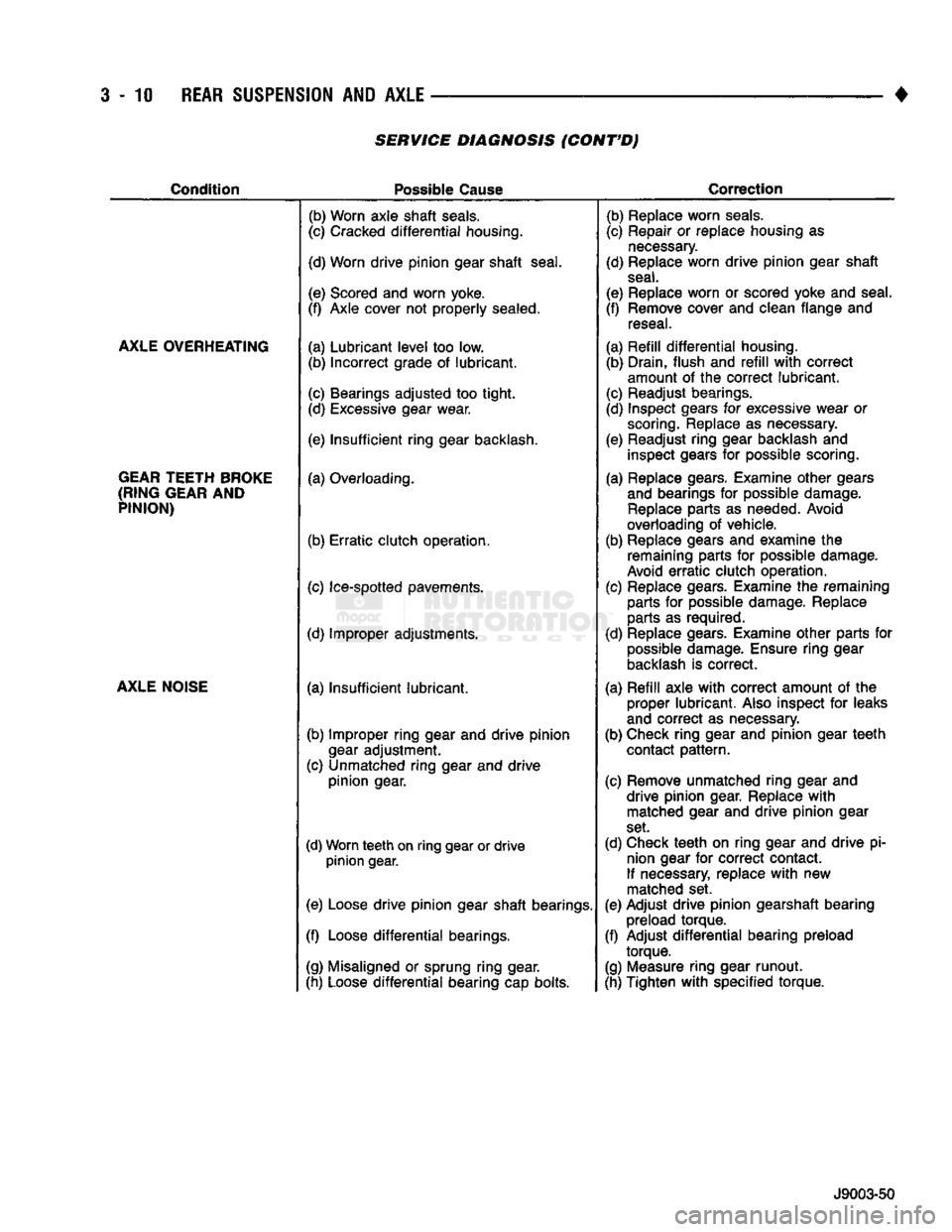

SERVICE DIAGNOSIS (CONT'D)

Condition

Possible

Cause

Correction

AXLE OVERHEATING

GEAR TEETH BROKE

(RING GEAR

AND

PINION)

AXLE NOISE

(b) Worn axle

shaft

seals.

(c) Cracked

differential

housing.

(d) Worn

drive

pinion

gear

shaft

seal.

(e) Scored and worn yoke.

(f) Axle cover not

properly

sealed.

(a)

Lubricant

level

too low. (b)

Incorrect

grade of

lubricant.

(c) Bearings

adjusted

too

tight.

(d) Excessive gear wear.

(e)

Insufficient

ring

gear backlash,

(a) Overloading.

(b)

Erratic

clutch

operation.

(c) Ice-spotted pavements.

(d) Improper adjustments.

(a)

Insufficient

lubricant.

(b) Improper

ring

gear and

drive

pinion

gear

adjustment.

(c) Unmatched

ring

gear and

drive

pinion

gear.

(d) Worn

teeth

on

ring

gear or

drive

pinion

gear.

(e) Loose

drive

pinion

gear

shaft

bearings.

(f) Loose

differential

bearings.

(g) Misaligned or sprung

ring

gear.

(h) Loose

differential

bearing cap bolts. (b) Replace worn

seals.

(c) Repair or replace housing as

necessary.

(d) Replace worn

drive

pinion

gear

shaft

seal.

(e) Replace worn or scored yoke and seal.

(f) Remove cover and clean flange and reseal.

(a)

Refill

differential

housing. (b) Drain,

flush

and

refill

with

correct

amount of the

correct

lubricant.

(c) Readjust bearings.

(d) Inspect gears for excessive wear or scoring. Replace as necessary.

(e) Readjust

ring

gear backlash and inspect gears for possible scoring.

(a) Replace gears. Examine

other

gears and bearings for possible damage. Replace parts as needed. Avoid

overloading of vehicle.

(b) Replace gears and examine the remaining parts for possible damage.

Avoid

erratic

clutch

operation.

(c) Replace gears. Examine the remaining parts for possible damage. Replace

parts as required.

(d) Replace gears. Examine

other

parts for possible damage. Ensure

ring

gear

backlash is

correct.

(a)

Refill

axle

with

correct

amount of the proper

lubricant.

Also inspect for leaks

and

correct

as necessary.

(b) Check

ring

gear and

pinion

gear

teeth

contact

pattern.

(c) Remove unmatched

ring

gear and

drive

pinion

gear. Replace

with

matched gear and

drive

pinion

gear

set.

(d) Check

teeth

on

ring

gear and

drive

pi nion gear for

correct

contact.

If necessary, replace

with

new

matched set.

(e) Adjust

drive

pinion

gearshaft bearing preload

torque.

(f) Adjust

differential

bearing preload

torque.

(g) Measure

ring

gear

runout.

(h) Tighten

with

specified

torque.

J9003-50

Page 140 of 1502

•

REAR

SUSPENSION

AND

AXLE

3 - 11 8 3/8 and 9 1/4

AXLE

INDEX

page

Axle Shaft, Seal

and

Bearing Service

......... 11

Complete Axle Removal/Installation

16

Differential

Service

16

Information

11

INFORMATION

The 8 3/8 and 9 1/4 axle (Fig. 1) housing consist of

a cast iron center section. They also have two steel

axle shaft tubes that are pressed into and welded to

the differential housing. The removable, stamped steel cover provides a

means for inspection and service without removing

the complete axle from the vehicle.

LUBRICANT

Multi-purpose, hypoid gear lubricant should be

used for 8 3/8 and 9 1/4 axles. The lubricant should

have MIL-L-2105C and API GL 5 quality specifica

tions.

MOPAR® Hypoid Gear Lubricant conforms to

both of these specifications.

Refer to Group 0, Lubrication and Maintenance for

additional information.

CAUTION:

If a

rear axle

is

submerged

in

water,

the

axle lubricant must

be

replaced immediately.

DRAIN

AND

REFILL

(1) Drive the vehicle until the gear lubricant

reaches normal operating temperature.

(2) Raise and support the vehicle.

(3) Remove the lubricant fill hole plug from the

differential housing cover.

(4) Remove the differential housing cover. Allow

the original lubricant to completely drain from the

housing and axle shaft tubes. (5) With standard differential, clean the differen

tial and the housing cavity with a flushing oil (or light engine oil). This will remove the residual lubri

cant and foreign matter.Do not use water, steam,

kerosene or gasoline for flushing.

CAUTION:

DO NOT

FLUSH

Sure-Grip differentials.

Sure-Grip

differentials

may be

cleaned only

by

wip

ing

with

clean,

lint-free

cloths.

(6)

Scrape the residual sealant from the housing

and cover mating surfaces. Clean the mating sur

faces with mineral spirits. Apply a bead of MOPAR® Silicone Rubber Sealant on the housing cover (Fig.

2).

Allow the sealant to cure for a few minutes.

page

Lubricant

11

Pinion Depth Measurement

and

Adjustment

with

Gauge

Set 20

Pinion

Seal

Replacement

14

Install the housing cover within 5 minutes af

ter applying the sealant. If not installed, the sealant must be removed and another bead ap

plied. (7) Install the cover on the differential. Install the

identification tag. Tighten the cover bolts to 47 N#m (35 ft. lbs.) torque.

CAUTION:

Overfilling

the

differential

can

result

in

the lubricant foaming

and

overheating.

(8) Refill the differential with the specified quan

tity of MOPAR® Hypoid Gear Lubricant. With Sure- Grip differentials, add a container of MOPAR®

Hypoid Gear Lubricant Additive.

(9) Install the fill hole plug.

(10) Road test the vehicle.

AXLE

SHAFT, SEAL AND BEARING

SERVICE

CAUTION:

When rear axle service

is

necessary, both rear wheels must

be

raised

off the

surface

so

that

they

are

free

to

rotate.

Be

cautious when

the

tires

are

being rotated

by the

engine

or by

other

means.

CAUTION:

If

equipped

with

a

Sure-Grip

differential,

do

not

rotate

either

axle shaft unless both

are

prop

erly

in-place. Rotation

of one

axle shaft without

the

other being installed

can

result

in

misalignment

of

the side gears/splines. This

will

necessitate side

gear

re-alignment before

the

axle shaft

can be in

stalled.

AXLE SHAFT REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel.

(3) Remove the brake drum.

(4) Clean all the foreign material from housing

cover area.

(5) Loosen the housing cover bolts. Drain the lubri

cant from the housing. Remove the housing cover.

(6)

Rotate the differential case so the pinion mate

gear shaft lock screw is accessible. Remove the lock screw and the pinion mate gear shaft from the case (Fig. 3).

Page 146 of 1502

•

REAR

SUSPENSION

AND

AXLE

3 - 11

ADAPTERS

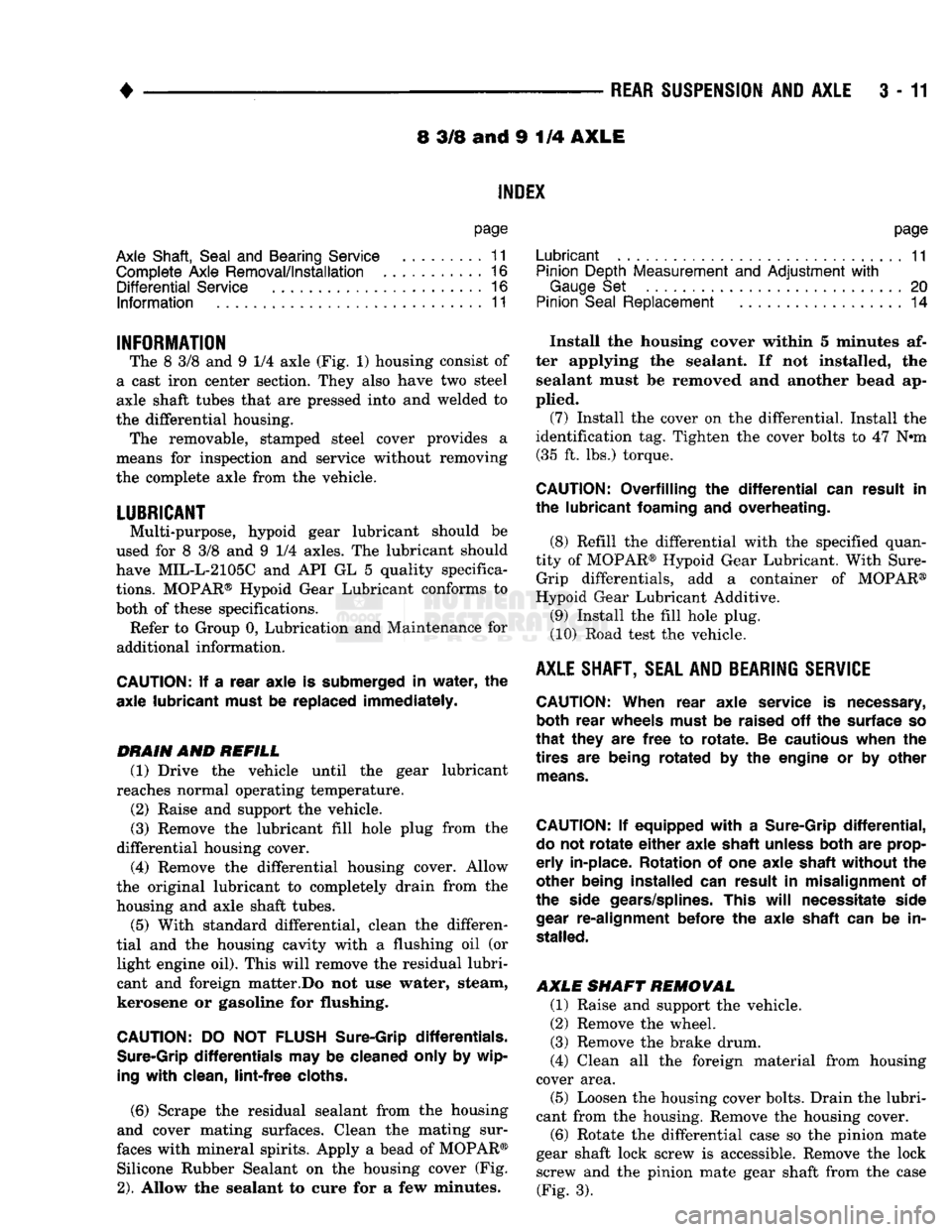

Fig.

17

Differential

Bearing

Removal

cloth should be moved around the circumfer

ence of the shaft (not in-line with the shaft).

When replacing a drive pinion gear bearing,

always replace the bearing and cup as a

matched set only.

(6) Inspect the axle shaft C-clip locks for cracks

and excessive wear. Replace them if necessary.

(7) Test each threaded adjuster to determine if it

rotates freely. (8) If an adjuster binds, repair the damaged

threads or replace the adjuster.

EXCITER

RING

REPLACEMENT

The ring gear must be removed before the RWAL

brake exciter ring can be replaced.

(1) Remove exciter ring with a hammer and drift.

(2) Heat the replacement exciter ring with a heat

lamp or by immersing in a hot fluid. The tempera

ture should not exceed 149°C (300°F). Do not use a

torch to heat the ring.

(3) After heating, quickly position the exciter ring

on the differential case adjacent to the flange.

DIFFERENTIAL

CASE ASSEMBLY

(1) Lubricate all the differential case components

with gear lubricant. (2) Place the thrust washers on the differential

side gears. Position the gears in the differential case

counterbores.

If replacement side gears or thrust washers

are used, refer to Differential Side Gear Clear ance Measurement And Adjustment.

(3) Position the thrust washers on the differential

pinion gears. Mesh the pinion gears with the side

gears.

Ensure that the pinion gears are exactly 180 degrees opposite each other.

(4) Rotate the side gears to align the pinion gears

and thrust washers. Align these components with the

mate shaft bores in the case.

(5) If the ring gear was removed, clean all contact

surfaces. Use an Arkansas stone or fine file to re

move any sharp areas from the chamfered inside di ameter.

(6) If removed, heat ring gear with a heat lamp or

by immersing in a hot fluid. The temperature should not exceed 149°C (300°F). Do not use a torch to

heat the ring.

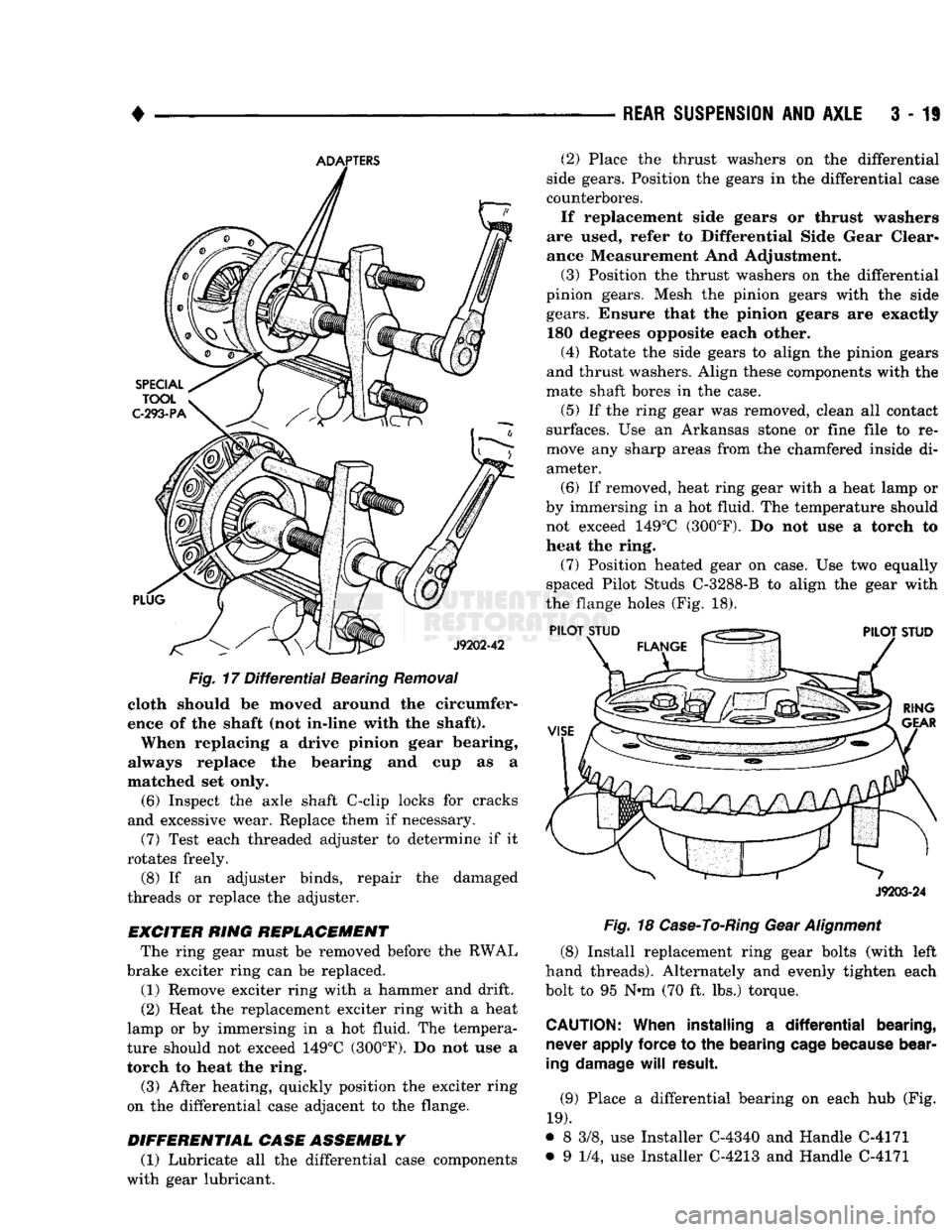

(7) Position heated gear on case. Use two equally

spaced Pilot Studs C-3288-B to align the gear with

the flange holes (Fig. 18).

J9203-24

Fig.

18

Case-To-Ring

Gear

Alignment

(8) Install replacement ring gear bolts (with left

hand threads). Alternately and evenly tighten each

bolt to 95 N-m (70 ft. lbs.) torque.

CAUTION:

When

installing a

differential

bearing,

never apply force to the bearing

cage

because

bear

ing

damage

will

result.

(9) Place a differential bearing on each hub (Fig.

19).

• 8 3/8, use Installer C-4340 and Handle C-4171

• 9 1/4, use Installer C-4213 and Handle C-4171