rear view mirror DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 492 of 1502

WIRING

DIAGRAMS SW - 17

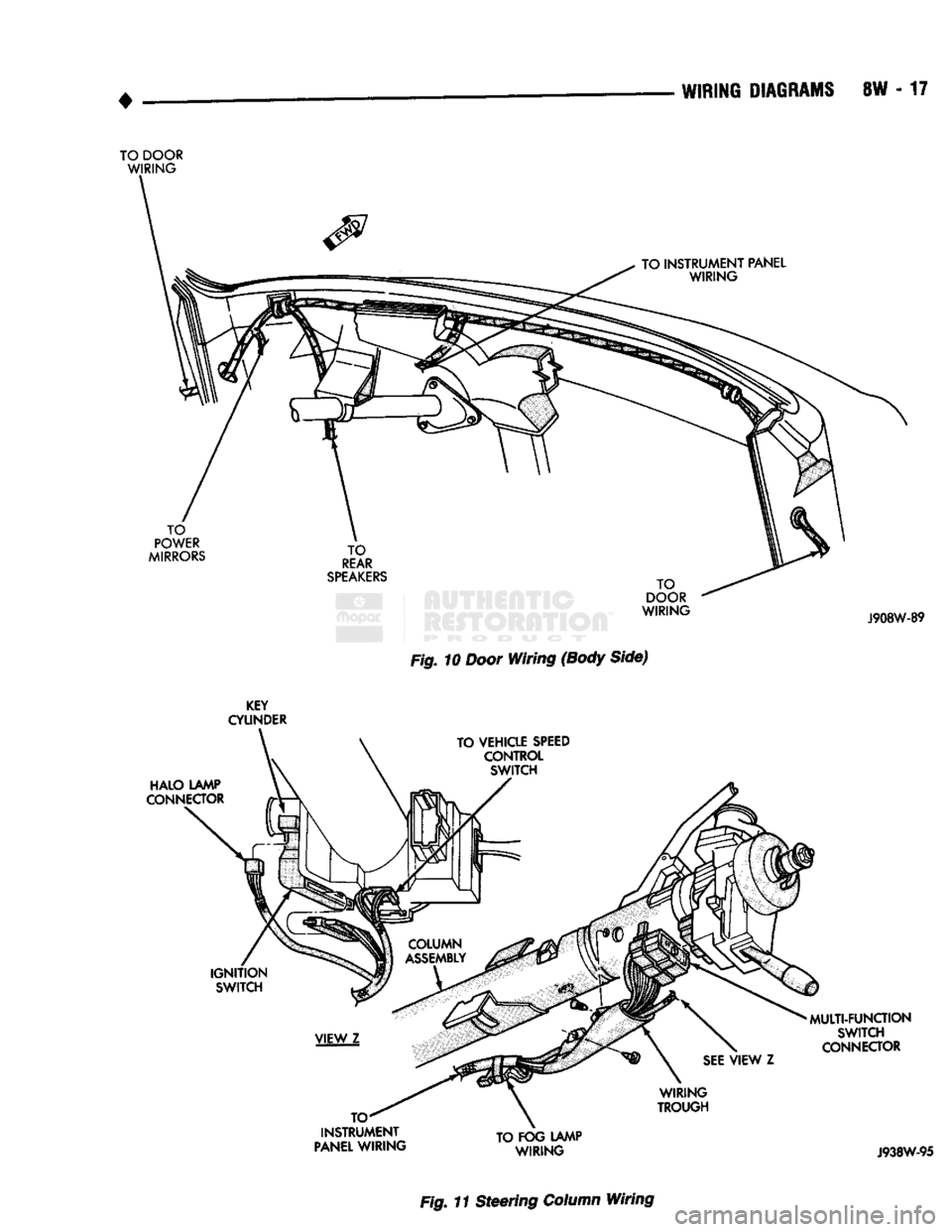

TO DOOR WIRING

TO

POWER

MIRRORS

TO

REAR

SPEAKERS

TO INSTRUMENT PANEL

WIRING

TO

DOOR

WIRING

J908W-89

Fig. 10 Door

Wiring

(Body

Side)

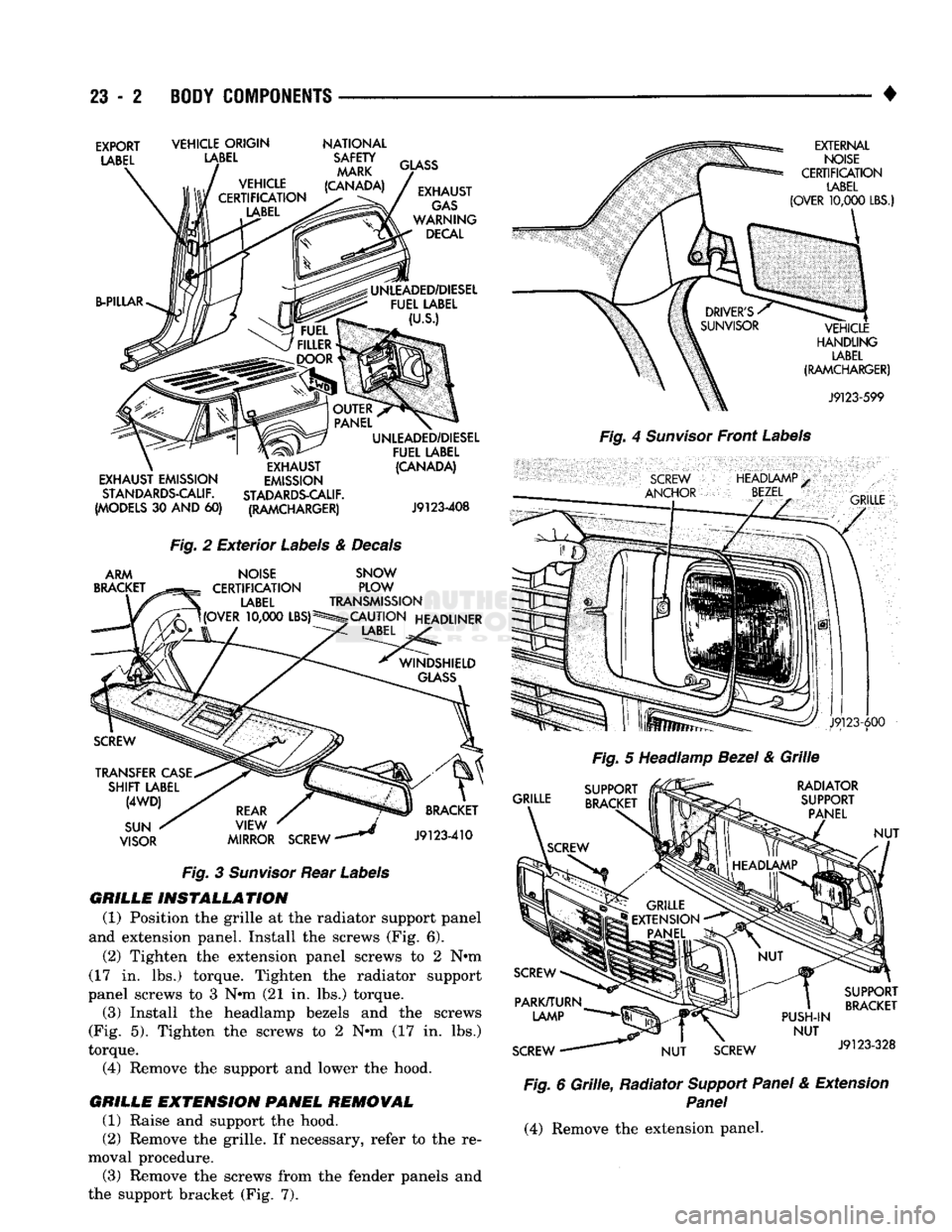

KEY

CYLINDER

HALO LAMP

CONNECTOR IGNITION

SWITCH TO VEHICLE

SPEED

CONTROL SWITCH

SEE

VIEW Z MULTI-FUNCTION

SWITCH

CONNECTOR TO

INSTRUMENT

PANEL

WIRING WIRING

TROUGH

TO FOG LAMP WIRING

J938W-95

Fig. 11

Steering

Column

Wiring

Page 1385 of 1502

23

- 2

BODY COMPONENTS

•

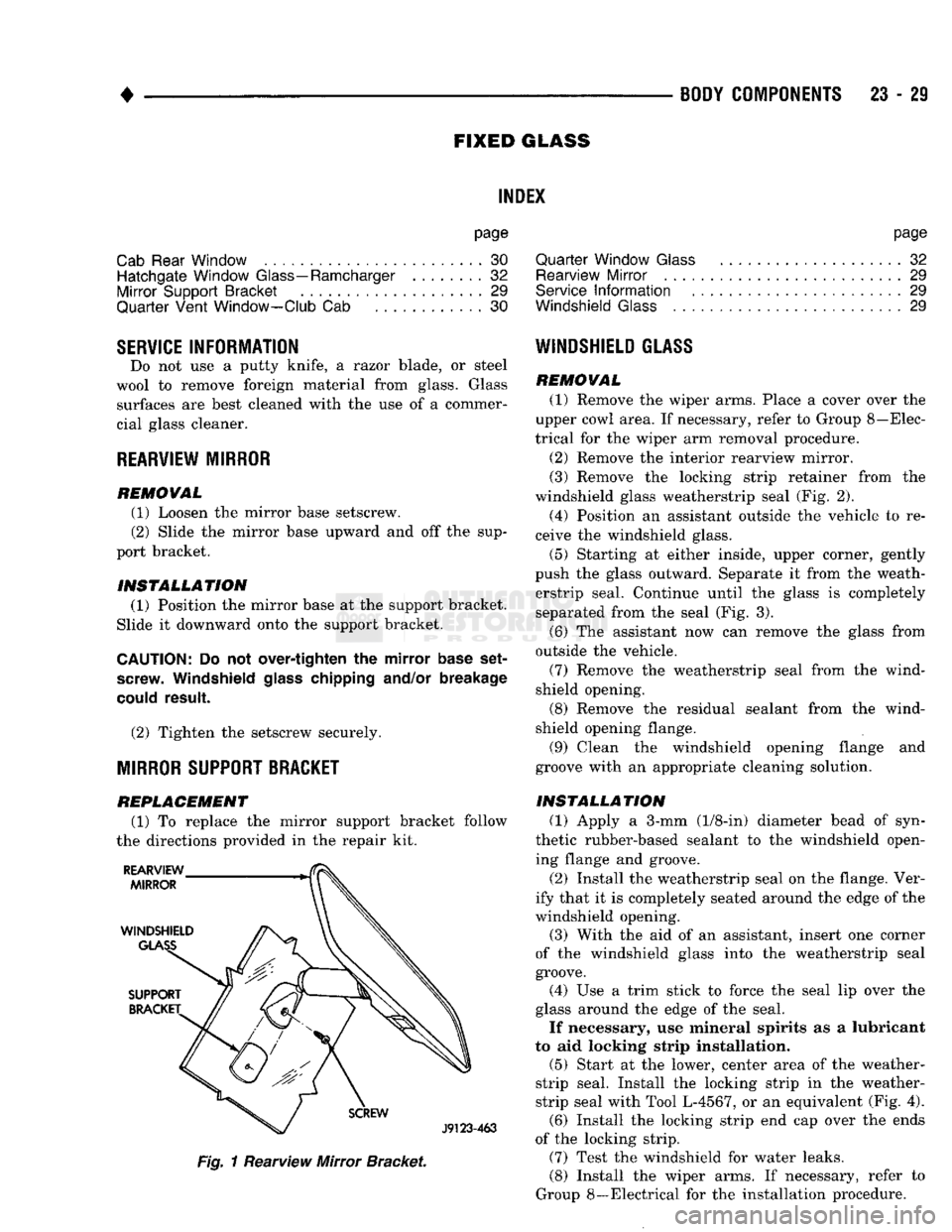

EXPORT

LABEL

VEHICLE ORIGIN

LABEL

NATIONAL

SAFETY MARK

(CANADA) B-PILLAR

GLASS

EXHAUST

GAS

WARNING DECAL

UNLEADED/DIESEL FUEL LABEL

(U.S.)

EXHAUST EMISSION STANDARDS-CALIF.

(MODELS

30 AND 60)

EXHAUST

EMISSION

STADARDS-CALIF. (RAMCHARGER) UNLEADED/DIESEL

FUEL LABEL (CANADA)

J9123-408

Fig.

2

Exterior

Labels

&

Decals

ARM

BRACKET

NOISE

CERTIFICATION

LABEL

UOVER

10,000

LBS)5 SNOW

PLOW

TRANSMISSION

CAUTION HEADLINER

LABEL

TRANSFER

CASE

SHIFT

LABEL

(4WD)

SUN

VISOR

REAR

VIEW

MIRROR SCREW

*

BRACKET

J9123-410

Fig.

3

Sunvisor

Rear

Labels

GRILLE INSTALLATION

(1) Position

the

grille

at the

radiator support panel

and extension panel. Install

the

screws

(Fig. 6).

(2) Tighten

the

extension panel screws

to 2 N»m

(17

in. lbs.)

torque. Tighten

the

radiator support

panel screws

to 3 Nnn (21 in. lbs.)

torque. (3) Install

the

headlamp bezels

and the

screws

(Fig.

5).

Tighten

the

screws

to 2 Nnn (17 in. lbs.)

torque. (4) Remove

the

support

and

lower

the

hood.

GRILLE EMTENSION PANEL REMOVAL (1) Raise

and

support

the

hood.

(2) Remove

the

grille.

If

necessary, refer

to the re

moval procedure. (3) Remove

the

screws from

the

fender panels

and

the support bracket

(Fig. 7).

EXTERNAL

NOISE

CERTIFICATION

LABEL

(OVER

10,000

LBS.)

VEHICLE

HANDLING

LABEL

(RAMCHARGER)

J9123-599

Fig.

4

Sunvisor

Front

Labels

SCREW

ANCHOR

HEADIAMP

BEZEL

•

GRILLE

J9123-600

Fig.

5

Headlamp

Bezel

&

Grille

GRILLE RADIATOR

SUPPORT PANEL

NUT

PUSH-IN

NUT

SCREW

NUT

SCREW SUPPORT

BRACKET

J9123-328

Fig.

6

Grille,

Radiator

Support Panel

&

Extension

Panel

(4) Remove

the

extension panel.

Page 1412 of 1502

•

IODY

COMPONENTS 23 - 29

FIXED

GLASS

1NDE1

page

Cab

Rear Window

30

Hatchgate Window Glass—Ramcharger

........ 32

Mirror Support Bracket

29

Quarter Vent Window-Club

Cab 30

page

Quarter Window

Glass

. 32

Rearview

Mirror

.......................... 29

Service

Information

29

Windshield

Glass

29

SERVICE

INFORMATION Do not use a putty knife, a razor blade, or steel

wool to remove foreign material from glass. Glass surfaces are best cleaned with the use of a commer

cial glass cleaner.

REARVIEW

MIRROR

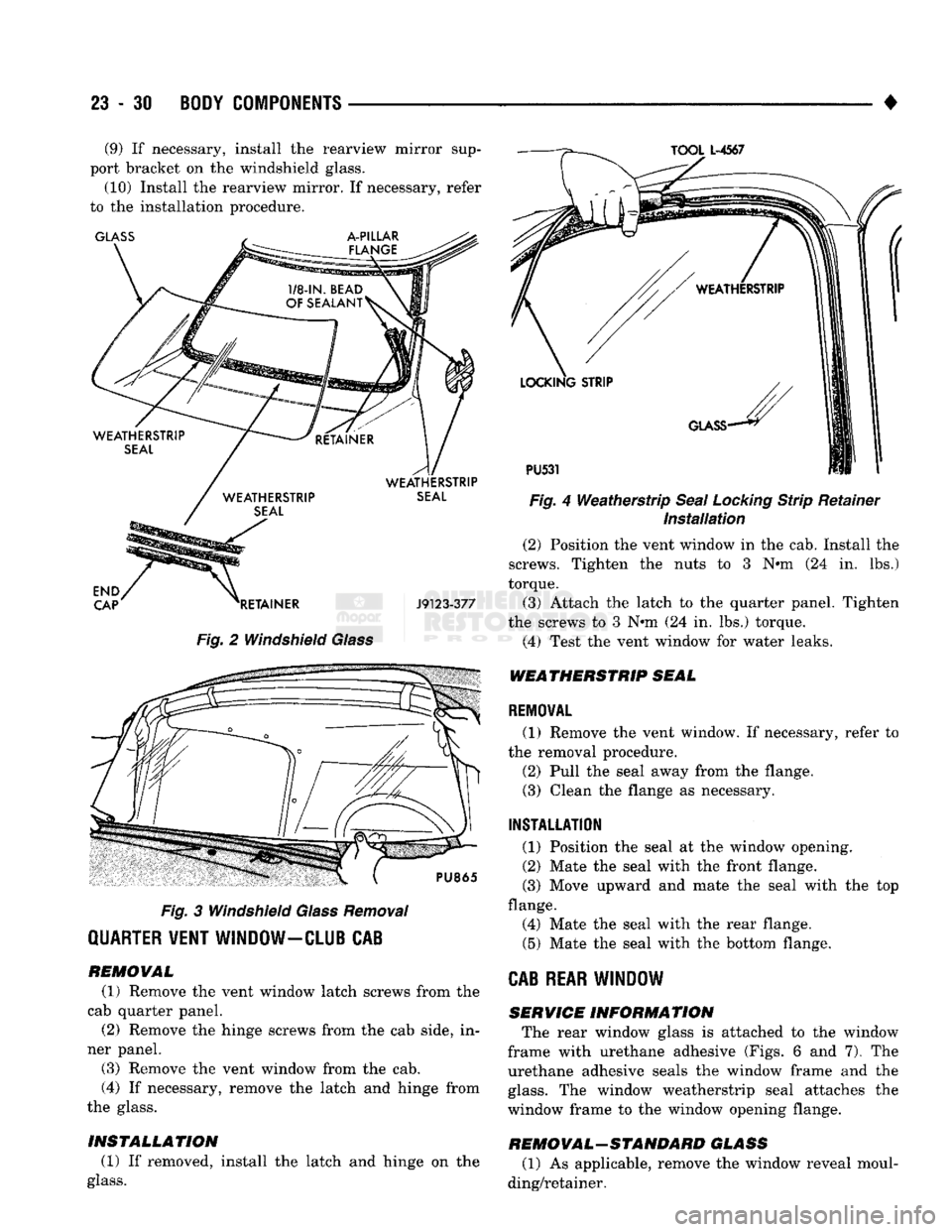

REMOVAL (1) Loosen the mirror base setscrew.

(2)

Slide the mirror base upward and off the sup

port bracket.

INSTALLATION (1) Position the mirror base at the support bracket.

Slide it downward onto the support bracket.

CAUTION:

Do not

over-tighten

the mirror

base

set-

screw.

Windshield

glass

chipping and/or breakage

could

result.

(2)

Tighten the setscrew securely.

MIRROR

SUPPORT BRACKET

REPLACEMENT (1) To replace the mirror support bracket follow

the directions provided in the repair kit. Fig. 1 Rearview Mirror Bracket.

WINDSHIELD

GLASS

REMOVAL (1) Remove the wiper arms. Place a cover over the

upper cowl area. If necessary, refer to Group 8—Elec

trical for the wiper arm removal procedure.

(2) Remove the interior rearview mirror.

(3) Remove the locking strip retainer from the

windshield glass weatherstrip seal (Fig. 2).

(4) Position an assistant outside the vehicle to re

ceive the windshield glass.

(5)

Starting at either inside, upper corner, gently

push the glass outward. Separate it from the weath erstrip seal. Continue until the glass is completely separated from the seal (Fig. 3).

(6) The assistant now can remove the glass from

outside the vehicle.

(7) Remove the weatherstrip seal from the wind

shield opening. (8) Remove the residual sealant from the wind

shield opening flange.

(9) Clean the windshield opening flange and

groove with an appropriate cleaning solution.

INSTALLATION (1) Apply a 3-mm (1/8-in) diameter bead of syn

thetic rubber-based sealant to the windshield open ing flange and groove.

(2) Install the weatherstrip seal on the flange. Ver

ify that it is completely seated around the edge of the

windshield opening.

(3) With the aid of an assistant, insert one corner

of the windshield glass into the weatherstrip seal groove. (4) Use a trim stick to force the seal lip over the

glass around the edge of the seal. If necessary, use mineral spirits as a lubricant

to aid locking strip installation.

(5)

Start at the lower, center area of the weather

strip seal. Install the locking strip in the weather

strip seal with Tool L-4567, or an equivalent (Fig. 4). (6) Install the locking strip end cap over the ends

of the locking strip. (7) Test the windshield for water leaks. (8) Install the wiper arms. If necessary, refer to

Group 8—Electrical for the installation procedure.

Page 1413 of 1502

23

- 30

BODY COMPONENTS

• (9) If necessary, install the rearview mirror sup

port bracket on the windshield glass. (10) Install the rearview mirror. If necessary, refer

to the installation procedure.

Fig.

2 Windshield

Glass

Fig.

3 Windshield

Glass

Removal

QUARTER WENT WINDOW-CLUB CAB

REMOVAL

(1) Remove the vent window latch screws from the

cab quarter panel.

(2) Remove the hinge screws from the cab side, in

ner panel.

(3) Remove the vent window from the cab.

(4) If necessary, remove the latch and hinge from

the glass.

INSTALLATION

(1) If removed, install the latch and hinge on the

glass.

Fig.

4

Weatherstrip

Seal Locking

Strip Retainer

Installation

(2) Position the vent window in the cab. Install the

screws. Tighten the nuts to 3 N#m (24 in. lbs.)

torque. (3) Attach the latch to the quarter panel. Tighten

the screws to 3 N«m (24 in. lbs.) torque. (4) Test the vent window for water leaks.

WEATHERSTRIP

SEAL

REMOVAL

(1) Remove the vent window. If necessary, refer to

the removal procedure. (2) Pull the seal away from the flange. (3) Clean the flange as necessary.

INSTALLATION

(1) Position the seal at the window opening.

(2) Mate the seal with the front flange.

(3) Move upward and mate the seal with the top

flange. (4) Mate the seal with the rear flange.

(5) Mate the seal with the bottom flange.

CAB REAR WINDOW

SERVICE

INFORMATION

The rear window glass is attached to the window

frame with urethane adhesive (Figs. 6 and 7). The

urethane adhesive seals the window frame and the

glass.

The window weatherstrip seal attaches the

window frame to the window opening flange.

REMOVAL-STANDARD

GLASS

(1) As applicable, remove the window reveal moul

ding/retainer.