oil additives DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 37 of 1502

0-18

LUBRICATION

AND

MAINTENANCE

• MAINTENANCE SCHEDULE

A crankcase ventilation system must be clean to

provide good operation and durability. Periodic main

tenance is necessary. Replace the PCV valve. Re

move residual combustion deposits from the hoses and throttle body/intake manifold passages.

The PCV valve should be replaced and the system

should be serviced at the interval specified in main

tenance schedule. If a vehicle is routinely used for short trips, the crankcase ventilation system could

possibly require more maintenance.

CRANKCASE AIR INLET FILTER

MAINTENANCE SCHEDULE Replace or clean, the air inlet filter at the interval

specified in maintenance schedule.

More frequent PCV system maintenance could be

required for:

• Vehicles routinely used for short trips

• Vehicles routinely involved in stop and go traffic

operation

• Vehicles routinely involved in extended periods of

engine idle

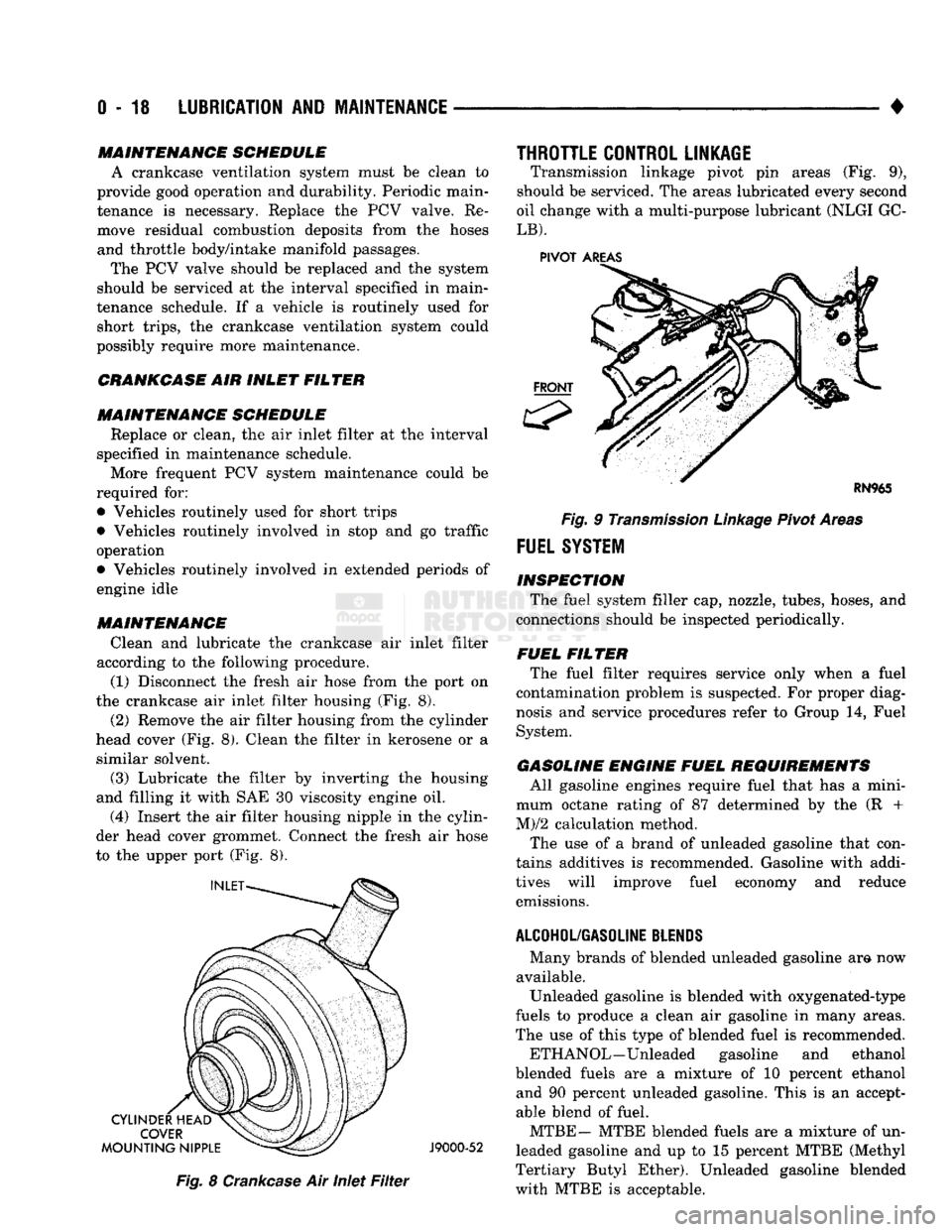

MAINTENANCE Clean and lubricate the crankcase air inlet filter

according to the following procedure. (1) Disconnect the fresh air hose from the port on

the crankcase air inlet filter housing (Fig. 8).

(2) Remove the air filter housing from the cylinder

head cover (Fig. 8). Clean the filter in kerosene or a similar solvent.

(3) Lubricate the filter by inverting the housing

and filling it with SAE 30 viscosity engine oil.

(4) Insert the air filter housing nipple in the cylin

der head cover grommet. Connect the fresh air hose

to the upper port (Fig. 8).

J9000-52

Fig.

8

Crankcase

Air Inlet

Filter

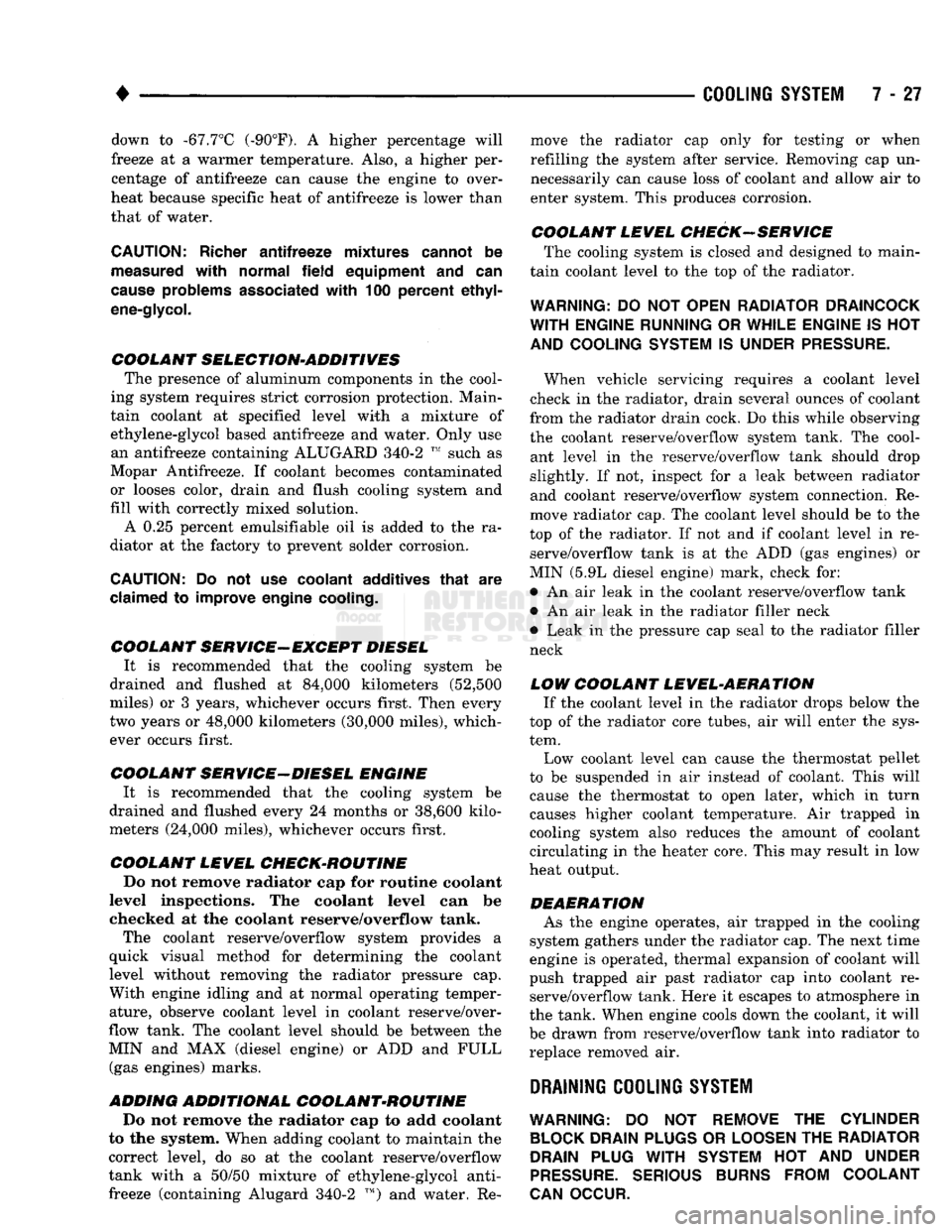

THROTTLE CONTROL LINKAGE

Transmission linkage pivot pin areas (Fig. 9),

should be serviced. The areas lubricated every second

oil change with a multi-purpose lubricant (NLGI GC-

LB).

PIVOT

AREAS

Fig.

9

Transmission

Linkage

Pivot Areas

FUEL

SYSTEM

INSPECTION The fuel system filler cap, nozzle, tubes, hoses, and

connections should be inspected periodically.

FUEL FILTER The fuel filter requires service only when a fuel

contamination problem is suspected. For proper diag

nosis and service procedures refer to Group 14, Fuel

System.

GASOLINE ENGINE FUEL REQUIREMENTS All gasoline engines require fuel that has a mini

mum octane rating of 87 determined by the (R +

M)/2 calculation method.

The use of a brand of unleaded gasoline that con

tains additives is recommended. Gasoline with addi

tives will improve fuel economy and reduce emissions.

ALCOHOL/GASOLINE

BLENDS

Many brands of blended unleaded gasoline am now

available. Unleaded gasoline is blended with oxygenated-type

fuels to produce a clean air gasoline in many areas.

The use of this type of blended fuel is recommended.

ETH ANOL—Unleaded gasoline and ethanol

blended fuels are a mixture of 10 percent ethanol and 90 percent unleaded gasoline. This is an accept

able blend of fuel.

MTBE— MTBE blended fuels are a mixture of un

leaded gasoline and up to 15 percent MTBE (Methyl

Tertiary Butyl Ether). Unleaded gasoline blended

with MTBE is acceptable.

Page 298 of 1502

•

COOLING

SYSTEM

7 - 27 down to -67.7°C (-90°F). A higher percentage will

freeze at a warmer temperature. Also, a higher per centage of antifreeze can cause the engine to over

heat because specific heat of antifreeze is lower than

that of water.

CAUTION:

Richer

antifreeze

mixtures

cannot

be

measured

with

normal

field

equipment

and can

cause

problems

associated

with 100

percent

ethyl

ene-glycol.

COOLANT SELECTION-ADDITIVES The presence of aluminum components in the cool

ing system requires strict corrosion protection. Main

tain coolant at specified level with a mixture of ethylene-glycol based antifreeze and water. Only use an antifreeze containing ALUGARD 340-2

™

such as

Mopar Antifreeze. If coolant becomes contaminated

or looses color, drain and flush cooling system and

fill with correctly mixed solution.

A 0.25 percent emulsifiable oil is added to the ra

diator at the factory to prevent solder corrosion.

CAUTION:

Do not use

coolant

additives

that are

claimed

to

improve

engine

cooling.

COOLANT SERVICE-EXCEPT DIESEL It is recommended that the cooling system be

drained and flushed at 84,000 kilometers (52,500

miles) or 3 years, whichever occurs first. Then every

two years or 48,000 kilometers (30,000 miles), which ever occurs first.

COOLANT SERVICE-DIESEL ENGINE It is recommended that the cooling system be

drained and flushed every 24 months or 38,600 kilo meters (24,000 miles), whichever occurs first.

COOLANT LEVEL CHECK-ROUTINE Do not remove radiator cap for routine coolant

level inspections. The coolant level can be checked at the coolant reserve/overflow tank.

The coolant reserve/overflow system provides a

quick visual method for determining the coolant

level without removing the radiator pressure cap.

With engine idling and at normal operating temper ature, observe coolant level in coolant reserve/over

flow tank. The coolant level should be between the MIN and MAX (diesel engine) or ADD and FULL (gas engines) marks.

ADDING ADDITIONAL COOLANT-ROUTINE Do not remove the radiator cap to add coolant

to the system. When adding coolant to maintain the correct level, do so at the coolant reserve/overflow

tank with a 50/50 mixture of ethylene-glycol anti

freeze (containing Alugard 340-2 ™) and water. Re move the radiator cap only for testing or when

refilling the system after service. Removing cap un necessarily can cause loss of coolant and allow air to

enter system. This produces corrosion.

COOLANT LEVEL CHECK-SERVICE The cooling system is closed and designed to main

tain coolant level to the top of the radiator.

WARNING:

DO

NOT OPEN RADIATOR DRAINCOCK

WITH

ENGINE RUNNING

OR

WHILE ENGINE

IS HOT

AND COOLING

SYSTEM

IS

UNDER

PRESSURE.

When vehicle servicing requires a coolant level

check in the radiator, drain several ounces of coolant

from the radiator drain cock. Do this while observing

the coolant reserve/overflow system tank. The cool ant level in the reserve/overflow tank should drop

slightly. If not, inspect for a leak between radiator and coolant reserve/overflow system connection. Re

move radiator cap. The coolant level should be to the

top of the radiator. If not and if coolant level in re serve/overflow tank is at the ADD (gas engines) or

MIN (5.9L diesel engine) mark, check for:

• An air leak in the coolant reserve/overflow tank

• An air leak in the radiator filler neck

• Leak in the pressure cap seal to the radiator filler

neck

LOW COOLANT LEVEL-AERATION If the coolant level in the radiator drops below the

top of the radiator core tubes, air will enter the sys

tem. Low coolant level can cause the thermostat pellet

to be suspended in air instead of coolant. This will cause the thermostat to open later, which in turn causes higher coolant temperature. Air trapped in

cooling system also reduces the amount of coolant

circulating in the heater core. This may result in low

heat output.

DEAERATION As the engine operates, air trapped in the cooling

system gathers under the radiator cap. The next time

engine is operated, thermal expansion of coolant will

push trapped air past radiator cap into coolant re serve/overflow tank. Here it escapes to atmosphere in

the tank. When engine cools down the coolant, it will

be drawn from reserve/overflow tank into radiator to replace removed air.

DRAINING

COOLING

SYSTEM

WARNING:

DO NOT

REMOVE

THE

CYLINDER BLOCK DRAIN PLUGS

OR

LOOSEN THE RADIATOR

DRAIN PLUG

WITH

SYSTEM

HOT AND

UNDER

PRESSURE.

SERIOUS BURNS

FROM

COOLANT

CAN OCCUR.