stop start DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 20 of 1502

•

• —

LUiRICATlON

AND

MAINTENANCE

0 - 1

CONTENTS

page

page

CHASSIS

AND

BODY

28

ENGINE MAINTENANCE

14

DRIVETRAIN

.,,, 22

GENERAL INFORMATION

1

GENERAL

INFORMATION INDEl

page

Classification

of

Lubricants

. 3

Components

Requiring

No

Lubrication

4

Fuel Requirements

. 2

Introduction

1

Lubrication

and

Replacement Parts Recommendation

3

page

Routine Maintenance

2

Starting

Assistance (Jump Starting)

9

Vehicle

Lifting

Recommendations

............ 10

Vehicle Noise

Control

2

Vehicle Towing Recommendations

11

INTRODUCTION

Lubrication and maintenance is divided into re

quired and recommended service tasks. The required service tasks must be completed to verify the emis

sion controls function correctly. The recommended

service tasks should be completed to maintain safety

and durability. This information will assist the service personnel

in providing maximum protection for each owner's

vehicle. Conditions can vary with individual driving habits.

It is necessary to schedule maintenance as a time in

terval as well as a distance interval. It is the owner's responsibility to determine the ap

plicable driving condition. Also to have the vehicle serviced according to the maintenance schedule, and

to pay for the necessary parts and labor. Vehicles with a Gross Vehicle Weight Rating

(GVWR) of 3 855 kg (8,500 lbs.) or less must conform

to light duty emission standards. Vehicles with a Gross Vehicle Weight Rating (GVWR) of 3 856 kg

(8,501 lbs.) or more must conform to heavy duty

emission standards. The GVWR for each vehicle is listed on the Safety

Certification Label. This label is affixed to the driver

side door pillar (Fig. 1).

Additional maintenance and lubrication informa

tion is listed in the Owner's Manual.

Mm

rv

CHRYSLER

DATE

OF MFR

MFD BY CORPORATION

GVWR

GAWR FRONT

GAWR REAR

WITH

TIRES

WITH

TIRES

RIMS

AT

RIMS

AT

PSI

COLD

PSI

COLD THIS VEHICLE CONFORMS

TO

ALL APPLICABLE FEDERAL MOTOR VEHICLE SAFETY

STANDARDS

IN

EFFECT ON

THE

DATE

OF

MANUFACTURE SHOWN ABOVE.

SINGLE

DUAL

BAR

CODE

VEHICLE MADE

IN

4648503

J9UN-25

Fig. 1 Vehicle Safety

Certification

Label

SEVERE DRIVING

CONDITIONS

Vehicles subjected to severe driving conditions

should decrease the interval between component

maintenance. Severe driving conditions are defined

as:

• Frequent short trip driving less than 24 km (15

miles)

• Frequent driving in dusty conditions

• Trailer towing

• Extensive engine idling

• Sustained high speed operation

• Desert operation

• Frequent starting and stopping

• Cold climate operation

LUBRICATION

AND

MAINTENANCE

Page 33 of 1502

0 - 14

LUBRICATION

AND

MAINTENANCE

•

ENGINE

MAINTENANCE

INDEX

page

Air

Injection

Systems/Air Pump

. 17

Air-Conditioner

Compressor

21

Battery

19

Cooling System

15

Crankcase

Ventilation

System

17

Diesel Engine

Air Filter

Canister

17

Drive Belts

20

Engine

Air

Cleaner

Filter

Element

16

Engine Break-In

14

Engine

Oil 14

Engine

Oil

Change

and Filter

Replacement

15

Exhaust Gas

Recirculation

(EGR) System

...... 19

page

Exhaust

Manifold

Heat

Control

Valve

. 17

Exhaust System

, 21

Fuel System

18

Hoses

and

Fittings

16

Ignition

Cables,

Distributor

Cap and

Rotor

...... 19

Ignition

Timing

. 19

Oxygen

(02)

Sensor

19

Rubber/Plastic Components

20

Spark Plugs

. 19

Throttle

Control

Linkage

18

Vacuum Operated, Emission

Control

Components

19

ENGINE BREAK-IN

After first starting a new engine, allow it to idle

for 15 seconds before shifting into a drive gear. Also:

• Drive the vehicle at varying speeds less than 88

km/h (55 mph) for the first 480 km (300 miles).

• Avoid fast acceleration and sudden stops.

• Do not drive at full-throttle for extended periods of

time

• Do not drive at constant speeds

• Do not idle the engine excessively A special break-in engine oil is not required. The

original engine oil installed is a high quality lubri

cant. New engines tend to consume more fuel and oil un

til after the break-in period has ended.

ENGINE

OIL SPECIFICATIONS

API SERWICE

GRADE

Use an engine oil that conforms to API Service

Grade S5 SG/CD or SG/CE. MOPAR®provides engine

oils that conform to all of these service grades.

SULFATED ASH—DIESEL ENGINES

Oils that contain an excessive amount of sulfated

ash can cause deposits to develop on Diesel engine

valves. These deposits can result in valve wear.

SAE

WISC0SITY

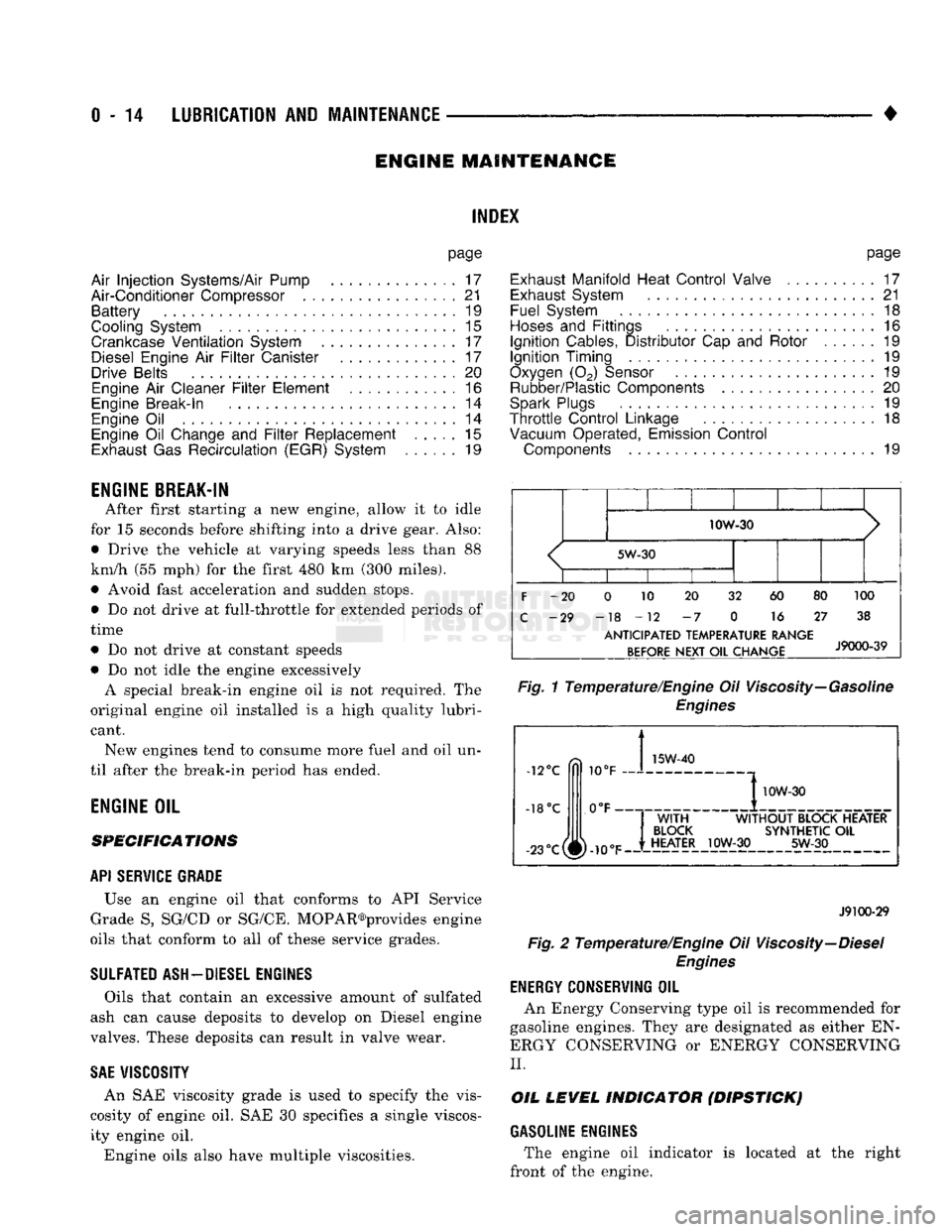

An SAE viscosity grade is used to specify the vis

cosity of engine oil. SAE 30 specifies a single viscos

ity engine oil.

Engine oils also have multiple viscosities. 10W-30

<

5W-30

1

1 1

F

-20 0 10 20 32 60 80 100

C

-29 -18 -12 -7 0 16 27 38

ANTICIPATED

TEMPERATURE RANGE BEFORE

NEXT

OIL

CHANGE

J9000-39

Fig.

1 Temperature/Engine Oil Viscosity—Gasoline

Engines

-12°C

-18°C 10°F

0°F- 15W-40

-23°c(^-10eF

I

10W-30

WITH

WITHOUT

BLOCK HEATER

BLOCK

SYNTHETIC

OIL

HEATER

10W-30 5W-30

J9100-29

Fig.

2 Temperature/Engine Oil Viscosity—Diesel

Engines

ENERGY

G0NSERWING

OIL

An Energy Conserving type oil is recommended for

gasoline engines. They are designated as either EN

ERGY CONSERVING or ENERGY CONSERVING

II.

OIL

LEVEL

INDICATOR (DIPSTICK)

GASOLINE ENGINES

The engine oil indicator is located at the right

front of the engine.

Page 34 of 1502

•

LUBRICATION

AND

MAINTENANCE

0 - 15

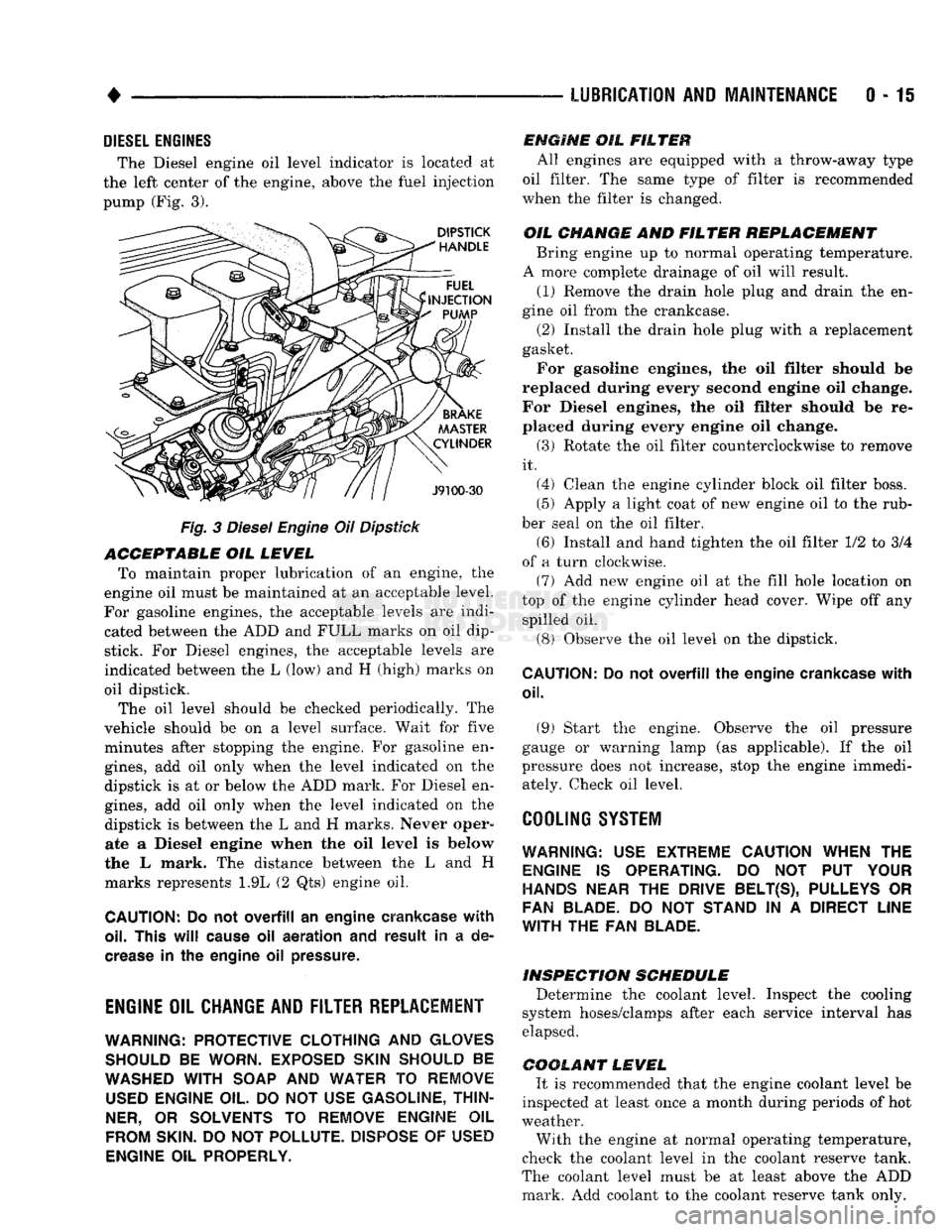

DIESEL

ENGINES

The Diesel engine oil level indicator is located at

the left center of the engine, above the

fuel

injection

pump (Fig. 3).

Fig.

3

Diesel

Engine

Oil

Dipstick

ACCEPTABLE

OIL

LEVEL

To maintain proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

For gasoline engines, the acceptable levels are indi cated between the ADD and

FULL

marks on oil

dip

stick. For Diesel engines, the acceptable levels are

indicated between the L (low) and H

(high) marks

on

oil dipstick. The oil level should be checked periodically. The

vehicle should be on a level surface. Wait for

five

minutes after stopping the engine. For gasoline en

gines,

add oil only when the level indicated on the

dipstick is at or below the ADD mark. For Diesel en

gines,

add oil only when the level indicated on the

dipstick is between the L and H marks.

Never oper

ate a Diesel

engine when

the oil

level

is below

the L mark. The distance between the L and H

marks represents 1.9L (2 Qts) engine oil.

CAUTION:

Do not

overfill

an

engine crankcase

with

oil. This

will

cause

oil

aeration

and

result

in a de

crease

in the

engine

oil

pressure.

ENGINE

OIL

CHANGE AND FILTER REPLACEMENT

WARNING: PROTECTIVE CLOTHING

AND

GLOVES SHOULD

BE

WORN. EXPOSED SKIN SHOULD

BE

WASHED

WITH

SOAP

AND

WATER

TO

REMOVE

USED

ENGINE

OIL.

DO NOT

USE

GASOLINE, THIN

NER,

OR

SOLVENTS

TO

REMOVE ENGINE

OIL

FROM

SKIN.

DO NOT

POLLUTE. DISPOSE

OF

USED

ENGINE

OIL

PROPERLY.

ENGINE

OIL

FILTER

All engines are equipped with a throw-away type

oil filter. The same type of filter is recommended

when the filter is changed.

OIL CHANGE

AND

FILTER

REPLACEMENT

Bring engine up to normal operating temperature.

A more complete drainage of oil will result.

(1) Remove the drain hole plug and drain the en

gine oil from the crankcase.

(2) Install the drain hole plug with a replacement

gasket. For gasoline engines, the oil filter should be

replaced during every second engine oil change.

For Diesel engines, the oil filter should be re

placed during every engine oil change.

(3) Rotate the oil filter counterclockwise to remove

it.

(4) Clean the engine cylinder block oil filter boss. (5) Apply a light coat of new engine oil to the rub

ber seal on the oil filter.

(6) Install and hand tighten the oil filter 1/2 to 3/4

of a turn clockwise. (7) Add new engine oil at the fill hole location on

top of the engine cylinder head cover. Wipe off any spilled oil.

(8) Observe the oil level on the dipstick.

CAUTION:

Do not

overfill

the

engine crankcase

with

oil.

(9)

Start the engine. Observe the oil pressure

gauge or warning lamp (as applicable). If the oil

pressure does not increase, stop the engine immedi ately. Check oil level.

COOLING SYSTEM

WARNING:

USE

EXTREME CAUTION WHEN

THE

ENGINE

IS

OPERATING.

DO NOT PUT

YOUR

HANDS NEAR

THE

DRIVE BELT(S), PULLEYS

OR

FAN BLADE.

DO NOT

STAND

IN A

DIRECT LINE

WITH

THE FAN

BLADE.

INSPECTION SCHEDULE

Determine the coolant level. Inspect the cooling

system hoses/clamps after each service interval has

elapsed.

COOLANT LEVEL

It is recommended that the engine coolant level be

inspected at least once a month during periods of hot

weather.

With the engine at normal operating temperature,

check the coolant level in the coolant reserve tank.

The coolant level must be at least above the ADD mark. Add coolant to the coolant reserve tank only.

Page 81 of 1502

2 - 28

FRONT

SUSPENSION

AND

AXLE

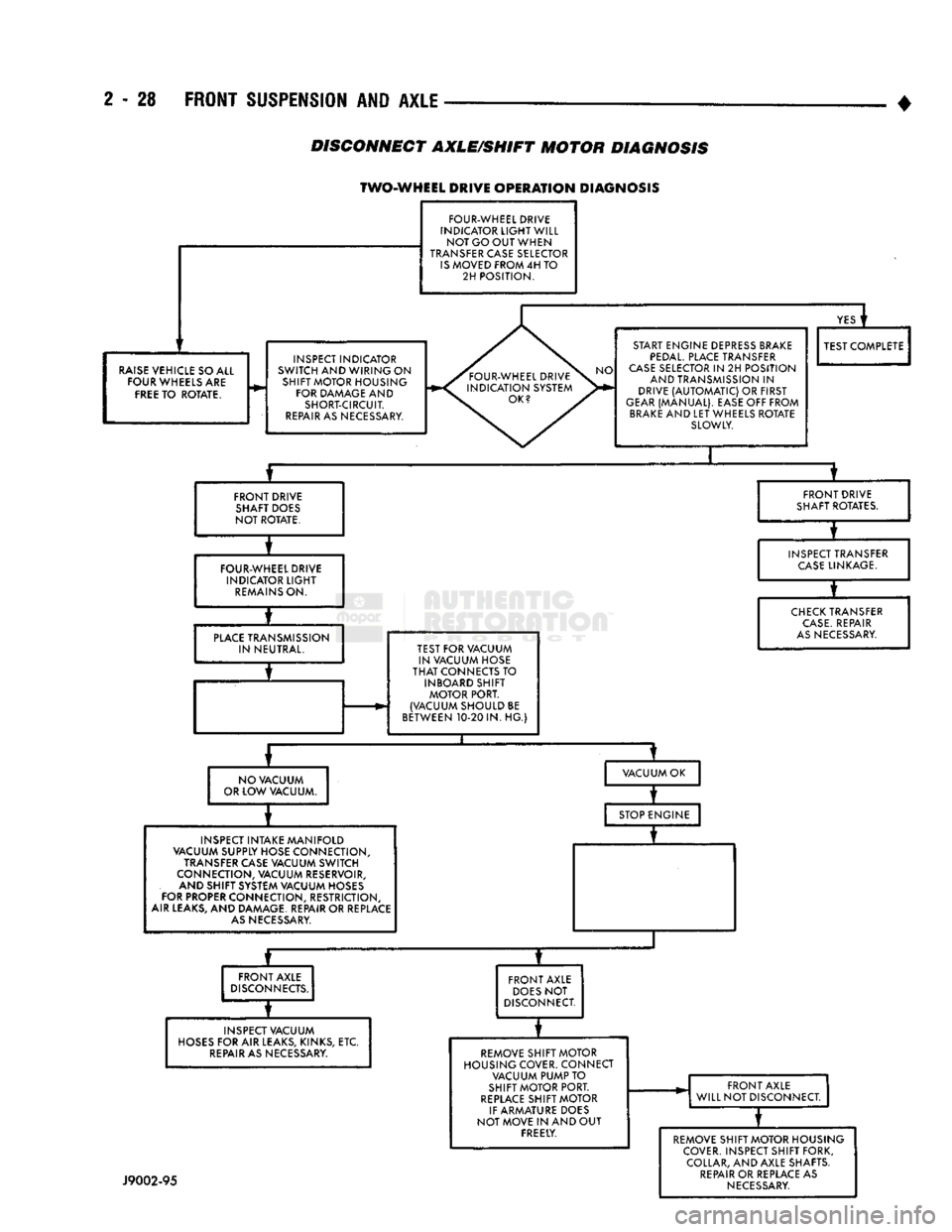

DISCONNECT

AXLE/SHIFT

MOTOR

DIAGNOSIS

TWO-WHEEL DRIVE

OPERATION

DIAGNOSIS

FOUR-WHEEL DRIVE

INDICATOR

LIGHT

WILL NOT GO OUT WHEN

TRANSFER CASE SELECTOR

IS

MOVED FROM 4H TO 2H POSITION.

RAISE

VEHICLE SO ALL FOUR WHEELS ARE

FREE

TO ROTATE. INSPECT INDICATOR

SWITCH AND WIRING ON SHIFT MOTOR HOUSING FOR DAMAGE AND SHORT-CIRCUIT.

REPAIR

AS NECESSARY.

YES

i

START ENGINE DEPRESS BRAKE

PEDAL.

PLACE TRANSFER

CASE

SELECTOR IN 2H POSITION AND TRANSMISSION IN

DRIVE

(AUTOMATIC)

OR FIRST

GEAR

(MANUAL). EASE OFF FROM

BRAKE

AND LET WHEELS ROTATE SLOWLY. TEST COMPLETE

FRONT DRIVE SHAFT DOES

NOT ROTATE. FRONT DRIVE

SHAFT ROTATES.

FOUR-WHEEL DRIVE INDICATOR

LIGHT

REMAINS

ON. INSPECT TRANSFER

CASE

LINKAGE.

PLACE

TRANSMISSION IN NEUTRAL. TEST FOR VACUUM

IN VACUUM HOSE

THAT

CONNECTS TO INBOARD SHIFT MOTOR PORT.

(VACUUM SHOULD BE

BETWEEN 10-20 IN. HG.)

CHECK

TRANSFER

CASE.

REPAIR

AS

NECESSARY.

NO VACUUM

OR LOW VACUUM. VACUUM OK

INSPECT INTAKE MANIFOLD

VACUUM SUPPLY HOSE CONNECTION,

TRANSFER CASE VACUUM SWITCH

CONNECTION, VACUUM RESERVOIR, AND SHIFT SYSTEM VACUUM HOSES

FOR PROPER CONNECTION, RESTRICTION,

AIR LEAKS, AND DAMAGE. REPAIR OR REPLACE

AS

NECESSARY. STOP ENGINE

—r~

FRONT AXLE

DISCONNECTS.

INSPECT VACUUM

HOSES

FOR AIR LEAKS, KINKS, ETC.

REPAIR

AS NECESSARY. FRONT AXLE

DOES

NOT

DISCONNECT.

REMOVE SHIFT MOTOR

HOUSING COVER. CONNECT VACUUM PUMP TO

SHIFT MOTOR PORT.

REPLACE

SHIFT MOTOR

IF ARMATURE DOES

NOT MOVE IN AND OUT FREELY. FRONT AXLE

WILL NOT DISCONNECT.

J9002-95

REMOVE SHIFT MOTOR HOUSING

COVER. INSPECT SHIFT FORK, COLLAR, AND AXLE SHAFTS.

REPAIR

OR REPLACE AS

NECESSARY

Page 82 of 1502

FRONT

SUSPENSION AND

AXLE

2 - 29

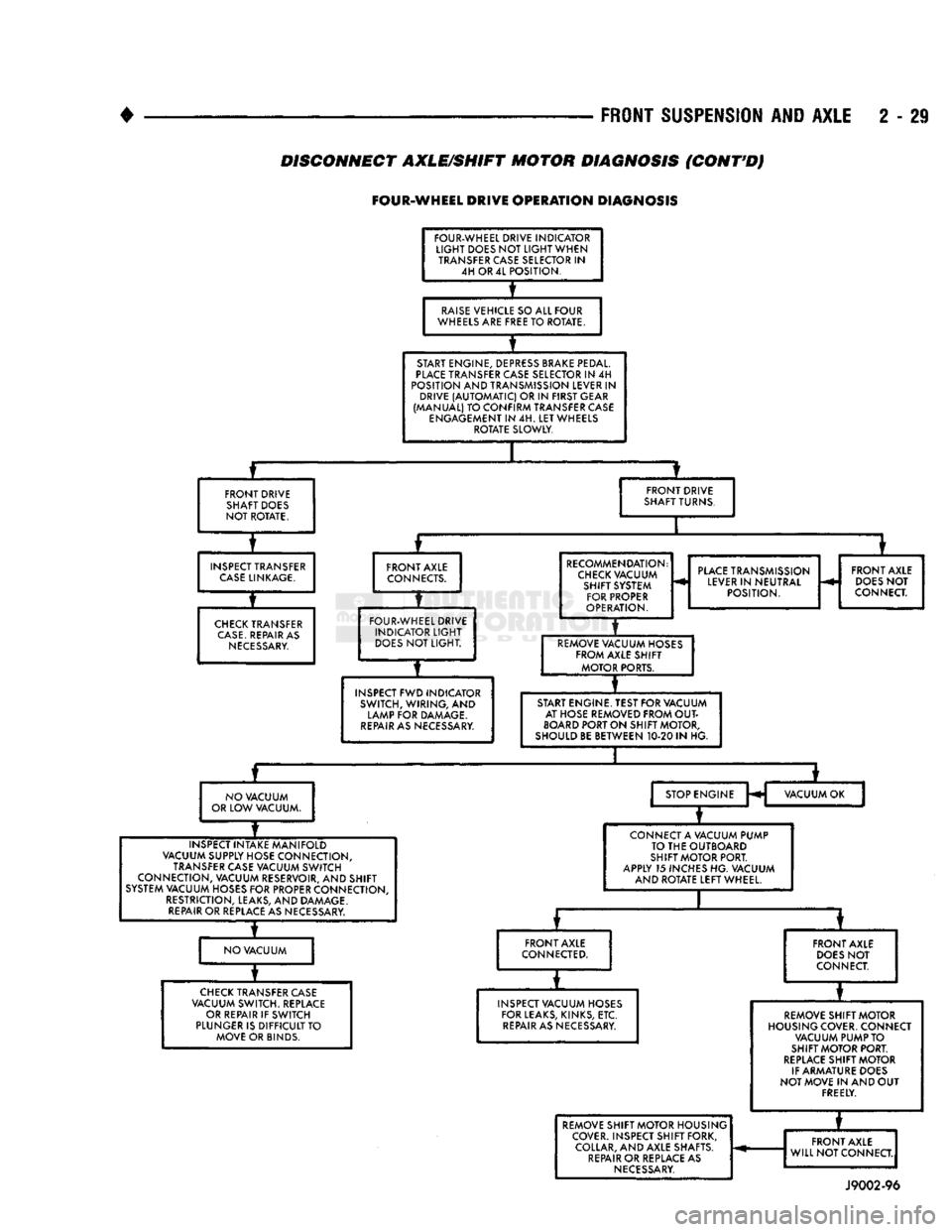

DISCONNECT AXLE/SHIFT MOTOR DIAGNOSIS

(CONT'D)

FOUR-WHEEL

DRIVE

OPERATION

DIAGNOSIS

FOUR-WHEEL DRIVE INDICATOR

LIGHT

DOES NOT

LIGHT

WHEN TRANSFER CASE SELECTOR IN 4H OR 4L POSITION.

RAISE

VEHICLE SO ALL FOUR

WHEELS ARE FREE TO ROTATE.

START ENGINE, DEPRESS BRAKE PEDAL.

PLACE

TRANSFER CASE SELECTOR IN 4H

POSITION AND TRANSMISSION LEVER IN DRIVE

(AUTOMATIC)

OR IN FIRST GEAR

(MANUAL) TO CONFIRM TRANSFER CASE ENGAGEMENT IN 4H. LET WHEELS ROTATE SLOWLY.

FRONT DRIVE SHAFT DOES

NOT ROTATE. FRONT DRIVE

SHAFT TURNS.

INSPECT TRANSFER

CASE

LINKAGE.

CHECK

TRANSFER

CASE.

REPAIR AS

NECESSARY.

FRONT AXLE

CONNECTS.

FOUR-WHEEL DRIVE INDICATOR

LIGHT

DOES

NOT LIGHT.

INSPECT FWD INDICATOR SWITCH, WIRING, AND

LAMP FOR DAMAGE.

REPAIR

AS NECESSARY. RECOMMENDATION:

CHECK

VACUUM SHIFT SYSTEM FOR PROPER

OPERATION.

PLACE

TRANSMISSION

LEVER IN NEUTRAL POSITION. FRONT AXLE

DOES

NOT

CONNECT.

REMOVE VACUUM HOSES FROM AXLE SHIFT MOTOR PORTS.

START ENGINE. TEST FOR VACUUM AT HOSE REMOVED FROM

OUT

BOARD

PORT ON SHIFT MOTOR,

SHOULD BE BETWEEN 10-20 IN HG.

NO VACUUM

OR LOW VACUUM. STOP ENGINE

H VACUUM OK

INSPECT INTAKE MANIFOLD

VACUUM SUPPLY HOSE CONNECTION, TRANSFER CASE VACUUM SWITCH

CONNECTION, VACUUM RESERVOIR, AND SHIFT

SYSTEM VACUUM HOSES FOR PROPER CONNECTION, RESTRICTION, LEAKS, AND DAMAGE.

REPAIR

OR REPLACE AS NECESSARY. CONNECT A VACUUM PUMP

TO THE OUTBOARD

SHIFT MOTOR PORT.

APPLY 15 INCHES HG. VACUUM AND ROTATE LEFT WHEEL.

NO VACUUM FRONT AXLE

CONNECTED.

CHECK

TRANSFER CASE

VACUUM SWITCH. REPLACE OR REPAIR IF SWITCH

PLUNGER IS DIFFICULT TO MOVE OR BINDS. FRONT AXLE

DOES

NOT

CONNECT.

INSPECT VACUUM HOSES FOR LEAKS, KINKS, ETC.

REPAIR

AS NECESSARY. REMOVE SHIFT MOTOR

HOUSING COVER. CONNECT VACUUM PUMP TO

SHIFT MOTOR PORT.

REPLACE

SHIFT MOTOR

IF ARMATURE DOES

NOT MOVE IN AND OUT FREELY. REMOVE SHIFT MOTOR HOUSING

COVER. INSPECT SHIFT FORK, COLLAR, AND AXLE SHAFTS.

REPAIR

OR REPLACE AS

NECESSARY.

*

REMOVE SHIFT MOTOR HOUSING

COVER. INSPECT SHIFT FORK, COLLAR, AND AXLE SHAFTS.

REPAIR

OR REPLACE AS

NECESSARY.

FRONT AXLE

WILL NOT CONNECT.

REMOVE SHIFT MOTOR HOUSING

COVER. INSPECT SHIFT FORK, COLLAR, AND AXLE SHAFTS.

REPAIR

OR REPLACE AS

NECESSARY.

FRONT AXLE

WILL NOT CONNECT.

REMOVE SHIFT MOTOR HOUSING

COVER. INSPECT SHIFT FORK, COLLAR, AND AXLE SHAFTS.

REPAIR

OR REPLACE AS

NECESSARY.

J9002-96

Page 192 of 1502

•

BRAKES

5 - 5 Disc brake rotors with excessive lateral runout or

thickness variation, or out of round brake drums are

the primary causes of pulsation. Other causes are loose

wheel bearings or calipers and worn, damaged tires.

PULL A

front pull condition could be the result of con

taminated lining in one caliper, seized caliper piston,

binding caliper, loose caliper, loose or corroded slide

pins,

improper brakeshoes, or a damaged rotor.

A worn, damaged wheel bearing or suspension compo

nent are further causes of pull. A damaged front tire (bruised, ply separation) can also cause pull.

A common and frequently misdiagnosed pull condi

tion is where direction of pull changes after a few

stops.

The cause is a combination of brake drag fol

lowed by fade at one of the brake units.

As the dragging brake overheats, efficiency is so

reduced that fade occurs. Since the opposite brake

unit is still functioning normally, its braking effect is

magnified. This causes pull to switch direction in fa

vor of the normally functioning brake unit.

When diagnosing a change in pull condition, re

member that pull will return to the original direction

if the dragging brake unit is allowed to cool down (and is not seriously damaged).

REAR BRAKE GRAB

OR

PULL

Rear grab or pull is usually caused by an improperly

adjusted or seized parking brake cable, contaminated

lining, bent or binding shoes and support plates, or im

properly assembled components. This is particularly

true when only one rear wheel is involved. However,

when both rear wheels are affected, the master cylinder or proportioning valve could be at fault.

BRAKES

DO NOT

HOLD

AFTER

DRIVING

THROUGH

DEEP

WATER

PUDDLES

This condition is generally caused by water soaked

lining. If the lining is only wet, it can be dried by driv

ing with the brakes very lightly applied for a few min

utes.

However, if the lining is thoroughly wet and dirty,

disassembly and cleaning will be necessary.

BRAKE NOISE

Squeak/Squeal

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or oil. Glazed linings and rotors with hard spots can also con

tribute to squeak. Dirt and foreign material embedded in the brake lining can also cause squeak/squeal.

A very loud squeak or squeal is frequently a sign of

severely worn brake lining. If the lining has worn

through to the brakeshoes in spots, metal-to-metal con

tact occurs. If the condition is allowed to continue, ro tors can become so scored that replacement is necessary.

Thump/Clunk

Thumping or clunk noises during braking are fre

quently not caused by brake components. In many

cases,

such noises are caused by loose or damaged steering, suspension, or engine components. How

ever, calipers that bind on the slide pins, or slide sur

faces,

can generate a thump or clunk noise. Worn

out, improperly adjusted, or improperly assembled

rear brakeshoes can also produce a thump noise.

Chatter

Brake chatter is usually caused by loose or worn

components, or glazed/burnt lining. Rotors with hard

spots can also contribute to chatter. Additional

causes of chatter are out of tolerance rotors, brake

lining not securely attached to the shoes, loose wheel

bearings and contaminated brake lining.

Brakelining Contamination Brakelining contamination is usually a product of

leaking calipers or wheel cylinders, driving through

deep water puddles, or lining that has become cov

ered with grease and grit during repair.

Wheel and

Tire

Problems Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

Severely worn tires with very little tread left can

produce a grab-like condition as the tire loses and re covers traction. Flat-spotted tires can cause vibration and wheel

tramp and generate shudder during brake operation. A tire with internal damage such as a severe

bruise or ply separation can cause pull and vibration.

MASTER

CYLINDER/POWER BOOSTER TEST

(1) Start engine and check booster vacuum hose

connections. Hissing noise indicates a vacuum leak. Correct any leaks before proceeding. (2) Stop engine and shift transmission into Neu

tral (3) Pump brake pedal until all vacuum reserve in

booster is depleted. (4) Press and hold brake pedal under light foot

pressure. (a) If pedal holds firm, proceed to step (5).

(b) If pedal does not hold firm and falls away,

master cylinder is faulty (internal leakage). (5) Start engine and note pedal action. (a) If pedal falls away slightly under light foot

pressure then holds firm, proceed to step (6). (b) If pedal is effort is high, or no pedal action is

discernible, power booster or vacuum check valve is

faulty. Install known good check valve and repeat steps (2) through (5).

Page 193 of 1502

5

- 6

BRAKES

• (c) On diesel models, vacuum pump hose or

pump component may have malfunctioned. Check

pump output with vacuum gauge and repair as necessary. Refer to service procedures in Power

Booster/Vacuum Pump section.

(6) Rebuild booster vacuum reserve as follows: Re

lease brake pedal. Increase engine speed to 1500

rpm, close throttle and immediately turn off ignition. (7) Wait a minimum of 90 seconds and try brake ac

tion again. Booster should provide two or more vacuum assisted pedal applications. If vacuum assist is not pro

vided, perform booster and check valve vacuum tests.

Also check vacuum output on diesel models.

POWER

BOOSTER

CHECK

VALVE

TEST

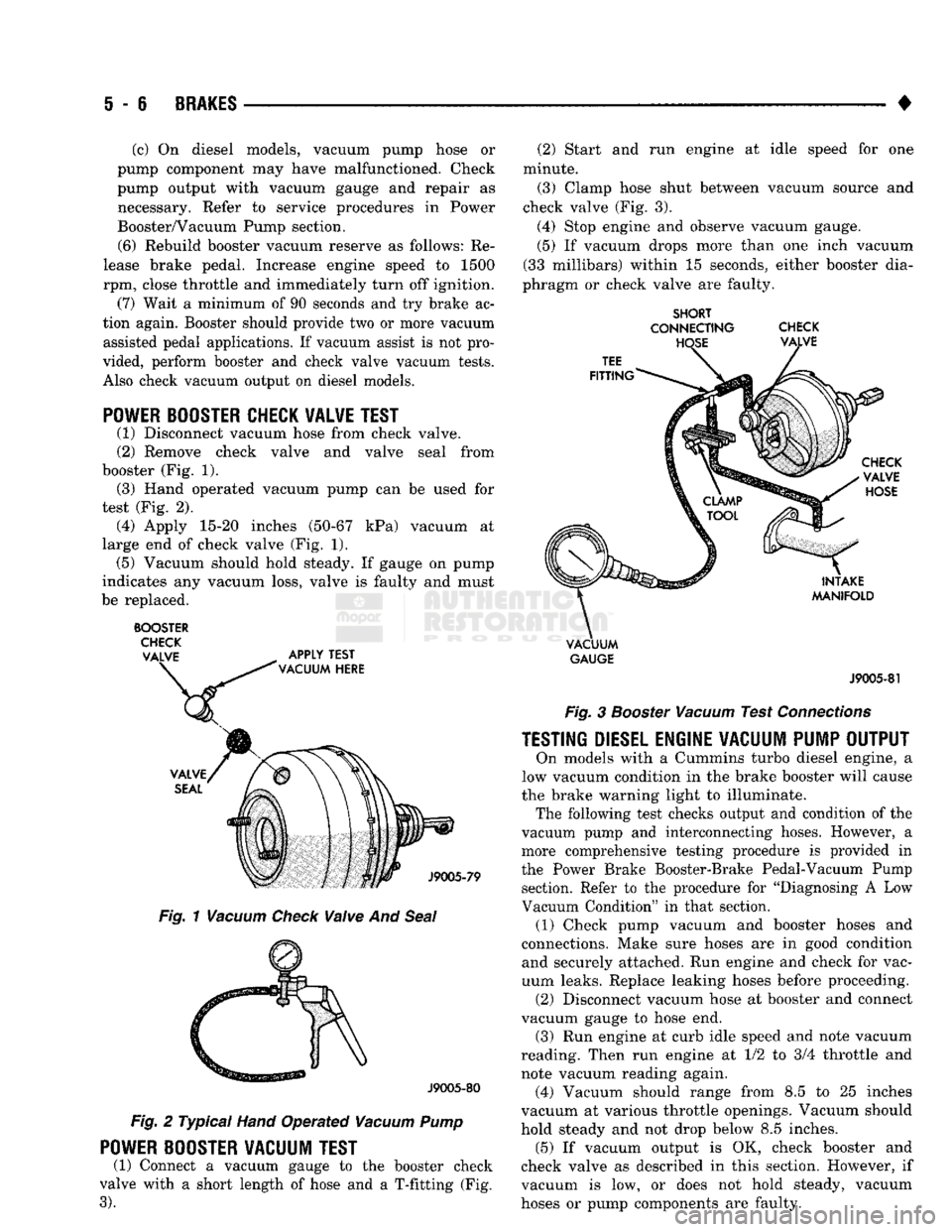

(1) Disconnect vacuum hose from check valve.

(2) Remove check valve and valve seal from

booster (Fig. 1). (3) Hand operated vacuum pump can be used for

test (Fig. 2). (4) Apply 15-20 inches (50-67 kPa) vacuum at

large end of check valve (Fig. 1). (5) Vacuum should hold steady. If gauge on pump

indicates any vacuum loss, valve is faulty and must

be replaced.

BOOSTER

CHECK

VALVE

APPLY

TEST

\

VACUUM

HERE

Fig.

1

Vacuum

Check

Vaive

And

Seal

J9005-80

Fig.

2 Typical

Hand

Operated

Vacuum

Pump

POWER

BOOSTER

VACUUM

TEST

(1) Connect a vacuum gauge to the booster check

valve with a short length of hose and a T-fitting (Fig.

3).

(2) Start and run engine at idle speed for one

minute.

(3) Clamp hose shut between vacuum source and

check valve (Fig. 3).

(4) Stop engine and observe vacuum gauge.

(5) If vacuum drops more than one inch vacuum

(33 millibars) within 15 seconds, either booster dia

phragm or check valve are faulty.

SHORT

CONNECTING

CHECK

VACUUM

GAUGE

J9005-81

Fig.

3

Booster

Vacuum

Test

Connections

TESTING

DIESEL

ENGINE

VACUUM

PUMP

OUTPUT

On models with a Cummins turbo diesel engine, a

low vacuum condition in the brake booster will cause

the brake warning light to illuminate. The following test checks output and condition of the

vacuum pump and interconnecting hoses. However, a

more comprehensive testing procedure is provided in

the Power Brake Booster-Brake Pedal-Vacuum Pump section. Refer to the procedure for "Diagnosing A Low

Vacuum Condition" in that section. (1) Check pump vacuum and booster hoses and

connections. Make sure hoses are in good condition and securely attached. Run engine and check for vac

uum leaks. Replace leaking hoses before proceeding. (2) Disconnect vacuum hose at booster and connect

vacuum gauge to hose end. (3) Run engine at curb idle speed and note vacuum

reading. Then run engine at 1/2 to 3/4 throttle and

note vacuum reading again. (4) Vacuum should range from 8.5 to 25 inches

vacuum at various throttle openings. Vacuum should

hold steady and not drop below 8.5 inches. (5) If vacuum output is OK, check booster and

check valve as described in this section. However, if

vacuum is low, or does not hold steady, vacuum

hoses or pump components are faulty.

Page 196 of 1502

BRAKES

i - 9

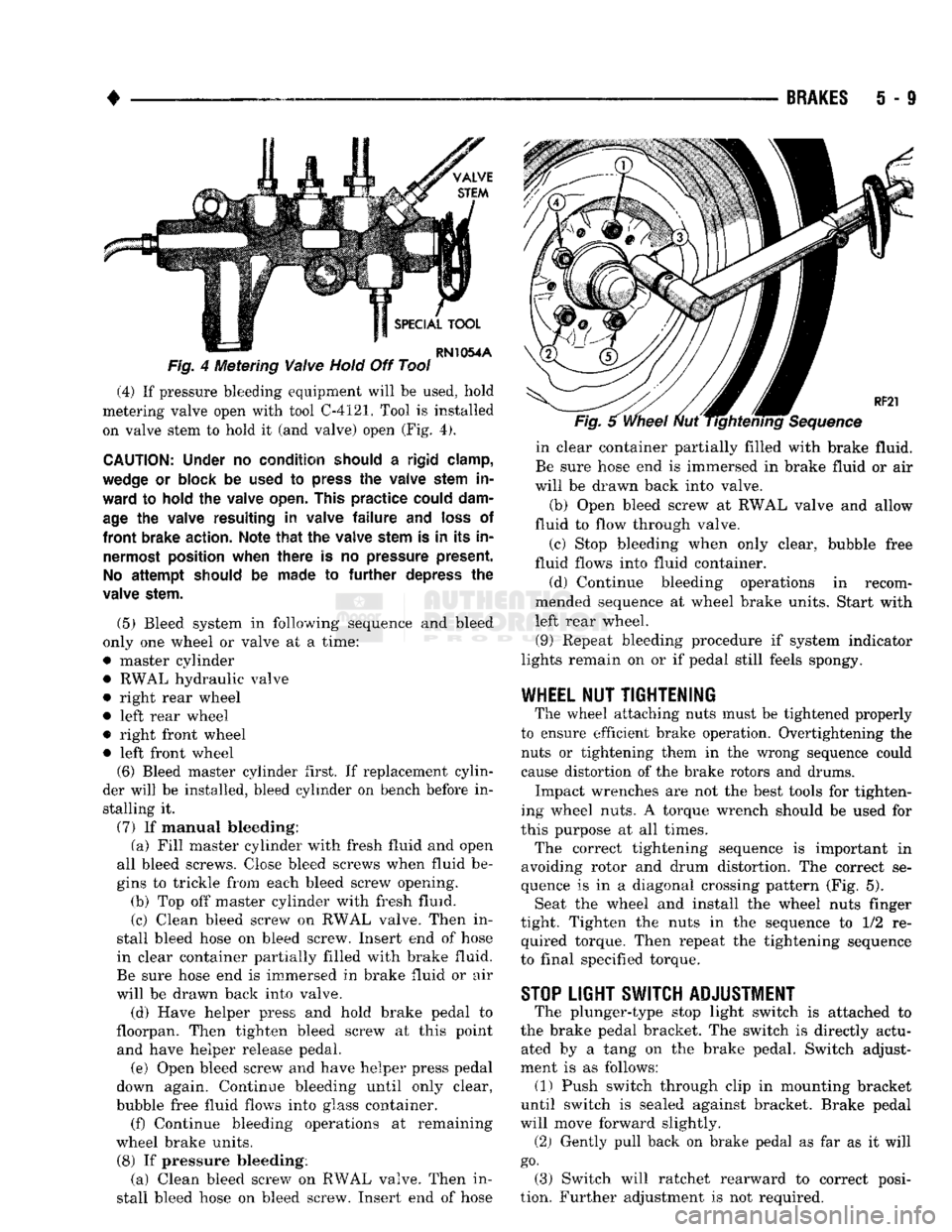

Fig.

4 Metering

Valve

Hold

Off Tool (4) If pressure bleeding equipment will be used, hold

metering valve open with tool C-4121. Tool is installed on valve stem to hold it (and valve) open (Fig. 4).

CAUTION:

Under

no

condition should

a

rigid clamp,

wedge

or

block

be

used

to

press

the

valve stem

in

ward

to

hold

the

valve open. This

practice

could dam

age

the

valve resulting

in

valve

failure and

loss

of

front

brake action. Note

that the

valve stem

is in its in

nermost position when

there

is no

pressure present.

No

attempt

should

be

made

to further

depress

the

valve stem.

(5) Bleed system in following sequence and bleed

only one wheel or valve at a time:

• master cylinder • RWAL hydraulic valve

• right rear wheel

• left rear wheel

• right front wheel • left front wheel (6) Bleed master cylinder first. If replacement cylin

der will be installed, bleed cylinder on bench before in stalling it.

(7) If manual bleeding: (a) Fill master cylinder with fresh fluid and open

all bleed screws. Close bleed screws when fluid be

gins to trickle from each bleed screw opening. (b) Top off master cylinder with fresh fluid.

(c) Clean bleed screw on RWAL valve. Then in

stall bleed hose on bleed screw. Insert end of hose

in clear container partially filled with brake fluid.

Be sure hose end is immersed in brake fluid or air

will be drawn back into valve.

(d) Have helper press and hold brake pedal to

floorpan. Then tighten bleed screw at this point and have helper release pedal.

(e) Open bleed screw and have helper press pedal

down again. Continue bleeding until only clear,

bubble free fluid flows into glass container. (f) Continue bleeding operations at remaining

wheel brake units.

(8) If pressure bleeding: (a) Clean bleed screw on RWAL valve. Then in

stall bleed hose on bleed screw. Insert end of hose in clear container partially filled with brake fluid.

Be sure hose end is immersed in brake fluid or air

will be drawn back into valve.

(b) Open bleed screw at RWAL valve and allow

fluid to flow through valve.

(c) Stop bleeding when only clear, bubble free

fluid flows into fluid container.

(d) Continue bleeding operations in recom

mended sequence at wheel brake units. Start with

left rear wheel.

(9) Repeat bleeding procedure if system indicator

lights remain on or if pedal still feels spongy.

WHEEL

NUT

TIGHTENING

The wheel attaching nuts must be tightened properly

to ensure efficient brake operation. Overtightening the nuts or tightening them in the wrong sequence could

cause distortion of the brake rotors and drums.

Impact wrenches are not the best tools for tighten

ing wheel nuts. A torque wrench should be used for

this purpose at all times.

The correct tightening sequence is important in

avoiding rotor and drum distortion. The correct se

quence is in a diagonal crossing pattern (Fig. 5). Seat the wheel and install the wheel nuts finger

tight. Tighten the nuts in the sequence to 1/2 re quired torque. Then repeat the tightening sequence

to final specified torque.

STOP

LIGHT SWITCH ADJUSTMENT

The plunger-type stop light switch is attached to

the brake pedal bracket. The switch is directly actu ated by a tang on the brake pedal. Switch adjust

ment is as follows: (1) Push switch through clip in mounting bracket

until switch is sealed against bracket. Brake pedal

will move forward slightly.

(2) Gently pull back on brake pedal as far as it will

go.

(3) Switch will ratchet rearward to correct posi

tion. Further adjustment is not required.

Page 198 of 1502

•

BRAKES

5 - 11

FROM

MASTER CYLINDER

^SWITCH

ASSEMBLY

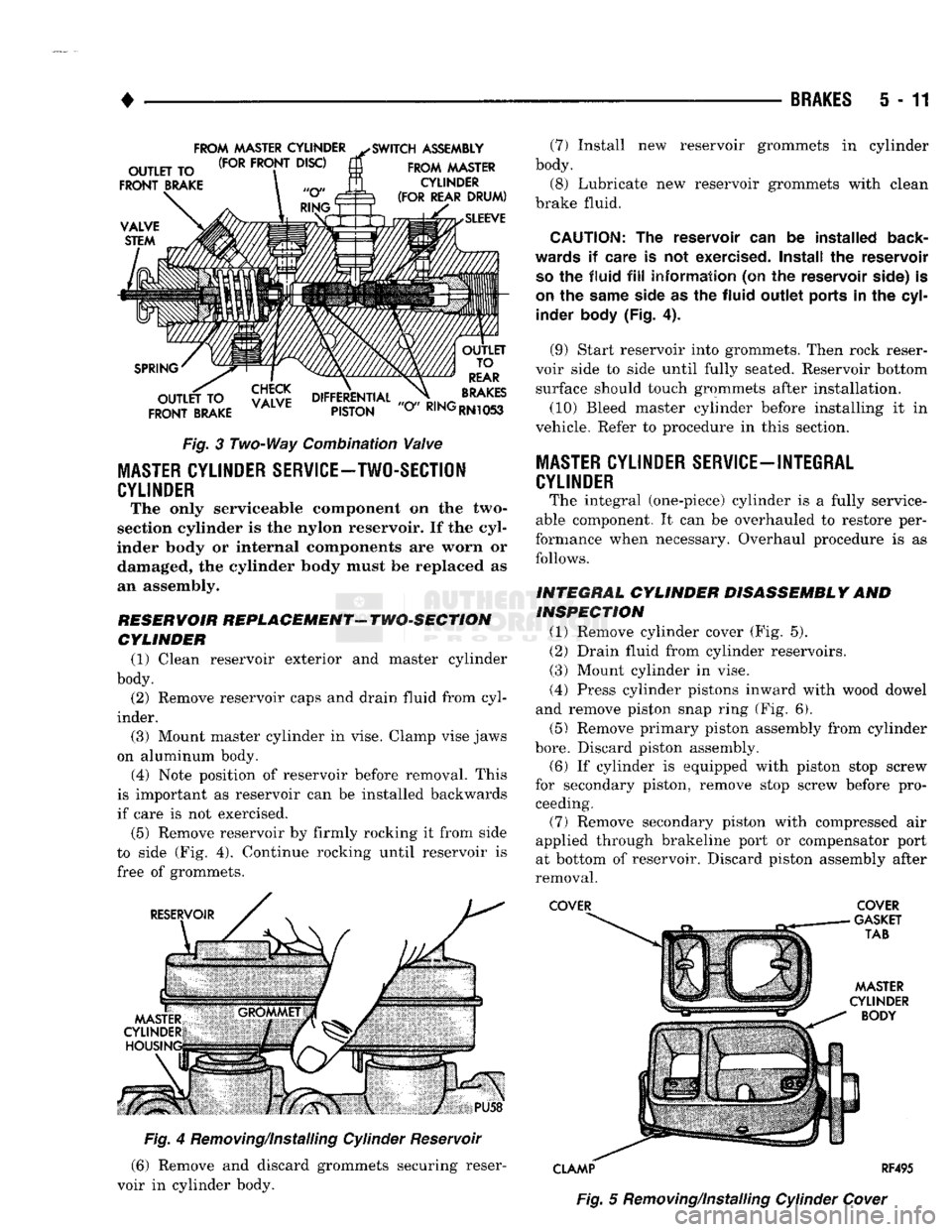

Fig.

3 Two-Way Combination

Valve

MASTER

CYLINDER SERVICE-TWO-SECTION

CYLINDER

The only serviceable component on the two-

section cylinder is the nylon reservoir. If the cyl

inder body or internal components are worn or damaged, the cylinder body must be replaced as

an assembly.

RESERVOIR REPLACEMENT- TWO-SECTION CYLINDER (1) Clean reservoir exterior and master cylinder

body. (2) Remove reservoir caps and drain fluid from cyl

inder. (3) Mount master cylinder in vise. Clamp vise jaws

on aluminum body.

(4) Note position of reservoir before removal. This

is important as reservoir can be installed backwards

if care is not exercised.

(5) Remove reservoir by firmly rocking it from side

to side (Fig. 4). Continue rocking until reservoir is

free of grommets.

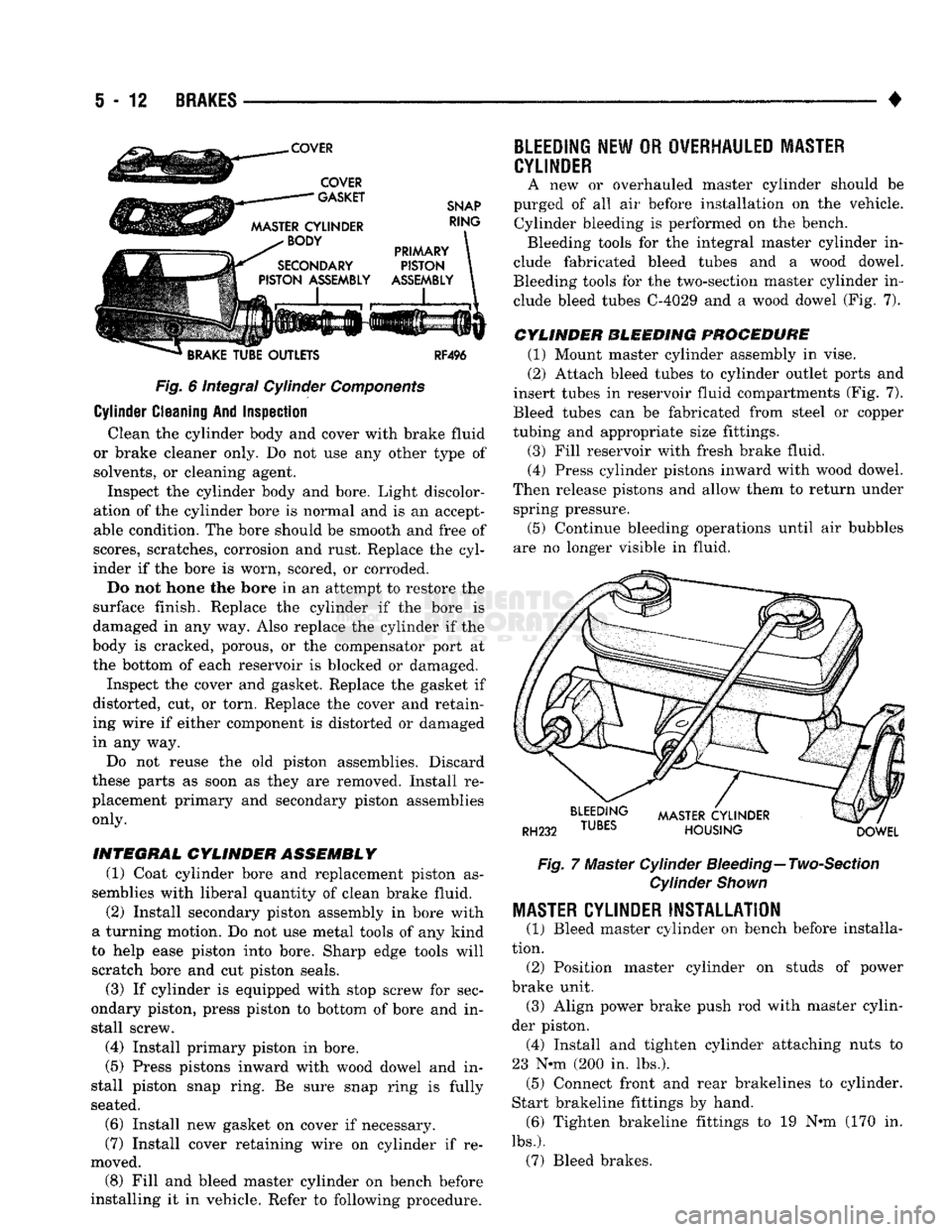

Fig.

4 Removing/Installing Cylinder Reservoir

(6) Remove and discard grommets securing reser

voir in cylinder body. (7) Install new reservoir grommets in cylinder

body. (8) Lubricate new reservoir grommets with clean

brake fluid.

CAUTION:

The reservoir can be installed

back

wards

if care is not

exercised.

Install the reservoir

so

the fluid

fill

information (on the reservoir

side)

is

on

the

same

side

as the fluid outlet

ports

in the

cyl

inder

body

(Fig. 4).

(9) Start reservoir into grommets. Then rock reser

voir side to side until fully seated. Reservoir bottom surface should touch grommets after installation.

(10) Bleed master cylinder before installing it in

vehicle. Refer to procedure in this section.

MASTER CYLINDER SERVICE-INTEGRAL

CYLINDER

The integral (one-piece) cylinder is a fully service

able component. It can be overhauled to restore per

formance when necessary. Overhaul procedure is as follows.

INTEGRAL CYLINDER DISASSEMBLY AND INSPECTION

(1) Remove cylinder cover (Fig. 5). (2) Drain fluid from cylinder reservoirs.

(3) Mount cylinder in vise.

(4) Press cylinder pistons inward with wood dowel

and remove piston snap ring (Fig. 6).

(5) Remove primary piston assembly from cylinder

bore.

Discard piston assembly.

(6) If cylinder is equipped with piston stop screw

for secondary piston, remove stop screw before pro ceeding. (7) Remove secondary piston with compressed air

applied through brakeline port or compensator port

at bottom of reservoir. Discard piston assembly after

removal.

COVER COVER

CLAMP RF495 Fig.

5 Removing/Installing Cylinder

Cover

Page 199 of 1502

i - 12

BRAKES

•

Fig.

6 integral Cylinder

Components

Cylinder Cleaning And Inspection Clean the cylinder body and cover with brake fluid

or brake cleaner only. Do not use any other type of solvents, or cleaning agent. Inspect the cylinder body and bore. Light discolor

ation of the cylinder bore is normal and is an accept

able condition. The bore should be smooth and free of

scores, scratches, corrosion and rust. Replace the cyl

inder if the bore is worn, scored, or corroded.

Do not hone the bore in an attempt to restore the

surface finish. Replace the cylinder if the bore is

damaged in any way. Also replace the cylinder if the

body is cracked, porous, or the compensator port at

the bottom of each reservoir is blocked or damaged.

Inspect the cover and gasket. Replace the gasket if

distorted, cut, or torn. Replace the cover and retain

ing wire if either component is distorted or damaged

in any way.

Do not reuse the old piston assemblies. Discard

these parts as soon as they are removed. Install re

placement primary and secondary piston assemblies

only.

INTEGRAL

CYLINDER ASSEMBLY

(1) Coat cylinder bore and replacement piston as

semblies with liberal quantity of clean brake fluid.

(2) Install secondary piston assembly in bore with

a turning motion. Do not use metal tools of any kind

to help ease piston into bore. Sharp edge tools will

scratch bore and cut piston seals.

(3) If cylinder is equipped with stop screw for sec

ondary piston, press piston to bottom of bore and in

stall screw.

(4) Install primary piston in bore.

(5) Press pistons inward with wood dowel and in

stall piston snap ring. Be sure snap ring is fully

seated.

(6) Install new gasket on cover if necessary.

(7) Install cover retaining wire on cylinder if re

moved. (8) Fill and bleed master cylinder on bench before

installing it in vehicle. Refer to following procedure.

BLEEDING

NEW

OR

OVERHAULED MASTER

CYLINDER

A new or overhauled master cylinder should be

purged of all air before installation on the vehicle. Cylinder bleeding is performed on the bench. Bleeding tools for the integral master cylinder in

clude fabricated bleed tubes and a wood dowel.

Bleeding tools for the two-section master cylinder in clude bleed tubes C-4029 and a wood dowel (Fig. 7).

CYLINDER BLEEDING PROCEDURE

(1) Mount master cylinder assembly in vise.

(2) Attach bleed tubes to cylinder outlet ports and

insert tubes in reservoir fluid compartments (Fig. 7).

Bleed tubes can be fabricated from steel or copper

tubing and appropriate size fittings.

(3) Fill reservoir with fresh brake fluid. (4) Press cylinder pistons inward with wood dowel.

Then release pistons and allow them to return under spring pressure.

(5) Continue bleeding operations until air bubbles

are no longer visible in fluid.

Fig.

7 Master Cylinder

Bleeding—

Two-Section

Cylinder

Shown

MASTER

CYLINDER INSTALLATION

(1) Bleed master cylinder on bench before installa

tion. (2) Position master cylinder on studs of power

brake unit. (3) Align power brake push rod with master cylin

der piston. (4) Install and tighten cylinder attaching nuts to

23 N-m (200 in. lbs.). (5) Connect front and rear brakelines to cylinder.

Start brakeline fittings by hand. (6) Tighten brakeline fittings to 19 N«m (170 in.

lbs.).

(7) Bleed brakes.