timing belt DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 25 of 1502

0 - 6

LUBRICATION

AND

MAINTENANCE

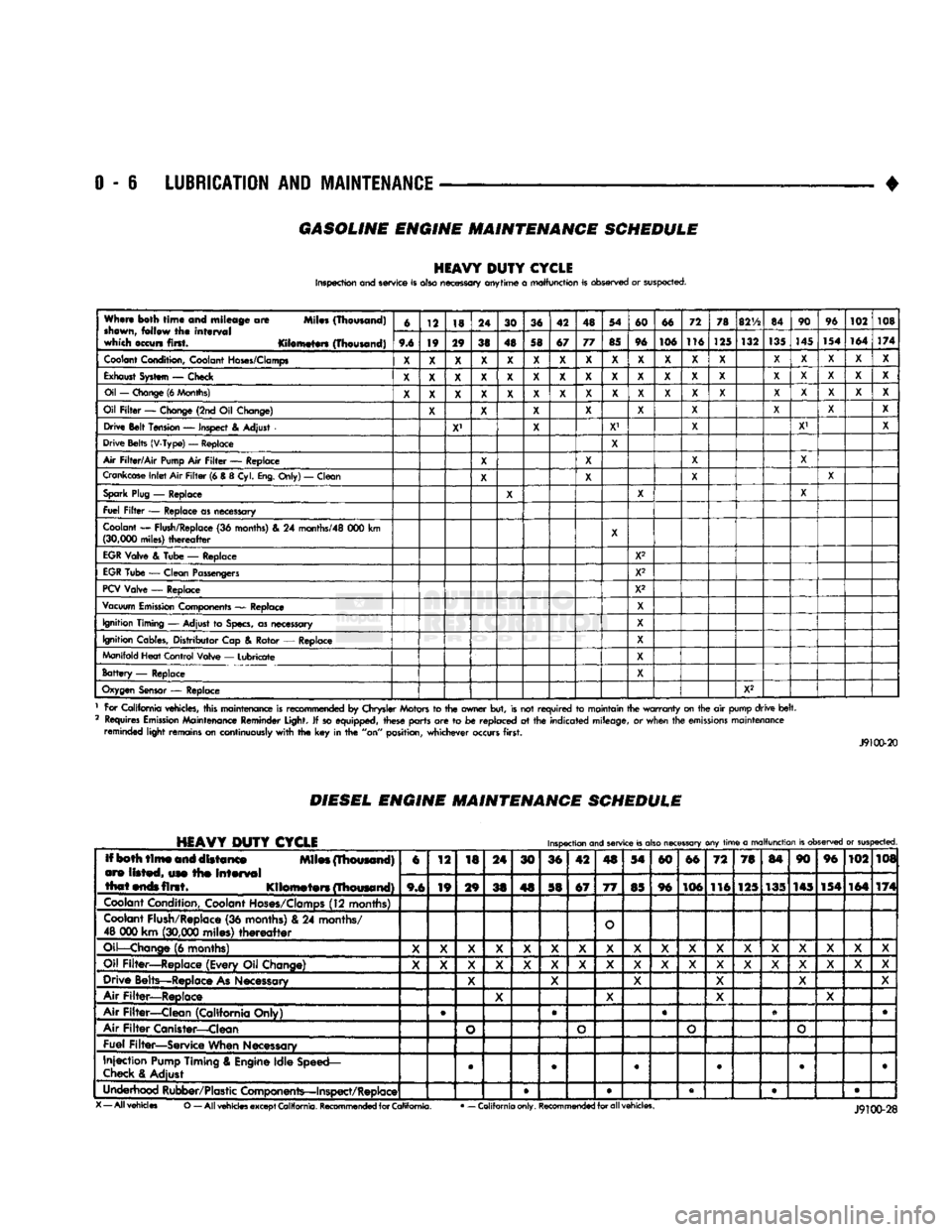

GASOLINE ENGINE MAINTENANCE SCHEDULE

HEAVY

DUTY

CYCLE

Inspection and service is also necessary anytime

a

malfunction is observed or suspected.

When both

time

and mileage

are

Miles (Thousand)

shewn,

follow

the

interval

which occurs first. Kilometers (Thousand) 6

12 18 24

30 36 42 48 54

60 66 72

78

82V2

84 90

96

102 108

When both

time

and mileage

are

Miles (Thousand)

shewn,

follow

the

interval

which occurs first. Kilometers (Thousand) 9.6 19 29

38 48 58 67 77

85 96 106 116

125 132

135

145

154 164

174

Coolant

Condition, Coolant

Hoses/Clamps

X

X X X

X X X X

X X X X

X X X

X X X

Exhaust

System

—

Check

X X X X X X X X X X X

X X X X X

X X

Oil

—

Change

(6

Months)

X X X X X X X

X X

X

X

X

X X X

X X

X

Oil

Filter

—

Change (2nd

Oil

Change)

X X X X

X X

X X

X

Drive Belt Tension

—

Inspect

&

Adjust

X' X

X1

X X' X

Drive Belts (V-Type)

—

Replace

X

Air

Filter/Air

Pump

Air

Filter

—

Replace

X X X

X

Crankcase

Inlet

Air

Filter

(6 &

8

Cyl.

Eng.

Only)

—

Clean

X X

X X

Spark

Plug

—

Replace

X X X

Fuel

Filter

—

Replace as necessary

Coolant

—

Flush/Replace

(36

months)

& 24

months/48

000 km

(30,000

miles)

thereafter

X

EGR

Valve

&

Tube

—

Replace X2

EGR

Tube

—

Clean Passengers

X2

PCV

Valve

—

Replace X2

Vacuum

Emission

Components

—

Replace

X

Ignition Timing

—

Adjust

to

Specs,

as necessary X

Ignition Cables, Distributor Cap

&

Rotor

—

Replace

X

Manifold Heat Control Valve

—

Lubricate

X

Battery

—

Replace X

Oxygen

Sensor

—

Replace

X2

1 For California vehicles, this maintenance is recommended

by

Chrysler Motors

to the

owner but, is not

required

to

maintain the

warranty

on the

air

pump drive

belt.

2 Requires

Emission

Maintenance Reminder Light.

If

so equipped, these parts

are to be

replaced

at the

indicated mileage,

or

when the

emissions

maintenance reminded light remains on continuously

with

the key in the

"on" position, whichever occurs first.

J9100-20

DIESEL

ENGINE

MAINTENANCE

SCHEDULE

HEAVY

DUTY

CYCLE

Inspection

and

service

is

also

necessary

any

time

a

malfunction

is

observed

or

suspected.

Iff both

time

and distance Miles (Thousand)

are listed, use the

interval

that

ends

first. Kilometers (Thousand) 6

12

18 24

30 36 42

4S

54

60 66

72 78

84 90 96

102 108

Iff both

time

and distance Miles (Thousand)

are listed, use the

interval

that

ends

first. Kilometers (Thousand) 9,6 19

29

38 48 58 67

77

85 96 106

116 125 135 145 154

164 174

Coolant

Condition, Coolant

Hoses/Clamps

(12 months)

Coolant

Flush/Replace (36 months) & 24 months/

48 000 km

(30,000

miles)

thereafter

O

Oil—Change

(6 months)

X X X

X X X

X X X X X

X X X X X X

X

Oil Filter—Replace (Every Oil Change)

X X X

X X X

X X

X X X

X

X X X X

X X

Drive Belts—Replace

As

Necessary

X X

X X X X

Air Filter—Replace

X X

X X

Air Filter—Clean (California Only) e

®

• •

Air

Filter

Canister—Clean

o o o

o

Fuel Filter—Service When Necessary

Injection

Pump

Timing & Engine Idle Speed—

Check

& Adjust

©

• 9 • • •

Underhood Rubber/Plastic Components—Inspect/Replace • • • • •

X

— All vehicles

O

— All

vehicles

except

California.

Recommended

for

California.

•

— California only.

Recommended

for all vehicles.

Page 33 of 1502

0 - 14

LUBRICATION

AND

MAINTENANCE

•

ENGINE

MAINTENANCE

INDEX

page

Air

Injection

Systems/Air Pump

. 17

Air-Conditioner

Compressor

21

Battery

19

Cooling System

15

Crankcase

Ventilation

System

17

Diesel Engine

Air Filter

Canister

17

Drive Belts

20

Engine

Air

Cleaner

Filter

Element

16

Engine Break-In

14

Engine

Oil 14

Engine

Oil

Change

and Filter

Replacement

15

Exhaust Gas

Recirculation

(EGR) System

...... 19

page

Exhaust

Manifold

Heat

Control

Valve

. 17

Exhaust System

, 21

Fuel System

18

Hoses

and

Fittings

16

Ignition

Cables,

Distributor

Cap and

Rotor

...... 19

Ignition

Timing

. 19

Oxygen

(02)

Sensor

19

Rubber/Plastic Components

20

Spark Plugs

. 19

Throttle

Control

Linkage

18

Vacuum Operated, Emission

Control

Components

19

ENGINE BREAK-IN

After first starting a new engine, allow it to idle

for 15 seconds before shifting into a drive gear. Also:

• Drive the vehicle at varying speeds less than 88

km/h (55 mph) for the first 480 km (300 miles).

• Avoid fast acceleration and sudden stops.

• Do not drive at full-throttle for extended periods of

time

• Do not drive at constant speeds

• Do not idle the engine excessively A special break-in engine oil is not required. The

original engine oil installed is a high quality lubri

cant. New engines tend to consume more fuel and oil un

til after the break-in period has ended.

ENGINE

OIL SPECIFICATIONS

API SERWICE

GRADE

Use an engine oil that conforms to API Service

Grade S5 SG/CD or SG/CE. MOPAR®provides engine

oils that conform to all of these service grades.

SULFATED ASH—DIESEL ENGINES

Oils that contain an excessive amount of sulfated

ash can cause deposits to develop on Diesel engine

valves. These deposits can result in valve wear.

SAE

WISC0SITY

An SAE viscosity grade is used to specify the vis

cosity of engine oil. SAE 30 specifies a single viscos

ity engine oil.

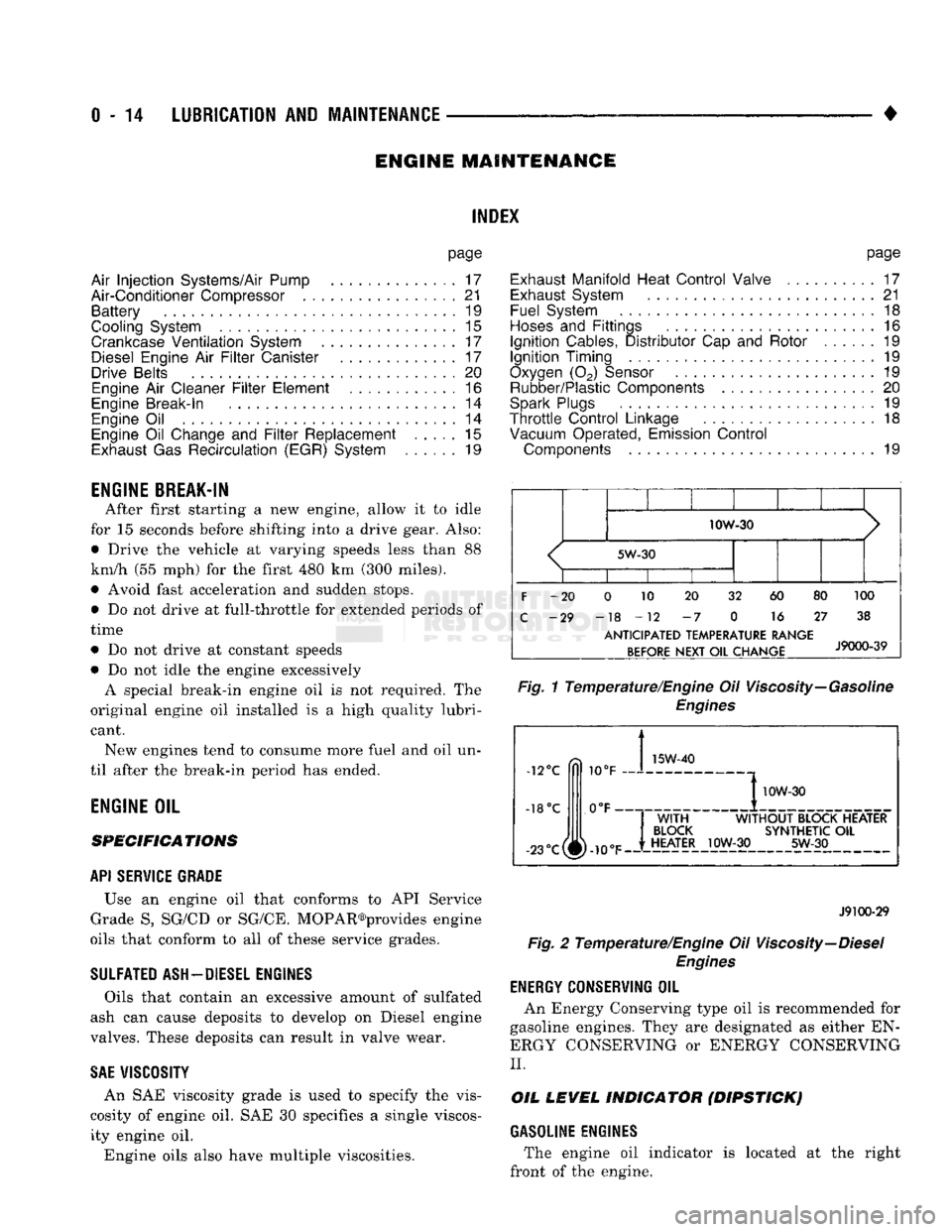

Engine oils also have multiple viscosities. 10W-30

<

5W-30

1

1 1

F

-20 0 10 20 32 60 80 100

C

-29 -18 -12 -7 0 16 27 38

ANTICIPATED

TEMPERATURE RANGE BEFORE

NEXT

OIL

CHANGE

J9000-39

Fig.

1 Temperature/Engine Oil Viscosity—Gasoline

Engines

-12°C

-18°C 10°F

0°F- 15W-40

-23°c(^-10eF

I

10W-30

WITH

WITHOUT

BLOCK HEATER

BLOCK

SYNTHETIC

OIL

HEATER

10W-30 5W-30

J9100-29

Fig.

2 Temperature/Engine Oil Viscosity—Diesel

Engines

ENERGY

G0NSERWING

OIL

An Energy Conserving type oil is recommended for

gasoline engines. They are designated as either EN

ERGY CONSERVING or ENERGY CONSERVING

II.

OIL

LEVEL

INDICATOR (DIPSTICK)

GASOLINE ENGINES

The engine oil indicator is located at the right

front of the engine.

Page 275 of 1502

DIAGNOSIS

PRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING Establish what driving conditions caused the com

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

1.

PROLONGED IDLE, VERY HIGH AMBI

ENT TEMPERATURE, SLIGHT TAIL WIND AT

IDLE, SLOW TRAFFIC, TRAFFIC JAMS, HIGH SPEED OR STEEP GRADES.

Driving techniques that avoid overheating are:

• Idle with A/C off when temperature gauge is at

end of normal range. * Increasing engine speed for more air flow is recom

mended.

2.

TRAILER TOWING: Consult Trailer Towing section of owners manual.

Do not exceed limits.

3.

AIR CONDITIONING; ADD-ON OR AFTER

MARKET: A maximum cooling package should have been or

dered with vehicle if add-on or after market A/C is

SYMPTOM AND ACTION

SYMPTOM

installed. If not, maximum cooling system compo

nents should be installed for model involved per

manufacturer's specifications.

4.

RECENT SERVICE OR ACCIDENT RE

PAIR:

Determine if any recent service has been performed

on vehicle that may effect cooling system. This may

be:

• Engine adjustments (incorrect timing)

• Slipping engine accessory drive belt(s) • Brakes (possibly dragging)

• Changed parts. Incorrect water pump or pump ro

tating in wrong direction due to belt not correctly

routed

• Reconditioned radiator or cooling system refilling (possibly under filled or air trapped in system).

If investigation reveals none of the above as a

cause for an engine overheating complaint, refer to

the following Symptom and Action chart:

PRELIMINARY FIRST) ACTION

Blinking Engine Temperature

Warning Light or High Gauge indication - Without Coolant Loss

Normal during temporary operation

with

heavy load, towing

a

trailer,

high

outdoor temperatures, and/or on

a

steep

Loss

grade.

Coolant Loss

Hot Vehicle (Not Engine) Heat Damage,

Hot Carpet, Seat,

Hot

Catalytic

Converter,

Smoke, Burnt Odor

Hot Engine Crackling Noise Hot Smell

Severe Local Hot Spots

Coolant Color

Coolant Reserve Bottle Level Changes

Coolant Not Returning To Radiator

Improper refilling procedures

can

result

in

trapped air

in

the

system.

Subsequent

operation

of the

pressure cap and coolant reserve system

will

deaereate

the

cooling

system.

A low

coolant

level

will

then result

in the

Coolant Reserve

Tank. Add coolant.

If

condition persists,

refer

to

System

Diagnosis.

Check

heat shielding, exhaust

system,

engine emission controls, ignition

timing, engine misfiring.

A

moderate amount

of

sound from heating

metal

can

be

expected

with

any

vehicle. However,

a

crackling sound from

trie

thermostat

housing,

a hot

smell and/or severe local

hot

spots on

an

engine can indicate blocked coolant

passages,

bad castina, core sand deposits and subsequent blockage,

cracked cylinder block

or

head,

or

blown cylinder head gasket. Usually

accompanied

with

coolant

loss.

Coolant

color is

not

necessarily

an

indication

of

adequate

temperature

or

corrosion

protection.

Level changes

are to be

expected as coolant volume fluctuates

with

engine

temperature.

If the

level

in the

bottle

is

between

the

Maximum and Minimum

marks

at

normal engine operating temperature,

the

level

should

return

to

within

that

range

after

operation

at

elevated temperatures.

Coolant

will

not

return

to the

radiator

if the

radiator cap vent valve does

not

function,

if

an

air

leak destroys vacuum,

or if the

overflow

passage

is

blocked

or

restricted. Inspect

all

portions

of the

overflow

passage,

pressure

cap,

filler

neck nipple, hose, and

passages

within

the

bottle

for

vacuum leak

only. Coolant

return

failure

will

be

evident

by a low

level

in the

radiator.

Reserve

bottle

level

should increase during heat-up.

J9207-31

Page 286 of 1502

•

COOLING SYSTEM

7 - 15

SERVICE

PROCEDURES

INDEX

page

Coolant

26

Coolant Reserve/Overflow System

30

Cooling System Cleaning/Reverse Flushing

28

Cooling System Fan—Diesel Engine

. 37

Cooling System

Fan—Gas

Engines

36

Cooling System

Hoses

34

Draining Cooling System

27

Pressure

Testing

Radiator

Caps

............. 32

Radiator Pressure

Cap 31

Radiators

32

Refilling

the

Cooling System

28

WATER PUMPS—EXCEPT DIESEL

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a drive belt. The water pump impeller is pressed onto the rear

of a shaft that rotates in a bearing pressed into the

water pump body. The body has a small hole for ven

tilation. The water pump seals are lubricated by an

tifreeze in the coolant mixture. Additional lubrication is not necessary. A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core. The water pump on all models can be removed

without discharging the air conditioning system (if equipped).

REMOVAL The water pump on all gas powered engines is

bolted directly to the engine timing chain case/cover.

A gasket is used as a seal between the water pump

and timing chain case/cover.

If water pump is replaced because of bearing/shaft

damage or leaking shaft seal, the mechanical cooling

fan assembly should also be inspected. Inspect for fa tigue cracks, loose blades or loose rivets that could

have resulted from excessive vibration. Replace fan if any of these conditions are found. Also check condi

tion of the thermal viscous fan drive. Refer to Vis

cous Fan Drive in this group. (1) Disconnect negative battery cable from battery.

(2) Drain cooling system. Refer to Draining Cool

ing System in this group. Do not waste reusable coolant. If solution is clean,

drain coolant into a clean container for reuse.

(3)

Disconnect throttle cable from clip at top of fan

shroud.

page

Testing

Cooling System

for

Leaks

. 29

Thermostat

22

Transmission

Oil

Cooler—Diesel

35

Transmission

Oil

Cooler—Except Diesel

35

Transmission Oil-To-Air Cooler

36

Viscous

Fan

Drive

38

Water

Pump

Bypass

Hose—All

Gas

Powered

Engines

.............................. 19

Water

Pumps—5.9L Diesel

18

Water

Pumps—Except Diesel

15

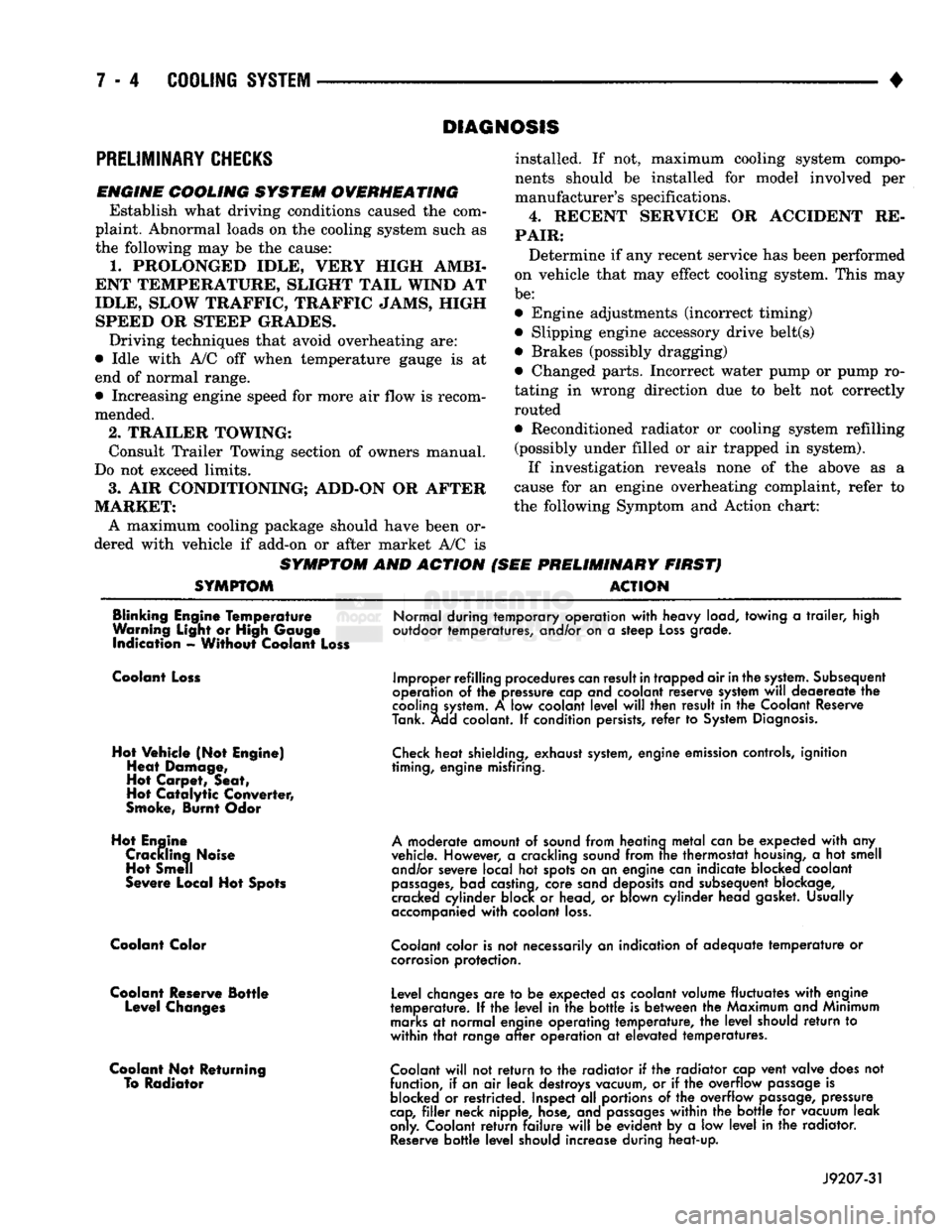

(4) Unsnap coolant reserve/overflow tank (up and

out) from the T-slots on side of fan shroud (Fig. 1) and lay aside. Do not disconnect hose or drain cool

ant from tank.

(5) Remove the fan shroud from the radiator. Do

not remove shroud from vehicle at this time.

FAN

SHROUD

J9107-67

Fig.

1 Fan

Shroud—Except

Diesel

(6) Remove upper radiator hose at radiator. Special

Clamp Tool number 6094 (Fig. 2) may be used to re

move the constant tension clamps.

(7) The thermal viscous fan drive is attached

(threaded) to the water pump hub shaft (Fig. 3). Re

move the fan/fan drive assembly from water pump by

turning the mounting nut counterclockwise (as viewed from front). Threads on the fan drive are RIGHT HAND. A Snap-On 36 MM Fan Wrench (number SP346 from Snap-On Cummins Diesel Tool

Set number 2017DSP) can be used. Place a bar or

screwdriver between the water pump pulley bolts (Fig. 3) to prevent the pulley from rotating.

If water pump is being replaced, do not unbolt fan

blade assembly (Fig. 3) from the thermal control fan drive.

Page 354 of 1502

•

IGNITION

SYSTEMS

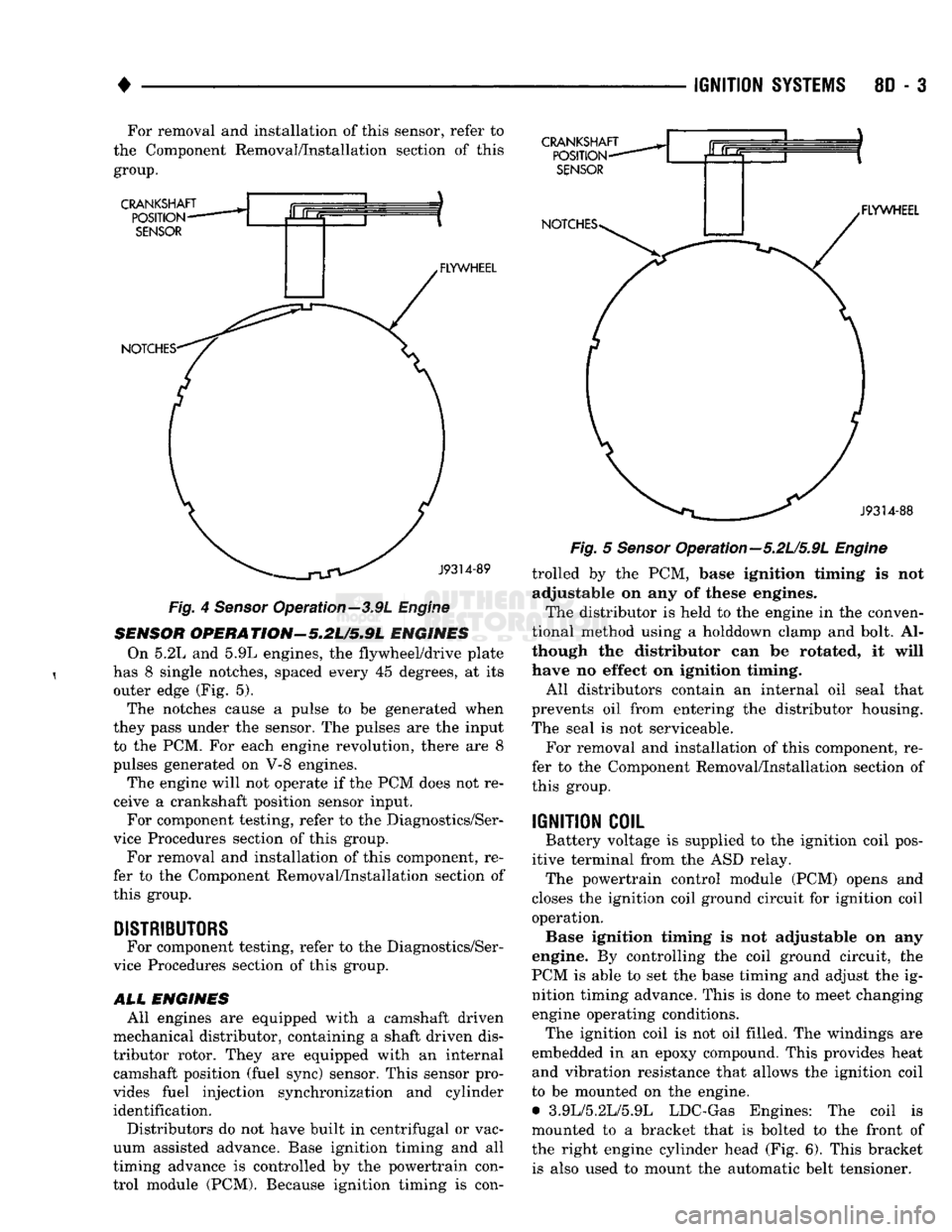

8D - 3 For removal and installation of this sensor, refer to

the Component Removal/Installation section of this

group.

CRANKSHAFT

POSITION

SENSOR

NOTCHES- FLYWHEEL CRANKSHAFT

POSITION-

SENSOR

NOTCHES* .FLYWHEEL

J9314-88

—^^j^jV^

J9314-89

Fig.

4

Sensor

Operation—3.9L

Engine

SENSOR

OPERATION'-5.2U5.9L

ENGINES On 5.2L and 5.9L engines, the flywheel/drive plate

has 8 single notches, spaced every 45 degrees, at its outer edge (Fig. 5).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input to the PCM. For each engine revolution, there are 8

pulses generated on V-8 engines.

The engine will not operate if the PCM does not re

ceive a crankshaft position sensor input. For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

DISTRIBUTORS

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

ALL

ENGINES All engines are equipped with a camshaft driven

mechanical distributor, containing a shaft driven dis

tributor rotor. They are equipped with an internal camshaft position (fuel sync) sensor. This sensor pro

vides fuel injection synchronization and cylinder identification.

Distributors do not have built in centrifugal or vac

uum assisted advance. Base ignition timing and all

timing advance is controlled by the powertrain con

trol module (PCM). Because ignition timing is con-

Fig.

5

Sensor

Opera tion—5.2L/5.9L

Engine

trolled by the PCM, base ignition timing is not adjustable on any of these engines.

The distributor is held to the engine in the conven

tional method using a holddown clamp and bolt. Al

though the distributor can be rotated, it will

have no effect on ignition timing.

All distributors contain an internal oil seal that

prevents oil from entering the distributor housing.

The seal is not serviceable.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

IGNITION

COIL

Battery voltage is supplied to the ignition coil pos

itive terminal from the ASD relay. The powertrain control module (PCM) opens and

closes the ignition coil ground circuit for ignition coil operation. Base ignition timing is not adjustable on any

engine. By controlling the coil ground circuit, the

PCM is able to set the base timing and adjust the ig nition timing advance. This is done to meet changing engine operating conditions. The ignition coil is not oil filled. The windings are

embedded in an epoxy compound. This provides heat and vibration resistance that allows the ignition coil

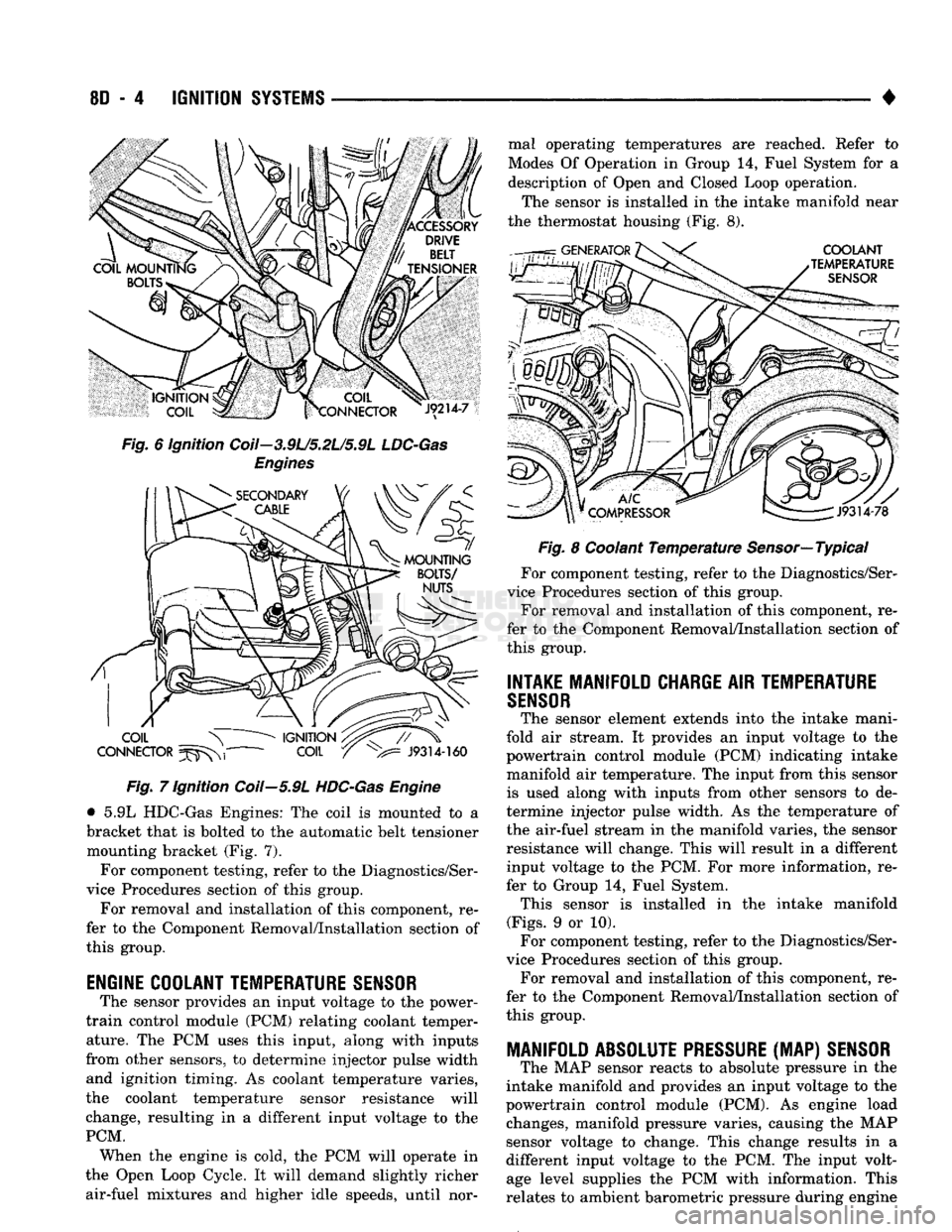

to be mounted on the engine. • 3.9L/5.2L/5.9L LDC-Gas Engines: The coil is

mounted to a bracket that is bolted to the front of the right engine cylinder head (Fig. 6). This bracket is also used to mount the automatic belt tensioner.

Page 355 of 1502

8D

- 4

IGNITION

SYSTEMS

•

Fig. 6 ignition Coil—3.9L/5.2L/5.9L

LDC-Gas

Engines Fig. 7 Ignition Coil—5.9L

HDC-Gas

Engine

• 5.9L HDC-Gas Engines: The coil is mounted to a

bracket that is bolted to the automatic belt tensioner mounting bracket (Fig. 7).

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

ENGINE COOLANT TEMPERATURE

SENSOR

The sensor provides an input voltage to the power-

train control module (PCM) relating coolant temper ature. The PCM uses this input, along with inputs

from other sensors, to determine injector pulse width and ignition timing. As coolant temperature varies,

the coolant temperature sensor resistance will

change, resulting in a different input voltage to the

PCM. When the engine is cold, the PCM will operate in

the Open Loop Cycle. It will demand slightly richer air-fuel mixtures and higher idle speeds, until nor mal operating temperatures are reached. Refer to

Modes Of Operation in Group 14, Fuel System for a

description of Open and Closed Loop operation.

The sensor is installed in the intake manifold near

the thermostat housing (Fig. 8).

Fig. 8 Coolant Temperature Sensor—Typical

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

INTAKE MANIFOLD CHARGE

AIR

TEMPERATURE

SENSOR

The sensor element extends into the intake mani

fold air stream. It provides an input voltage to the

powertrain control module (PCM) indicating intake

manifold air temperature. The input from this sensor is used along with inputs from other sensors to de

termine injector pulse width. As the temperature of

the air-fuel stream in the manifold varies, the sensor

resistance will change. This will result in a different input voltage to the PCM. For more information, re

fer to Group 14, Fuel System. This sensor is installed in the intake manifold

(Figs.

9 or 10). For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

MANIFOLD ABSOLUTE

PRESSURE

(MAP)

SENSOR

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

powertrain control module (PCM). As engine load changes, manifold pressure varies, causing the MAP

sensor voltage to change. This change results in a

different input voltage to the PCM. The input volt age level supplies the PCM with information. This

relates to ambient barometric pressure during engine

Page 372 of 1502

IGNITION

SYSTEMS

80 - 21

DISTRIBUTOR

J9314-81

Fig.

7 Rotor Alignment Mark Fig. 8 Distributor Holddown Clamp

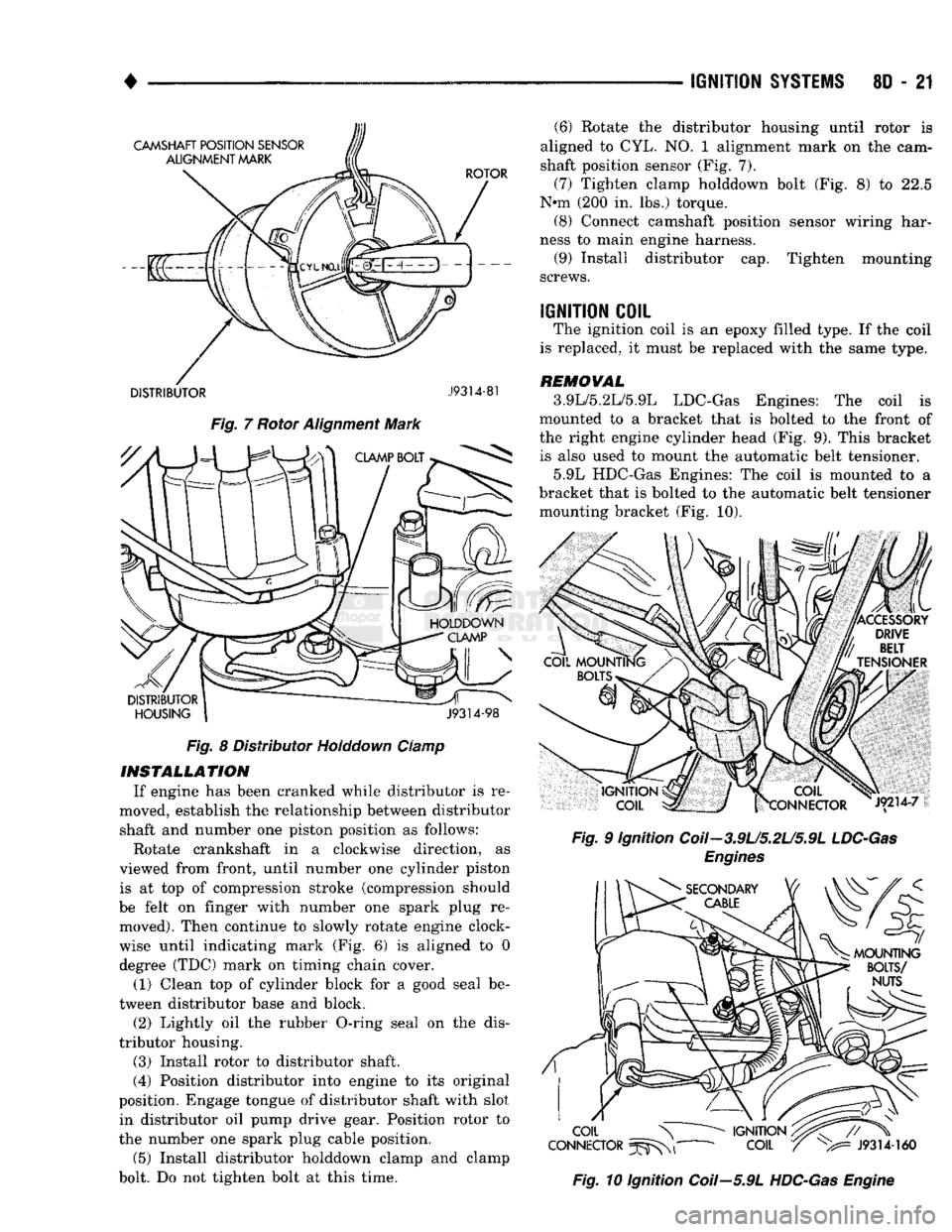

INSTALLATION

If engine has been cranked while distributor is re

moved, establish the relationship between distributor shaft and number one piston position as follows:

Rotate crankshaft in a clockwise direction, as

viewed from front, until number one cylinder piston is at top of compression stroke (compression should

be felt on finger with number one spark plug re moved). Then continue to slowly rotate engine clock

wise until indicating mark (Fig. 6) is aligned to 0

degree (TDC) mark on timing chain cover.

(1) Clean top of cylinder block for a good seal be

tween distributor base and block.

(2) Lightly oil the rubber O-ring seal on the dis

tributor housing.

(3) Install rotor to distributor shaft.

(4) Position distributor into engine to its original

position. Engage tongue of distributor shaft with slot in distributor oil pump drive gear. Position rotor to

the number one spark plug cable position.

(5) Install distributor holddown clamp and clamp

bolt. Do not tighten bolt at this time. (6) Rotate the distributor housing until rotor is

aligned to CYL. NO. 1 alignment mark on the cam

shaft position sensor (Fig. 7).

(7) Tighten clamp holddown bolt (Fig. 8) to 22.5

N*m (200 in. lbs.) torque. (8) Connect camshaft position sensor wiring har

ness to main engine harness. (9) Install distributor cap. Tighten mounting

screws.

IGNITION

COIL

The ignition coil is an epoxy filled type. If the coil

is replaced, it must be replaced with the same type.

REMOVAL

3.9L/5.2L/5.9L LDC-Gas Engines: The coil is

mounted to a bracket that is bolted to the front of

the right engine cylinder head (Fig. 9). This bracket is also used to mount the automatic belt tensioner.

5.9L HDC-Gas Engines: The coil is mounted to a

bracket that is bolted to the automatic belt tensioner mounting bracket (Fig. 10).

Fig.

9 Ignition Coil-3.9U5.2U5.9L

LDC-Gas

Engines

Fig.

10 Ignition Coil—5.9L

HDC-Gas

Engine

Page 607 of 1502

9

- 2

ENGINES

rial surrounds each mounting hole. Excess material

can easily be wiped off. Components should be

torqued in place within 15 minutes. The use of a lo cating dowel is recommended during assembly to pre

vent smearing the material off location.

ENGINE PERFORMANCE

To provide best vehicle performance and lowest ve

hicle emissions, it is most important that the tune-up

be done accurately. Use the specifications listed on

the Vehicle Emission Control Information label found on the engine compartment hood.

(1) Test cranking amperage draw (refer to Group

8B,

Battery/Starter/Generator Service for the proper

procedures).

(2) Tighten the intake manifold bolts (refer to

Group 11, Exhaust System and Intake Manifold for

the proper specifications). (3) Perform cylinder compression test:

(a) Check engine oil level and add oil, if neces

sary.

(b) Drive the vehicle until engine reaches normal

operating temperature. (c) Select a route free from traffic and other

forms of congestion, observe all traffic laws and

briskly accelerate through the gears several times. The higher engine speed may help clean out valve seat deposits which can prevent accurate compres

sion readings.

CAUTION:

DO NOT

overspeed

the

engine.

(d) Remove all spark plugs from engine. As

spark plugs are being removed, check electrodes for

abnormal firing indicators - fouled, hot, oily, etc.

Record cylinder number of spark plug for future

reference.

(e) Disconnect coil wire from distributor and se

cure to good ground to prevent a spark from start

ing a fire.

(f) Be sure throttle blades are fully open during

the compression check. (g) Insert compression gage adaptor into the

No.l spark plug hole. Crank engine until maxi

mum pressure is reached on gauge. Record this

pressure as No.l cylinder pressure.

(h) Repeat Step 3g for all remaining cylinders.

(i) Compression should not be less than 689 kPa

(100 psi) and not vary more than 172 kPa (25 psi)

from cylinder to cylinder.

(j) If cylinder(s) have abnormally low compres

sion pressures, repeat steps 3a through 3h. (k) If the same cylinder(s) repeat an abnormally

low reading, it could indicate the existence of a

problem in the cylinder.

The recommended compression pressures are

to be used only as a guide to diagnosing engine

problems. An engine should NOT be disassem bled to determine the cause of low compression

unless some malfunction is present. (4) Clean or replace spark plugs as necessary. Ad

just gap (refer to Group 8D, Ignition System for gap adjustment and torque).

(5) Test resistance of spark plug cables (refer to

Group 8D, Ignition System.

(6) Inspect the primary wire. Test coil output volt

age,

primary and secondary resistance. Replace parts as necessary (refer to Group 8D, Ignition System and

make necessary adjustment).

(7) Set ignition timing to specifications (refer to

Specification Label on engine compartment hood).

(8) Perform a combustion analysis.

(9) Test fuel pump for pressure and vacuum (refer

to Group 14, Fuel System for the proper specifica

tions).

(10) Inspect air filter element (refer to Group 0,

Lubrication and Maintenance for the proper proce

dure).

(11) Inspect crankcase ventilation system (refer to

Group 0, Lubrication and Maintenance for the proper

procedure).

(12) For emission controls refer to Group 25, Emis

sion Controls System for service procedures.

(13) Inspect and adjust accessory belt drives (refer

to Group 7, Cooling System for the proper adjust

ments).

(14) Road test vehicle as a final test.

H0NIN6

CYLINDER

BORES

Before honing, stuff plenty of clean shop towels un

der the bores and over the crankshaft to keep abra sive materials from entering the crankshaft area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823 equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light scuffing, scoring or scratches. Usually a few strokes

will clean up a bore and maintain the required lim

its.

CAUTION:

DO NOT use rigid type

hones

to remove

cylinder

wall

glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). 20-60 strokes, de

pending on the bore condition, will be sufficient to

provide a satisfactory surface. Using honing oil C-3501-3880 or a light honing oil available from ma

jor oil distributors.

CAUTION:

DO NOT use engine or

transmission

oil, mineral

spirits

or

kerosene.

Page 617 of 1502

9

- 12

ENGINES

•

CONDITION

POSSIBLE

CAUSES

CORRECTION

EXCESSIVE

EXHAUST

SMOKE

(Cont'd)

More

than

one

sealing washer

under an injector.

Check

and remove

extra

washer.

Improperly operating injectors.

Check

and replace inoperative injectors.

Improperly operating or over-

fueled injection pump.

Replace

injection pump.

Piston

rings

not sealing

(blue smoke). Perform blow-by check. Correct as required.

ENGINE

WILL

NOT

SHUT-OFF

Fuel shutoff valve inoperative.

Engine

running on fumes drawn into the air intake.

Stop

the engine mechanically

with

lever on the

fuel

pump.

Check/replace

sealing washer, piston and

spring.

Check

the air intake ducts for the source of the fumes.

WARNING:

In

ease

of engine runaway due to flammable

fumes

from gasoline spills or turbocharger oil leaks

being

sucked

into the

engine,

shut off engine ignition switch first then use a CO* or dry

chemical type

fire

extinguisher

and direct the

spray

under

the

front

bumper to

remove

oxygen

supply. The engine air

intake

is on the

passenger

side

behind the bumper. The

fire

extinguisher

must

bo

directed at this location for emergency shutdown conditions.

COOLANT

TEMPERA

TURE

ABOVE

NORMAL

Low

coolant level.

(a) Check coolant level. Add coolant, if necessary.

(b) Locate and correct the source of the coolant leak. Refer to

troubleshooting

logic for coolant

loss.

Incorrect/improperly operating

pressure

cap.

Replace

cap

with

the correct rating for the

system.

High

lube oil level.

Check/drain

oil to correct level.

Loose

drive belt on water

pump/fan.

Check/replace

belt or belt tensioner.

Inadequate air flow to the radiator. Check/repair radiator core, fan shroud and fan clutch as

required.

Radiator

fins

plugged.

Blow

debris from fins.

Collapsed

radiator

hose.

Replace

the

hose.

Improperly operating tempera

ture

sensor/gauge.

Verify

that

the

gauge

and temperature

sensor

are accurate.

Replace

gauge/sensor,

if bad.

Improperly operating, incorrect

or

no thermostat.

Check

and replace the thermostat.

Air

in the cooling

system.

(a) Make sure the

fill

rate

is not being exceeded and the correct

vented thermostat is installed.

(b) Check for loose hose

clamps.

Tighten if

loose.

(c) If aeration continued, check for a

compression

leak through the head gasket.

Inoperative water pump.

Check

and replace the water pump.

incorrect injection pump timing. Verify pump timing marks are aligned. Check/time the injector

pump

(refer

to Group 7,

Cooling

System).

J9209-56

SERVICE DIAGNOSIS (DIESEL ENGINE) - PERFORMANCE (CONT.)

Page 634 of 1502

•

3.9L

ENGINE

I - 21

VIBRATION

DAMPER

REMOVAL

(1) Disconnect the negative cable from the battery,

(2) Remove fan shroud retainer bolts and set

shroud back over engine.

(3) Remove the cooling system fan.

(4) Remove the serpentine belt (refer to Group 7,

Cooling System).

(5) Remove the vibration damper pulley.

(6) Remove vibration damper bolt and washer from

end of crankshaft.

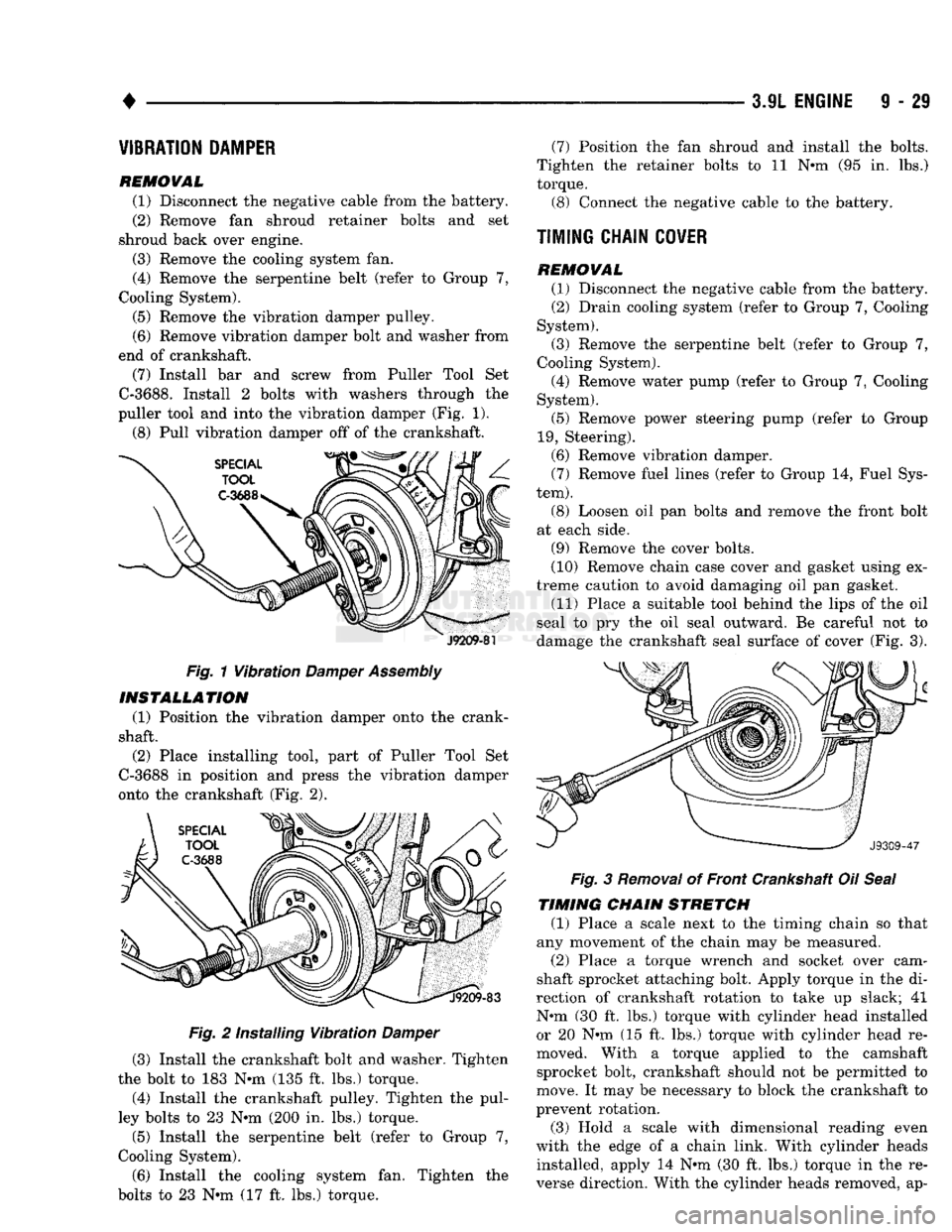

(7) Install bar and screw from Puller Tool Set

C-3688.

Install 2 bolts with washers through the

puller tool and into the vibration damper (Fig. 1).

(8) Pull vibration damper off of the crankshaft.

J9209-81

Fig. 1 Vibration

Damper

Assembly INSTALLATION

(1) Position the vibration damper onto the crank

shaft.

(2) Place installing tool, part of Puller Tool Set

C-3688 in position and press the vibration damper

onto the crankshaft (Fig. 2).

Fig. 2 Installing Vibration Damper

(3) Install the crankshaft bolt and washer. Tighten

the bolt to 183 N*m (135 ft. lbs.) torque.

(4) Install the crankshaft pulley. Tighten the pul

ley bolts to 23 N*m (200 in. lbs.) torque.

(5) Install the serpentine belt (refer to Group 7,

Cooling System).

(6) Install the cooling system fan. Tighten the

bolts to 23 N*m (17 ft. lbs.) torque. (7) Position the fan shroud and install the bolts.

Tighten the retainer bolts to 11 N*m (95 in. lbs.)

torque.

(3)

Connect the negative cable to the battery.

TIMING CHAIN

COVER

REMOVAL (1)

Disconnect the negative cable from the battery.

(2)

Drain cooling system (refer to Group 7, Cooling

System).

(3)

Remove the serpentine belt (refer to Group 7,

Cooling System).

(4)

Remove water pump (refer to Group 7, Cooling

System).

(5)

Remove power steering pump (refer to Group

19,

Steering).

(6)

Remove vibration damper. (7) Remove fuel lines (refer to Group 14, Fuel Sys

tem).

(8) Loosen oil pan bolts and remove the front bolt

at each side.

(9)

Remove the cover bolts.

(10)

Remove chain case cover and gasket using ex

treme caution to avoid damaging oil pan gasket.

(11)

Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of cover (Fig. 3). Fig. 3 Removal of Front Crankshaft Oil Seal

TIMING CHAIN STRETCH

(1) Place a scale next to the timing chain so that

any movement of the chain may be measured.

(2)

Place a torque wrench and socket over cam

shaft sprocket attaching bolt. Apply torque in the di

rection of crankshaft rotation to take up slack; 41

N#m (30 ft. lbs.) torque with cylinder head installed or 20 N»m (15 ft. lbs.) torque with cylinder head re

moved. With a torque applied to the camshaft sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block the crankshaft to

prevent rotation.

(3)

Hold a scale with dimensional reading even

with the edge of a chain link. With cylinder heads installed, apply 14 N*m (30 ft. lbs.) torque in the re

verse direction. With the cylinder heads removed, ap-