warning DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 15 of 1502

10 INTRODUCTION

•

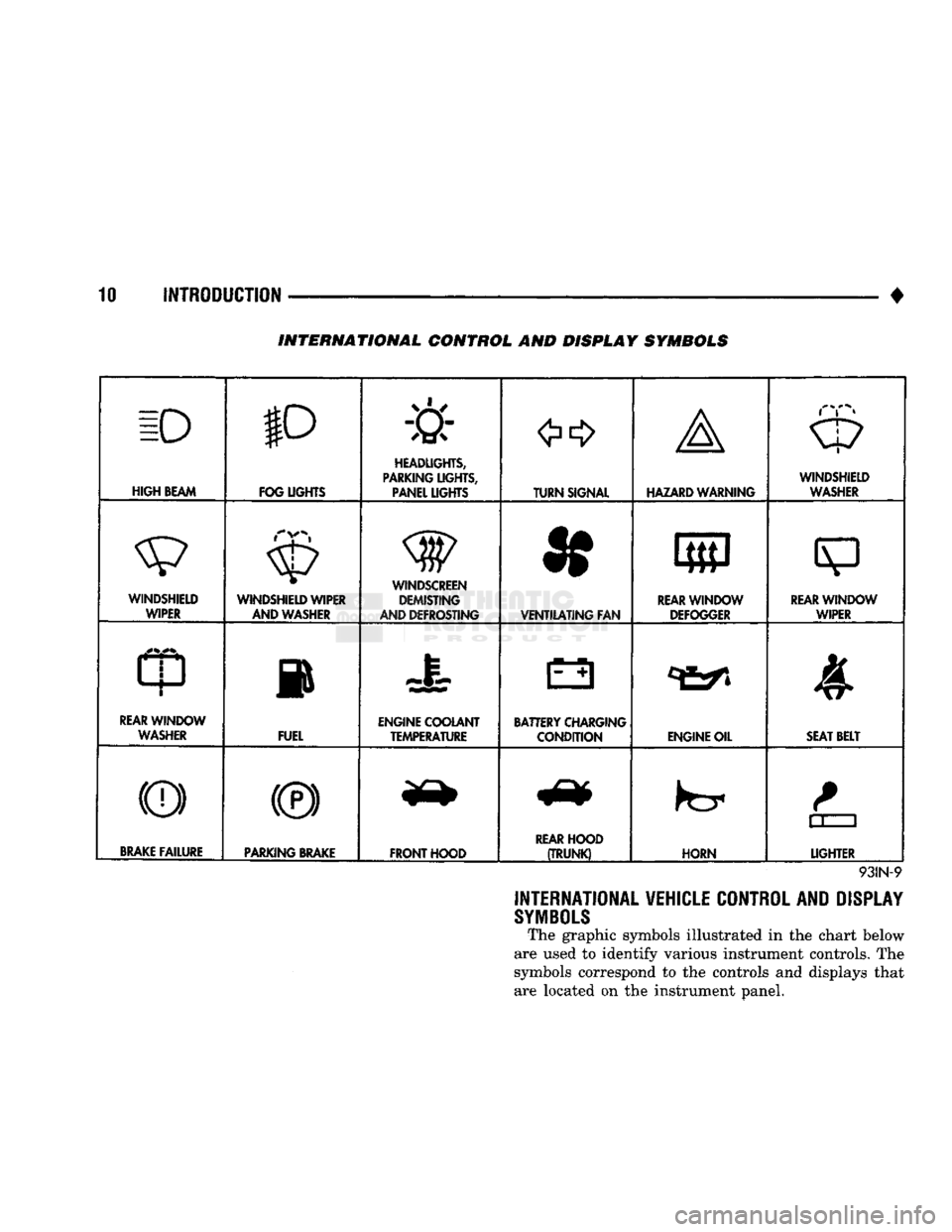

INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

ID

HIGH

BEAM P

FOG UGHTS -&

HEADLIGHTS,

PARKING UGHTS, PANEL UGHTS TURN SIGNAL A

HAZARD WARNING WINDSHIELD

WASHER

WINDSHIELD WIPER WINDSHIELD WIPER

AND WASHER

AND DEFROSTING *

VENTILATING

FAN 8

M f

REAR

WINDOW DEFOGGER

sp

REARWINLX)W WIPER

CD

l

m

REAR

WINDOW WASHER FUEL ENGINE COOLANT

TEMPERATURE BATTERY CHARGING

CONDITION ENGINE OIL

SEAT

BELT

(©) (®) ky

11 J

LIGHTER

BRAKE

FAILURE

PARKING

BRAKE

FRONT HOOD

REAR

HOOD

(TRUNK)

HORN

11 J

LIGHTER

93IN-9

INTERNATIONAL VEHICLE CONTROL AND DISPLAY

SYMBOLS

The graphic symbols illustrated in the chart below

are used to identify various instrument controls. The

symbols correspond to the controls and displays that are located on the instrument panel.

Page 16 of 1502

•

INTRODUCTION

11

MEASUREMENT

AND

TORQUE SPECIFICATIONS

INDEX

page

Metric

and

English/SAE

Conversion

11

Specification

Notations

11

SPECIFICATION NOTATIONS

WARNING:

THE USE OF

INCORRECT

ATTACHING

HARDWARE

CAN

RESULT

IN

COMPONENT

DAM

AGE

AND/OR

PERSONAL

INJURY.

It is important to retain the original attaching

hardware for assembly of the components. If the at

taching hardware is not reusable, hardware with

equivalent specifications must be used.

METRIC

AND

ENGLISH/SAE

CONVERSION

The following chart will assist in converting metric

units to equivalent English and SAE units, or vise versa.

TORQUE SPECIFICATIONS

TORQUE

CHARTS

A torque chart for fasteners is provided at the end

of each group (of service information). Refer to the Standard Torque Specifications chart to determine

torque values not listed in the group (Figs. 1 and 2).

It is important to be aware that the torque values

listed in the chart are based on clean and dry bolt

page

Torque Specifications

11

threads. Reduce the torque value by 10 percent when the bolt threads are lubricated and by 20 percent if new.

BOLT

THREAD

AND

GRADE/CLASS

IDENTIFICATION

THREAD

IDENTIFICATION

SAE and metric bolt/nut threads are not the same.

The difference is described in the Thread Notation chart.

GRADE/CLASS

IDENTIFICATION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the line marks on the top of each bolt head (Fig. 1). The

actual bolt strength grade corresponds to the number

of line marks plus 2.

• A grade 2 bolt has no line marks on top of the bolt

head

• A grade 5 bolt has 3 line marks on top of the bolt

head • A grade 7 bolt has 5 line marks on top of the bolt

head

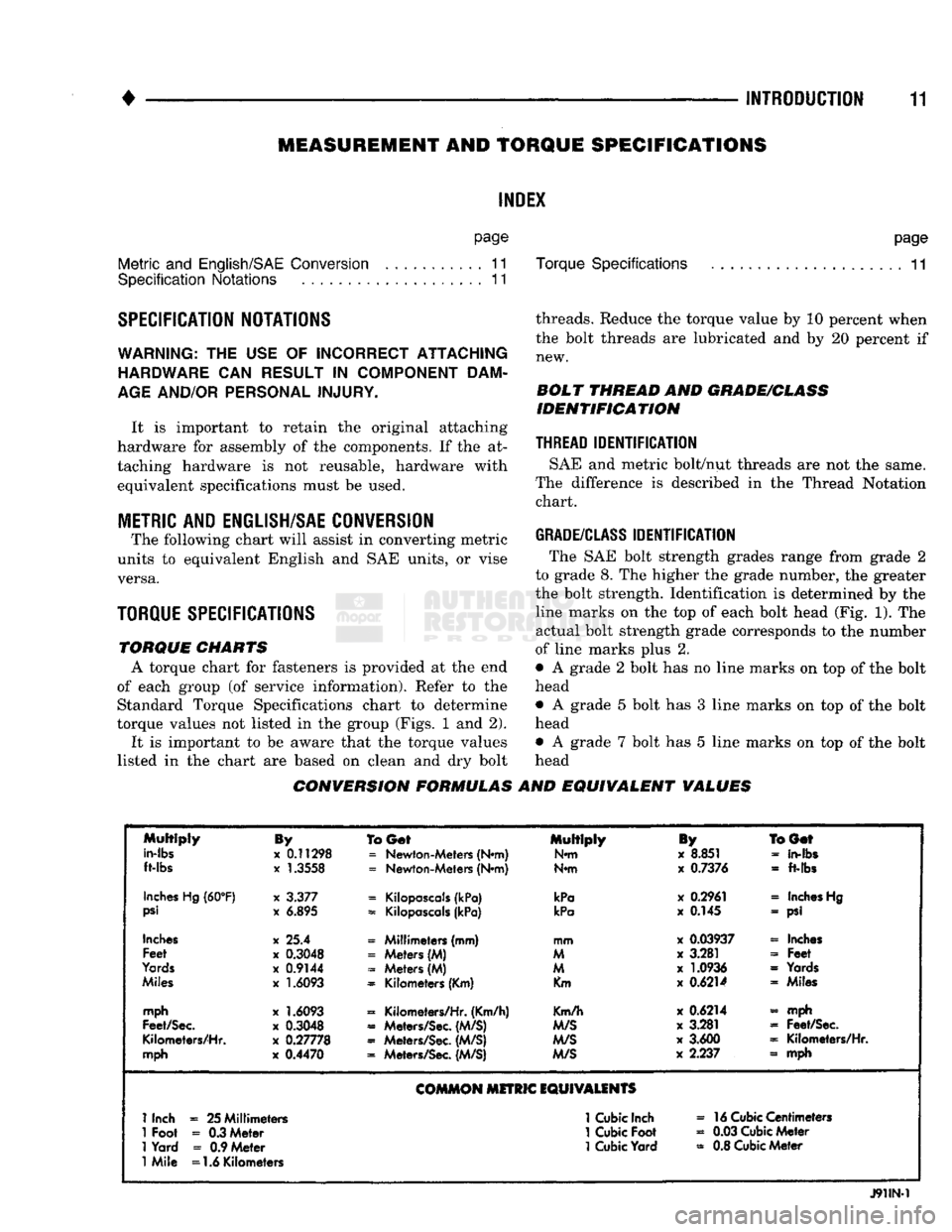

CONVERSION FORMULAS

AND

EQUIVALENT

VALUES

Multiply

in-lbs

ft-lbs

By

x

0.11298

x

1.3558

To

Get

=

Newton-Meters (N*m)

=

Newton-Meters (N*m) Multiply

N*m

iy

x

8.851

x

0.7376

BGef

-

in-fbs

-

ft-lbs

Inches

Hg

(60°F)

psi

x

3.377

x

6.895

=

Kilopascals

(kPa)

=

Kilopascals

(kPa)

kPa

kPa

x

0.2961

x

0.145

«

Inches

Hg

- psi

Inches

Feet

Yards

Miles

x 25.4

x

0.3048

x

0.9144

x

1.6093

« Millimeters (mm)

=

Meters (M)

-

Meters (M)

=

Kilometers (Km) mm

M

M

Km

x

0.03937

x

3.281

x

1.0936

x

0.6214

« Inches

-

Feet

=

Yards « Miles

mph

Feet/Sec.

Kilometers/Hr.

mph

x

1.6093

x

0.3048

x

0.27778

x

0.4470

=

Kilometers/Hr. (Km/h)

«

Meters/Sec.

(M/S)

«

Meters/Sec.

(M/S)

=

Meters/Sec.

(M/S)

Km/h

M/S

M/S

M/S

x

0.6214

x

3.281

x

3.600

x

2.237 - mph

=

Feet/Sec.

=

Kilometers/Hr.

» mph

COMMON

MITRIC

EQUIVALENTS

1

Inch

=

25 Millimeters

1

Cubic

Inch

»

16

Cubic

Centimeters

1

Foot

-

0.3 Meter

1

Cubic

Foot

«

0.03

Cubic

Meter

1

Yard

=

0.9 Meter

1

Cubic

Yard

=

0.8

Cubic

Meter

1

Mile =1.6 Kilometers

J91IN-1

Page 28 of 1502

•

LUBRICATION AND MAINTENANCE

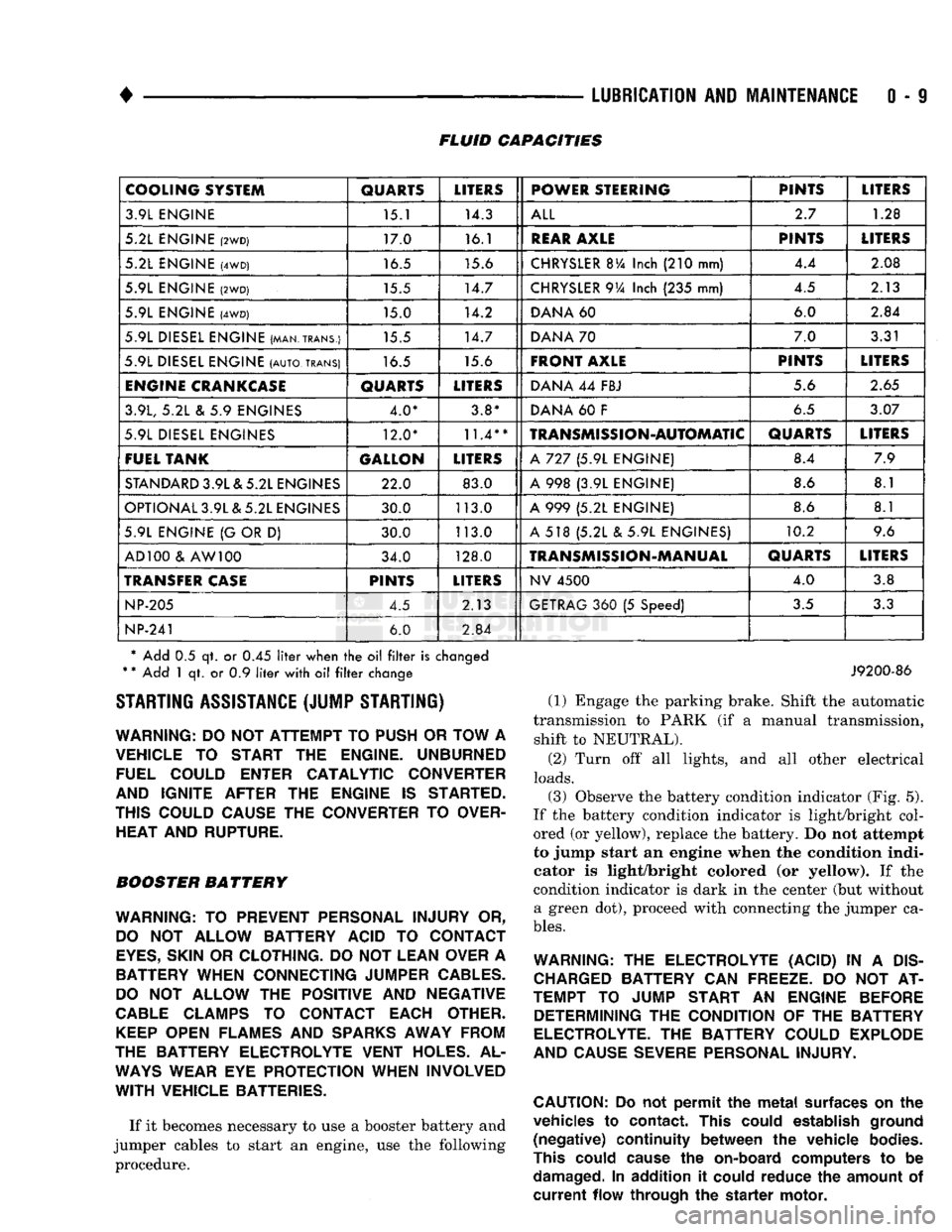

0 - 9 FLUID CAPACITIES

COOLING SYSTEM

QUARTS

LITERS

POWER STEERING PINTS

LITERS

3.9L ENGINE 15.1 14.3

ALL

2.7

1.28

5.2L ENGINE

(2WD)

17.0 16.1

REAR

AXLE

PINTS

LITERS

5.2L ENGINE

(4WD)

16.5 15.6

CHRYSLER

BVa

Inch

(210

mm) 4.4

2.08

5.9L ENGINE

(2WD)

15.5 14.7

CHRYSLER

9Va

Inch

(235

mm) 4.5

2.13

5.9L ENGINE

(4WD)

15.0 14.2

DANA

60 6.0

2.84

5.9L DIESEL ENGINE (MAN.TRANS.) 15.5 14.7

DANA

70 7.0

3.31

5.9L DIESEL ENGINE

(AUTO,

TRANS)

16.5 15.6

FRONT AXLE

PINTS

LITERS

ENGINE

CRANKCASE

QUARTS

LITERS

DANA

44

FBJ 5.6

2.65

3.9L,

5.2L & 5.9

ENGINES 4.0* 3.8*

DANA

60 F

6.5

3.07

5.9L DIESEL ENGINES 12.0*

11.4**

TRANSMISSION-AUTOMATIC

QUARTS

LITERS

FUEL TANK GALLON

LITERS

A

727 (5.9L

ENGINE) 8.4

7.9

STANDARD

3.9L & 5.2L ENGINES 22.0 83.0

A

998 (3.9L

ENGINE) 8.6

8.1

OPTIONAL 3.9L & 5.2L ENGINES 30.0 113.0

A

999 (5.2L

ENGINE) 8.6

8.1

5.9L ENGINE

{G

OR

D)

30.0 113.0

A

518 (5.2L & 5.9L

ENGINES) 10.2

9.6

AD 100

&

AW 100 34.0 128.0

TRANSMISSION-MANUAL

QUARTS

LITERS

TRANSFER

CASE

PINTS

LITERS

NV

4500

4.0

3.8

NP-205

4.5 2.13

GETRAG

360 (5

Speed)

3.5

3.3

NP-241

6.0

2.84

* Add

0.5 qt. or 0.45

liter

when

the oil filter

is

changed

*

*

Add

1 qt. or 0.9

liter

with

oil filter

change STARTING ASSISTANCE (JUMP STARTING)

WARNING:

DO NOT

ATTEMPT

TO

PUSH

OR

TOW

A

VEHICLE

TO

START

THE

ENGINE. UNBURNED FUEL COULD ENTER CATALYTIC CONVERTER

AND IGNITE AFTER

THE

ENGINE

IS

STARTED.

THIS COULD CAUSE

THE

CONVERTER

TO

OVER HEAT AND RUPTURE.

BOOSTER BATTERY

WARNING:

TO

PREVENT PERSONAL INJURY

OR,

DO

NOT

ALLOW BATTERY ACID

TO

CONTACT

EYES,

SKIN

OR

CLOTHING.

DO NOT

LEAN OVER

A

BATTERY WHEN CONNECTING JUMPER

CABLES.

DO

NOT

ALLOW

THE

POSITIVE

AND

NEGATIVE

CABLE

CLAMPS

TO

CONTACT EACH OTHER.

KEEP

OPEN FLAMES

AND

SPARKS

AWAY FROM

THE BATTERY ELECTROLYTE VENT HOLES.

AL

WAYS

WEAR

EYE

PROTECTION WHEN INVOLVED

WITH

VEHICLE BATTERIES.

If it becomes necessary to use a booster battery and

jumper cables to start an engine, use the following procedure.

J9200-86

(1) Engage the parking brake. Shift the automatic

transmission to PARK (if a manual transmission, shift to NEUTRAL).

(2) Turn off all lights, and all other electrical

loads.

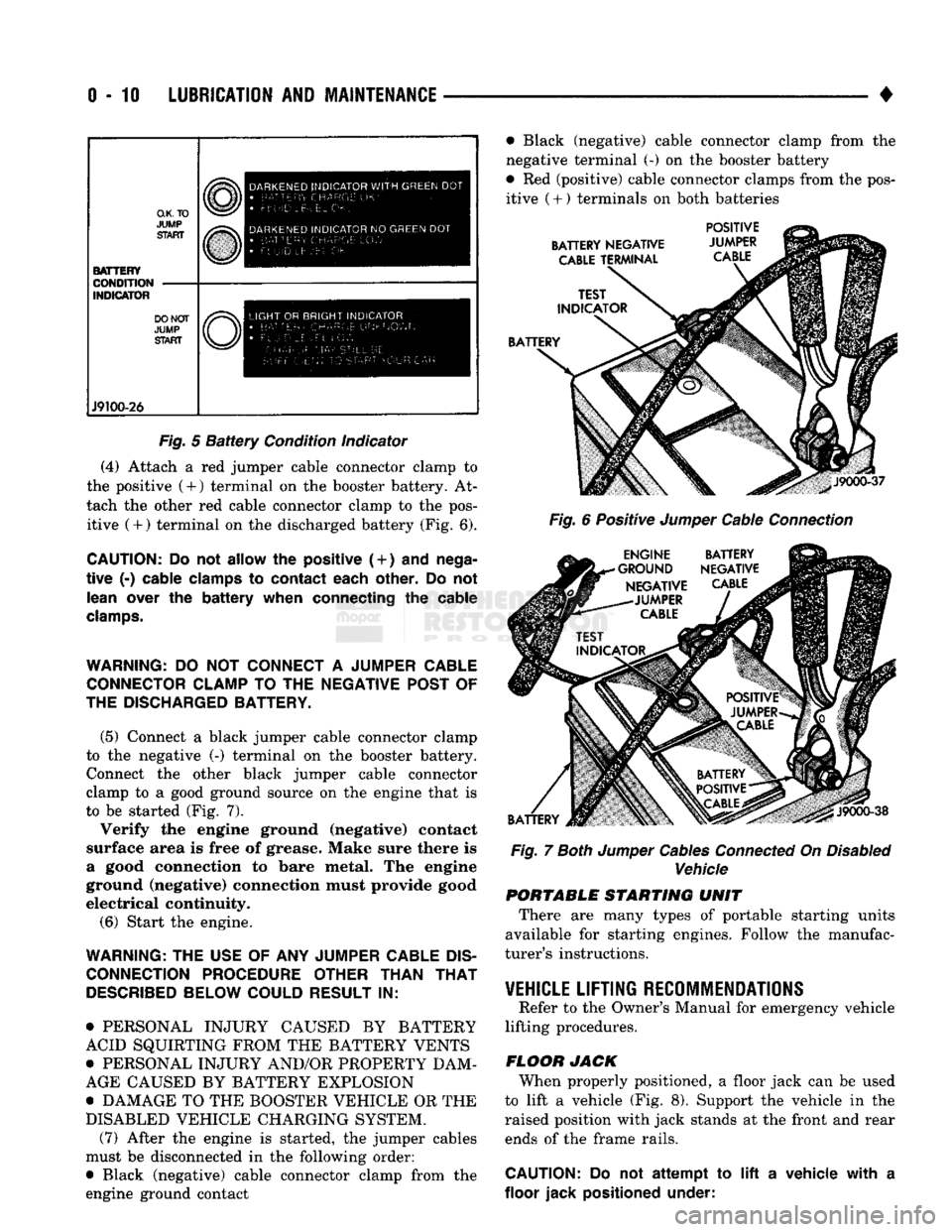

(3)

Observe the battery condition indicator (Fig. 5).

If the battery condition indicator is light/bright col

ored (or yellow), replace the battery. Do not attempt

to jump start an engine when the condition indi

cator is light/bright colored (or yellow). If the

condition indicator is dark in the center (but without a green dot), proceed with connecting the jumper ca

bles.

WARNING:

THE

ELECTROLYTE (ACID)

IN A

DIS

CHARGED

BATTERY

CAN

FREEZE.

DO NOT AT

TEMPT

TO

JUMP START

AN

ENGINE BEFORE DETERMINING

THE

CONDITION

OF THE

BATTERY

ELECTROLYTE.

THE

BATTERY COULD EXPLODE

AND CAUSE SEVERE PERSONAL INJURY.

CAUTION:

Do not

permit

the

metal

surfaces

on the

vehicles

to

contact.

This

could

establish

ground

(negative)

continuity

between

the

vehicle

bodies.

This

could

cause

the

on-board

computers

to be

damaged.

In

addition

it

could

reduce

the

amount

of

current

flow

through

the

starter

motor.

Page 29 of 1502

0-10

LUBRICATION

AND

MAINTENANCE

•

O.K.TO

JUMP

START BATTERY

CONDITION

INDICATOR DO NOT

JUMP

START J9100-26 DARKENED

INDICATOR

WITH

GREEN

DOT

•

LETTERS

Uk-

FLUID

Lt- E:L .

DARKENED

INDICATOR

NO

GREEN

DOT •

BATTERY CHARGE

10'//

• Ft UID

L

EVEl

OK

LIGHT

OR

BRIGHT

INDICATOR

•

RAT-cci,

C

H

A

P

C;

F

R^'^Owh

AM.w-GE

FlAf StIll BE

r-

•

!

F-

r tjr r

?

STA

F

•

r

O U n

C

AI:

Fig.

5

Battery

Condition indicator

(4) Attach a red jumper cable connector clamp to

the positive (4-) terminal on the booster battery. At

tach the other red cable connector clamp to the pos itive (+) terminal on the discharged battery (Fig. 6).

CAUTION:

Do not

allow

the

positive (

+

)

and

nega

tive

(-)

cable clamps

to

contact each other.

Do not

lean over

the

battery when connecting

the

cable

clamps.

WARNING:

DO NOT

CONNECT

A

JUMPER CABLE CONNECTOR CLAMP

TO THE

NEGATIVE POST

OF

THE DISCHARGED BATTERY.

(5) Connect a black jumper cable connector clamp

to the negative (-) terminal on the booster battery. Connect the other black jumper cable connector

clamp to a good ground source on the engine that is

to be started (Fig. 7).

Verify the engine ground (negative) contact

surface area is free of grease. Make sure there is

a good connection to bare metal. The engine

ground (negative) connection must provide good

electrical continuity.

(6) Start the engine.

WARNING:

THE

USE

OF ANY

JUMPER CABLE

DIS

CONNECTION PROCEDURE OTHER THAN

THAT

DESCRIBED

BELOW COULD RESULT

IN:

• PERSONAL INJURY CAUSED BY BATTERY

ACID SQUIRTING FROM THE BATTERY VENTS

• PERSONAL INJURY AND/OR PROPERTY DAM

AGE CAUSED BY BATTERY EXPLOSION

• DAMAGE TO THE BOOSTER VEHICLE OR THE

DISABLED VEHICLE CHARGING SYSTEM. (7) After the engine is started, the jumper cables

must be disconnected in the following order:

• Black (negative) cable connector clamp from the

engine ground contact • Black (negative) cable connector clamp from the

negative terminal (-) on the booster battery

• Red (positive) cable connector clamps from the pos itive

(

+ ) terminals on both batteries

BATTERY NEGATIVE

CABLE

TERMINAL POSITIVE

JUMPER

CABLE

BATTERY

J9000-37

Fig.

6 Positive

Jumper

Cable

Connection

ENGINE BATTERY

•GROUND NEGATIVE NEGATIVE

CABLE

-JUMPER

CABLE

BATTERY

J9000-38

Fig.

7

Both

Jumper

Cables

Connected

On

Disabled

Vehicle PORTABLE STARTING UNIT

There are many types of portable starting units

available for starting engines. Follow the manufac

turer's instructions.

VEHICLE

LIFTING RECOMMENDATIONS

Refer to the Owner's Manual for emergency vehicle

lifting procedures.

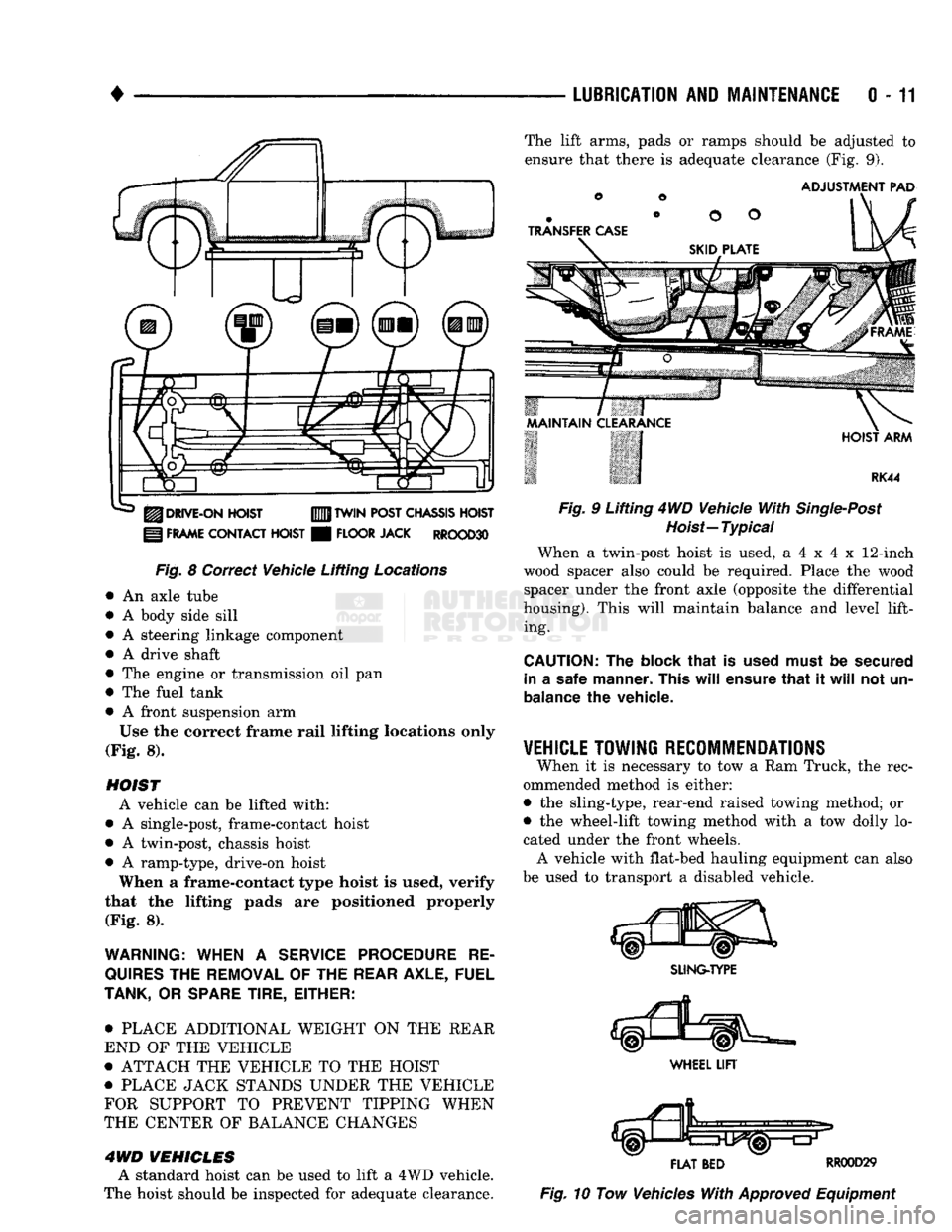

FLOOR JACK When properly positioned, a floor jack can be used

to lift a vehicle (Fig. 8). Support the vehicle in the

raised position with jack stands at the front and rear ends of the frame rails.

CAUTION:

Do not

attempt

to lift a

vehicle with

a

floor jack positioned under:

Page 30 of 1502

LUBRICATION

AND

MAINTENANCE

0-11

J

DRIVE-ON

HOIST

I

FRAME

CONTACT

HOIST

TWIN

POST

CHASSIS

HOIST

FLOOR

JACK

RROOD30

Fig.

8 Correct Vehicle Lifting

Locations

An axle tube

A body side sill

A steering linkage component

A drive shaft

The engine or transmission oil pan

The fuel tank

• A front suspension arm Use the correct frame rail lifting locations only

(Fig. 8).

HOIST A vehicle can be lifted with:

• A single-post, frame-contact hoist

• A twin-post, chassis hoist

• A ramp-type, drive-on hoist

When a frame-contact type hoist is used, verify

that the lifting pads are positioned properly (Fig. 8).

WARNING:

WHEN

A

SERVICE

PROCEDURE

RE

QUIRES

THE

REMOVAL

OF

THE

REAR

AXLE,

FUEL

TANK,

OR

SPARE

TIRE,

EITHER:

• PLACE ADDITIONAL WEIGHT ON THE REAR

END OF THE VEHICLE

« ATTACH THE VEHICLE TO THE HOIST

« PLACE JACK STANDS UNDER THE VEHICLE

FOR SUPPORT TO PREVENT TIPPING WHEN

THE CENTER OF BALANCE CHANGES

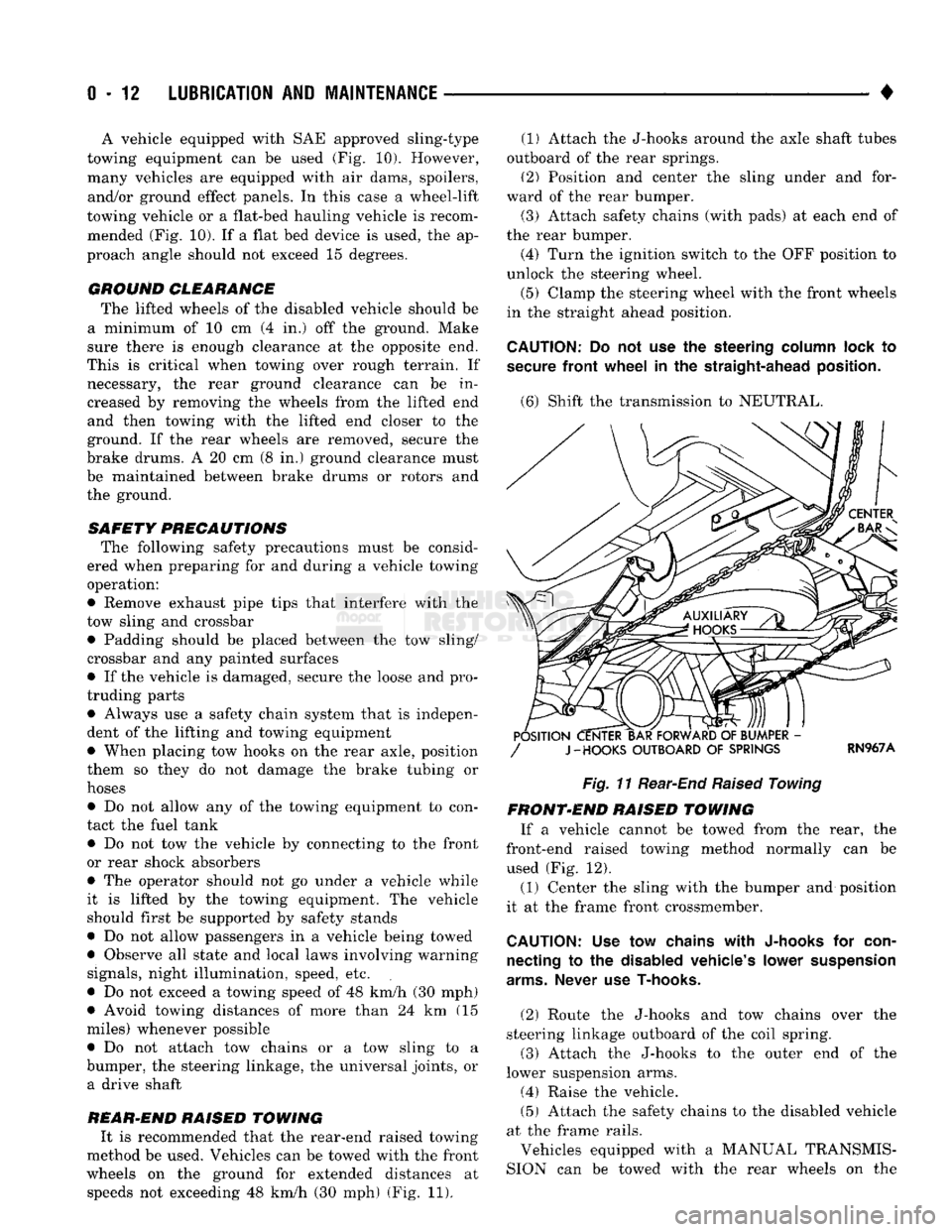

4WD VEHICLES A standard hoist can be used to lift a 4WD vehicle.

The hoist should be inspected for adequate clearance. The lift arms, pads or ramps should be adjusted to

ensure that there is adequate clearance (Fig. 9).

ADJUSTMENT

PAD

ii 7

MAINTAIN

CLEARANCE

HOIST

ARM

RK44

Fig.

9 Lifting 4WD Vehicle

With

Single-Post

Hoist—

Typical

When a twin-post hoist is used, a 4 x 4 x 12-inch

wood spacer also could be required. Place the wood spacer under the front axle (opposite the differential

housing). This will maintain balance and level lift ing.

CAUTION:

The

block

that

is

used must

be

secured in

a

safe manner. This

will

ensure

that

it

will

not un

balance

the

vehicle.

VEHICLE

TOWING

RECOMMENDATIONS

When it is necessary to tow a Ram Truck, the rec

ommended method is either:

• the sling-type, rear-end raised towing method; or

• the wheel-lift towing method with a tow dolly lo

cated under the front wheels. A vehicle with flat-bed hauling equipment can also

be used to transport a disabled vehicle.

SLING-TYPE

FLAT

BED

RR0OD29

Fig.

10 Tow Vehicles

With

Approved

Equipment

Page 31 of 1502

0 - 12

LUBRICATION

AND

MAINTENANCE

• A vehicle equipped with SAE approved sling-type

towing equipment can be used (Fig. 10). However,

many vehicles are equipped with air dams, spoilers, and/or ground effect panels. In this case a wheel-lift

towing vehicle or a flat-bed hauling vehicle is recom mended (Fig. 10). If a flat bed device is used, the ap

proach angle should not exceed 15 degrees.

GROUND CLEARANCE The lifted wheels of the disabled vehicle should be

a minimum of 10 cm (4 in.) off the ground. Make

sure there is enough clearance at the opposite end.

This is critical when towing over rough terrain. If necessary, the rear ground clearance can be increased by removing the wheels from the lifted end

and then towing with the lifted end closer to the

ground. If the rear wheels are removed, secure the

brake drums. A 20 cm (8 in.) ground clearance must

be maintained between brake drums or rotors and the ground.

SAFETY PRECAUTIONS The following safety precautions must be consid

ered when preparing for and during a vehicle towing operation:

• Remove exhaust pipe tips that interfere with the

tow sling and crossbar • Padding should be placed between the tow sling/

crossbar and any painted surfaces

• If the vehicle is damaged, secure the loose and pro

truding parts

• Always use a safety chain system that is indepen dent of the lifting and towing equipment

• When placing tow hooks on the rear axle, position them so they do not damage the brake tubing or

hoses

• Do not allow any of the towing equipment to con

tact the fuel tank

• Do not tow the vehicle by connecting to the front

or rear shock absorbers

• The operator should not go under a vehicle while

it is lifted by the towing equipment. The vehicle

should first be supported by safety stands

• Do not allow passengers in a vehicle being towed

• Observe all state and local laws involving warning signals, night illumination, speed, etc.

• Do not exceed a towing speed of 48 km/h (30 mph)

• Avoid towing distances of more than 24 km (15

miles) whenever possible • Do not attach tow chains or a tow sling to a

bumper, the steering linkage, the universal joints, or a drive shaft

REAR-END RAISED TOWING It is recommended that the rear-end raised towing

method be used. Vehicles can be towed with the front

wheels on the ground for extended distances at speeds not exceeding 48 km/h (30 mph) (Fig. 11). (1) Attach the J-hooks around the axle shaft tubes

outboard of the rear springs. (2) Position and center the sling under and for

ward of the rear bumper. (3) Attach safety chains (with pads) at each end of

the rear bumper.

(4) Turn the ignition switch to the OFF position to

unlock the steering wheel. (5) Clamp the steering wheel with the front wheels

in the straight ahead position.

CAUTION:

Do not use the steering

column

lock

to

secure

front

wheel

in the straight-ahead

position.

(6) Shift the transmission to NEUTRAL.

POSITION CENTER BAR FORWARD

OF

BUMPER

-

/

J-HOOKS OUTBOARD

OF

SPRINGS

RN967A

Fig. 11 Rear-End

Raised

Towing

FRONT'END RAISED TOWING If a vehicle cannot be towed from the rear, the

front-end raised towing method normally can be

used (Fig. 12). (1) Center the sling with the bumper and position

it at the frame front crossmember.

CAUTION:

Use tow

chains

with

J-hooks

for

con

necting

to the

disabled

vehicle's

lower

suspension

arms.

Never use

T-hooks.

(2) Route the J-hooks and tow chains over the

steering linkage outboard of the coil spring.

(3) Attach the J-hooks to the outer end of the

lower suspension arms.

(4) Raise the vehicle.

(5.) Attach the safety chains to the disabled vehicle

at the frame rails.

Vehicles equipped with a MANUAL TRANSMIS

SION can be towed with the rear wheels on the

Page 34 of 1502

•

LUBRICATION

AND

MAINTENANCE

0 - 15

DIESEL

ENGINES

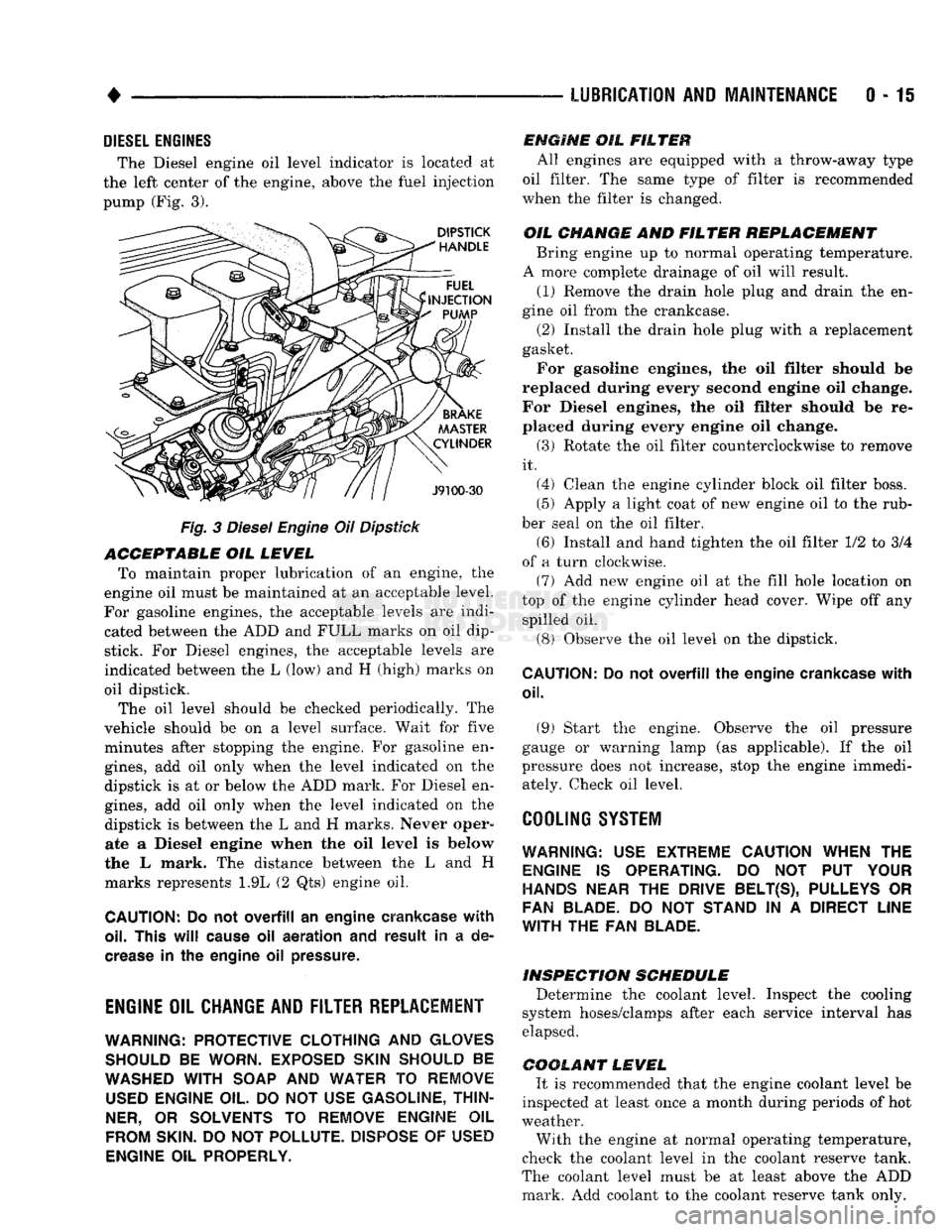

The Diesel engine oil level indicator is located at

the left center of the engine, above the

fuel

injection

pump (Fig. 3).

Fig.

3

Diesel

Engine

Oil

Dipstick

ACCEPTABLE

OIL

LEVEL

To maintain proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

For gasoline engines, the acceptable levels are indi cated between the ADD and

FULL

marks on oil

dip

stick. For Diesel engines, the acceptable levels are

indicated between the L (low) and H

(high) marks

on

oil dipstick. The oil level should be checked periodically. The

vehicle should be on a level surface. Wait for

five

minutes after stopping the engine. For gasoline en

gines,

add oil only when the level indicated on the

dipstick is at or below the ADD mark. For Diesel en

gines,

add oil only when the level indicated on the

dipstick is between the L and H marks.

Never oper

ate a Diesel

engine when

the oil

level

is below

the L mark. The distance between the L and H

marks represents 1.9L (2 Qts) engine oil.

CAUTION:

Do not

overfill

an

engine crankcase

with

oil. This

will

cause

oil

aeration

and

result

in a de

crease

in the

engine

oil

pressure.

ENGINE

OIL

CHANGE AND FILTER REPLACEMENT

WARNING: PROTECTIVE CLOTHING

AND

GLOVES SHOULD

BE

WORN. EXPOSED SKIN SHOULD

BE

WASHED

WITH

SOAP

AND

WATER

TO

REMOVE

USED

ENGINE

OIL.

DO NOT

USE

GASOLINE, THIN

NER,

OR

SOLVENTS

TO

REMOVE ENGINE

OIL

FROM

SKIN.

DO NOT

POLLUTE. DISPOSE

OF

USED

ENGINE

OIL

PROPERLY.

ENGINE

OIL

FILTER

All engines are equipped with a throw-away type

oil filter. The same type of filter is recommended

when the filter is changed.

OIL CHANGE

AND

FILTER

REPLACEMENT

Bring engine up to normal operating temperature.

A more complete drainage of oil will result.

(1) Remove the drain hole plug and drain the en

gine oil from the crankcase.

(2) Install the drain hole plug with a replacement

gasket. For gasoline engines, the oil filter should be

replaced during every second engine oil change.

For Diesel engines, the oil filter should be re

placed during every engine oil change.

(3) Rotate the oil filter counterclockwise to remove

it.

(4) Clean the engine cylinder block oil filter boss. (5) Apply a light coat of new engine oil to the rub

ber seal on the oil filter.

(6) Install and hand tighten the oil filter 1/2 to 3/4

of a turn clockwise. (7) Add new engine oil at the fill hole location on

top of the engine cylinder head cover. Wipe off any spilled oil.

(8) Observe the oil level on the dipstick.

CAUTION:

Do not

overfill

the

engine crankcase

with

oil.

(9)

Start the engine. Observe the oil pressure

gauge or warning lamp (as applicable). If the oil

pressure does not increase, stop the engine immedi ately. Check oil level.

COOLING SYSTEM

WARNING:

USE

EXTREME CAUTION WHEN

THE

ENGINE

IS

OPERATING.

DO NOT PUT

YOUR

HANDS NEAR

THE

DRIVE BELT(S), PULLEYS

OR

FAN BLADE.

DO NOT

STAND

IN A

DIRECT LINE

WITH

THE FAN

BLADE.

INSPECTION SCHEDULE

Determine the coolant level. Inspect the cooling

system hoses/clamps after each service interval has

elapsed.

COOLANT LEVEL

It is recommended that the engine coolant level be

inspected at least once a month during periods of hot

weather.

With the engine at normal operating temperature,

check the coolant level in the coolant reserve tank.

The coolant level must be at least above the ADD mark. Add coolant to the coolant reserve tank only.

Page 35 of 1502

0-18

LUBRICATION

AND

MAINTENANCE

•

COOLANT FREEZE PROTECTION

Cooling systems contain a 50/50 mixture of anti

freeze (ethylene glycol) and distilled water. This is

the recommended coolant mixture.

It is recommended that the degree of coolant pro

tection be tested every 12 months. If the coolant is

contaminated or rusty, the cooling system should be

drained, flushed. Refill with a 50/50 mixture of fresh

coolant. Refer to Group 7—Cooling Systems for addi

tional information.

SYSTEM

INSPECTION

WARNING:

IF THE

ENGINE

HAS

BEEN RECENTLY

OPERATED,

DO NOT

REMOVE

THE

RADIATOR

CAP.

THIS WILL AVOID

YOU

BEING SCALDED

WITH

HOT, PRESSURIZED COOLANT.

(1) Test the radiator cap for proper sealing and op

eration. Use caution when removing the radiator cap

to avoid contact with hot coolant. Place a heavy rag

or towel over the cap and turn to the first stop. Do

not press down. Pause to allow the pressure to re

lease through the overflow tube. Then press down

and turn counterclockwise to remove the cap.

(2) Inspect the coolant overflow tubing and the

connections at the coolant reserve tank and at the

radiator.

(3) Inspect the entire cooling system for leaks. A

black-light detector can be used as an aid in detect ing the source of coolant leaks.

(4) Inspect the radiator and air conditioner con

denser fins for debris, etc. (5) If necessary, refer to Group 7—Cooling Systems

for additional information and service procedures.

RADIATOR CAP

The radiator cap must be completely tightened to

provide proper pressure. Inspect and test radiator cap

when cooling system service is performed.

MAIN,

FLUSH

AND

FILL

WARNING: ANTI-FREEZE (ETHYLENE GLYCOL)

IS

POISONOUS.

KEEP

OUT OF THE

REACH

OF

CHIL

DREN.

Drain, flush, and fill the cooling system at the in

terval specified in maintenance schedule. For proper service instructions see Group 7, Cooling System.

HOSES AND

FITTINGS

It is recommended that rubber hoses be periodi

cally inspected. Inspect all hose fittings for looseness and corrosion.

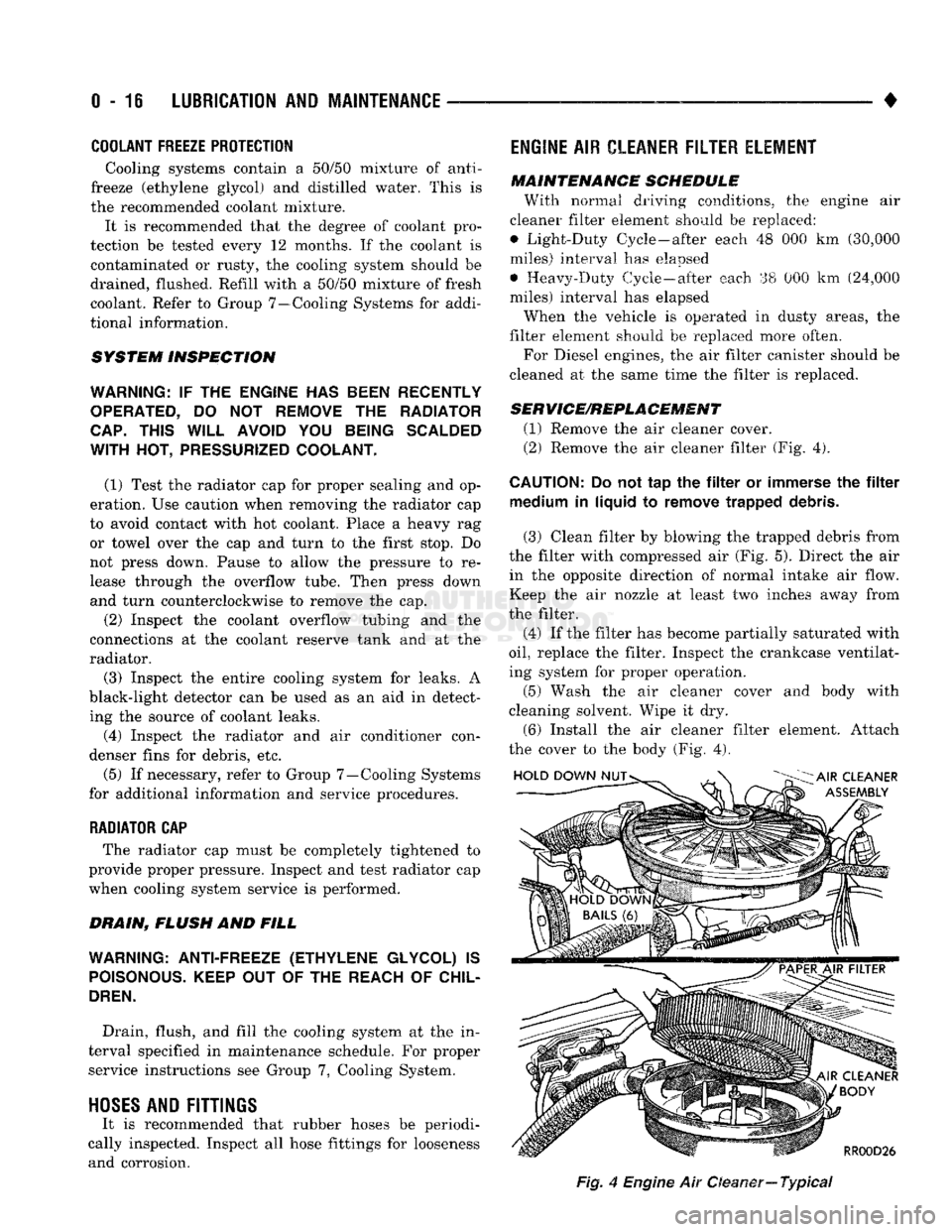

ENGINE

AIR

CLEANER

FILTER

ELEMENT

MAINTENANCE

SCHEDULE

With normal driving conditions, the engine air

cleaner filter element should be replaced:

• Light-Duty Cycle-after each 48 000 km (30,000

miles) interval has elapsed

• Heavy-Duty Cycle-after

each

38 000 km (24,000

miles) interval has elapsed

When the vehicle is operated in dusty areas, the

filter element should be replaced more often.

For Diesel engines, the air filter canister should be

cleaned at the same time the filter is replaced.

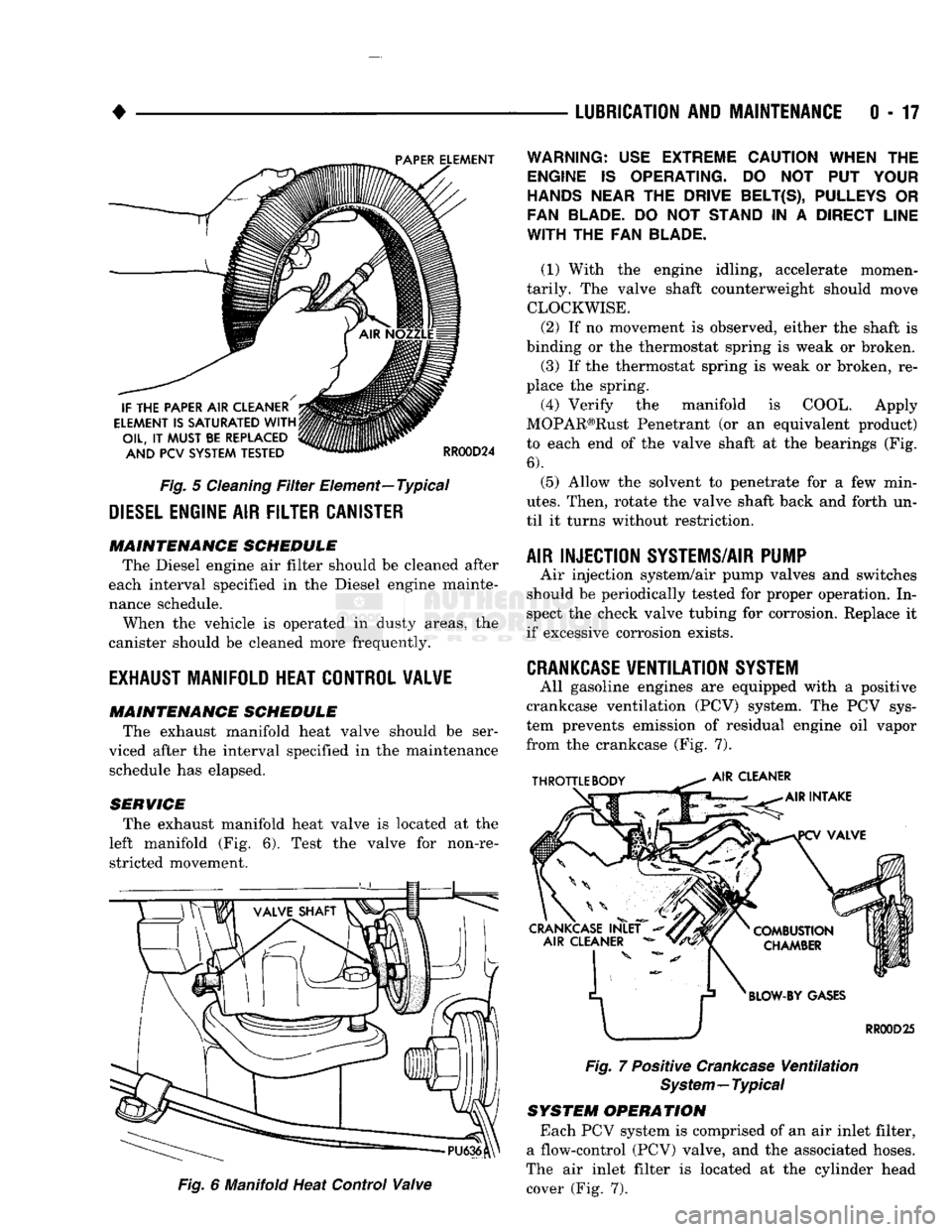

SERVICE/REPLACEMENT

(1) Remove the air cleaner cover.

(2) Remove the air cleaner filter (Fig. 4).

CAUTION:

Do not tap the filter or immerse the filter medium in liquid to remove trapped debris.

(3) Clean filter by blowing the trapped debris from

the filter with compressed air (Fig. 5). Direct the air in the opposite direction of normal intake air flow.

Keep the air nozzle at least two inches away from

the filter.

(4) If the filter has become partially saturated with

oil,

replace the filter. Inspect the crankcase ventilat

ing system for proper operation.

(5) Wash the air cleaner cover and body with

cleaning solvent. Wipe it dry.

(6) Install the air cleaner filter element. Attach

the cover to the body (Fig. 4).

Fig,

4

Engine

Air Oeaner—

Typical

Page 36 of 1502

•

Fig.

5

Cleaning

Filter

Element—Typical

DIESEL

ENGINE

AIR

FILTER CANISTER MAINTENANCE SCHEDULE

The Diesel engine air filter should be cleaned after

each interval specified in the Diesel engine mainte

nance schedule.

When the vehicle is operated in dusty areas, the

canister should be cleaned more frequently.

EXHAUST

MANIFOLD HEAT CONTROL VALVE

MAINTENANCE SCHEDULE

The exhaust manifold heat valve should be ser

viced after the interval specified in the maintenance schedule has elapsed.

SERVICE The exhaust manifold heat valve is located at the

left manifold (Fig. 6). Test the valve for non-re stricted movement.

Fig.

6 Manifold Heat Control

Valve

LUBRICATION

AND

MAINTENANCE

0 - 17

Fig.

7 Positive

Crankcase

Ventilation

System—Typical

SYSTEM OPERATION

Each PCV system is comprised of an air inlet filter,

a flow-control (PCV) valve, and the associated hoses.

The air inlet filter is located at the cylinder head cover (Fig. 7).

WARNING:

USE

EXTREME CAUTION WHEN

THE

ENGINE

IS

OPERATING.

DO NOT PUT

YOUR

HANDS NEAR

THE

DRIVE BELT(S), PULLEYS

OR

FAN BLADE.

DO NOT

STAND

IN A

DIRECT LINE

WITH

THE FAN

BLADE.

(1) With the engine idling, accelerate momen

tarily. The valve shaft counterweight should move CLOCKWISE.

(2) If no movement is observed, either the shaft is

binding or the thermostat spring is weak or broken. (3) If the thermostat spring is weak or broken, re

place the spring.

(4) Verify the manifold is COOL. Apply

MOPAR®Rust Penetrant (or an equivalent product)

to each end of the valve shaft at the bearings (Fig.

6).

(5) Allow the solvent to penetrate for a few min

utes.

Then, rotate the valve shaft back and forth un

til it turns without restriction.

AIR INJECTION SYSTEMS/AIR PUMP

Air injection system/air pump valves and switches

should be periodically tested for proper operation. In

spect the check valve tubing for corrosion. Replace it

if excessive corrosion exists.

CRANKCASE

VENTILATION

SYSTEM

All gasoline engines are equipped with a positive

crankcase ventilation (PCV) system. The PCV sys

tem prevents emission of residual engine oil vapor

from the crankcase (Fig. 7).

Page 39 of 1502

0

- 21

LUBRICATION

AND

MAINTENANCE

• SERVICE INFORMATION

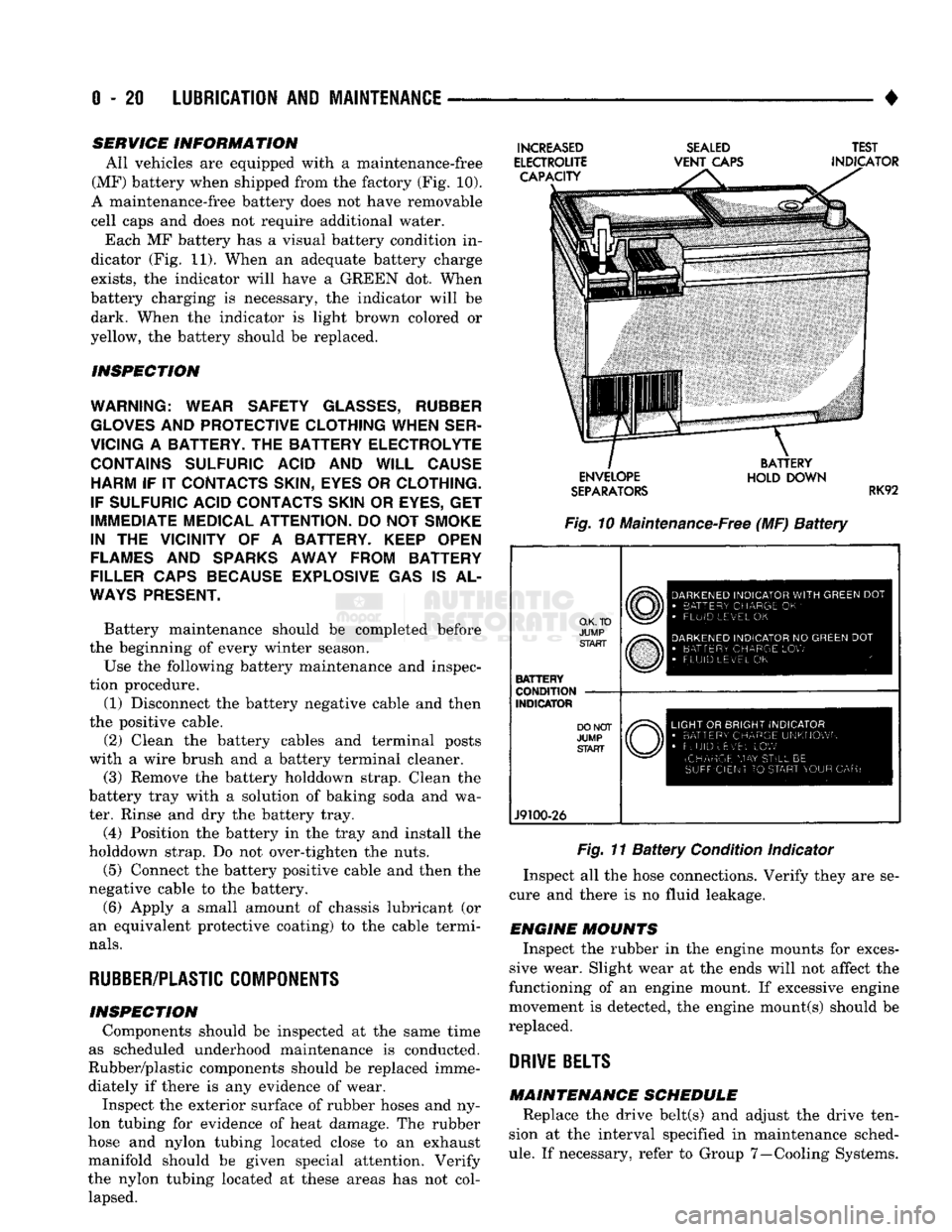

All vehicles are equipped with a maintenance-free

(MF) battery when shipped from the factory (Fig. 10).

A maintenance-free battery does not have removable

cell caps and does not require additional water. Each MF battery has a visual battery condition in

dicator (Fig. 11). When an adequate battery charge

exists,

the indicator will have a GREEN dot. When

battery charging is necessary, the indicator will be dark. When the indicator is light brown colored or

yellow, the battery should be replaced.

INSPECTION

WARNING; WEAR SAFETY

GLASSES,

RUBBER

GLOVES

AND

PROTECTIVE CLOTHING WHEN SER

VICING

A

BATTERY.

THE

BATTERY ELECTROLYTE CONTAINS SULFURIC ACID

AND

WILL CAUSE HARM

IF IT

CONTACTS SKIN, EYES

OR

CLOTHING.

IF SULFURIC ACID CONTACTS SKIN

OR

EYES,

GET

IMMEDIATE MEDICAL ATTENTION.

DO

NOT

SMOKE

IN

THE

VICINITY

OF A

BATTERY. KEEP OPEN

FLAMES

AND

SPARKS AWAY FROM BATTERY

FILLER CAPS BECAUSE EXPLOSIVE

GAS IS AL

WAYS

PRESENT.

Battery maintenance should be completed before

the beginning of every winter season.

Use the following battery maintenance and inspec

tion procedure. (1) Disconnect the battery negative cable and then

the positive cable.

(2) Clean the battery cables and terminal posts

with a wire brush and a battery terminal cleaner. (3) Remove the battery holddown strap. Clean the

battery tray with a solution of baking soda and wa

ter. Rinse and dry the battery tray.

(4) Position the battery in the tray and install the

holddown strap. Do not over-tighten the nuts.

(5) Connect the battery positive cable and then the

negative cable to the battery.

(6) Apply a small amount of chassis lubricant (or

an equivalent protective coating) to the cable termi

nals.

RUBBER/PLASTIC

COMPONENTS

INSPECTION Components should be inspected at the same time

as scheduled underhood maintenance is conducted.

Rubber/plastic components should be replaced imme diately if there is any evidence of wear. Inspect the exterior surface of rubber hoses and ny

lon tubing for evidence of heat damage. The rubber

hose and nylon tubing located close to an exhaust

manifold should be given special attention. Verify

the nylon tubing located at these areas has not col lapsed.

INCREASED

ELECTROUTE CAPACITY

SEALED

VENT

CAPS TEST

INDICATOR ENVELOPE

SEPARATORS

BATTERY

HOLD DOWN

RK92

Fig. 10 Maintenance-Free (MF)

Battery

O.K. TO

JUMP START

BATTERY

CONDITION

INDICATOR

J9100-26

DARKENED

INDICATOR

WITH

GREEN

DOT

•

BATTERY CHARGE

OK '

•

FLUID LEVEL

OK

DARKENED

INDICATOR

NO

GREEN

DOT

•

BATTERY CHARGE

LOW

FLUID LEVEL

OK

LIGHT

OR

BRIGHT INDICATOR

•

BATTERY CHARGE UNKNOWN

•

FLUID uEv'EL

LOW

(CHARGE

MAY

STILL

BE

SUFFICIENT

TO

START YOUR

CAR)

Fig. 11

Battery

Condition Indicator

Inspect all the hose connections. Verify they are se

cure and there is no fluid leakage.

ENGINE MOUNTS Inspect the rubber in the engine mounts for exces

sive wear. Slight wear at the ends will not affect the

functioning of an engine mount. If excessive engine

movement is detected, the engine mount(s) should be

replaced.

DRIVE

BELTS

MAINTENANCE SCHEDULE Replace the drive belt(s) and adjust the drive ten

sion at the interval specified in maintenance sched

ule.

If necessary, refer to Group 7—Cooling Systems.