steering FIAT 124 SPIDER 2017 2.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: 124 SPIDER, Model: FIAT 124 SPIDER 2017 2.GPages: 300, PDF Size: 121.24 MB

Page 159 of 300

Caution!

Changing to manual shift mode while

driving will not damage the transmission.

Note:

If you change to manual shift mode

when the vehicle is stopped, the gear

will shift to M1.

If you change to manual shift mode

while the vehicle is moving it will remain

in the current gear until a manual shift

request is made.

Indicators

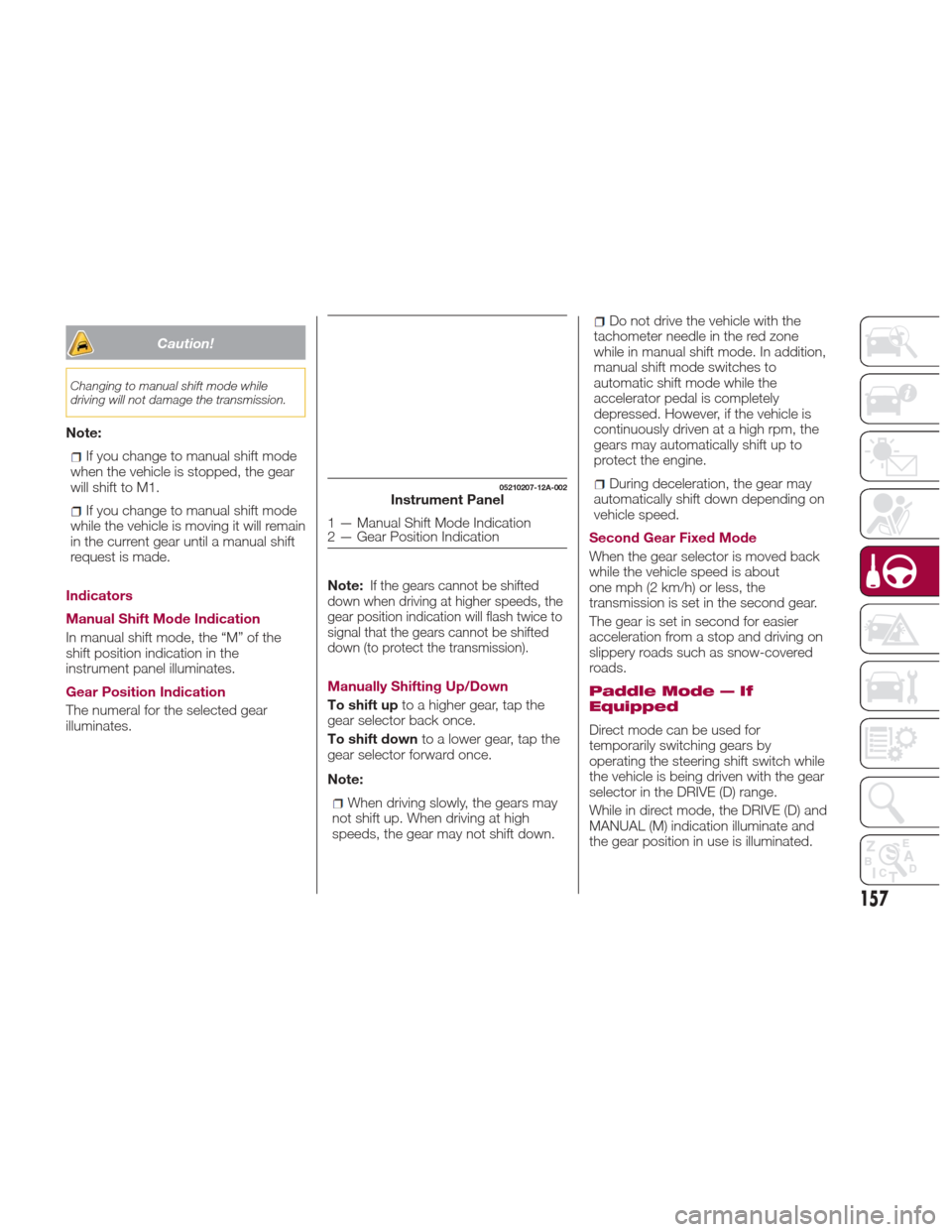

Manual Shift Mode Indication

In manual shift mode, the “M” of the

shift position indication in the

instrument panel illuminates.

Gear Position Indication

The numeral for the selected gear

illuminates. Note:

If the gears cannot be shifted

down when driving at higher speeds, the

gear position indication will flash twice to

signal that the gears cannot be shifted

down (to protect the transmission).

Manually Shifting Up/Down

To shift up to a higher gear, tap the

gear selector back once.

To shift down to a lower gear, tap the

gear selector forward once.

Note:

When driving slowly, the gears may

not shift up. When driving at high

speeds, the gear may not shift down.

Do not drive the vehicle with the

tachometer needle in the red zone

while in manual shift mode. In addition,

manual shift mode switches to

automatic shift mode while the

accelerator pedal is completely

depressed. However, if the vehicle is

continuously driven at a high rpm, the

gears may automatically shift up to

protect the engine.

During deceleration, the gear may

automatically shift down depending on

vehicle speed.

Second Gear Fixed Mode

When the gear selector is moved back

while the vehicle speed is about

one mph (2 km/h) or less, the

transmission is set in the second gear.

The gear is set in second for easier

acceleration from a stop and driving on

slippery roads such as snow-covered

roads.

Paddle Mode — If

Equipped

Direct mode can be used for

temporarily switching gears by

operating the steering shift switch while

the vehicle is being driven with the gear

selector in the DRIVE (D) range.

While in direct mode, the DRIVE (D) and

MANUAL (M) indication illuminate and

the gear position in use is illuminated.

05210207-12A-002Instrument Panel

1 — Manual Shift Mode Indication

2 — Gear Position Indication

157

Page 171 of 300

Note:If it is difficult to see the display

under the following conditions, it does

notmeanthatthisisduetoa

malfunction:

In dark areas.

When the temperature around the

lens is particularly high/low.

When the camera is wet from rain

or due to a high atmospheric humidity.

When there is some foreign deposit

around the camera, for example mud.

When the camera lens reflects

sunlight or a headlight beam.

The image on the display may be

delayed if the temperature around the

camera is low.

Caution!

To avoid vehicle damage, ParkView

should only be used as a parking aid. The

ParkView camera is unable to view every

obstacle or object in your drive path.

To avoid vehicle damage, the vehicle

must be driven slowly when using ParkView

to be able to stop in time when an obstacle

is seen. It is recommended that the driver

look frequently over his/her shoulder when

using ParkView.

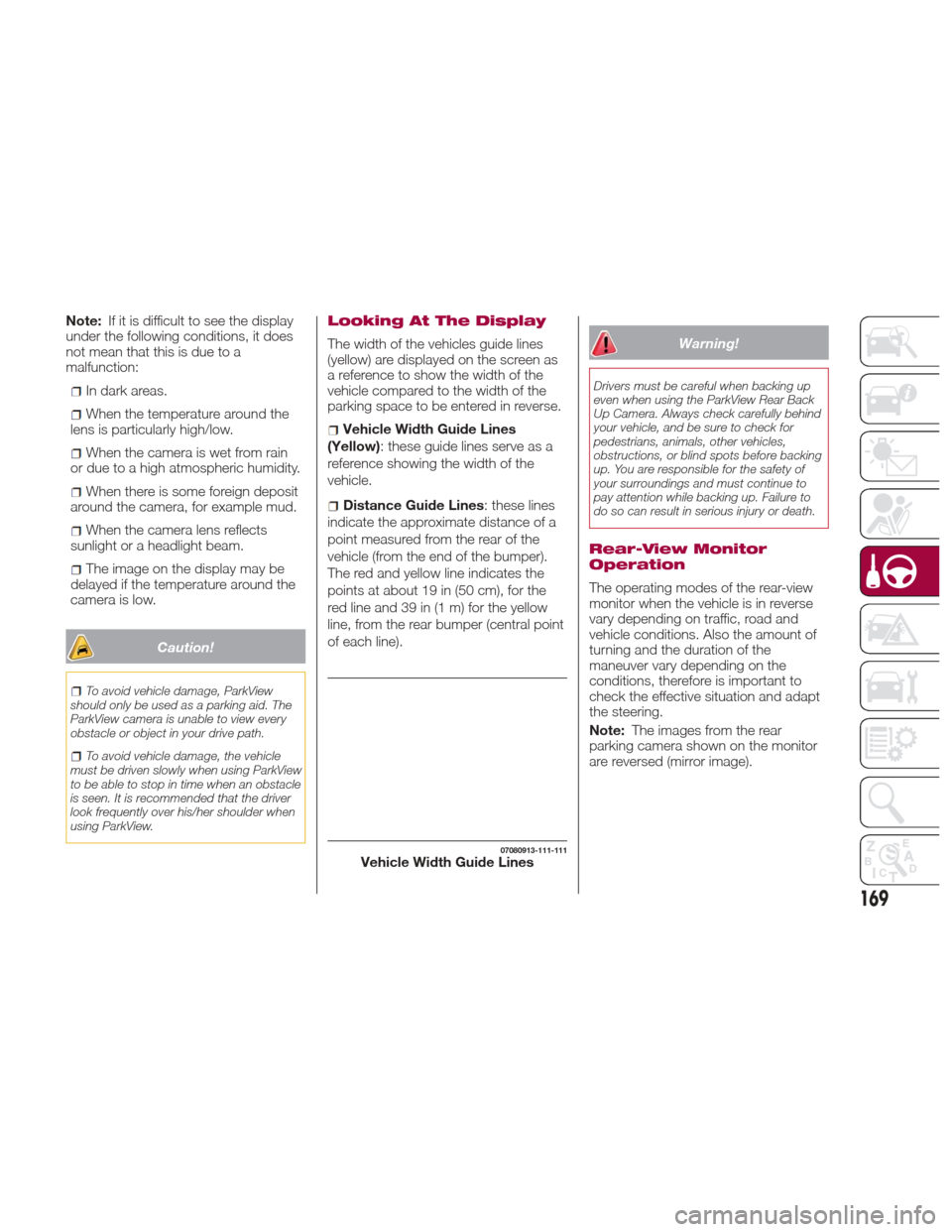

Looking At The Display

The width of the vehicles guide lines

(yellow) are displayed on the screen as

a reference to show the width of the

vehicle compared to the width of the

parking space to be entered in reverse.

Vehicle Width Guide Lines

(Yellow): these guide lines serve as a

reference showing the width of the

vehicle.

Distance Guide Lines : these lines

indicate the approximate distance of a

point measured from the rear of the

vehicle (from the end of the bumper).

The red and yellow line indicates the

pointsatabout19in(50cm),forthe

red line and 39 in (1 m) for the yellow

line, from the rear bumper (central point

of each line).

Warning!

Drivers must be careful when backing up

even when using the ParkView Rear Back

Up Camera. Always check carefully behind

your vehicle, and be sure to check for

pedestrians, animals, other vehicles,

obstructions, or blind spots before backing

up. You are responsible for the safety of

your surroundings and must continue to

pay attention while backing up. Failure to

do so can result in serious injury or death.

Rear-View Monitor

Operation

The operating modes of the rear-view

monitor when the vehicle is in reverse

vary depending on traffic, road and

vehicle conditions. Also the amount of

turning and the duration of the

maneuver vary depending on the

conditions, therefore is important to

check the effective situation and adapt

the steering.

Note: The images from the rear

parking camera shown on the monitor

are reversed (mirror image).

07080913-111-111Vehicle Width Guide Lines

169

Page 172 of 300

Give consideration to the below

information before you use the

rear-view camera:

1. Put the gear selector in the Reverse

(R) position to switch the display to

rear-view camera mode.

2. Check the surrounding conditions

and begin backing up.3. Once the vehicle starts to enter the

parking space, proceed slowly in

reverse keeping the vehicle width guide

lines away from the two sides of the

parking space.

4. Continue to make corrections with

the steering wheel until the vehicle

width guide lines are parallel with the

two sides of the parking space.

5. Once they are parallel, straighten the

steering wheel and reverse slowly into

the parking space. Continue to check

the vehicle’s surroundings and stop in

the best position possible (if the parking

space has dividing lines, check that the

vehicle width guide lines are parallel

with them).

6. When the gear selector is moved

from the Reverse (R) position and put in

any other position, the screen returns to

the previous display mode.

Note:

Since there may be some differences

between the displayed image, as

indicated below, and the real

conditions, always check with your own

GUID-07080913989989Entering Parking Spot

A — Rear Camera View

B — Check Surrounding Area

GUID-07080913990990Entering Parking Spot

A — Rear Camera View

B — Check Surrounding Area

170

STARTING AND OPERATING

Page 190 of 300

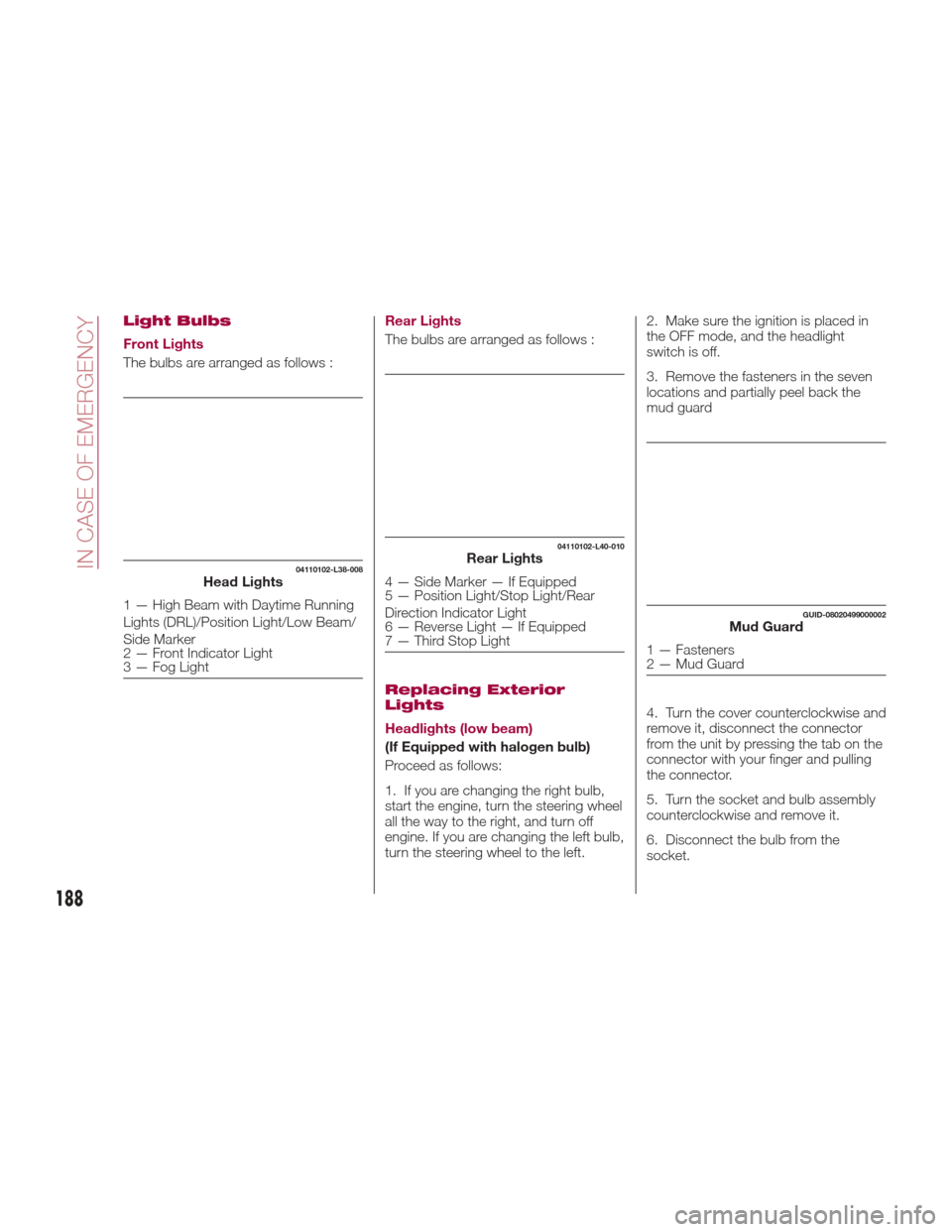

Light Bulbs

Front Lights

The bulbs are arranged as follows :Rear Lights

The bulbs are arranged as follows :

Replacing Exterior

Lights

Headlights (low beam)

(If Equipped with halogen bulb)

Proceed as follows:

1. If you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left.2. Make sure the ignition is placed in

the OFF mode, and the headlight

switch is off.

3. Remove the fasteners in the seven

locations and partially peel back the

mud guard

4. Turn the cover counterclockwise and

remove it, disconnect the connector

from the unit by pressing the tab on the

connector with your finger and pulling

the connector.

5. Turn the socket and bulb assembly

counterclockwise and remove it.

6. Disconnect the bulb from the

socket.

04110102-L38-008Head Lights

1 — High Beam with Daytime Running

Lights (DRL)/Position Light/Low Beam/

Side Marker

2 — Front Indicator Light

3 — Fog Light

04110102-L40-010Rear Lights

4 — Side Marker — If Equipped

5 — Position Light/Stop Light/Rear

Direction Indicator Light

6 — Reverse Light — If Equipped

7 — Third Stop Light

GUID-08020499000002Mud Guard

1 — Fasteners

2 — Mud Guard

188

IN CASE OF EMERGENCY

Page 191 of 300

7. Install the new bulb in the reverse

order of the removal procedure.

Headlights (high beam) with

Daytime Running Lights

(If Equipped with LED Lamps)

Proceed as follows:

1. If you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left.

2. Make sure the ignition is placed in

the OFF mode, and the headlight

switch is off.

3. Remove the fasteners in the seven

locations and partially peel back the

mud guard.

4. Turn the socket and bulb assembly

counterclockwise and remove it.

5. Turn the cover counterclockwise and

remove it, disconnect the connector

from the unit by pressing the tab on the

connector with your finger and pulling

the connector.

6. Turn the socket and bulb assembly

counterclockwise and remove it.

7. Disconnect the bulb from the

socket.

8. Install the new bulb in the reverse

order of the removal procedure.Front Direction Indicator Lights

Proceed as follows:

1. If you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left.

2. Make sure the ignition is switched

off, and the headlight switch is off.

3. Remove the fasteners in the five

locations and partially peel back the

mud guard.

4. Disconnect the connector from the

unit by pressing the tab on the

connector with your finger and pulling

the connector rearward.

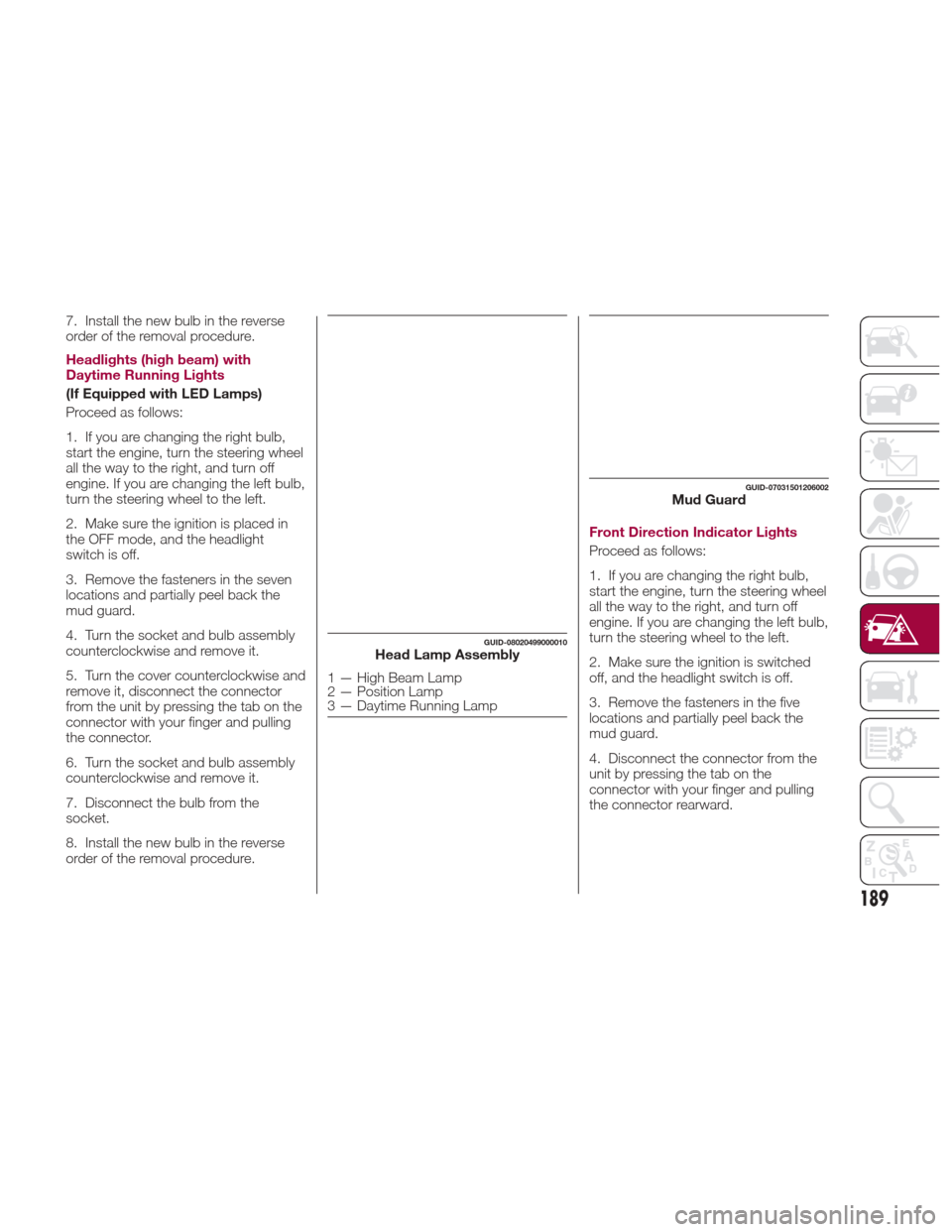

GUID-08020499000010Head Lamp Assembly

1 — High Beam Lamp

2 — Position Lamp

3 — Daytime Running Lamp

GUID-07031501206002Mud Guard

189

Page 192 of 300

5. Turn the socket and bulb assembly

counterclockwise and remove it.

6. Disconnect the bulb from the

socket.7. Install the new bulb in the reverse

order of the removal procedure.

Fog Lights

Proceed as follows:

1. If you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left.

2. Make sure the ignition is switched

off, and the headlight switch is off.

3. Remove the fasteners in the five

locations and partially peel back the

mud guard.

4. Disconnect the connector from the

unit by pressing the tab on the

connector with your finger and pulling

the connector.

5. Turn the socket and bulb assembly

counterclockwise, extract the bulb and

remove it;

6. Disconnect the bulb from the

socket.

7. Install the new bulb in the reverse

order of the removal procedure.Brake lights / Tail lights

Go to your authorized dealer when the

replacement of this lights is necessary.

Side Direction Indicator Lights

Proceed as follows:

1. Make sure the ignition is placed in

the OFF mode, and the headlight

switch is off.

2. If you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left.

3. Remove the fasteners in the five

locations and partially peel back the

mud guard.

4. Disconnect the electrical connector

from the bulb by pressing the tab on

the connector with your finger and

pulling the connector.

5. Remove the lens assembly by

pressing the tab on the unit with your

finger and pulling the unit forward to

compress in the internal catch, then pull

the cluster outwards.

6. Lift up the lens assembly, and then

remove the cluster and install the new

side direction indicator lens assembly in

the reverse order of the removal

procedure.

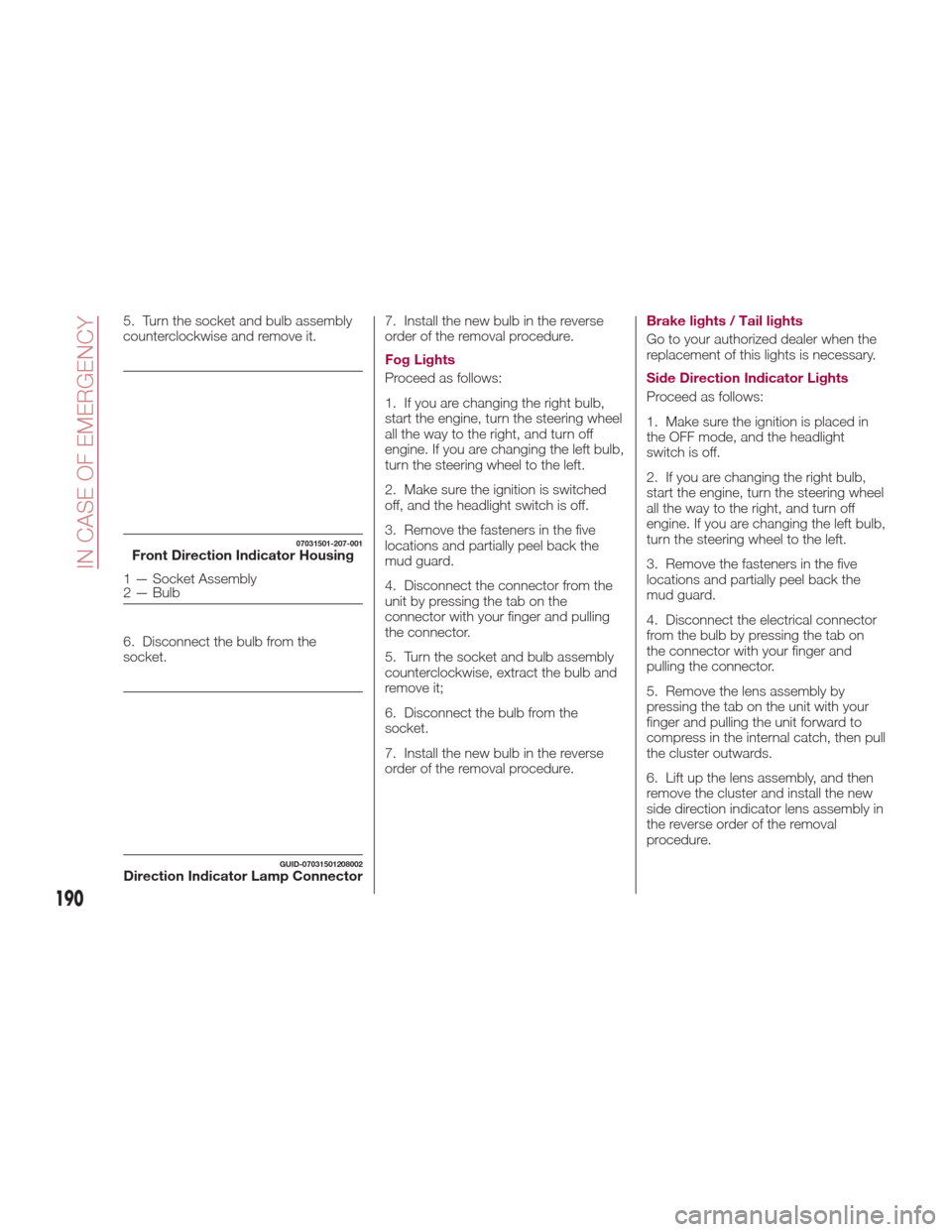

07031501-207-001Front Direction Indicator Housing

1 — Socket Assembly

2 — Bulb

GUID-07031501208002Direction Indicator Lamp Connector

190

IN CASE OF EMERGENCY

Page 198 of 300

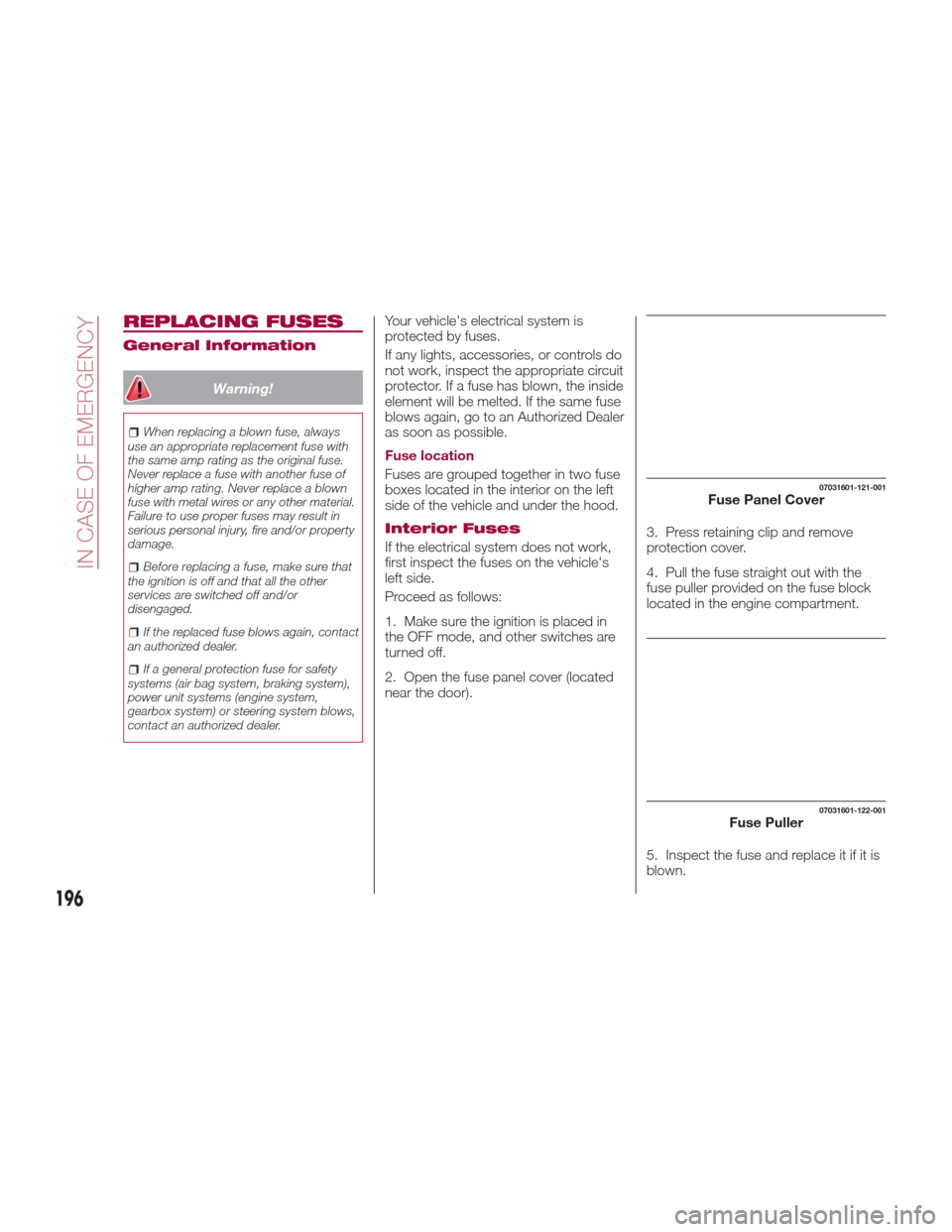

REPLACING FUSES

General Information

Warning!

When replacing a blown fuse, always

use an appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a blown

fuse with metal wires or any other material.

Failure to use proper fuses may result in

serious personal injury, fire and/or property

damage.

Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or

disengaged.

If the replaced fuse blows again, contact

an authorized dealer.

If a general protection fuse for safety

systems (air bag system, braking system),

power unit systems (engine system,

gearbox system) or steering system blows,

contact an authorized dealer.

Your vehicle's electrical system is

protected by fuses.

If any lights, accessories, or controls do

not work, inspect the appropriate circuit

protector. If a fuse has blown, the inside

element will be melted. If the same fuse

blows again, go to an Authorized Dealer

as soon as possible.

Fuse location

Fuses are grouped together in two fuse

boxes located in the interior on the left

side of the vehicle and under the hood.

Interior Fuses

If the electrical system does not work,

first inspect the fuses on the vehicle's

left side.

Proceed as follows:

1. Make sure the ignition is placed in

the OFF mode, and other switches are

turned off.

2. Open the fuse panel cover (located

near the door). 3. Press retaining clip and remove

protection cover.

4. Pull the fuse straight out with the

fuse puller provided on the fuse block

located in the engine compartment.

5. Inspect the fuse and replace it if it is

blown.

07031601-121-001Fuse Panel Cover

07031601-122-001Fuse Puller

196

IN CASE OF EMERGENCY

Page 202 of 300

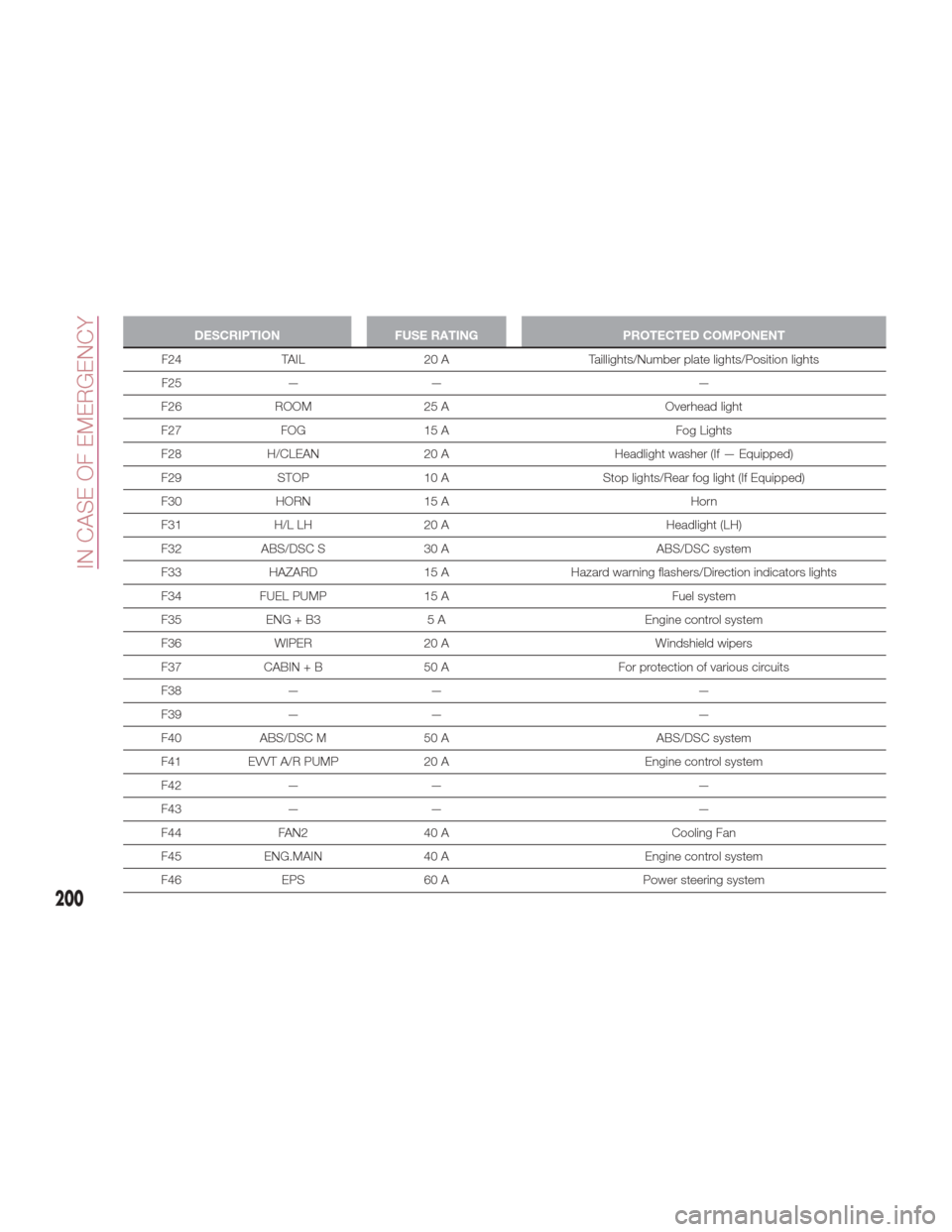

DESCRIPTIONFUSE RATING PROTECTED COMPONENT

F24 TAIL 20 A Taillights/Number plate lights/Position lights

F25

— — —

F26 ROOM 25 A Overhead light

F27 FOG 15 A Fog Lights

F28 H/CLEAN 20 A Headlight washer (If — Equipped)

F29 STOP 10 A Stop lights/Rear fog light (If Equipped)

F30 HORN 15 A Horn

F31 H/L LH 20 A Headlight (LH)

F32 ABS/DSC S 30 A ABS/DSC system

F33 HAZARD 15 AHazard warning flashers/Direction indicators lights

F34 FUEL PUMP 15 A Fuel system

F35 ENG + B3 5 A Engine control system

F36 WIPER 20 A Windshield wipers

F37 CABIN + B 50 A For protection of various circuits

F38 — — —

F39 — — —

F40 ABS/DSC M 50 A ABS/DSC system

F41 EVVT A/R PUMP 20 A Engine control system

F42 — — —

F43 — — —

F44 FAN2 40 A Cooling Fan

F45 ENG.MAIN 40 A Engine control system

F46 EPS 60 A Power steering system

200

IN CASE OF EMERGENCY

Page 215 of 300

Warning!

Never use the air compressor above

43.5 psi (3 Bar). Using the air compressor

at an inflation pressure above 3 Bar

(43.5 psi) continuously is dangerous. If the

air compressor overheats, hot air will be

exhausted and you could get burned.

Caution!

If the tire inflation pressure does not

increase, repair of the tire is not possible. If

the tire does not reach the specified tire

inflation pressure within 10 minutes, it may

have received extensive damage. In this

case, the repair using the tire service kit

was not successful.

Do not operate the air compressor for a

continuous 10 minutes or longer because

using it for long periods could cause a

malfunction.

13. Adhere the speed restriction sticker

to an area where it can be viewed easily

by the driver.

Warning!

Do not adhere the speed restriction sticker

to the padded area on the steering wheel.

Adhering the speed restriction sticker to

the padded area on the steering wheel is

dangerous because the air bag may not

operate (deploy) normally resulting in

serious injury. In addition, do not adhere

the sticker to areas where warning lights or

the speedometer cannot be viewed.

14. Adhere the repaired tire sticker to

the wheel of the flat tire.

15. When the tire inflates to the

specified tire inflation pressure, turn the

air compressor switch off, turn the

sleeve of the injection hose to the left,

and pull it out of the tire valve. 16. Remove the air compressor hose

from the injection valve of the bottle.

Then, install the injection hose to the

injection valve of the bottle to prevent

leakage of any remaining sealant.

Note:

The remaining sealant in the

hose may spray out when the hose is

removed. Remove the hose carefully

because you may not be able to

remove the sealant contacting clothing

or other objects.

17. Install the tire valve cap.

18. Place the tire service kit back into

its storage location.

19. Start driving immediately to spread

the sealant in the tire.

08020202-031-667Repaired Tire Sticker

08020202-031-668Install Injection Hose To Sealant Bottle

213

Page 219 of 300

13. Reinsert the valve core into the

valve and turn it clockwise to install.

Note:

The tire sealant cannot be reused.

If the tire sealant kit has been used, or

is expired, purchase new one at an

Authorized Dealer.

Do not throw away the empty tire

sealant bottle after use. Return the

empty tire sealant bottle to an

Authorized Dealer when replacing the

tire. The empty tire sealant bottle will

need to be used to extract and dispose

of the used sealant from the tire.

14. Install the injection hose to the tab

of the bottle to prevent leakage of any

remaining sealant.

15. Adhere the speed restriction sticker

to an area where it can be viewed easily

by the driver.

Warning!

Do not adhere the speed restriction sticker

to the padded area on the steering wheel.

Adhering the speed restriction sticker to

the padded area on the steering wheel is

dangerous because the air bag may not

operate (deploy) normally resulting in

serious injury. In addition, do not adhere

the sticker to areas where warning lights or

the speedometer cannot be viewed.

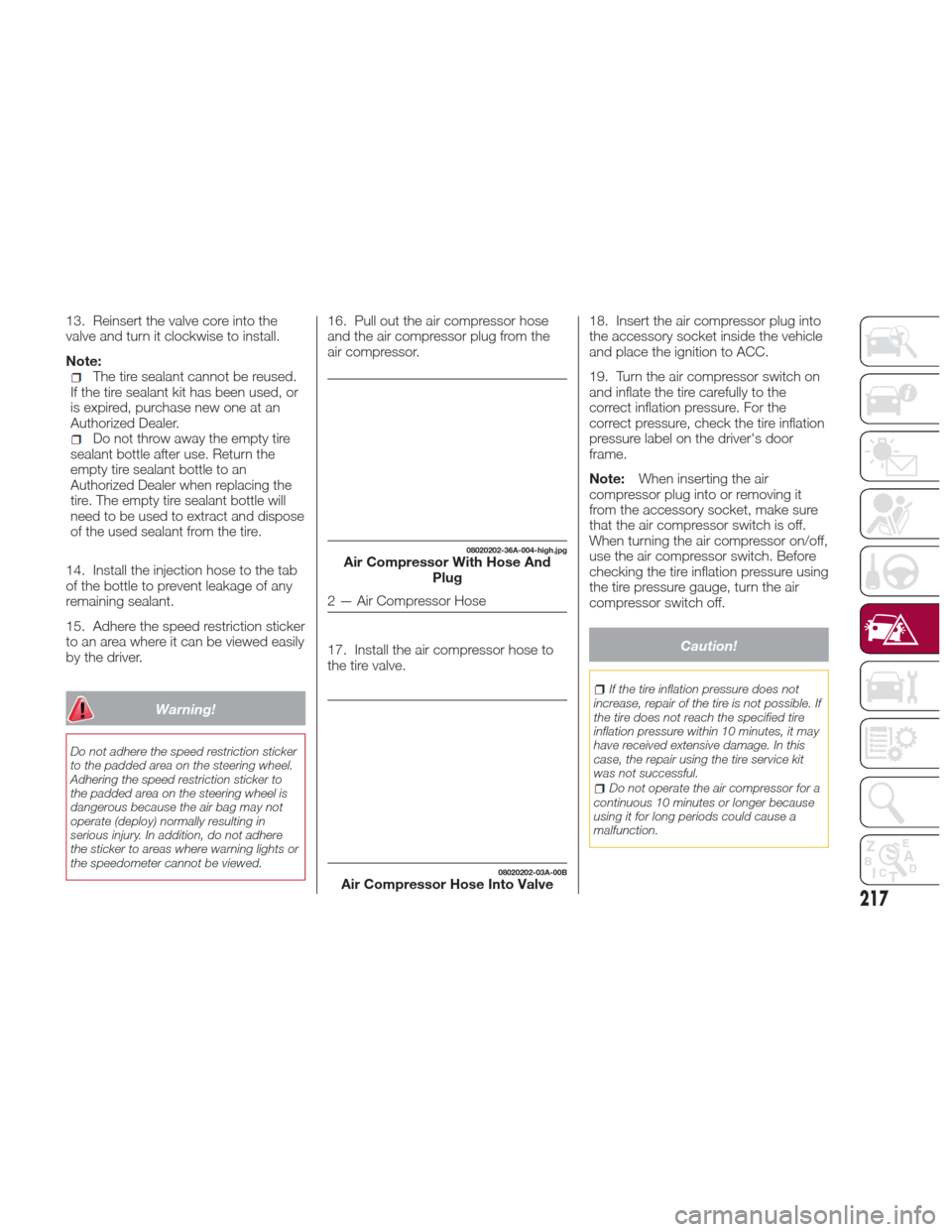

16. Pull out the air compressor hose

and the air compressor plug from the

air compressor.

17. Install the air compressor hose to

the tire valve. 18. Insert the air compressor plug into

the accessory socket inside the vehicle

and place the ignition to ACC.

19. Turn the air compressor switch on

and inflate the tire carefully to the

correct inflation pressure. For the

correct pressure, check the tire inflation

pressure label on the driver's door

frame.

Note:

When inserting the air

compressor plug into or removing it

from the accessory socket, make sure

that the air compressor switch is off.

When turning the air compressor on/off,

use the air compressor switch. Before

checking the tire inflation pressure using

the tire pressure gauge, turn the air

compressor switch off.

Caution!

If the tire inflation pressure does not

increase, repair of the tire is not possible. If

the tire does not reach the specified tire

inflation pressure within 10 minutes, it may

have received extensive damage. In this

case, the repair using the tire service kit

was not successful.

Do not operate the air compressor for a

continuous 10 minutes or longer because

using it for long periods could cause a

malfunction.

08020202-36A-004-high.jpgAir Compressor With Hose And Plug

2 — Air Compressor Hose

08020202-03A-00BAir Compressor Hose Into Valve

217