ECO mode FIAT 127 1979 2.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1979, Model line: 127, Model: FIAT 127 1979 2.GPages: 34, PDF Size: 6.87 MB

Page 8 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

8/34

Air correction jet 0.0728 in (1.85 mm)

Slow running jet 0.0177 in (0.45 mm)

Emulsion tube type F74

Accelerator pump jet 0.0157 in (0.40 mm)

Needle valve seat 0.0591 in (1.50 mm)

Accelerator pump output (10 strokes) 2 to 3 cm

3

Cold starting device Automatic choke

Float level 1.4016 to 1.4213 in (35.6 to 36. 1 mm)

CO level 2.5%

Solex C32 TDI/4 carburettor (C, L and CL models)

Venturi diameter 0.8465 in (21.5 mm)

Main jet 0.0453 in (1.15 mm)

Air correction jet 0.0768 in (1.95 mm)

Slow running jet 0.0177 in (0.45 mm)

Emulsion tube type 71

Accelerator pump jet 0.0177 in (0.45 mm)

Needle valve seat 0.0630 in (1.60 mm)

Accelerator pump output I10 strokes) 3 to 5 cm

3

Cold starting device Automatic choke

Float level 0.8661 to 0.9449 in (22.0 to 24. 0 mm)

CO level 2.5%

Weber 34 DMTR 47/250 carburettor (Sport models) Primary venturi Secondary venturi

Venturi diameter 0.8661 in (22.0 mm) 0.9449 in (24.0 mm)

Main jet 0.0421 in (1.07 mm) 0.0500 in (1. 27 mm)

Air correction jet 0.0728 in (1.85 mm) 0.086 6 in (2.20 mm)

Slow running jet 0.0177 in (0.45 mm) 0.0276 in (0. 70 mm)

Slow running air bleed 0.0413 in (1.05 mm) 0.027 6 in (0.70 mm)

Accelerator pump jet 0.0157 in (0.40 mm) ---

Needle valve seat 0.0689 in (1.75 mm)

Accelerator pump output (10 strokes) 8.55 cm

3

Cold starting device Manually operated strangler ch oke

Float level 0.2657 to 0.2854 in (6.75 to 7.25 mm)

Fuel pump

Output 75 litres/hr (16.5 gal/hr)

Actuating lever stroke (C, L and CL) 2.4 to 2.6 mm (0.0949 to 0.1024 in)

Actuating lever stroke (Sport) 2.4 to 2.9 mm (0.09 49 to 0.1142 in)

Delivery pressure at 4000 engine rpm 0.17 kgf/cm2 (2.55 Ibf/in2)

and fuel temp 30°C (86°F)

lgnition system

Distributor

Type and code Magneti Marelli S155HX

Automatic centrifugal advance 25° ± 2° at 4500 rpm

Condenser capacity (50 to 1000 Hz) 0.20 to 0.25 µF

Clutch

Lining outer diameter 181.5 mm (7.146 in)

Lining inner diameter 127.0 mm (5.0 in)

Page 9 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

9/34

Maximum run-out of driven plate linings 0.2 mm (0.008 in)

Travel of release flange, corresponding

to a pressure plate displacement of not less

than 0.067 in ~1.7 mm) 8.5 mm (0.3346 in)

Transmission

Synchromesh 1st and 2nd, Borg-Warner baulk ring type,

3rd and 4th, Porsche spring ring type

Gear ratios

First 3.910 : 1

Second 2.055 : 1

Third 1.348 : 1

Fourth 0.963 : 1

Reverse 3.615 : 1

Final drive ratio (C,L and CL) 4.071 : 1 (14/57)

Final drive ratio (Sport) 4.462 : 1 (13/58)

Overall ratios

Gears 1st 2nd 3rd 4th Reverse

C, L and CL 15.92 8.7 5.49 3.92 14.72

Sport 17.45 9.17 6.01 4.30 16.13

Electrical system

Alternator

Type (C, L and CL) Magneti Marelli AA 108-14V-33A

Type (Sport) Lucas 18ACR-A4V-45A

Maximum output (approx) 570 watts

Maximum current (approx) 40 amps (C, L and CL) 50 amps (Sport)

Cut-in speed at 12V and 20°C (68°F) 1050 to 1150 r pm (C, L and CL)

1100 to 1200 rpm (Sport)

Field winding resistance across slip rings at 20°C (68°F) 3.4 to 3.8 ohms (C, L and CL)

3.18 to 3.22 ohms (Sport)

Direction of rotation (drive end) Clockwise

Engine/alternator drive ratio 1.8 : 1

Alternator regulator (C, L and CL models)

Type Magneti Marelli RTT 110 AB

Alternator speed for adjustment 6000 rpm

Current for thermal balance 20 amps

Regulating voltage 14.2

+0.3

–0.2 volts

Page 32 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

32/34

altering the throttle speed screw.

16 On earlier carburettors, or if new components

have been fitted to carburettors having a

tamperproof screw, then the slow-running and

mixture can be altered, but only if an exhaust

gas analyser is available in the case of later

carburettors, after the tamperproof cap has been

broken off.

17 On earlier units, use a device such as a

mixture adjustment aid or a vacuum gauge fitted

in accordance with the manufacturers'

instructions to obtain the correct slow-running

adjustment.

18 On later units, an exhaust gas analyser,

again used in accordance with the maker's

instructions, will ensure that the CO level is

within the limits specified. Fit a new tamperproof

cap on completion.

Weber dual venturi carburettor

Removal and refitting

19 These operations are similar to the

operations described in paragraphs 3 to 9 of this

Section, but the unit is of manually operated

choke design and will therefore not have coolant

hose attachments. A choke cable is fitted

instead.

Dismantling and adjustment

20 The operations are similar to those described

for the single venturi type carburettor, once the

upper body has been removed (six screws).

21 If jets are extracted, identify them as to which

side of the carburettor (primary or secondary)

they came from.

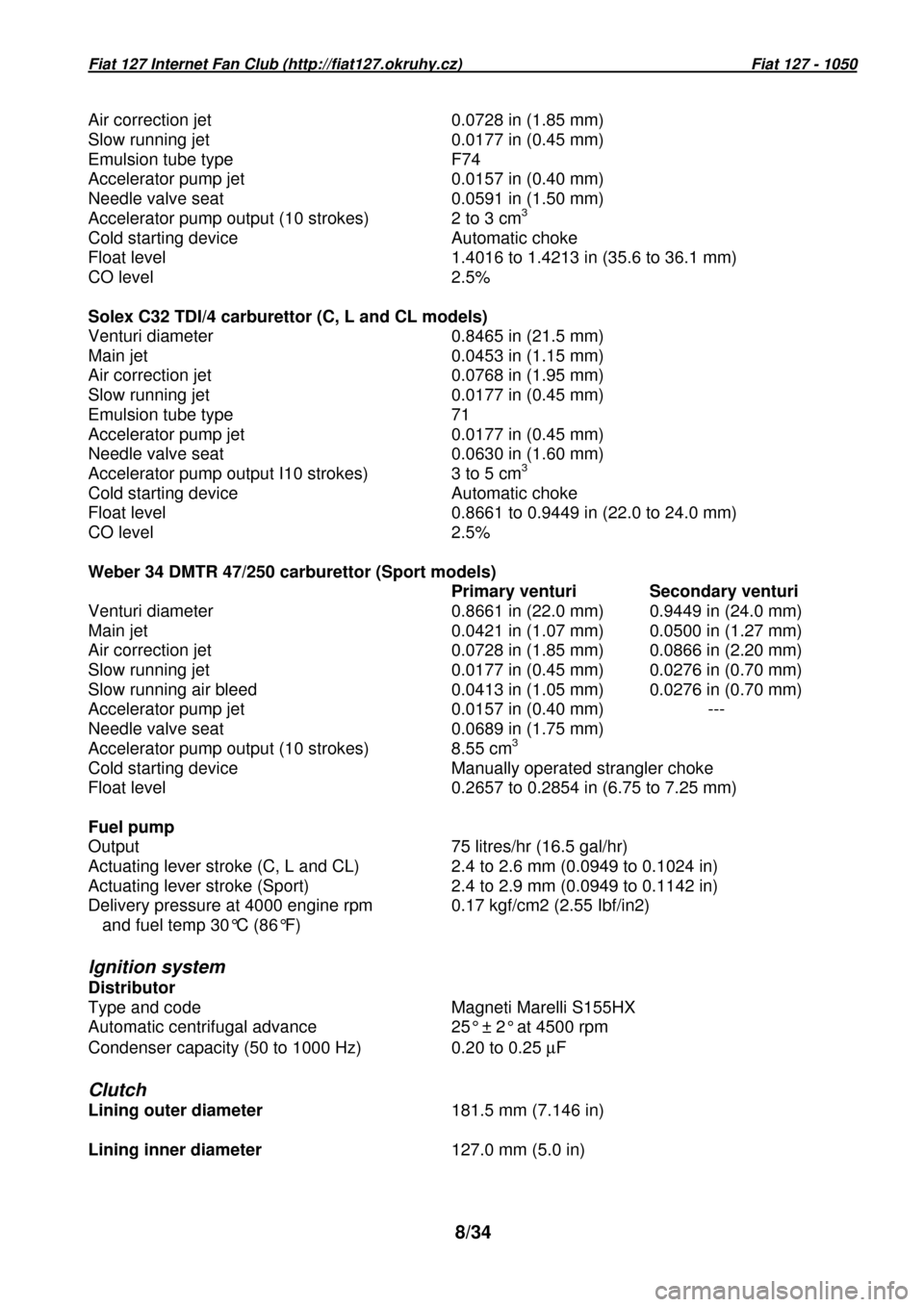

4.4 Throttle cable connection to Weber single ventu ri

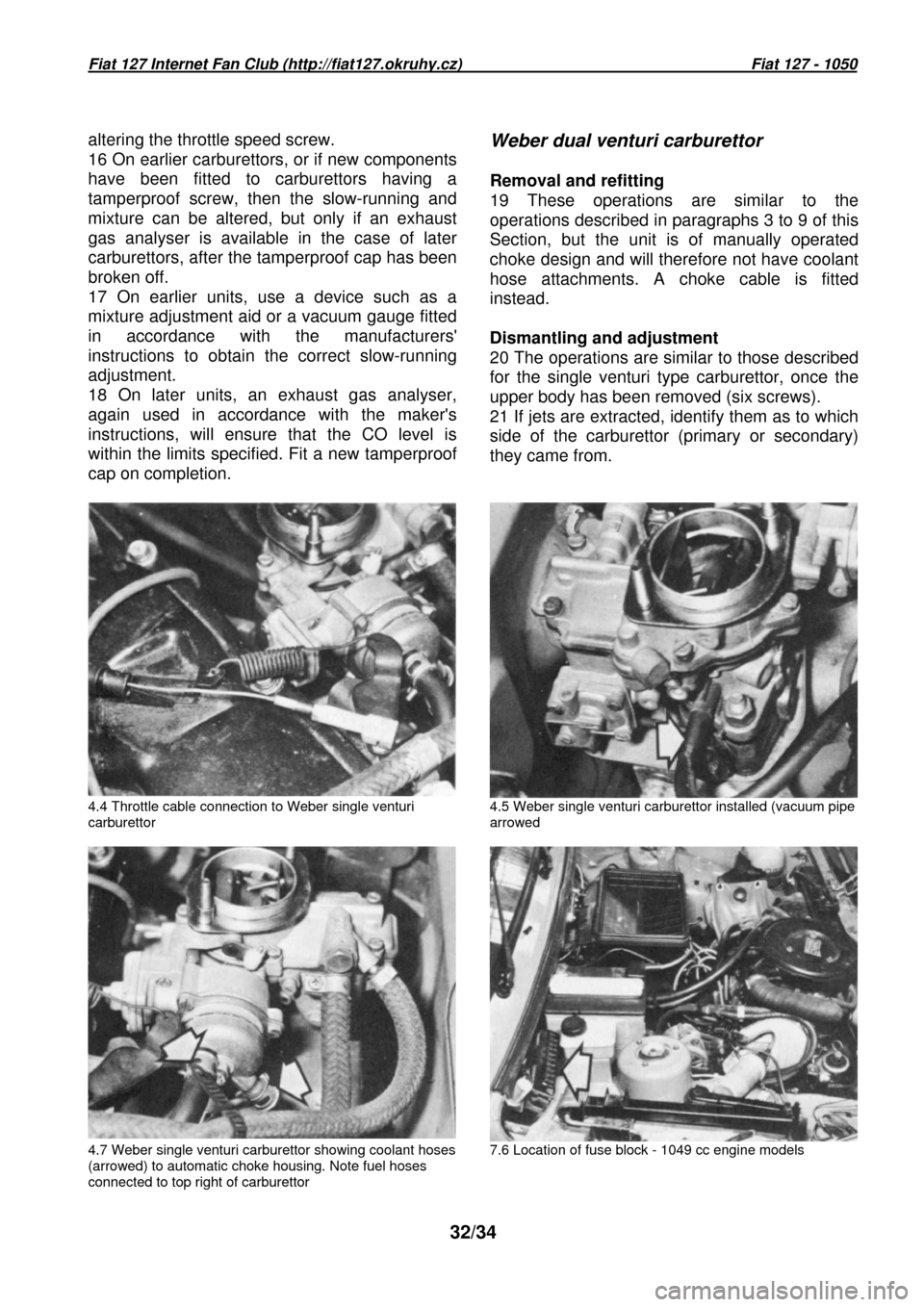

carburettor 4.5 Weber single venturi carburettor installed (va

cuum pipe

arrowed

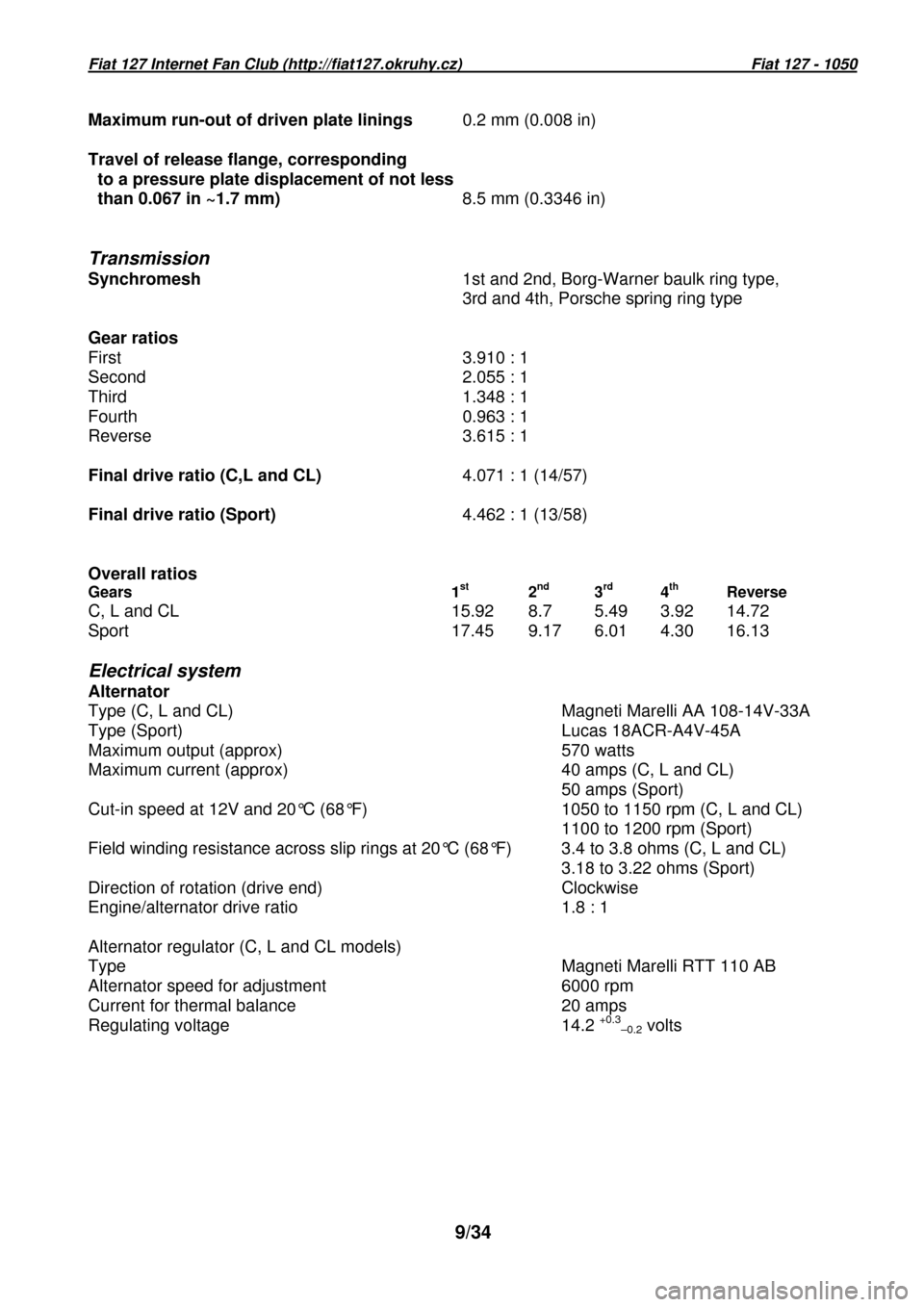

4.7 Weber single venturi carburettor showing coolan t hoses

(arrowed) to automatic choke housing. Note fuel hos es

connected to top right of carburettor 7.6 Location of fuse block - 1049 cc engine models