torque FIAT 500 1961 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1961, Model line: 500, Model: FIAT 500 1961 1.GPages: 128, PDF Size: 9.01 MB

Page 56 of 128

lubricated using Fiat Jota 3 grease.

1 Pressure plate—boss outer faces.

2 Clutch cover—withdrawal lever fulcrum.

3 Withdrawal lever stopnuts—contact face.

4 Withdrawal lever carrier ring — lever contact face.

5 Crankcase end pilot bushing lubricated with Fiat KG.15

grease.

6 Lubricate contact faces of driven plate and clutch shaft.

To install the clutch assembly proceed as follows:

1 Ensure t h a t there is no grease or oil on the faces of the

driven plate or flywheel face and position with the

raised part of the hub towards the transmission unit.

2 Locate Fiat tool A.70085 (diaphragm clutch) or

A . 6 2 0 2 3 (coil spring clutch) or a suitably sized drift,

through the driven plate hub and position in crankshaft

pilot bushing. Gradually tighten the clutch unit

mounting screws working diagonally and finally tighten

to a torque wrench setting of 5.8 to 7.2 Ib ft.

5 : 6 Pilot bushing

Whenever the clutch unit is being renewed or over-

hauled it is essential that the crankshaft pilot bush is

checked for excessive wear or damage. Also check that

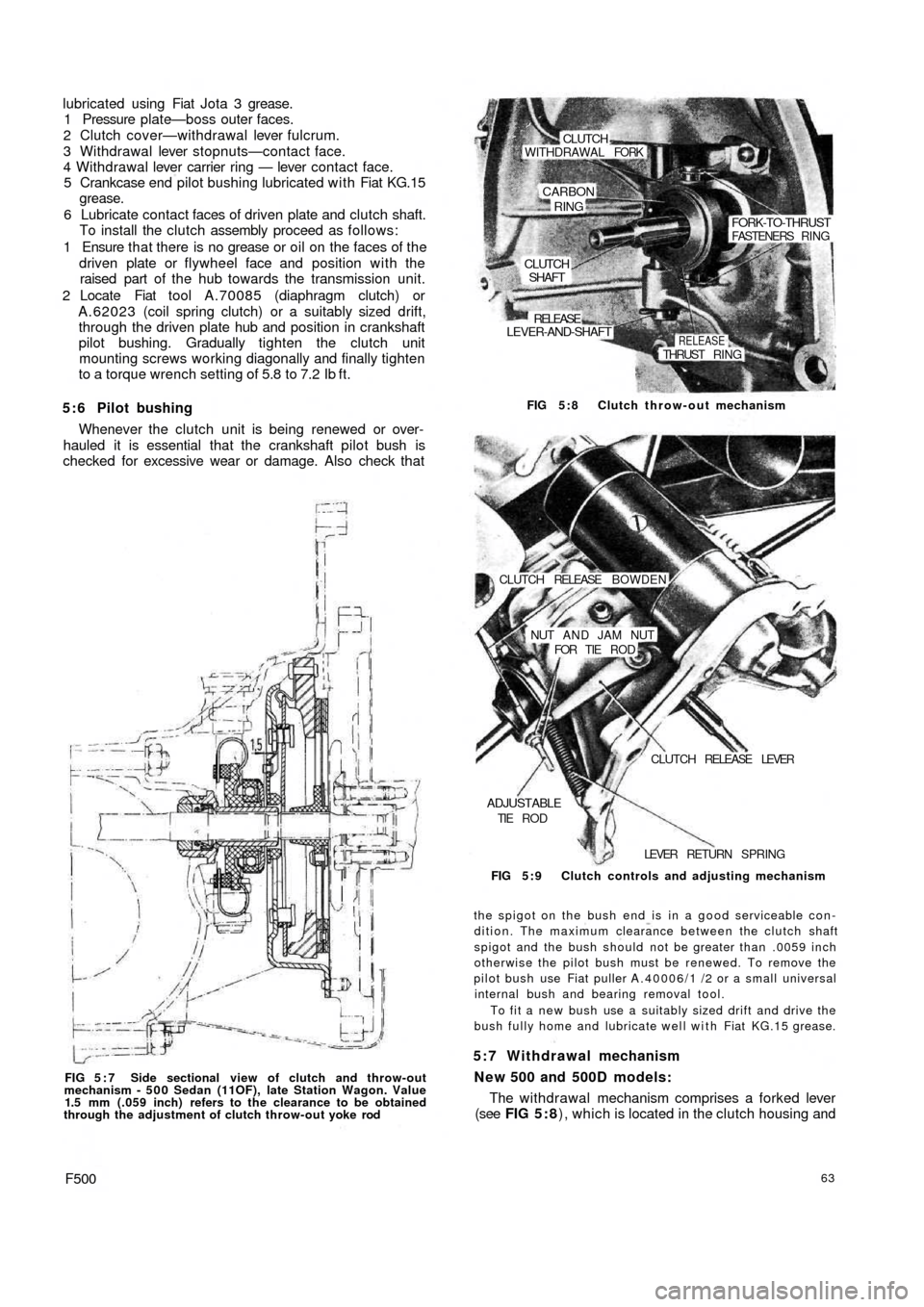

FIG 5 : 7 Side sectional view of clutch and throw-out

mechanism - 5 0 0 Sedan (11OF), late Station Wagon. Value

1.5 mm (.059 inch) refers to the clearance to be obtained

through the adjustment of clutch throw-out yoke rod

F50063

The withdrawal mechanism comprises a forked lever

(see FIG 5 : 8), which is located in the clutch housing and 5:7 Withdrawal mechanism

New 500 and 500D models:

the spigot on the bush end is in a good serviceable con-

dition. The maximum clearance between the clutch shaft

spigot and the bush should not be greater than .0059 inch

otherwise the pilot bush must be renewed. To remove the

pilot bush use Fiat puller A.40006/1 /2 or a small universal

internal bush and bearing removal tool.

To fit a new bush use a suitably sized drift and drive the

bush fully home and lubricate well with Fiat KG.15 grease. FIG 5 : 9 Clutch controls and adjusting mechanism LEVER RETURN SPRING

ADJUSTABLETIE R O DCLUTCH RELEASE LEVER NUT A N D JAM NUT

FOR TIE R O D CLUTCH RELEASE BOWDEN FIG 5:8 Clutch throw-out mechanism

CLUTCHSHAFT

LEVER-AND-SHAFT

RELEASE

RELEASETHRUST RING

FORK-TO-THRUSTFASTENERS RING

CARBON

RING

WITHDRAWAL FORKCLUTCH

Page 63 of 128

3 Check the layshaft and the primary shaft between

centres and using a dial gauge ensure that there is no

distortion. The out of true reading for bearing seats

should be less than .0008 inch. Inspect the splines and

ensure that the side and outerfaces are not indented.

Replace if there are signs of wear. Also inspect the

reverse shaft to ensure that it is perfectly smooth and

not showing signs of pitting or partial seizure.

4 Carefully inspect all gear teeth for signs of excessive

wear or damage. The contact faces must be smooth and

show no signs of indentation marks. Also check that

the backlash between the gears, when correctly

mounted on the surface plate is not greater than .0039

inch. The maximum wear limit is .0079 inch. Check that

the quick engagement front teeth of the second-, third-

and fourth-speed gears are not damaged or excessively

worn. Renew if there are signs of gearchange lever

misuse.

5 Inspect the sliding sleeves and the relevent hubs, ensure

that all the working surfaces are perfectly smooth. The

clearance between the mating parts should not be

greater than .0059 inch. Also inspect the meshing teeth

and ensure that they are in good condition.

6 Check that the gear shifting selector forks are not dis-

torted and that the striker rods freely slide in their seats

in the gearbox casing.

7 Carefully inspect that all the oil seals are in perfect con-

dition and if there is any doubt they should be renewed.

8 Inspect the striker rod locking balls and the safety rollers

and ensure that they slide freely in their seatings. Also

check the ball load spring efficiency and if this shows

signs of weakness then it should be renewed. Any

faults with these items will cause difficulty in engaging

gears or autodisengagement during engine acceleration.

6 : 4 Reassembly—gearbox

To reassemble the components to the gearbox ensure

that all components are thoroughly clean and then pro-

ceed as follows:

1 Press t h e pinion rear roller bearing onto the layshaft.

Install the layshaft in the casing, and at the same time

fit the adjustment shim, the fourth-speed driven gear

together w i t h its bush, the sleeve and hub for third and

fourth gear engagement, the first-speed and reverse

driven gear and the third-speed driven gear with its

hub.

2 Install the front layshaft ballbearing securing the

bearing retainment plate w i t h the screws and finally

lock the screws in position.

3 Insert the primary shaft together with the first, third

and fourth driving gear train in the gearbox housing

and slide t h e rear bearing onto the shaft. Push the

input shaft forward to enable the clutch shaft coupling

to be inserted in t h e rear and to be pulled up the

primary shaft by means of the pin. Do not forget the

retaining ring.

4 Slide the primary shaft backwards so pushing the rear

bearing into its bore. Refit the front bearing onto the

primary shaft.

5 On the layshaft insert the second-speed driven shaft

and bush, the second gear sliding dog sleeve and the

hub. Also insert the second-speed striker rod and the

first-speed fork. Do not forget to fit the safety roller

into its seating.

70

6 Slide the second-speed driving gear onto the primary

shaft. Place the engagement fork on the third- and

fourth-speed engagement sliding sleeve, and insert

the striker rod, lock the relevent fork and fit the safety

roller.

7 Insert the third safety roller and install the reverse shaft

and insert the reverse gear cluster onto it and secure

the shaft by tightening its block bolt. Install the reverse

striker rod w i t h its relevent fork.

8 Now refit the speedometer drive worm gear onto the

layshraft. Tighten the nuts on the primary shaft and the

layshaft, not forgetting to interpose the plain washer

between the speedometer driving worm and the nut,

to a torque wrench setting of 1 8.1 Ib ft to 25.3 Ib ft

(primary shaft) and 28.9 to 36.2 Ib ft (layshaft). It is

recommended that the input shaft and layshaft are

locked together by engaging t w o gears at the same

time. Finally, fit the splitpins.

9 Lock the shifter forks onto their shafts by tightening

their respective bolts and bend up the special locking

plates. Install the three positioning balls and relevant

springs into their bores and refit the cover plate.

10 Install the casing cover together with its relevant

gasket. This will enable correct positioning of the shift

shaft lever so that it engages in the outer ends of the

shifter shafts protruding from the gearbox casing.

11 Install the speedometer drive support on the gearbox

casing and refit the upper gearbox cover.

For subsequent differential operations and adjustments

see Sections 6:6.

6:5 Dismantling—differential and final drive

For the removal of the differential and final drive unit

from the gearbox refer to Section 6:3. To dismantle the

differential assembly

proceed as follows:

1 Remove the retaining ring 2 (see FIG 6 : 7) retaining

the splined sleeve 4 and slide the sleeve off the drive

shaft.

2 Remove t h e retaining covers 7 and the oil boots all

together with the bushes and seals, adjuster ring lock

rings 13, adjuster rings housing 14, and bearing

adjuster and roller bearing outer races.

3 Separate the differential housing halves by unscrewing

and removing the six bolts that keep both the halves and

the crownwheel together. It is advisable to mark the

respective components to ensure correct matching

upon reassembly.

4 Remove the differential pinion shaft retainer ring, also

the differential pinions 10 by removing the shaft and

withdrawing the two axle shafts 1.

5 Remove the differential side gears 6 and relevent thrust

rings 8.

6 Using a press remove the differential bearing inner

races from their seats on the carrier halves.

7 Thoroughly clean all parts and dry using a compressed

air jet.

Inspection:

The components of the differential unit must be

thoroughly inspected for correct operation and to deter-

mine the presence of any wear, damage or other irregulari-

ties. To check the items concerned proceed as follows:

1 Check thoroughly the idle pinion carrier shaft for signs

Page 64 of 128

of wear, distorting or unevenness of the surfaces as this

part is very heavily pressed when the vehicle is negotia-

ting a corner. If the clearance to the idle pinions exceeds

.0059 inch the shaft must be renewed.

2 Inspect the ring gear and pinion seat, the side gears.and

the idle pinions for correct meshing. This will be shown

up by white marks on the sides of the gear teeth. Check

that none of the teeth are broken, chipped or exces-

sively worn and if any part is suspect then it must be

renewed not forgetting that the ring gear and pinion

come as a matched pair.

3 Inspect the condition of the ball and roller bearings, the

rollers and balls and working faces must not show signs

of pitting wear or cracking and if any part is suspect then

the race must be renewed.

4 Check that there is not any undue wear on the faces of

the thrust rings. Any slight indentations may be evened

out using a fine oil stone but if the damage is excessive

then new rings or oversize rings must befitted as neces-

sary. Thrust rings are supplied as service spares in the

following thicknesses.

Standard .0394 inch

Oversize .0512-.0591 inch

6:6 Reassembly—differential unit

To reassemble the differential case proceed as follows:

1 Press onto the differential half housing which carries

the ring gear one differential bearing inner race ensuring

that it is pushed fully home onto its seating. Install the

thrust ring and side gear (see FIG 6 : 7).

2 From t h e inside of the case insert the axle shaft com-

plete with pivot and runners that form the slip joint.

Also install the idle pinions and carrier shaft. Position

the ring gear onto the housing half and install the

differential pinion shaft retainer ring.

3 Press the other differential bearing inner race onto its

seating on the left differential housing half and replace

the left axle shaft complete with slip joint.

4 J o i n the t w o case halves together and tighten the

retaining screws and also the retaining screws of the

ring gear to a torque wrench setting of 23.1 Ib ft. Secure

all screws by bending up the lockplates.

5 Press t h e differential bearing outer races into their

seatings in the bearing housings and also f i t the o i l seals.

Also install the bearing housings over the driving shafts

together with the adjuster rings.

6 Install the differential unit assembly into the final drive

housing front half and bolt the rear

half onto it. Tighten

the six mounting nuts to a torque wrench setting of

27.5 Ib ft. Finally place the bearing housings in their

seats and tighten the mounting nuts to a torque wrench

setting of 13 lb ft.

It should be noted that after the gearbox has been over-

hauled the complete differential unit should only be in-

stalled after the drive pinion depth adjustments has been

carried out.

6 : 7 Final drive gear set adjustment

The installation and adjustment of the final drive gear

set requires special care otherwise the unit may have to be

dismantled again for further adjustment. So as to establish

the correct mesh of the t w o gears, their relative position is

accurately set during initial assembly at the factory.

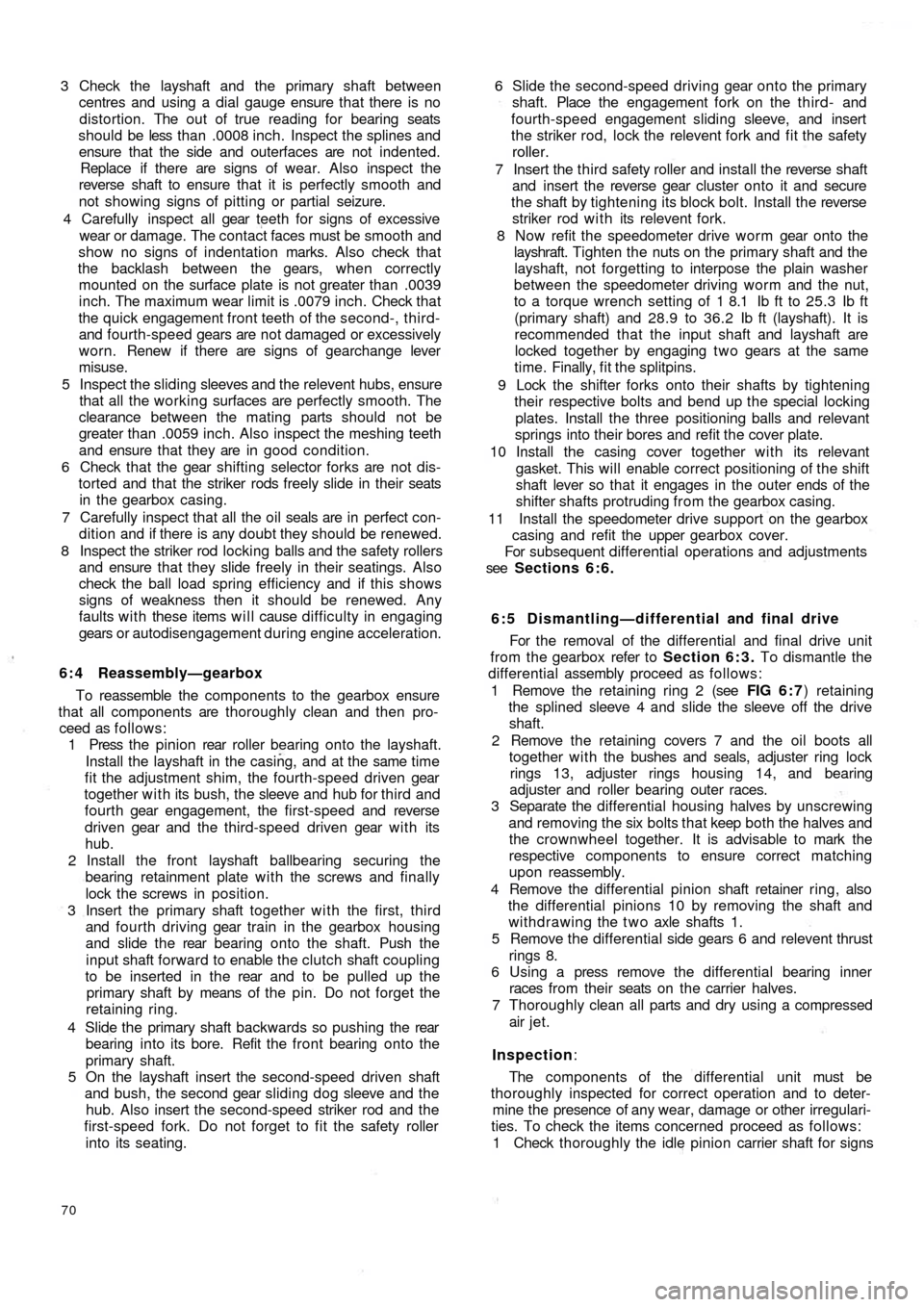

F50071 Refer to FIG 6 :8 where it will be seen that t w o numbers

are stamped on the pinion shaft near to the threaded end,

the upper number is the matching number which should

also appear on the crownwheel. The lower number indi-

cates the positive or negative deviation from the theoretical

distance between the centre line of the ring gear and the

pinion face. It is this number which must be taken into

account when calculating the adjusting shim thickness

which has to be fitted between the rear roller bearing and

the fourth-speed gear on the layshaft.

The formula from which the adjusting shim thickness

can be calculated is as follows:

S=A—(B + C)

Where S=shim thickness.

A= distance between the front bearing inner

race and the centre line of the ring gear.

B = distance of the drive pinion face to the ring

gear centre line.

C = t h e total of the widths of the third-speed

gear bush, third- and fourth-speed hub,

fourth-speed gear bush and rear roller

bearing inner race fitted onto the mainshaft

It should be noted that 'A' is the total of half the diameter

of the differential bearing housing seat which is in actual

fact 41.00 mm, and the distance measured between the

front bearing inner race and the differential bearing housing

seat. The last

dimension will have a minimum manufactu-

ring limit of 150.54 mm. Any deviation from this value

must be determined and considered when determining

the total shim thickness 'S'.

A= 150.54 + 41.00 + a (deviation)

To determine deviation 'a' Fiat tool A.62036 should be

assembled to the gearbox casing as shown in FIG 6 : 9

and to take the reading proceed as follows:

1 Assemble the front ballbearing and its retainer into the

gearbox housing and tighten the retainer bolts.

2 Hold the gearbox housing in the vertical position with

the differential side upwards and insert Fiat tool

A.62036 carefully from above into the bearing bore and

lock it firmly by tightening the knurled nut.

3 Using Fiat dial gauge C.689 which has been previously

zeroed on a surface plate should next be mounted

onto the t o p of Fiat tool A.62036 with its pointer resting

on the lowest position of the differential bearing hous-

ing bore as shown in FIG 6:10. To obtain the lowest

point move the pointer to both sides of the bottom dead

centre position so as to obtain the maximum reading.

The distance ' B ' in the formula for calculating the shim

thickness is designed to have a lower manufacturing limit

of 75 mm. Any deviation ' b ' is stamped on the drive pinion.

Therefore to calculate the value of ' B '

B = 7 5 + b (deviation)

The distance 'C' in the formula for calculating the shim

thickness is designed to have a lower manufacturing limit

FIG 6 : 8 Layshaft w i t h final drive pinion. The arrow

points to the number (14) for correct mating with ring

gear and to the centesimal figure (—10) for accurate

mating position of pinion and gear

Page 67 of 128

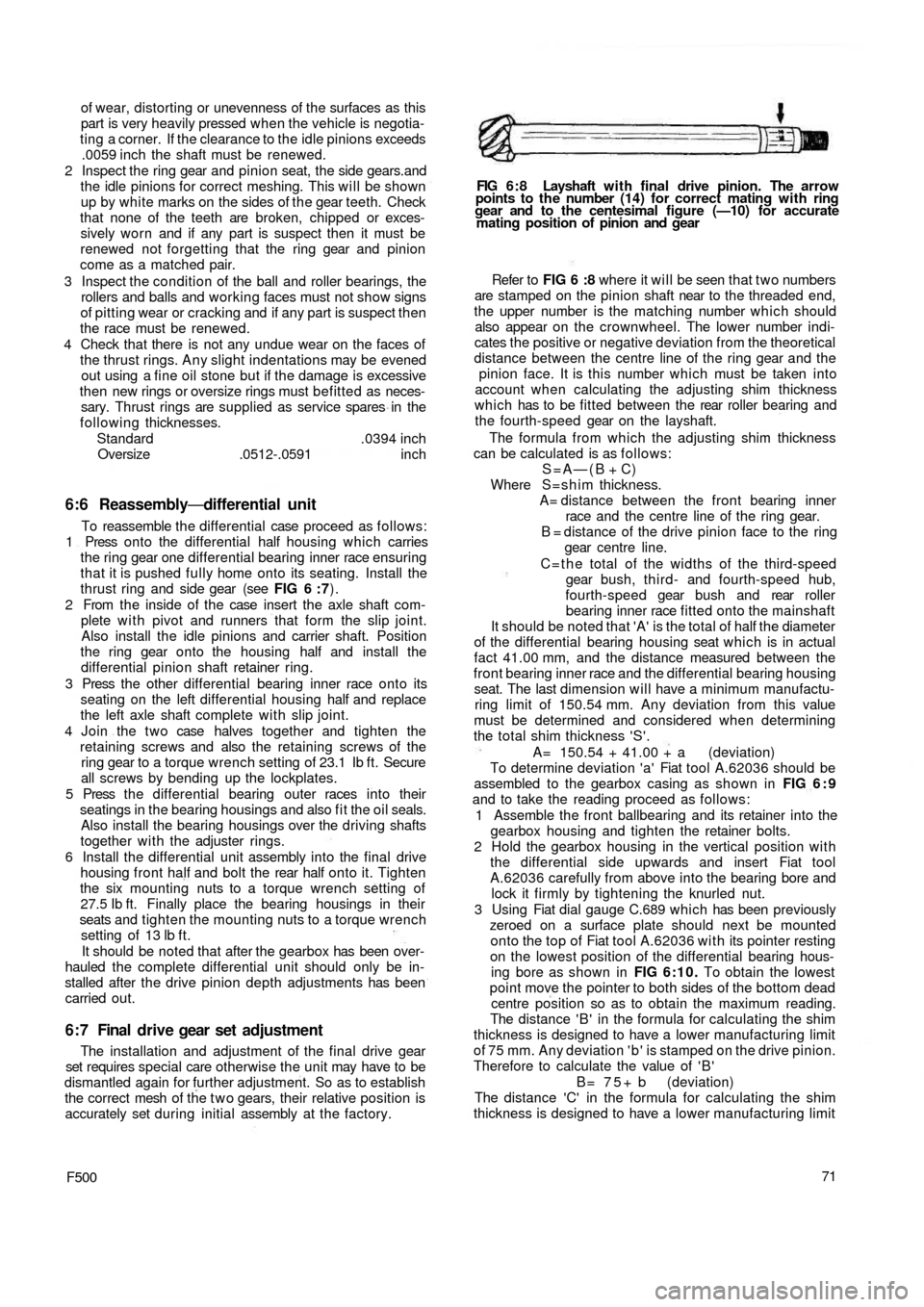

TOOL A 62039

TOOLA. 62040 PIN WRENCH A. 52022

FIG 6:15 Adjusting ring gear-to-pinion backlash and

differential bearing play, using special wrench A.52022

reading on the dial gauge should be between .0031 to

.0047 inch. The actual clearance is adjusted by

screwing in one adjusting nut and screwing out the

other by the equivalent amount using Fiat spanner

A.52022 as shown in FIG 6:15.

4 Remove Fiat tool A.62041 and using Fiat support

A.62040 mount the special dynamometer A.95697 and

adaptor on the axle shaft. Rotate the axle shaft several

turns so seating the bearings and then check using

the dynamometer the rotation torque.

5 If necessary tighten or slacken the adjusters until the

specified torque of 1.01 ± .07 lb ft is obtained. This

operation must be very carefully carried out because if

one adjuster is set differently with respect to the other,

a variation in ring gear to pinion backlash may take

place, resulting in a variation of rotation torque. After

any adjustments always recheck on the ring gear to

pinion backlash and if necessary readjust and then

repeat the rotation torque check.

6 Finally check the tooth contact between the pinion

and ring gear as detailed in the following instructions:

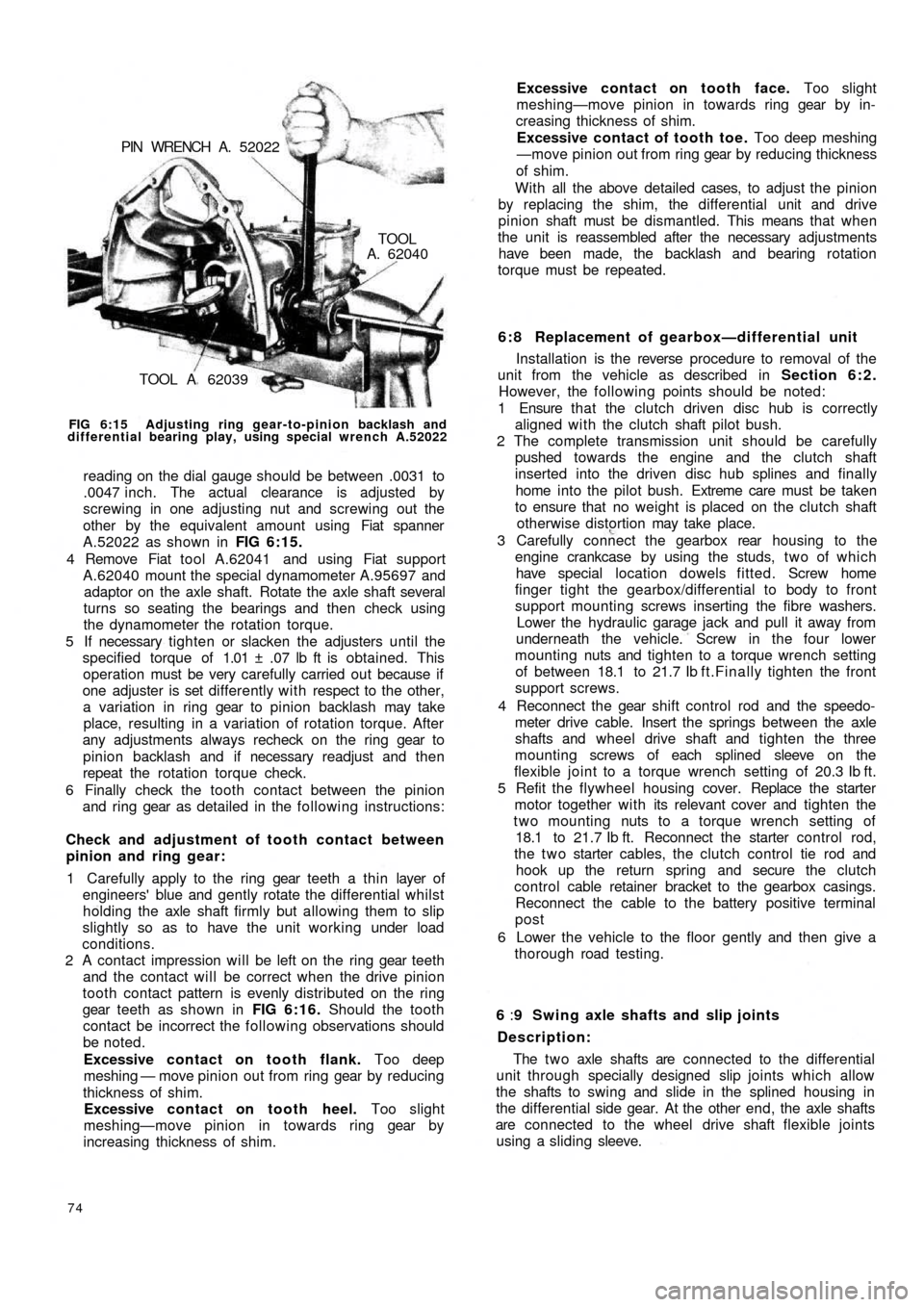

Check and adjustment of tooth contact between

pinion and ring gear:

1 Carefully apply to the ring gear teeth a thin layer of

engineers' blue and gently rotate the differential whilst

holding the axle shaft firmly but allowing them to slip

slightly so as to have the unit working under load

conditions.

2 A contact impression will be left on the ring gear teeth

and the contact will be correct when the drive pinion

tooth contact pattern is evenly distributed on the ring

gear teeth as shown in FIG 6:16. Should the tooth

contact be incorrect the following observations should

be noted.

Excessive contact on tooth flank. Too deep

meshing — move pinion out from ring gear by reducing

thickness of shim.

Excessive contact on tooth heel. Too slight

meshing—move pinion in towards ring gear by

increasing thickness of shim.

74

6 : 8 Replacement of gearbox—differential unit

Installation is the reverse procedure to removal of the

unit from the vehicle as described in Section 6:2.

However, the following points should be noted:

1 Ensure that the clutch driven disc hub is correctly

aligned with the clutch shaft pilot bush.

2 The complete transmission unit should be carefully

pushed towards the engine and the clutch shaft

inserted into the driven disc hub splines and finally

home into the pilot bush. Extreme care must be taken

to ensure that no weight is placed on the clutch shaft

otherwise distortion may take place.

3 Carefully connect the gearbox rear housing to the

engine crankcase by using the studs, t w o of which

have special location dowels fitted. Screw home

finger tight the gearbox/differential to body to front

support mounting screws inserting the fibre washers.

Lower the hydraulic garage jack and pull it away from

underneath the vehicle. Screw in the four lower

mounting nuts and tighten to a torque wrench setting

of between 18.1 to 21.7 Ib f t.Finally tighten the front

support screws.

4 Reconnect the gear shift control rod and the speedo-

meter drive cable. Insert the springs between the axle

shafts and wheel drive shaft and tighten the

three

mounting screws of each splined sleeve on the

flexible joint to a torque wrench setting of 20.3 Ib ft.

5 Refit the flywheel housing cover. Replace the starter

motor together with its relevant cover and tighten the

two mounting nuts to a torque wrench setting of

18.1 to 21.7 Ib ft. Reconnect the starter control rod,

the t w o starter cables, the clutch control tie rod and

hook up the return spring and secure the clutch

control cable retainer bracket to the gearbox casings.

Reconnect the cable to the battery positive terminal

post

6 Lower the vehicle to the floor gently and then give a

thorough road testing.

6 :9 Swing axle shafts and slip joints

Description:

The t w o axle shafts are connected to the differential

unit through specially designed slip joints which allow

the shafts to swing and slide in the splined housing in

the differential side gear. At the other end, the axle shafts

are connected to the wheel drive shaft flexible joints

using a sliding sleeve. Excessive contact on tooth face. Too slight

meshing—move pinion in towards ring gear by in-

creasing thickness of shim.

Excessive contact of tooth toe. Too deep meshing

—move pinion out from ring gear by reducing thickness

of shim.

With all the above detailed cases, to adjust the pinion

by replacing the shim, the differential unit and drive

pinion shaft must be dismantled. This means that when

the unit is reassembled after the necessary adjustments

have been made, the backlash and bearing rotation

torque must be repeated.

Page 75 of 128

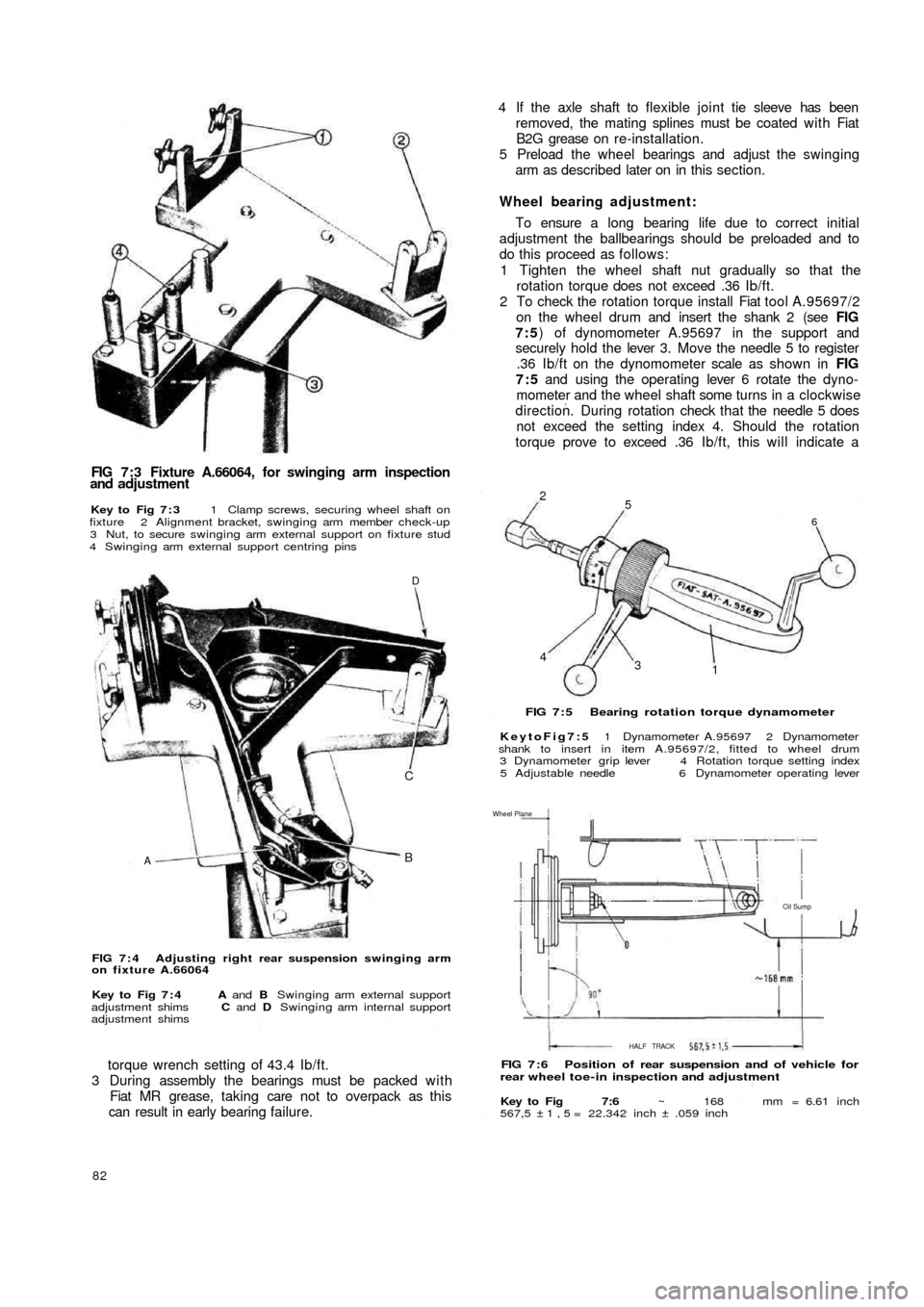

FIG 7 : 3 Fixture A.66064, for swinging arm inspection

and adjustment

Key to Fig 7 : 3 1 Clamp screws, securing wheel shaft on

fixture 2 Alignment bracket, swinging arm member check-up

3 Nut, to secure swinging arm external support on fixture stud

4 Swinging arm external support centring pins

AB C

D

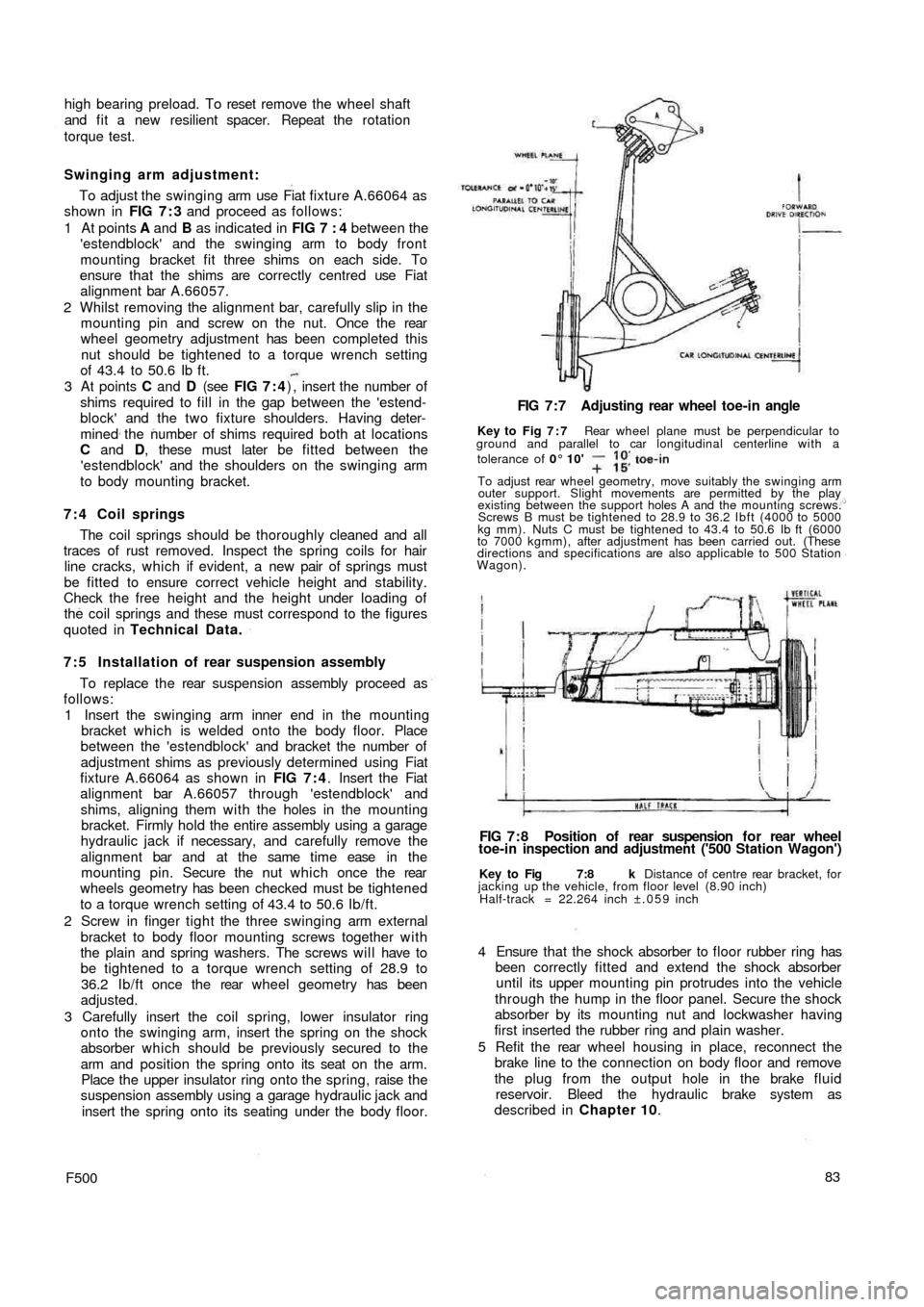

FIG 7 : 4 Adjusting right rear suspension swinging arm

on fixture A.66064

Key to Fig 7 : 4 A and B Swinging arm external support

adjustment shims C and D Swinging arm internal support

adjustment shims

torque wrench setting of 43.4 Ib/ft.

3 During assembly the bearings must be packed w i t h

Fiat MR grease, taking care not to overpack as this

can result in early bearing failure.

82

4 If the axle shaft to flexible joint tie sleeve has been

removed, the mating splines must be coated w i t h Fiat

B2G grease on re-installation.

5 Preload the wheel bearings and adjust the swinging

arm as described later on in this section.

Wheel bearing adjustment:

To ensure a long bearing life due to correct initial

adjustment the ballbearings should be preloaded and to

do this proceed as follows:

1 Tighten the wheel shaft nut gradually so that the

rotation torque does not exceed .36 Ib/ft.

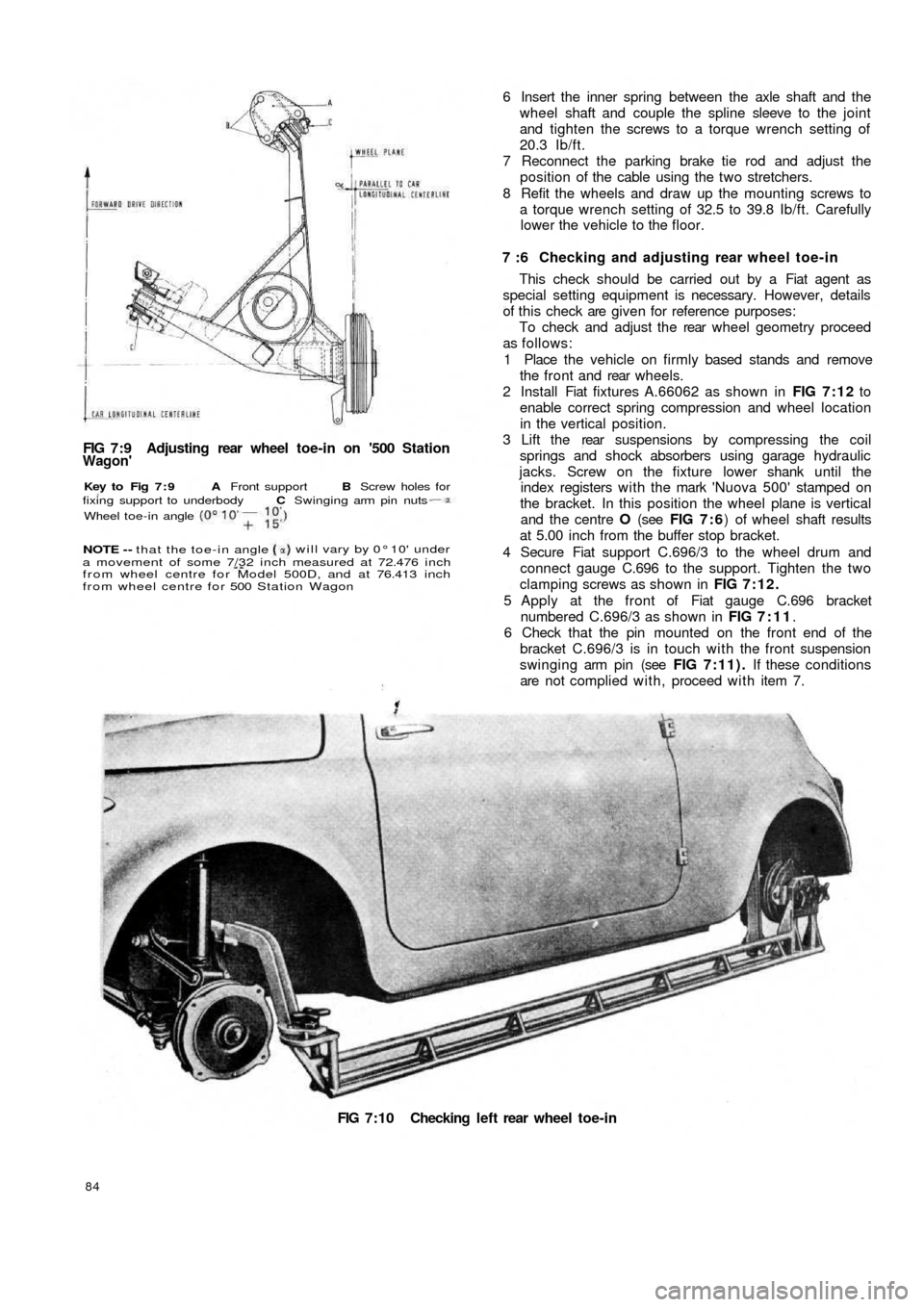

2 To check the rotation torque install Fiat tool A.95697/2

on the wheel drum and insert the shank 2 (see FIG

7:5) of dynomometer A.95697 in the support and

securely hold the lever 3. Move the needle 5 to register

.36 Ib/ft on the dynomometer scale as shown in FIG

7:5 and using the operating lever 6 rotate the dyno-

mometer and the wheel shaft some turns in a clockwise

direction. During rotation check that the needle 5 does

not exceed the setting index 4. Should the rotation

torque prove to exceed .36 Ib/ft, this will indicate a

4

3

1

6

5 2

FIG 7 : 5 Bearing rotation torque dynamometer

KeytoFig7:5 1 Dynamometer A.95697 2 Dynamometer

shank to insert in item A.95697/2, fitted to wheel drum

3 Dynamometer grip lever 4 Rotation torque setting index

5 Adjustable needle 6 Dynamometer operating lever

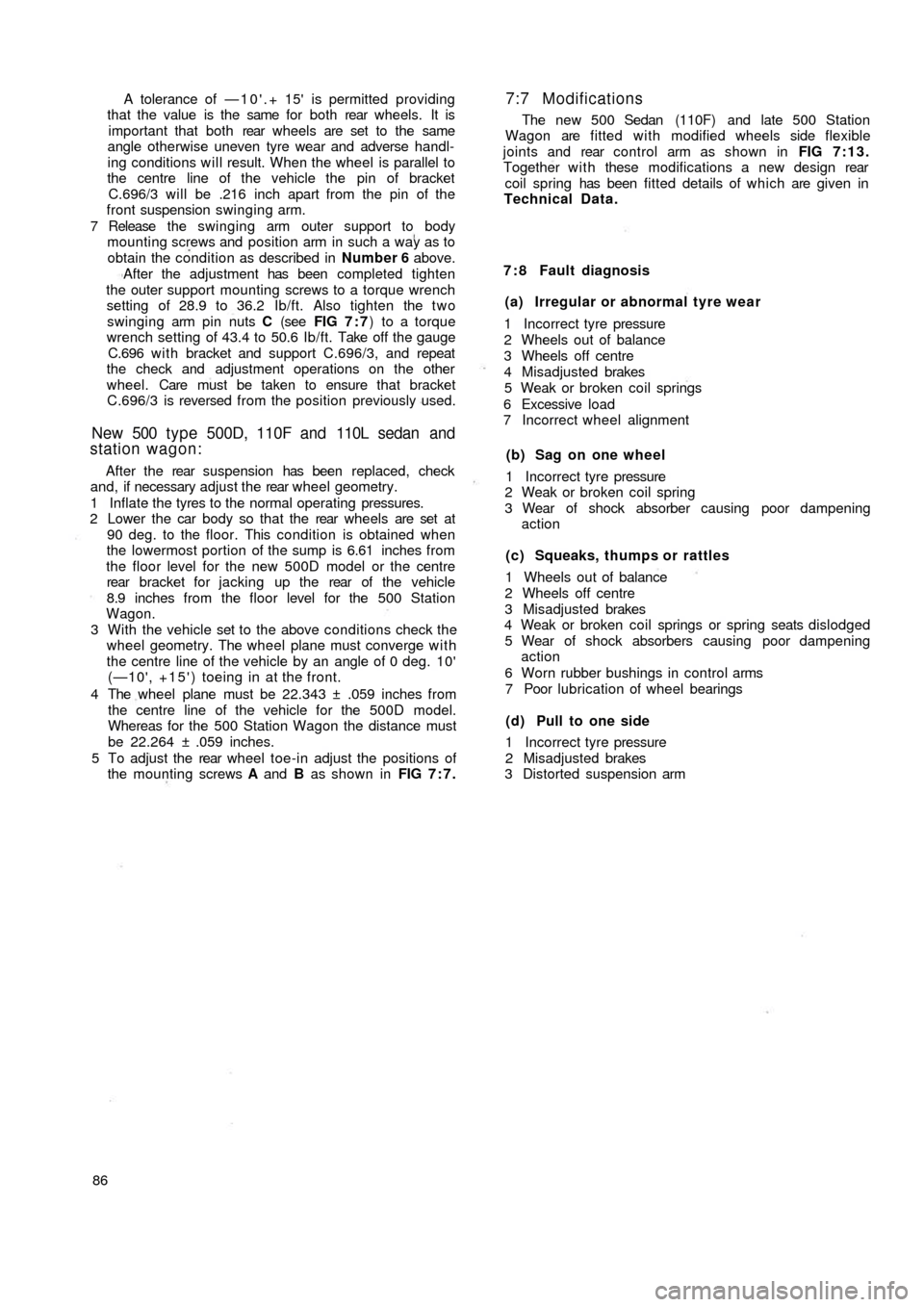

Oil Sump Wheel Plane

HALF TRACK

FIG 7 : 6 Position of rear suspension and of vehicle for

rear wheel toe-in inspection and adjustment

Key to Fig 7:6 ~ 168 mm = 6.61 inch

567,5 ±1,5= 22.342 inch ± .059 inch

Page 76 of 128

high bearing preload. To reset remove the wheel shaft

and fit a new resilient spacer. Repeat the rotation

torque test.

Swinging arm adjustment:

To adjust the swinging arm use Fiat fixture A.66064 as

shown in FIG 7 : 3 and proceed as follows:

1 At points A and B as indicated in FIG 7 : 4 between the

'estendblock' and the swinging arm to body front

mounting bracket fit three shims on each side. To

ensure that the shims are correctly centred use Fiat

alignment bar A.66057.

2 Whilst removing the alignment bar, carefully slip in the

mounting pin and screw on the nut. Once the rear

wheel geometry adjustment has been completed this

nut should be tightened to a torque wrench setting

of 43.4 to 50.6 Ib ft.

3 At points C and D (see FIG 7 : 4) , insert the number of

shims required to fill in the gap between the 'estend-

block' and the two fixture shoulders. Having deter-

mined the number of shims required both at locations

C and D, these must later be fitted between the

'estendblock' and the shoulders on the swinging arm

to body mounting bracket.

7 : 4 Coil springs

The coil springs should be thoroughly cleaned and all

traces of rust removed. Inspect the spring coils for hair

line cracks, which if evident, a new pair of springs must

be fitted to ensure correct vehicle height and stability.

Check the free

height and the height under loading of

the coil springs and these must correspond to the figures

quoted in Technical Data.

7:5 Installation of rear suspension assembly

To replace the rear suspension assembly proceed as

follows:

1 Insert the swinging arm inner end in the mounting

bracket which is welded onto the body floor. Place

between the 'estendblock' and bracket the number of

adjustment shims as previously determined using Fiat

fixture A.66064 as shown in FIG 7 : 4. Insert the Fiat

alignment bar A.66057 through 'estendblock' and

shims, aligning them with the holes in the mounting

bracket. Firmly hold the entire assembly using a garage

hydraulic jack if necessary, and carefully remove the

alignment bar and at the same time ease in t h e

mounting pin. Secure the nut which once the rear

wheels geometry has been checked must be tightened

to a torque wrench setting of 43.4 to 50.6 Ib/ft.

2 Screw in finger tight the three swinging arm external

bracket to body floor mounting screws together w i t h

the plain and spring washers. The screws will have to

be tightened to a torque wrench setting of 28.9 to

36.2 Ib/ft once the rear wheel geometry has been

adjusted.

3 Carefully insert the coil spring, lower insulator ring

onto the swinging arm, insert the spring on the shock

absorber which should be previously secured to the

arm and position the spring onto its seat on the arm.

Place the upper insulator ring onto the spring, raise the

suspension assembly using a garage hydraulic jack and

insert the spring onto its seating under the body floor.

F50083 4 Ensure that the shock absorber to floor rubber ring has

been correctly fitted and extend the shock absorber

until its upper mounting pin protrudes into the vehicle

through the hump in the floor panel. Secure the shock

absorber by its mounting nut and lockwasher having

first inserted the rubber ring and plain washer.

5 Refit the rear wheel housing in place, reconnect the

brake line to the connection on body floor and remove

the plug from the output hole in the brake fluid

reservoir. Bleed the hydraulic brake system as

described in Chapter 10.

Key to Fig 7:8 k Distance of centre rear bracket, for

jacking up the vehicle, from floor level (8.90 inch)

Half-track = 22.264 inch ±.059 inch

FIG 7 : 8 Position of rear suspension f o r rear wheel

toe-in inspection and adjustment ('500 Station Wagon') FIG 7 : 7 Adjusting rear wheel toe-in angle

Key to Fig 7 : 7 Rear wheel plane must be perpendicular to

ground and parallel to car longitudinal centerline with a

tolerance of 0° 10'

To adjust rear wheel geometry, move suitably the swinging arm

outer support. Slight movements are permitted by the play

existing between the support holes A and the mounting screws.

Screws B must be tightened to 28.9 to 36.2 Ibft (4000 to 5000

kg mm). Nuts C must be tightened to 43.4 to 50.6 Ib ft (6000

to 7000 kgmm), after adjustment has been carried out. (These

directions and specifications are also applicable to 500 Station

Wagon).

Page 77 of 128

FIG 7:9 Adjusting rear wheel toe-in on '500 StationWagon'

FIG 7:10 Checking left rear wheel toe-in

84

6 Insert the inner spring between the axle shaft and the

wheel shaft and couple the spline sleeve to the joint

and tighten the screws to a torque wrench setting of

20.3 Ib/ft.

7 Reconnect the parking brake tie rod and adjust the

position of the cable using the two stretchers.

8 Refit the wheels and draw up the mounting screws to

a torque wrench setting of 32.5 to 39.8 Ib/ft. Carefully

lower the vehicle to the floor.

7 :6 Checking and adjusting rear wheel toe-in

This check should be carried out by a Fiat agent as

special setting equipment is necessary. However, details

of this check are given for reference purposes:

To check and adjust the rear wheel geometry proceed

as follows:

1 Place the vehicle on firmly based stands and remove

the front and rear wheels.

2 Install Fiat fixtures A.66062 as shown in FIG 7:12 to

enable correct spring compression and wheel location

in the vertical position.

3 Lift the rear suspensions by compressing the coil

springs and shock absorbers using garage hydraulic

jacks. Screw on the fixture lower shank until the

index registers with the mark 'Nuova 500' stamped on

the bracket. In this position the wheel plane is vertical

and the centre O (see FIG 7 : 6) of wheel shaft results

at 5.00 inch from the buffer stop bracket.

4 Secure Fiat support C.696/3 to the wheel drum and

connect gauge C.696 to the support. Tighten the two

clamping screws as shown in FIG 7:12.

5 Apply at the front of Fiat gauge C.696 bracket

numbered C.696/3 as shown in FIG 7:11.

6 Check that the pin mounted on the front end of the

bracket C.696/3 is in touch with the front suspension

swinging arm pin (see FIG 7:11). If these conditions

are not complied with, proceed with item 7.

Wheel toe-in angle

will vary by 0° 10' under

a movement of some 7/32 inch measured at 72.476 inch

from wheel centre for Model 500D, and at 76.413 inch

from wheel centre for 500 Station Wagon NOTE - - that the toe-in angle

Key to Fig 7 : 9 A Front support B Screw holes for

fixing support to underbody C Swinging arm pin nuts

Page 79 of 128

A tolerance of —10'.+ 15' is permitted providing

that the value is the same for both rear wheels. It is

important that both rear wheels are set to the same

angle otherwise uneven tyre wear and adverse handl-

ing conditions will result. When the wheel is parallel to

the centre line of the vehicle the pin of bracket

C.696/3 will be .216 inch apart from the pin of the

front suspension swinging arm.

7 Release the swinging arm outer support to body

mounting screws and position arm in such a way as to

obtain the condition as described in Number 6 above.

After the adjustment has been completed tighten

the outer support mounting screws to a torque wrench

setting of 28.9 to 36.2 Ib/ft. Also tighten the two

swinging arm pin nuts C (see FIG 7 : 7) to a torque

wrench setting of 43.4 to 50.6 Ib/ft. Take off the gauge

C.696 w i t h bracket and support C.696/3, and repeat

the check and adjustment operations on the other

wheel. Care must be taken to ensure that bracket

C.696/3 is reversed from the position previously used.

New 500 type 500D, 110F and 110L sedan and

station wagon:

After the rear suspension has been replaced, check

and, if necessary adjust the rear wheel geometry.

1 Inflate the tyres to the normal operating pressures.

2 Lower the car body so that the rear wheels are set at

90 deg. to the floor. This condition is obtained when

the lowermost portion of the sump is 6.61 inches from

the floor level for the new 500D model or the centre

rear bracket for jacking up the rear of t h e vehicle

8.9 inches from the floor level for the 500 Station

Wagon.

3 With the vehicle set to the above conditions check the

wheel geometry. The wheel plane must converge w i t h

the centre line of the vehicle by an angle of 0 deg. 10'

(—10', +15') toeing in at the front.

4 The wheel plane must be 22.343 ± .059 inches from

the centre line of the vehicle for the 500D model.

Whereas for the 500 Station Wagon the distance must

be 22.264 ± .059 inches.

5 To adjust the rear wheel toe-in adjust the positions of

the mounting screws A and B as shown in FIG 7:7.

86

7:7 Modifications

The new 500 Sedan (110F) and late 500 Station

Wagon are fitted with modified wheels side flexible

joints and rear control arm as shown in FIG 7:13.

Together w i t h these modifications a new design rear

coil spring has been fitted details of which are given in

Technical Data.

7 : 8 Fault diagnosis

(a) Irregular or abnormal tyre wear

1 Incorrect tyre pressure

2 Wheels out of balance

3 Wheels off centre

4 Misadjusted brakes

5 Weak or broken coil springs

6 Excessive load

7 Incorrect wheel alignment

(b) Sag on one wheel

1 Incorrect tyre pressure

2 Weak or broken coil spring

3 Wear of shock absorber causing poor dampening

action

(c) Squeaks, thumps or rattles

1 Wheels out of balance

2 Wheels off centre

3 Misadjusted brakes

4 Weak or broken coil springs or spring seats dislodged

5 Wear of shock absorbers causing poor dampening

action

6 Worn rubber bushings in control arms

7 Poor lubrication of wheel bearings

(d) Pull to one side

1 Incorrect tyre pressure

2 Misadjusted brakes

3 Distorted suspension arm

Page 87 of 128

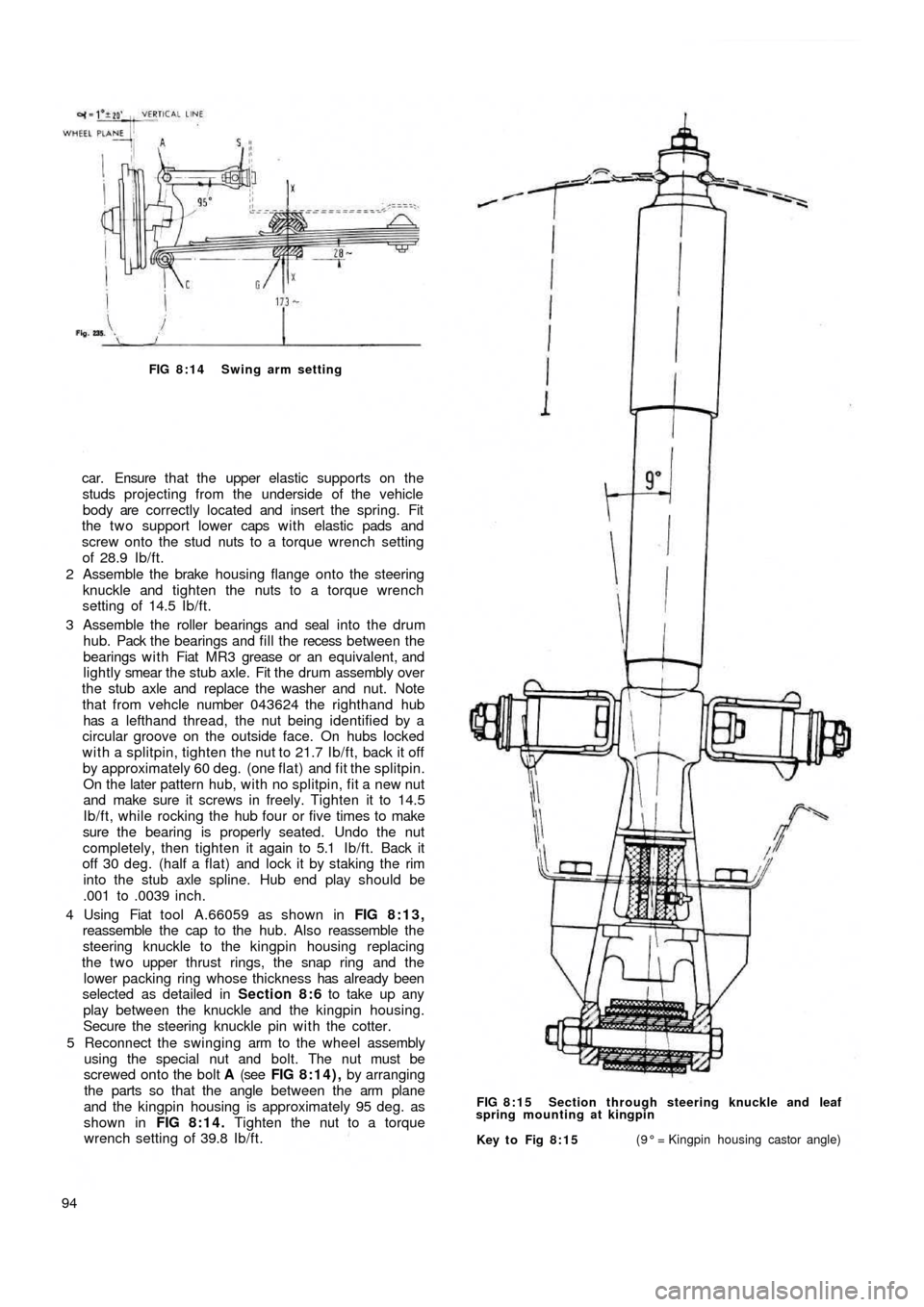

FIG 8:14 Swing arm setting

car. Ensure t h a t the upper elastic supports on the

studs projecting from the underside of the vehicle

body are correctly located and insert the spring. Fit

the two support lower caps w i t h elastic pads and

screw onto the stud nuts to a torque wrench setting

of 28.9 Ib/ft.

2 Assemble the brake housing flange onto the steering

knuckle and tighten the nuts to a torque wrench

setting of 14.5 Ib/ft.

3 Assemble the roller bearings and seal into the drum

hub. Pack the bearings and fill the recess between the

bearings w i t h Fiat MR3 grease or an equivalent, and

lightly smear the stub axle. Fit the drum assembly over

the stub axle and replace the washer and nut. Note

that from vehcle number 043624 the righthand hub

has a lefthand thread, the nut being identified by a

circular groove on the outside face. On hubs locked

with a splitpin, tighten the nut to 21.7 Ib/ft, back it off

by approximately 60 deg. (one flat) and fit the splitpin.

On the later pattern hub, with no splitpin, fit a new nut

and make sure it screws in freely. Tighten it to 14.5

Ib/ft, while rocking the hub four or five times to make

sure the bearing is properly seated. Undo the nut

completely, then tighten it again to 5.1 Ib/ft. Back it

off 30 deg. (half a flat) and lock it by staking the rim

into the stub axle spline. Hub end play should be

.001 to .0039 inch.

4 Using Fiat tool A.66059 as shown in FIG 8:13,

reassemble the cap to the hub. Also reassemble the

steering knuckle to the kingpin housing replacing

the t w o upper

thrust rings, the snap ring and the

lower packing ring whose thickness has already been

selected as detailed in Section 8:6 to take up any

play between the knuckle and the kingpin housing.

Secure the steering knuckle pin with the cotter.

5 Reconnect the swinging arm to the wheel assembly

using the special nut and bolt. The nut must be

screwed onto the bolt A (see FIG 8:14), by arranging

the parts so that the angle between the arm plane

and the kingpin housing is approximately 95 deg. as

shown in FIG 8:14. Tighten the nut to a torque

wrench setting of 39.8 Ib/ft.

94

Key to Fig 8:15(9° = Kingpin housing castor angle) FIG 8:15 Section through steering knuckle and leaf

spring mounting at kingpin

Page 88 of 128

VERTICAL LINE DB

S

EB

OIL SUMPF

GF

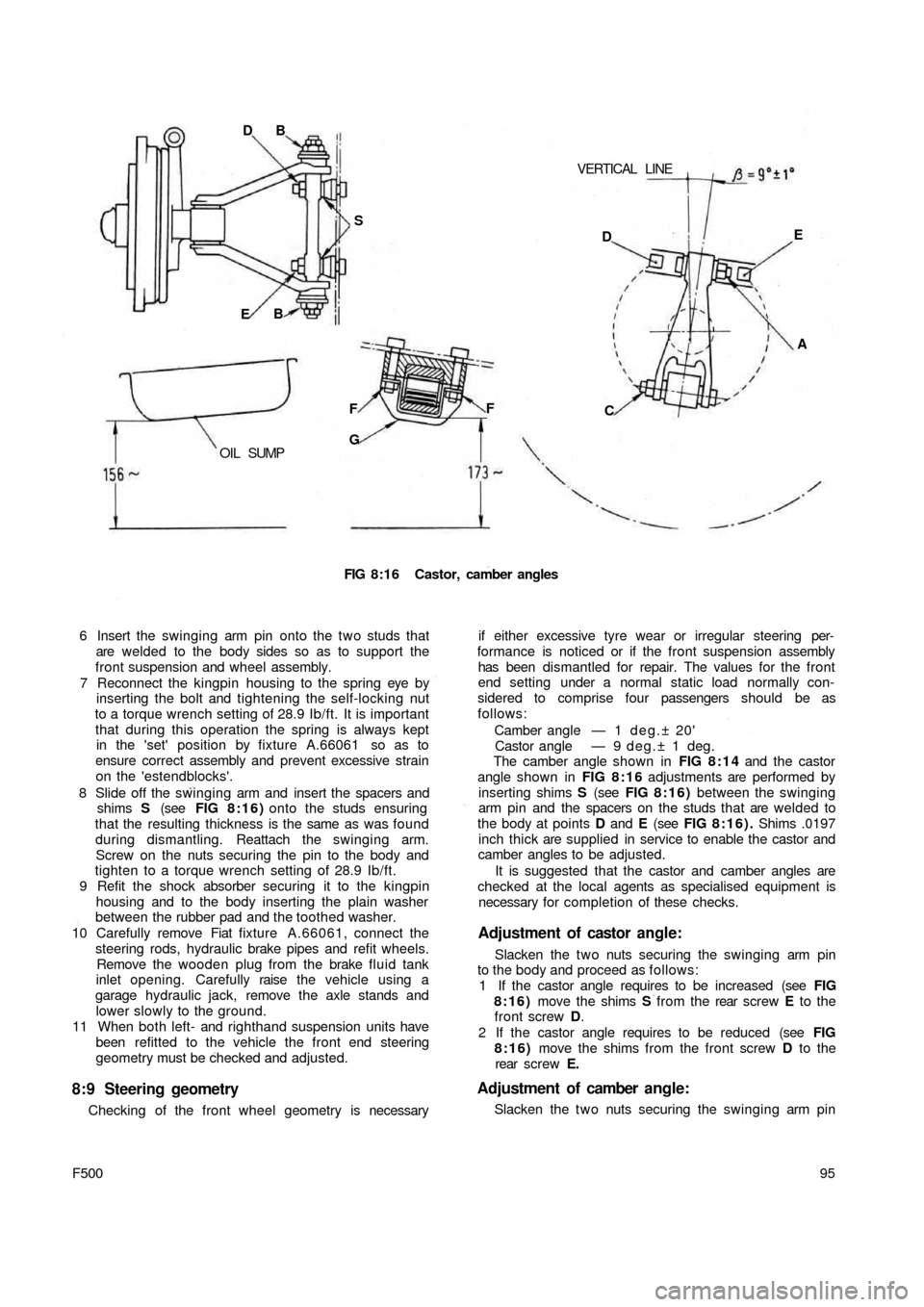

FIG 8:16 Castor, camber angles

6 Insert the swinging arm pin onto the two studs that

are welded to the body sides so as to support the

front suspension and wheel assembly.

7 Reconnect the kingpin housing to the spring eye by

inserting the bolt and tightening the self-locking nut

to a torque wrench setting of 28.9 Ib/ft. It is important

that during this operation the spring is always kept

in the 'set' position by fixture A.66061 so as to

ensure correct assembly and prevent excessive strain

on the 'estendblocks'.

8 Slide off the swinging arm and insert the spacers and

shims S (see FIG 8:16) onto the studs ensuring

that the resulting thickness is the same as was found

during dismantling. Reattach the swinging arm.

Screw on the nuts securing the pin to the body and

tighten to a torque wrench setting of 28.9 Ib/ft.

9 Refit the shock absorber securing it to the kingpin

housing and to the body inserting the plain washer

between the rubber pad and the toothed washer.

10 Carefully remove Fiat fixture A.66061, connect the

steering rods, hydraulic brake pipes and refit wheels.

Remove the wooden plug from the brake fluid tank

inlet opening. Carefully raise the vehicle using a

garage hydraulic jack, remove the axle stands and

lower slowly to the ground.

11 When both left- and righthand suspension units have

been refitted to the vehicle the front end steering

geometry must be checked and adjusted.

8:9 Steering geometry

Checking of the front wheel geometry is necessary

95

F500

if either excessive tyre wear or irregular steering per-

formance is noticed or if the front suspension assembly

has been dismantled for repair. The values for the front

end setting under a normal static load normally con-

sidered to comprise four passengers should be as

follows:

Camber angle — 1 d e g . ± 20'

Castor angle — 9 deg.± 1 deg.

The camber angle shown in FIG 8:14 and the castor

angle shown in FIG 8 : 1 6 adjustments are performed by

inserting shims S (see FIG 8 : 1 6 ) between the swinging

arm pin and the spacers on the studs that are welded to

the body at points D and E (see FIG 8:16). Shims .0197

inch thick are supplied in service to enable the castor and

camber angles to be adjusted.

It is suggested that the castor and camber angles are

checked at the local agents as specialised equipment is

necessary for completion of these checks.

Adjustment of castor angle:

Slacken the t w o nuts securing the swinging arm pin

to the body and proceed as follows:

1 If the castor angle requires to be increased (see FIG

8:16) move the shims S from the rear screw E to the

front screw D.

2 If the castor angle requires to be reduced (see FIG

8:16) move the shims from the front screw D to the

rear screw E.

Adjustment of camber angle:

Slacken the t w o nuts securing the swinging arm pin DE

A

C