lock FIAT 500 1964 1.G Service Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1964, Model line: 500, Model: FIAT 500 1964 1.GPages: 128, PDF Size: 9.01 MB

Page 87 of 128

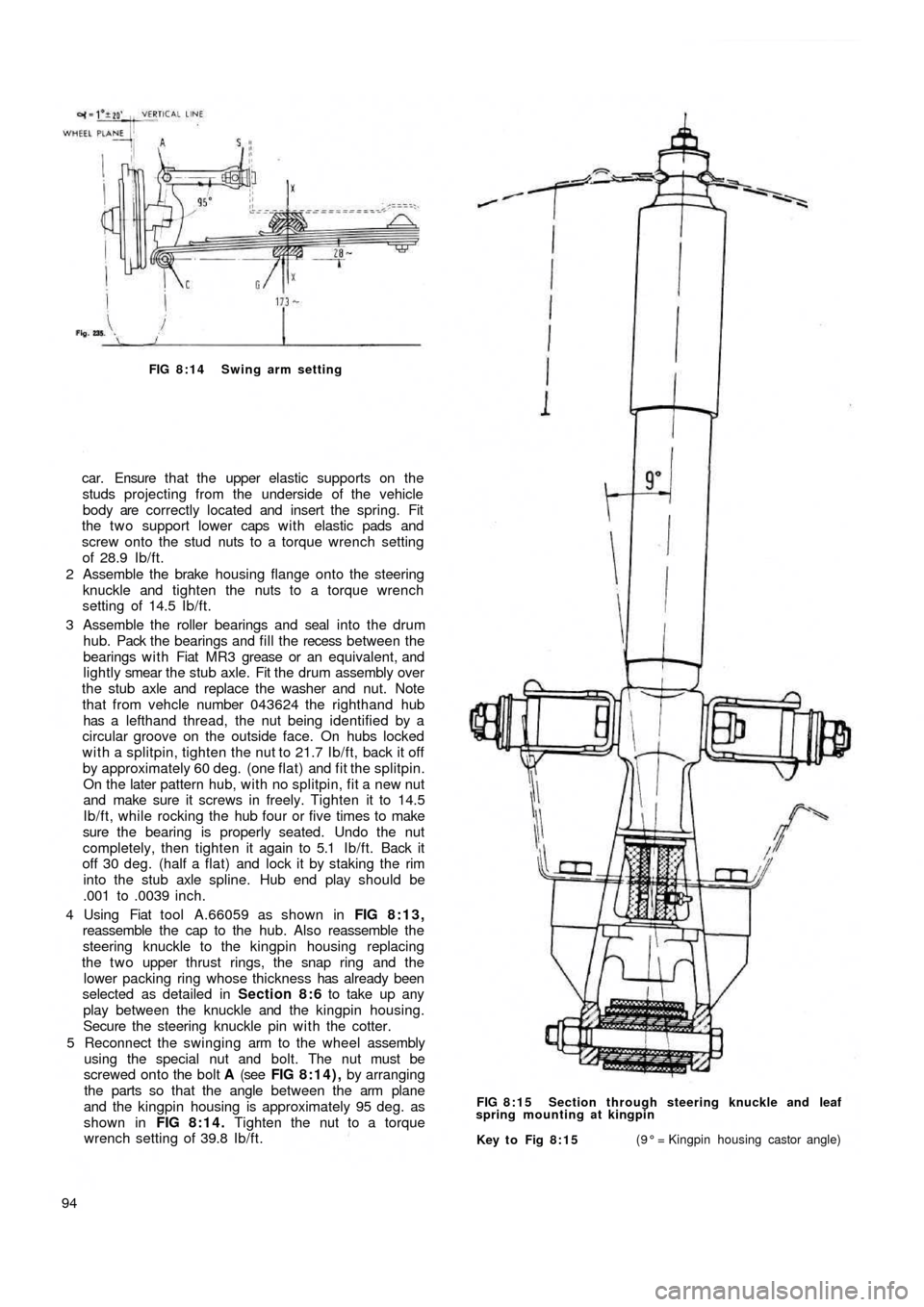

FIG 8:14 Swing arm setting

car. Ensure t h a t the upper elastic supports on the

studs projecting from the underside of the vehicle

body are correctly located and insert the spring. Fit

the two support lower caps w i t h elastic pads and

screw onto the stud nuts to a torque wrench setting

of 28.9 Ib/ft.

2 Assemble the brake housing flange onto the steering

knuckle and tighten the nuts to a torque wrench

setting of 14.5 Ib/ft.

3 Assemble the roller bearings and seal into the drum

hub. Pack the bearings and fill the recess between the

bearings w i t h Fiat MR3 grease or an equivalent, and

lightly smear the stub axle. Fit the drum assembly over

the stub axle and replace the washer and nut. Note

that from vehcle number 043624 the righthand hub

has a lefthand thread, the nut being identified by a

circular groove on the outside face. On hubs locked

with a splitpin, tighten the nut to 21.7 Ib/ft, back it off

by approximately 60 deg. (one flat) and fit the splitpin.

On the later pattern hub, with no splitpin, fit a new nut

and make sure it screws in freely. Tighten it to 14.5

Ib/ft, while rocking the hub four or five times to make

sure the bearing is properly seated. Undo the nut

completely, then tighten it again to 5.1 Ib/ft. Back it

off 30 deg. (half a flat) and lock it by staking the rim

into the stub axle spline. Hub end play should be

.001 to .0039 inch.

4 Using Fiat tool A.66059 as shown in FIG 8:13,

reassemble the cap to the hub. Also reassemble the

steering knuckle to the kingpin housing replacing

the t w o upper

thrust rings, the snap ring and the

lower packing ring whose thickness has already been

selected as detailed in Section 8:6 to take up any

play between the knuckle and the kingpin housing.

Secure the steering knuckle pin with the cotter.

5 Reconnect the swinging arm to the wheel assembly

using the special nut and bolt. The nut must be

screwed onto the bolt A (see FIG 8:14), by arranging

the parts so that the angle between the arm plane

and the kingpin housing is approximately 95 deg. as

shown in FIG 8:14. Tighten the nut to a torque

wrench setting of 39.8 Ib/ft.

94

Key to Fig 8:15(9° = Kingpin housing castor angle) FIG 8:15 Section through steering knuckle and leaf

spring mounting at kingpin

Page 88 of 128

VERTICAL LINE DB

S

EB

OIL SUMPF

GF

FIG 8:16 Castor, camber angles

6 Insert the swinging arm pin onto the two studs that

are welded to the body sides so as to support the

front suspension and wheel assembly.

7 Reconnect the kingpin housing to the spring eye by

inserting the bolt and tightening the self-locking nut

to a torque wrench setting of 28.9 Ib/ft. It is important

that during this operation the spring is always kept

in the 'set' position by fixture A.66061 so as to

ensure correct assembly and prevent excessive strain

on the 'estendblocks'.

8 Slide off the swinging arm and insert the spacers and

shims S (see FIG 8:16) onto the studs ensuring

that the resulting thickness is the same as was found

during dismantling. Reattach the swinging arm.

Screw on the nuts securing the pin to the body and

tighten to a torque wrench setting of 28.9 Ib/ft.

9 Refit the shock absorber securing it to the kingpin

housing and to the body inserting the plain washer

between the rubber pad and the toothed washer.

10 Carefully remove Fiat fixture A.66061, connect the

steering rods, hydraulic brake pipes and refit wheels.

Remove the wooden plug from the brake fluid tank

inlet opening. Carefully raise the vehicle using a

garage hydraulic jack, remove the axle stands and

lower slowly to the ground.

11 When both left- and righthand suspension units have

been refitted to the vehicle the front end steering

geometry must be checked and adjusted.

8:9 Steering geometry

Checking of the front wheel geometry is necessary

95

F500

if either excessive tyre wear or irregular steering per-

formance is noticed or if the front suspension assembly

has been dismantled for repair. The values for the front

end setting under a normal static load normally con-

sidered to comprise four passengers should be as

follows:

Camber angle — 1 d e g . ± 20'

Castor angle — 9 deg.± 1 deg.

The camber angle shown in FIG 8:14 and the castor

angle shown in FIG 8 : 1 6 adjustments are performed by

inserting shims S (see FIG 8 : 1 6 ) between the swinging

arm pin and the spacers on the studs that are welded to

the body at points D and E (see FIG 8:16). Shims .0197

inch thick are supplied in service to enable the castor and

camber angles to be adjusted.

It is suggested that the castor and camber angles are

checked at the local agents as specialised equipment is

necessary for completion of these checks.

Adjustment of castor angle:

Slacken the t w o nuts securing the swinging arm pin

to the body and proceed as follows:

1 If the castor angle requires to be increased (see FIG

8:16) move the shims S from the rear screw E to the

front screw D.

2 If the castor angle requires to be reduced (see FIG

8:16) move the shims from the front screw D to the

rear screw E.

Adjustment of camber angle:

Slacken the t w o nuts securing the swinging arm pin DE

A

C

Page 89 of 128

to the body and proceed as follows:

1 If the camber angle requires to be increased (see FIG

8:16) add the same number of shims S on both

screws D and E.

2 If the camber angle requires to be reduced (see FIG

8:16) remove the same number of shims from both

screws D and E.

The addition or removal of shims at the t w o points D

and E permits camber adjustment to be made without

any disturbing of the castor angle.

8:10 Modifications

Checking and adjusting castor and camber angles:

When checking the castor and camber angle the

static loading should be such that the distance between

the semi-elliptic spring mountings G (see FIG 8:16)

and the floor level to be approximately 6.81 inches, also a

distance between the lowermost portion of the sump and

the floor level of approximately 6.14 inch for the Model

500D. For the 500 Station Wagon version the distance

between centre rear bracket for jacking-up the vehicle

and the floor level should be approximately 8.90 inches.

All other front wheel alignment specifications are the

same as for the remaining 500 saloon models.

8:11 Fault diagnosis

(a) Wheel bounce

1 Tyre casing faulty

2 Uneven tyre pressures

3 Wheels out of balance

4 Semi-elliptic mounting spring worn5 Weak or seized shock absorber

6 Wheel rim or tyre misaligned

(b) Suspension noise

1 Lack of lubrication

2 Noisy or inoperative shock absorbers

3 Worn or loose wheel bearings

(c) Pull to one side

1 Low or uneven tyre pressures

2 Incorrect front wheel alignment

3 Suspension arms distorted

4 Inoperative shock absorbers

5 Brakes binding

(d) Excessive t y r e wear

1 Incorrect tyre rotation during servicing periods

2 Incorrect camber angle

3 Incorrect toe-in

4 Incorrect tyre inflation

5 Excessive play at wheel bearings

6 Wheel wobble

7 Stiff suspension arms

8 Brakes out of adjustment

(e) Wheel wobble

1 Uneven tyre pressures

2 Loose or worn wheel bearings

3 Inoperative shock absorbers

4 Loose steering knuckle or kingpin housing

5 Incorrect front wheel alignment

6 Control arm rubber bushings, or kingpin housing and

semi-elliptic spring 'estendblock' worn

96

Page 90 of 128

CHAPTER 9

THE STEERING SYSTEM

9 : 5 Relay lever and support

9 : 6 Steering rods

9 : 7 Front wheel toe-in

9 : 8 Fault diagnosis 9:1 Description

9 : 2 Steering wheel removal and refitting

9 : 3 Steering box removal and refitting

9 : 4 Steering box dismantling and reassembly

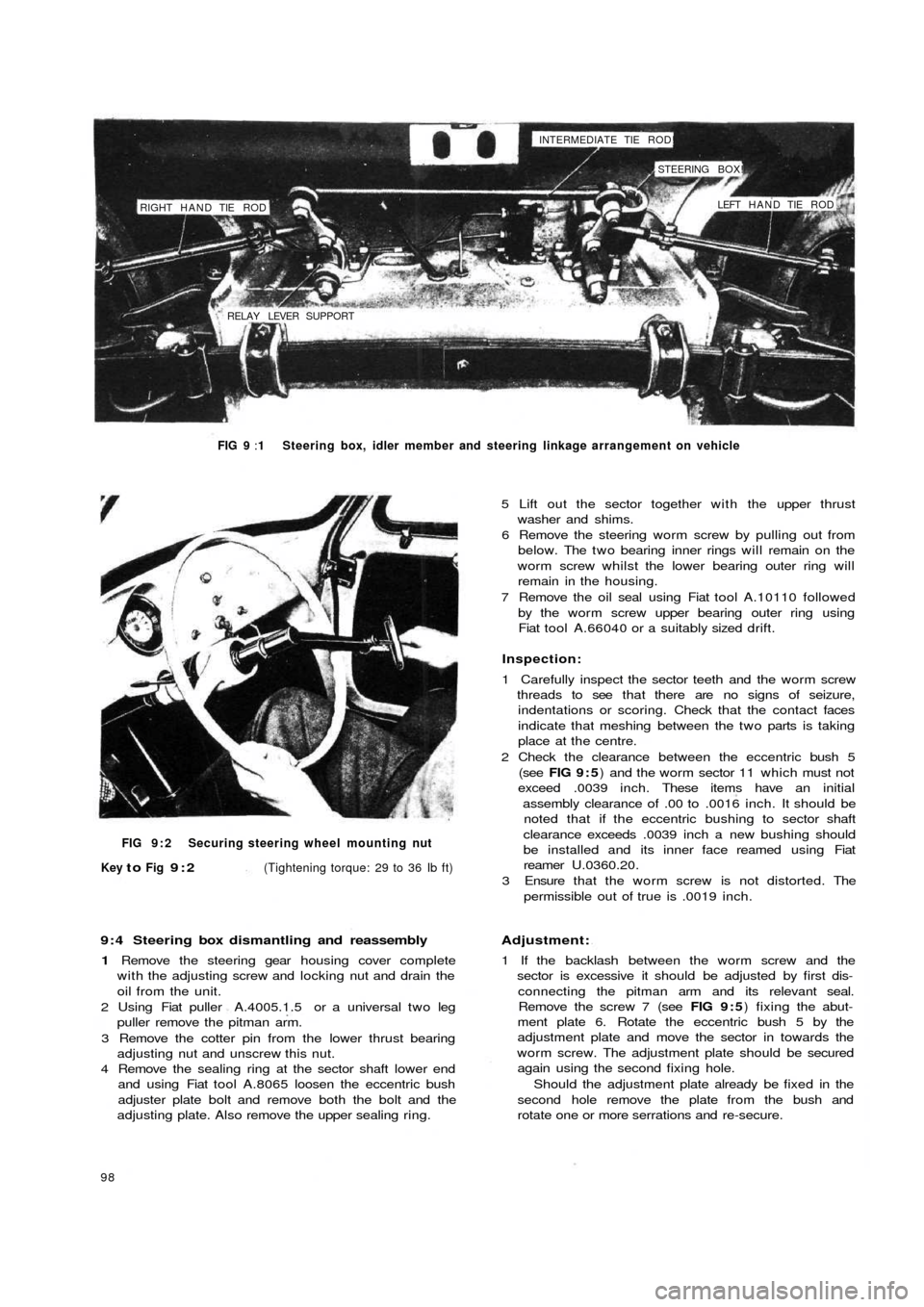

9:1 Description

The steering gear fitted to the new 500 range of

vehicles is of the worm screw and sector type with a

steering ratio of 1:13. The steering gearbox is located on

the front lefthand side of the dash wall on the scuttle as

shown in FIG 9:1. The steering gear comprises a pitman

arm and relay lever pivoting on a pin supported on the

body. A central track rod connects the pitman arm to the

relay lever. T w o track rods connect the pitman arm and

relay lever to the knuckle arms.

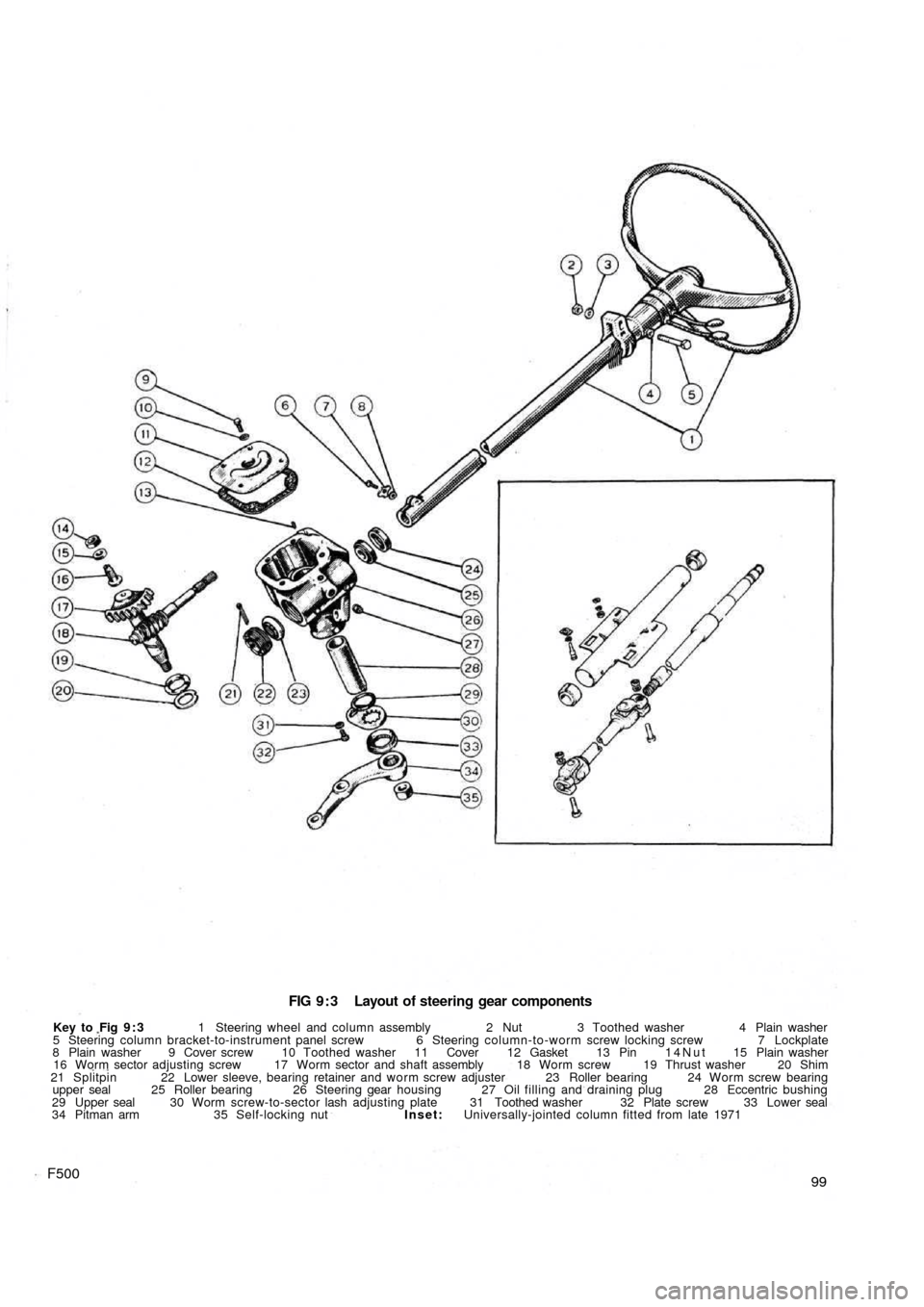

9:2 Steering wheel removal and refitting

To remove the steering wheel proceed as follows:

1 Disconnect the battery positive terminal clamp and

remove the horn control from the steering wheel.

2 Remove the cable from the push button seating and the

cable insulation sleeve.

3 Using a suitably sized box spanner or Fiat wrench

A.8279 unscrew the steering wheel to shaft nut as

shown in FIG 9:2.

4 Using the palm of the hands against the back of the

steering wheel rim gently tap the steering wheel

forwards so releasing it from the inner shaft.

F50097 5 Reassembly is the reverse procedure to dismantling.

Care should be taken to ensure that the front wheels

are located in the straight ahead position when the

steering wheel is being replaced otherwise the steering

wheel spokes will not be correctly positioned.

9 : 3 Steering box removal and refitting

To remove the steering box from the vehicle proceed

as follows:

1 From inside the vehicle remove the steering column

clamp bolt 6 (see FIG 9 : 3) after flattening the lock-

washer 7.

2 From the underside of the vehicle remove the t w o

tie rod locking nuts from the pitman arm and then using

Fiat tool A.46006 or a suitable t w o leg puller withdraw

the pins from the seats.

3 Remove the three nuts holding the steering box to the

body panel. Ease out the worm screw from the

steering shaft and lift away the steering box.

4 To refit the steering box is the reverse procedure to

dismantling. The steering box to body mounting nuts

should be tightened to a torque wrench setting of

14 Ib/ft to 18 Ib/ft.

Page 91 of 128

RIGHT HAND TIE ROD

RELAY LEVER SUPPORTINTERMEDIATE TIE ROD!

STEERING BOX!

LEFT HAND TIE ROD

FIG 9 :1 Steering box, idler member and steering linkage arrangement on vehicle

FIG 9 : 2 Securing steering wheel mounting nut

Key

to Fig 9:2(Tightening torque: 29 to 36 Ib ft)

9 : 4 Steering box dismantling and reassembly

1 Remove the steering gear housing cover complete

with the adjusting screw and locking nut and drain the

oil from the unit.

2 Using Fiat puller A.4005.1.5 or a universal t w o leg

puller remove the pitman arm.

3 Remove the cotter pin from the lower thrust bearing

adjusting nut and unscrew this nut.

4 Remove the sealing ring at the sector shaft lower end

and using Fiat tool A.8065 loosen the eccentric bush

adjuster plate bolt and remove both the bolt and the

adjusting plate. Also remove the upper sealing ring.

98

5 Lift out the sector together with the upper thrust

washer and shims.

6 Remove the steering worm screw by pulling out from

below. The two bearing inner rings will remain on the

worm screw whilst the lower bearing outer ring will

remain in the housing.

7 Remove the oil seal using Fiat tool A.10110 followed

by the worm screw upper bearing outer ring using

Fiat tool A.66040 or a suitably sized drift.

Inspection:

1 Carefully inspect the sector teeth and the worm screw

threads to see that there are no signs of seizure,

indentations or scoring. Check that the contact faces

indicate that meshing between the two parts is taking

place at the centre.

2 Check the clearance between the eccentric bush 5

(see FIG 9 : 5) and the worm sector 11 which must not

exceed .0039 inch. These items have an initial

assembly clearance of .00 to .0016 inch. It should be

noted that if the eccentric bushing to sector shaft

clearance exceeds .0039 inch a new bushing should

be installed and its inner face reamed using Fiat

reamer U.0360.20.

3 Ensure that the worm screw is not distorted. The

permissible out of true is .0019 inch.

Adjustment:

1 If the backlash between the worm screw and the

sector is excessive it should be adjusted by first dis-

connecting the pitman arm and its relevant seal.

Remove the screw 7 (see FIG 9 : 5) fixing the abut-

ment plate 6. Rotate the eccentric bush 5 by the

adjustment plate and move the sector in towards the

worm screw. The adjustment plate should be secured

again using the second fixing hole.

Should the adjustment plate already be fixed in the

second hole remove the plate from the bush and

rotate one or more serrations and re-secure.

Page 92 of 128

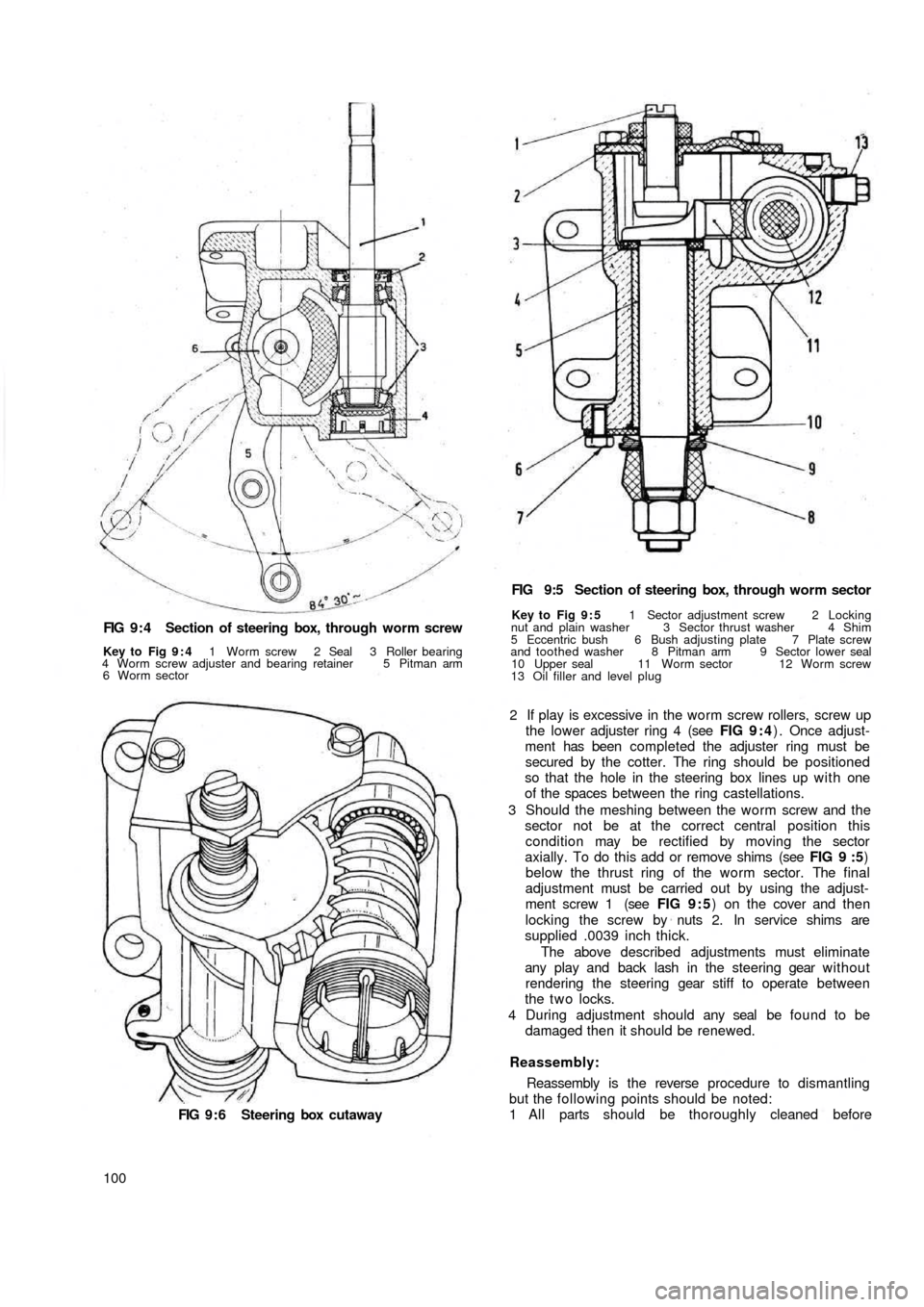

FIG 9 : 3 Layout of steering gear components

Key to Fig 9 : 3 1 Steering wheel and column assembly 2 Nut 3 Toothed washer 4 Plain washer

5 Steering column bracket-to-instrument panel screw 6 Steering column-to-worm screw locking screw 7 Lockplate

8 Plain washer 9 Cover screw 10 Toothed washer 11 Cover 12 Gasket 13 Pin 14Nut 15 Plain washer

16 Worm sector adjusting screw 17 Worm sector and shaft assembly 18 Worm screw 19 Thrust washer 20 Shim

21 Splitpin 22 Lower sleeve, bearing retainer and worm screw adjuster 23 Roller bearing 24 Worm screw bearing

upper seal 25 Roller bearing 26 Steering gear housing 27 Oil filling and draining plug 28 Eccentric bushing

29 Upper seal 30 Worm screw-to-sector lash adjusting plate 31 Toothed washer 32 Plate screw 33 Lower seal

34 Pitman arm 35 Self-locking nut Inset: Universally-jointed column fitted from late 1971

99F500

Page 93 of 128

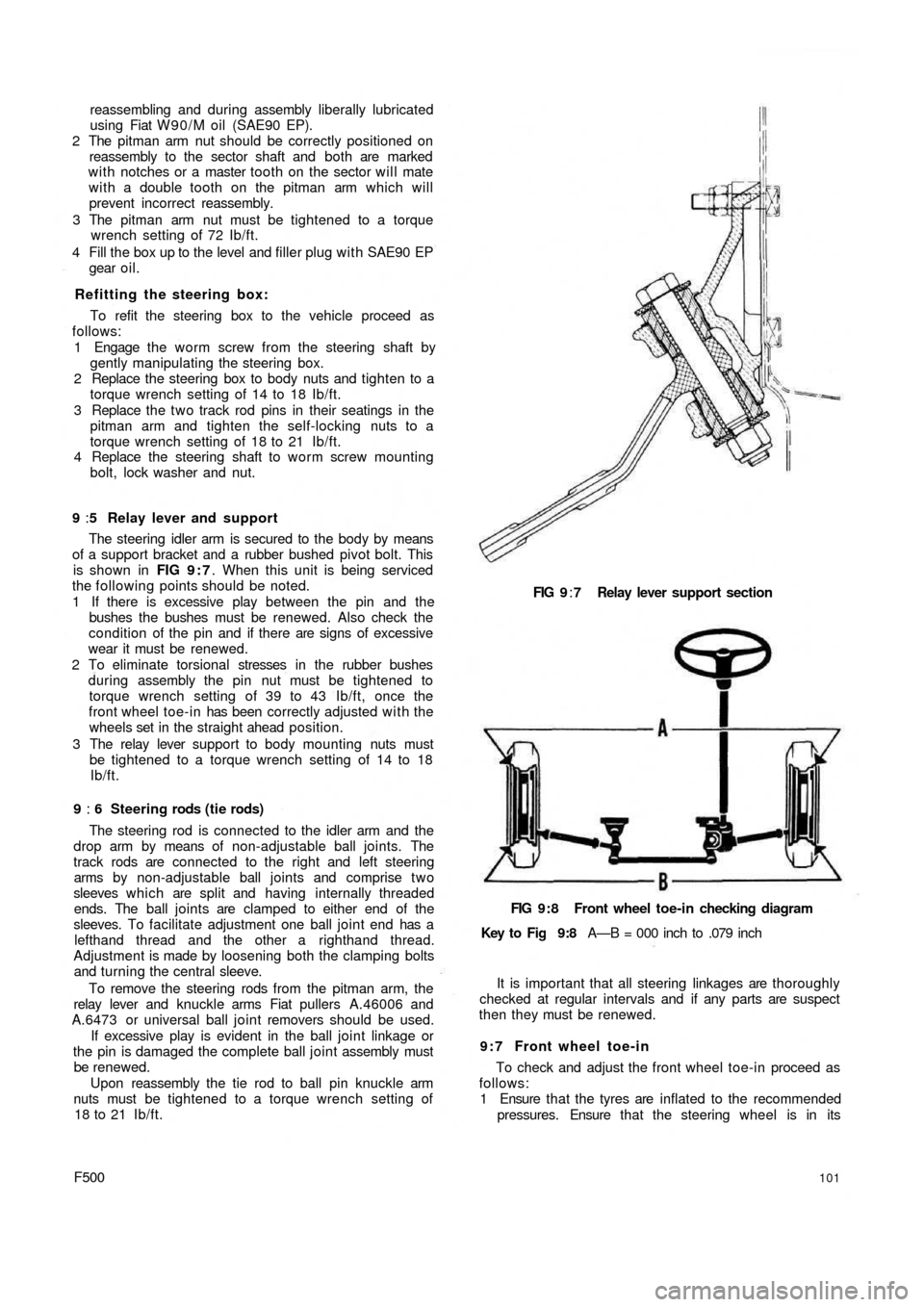

FIG 9 : 4 Section of steering box, through worm screw

Key to Fig 9 : 4 1 Worm screw 2 Seal 3 Roller bearing

4 Worm screw adjuster and bearing retainer 5 Pitman arm

6 Worm sector

FIG 9 : 6 Steering box cutaway

100FIG 9:5 Section of steering box, through worm sector

Key to Fig 9 : 5 1 Sector adjustment screw 2 Locking

nut and plain washer 3 Sector thrust washer 4 Shim

5 Eccentric bush 6 Bush adjusting plate 7 Plate screw

and toothed washer 8 Pitman arm 9 Sector lower seal

10 Upper seal 11 Worm sector 12 Worm screw

13 Oil filler and level plug

2 If play is excessive in the worm screw rollers, screw up

the lower adjuster ring 4 (see FIG 9 : 4) . Once adjust-

ment has been completed the adjuster ring must be

secured by the cotter. The ring should be positioned

so that the hole in the steering box lines up w i t h one

of the spaces between the ring castellations.

3 Should the meshing between the worm screw and the

sector not be at the correct central position this

condition may be rectified by moving the sector

axially. To do this add or remove shims (see FIG 9 :5)

below the thrust ring of the worm sector. The final

adjustment must be carried out by using the adjust-

ment screw 1 (see FIG 9 : 5) on the cover and then

locking the screw by nuts 2. In service shims are

supplied .0039 inch thick.

The above described adjustments must eliminate

any play and back lash in the steering gear without

rendering the steering gear stiff to operate between

the t w o locks.

4 During adjustment should any seal be found to be

damaged then it should be renewed.

Reassembly:

Reassembly is the reverse procedure to dismantling

but the following points should be noted:

1 All parts should be thoroughly cleaned before

Page 94 of 128

reassembling and during assembly liberally lubricated

using Fiat W90/M oil (SAE90 EP).

2 The pitman arm nut should be correctly positioned on

reassembly to the sector shaft and both are marked

with notches or a master tooth on the sector will mate

with a double tooth on the pitman arm which will

prevent incorrect reassembly.

3 The pitman arm nut must be tightened to a torque

wrench setting of 72 Ib/ft.

4 Fill the box up to the level and filler plug with SAE90 EP

gear oil.

Refitting the steering box:

To refit the steering box to the vehicle proceed as

follows:

1 Engage the w o r m screw f r o m the steering shaft by

gently manipulating the steering box.

2 Replace the steering box to body nuts and tighten to a

torque wrench setting of 14 to 18 Ib/ft.

3 Replace the t w o track rod pins in their seatings in the

pitman arm and tighten the self-locking nuts to a

torque wrench setting of 18 to 21 Ib/ft.

4 Replace the steering shaft to worm screw mounting

bolt, lock washer and nut.

9 :5 Relay lever and support

The steering idler arm is secured to the body by means

of a support bracket and a rubber bushed pivot bolt. This

is shown in FIG 9 : 7. When this unit is being serviced

the following points should be noted.

1 If there is excessive play between the pin and the

bushes the bushes must be renewed. Also check the

condition of the pin and if there are signs of excessive

wear it must be renewed.

2 To eliminate torsional stresses in the rubber bushes

during assembly the pin nut must be tightened to

torque wrench setting of 39 to 43 Ib/ft, once the

front wheel toe-in has been correctly adjusted w i t h the

wheels set in the straight ahead position.

3 The relay lever support to body mounting nuts must

be tightened to a torque wrench setting of 14 to 18

Ib/ft.

9 : 6 Steering rods (tie rods)

The steering rod is connected to the idler arm and the

drop arm by means of non-adjustable ball joints. The

track rods are connected to the right and left steering

arms by non-adjustable ball joints and comprise t w o

sleeves which are split and having internally threaded

ends. The ball joints are clamped to either end of the

sleeves. To facilitate adjustment one ball joint end has a

lefthand thread and the other a righthand thread.

Adjustment is made by loosening both the clamping bolts

and turning the central sleeve.

To remove the steering rods from the pitman arm, the

relay lever and knuckle arms Fiat pullers A.46006 and

A.6473 or universal ball joint removers should be used.

If excessive play is evident in the ball joint linkage or

the pin is damaged the complete ball joint assembly must

be renewed.

Upon reassembly the tie rod to ball pin knuckle arm

nuts must be tightened to a torque wrench setting of

18 to 21 Ib/ft.

F500101

FIG 9:7 Relay lever support section

FIG 9:8 Front wheel toe-in checking diagram

Key to Fig 9:8 A—B = 000 inch to .079 inch

It is important that all steering linkages are thoroughly

checked at regular intervals and if any parts are suspect

then they must be renewed.

9 : 7 Front wheel toe-in

To check and adjust the front wheel toe-in proceed as

follows:

1 Ensure that the tyres are inflated to the recommended

pressures. Ensure that the steering wheel is in its

Page 98 of 128

2 Using Fiat puller A.46023 as shown in FIG 8 : 9

remove the wheel grease cap.

3 Using a universal t w o leg puller or Fiat puller A.40005

together w i t h items 1 and 9 remove the wheel hub/

drum assembly having first extracted the splitpin if

fitted and released the hub retaining nut (see FIG

8:10).

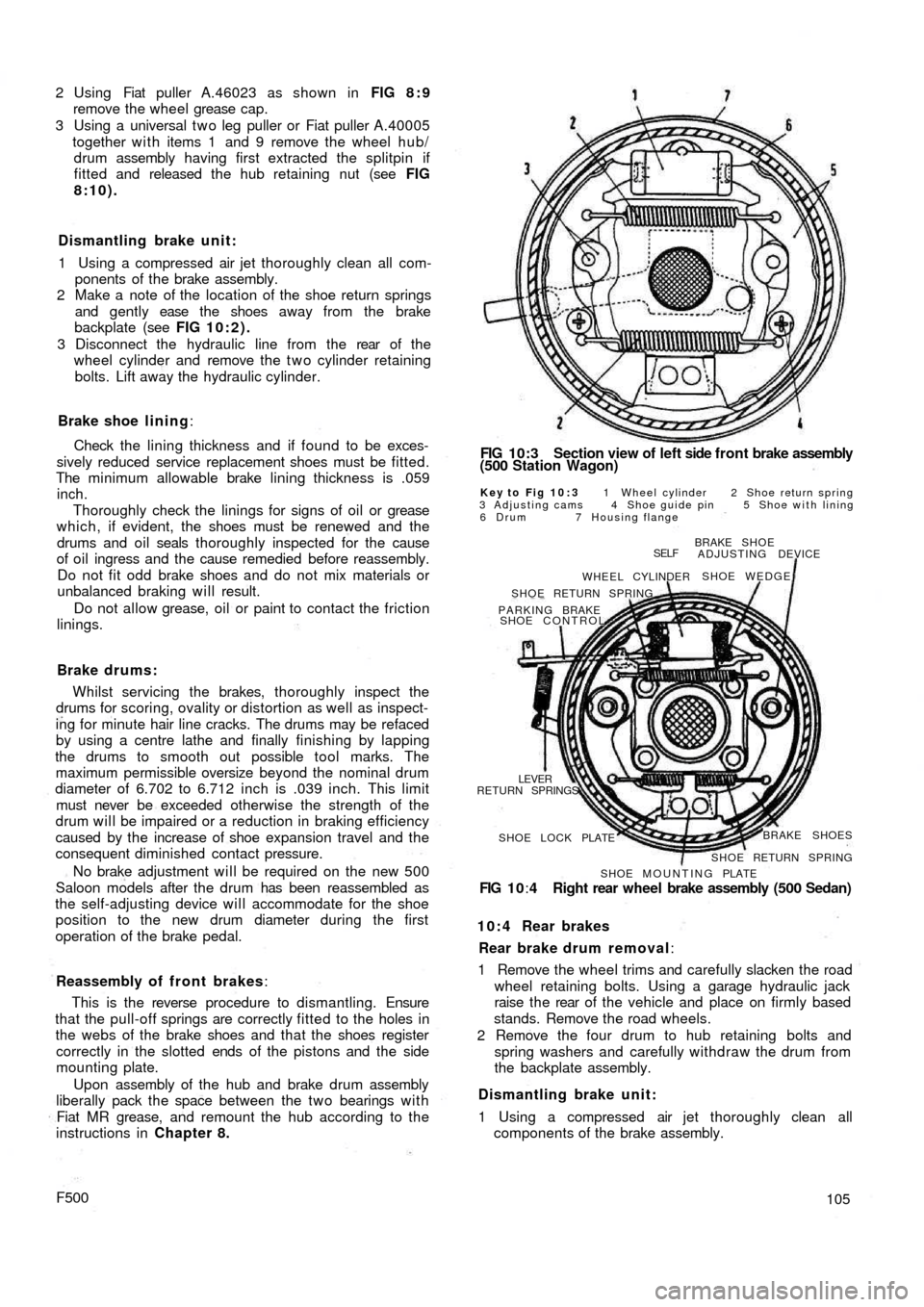

Dismantling brake unit:

1 Using a compressed air jet thoroughly clean all com-

ponents of the brake assembly.

2 Make a note of the location of the shoe return springs

and gently ease the shoes away from the brake

backplate (see FIG 10:2).

3 Disconnect the hydraulic line from the rear of t h e

wheel cylinder and remove the t w o cylinder retaining

bolts. Lift away the hydraulic cylinder.

Brake shoe lining:

Check the lining thickness and if found to be exces-

sively reduced service replacement shoes must be fitted.

The minimum allowable brake lining thickness is .059

inch.

Thoroughly check the linings for signs of oil or grease

which, if evident, the shoes must be renewed and the

drums and oil seals thoroughly inspected for the cause

of oil ingress and the cause remedied before reassembly.

Do not fit odd brake shoes and do not mix materials or

unbalanced braking will result.

Do not allow grease, oil or paint to contact the friction

linings.

Brake drums:

Whilst servicing the brakes, thoroughly inspect the

drums for scoring, ovality or distortion as well as inspect-

ing for minute hair line cracks. The drums may be refaced

by using a centre lathe and finally finishing by lapping

the drums to smooth out possible tool marks. The

maximum permissible oversize beyond the nominal drum

diameter of 6.702 to 6.712 inch is .039 inch. This limit

must never be exceeded otherwise the strength of the

drum will be impaired or a reduction in braking efficiency

caused by the increase of shoe expansion travel and the

consequent diminished contact pressure.

No brake adjustment will be required on the new 500

Saloon models after the drum has been reassembled as

the self-adjusting device will accommodate for the shoe

position to the new drum diameter during the first

operation of the brake pedal.

Reassembly of front brakes:

This is the reverse procedure to dismantling. Ensure

that the pull-off springs are correctly fitted to the holes in

the webs of the brake shoes and that the shoes register

correctly in the slotted ends of the pistons and the

side

mounting plate.

Upon assembly of the hub and brake drum assembly

liberally pack the space between the two bearings w i t h

Fiat MR grease, and remount the hub according to the

instructions in Chapter 8.

F500

FIG 10:3 Section view of left side f r o n t brake assembly

(500 Station Wagon)

Key to Fig 10:3 1 Wheel cylinder 2 Shoe return spring

3 Adjusting cams 4 Shoe guide pin 5 Shoe with lining

6 Drum 7 Housing flange

BRAKE SHOE

ADJUSTING DEVICE

SHOE WEDGE

SELF

WHEEL CYLINDER

SHOE RETURN SPRING

PARKING BRAKE

SHOE CONTROL

RETURN SPRINGS

LEVER

SHOE LOCK PLATEBRAKE SHOES

SHOE RETURN SPRING

SHOE MOUNTING PLATE

FIG 1 0:4 Right rear wheel brake assembly (500 Sedan)

10:4 Rear brakes

Rear brake drum removal:

1 Remove the wheel trims and carefully slacken the road

wheel retaining bolts. Using a garage hydraulic jack

raise the rear of t h e vehicle and place on firmly based

stands. Remove the road wheels.

2 Remove the four drum to hub retaining bolts and

spring washers and carefully withdraw the drum from

the backplate assembly.

Dismantling brake unit:

1 Using a compressed air jet thoroughly clean all

components of the brake assembly.

105

Page 101 of 128

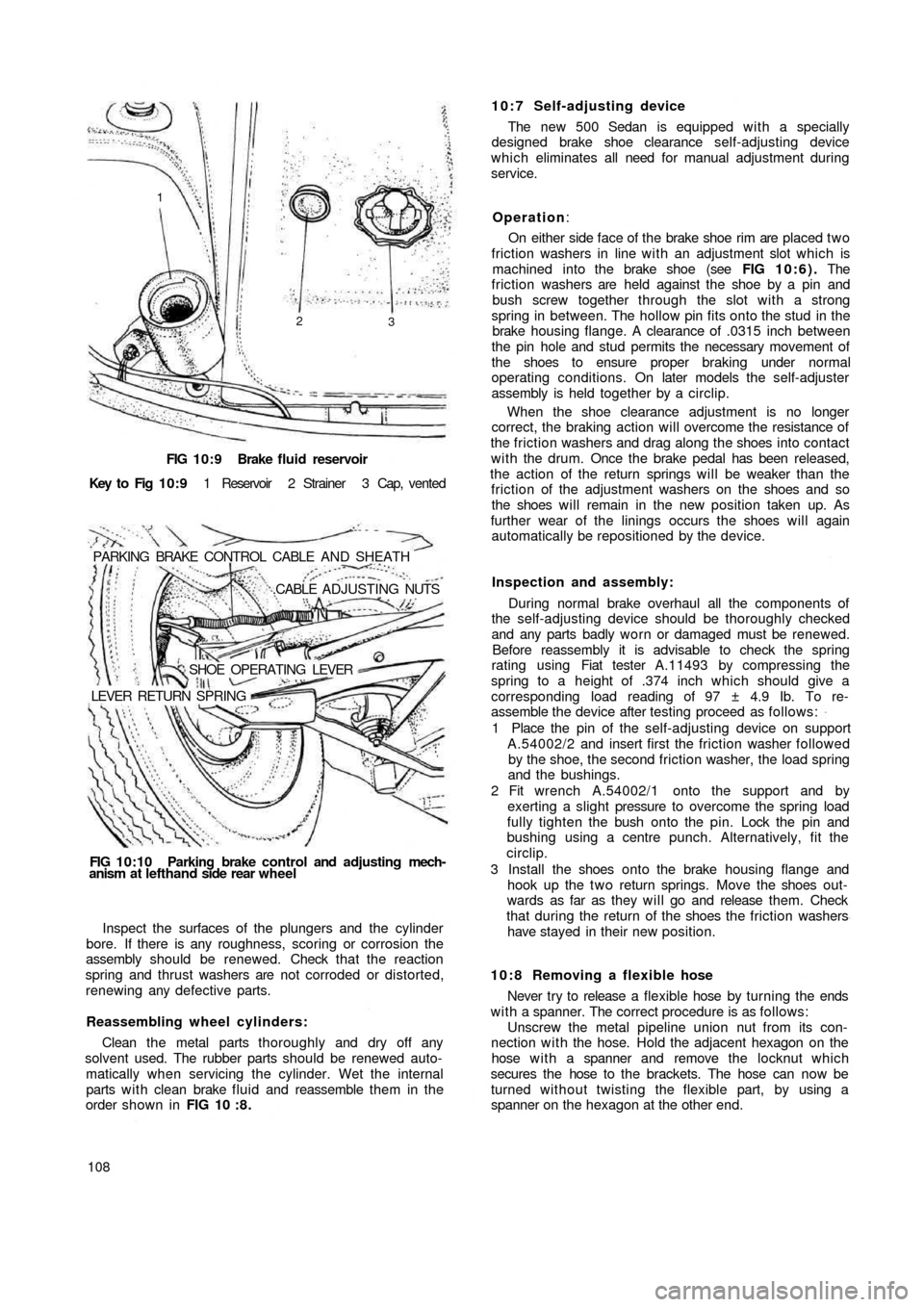

FIG 10:9 Brake fluid reservoir

Key to Fig 1 0 : 9 1 Reservoir 2 Strainer 3 Cap, vented

PARKING BRAKE CONTROL CABLE AND SHEATH

.CABLE ADJUSTING NUTS

SHOE OPERATING LEVER

LEVER RETURN SPRING

FIG 10:10 Parking brake control and adjusting mech-

anism at lefthand side rear wheel

Inspect the surfaces of the plungers and the cylinder

bore. If there is any roughness, scoring or corrosion the

assembly should be renewed. Check that the reaction

spring and thrust washers are not corroded or distorted,

renewing any defective parts.

Reassembling wheel cylinders:

Clean the metal parts thoroughly and dry off any

solvent used. The rubber parts should be renewed auto-

matically when servicing the cylinder. Wet the internal

parts w i t h clean brake f l u i d and reassemble them in the

order shown in FIG 10 : 8 .

10810:7 Self-adjusting device

The new 500 Sedan is equipped with a specially

designed brake shoe clearance self-adjusting device

which eliminates all need for manual adjustment during

service.

Operation:

On either side face of the brake shoe rim are placed t w o

friction washers in line with an adjustment slot which is

machined into the brake shoe (see FIG 10:6). The

friction washers are held against the shoe by a pin and

bush screw together through the slot with a strong

spring in between. The hollow pin fits onto the stud in the

brake housing flange. A clearance of .0315 inch between

the pin hole and stud permits the necessary movement of

the shoes to ensure proper braking under normal

operating conditions. On later models the self-adjuster

assembly is held together by a circlip.

When the shoe clearance adjustment is no longer

correct, the braking action will overcome the resistance of

the friction washers and drag along the shoes into contact

with the drum. Once the brake pedal has been released,

the action of the return springs will be weaker than the

friction of the adjustment washers on the shoes and so

the shoes will remain in the new position taken up. As

further wear of the linings occurs the shoes will again

automatically be repositioned by the device.

Inspection and assembly:

During normal brake overhaul all the components of

the self-adjusting device should be thoroughly checked

and any parts badly worn or damaged must be renewed.

Before reassembly it is advisable to check the spring

rating using Fiat tester A.11493 by

compressing the

spring to a height of .374 inch which should give a

corresponding load reading of 97 ± 4.9 Ib. To re-

assemble the device after testing proceed as follows:

1 Place the pin of the self-adjusting device on support

A.54002/2 and insert first the friction washer followed

by the shoe, the second friction washer, the load spring

and the bushings.

2 Fit wrench A.54002/1 onto the support and by

exerting a slight pressure to overcome the spring load

fully tighten the bush onto the pin. Lock the pin and

bushing using a centre punch. Alternatively, fit the

circlip.

3 Install the shoes onto the brake housing flange and

hook up the t w o return springs. Move the shoes out-

wards as far as they will go and release them. Check

that during the return of the shoes the friction washers

have stayed in their new position.

10:8 Removing a flexible hose

Never try to release a flexible hose by turning the ends

w i t h a spanner. The correct procedure is as follows:

Unscrew the metal pipeline union nut from its con-

nection with the hose. Hold the adjacent hexagon on the

hose w i t h a spanner and remove the locknut which

secures the hose to the brackets. The hose can now be

turned without twisting the flexible part, by using a

spanner on the hexagon at the other end.

1

2

3