engine FIAT 500 1967 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1967, Model line: 500, Model: FIAT 500 1967 1.GPages: 128, PDF Size: 9.01 MB

Page 2 of 128

CHAPTER 1

THE ENGINE

1 :1

1 :2

1 :3

1 :4

1 :5

1 :6

1 :7

1 :8

1:9

1 :10

1 :11Description

Engine removal (sedan—all versions)

Engine removal (station wagon)

Engine disassembly (sedan—all versions)

Engine disassembly (station wagon)

Cylinder head removal, servicing and

replacement

Timing gear overhaul

Crankcase and cylinders

Piston assembly

Connecting rods

Crankshaft and main bearings

1 :1 Description

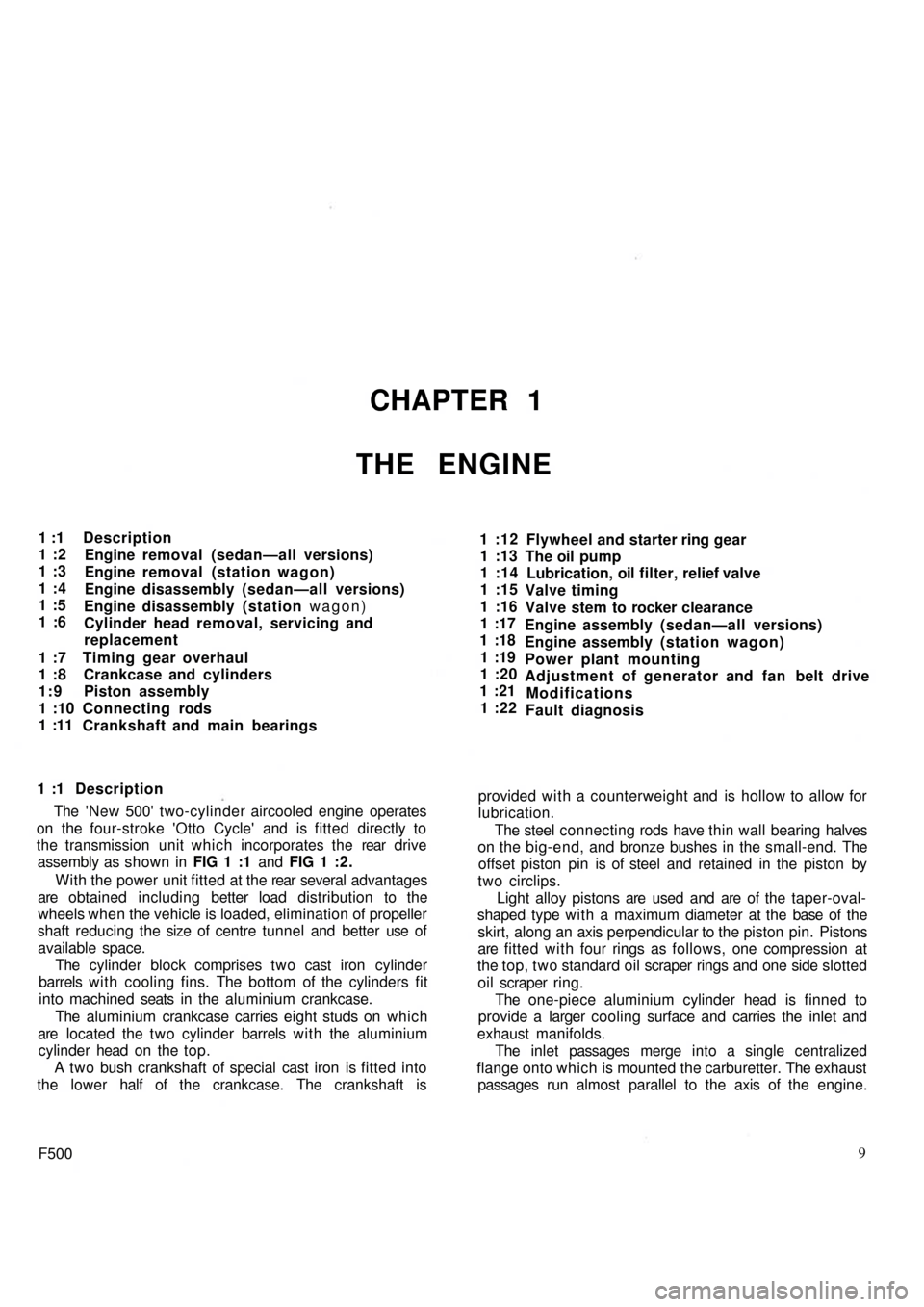

The 'New 500' two-cylinder aircooled engine operates

on the four-stroke 'Otto Cycle' and is fitted directly to

the transmission unit which incorporates the rear drive

assembly as shown in FIG 1 :1 and FIG 1 :2.

With the power unit fitted at the rear several advantages

are obtained including better load distribution to the

wheels when the vehicle is loaded, elimination of propeller

shaft reducing the size of centre tunnel and better use of

available space.

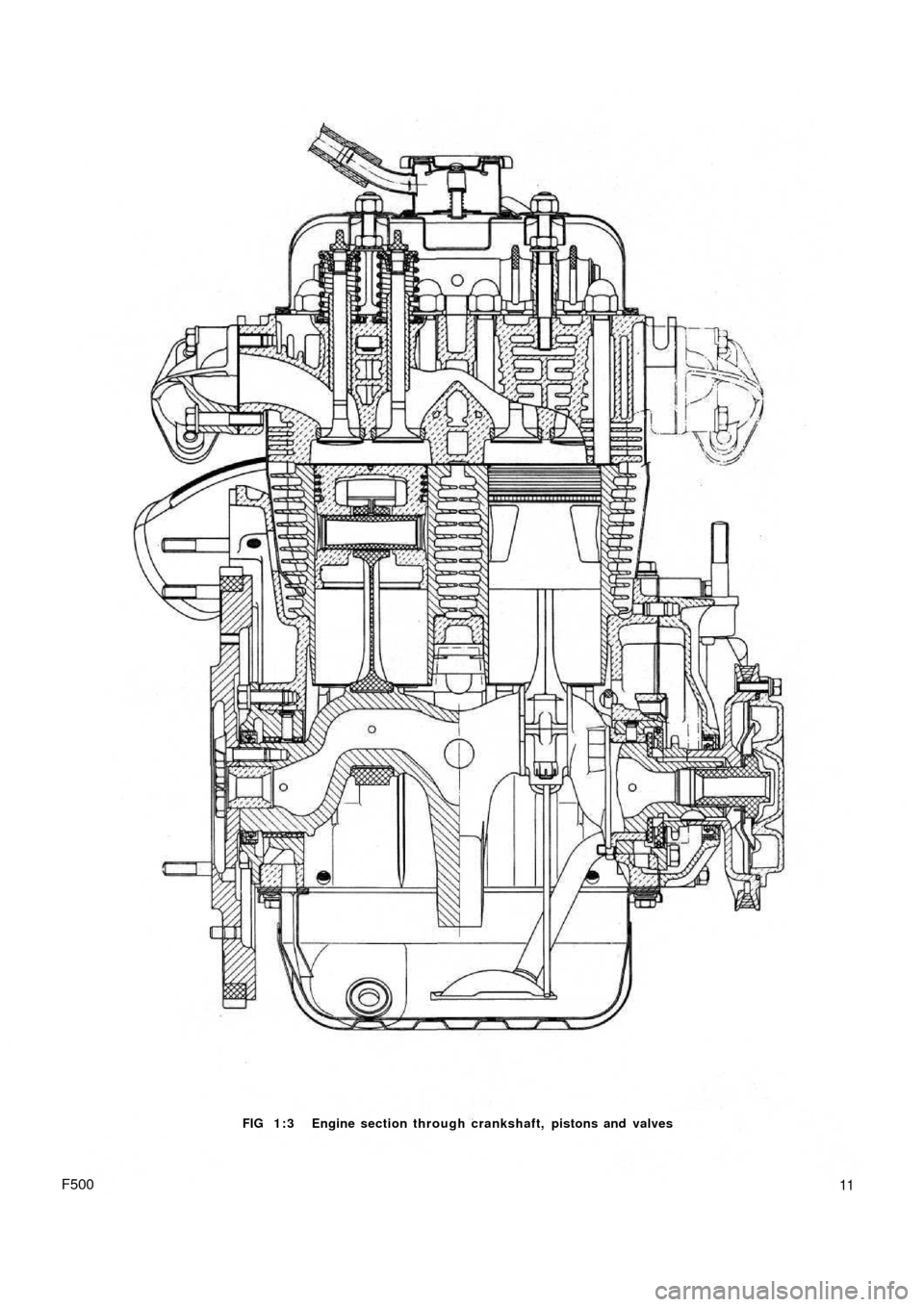

The cylinder block comprises t w o cast iron cylinder

barrels w i t h cooling fins. The bottom of the cylinders fit

into machined seats in the aluminium crankcase.

The aluminium crankcase carries eight studs on which

are located the t w o cylinder barrels w i t h the aluminium

cylinder head on the top.

A two bush crankshaft of special cast iron is fitted into

the lower half of the crankcase. The crankshaft is

F5009 provided with a counterweight and is hollow to allow for

lubrication.

The steel connecting rods have thin wall bearing halves

on the big-end, and bronze bushes in the small-end. The

offset piston pin is of steel and retained in the piston by

two circlips.

Light alloy pistons are used and are of the taper-oval-

shaped type with a maximum diameter at the base of the

skirt, along an axis perpendicular to the piston pin. Pistons

are fitted with four rings as follows, one compression at

the top, two standard oil scraper rings and one side slotted

oil scraper ring.

The one-piece aluminium cylinder head is finned to

provide a larger cooling surface and carries the inlet and

exhaust manifolds.

The inlet passages merge into a single centralized

flange onto which is mounted the carburetter. The exhaust

passages run almost parallel to the axis of the engine. 1 :12

1 :13

1 :14

1 :15

1 :16

1 :17

1 :18

1 :19

1 :20

1 :21

1 :22Flywheel and starter ring gear

The oil pump

Lubrication, oil filter, relief valve

Valve timing

Valve stem to rocker clearance

Engine assembly (sedan—all versions)

Engine assembly (station wagon)

Power plant mounting

Adjustment of generator and fan belt drive

Modifications

Fault diagnosis

Page 3 of 128

FIG 1:1 Left side view of the power plant to suit

500 Sedan

10

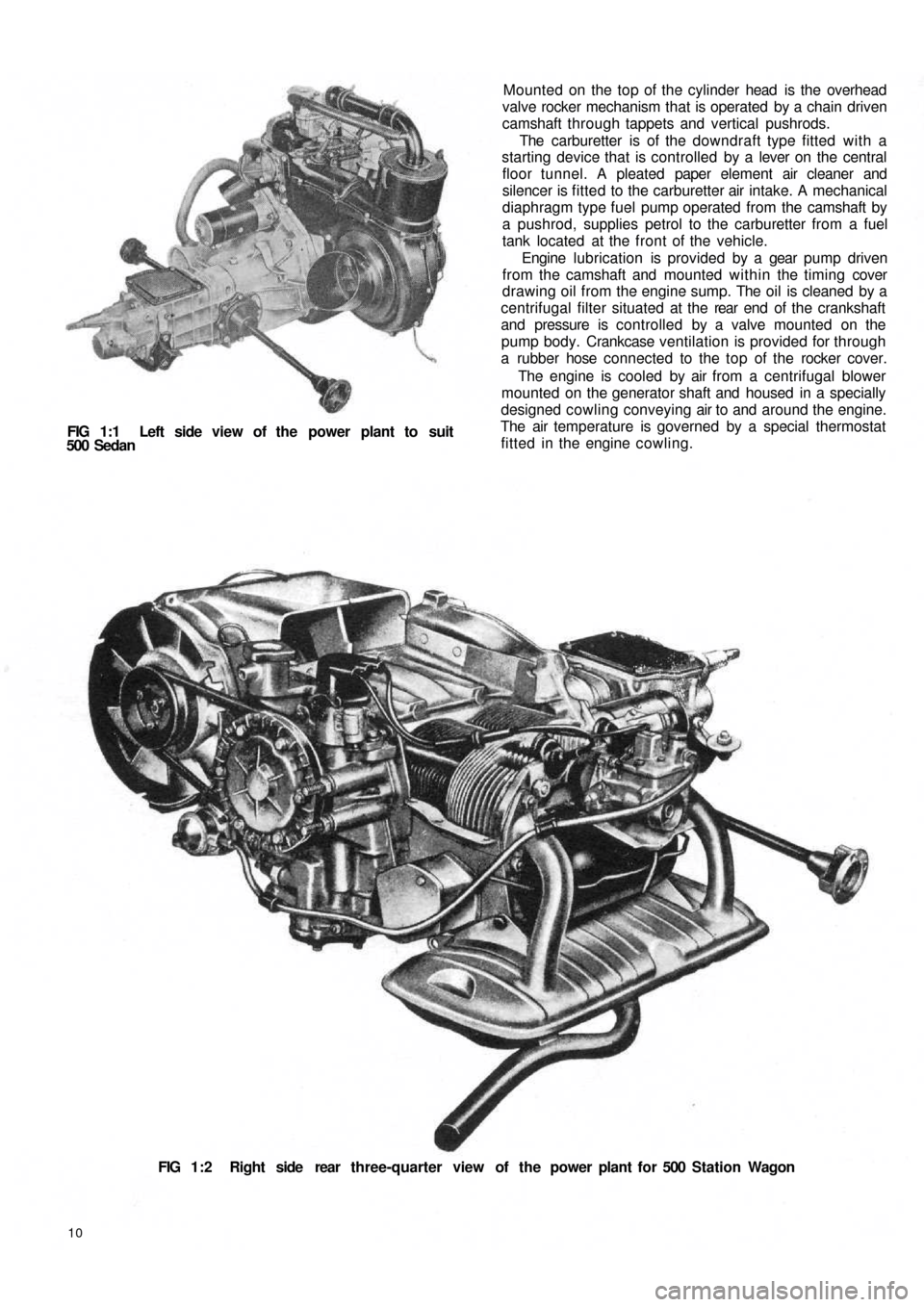

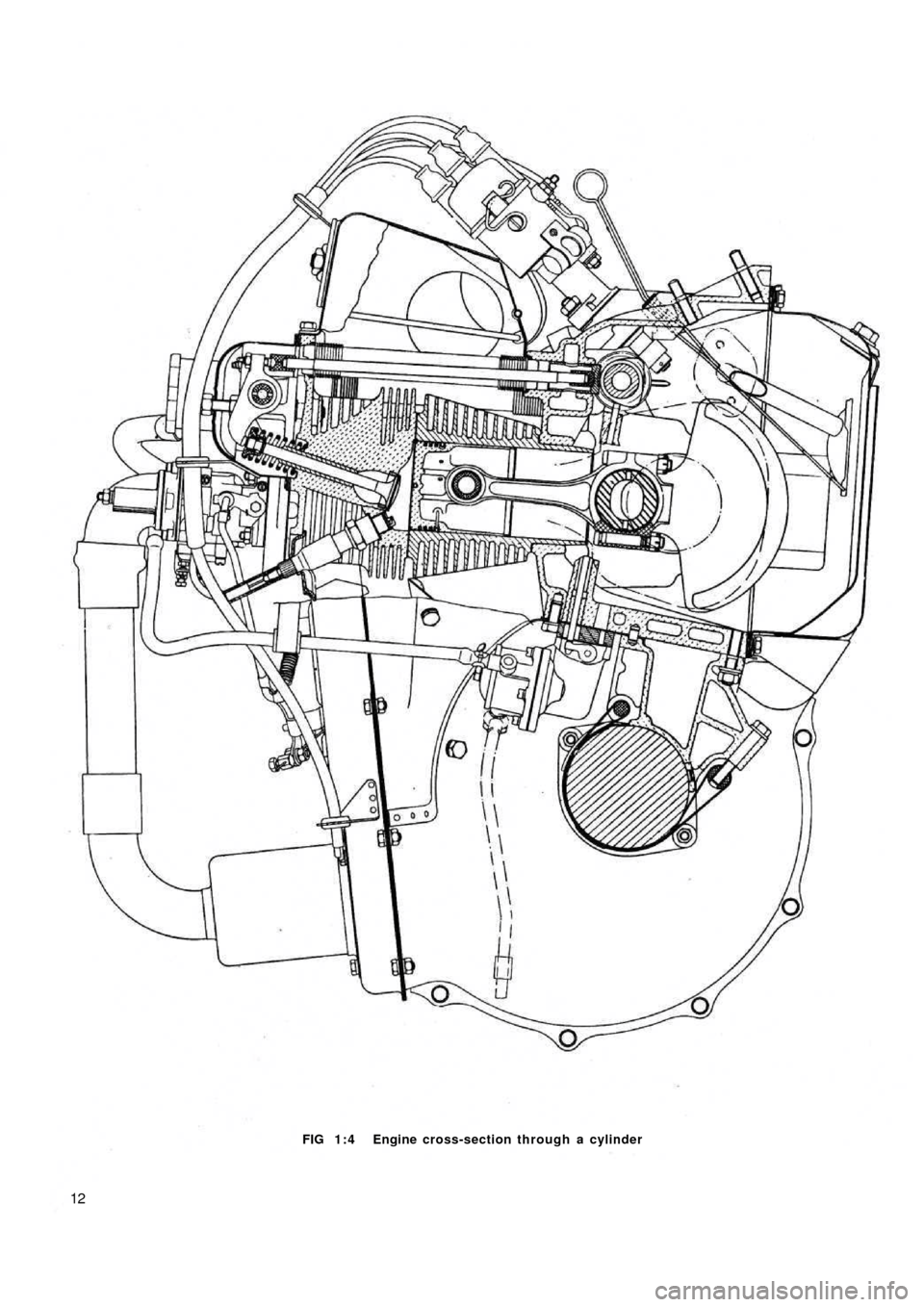

FIG 1:2 Right side rear three-quarter view of the power plant for 500 Station Wagon Mounted on the top of the cylinder head is the overhead

valve rocker mechanism that is operated by a chain driven

camshaft through tappets and vertical pushrods.

The carburetter is of the downdraft type fitted with a

starting device that is controlled by a lever on the central

floor tunnel. A pleated paper element air cleaner and

silencer is fitted to the carburetter air intake. A mechanical

diaphragm type fuel pump operated from the camshaft by

a pushrod, supplies petrol to the carburetter from a fuel

tank located at the front of the vehicle.

Engine lubrication is provided by a gear pump driven

from the camshaft and mounted within the timing cover

drawing oil from the engine sump. The oil is cleaned by a

centrifugal filter situated at the rear end of t h e crankshaft

and pressure is controlled by a valve mounted on the

pump body. Crankcase ventilation is provided for through

a rubber hose connected to the top of the rocker cover.

The engine is cooled by air from a centrifugal blower

mounted on the generator shaft and housed in a specially

designed cowling conveying air to and around the engine.

The air temperature is governed by a special thermostat

fitted in the engine cowling.

Page 4 of 128

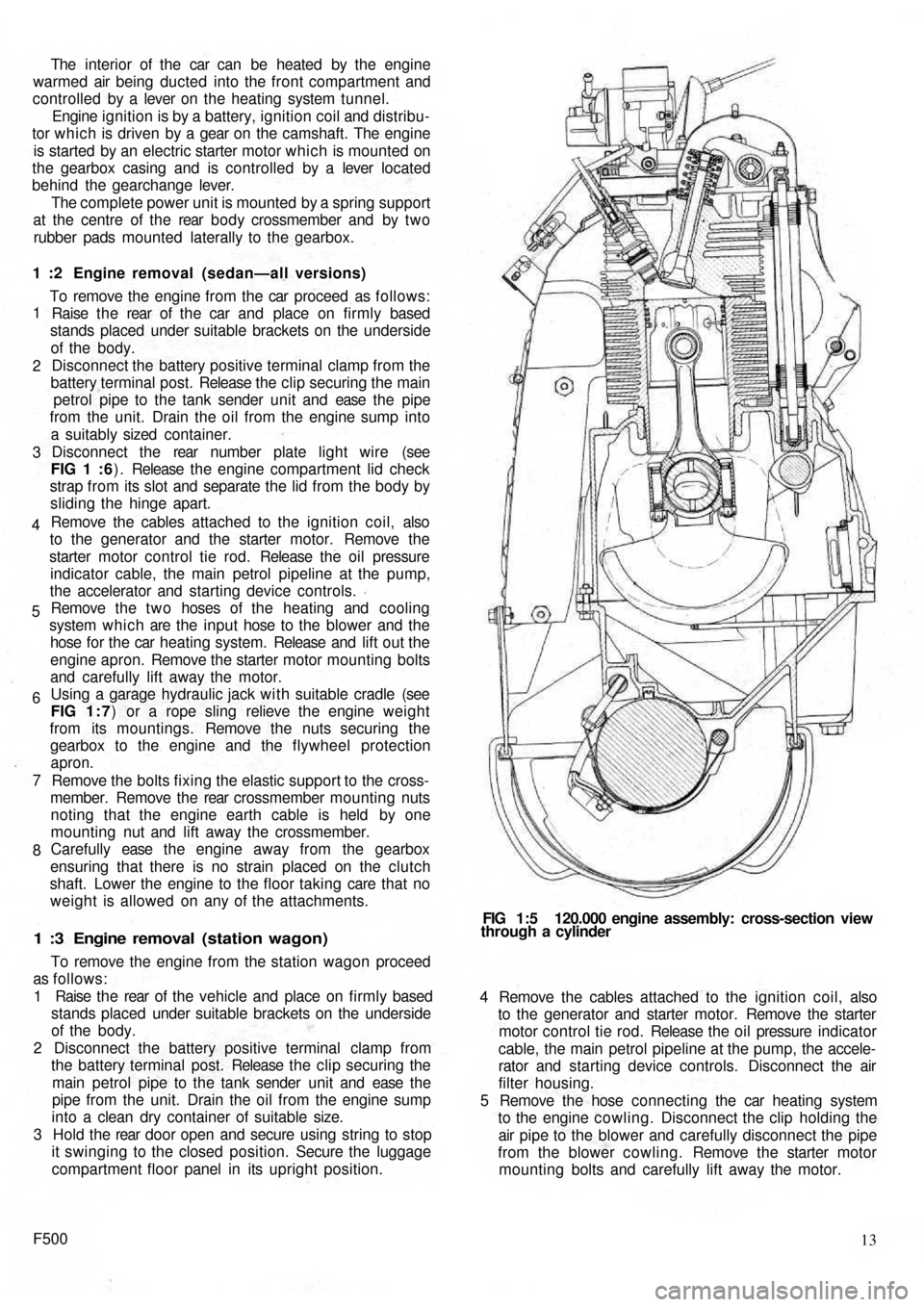

FIG 1 : 3 Engine section through crankshaft, pistons and valves

F50011

Page 5 of 128

FIG 1 : 4 Engine cross-section through a cylinder

12

Page 6 of 128

The interior of the car can be heated by the engine

warmed air being ducted into the front compartment and

controlled by a lever on the heating system tunnel.

Engine ignition is by a battery, ignition coil and distribu-

tor which is driven by a gear on the camshaft. The engine

is started by an electric starter motor which is mounted on

the gearbox casing and is controlled by a lever located

behind the gearchange lever.

The complete power unit is mounted by a spring support

at the centre of the rear b o d y crossmember and by t w o

rubber pads mounted laterally to the gearbox.

1 :2 Engine removal (sedan—all versions)

To remove the engine from the car proceed as follows:

Raise t h e rear of t h e car and place on firmly based

stands placed under suitable brackets on the underside

of the body.

Disconnect the battery positive terminal clamp from the

battery terminal post. Release the clip securing the main

petrol pipe to the tank sender unit and ease t h e pipe

from the unit. Drain the oil from the engine sump into

a suitably sized container.

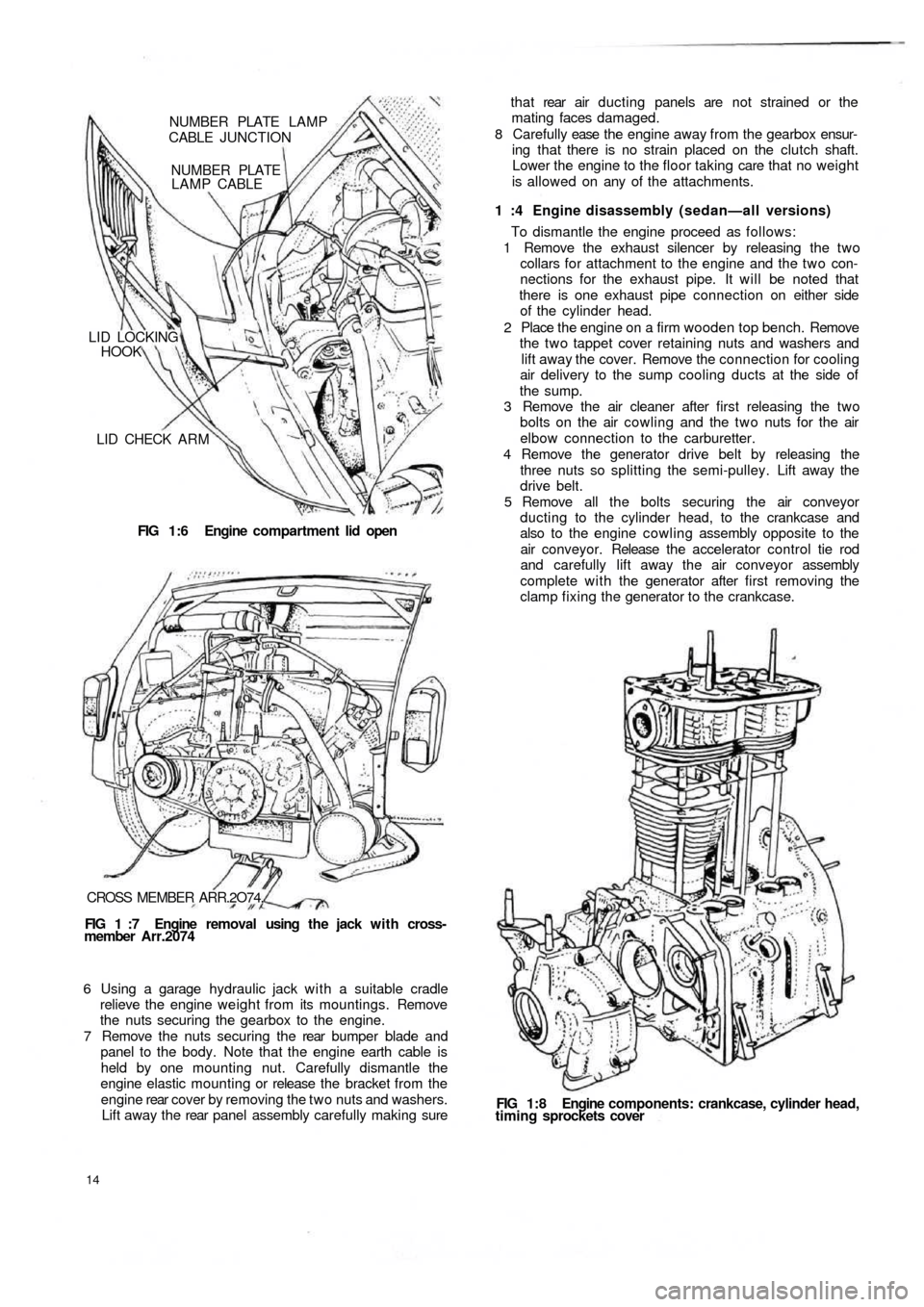

D i s c o n n e c t t h e rear number plate light wire (see

FIG 1 : 6) . Release t h e engine compartment lid check

strap from its slot and separate the lid from the body by

sliding the hinge apart.

Remove the cables attached to the ignition coil, also

to the generator and the starter motor. Remove the

starter motor control tie rod.

Release the oil pressure

indicator cable, the main petrol pipeline at the pump,

the accelerator and starting device controls.

Remove the t w o hoses of the heating and cooling

system which are the input hose to the blower and the

hose for the car heating system. Release and lift out the

engine apron. Remove the starter motor mounting bolts

and carefully lift away the motor.

Using a garage hydraulic jack with suitable cradle (see

FIG 1 : 7) or a rope sling relieve the engine weight

from its mountings. Remove the nuts securing the

gearbox to the engine and the flywheel protection

apron.

Remove the bolts fixing the elastic support to the cross-

member. Remove the rear crossmember mounting nuts

noting that the engine earth cable is held by one

mounting nut and lift away the crossmember.

Carefully ease t h e engine away from the gearbox

ensuring that there is no strain placed on the clutch

shaft. Lower the engine to the floor taking care that no

weight is allowed on any of the attachments. 1

2

3

4

5

6

7

8

1 :3 Engine removal (station wagon)

To remove the engine from the station wagon proceed

as follows:

1 Raise t h e rear of the vehicle and place on firmly based

stands placed under suitable brackets on the underside

of the body.

2 Disconnect the battery positive terminal clamp from

the battery terminal post. Release the clip securing the

main petrol pipe to the tank sender unit and ease the

pipe from the unit. Drain the oil from the engine sump

into a clean dry container of suitable size.

3 H o l d t h e rear door open and secure using string to stop

it swinging to the closed position. Secure the luggage

compartment floor panel in its upright position.

F50013 4 Remove the cables attached to the ignition coil, also

to the generator and starter motor. Remove the starter

motor control tie rod. Release the o i l pressure indicator

cable, the main petrol pipeline at the pump, the accele-

rator and starting device controls. Disconnect the air

filter housing.

5 Remove the hose connecting the car heating system

to the engine cowling. Disconnect the clip holding the

air pipe to the blower and carefully disconnect the pipe

from the blower cowling. Remove the starter motor

mounting bolts and carefully lift away the motor. FIG 1:5 120.000 engine assembly: cross-section view

through a cylinder

Page 7 of 128

LID CHECK A R M

FIG 1:6 Engine compartment lid open LID LOCKING

HOOK

NUMBER PLATE

LAMP CABLE NUMBER PLATE LAMP

CABLE JUNCTION

CROSS MEMBER ARR.2O74.

FIG 1 :7 Engine removal using the jack with cross-

member Arr.2074

6 Using a garage hydraulic jack with a suitable cradle

relieve the engine weight from its mountings. Remove

the nuts securing the gearbox to the engine.

7 Remove the nuts securing the rear bumper blade and

panel to the body. Note that the engine earth cable is

held by one mounting nut. Carefully dismantle the

engine elastic mounting or release the bracket from the

engine rear cover by removing the two nuts and washers.

Lift away t h e rear panel assembly carefully making sure

14

FIG 1 : 8 Engine components: crankcase, cylinder head,

timing sprockets cover To dismantle the engine proceed as follows:

1 Remove the exhaust silencer by releasing the two

collars for attachment to the engine and the two con-

nections for the exhaust pipe. It will be noted that

there is one exhaust pipe connection on either side

of the cylinder head.

2 Place the engine on a firm wooden top bench. Remove

the two tappet cover retaining nuts and washers and

lift away the cover. Remove the connection for cooling

air delivery to the sump cooling ducts at the side of

the sump.

3 Remove the air cleaner after first releasing the two

bolts on the air cowling and the two nuts for the air

elbow connection to the carburetter.

4 Remove the generator drive belt by releasing the

three nuts so splitting the semi-pulley. Lift away the

drive belt.

5 Remove all the bolts securing the air conveyor

ducting to the cylinder head, to the crankcase and

also to the engine cowling assembly opposite to the

air conveyor. Release the accelerator control tie rod

and carefully lift away the air conveyor assembly

complete with the generator after first removing the

clamp fixing the generator to the crankcase. 1 :4 Engine disassembly (sedan—all versions) t h a t rear air ducting panels are not strained or the

mating faces damaged.

8 Carefully ease the engine away from the gearbox ensur-

ing that there is no strain placed on the clutch shaft.

Lower the engine to the floor taking care that no weight

is allowed on any of the attachments.

Page 8 of 128

6 Release the ignition distributor support retaining nut

and lift away the distributor together w i t h its support.

7 Remove all the mounting bolts of the engine cooling

cowling and lift away the assembly. Release the t w o

carburetter retaining nuts and carefully remove the

carburetter together with its drip tray.

8 Lift away the valve rocker assembly having first

released the t w o retaining nuts together with the plain

washers and lock washers. Carefully lift out the valve

rocker pushrods noting their relevant positions.

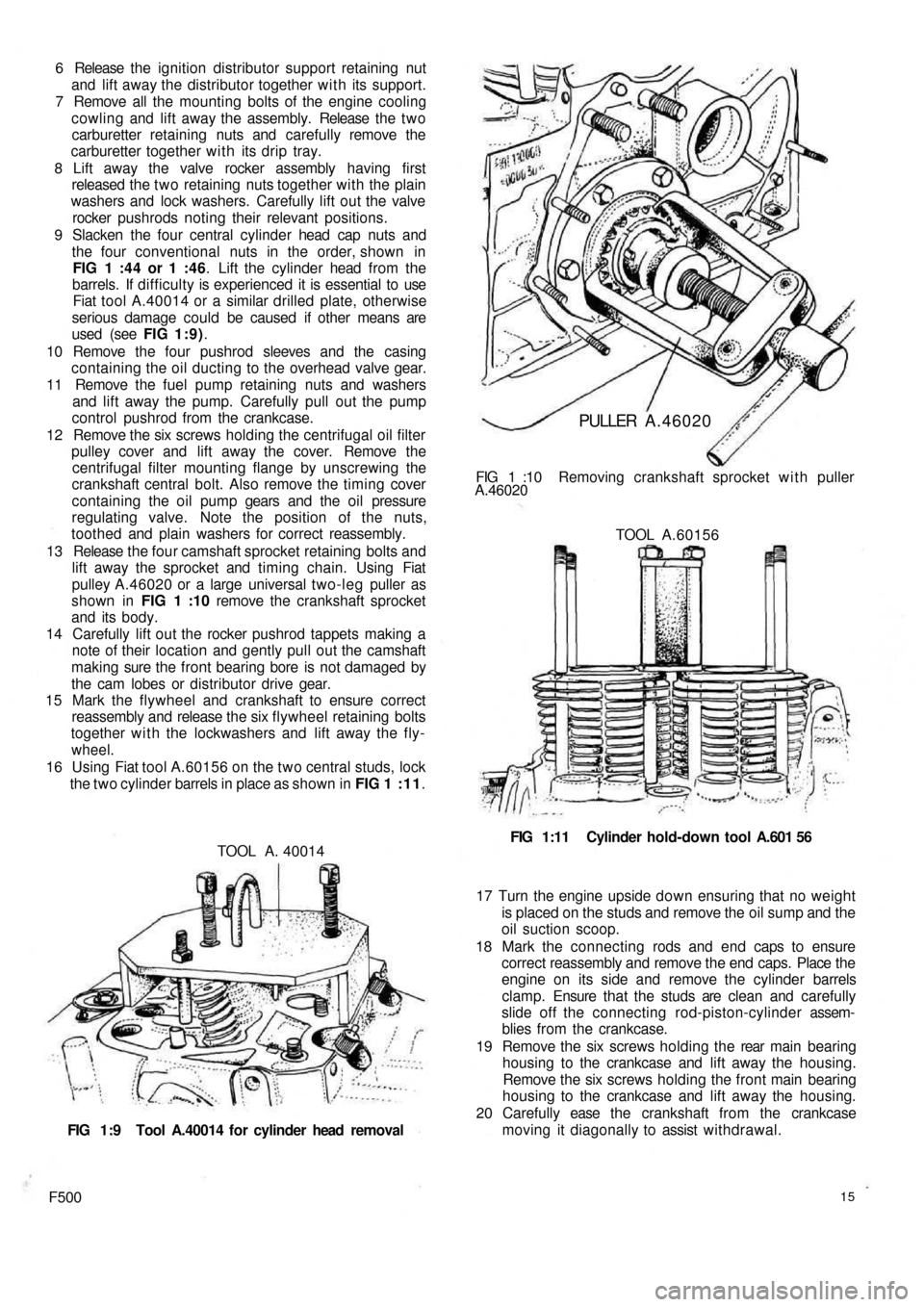

9 Slacken the four central cylinder head cap nuts and

the four conventional nuts in the order, shown in

FIG 1 :44 or 1 :46. Lift the cylinder head from the

barrels. If difficulty is experienced it is essential to use

Fiat tool A.40014 or a similar drilled plate, otherwise

serious damage could be caused if other means are

used (see FIG 1:9).

10 Remove the four pushrod sleeves and the casing

containing the oil ducting to the overhead valve gear.

11 Remove the fuel pump retaining nuts and washers

and lift away the pump. Carefully pull out the pump

control pushrod from the crankcase.

12 Remove the six screws holding the centrifugal oil filter

pulley cover and lift away the cover. Remove the

centrifugal filter mounting flange by unscrewing the

crankshaft central bolt. Also remove the timing cover

containing the oil pump gears and the oil pressure

regulating valve. Note the position of the nuts,

toothed and plain

washers for correct reassembly.

13 Release t h e four camshaft sprocket retaining bolts and

lift away the sprocket and timing chain. Using Fiat

pulley A.46020 or a large universal two-leg puller as

shown in FIG 1 :10 remove the crankshaft sprocket

and its body.

14 Carefully lift out the rocker pushrod tappets making a

note of their location and gently pull out the camshaft

making sure the front bearing bore is not damaged by

the cam lobes or distributor drive gear.

15 Mark the flywheel and crankshaft to ensure correct

reassembly and release the six f l y w h e e l retaining bolts

together w i t h the lockwashers and lift away the fly-

wheel.

16 Using Fiat tool A.60156 on the two central studs, lock

the two cylinder barrels in place as shown in FIG 1 : 1 1.

TOOL A. 40014

FIG 1:9 Tool A.40014 for cylinder head removal

F50015

17 Turn the engine upside down ensuring that no weight

is placed on the studs and remove the oil sump and the

oil suction scoop.

18 Mark the connecting rods and end caps to ensure

correct reassembly and remove the end caps. Place the

engine on its side and remove the cylinder barrels

clamp. Ensure that the studs are clean and carefully

slide off the connecting rod-piston-cylinder assem-

blies from the crankcase.

19 Remove the six screws holding the rear main bearing

housing to the crankcase and lift away the housing.

Remove the six screws holding the front main bearing

housing to the crankcase and lift away the housing.

20 Carefully ease the crankshaft from the crankcase

moving it diagonally to assist withdrawal. FIG 1:11 Cylinder hold-down tool A.601 56 TOOL A.60156 FIG 1 :10 Removing crankshaft sprocket w i t h puller

A.46020

PULLER A.46020

Page 9 of 128

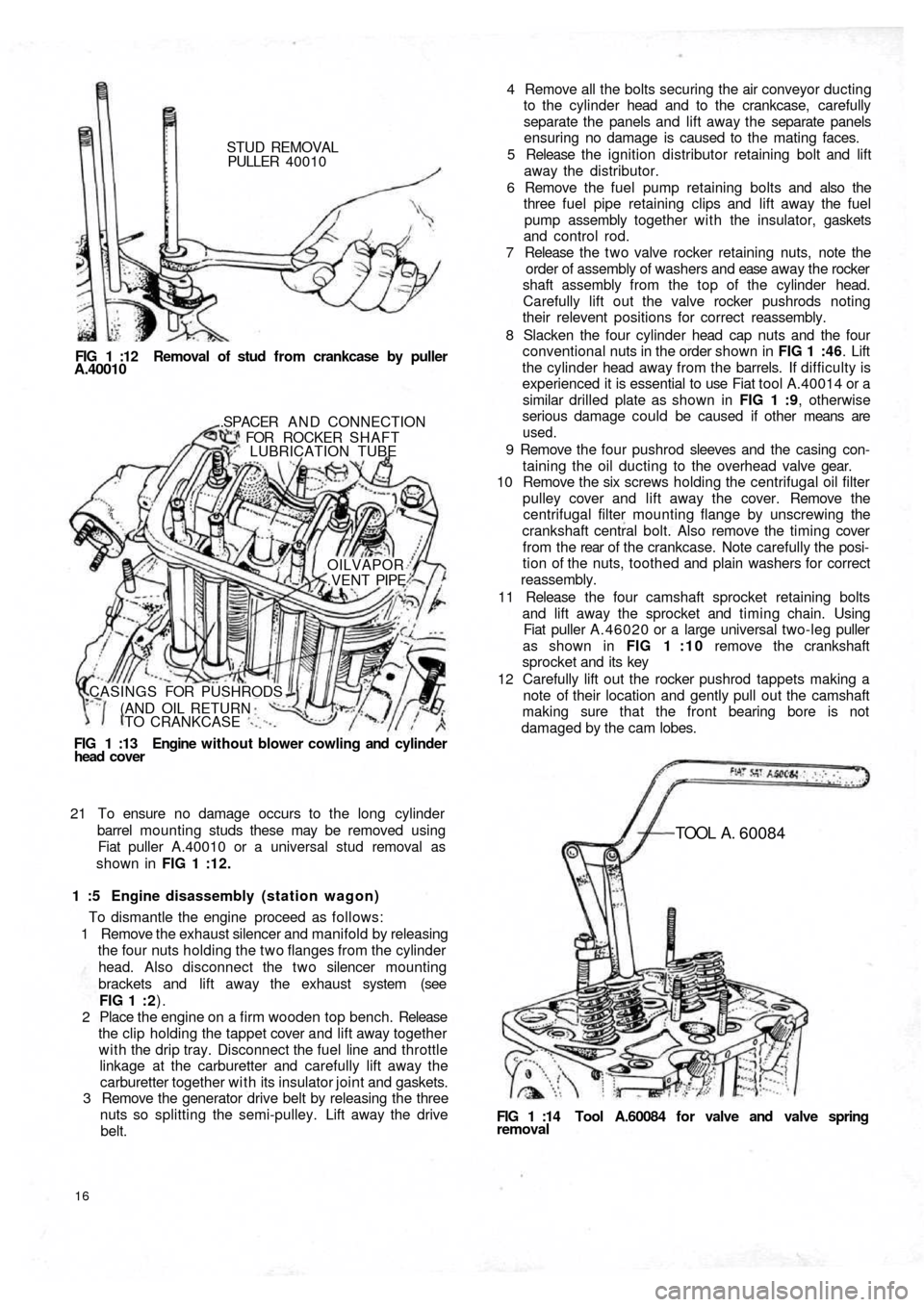

STUD REMOVAL

PULLER 40010

FIG 1 :12 Removal of stud from crankcase by puller

A.40010

FIG 1 :13 Engine without blower cowling and cylinder

head cover.SPACER A N D CONNECTION

FOR ROCKER SHAFT

LUBRICATION TUBE

OILVAPOR

.VENT PIPE

CASINGS FOR PUSHRODS

(AND OIL RETURN

TO CRANKCASE

21 To ensure no damage occurs to the long cylinder

barrel mounting studs these may be removed using

Fiat puller A.40010 or a universal stud removal as

shown in FIG 1 :12.

1 :5 Engine disassembly (station wagon)

To dismantle the engine proceed as follows:

1 Remove the exhaust silencer and manifold by releasing

the four nuts holding the two flanges from the cylinder

head. Also disconnect the two silencer mounting

brackets and lift away the exhaust system (see

FIG 1 : 2).

2 Place the engine on a firm wooden top bench. Release

the clip holding the tappet cover and lift away together

with the drip tray. Disconnect the fuel line and throttle

linkage at the carburetter and carefully lift away the

carburetter together with its insulator joint and gaskets.

3 Remove the generator drive belt by releasing the three

nuts so splitting the semi-pulley. Lift away the drive

belt.

16

FIG 1 :14 Tool A.60084 for valve and valve springremoval

TOOL A . 60084

4 Remove all the bolts securing the air conveyor ducting

to the cylinder head and to the crankcase, carefully

separate the panels and lift away the separate panels

ensuring no damage is caused to the mating faces.

5 Release the ignition distributor retaining bolt and lift

away the distributor.

6 Remove the fuel pump retaining bolts and also the

three fuel pipe retaining clips and lift away the fuel

pump assembly together with the insulator, gaskets

and control rod.

7 Release the t w o valve rocker retaining nuts, note the

order of assembly of washers and ease away the rocker

shaft assembly from the top of the cylinder head.

Carefully lift out the valve rocker pushrods noting

their relevent positions for correct reassembly.

8 Slacken the four cylinder head cap nuts and the four

conventional nuts in the order shown in FIG 1 :46. Lift

the cylinder head away from the barrels. If difficulty is

experienced it is essential to use Fiat tool A.40014 or a

similar drilled plate as shown in FIG 1 :9, otherwise

serious damage could be caused if other means are

used.

9 Remove the four pushrod sleeves and the casing con-

taining the oil ducting to the overhead valve gear.

10 Remove the six screws holding the centrifugal oil filter

pulley cover and lift away the cover. Remove the

centrifugal filter mounting flange by unscrewing the

crankshaft central bolt. Also remove the timing cover

f r o m t h e rear of t h e crankcase. Note carefully the posi-

tion of the nuts, toothed and plain washers for correct

reassembly.

11 Release the four camshaft sprocket retaining bolts

and lift away the sprocket and timing chain. Using

Fiat puller A.46020 or a large universal two-leg puller

as shown in FIG 1 : 1 0 remove the crankshaft

sprocket and its key

12 Carefully lift out the rocker pushrod tappets making a

note of their location and gently pull out the camshaft

making sure that the front bearing bore is not

damaged by the cam lobes.

Page 10 of 128

13 Remove all the bolts and washers joining the sump

casting to the crankcase making a special note of the

location of bolts of different lengths.

14 Mark the flywheel and crankshaft to ensure correct

reassembly and release the six flywheel retaining bolts

together with the lockwashers and lift away the fly-

wheel.

15 Using Fiat tool A.60156 on the two central studs, lock

the t w o cylinder barrels in place (see FIG 1 :11).

16 Turn the engine upside down ensuring that no weight

is placed on the studs.

17 Mark the connecting rods and end caps to ensure cor-

rect reassembly and remove the end caps. Place the

engine on its side and remove the cylinder barrels

clamp. Ensure t h a t t h e studs are clean and carefully

slide off the connecting rod-piston-cylinder assem-

blies from the crankcase.

18 Remove the six screws holding the rear bearing hous-

ing to the crankcase and lift away the housing. Remove

the six screws holding the front main bearing housing

to the crankcase and lift away its housing.

19 Carefully ease t h e crankshaft from the crankcase

moving it diagonally to assist w i t h d r a w a l .

20 To ensure no damage occurs to the long cylinder

barrel mounting studs these may be removed using

Fiat puller A.40010 or a universal stud remover as

shown in FIG 1 :12.

1 :6 Cylinder head removal, servicing and replace-

ment

Description:

The aluminium cylinder head is finned to increase the

cooling surface. Through bolts secure the head and the

two cylinders to the crankcase. The valves are controlled

by a camshaft through tappets, pushrods and rockers. The

connection between the head and the crankcase is via five

sleeves mounted directly between the head and crankcase,

and these accommodate the pushrods, lubricating oil and

passage for the crankcase gases. The cylinder head has

been

modified for the 110 F and later 120 engines as

they now incorporate a heater safety device as described

in Section 4 : 4 .

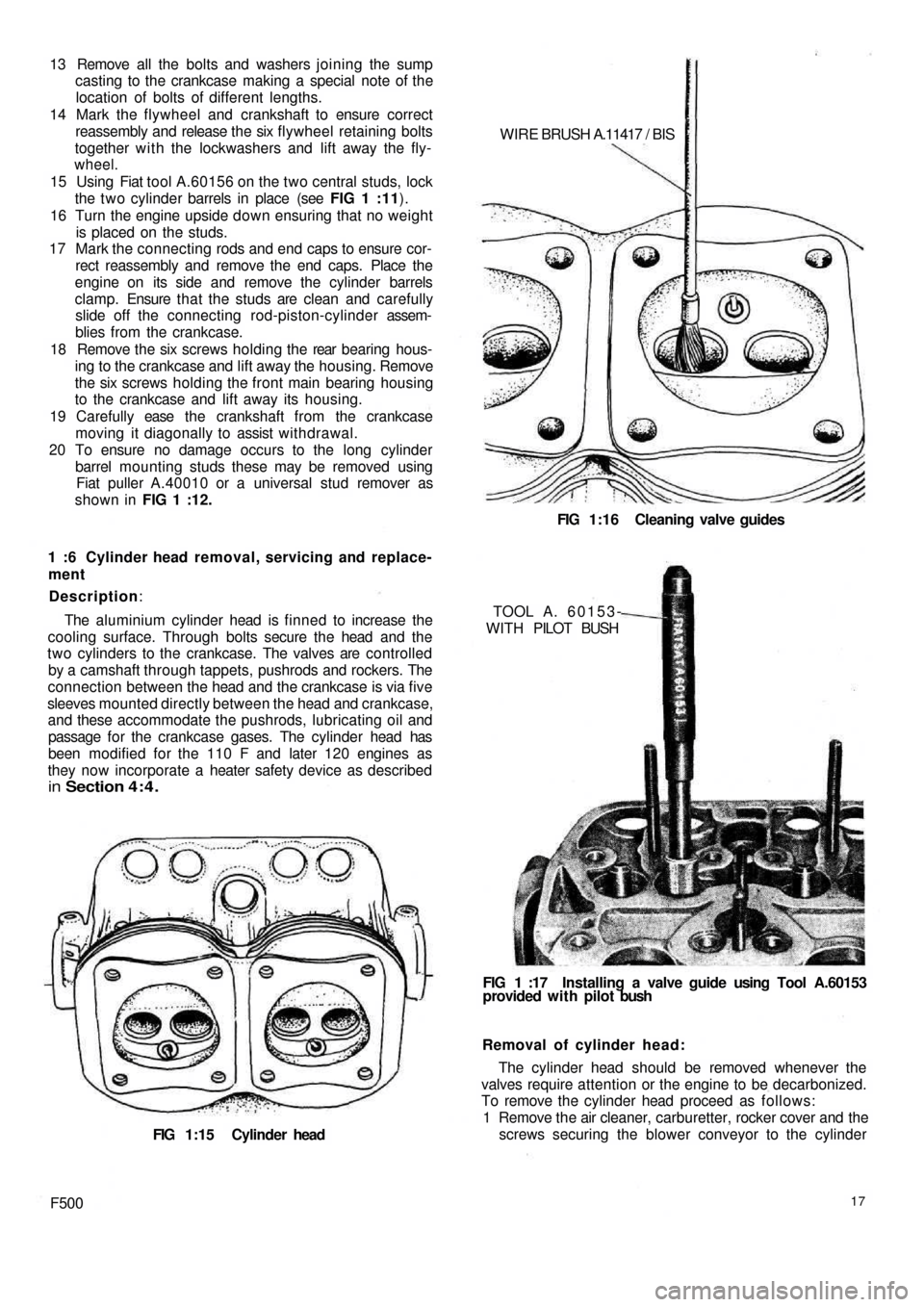

FIG 1:15 Cylinder head

17F500

The cylinder head should be removed whenever the

valves require attention or the engine to be decarbonized.

To remove the cylinder head proceed as f o l l o w s :

1 Remove the air cleaner, carburetter, rocker cover and the

screws securing the blower conveyor to the cylinder Removal of cylinder head: FIG 1 :17 Installing a valve guide using Tool A.60153

provided with pilot bush TOOL A. 6 0 1 5 3 -

WITH PILOT BUSH FIG 1:16 Cleaning valve guides

W I R E BRUSH A.11417 / BIS

Page 11 of 128

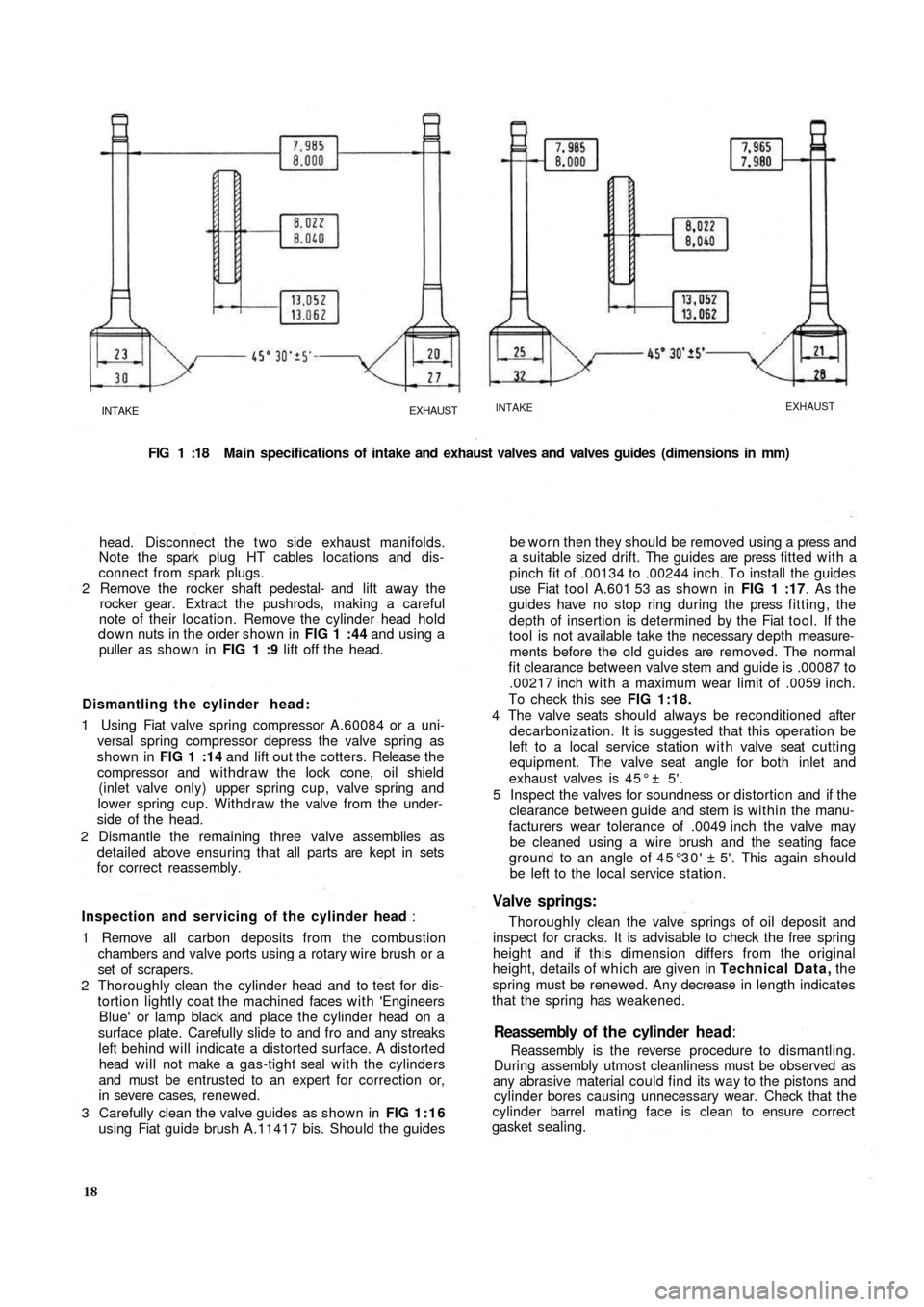

INTAKEEXHAUSTINTAKEEXHAUST

FIG 1 :18 Main specifications of intake and exhaust valves and valves guides (dimensions in mm)

head. Disconnect the t w o side exhaust manifolds.

Note the spark plug HT cables locations and dis-

connect from spark plugs.

2 Remove the rocker shaft pedestal- and lift away the

rocker gear. Extract the pushrods, making a careful

note of their location. Remove the cylinder head hold

down nuts in the order shown in FIG 1 :44 and using a

puller as shown in FIG 1 :9 lift off the head.

Dismantling the cylinder head:

1 Using Fiat valve spring compressor A.60084 or a uni-

versal spring compressor depress the valve spring as

shown in FIG 1 :14 and lift out the cotters. Release t h e

compressor and withdraw the lock cone, oil shield

(inlet valve only) upper spring cup, valve spring and

lower spring cup. Withdraw the valve from the under-

side of the head.

2 Dismantle the remaining three valve assemblies as

detailed above ensuring that all parts are kept in sets

for correct reassembly.

Inspection and servicing of the cylinder head :

1 Remove all carbon deposits from the combustion

chambers and valve ports using a rotary wire brush or a

set of scrapers.

2 Thoroughly clean the cylinder head and to test for dis-

tortion lightly coat the machined faces with 'Engineers

Blue' or lamp

black and place the cylinder head on a

surface plate. Carefully slide to and fro and any streaks

left behind will indicate a distorted surface. A distorted

head will not make a gas-tight seal with the cylinders

and must be entrusted to an expert for correction or,

in severe cases, renewed.

3 Carefully clean the valve guides as shown in FIG 1:16

using Fiat guide brush A.11417 bis. Should the guides

18Reassembly is the reverse procedure to dismantling.

During assembly utmost cleanliness must be observed as

any abrasive material could find its way to the pistons and

cylinder bores causing unnecessary wear. Check that the

cylinder barrel mating face is clean to ensure correct

gasket sealing.Reassembly of t h e cylinder head:

be worn then they should be removed using a press and

a suitable sized drift. The guides are press fitted with a

pinch fit of .00134 to .00244 inch. To install the guides

use Fiat tool A.601 53 as shown in FIG 1 :17. As the

guides have no stop ring during the press fitting, the

depth of insertion is determined by the Fiat tool. If the

tool is not available take the necessary depth measure-

ments before the old guides are removed. The normal

fit clearance between valve stem and guide is .00087 to

.00217 inch with a maximum wear limit of .0059 inch.

To check this see FIG 1:18.

4 The valve seats should always be reconditioned after

decarbonization. It is suggested that this operation be

left to a local service station with valve seat cutting

equipment. The valve seat angle for both inlet and

exhaust valves is 4 5 ° ± 5'.

5 Inspect the valves for soundness or distortion and if the

clearance between guide and stem is within the manu-

facturers wear tolerance of .0049 inch the valve may

be cleaned using a wire brush and the seating face

ground to an angle of 45°30' ± 5'. This again should

be left to the local service station.

Valve springs:

Thoroughly clean the valve springs of oil deposit and

inspect for cracks. It is advisable to check the free spring

height and if this dimension differs from the original

height, details of which are given in Technical Data, the

spring must be renewed. Any decrease in length indicates

that the spring has weakened.