engine FIAT 500 1967 1.G Service Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1967, Model line: 500, Model: FIAT 500 1967 1.GPages: 128, PDF Size: 9.01 MB

Page 46 of 128

CHAPTER 4

THE COOLING SYSTEM

4:1

4:2

4:3Description

Air outlet thermostat and shutter

Tension adjustment4:4

4:5

4:6Heating system safety device

Maintenance

Fault diagnosis

4:1Description

Sedan:

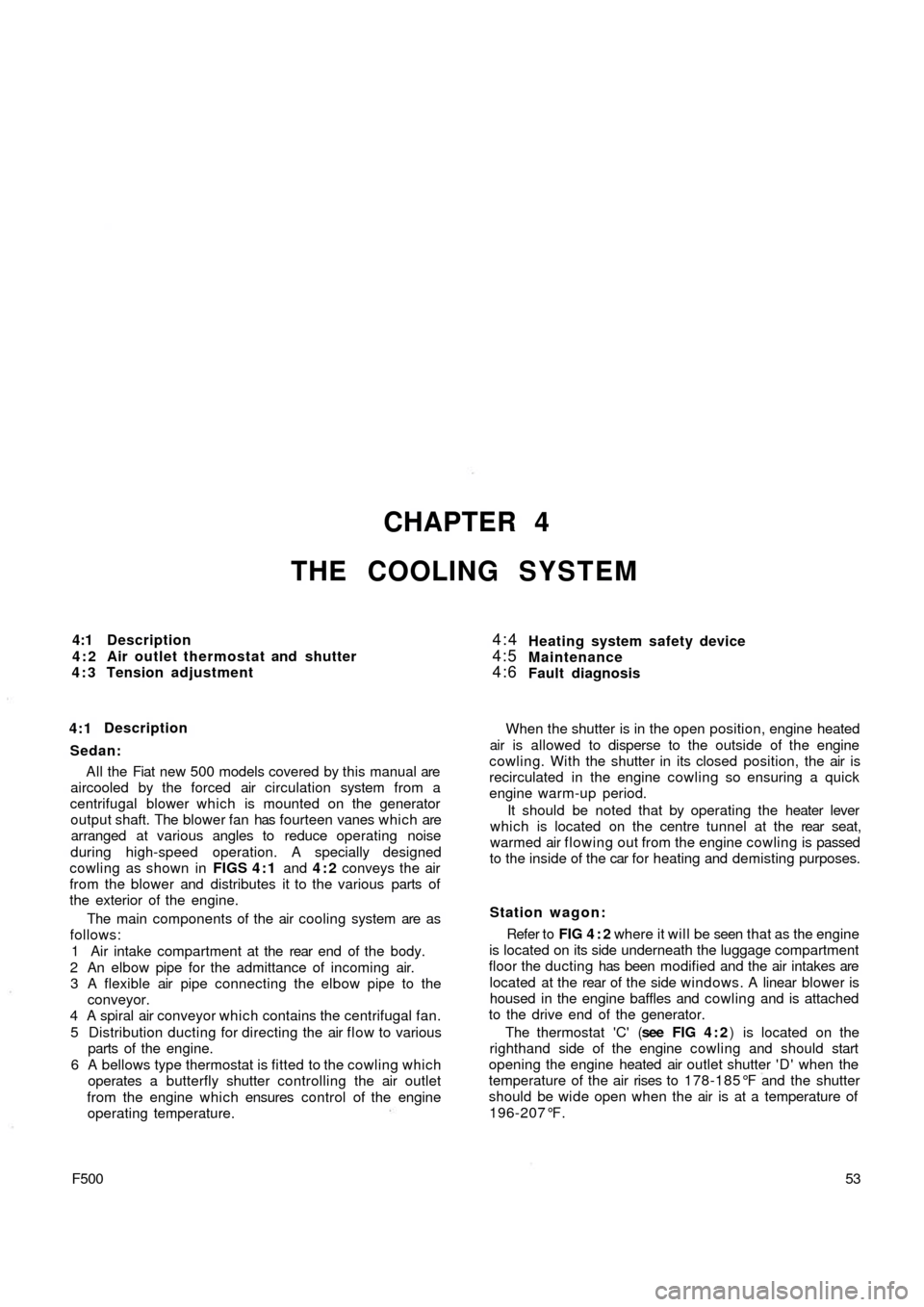

A l l the Fiat new 500 models covered by this manual are

aircooled by the forced air circulation system from a

centrifugal blower which is mounted on the generator

output shaft. The blower fan has fourteen vanes which are

arranged at various angles to reduce operating noise

during high-speed operation. A specially designed

cowling as shown in FIGS 4 : 1 and 4:2 conveys the air

from the blower and distributes it to the various parts of

the exterior of the engine.

The main components of the air cooling system are as

follows:

1 Air intake compartment at the rear end of t h e body.

2 An elbow pipe for the admittance of incoming air.

3 A flexible air pipe connecting the elbow pipe to the

conveyor.

4 A spiral air conveyor which contains the centrifugal fan.

5 Distribution ducting for directing the air flow to various

parts of the engine.

6 A bellows type thermostat is fitted to the cowling which

operates a butterfly shutter controlling the air outlet

from the engine which ensures control of the engine

operating temperature.

F50053 When the shutter is in the open position, engine heated

air is allowed to disperse to the outside of the engine

cowling. With the shutter in its closed position, the air is

recirculated in the engine cowling so ensuring a quick

engine warm-up period.

It should be noted that by operating the heater lever

which is located on the centre tunnel at the rear seat,

warmed air flowing out from the engine cowling is passed

to the inside of the car for heating and demisting purposes.

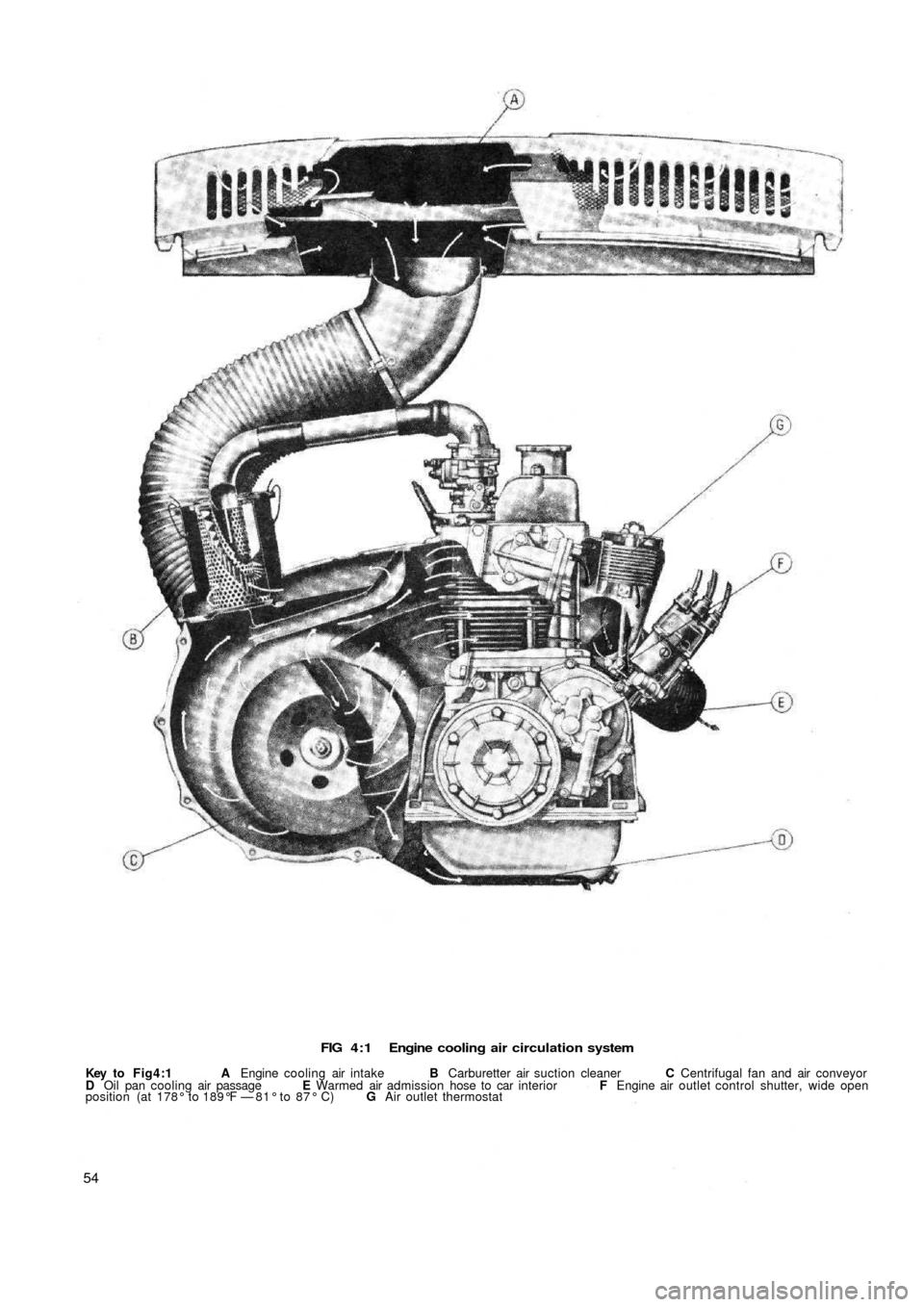

Station wagon:

Refer to FIG 4 : 2 where it will be seen that as the engine

is located on its side underneath the luggage compartment

floor the ducting has been modified and the air intakes are

located at the rear of the side windows. A linear blower is

housed in the engine baffles and cowling and is attached

to the drive end of the generator.

The thermostat 'C' (see FIG 4 : 2) is located on the

righthand side of the engine cowling and should start

opening the engine heated air outlet shutter ' D ' when the

temperature of the air rises to 1 7 8 - 1 8 5 ° F and the shutter

should be wide open when the air is at a temperature of

196-207°F.

Page 47 of 128

FIG 4 : 1 Engine cooling air circulation system

Key to Fig4:1 A Engine cooling air intake B Carburetter air suction cleaner C Centrifugal fan and air conveyor

D Oil pan cooling air passage E Warmed air admission hose to car interior F Engine air outlet control shutter, wide open

position (at 178° to 189°F — 81° to 87° C) G Air outlet thermostat

54

Page 48 of 128

55F500

FIG 4 : 2 Cooling air circulation system of engine 120.000

Key to Fig 4 : 2 A Air intakes B Fan C Thermostat, engine air draft shutter control D Shutter enqine air draft

E Carburetter air cleaner F Duct, warmed air-to-car interior G Lever, air-to-car interior valve control

Page 49 of 128

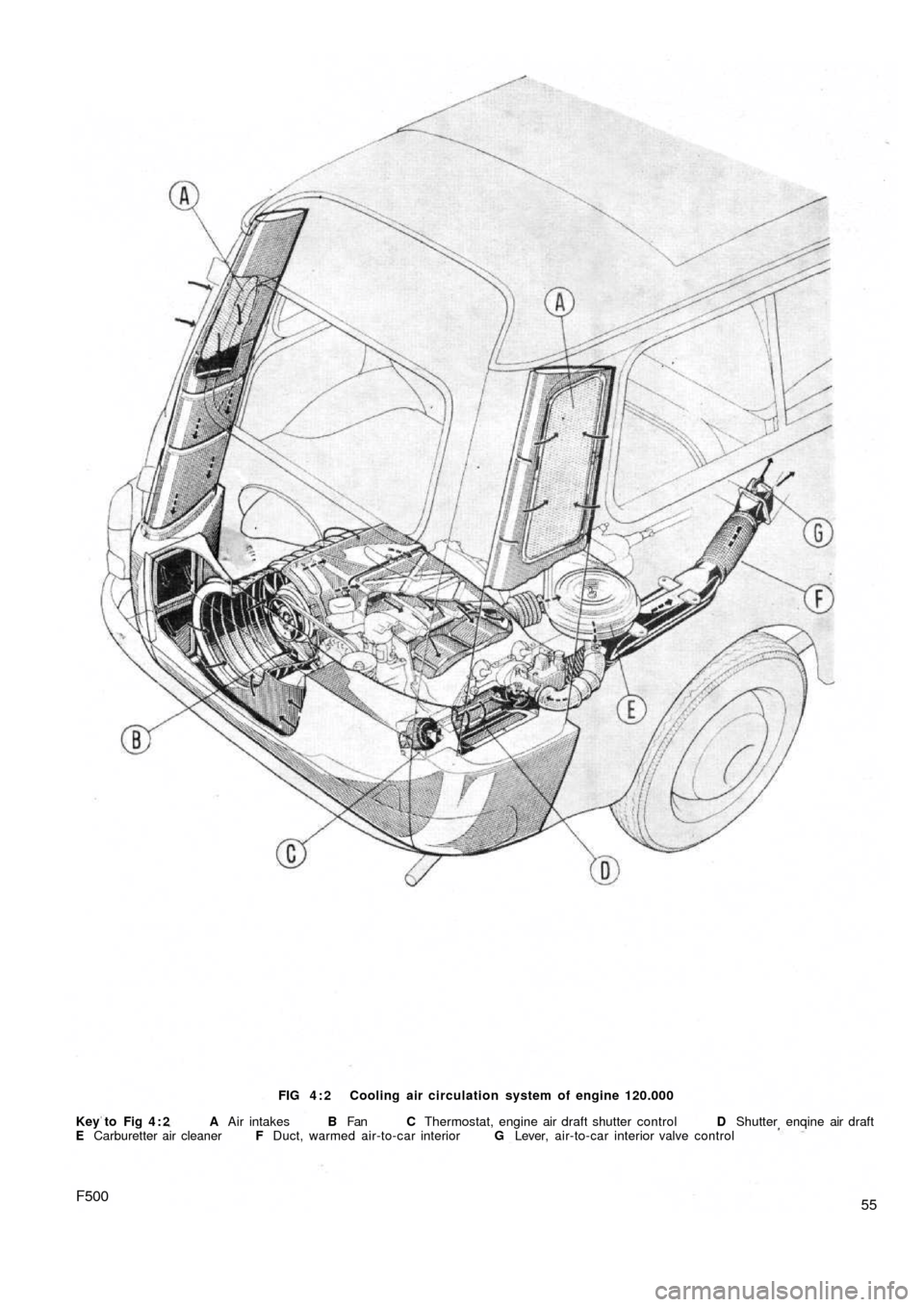

OIL DRAIN PLUG COOLING AIR DUCTS

FIG 4 : 3 Oil sump with blower cowling. Arrows indicate

air outlets

BLOWER

SHAFT GENERATOR ARMATURE

VENT TUBE

FIG 4 : 4 Cooling blower mounted on generator shaft

extension

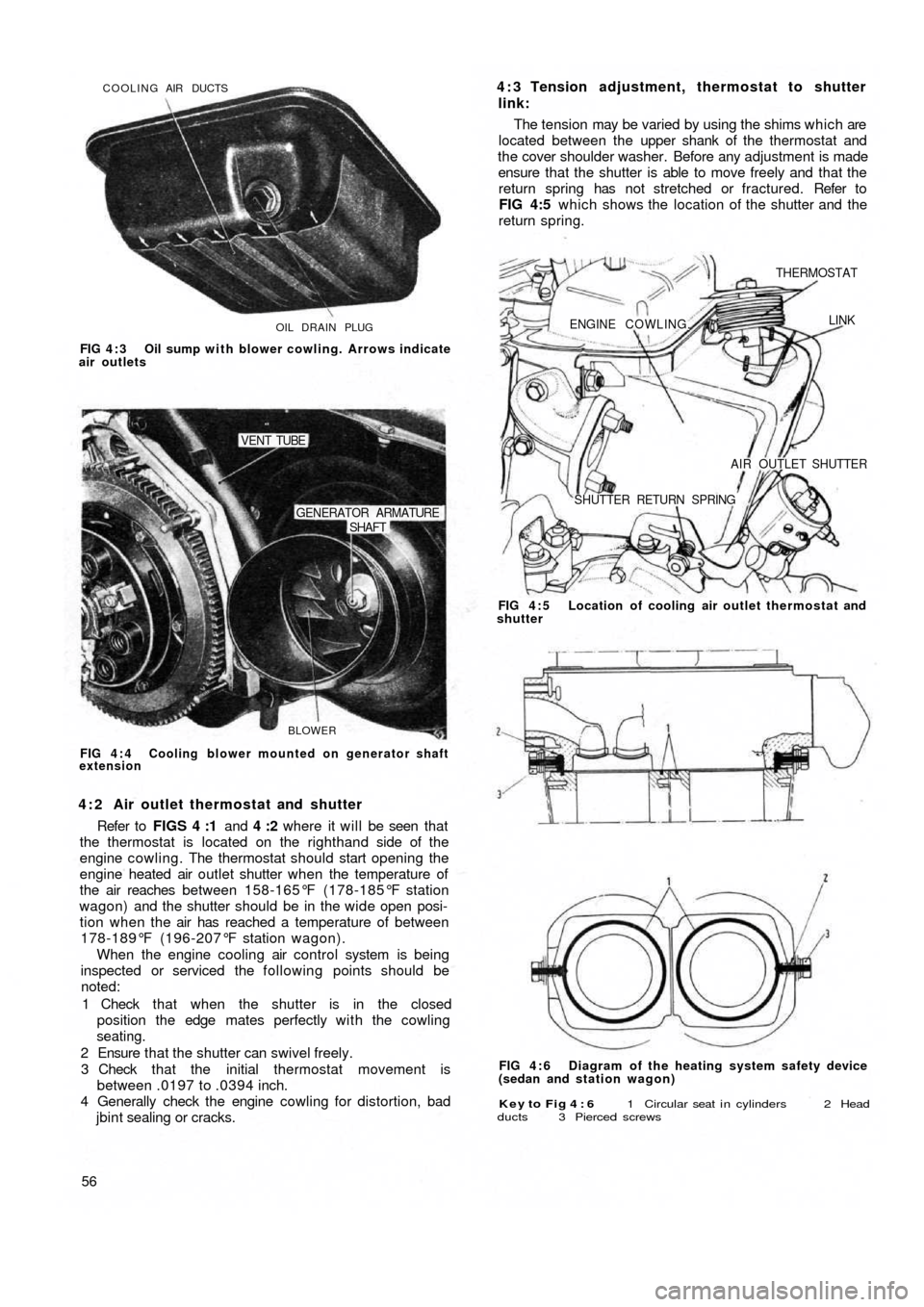

4 : 2 Air outlet thermostat and shutter

Refer to FIGS 4 :1 and 4 :2 where it will be seen that

the thermostat is located on the righthand side of the

engine cowling. The thermostat should start opening the

engine heated air outlet shutter when the temperature of

the air reaches between 158-165°F (178-185°F station

wagon) and the shutter should be in the wide open posi-

tion when the air has reached a temperature of between

178-189°F (196-207°F station wagon).

When the engine cooling air control system is being

inspected or serviced the following points should be

noted:

1 Check that when the shutter is in the closed

position the edge mates perfectly with the cowling

seating.

2 Ensure that the shutter can swivel freely.

3 Check that the initial thermostat movement is

between .0197 to .0394 inch.

4 Generally check the engine cowling for distortion, bad

jbint sealing or cracks.

56

Key to Fig 4 : 6 1 Circular seat i n cylinders 2 Head

ducts 3 Pierced screws

FIG 4 : 6 Diagram of the heating system safety device

(sedan and station wagon) FIG 4 : 5 Location of cooling air outlet thermostat and

shutter

ENGINE COWLING.

THERMOSTAT

LINK

AIR OUTLET SHUTTER

SHUTTER RETURN SPRING

4 : 3 Tension adjustment, thermostat to shutter

link:

The tension may be varied by using the shims which are

located between the upper shank of the thermostat and

the cover shoulder washer. Before any adjustment is made

ensure that the shutter is able to move freely and that the

return spring has not stretched or fractured. Refer to

FIG 4:5 which shows the location of the shutter and the

return spring.

Page 50 of 128

4 : 4 Heating system safety device

110F series sedan engines and later station wagon

engines incorporate a modification to the cylinder head

designed so that in the event of cylinder head gasket

failure exhaust gases are expelled outside the engine and

not leaked into the heating system.

The safety device comprises a square section circular

seat 1 (see FIG 4 :6) which is formed in the upper face of

the cylinder, a special duct in the cylinder head and a

pierced screw 3 for each cylinder.

The system is so designed that the exhaust gases are

released to the atmosphere from the circular seat in the

cylinder via the duct 2 and the pierced screw 3. It should

be noted that the screw 3 is also used for securing the

conveyor.

4 : 5 Maintenance

Due to the simple design of the air cooling system

maintenance has been kept to an absolute minimum and

should consist of the following checks:1 Inspect all the air conveyor system joints and ensure

that all the joint nuts and bolts are tight and that there

is no distortion between two joint faces.

2 Check that the tension of the generator and fan drive

belt is correct: with a hand pressure of approximately

22 Ib the belt should sag 13/32 inch. Adjust if necessary

as detailed in Chapter 1.

3 Ensure that the shutter can swivel freely and that the

spring is in a serviceable condition.

4 : 6 Fault diagnosis

(a) Engine overheating

1 Generator and fan drive belt slipping

2 Shutter control thermostat defective

3 Shutter unable to swivel freely

4 Shutter return spring broken

5 Leaking joints in conveyor system

F50057

Page 53 of 128

*Dimension to be obtained by

adjusting the throwout lever.

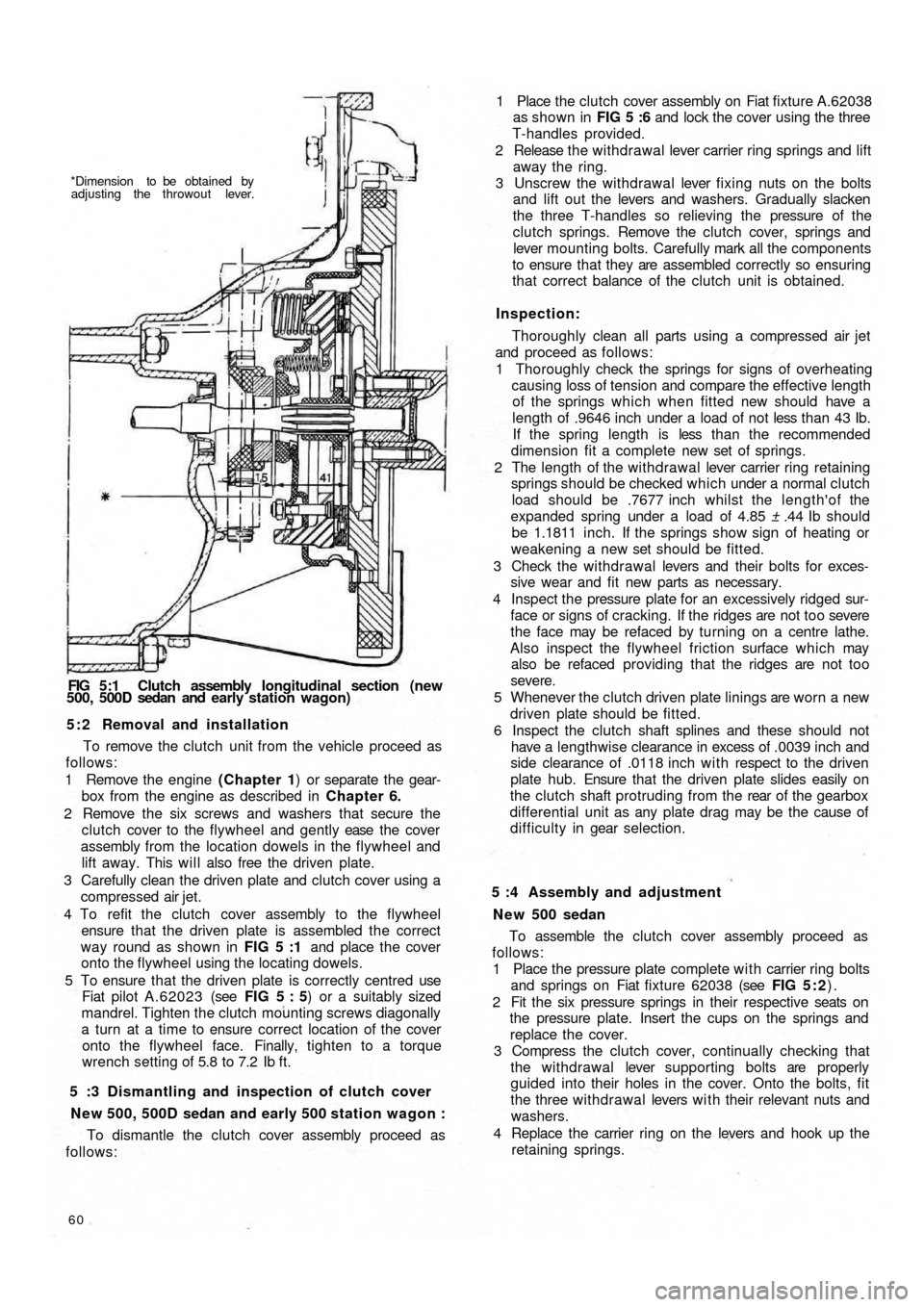

FIG 5:1 Clutch assembly longitudinal section (new

500, 500D sedan and early station wagon)

5 : 2 Removal and installation

To remove the clutch unit from the vehicle proceed as

follows:

1 Remove the engine (Chapter 1) or separate the gear-

box from the engine as described in Chapter 6.

2 Remove the six screws and washers that secure the

clutch cover to the flywheel and gently ease the cover

assembly from the location dowels in the flywheel and

lift away. This will also free the driven plate.

3 Carefully clean the driven plate and clutch cover using a

compressed air jet.

4 To refit the clutch cover assembly to the flywheel

ensure that the driven plate is assembled the correct

way round as shown in FIG 5 :1 and place the cover

onto the flywheel using the locating dowels.

5 To ensure that the driven plate is correctly centred use

Fiat pilot A.62023 (see FIG 5 : 5) or a suitably sized

mandrel. Tighten the clutch mounting screws diagonally

a turn at a time to ensure correct location of the cover

onto the flywheel face. Finally, tighten to a torque

wrench setting of 5.8 to 7.2 Ib ft.

5 :3 Dismantling and inspection of clutch cover

New 500, 500D sedan and early 500 station wagon :

To dismantle the clutch cover assembly proceed as

follows:

60

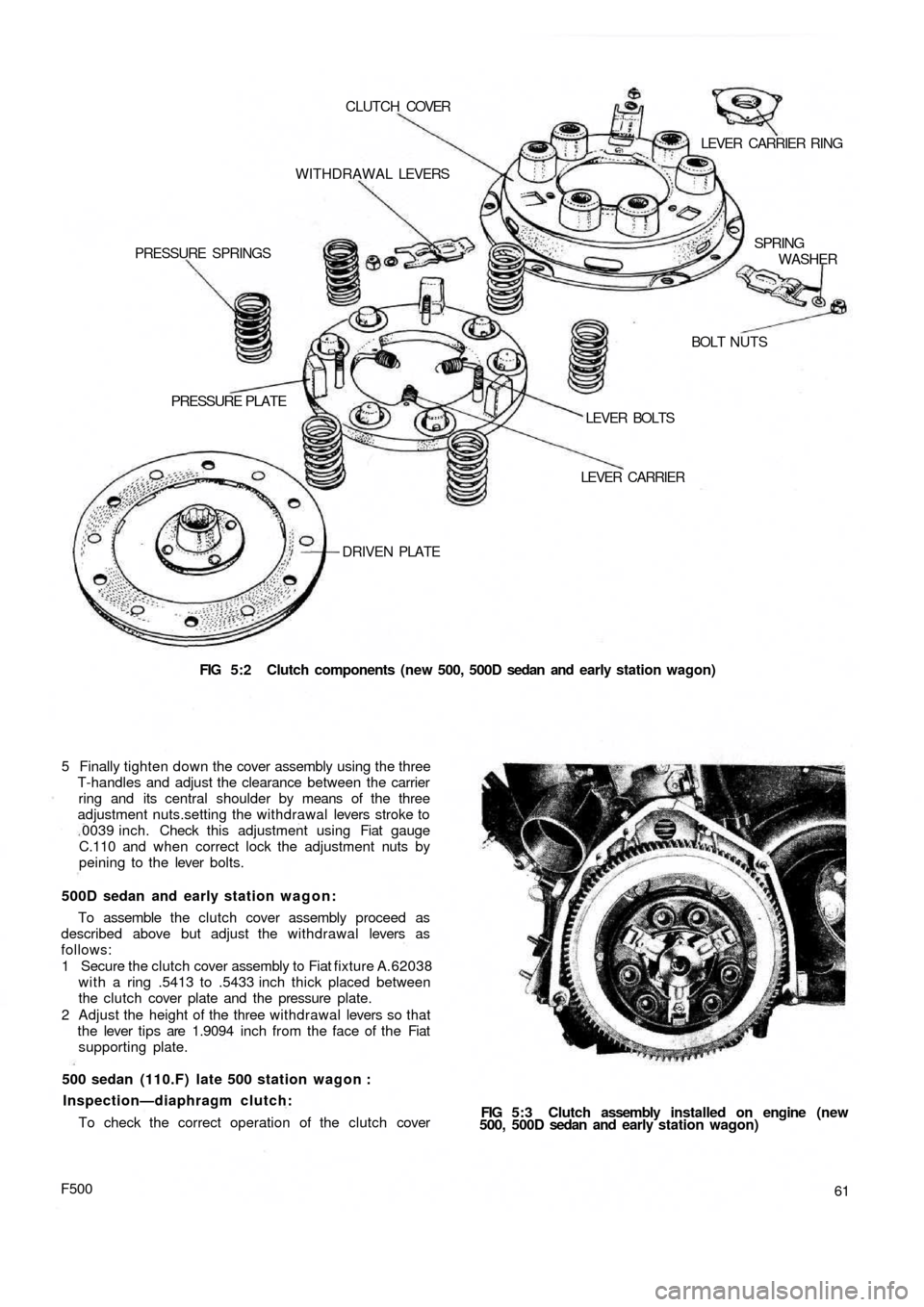

To assemble the clutch cover assembly proceed as

follows:

1 Place the pressure plate complete with carrier ring bolts

and springs on Fiat fixture 62038 (see FIG 5 : 2).

2 Fit the six pressure springs in their respective seats on

the pressure plate. Insert the cups on the springs and

replace the cover.

3 Compress the clutch cover, continually checking that

the withdrawal lever supporting bolts are properly

guided into their holes in the cover. Onto the bolts, fit

the three withdrawal levers w i t h their relevant nuts and

washers.

4 Replace the carrier ring on the levers and hook up the

retaining springs. 5 :4 Assembly and adjustment

N e w 500 sedan1 Place the clutch cover assembly on Fiat fixture A.62038

as shown in FIG 5 :6 and lock the cover using the three

T-handles provided.

2 Release the w i thdrawal lever carrier ring springs and lift

away the ring.

3 Unscrew the withdrawal lever fixing nuts on the bolts

and lift out the levers and washers. Gradually slacken

the three T-handles so relieving the pressure of the

clutch springs. Remove the clutch cover, springs and

lever mounting bolts. Carefully mark all the components

to ensure that they are assembled correctly so ensuring

that correct balance of the clutch unit is obtained.

Inspection:

Thoroughly clean all parts using a compressed air jet

and proceed as follows:

1 Thoroughly check the springs for signs of overheating

causing loss of tension and compare the effective length

of the springs which when fitted new should have a

length of .9646 inch under a load of not less than 43 Ib.

If the spring length is less t h a n t h e recommended

dimension fit a complete new set of springs.

2 The length of the withdrawal lever carrier ring retaining

springs should be checked which under a normal clutch

load should be .7677 inch whilst the length'of the

expanded spring under a load of 4.85 ± .44 Ib should

be 1.1811 inch. If the springs show sign of heating or

weakening a new set should be fitted.

3 Check the withdrawa l levers and their bolts for exces-

sive wear and fit new parts as necessary.

4 Inspect the pressure plate for an excessively ridged sur-

face or signs of cracking. If the ridges are not too severe

the face may be refaced by turning on a centre lathe.

Also inspect the flywheel friction surface which may

also be refaced providing that the ridges are not too

severe.

5 Whenever the clutch driven plate linings are worn a new

driven plate should be fitted.

6 Inspect the clutch shaft splines and these should not

have a lengthwise clearance in excess of .0039 inch and

side clearance of .0118 inch w i t h respect to the driven

plate hub. Ensure that the driven plate slides easily on

the clutch shaft protruding from the rear of the gearbox

differential unit as any plate drag may be the cause of

d i f f i c u l t y in gear selection.

Page 54 of 128

FIG 5:2 Clutch components (new 500, 500D sedan and early station wagon) DRIVEN PLATE

PRESSURE PLATE

LEVER CARRIER LEVER BOLTSBOLT NUTS PRESSURE SPRINGSWITHDRAWAL LEVERS CLUTCH COVER

LEVER CARRIER RING

SPRING

WASHER

FIG 5:3 Clutch assembly installed on engine (new

500, 500D sedan and early station wagon)

61

F500

To check the correct operation of the clutch cover 500 sedan (110.F) late 500 station wagon :

Inspection—diaphragm clutch: 5 Finally tighten down the cover assembly using the three

T-handles and adjust the clearance between the carrier

ring and its central shoulder by means of the three

adjustment nuts.setting the withdrawal levers stroke to

0039 inch. Check this adjustment using Fiat gauge

C.110 and when correct lock the adjustment nuts by

peining to the lever bolts.

500D sedan and early station wagon:

To assemble the clutch cover assembly proceed as

described above but adjust the withdrawal levers as

follows:

1 Secure the clutch cover assembly to Fiat fixture A.62038

with a ring .5413 to .5433 inch thick placed between

the clutch cover plate and the pressure plate.

2 Adjust the height of the three withdrawal levers so that

the lever tips are 1.9094 inch from the face of the Fiat

supporting plate.

Page 57 of 128

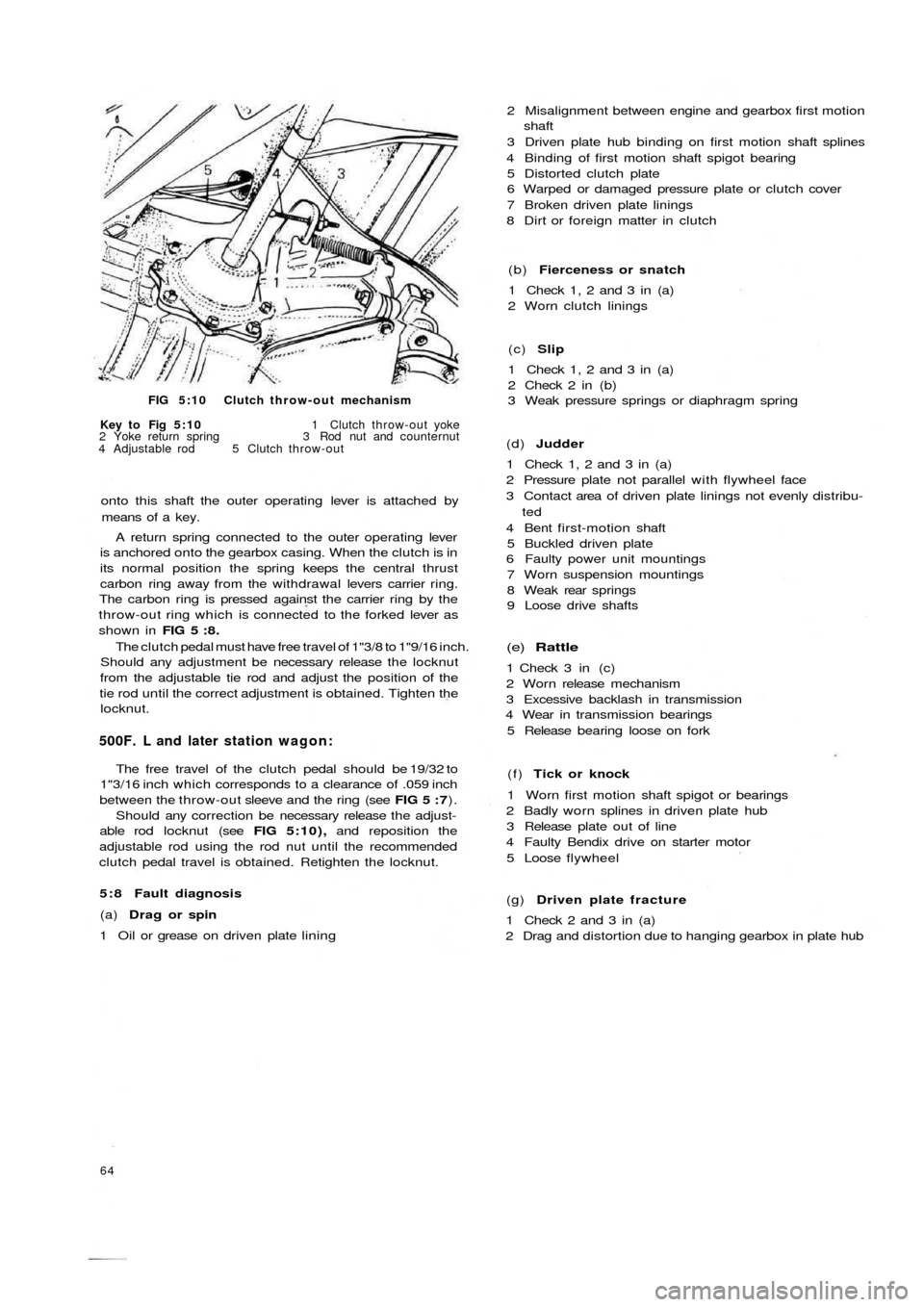

FIG 5:10 Clutch throw-out mechanism

Key to Fig 5:10 1 Clutch throw-out yoke

2 Yoke return spring 3 Rod nut and counternut

4 Adjustable rod 5 Clutch throw-out

onto this shaft the outer operating lever is attached by

means of a key.

A return spring connected to the outer operating lever

is anchored onto the gearbox casing. When the clutch is in

its normal position the spring keeps the central thrust

carbon ring away from the withdrawal levers carrier ring.

The carbon ring is pressed against the carrier ring by the

throw-out ring which is connected to the forked lever as

shown in FIG 5 : 8 .

The clutch pedal must have free travel of 1"3/8 to 1"9/16 inch.

Should any adjustment be necessary release the locknut

from the adjustable tie rod and adjust the position of the

tie rod until the correct adjustment is obtained. Tighten the

locknut.

500F. L and later station wagon:

The free travel of the clutch pedal should be 19/32 to

1"3/16 inch which corresponds to a clearance of .059 inch

between the throw-out sleeve and the ring (see FIG 5 : 7).

Should any correction be necessary release the adjust-

able rod locknut (see FIG 5:10), and reposition the

adjustable rod using the rod nut until the recommended

clutch pedal travel is obtained. Retighten the locknut.

5 : 8 Fault diagnosis

(a) Drag or spin

1 Oil or grease on driven plate lining

64

(g) Driven plate fracture

1 Check 2 and 3 in (a)

2 Drag and distortion due to hanging gearbox in plate hub (f) Tick or knock

1 Worn first motion shaft spigot or bearings

2 Badly worn splines in driven plate hub

3 Release plate out of line

4 Faulty Bendix drive on starter motor

5 Loose flywheel

(e) Rattle

1 Check 3 in (c)

2 Worn release mechanism

3 Excessive backlash in transmission

4 Wear in transmission bearings

5 Release bearing loose on fork (d) Judder

1 Check 1, 2 and 3 in (a)

2 Pressure plate not parallel with flywheel face

3 Contact area of driven plate linings not evenly distribu-

ted

4 Bent first-motion shaft

5 Buckled driven plate

6 Faulty power unit mountings

7 Worn suspension mountings

8 Weak rear springs

9 Loose drive shafts (c) Slip

1 Check 1, 2 and 3 in (a)

2 Check 2 in (b)

3 Weak pressure springs or diaphragm spring (b) Fierceness or snatch

1 Check 1, 2 and 3 in (a)

2 Worn clutch linings 2 Misalignment between engine and gearbox first motion

shaft

3 Driven plate hub binding on first motion shaft splines

4 Binding of first motion shaft spigot bearing

5 Distorted clutch plate

6 Warped or damaged pressure plate or clutch cover

7 Broken driven plate linings

8 Dirt or foreign matter in clutch

Page 58 of 128

CHAPTER 6

GEARBOX AND DIFFERENTIAL UNIT

6:1

6:2

6:3

6:4

6:5

6:6Description

Removal of gearbox/differential unit

Dismantling — gearbox

Reassembly — gearbox

Dismantling — differential and final drive

Reassembly— differential and final drive6:7

6:8

6:9

6:10

6:11

6:12Final drive gear set adjustment

Replacement of gearbox/differential unit

Swing axle shafts and slip joints

Gear shift control mechanism

Modifications

Fault diagnosis

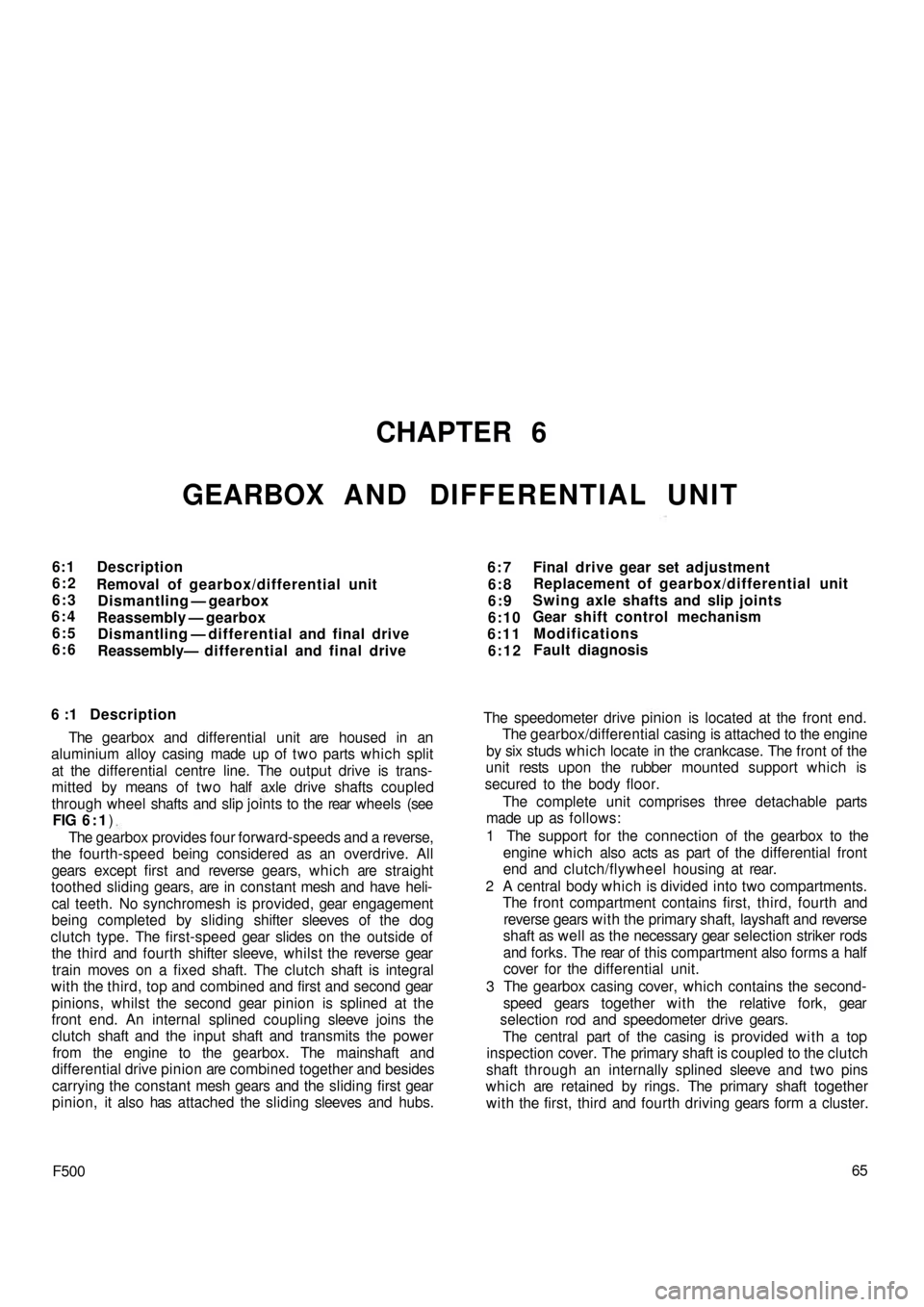

6 :1 Description

The gearbox and differential unit are housed in an

aluminium alloy casing made up of t w o parts which split

at the differential centre line. The output drive is trans-

mitted by means of t w o half axle drive shafts coupled

through wheel shafts and slip joints to the rear wheels (see

FIG 6 : 1)

The gearbox provides four forward-speeds and a reverse,

the fourth-speed being considered as an overdrive. All

gears except first and reverse gears, which are straight

toothed sliding gears, are in constant mesh and have heli-

cal teeth. No synchromesh is provided, gear engagement

being completed by sliding shifter sleeves of the dog

clutch type. The first-speed gear slides on the outside of

the third and fourth shifter sleeve, whilst the reverse gear

train moves on a fixed shaft. The clutch shaft is integral

with the third, top and combined and first and second gear

pinions, whilst the second gear pinion is splined at the

front end. An internal splined

coupling sleeve joins the

clutch shaft and the input shaft and transmits the power

from the engine to the gearbox. The mainshaft and

differential drive pinion are combined together and besides

carrying the constant mesh gears and the sliding first gear

pinion, it also has attached the sliding sleeves and hubs.

F50065 The speedometer drive pinion is located at the front end.

The gearbox/differential casing is attached to the engine

by six studs which locate in the crankcase. The front of the

unit rests upon the rubber mounted support which is

secured to the body floor.

The complete unit comprises three detachable parts

made up as follows:

1 The support for the connection of the gearbox to the

engine which also acts as part of the differential front

end and clutch/flywheel housing at rear.

2 A central body which is divided into two compartments.

The front compartment contains first, third, fourth and

reverse gears w i t h the primary shaft, layshaft and reverse

shaft as well as the necessary gear selection striker rods

and forks. The rear of this compartment also forms a half

cover for the differential unit.

3 The gearbox casing cover, which contains the second-

speed gears together with the relative fork, gear

selection rod and speedometer drive gears.

The central part of the casing is provided with a top

inspection cover. The primary shaft is coupled to the clutch

shaft through an internally splined sleeve and t w o pins

which are retained by rings. The primary shaft together

with the first, third and fourth driving gears form a cluster.

Page 59 of 128

PRIMARY SHAFT-TO-CLUTCH

SHAFT MOUNTING PINCLUTCH SHAFT SEAL PRIMARY SHAFT WITH

1st, 3 r d A N D 4 t h SPEED

GEAR CLUSTER

2 n d SPEED

DRIVE GEARPRIMARY SHAFT

FRONT BALL BEARINGPRIMARY SHAFT

REAR BALL BEARING

PRIMARY

SHAFT-TO-CLUTCH

i SHAFT JOINING SLEEVEJOINING SLEEVELOCKRING

SPEED SELECTOR LEVER

CLUTCH SHAFT

LAYSHAFT WITH BEVEL PINION

SPEEDOMETER DRIVE GEAR

2 n d SPEED ENGAGEMENT

SLIDING SLEEVE

2 N D SPEED DRIVEN GEAR

LAYSHAFT FRONT BALL

BEARING

3 r d SPEED DRIVEN GEARHUB FOR

SLEEVE

3rd AND 4th/

SPEED ENGAGEMENT

SLIDING SLEEVE4 t h SPEED

DRIVEN GEARLAYSHAFT REAR ROLLER BEARING

LAYSHAFT-TO-PINION

ADJUSTMENT WASHER 1st SPEED AND)

REVERSE SLIDING GEAR

FIG 6:1Gearbox-differential unit longitudinal section

On the primary shaft extension outside the main central

body is mounted the second-speed driving gear. The

primary shaft is supported at both ends by ballbearings

whilst the clutch shaft rotates in a bronze spigot bush which

is press fitted into the end of the crankshaft. An oil seal is

fitted in the clutch shaft passage seat in the c o n n e c t i o n

support. The layshaft, together with the drive pinion of the

differential unit is supported at the front by a ballbearing

race. The layshaft carries the pinion adjustment shim, the

fourth-speed driven gear and its bushing, the hub and

relevant engagement sleeve for the t h i r d - and fourth-

speed w i t h first-speed and reverse-speed, the third-speed

gear and bushing and, outside the casing the second gear

and bushing, the hub with relevant second-speed engage-

ment sleeve and the speedometer drive gear.

The gears are operated by a gear selection lever mounted

on the tunnel situated between the two front seats. This

operates through a rod actuating the selector and shifting

mechanism which is housed in the gearbox casing cover.

Refer to FIG 6 :3 where it will be seen th a t the positioning

of the striker rods is ensured by a spring-loaded ball-

bearing. The risk of engaging two gears at the same time is

eliminated by three rollers which slide in suitable slots

machined in the rod (see FIG 6 : 4).

The differential unit and the final drive gear train are

housed in the t w o semi-covers which

have previously

been described, the final drive pinion being integral with

the layshaft. The differential casing may be split into t w o

halves. The bevel gear is fitted on one of the halves and is

66

secured by the same screws joining the two halves

together. The differential side gears are internally splined

into which are located the splined axle shaft ends which

are able to slide by means of a specially designed slip joint.

Two specially shaped rubber oil boots are inserted on the

swing axle shafts and fit over the side gear extensions to

ensure that there is no loss of lubricant or the ingress

of dirt.

The transmission and differential unit to suit the station

wagon differs from the sedan in that the transmission to

engine mounting plate and the bellhousing are modified to

suit the engine repositioned on its side.

6 : 2 Removal of gearbox/differential unit:

The complete unit may be removed whilst the engine

remains in situ and to remove this unit proceed as follows:

1 Disconnect the battery positive cable and jack up the

rear of t h e vehicle and place on firmly based stands.

2 Disconnect all control cables and wiring from the

starter motor and the clutch lever. Remove the starter

motor, the clutch lever reaction spring and the clutch

cable support on the gearbox.

3 Remove the three bolts securing each of the driving

shaft flanges to the flexible coupling at the wheel ends

and carefully take out the inner spring.

4 Disconnect the shifter rod from the gearshift lever at the

gearbox extension and also the

speedometer drive

cable. Remove also the flywheel undercover. Place a

suitable support under the engine.