remove seats FIAT 500 1967 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1967, Model line: 500, Model: FIAT 500 1967 1.GPages: 128, PDF Size: 9.01 MB

Page 11 of 128

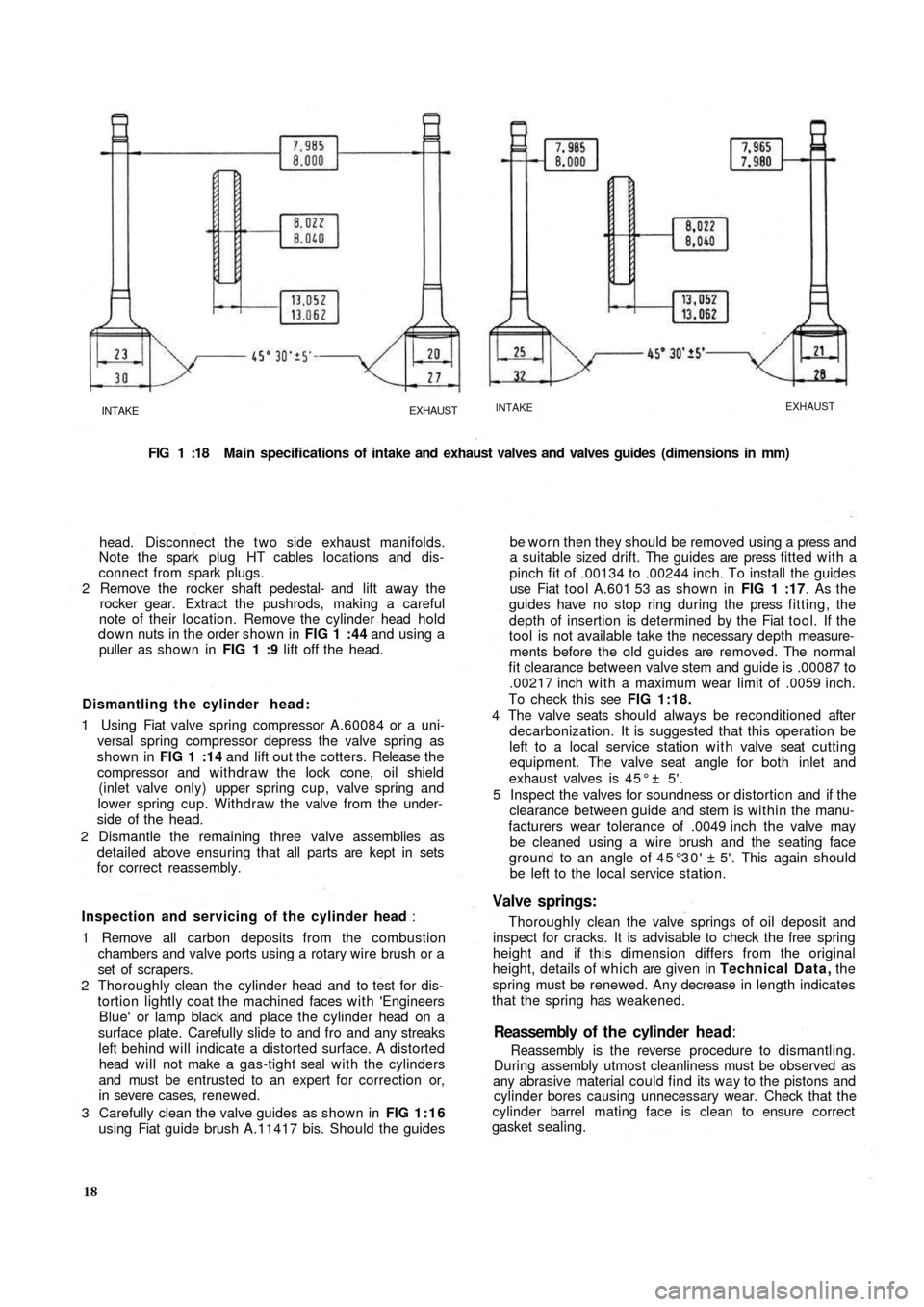

INTAKEEXHAUSTINTAKEEXHAUST

FIG 1 :18 Main specifications of intake and exhaust valves and valves guides (dimensions in mm)

head. Disconnect the t w o side exhaust manifolds.

Note the spark plug HT cables locations and dis-

connect from spark plugs.

2 Remove the rocker shaft pedestal- and lift away the

rocker gear. Extract the pushrods, making a careful

note of their location. Remove the cylinder head hold

down nuts in the order shown in FIG 1 :44 and using a

puller as shown in FIG 1 :9 lift off the head.

Dismantling the cylinder head:

1 Using Fiat valve spring compressor A.60084 or a uni-

versal spring compressor depress the valve spring as

shown in FIG 1 :14 and lift out the cotters. Release t h e

compressor and withdraw the lock cone, oil shield

(inlet valve only) upper spring cup, valve spring and

lower spring cup. Withdraw the valve from the under-

side of the head.

2 Dismantle the remaining three valve assemblies as

detailed above ensuring that all parts are kept in sets

for correct reassembly.

Inspection and servicing of the cylinder head :

1 Remove all carbon deposits from the combustion

chambers and valve ports using a rotary wire brush or a

set of scrapers.

2 Thoroughly clean the cylinder head and to test for dis-

tortion lightly coat the machined faces with 'Engineers

Blue' or lamp

black and place the cylinder head on a

surface plate. Carefully slide to and fro and any streaks

left behind will indicate a distorted surface. A distorted

head will not make a gas-tight seal with the cylinders

and must be entrusted to an expert for correction or,

in severe cases, renewed.

3 Carefully clean the valve guides as shown in FIG 1:16

using Fiat guide brush A.11417 bis. Should the guides

18Reassembly is the reverse procedure to dismantling.

During assembly utmost cleanliness must be observed as

any abrasive material could find its way to the pistons and

cylinder bores causing unnecessary wear. Check that the

cylinder barrel mating face is clean to ensure correct

gasket sealing.Reassembly of t h e cylinder head:

be worn then they should be removed using a press and

a suitable sized drift. The guides are press fitted with a

pinch fit of .00134 to .00244 inch. To install the guides

use Fiat tool A.601 53 as shown in FIG 1 :17. As the

guides have no stop ring during the press fitting, the

depth of insertion is determined by the Fiat tool. If the

tool is not available take the necessary depth measure-

ments before the old guides are removed. The normal

fit clearance between valve stem and guide is .00087 to

.00217 inch with a maximum wear limit of .0059 inch.

To check this see FIG 1:18.

4 The valve seats should always be reconditioned after

decarbonization. It is suggested that this operation be

left to a local service station with valve seat cutting

equipment. The valve seat angle for both inlet and

exhaust valves is 4 5 ° ± 5'.

5 Inspect the valves for soundness or distortion and if the

clearance between guide and stem is within the manu-

facturers wear tolerance of .0049 inch the valve may

be cleaned using a wire brush and the seating face

ground to an angle of 45°30' ± 5'. This again should

be left to the local service station.

Valve springs:

Thoroughly clean the valve springs of oil deposit and

inspect for cracks. It is advisable to check the free spring

height and if this dimension differs from the original

height, details of which are given in Technical Data, the

spring must be renewed. Any decrease in length indicates

that the spring has weakened.

Page 16 of 128

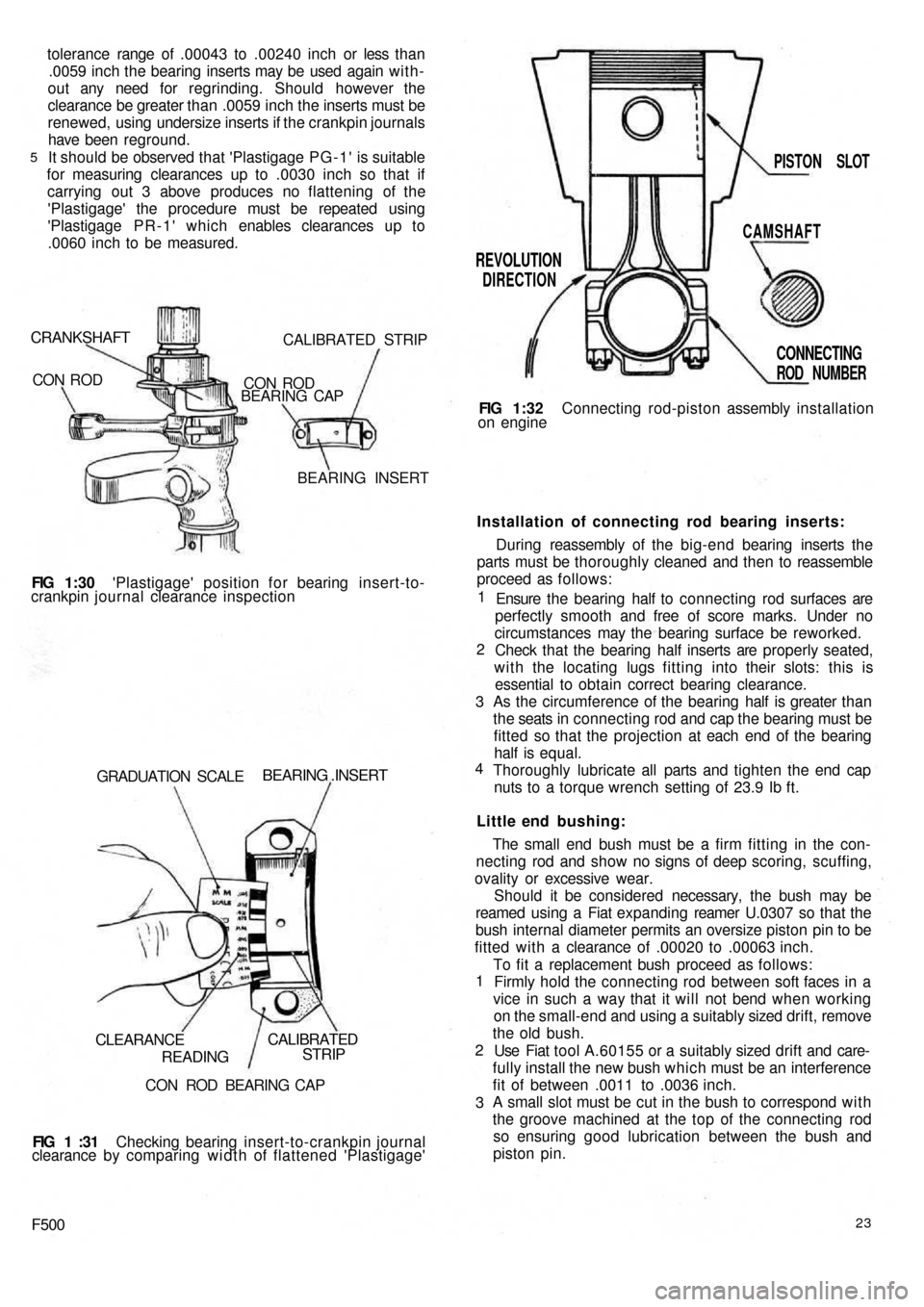

tolerance range of .00043 to .00240 inch or less than

.0059 inch the bearing inserts may be used again with-

out any need for regrinding. Should however the

clearance be greater than .0059 inch the inserts must be

renewed, using undersize inserts if the crankpin journals

have been reground.

It should be observed that 'Plastigage PG-1' is suitable

for measuring clearances up to .0030 inch so that if

carrying out 3 above produces no flattening of the

'Plastigage' the procedure must be repeated using

'Plastigage PR-1' which enables clearances up to

.0060 inch to be measured.

5

CRANKSHAFT

CON RODCALIBRATED STRIP

CON ROD

BEARING CAP

BEARING INSERT

FIG 1:30 'Plastigage' position for bearing insert-to-

crankpin journal clearance inspection

GRADUATION SCALE

BEARING .INSERT

CLEARANCE

READINGCALIBRATED

STRIP

CON ROD BEARING CAP

FIG 1 :31 Checking bearing insert-to-crankpin journal

clearance by comparing width of flattened 'Plastigage'

F50023

To fit a replacement bush proceed as follows:

Firmly hold the connecting rod between soft faces in a

vice in such a way that it will not bend when working

on the small-end and using a suitably sized drift, remove

the old bush.

Use Fiat tool A.60155 or a suitably sized drift and care-

fully install the new bush which must be an interference

fit of between .0011 to .0036 inch.

A small slot must be cut in the bush to correspond w i t h

the groove machined at the top of the connecting rod

so ensuring good lubrication between the bush and

piston pin. 1

2

3The small end bush must be a firm fitting in the con-

necting rod and show no signs of deep scoring, scuffing,

ovality or excessive wear.

Should it be considered necessary, the bush may be

reamed using a Fiat expanding reamer U.0307 so that the

bush internal diameter permits an oversize piston pin to be

fitted with a clearance of .00020 to .00063 inch. Little end bushing:Installation of connecting rod bearing inserts:

During reassembly of the big-end bearing inserts the

parts must be thoroughly cleaned and then to reassemble

proceed as follows:

Ensure the bearing half to connecting rod surfaces are

perfectly smooth and free of score marks. Under no

circumstances may the bearing surface be reworked.

Check that the bearing half inserts are properly seated,

with the locating lugs fitting into their slots: this is

essential to obtain

correct bearing clearance.

As the circumference of the bearing half is greater than

the seats in connecting rod and cap the bearing must be

fitted so that the projection at each end of the bearing

half is equal.

Thoroughly lubricate all parts and tighten the end cap

nuts to a torque wrench setting of 23.9 Ib ft. 1

2

3

4FIG 1:32 Connecting rod-piston assembly installation

on engine

REVOLUTION

DIRECTIONPISTON SLOT

CAMSHAFT

CONNECTING

ROD NUMBER

Page 22 of 128

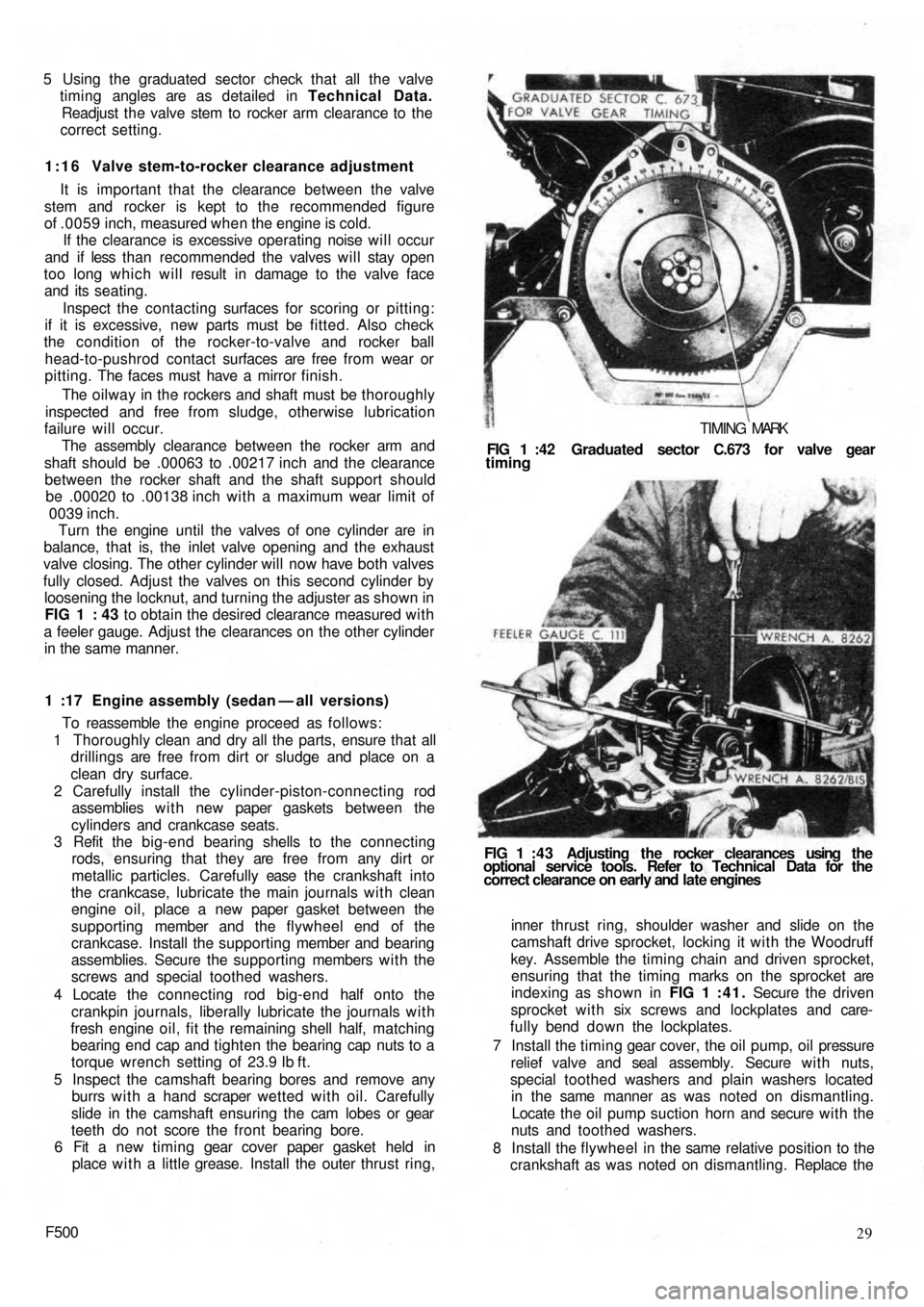

5 Using the graduated sector check that all the valve

timing angles are as detailed in Technical Data.

Readjust the valve stem to rocker arm clearance to the

correct setting.

1:16 Valve stem-to-rocker clearance adjustment

It is important that the clearance between the valve

stem and rocker is kept to the recommended figure

of .0059 inch, measured when the engine is cold.

If the clearance is excessive operating noise will occur

and if less than recommended the valves will stay open

too long which will result in damage to the valve face

and its seating.

Inspect the contacting surfaces for scoring or pitting:

if it is excessive, new parts must be fitted. Also check

the condition of the rocker-to-valve and rocker ball

head-to-pushrod contact surfaces are free from wear or

pitting. The faces must have a mirror finish.

The oilway in the rockers and shaft must be thoroughly

inspected and free from sludge, otherwise lubrication

failure will occur.

The assembly clearance between the rocker arm and

shaft should be .00063 to .00217 inch and the clearance

between the rocker shaft and the shaft support should

be .00020 to .00138 inch with a maximum wear limit of

0039 inch.

Turn the engine until the valves of one cylinder are in

balance, that is, the inlet valve opening and the exhaust

valve closing. The other cylinder will now have both valves

fully closed. Adjust the valves on this second cylinder by

loosening the locknut, and turning the

adjuster as shown in

FIG 1 : 43 to obtain the desired clearance measured with

a feeler gauge. Adjust the clearances on the other cylinder

in the same manner.

1 :17 Engine assembly (sedan — all versions)

To reassemble the engine proceed as follows:

1 Thoroughly clean and dry all the parts, ensure that all

drillings are free from dirt or sludge and place on a

clean dry surface.

2 Carefully install the cylinder-piston-connecting rod

assemblies w i t h new paper gaskets between the

cylinders and crankcase seats.

3 Refit the big-end bearing shells to the connecting

rods, ensuring that they are free from any dirt or

metallic particles. Carefully ease t h e crankshaft into

the crankcase, lubricate the main journals with clean

engine oil, place a new paper gasket between the

supporting member and the flywheel end of the

crankcase. Install the supporting member and bearing

assemblies. Secure the supporting members with the

screws and special toothed washers.

4 Locate the connecting rod big-end half onto the

crankpin journals, liberally lubricate the journals with

fresh engine oil, fit the remaining shell half, matching

bearing end cap and tighten the bearing cap nuts to a

torque wrench setting of 23.9 Ib ft.

5 Inspect the camshaft bearing bores and remove any

burrs w i t h a hand scraper wetted with oil. Carefully

slide in the camshaft ensuring the cam lobes or gear

teeth do not score the front bearing bore.

6 Fit a new timing gear cover paper gasket held in

place w i t h a little grease. Install the outer thrust ring,

F50029 inner thrust ring, shoulder washer and slide on the

camshaft drive sprocket, locking it with the Woodruff

key. Assemble the timing chain and driven sprocket,

ensuring that the timing marks on the sprocket are

indexing as shown in FIG 1 :41. Secure the driven

sprocket with six screws and lockplates and care-

fully bend down the lockplates.

7 Install the timing gear cover, the oil pump, oil pressure

relief valve and seal assembly. Secure w i t h nuts,

special toothed washers and plain washers located

in the same manner as was noted on dismantling.

Locate the oil pump suction horn and secure with the

nuts and toothed washers.

8 Install the flywheel in the same relative position to the

crankshaft as was noted on dismantling. Replace the FIG 1 : 4 3 Adjusting the rocker clearances using the

optional service tools. Refer to Technical Data for the

correct clearance on early and late engines FIG 1 :42 Graduated sector C.673 for valve gear

timing

TIMING MARK

Page 53 of 128

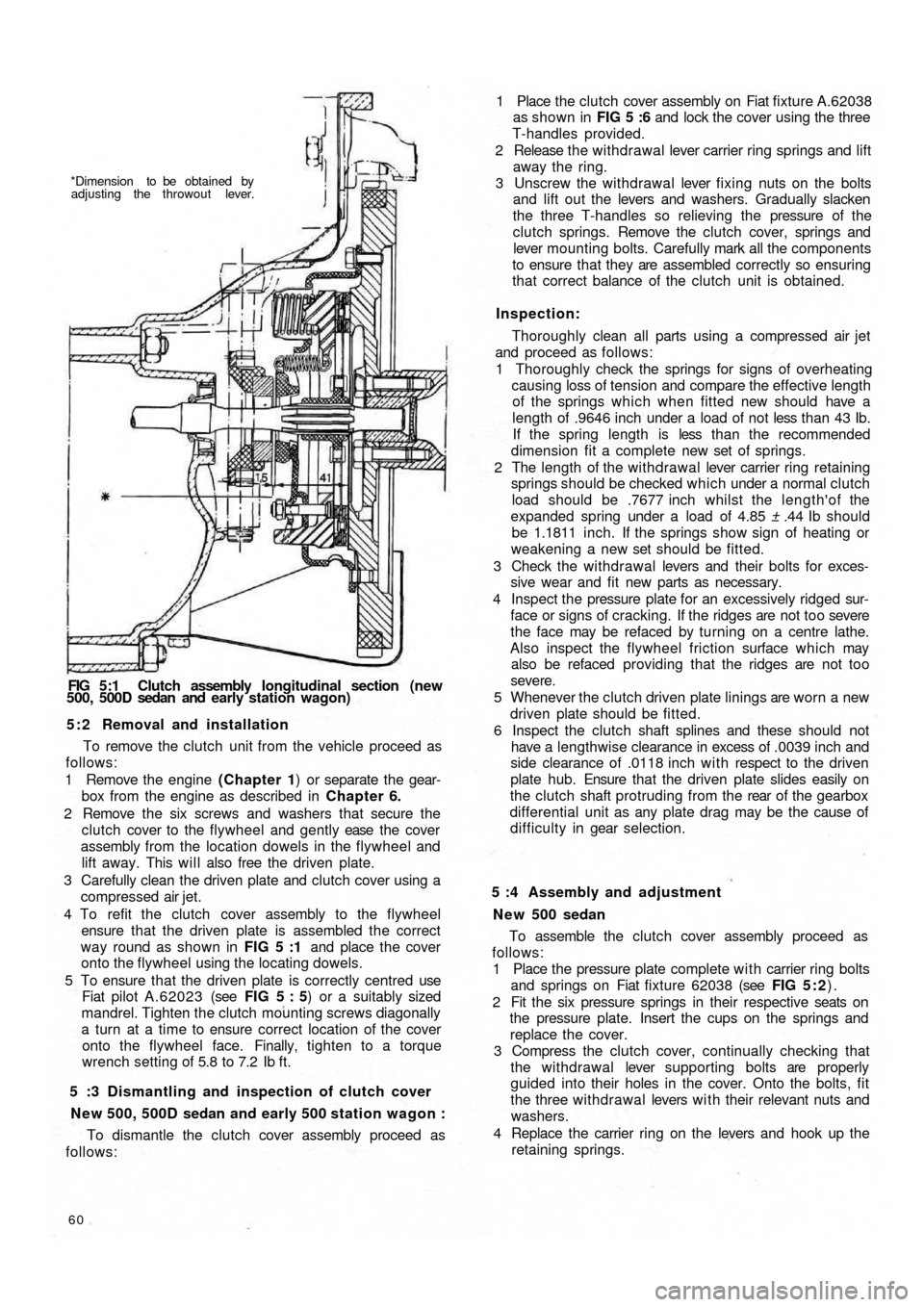

*Dimension to be obtained by

adjusting the throwout lever.

FIG 5:1 Clutch assembly longitudinal section (new

500, 500D sedan and early station wagon)

5 : 2 Removal and installation

To remove the clutch unit from the vehicle proceed as

follows:

1 Remove the engine (Chapter 1) or separate the gear-

box from the engine as described in Chapter 6.

2 Remove the six screws and washers that secure the

clutch cover to the flywheel and gently ease the cover

assembly from the location dowels in the flywheel and

lift away. This will also free the driven plate.

3 Carefully clean the driven plate and clutch cover using a

compressed air jet.

4 To refit the clutch cover assembly to the flywheel

ensure that the driven plate is assembled the correct

way round as shown in FIG 5 :1 and place the cover

onto the flywheel using the locating dowels.

5 To ensure that the driven plate is correctly centred use

Fiat pilot A.62023 (see FIG 5 : 5) or a suitably sized

mandrel. Tighten the clutch mounting screws diagonally

a turn at a time to ensure correct location of the cover

onto the flywheel face. Finally, tighten to a torque

wrench setting of 5.8 to 7.2 Ib ft.

5 :3 Dismantling and inspection of clutch cover

New 500, 500D sedan and early 500 station wagon :

To dismantle the clutch cover assembly proceed as

follows:

60

To assemble the clutch cover assembly proceed as

follows:

1 Place the pressure plate complete with carrier ring bolts

and springs on Fiat fixture 62038 (see FIG 5 : 2).

2 Fit the six pressure springs in their respective seats on

the pressure plate. Insert the cups on the springs and

replace the cover.

3 Compress the clutch cover, continually checking that

the withdrawal lever supporting bolts are properly

guided into their holes in the cover. Onto the bolts, fit

the three withdrawal levers w i t h their relevant nuts and

washers.

4 Replace the carrier ring on the levers and hook up the

retaining springs. 5 :4 Assembly and adjustment

N e w 500 sedan1 Place the clutch cover assembly on Fiat fixture A.62038

as shown in FIG 5 :6 and lock the cover using the three

T-handles provided.

2 Release the w i thdrawal lever carrier ring springs and lift

away the ring.

3 Unscrew the withdrawal lever fixing nuts on the bolts

and lift out the levers and washers. Gradually slacken

the three T-handles so relieving the pressure of the

clutch springs. Remove the clutch cover, springs and

lever mounting bolts. Carefully mark all the components

to ensure that they are assembled correctly so ensuring

that correct balance of the clutch unit is obtained.

Inspection:

Thoroughly clean all parts using a compressed air jet

and proceed as follows:

1 Thoroughly check the springs for signs of overheating

causing loss of tension and compare the effective length

of the springs which when fitted new should have a

length of .9646 inch under a load of not less than 43 Ib.

If the spring length is less t h a n t h e recommended

dimension fit a complete new set of springs.

2 The length of the withdrawal lever carrier ring retaining

springs should be checked which under a normal clutch

load should be .7677 inch whilst the length'of the

expanded spring under a load of 4.85 ± .44 Ib should

be 1.1811 inch. If the springs show sign of heating or

weakening a new set should be fitted.

3 Check the withdrawa l levers and their bolts for exces-

sive wear and fit new parts as necessary.

4 Inspect the pressure plate for an excessively ridged sur-

face or signs of cracking. If the ridges are not too severe

the face may be refaced by turning on a centre lathe.

Also inspect the flywheel friction surface which may

also be refaced providing that the ridges are not too

severe.

5 Whenever the clutch driven plate linings are worn a new

driven plate should be fitted.

6 Inspect the clutch shaft splines and these should not

have a lengthwise clearance in excess of .0039 inch and

side clearance of .0118 inch w i t h respect to the driven

plate hub. Ensure that the driven plate slides easily on

the clutch shaft protruding from the rear of the gearbox

differential unit as any plate drag may be the cause of

d i f f i c u l t y in gear selection.

Page 59 of 128

PRIMARY SHAFT-TO-CLUTCH

SHAFT MOUNTING PINCLUTCH SHAFT SEAL PRIMARY SHAFT WITH

1st, 3 r d A N D 4 t h SPEED

GEAR CLUSTER

2 n d SPEED

DRIVE GEARPRIMARY SHAFT

FRONT BALL BEARINGPRIMARY SHAFT

REAR BALL BEARING

PRIMARY

SHAFT-TO-CLUTCH

i SHAFT JOINING SLEEVEJOINING SLEEVELOCKRING

SPEED SELECTOR LEVER

CLUTCH SHAFT

LAYSHAFT WITH BEVEL PINION

SPEEDOMETER DRIVE GEAR

2 n d SPEED ENGAGEMENT

SLIDING SLEEVE

2 N D SPEED DRIVEN GEAR

LAYSHAFT FRONT BALL

BEARING

3 r d SPEED DRIVEN GEARHUB FOR

SLEEVE

3rd AND 4th/

SPEED ENGAGEMENT

SLIDING SLEEVE4 t h SPEED

DRIVEN GEARLAYSHAFT REAR ROLLER BEARING

LAYSHAFT-TO-PINION

ADJUSTMENT WASHER 1st SPEED AND)

REVERSE SLIDING GEAR

FIG 6:1Gearbox-differential unit longitudinal section

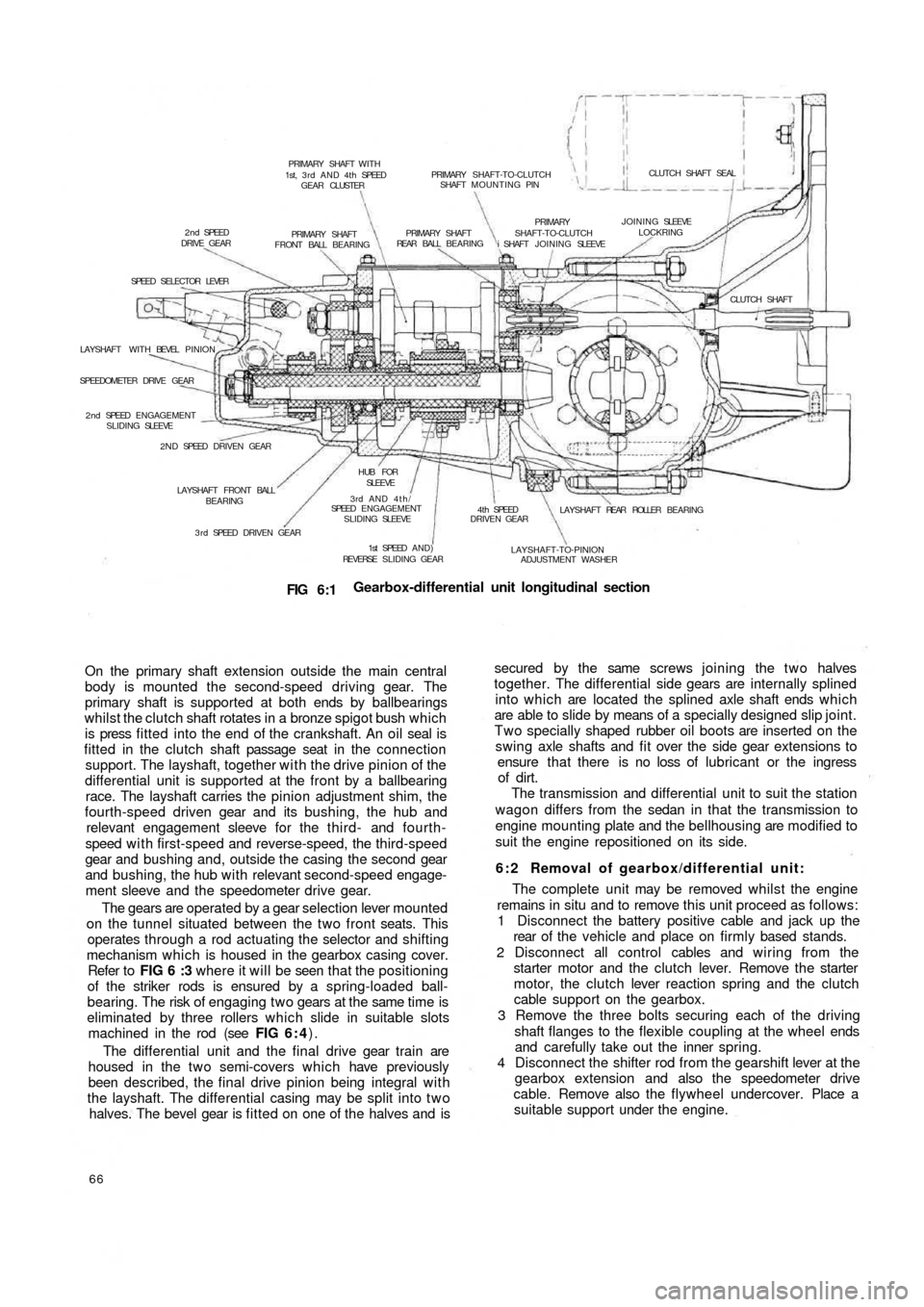

On the primary shaft extension outside the main central

body is mounted the second-speed driving gear. The

primary shaft is supported at both ends by ballbearings

whilst the clutch shaft rotates in a bronze spigot bush which

is press fitted into the end of the crankshaft. An oil seal is

fitted in the clutch shaft passage seat in the c o n n e c t i o n

support. The layshaft, together with the drive pinion of the

differential unit is supported at the front by a ballbearing

race. The layshaft carries the pinion adjustment shim, the

fourth-speed driven gear and its bushing, the hub and

relevant engagement sleeve for the t h i r d - and fourth-

speed w i t h first-speed and reverse-speed, the third-speed

gear and bushing and, outside the casing the second gear

and bushing, the hub with relevant second-speed engage-

ment sleeve and the speedometer drive gear.

The gears are operated by a gear selection lever mounted

on the tunnel situated between the two front seats. This

operates through a rod actuating the selector and shifting

mechanism which is housed in the gearbox casing cover.

Refer to FIG 6 :3 where it will be seen th a t the positioning

of the striker rods is ensured by a spring-loaded ball-

bearing. The risk of engaging two gears at the same time is

eliminated by three rollers which slide in suitable slots

machined in the rod (see FIG 6 : 4).

The differential unit and the final drive gear train are

housed in the t w o semi-covers which

have previously

been described, the final drive pinion being integral with

the layshaft. The differential casing may be split into t w o

halves. The bevel gear is fitted on one of the halves and is

66

secured by the same screws joining the two halves

together. The differential side gears are internally splined

into which are located the splined axle shaft ends which

are able to slide by means of a specially designed slip joint.

Two specially shaped rubber oil boots are inserted on the

swing axle shafts and fit over the side gear extensions to

ensure that there is no loss of lubricant or the ingress

of dirt.

The transmission and differential unit to suit the station

wagon differs from the sedan in that the transmission to

engine mounting plate and the bellhousing are modified to

suit the engine repositioned on its side.

6 : 2 Removal of gearbox/differential unit:

The complete unit may be removed whilst the engine

remains in situ and to remove this unit proceed as follows:

1 Disconnect the battery positive cable and jack up the

rear of t h e vehicle and place on firmly based stands.

2 Disconnect all control cables and wiring from the

starter motor and the clutch lever. Remove the starter

motor, the clutch lever reaction spring and the clutch

cable support on the gearbox.

3 Remove the three bolts securing each of the driving

shaft flanges to the flexible coupling at the wheel ends

and carefully take out the inner spring.

4 Disconnect the shifter rod from the gearshift lever at the

gearbox extension and also the

speedometer drive

cable. Remove also the flywheel undercover. Place a

suitable support under the engine.

Page 62 of 128

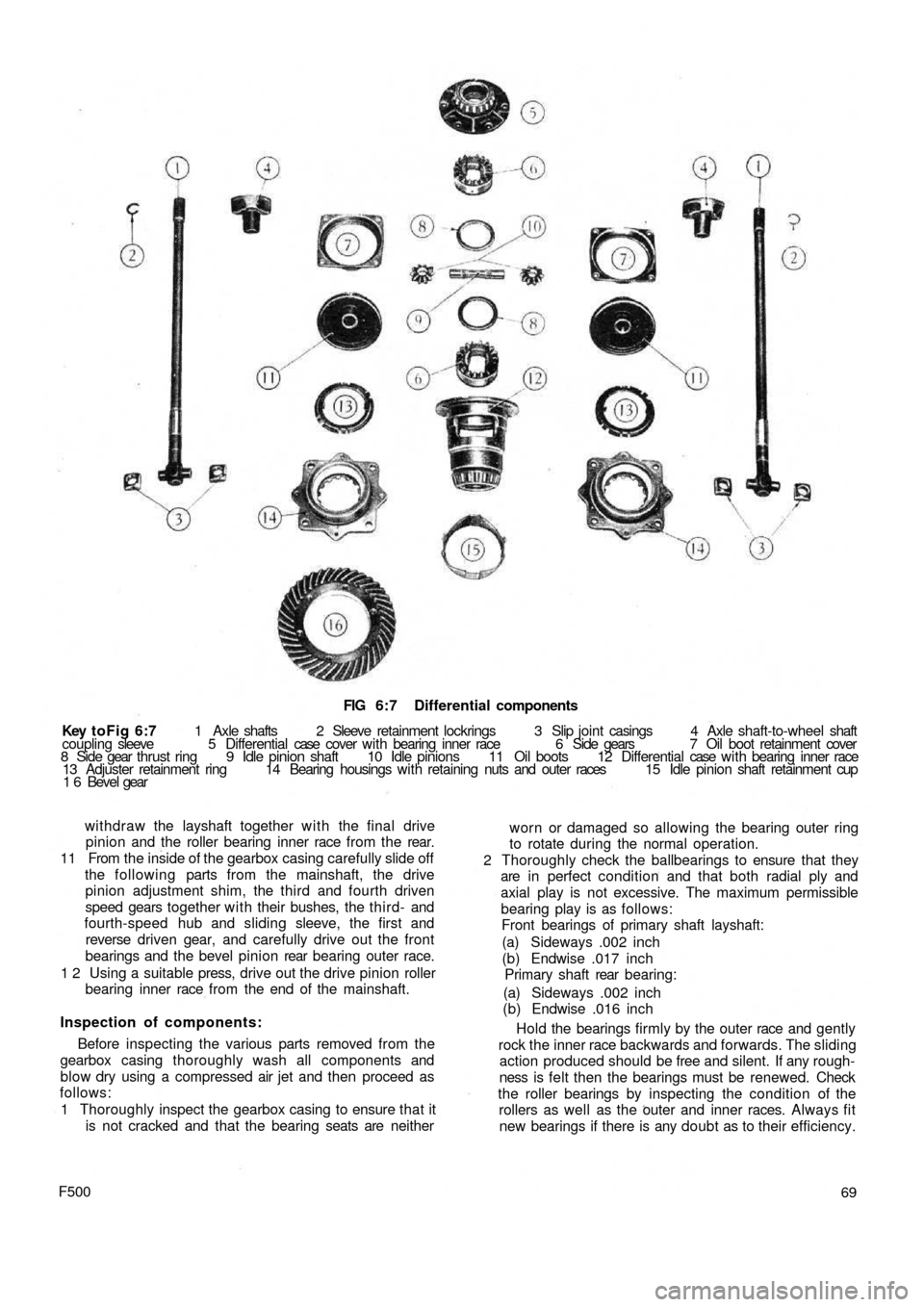

FIG 6:7 Differential components

Key toFig 6:7 1 Axle shafts 2 Sleeve retainment lockrings 3 Slip joint casings 4 Axle shaft-to-wheel shaft

coupling sleeve 5 Differential case cover w i t h bearing inner race 6 Side gears 7 Oil boot retainment cover

8 Side gear thrust ring 9 Idle pinion shaft 10 Idle pinions 11 Oil boots 12 Differential case w i t h bearing inner race

13 Adjuster retainment ring 14 Bearing housings with retaining nuts and outer races 15 Idle pinion shaft retainment cup

1 6 Bevel gear

withdraw the layshaft together w i t h the final drive

pinion and the roller bearing inner race from the rear.

11 From the inside of the gearbox casing carefully slide off

the following parts from the mainshaft, the drive

pinion adjustment shim, the third and fourth driven

speed gears together with their bushes, the t hird- and

fourth-speed hub and sliding sleeve, the first and

reverse driven gear, and carefully drive out the front

bearings and the bevel pinion rear bearing outer race.

1 2 Using a suitable press, drive out the drive pinion roller

bearing inner race from the end of the mainshaft.

Inspection of components:

Before inspecting the various parts removed from the

gearbox casing thoroughly wash all components and

blow dry using a compressed air jet and then proceed as

follows:

1 Thoroughly inspect the gearbox casing to ensure that it

is not cracked and that the bearing seats are neither

F50069 worn or damaged so allowing the bearing outer ring

to rotate during the normal operation.

2 Thoroughly check the ballbearings to ensure that they

are in perfect condition and that both radial ply and

axial play is not excessive. The maximum permissible

bearing play is as follows:

Front bearings of primary shaft layshaft:

(a) Sideways .002 inch

(b) Endwise .017 inch

Primary shaft rear bearing:

(a) Sideways .002 inch

(b) Endwise .016 inch

Hold the bearings firmly by the outer race and gently

rock the inner race backwards and forwards. The sliding

action produced should be free and silent. If any rough-

ness is felt then the bearings must be renewed. Check

the roller bearings by inspecting the condition of the

rollers as well as the outer and inner races. Always fit

new bearings if there is any doubt as to their efficiency.

Page 63 of 128

3 Check the layshaft and the primary shaft between

centres and using a dial gauge ensure that there is no

distortion. The out of true reading for bearing seats

should be less than .0008 inch. Inspect the splines and

ensure that the side and outerfaces are not indented.

Replace if there are signs of wear. Also inspect the

reverse shaft to ensure that it is perfectly smooth and

not showing signs of pitting or partial seizure.

4 Carefully inspect all gear teeth for signs of excessive

wear or damage. The contact faces must be smooth and

show no signs of indentation marks. Also check that

the backlash between the gears, when correctly

mounted on the surface plate is not greater than .0039

inch. The maximum wear limit is .0079 inch. Check that

the quick engagement front teeth of the second-, third-

and fourth-speed gears are not damaged or excessively

worn. Renew if there are signs of gearchange lever

misuse.

5 Inspect the sliding sleeves and the relevent hubs, ensure

that all the working surfaces are perfectly smooth. The

clearance between the mating parts should not be

greater than .0059 inch. Also inspect the meshing teeth

and ensure that they are in good condition.

6 Check that the gear shifting selector forks are not dis-

torted and that the striker rods freely slide in their seats

in the gearbox casing.

7 Carefully inspect that all the oil seals are in perfect con-

dition and if there is any doubt they should be renewed.

8 Inspect the striker rod locking balls and the safety rollers

and ensure that they slide freely in their seatings. Also

check the ball load spring efficiency and if this shows

signs of weakness then it should be renewed. Any

faults with these items will cause difficulty in engaging

gears or autodisengagement during engine acceleration.

6 : 4 Reassembly—gearbox

To reassemble the components to the gearbox ensure

that all components are thoroughly clean and then pro-

ceed as follows:

1 Press t h e pinion rear roller bearing onto the layshaft.

Install the layshaft in the casing, and at the same time

fit the adjustment shim, the fourth-speed driven gear

together w i t h its bush, the sleeve and hub for third and

fourth gear engagement, the first-speed and reverse

driven gear and the third-speed driven gear with its

hub.

2 Install the front layshaft ballbearing securing the

bearing retainment plate w i t h the screws and finally

lock the screws in position.

3 Insert the primary shaft together with the first, third

and fourth driving gear train in the gearbox housing

and slide t h e rear bearing onto the shaft. Push the

input shaft forward to enable the clutch shaft coupling

to be inserted in t h e rear and to be pulled up the

primary shaft by means of the pin. Do not forget the

retaining ring.

4 Slide the primary shaft backwards so pushing the rear

bearing into its bore. Refit the front bearing onto the

primary shaft.

5 On the layshaft insert the second-speed driven shaft

and bush, the second gear sliding dog sleeve and the

hub. Also insert the second-speed striker rod and the

first-speed fork. Do not forget to fit the safety roller

into its seating.

70

6 Slide the second-speed driving gear onto the primary

shaft. Place the engagement fork on the third- and

fourth-speed engagement sliding sleeve, and insert

the striker rod, lock the relevent fork and fit the safety

roller.

7 Insert the third safety roller and install the reverse shaft

and insert the reverse gear cluster onto it and secure

the shaft by tightening its block bolt. Install the reverse

striker rod w i t h its relevent fork.

8 Now refit the speedometer drive worm gear onto the

layshraft. Tighten the nuts on the primary shaft and the

layshaft, not forgetting to interpose the plain washer

between the speedometer driving worm and the nut,

to a torque wrench setting of 1 8.1 Ib ft to 25.3 Ib ft

(primary shaft) and 28.9 to 36.2 Ib ft (layshaft). It is

recommended that the input shaft and layshaft are

locked together by engaging t w o gears at the same

time. Finally, fit the splitpins.

9 Lock the shifter forks onto their shafts by tightening

their respective bolts and bend up the special locking

plates. Install the three positioning balls and relevant

springs into their bores and refit the cover plate.

10 Install the casing cover together with its relevant

gasket. This will enable correct positioning of the shift

shaft lever so that it engages in the outer ends of the

shifter shafts protruding from the gearbox casing.

11 Install the speedometer drive support on the gearbox

casing and refit the upper gearbox cover.

For subsequent differential operations and adjustments

see Sections 6:6.

6:5 Dismantling—differential and final drive

For the removal of the differential and final drive unit

from the gearbox refer to Section 6:3. To dismantle the

differential assembly

proceed as follows:

1 Remove the retaining ring 2 (see FIG 6 : 7) retaining

the splined sleeve 4 and slide the sleeve off the drive

shaft.

2 Remove t h e retaining covers 7 and the oil boots all

together with the bushes and seals, adjuster ring lock

rings 13, adjuster rings housing 14, and bearing

adjuster and roller bearing outer races.

3 Separate the differential housing halves by unscrewing

and removing the six bolts that keep both the halves and

the crownwheel together. It is advisable to mark the

respective components to ensure correct matching

upon reassembly.

4 Remove the differential pinion shaft retainer ring, also

the differential pinions 10 by removing the shaft and

withdrawing the two axle shafts 1.

5 Remove the differential side gears 6 and relevent thrust

rings 8.

6 Using a press remove the differential bearing inner

races from their seats on the carrier halves.

7 Thoroughly clean all parts and dry using a compressed

air jet.

Inspection:

The components of the differential unit must be

thoroughly inspected for correct operation and to deter-

mine the presence of any wear, damage or other irregulari-

ties. To check the items concerned proceed as follows:

1 Check thoroughly the idle pinion carrier shaft for signs

Page 73 of 128

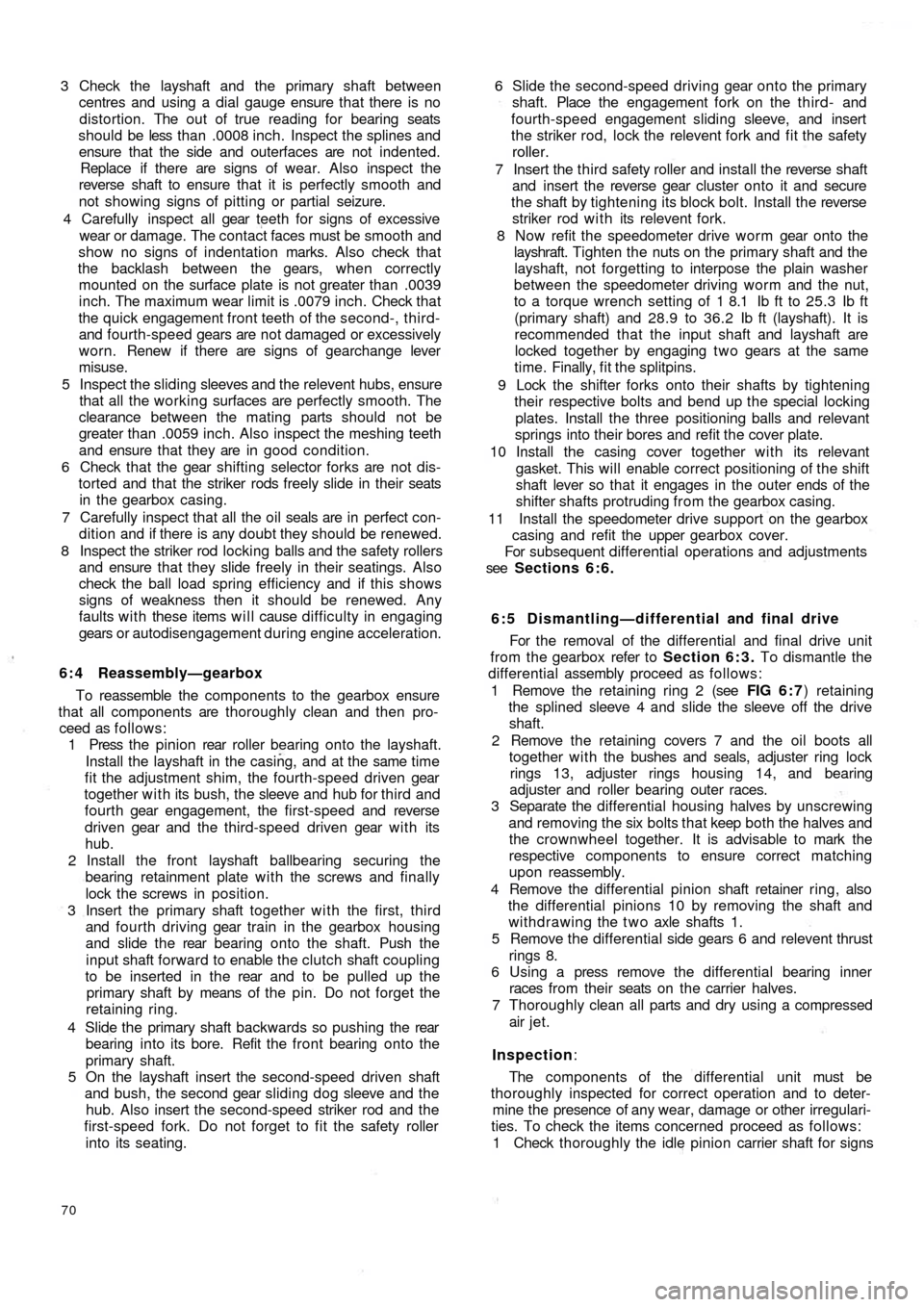

FIG 7 : 1 Rear suspension assembly

Key to Fig 7 : 1 1 Brake shoe control cable and sheath 2 Coil spring 3 Oil boot 4 Axle shaft 5 Bumper

6 Flexible joint 7 Swinging arm 8 Cable adjusting nut 9 Swinging arm-to-front bracket mounting pin

10 Swinging arm front bracket-to-underbody mounting screw 11 Engine front support crossmember 12 Swinging arm

rear self-locking nut 13 Shock absorber-to-swinging arm lower nut 14 Sleeve screws 15 Axle shaft-to-flexible joint sleeve

9 Remove the three swinging external support fixing

bolts securing the outer suspension arm bracket to the

vehicle floor and remove the rear suspension assembly.

Remove the special rubber pad located between the

support bracket and the vehicle floor.

7 : 3 Servicing swing arms

Dismantling:

1 Remove the cotter pin and release the nut fixing the

flexible joint to the wheel shaft. Remove the plain

washer and the joint.

2 Using Fiat tool A.40005.1.9 or a universal two-leg

puller, remove the wheel shaft and brake drum.

Extract the t w o oil seals and both the outer and inner

bearing inner rings, thrust ring of the joint and the

resilient spacer.

3 Using Fiat tool A.6511, remove the t w o bearing outer

rings.

4 Disconnect the brake hydraulic line at the wheel

cylinder and remove the swinging external support.

The bearing housing and brake housing flange may

then be removed.

Inspection :

Thoroughly clean all the parts and install the swinging

arm on Fiat fixture A.66064 as shown in FIG 7 : 4. If the

80

swinging arm has not been distorted its installation on the

fixture should be straightforward. Tighten the clamp

screws 1 (see FIG 7 : 3) on the road wheel brake drum,

connect the swinging arm inner member to the seating

2 on the fixture and finally fit the swinging arm external

support holes on the fixture pins 3. Should difficulty be

experienced in either one of these three operations then

this is an indication that the swinging arm is distorted and

should be straightened or a new assembly fitted. If this

check is satisfactory proceed as follows:

1 Check that the 'estendblocks' are a snug fit in their

respective seatings in the swinging arm and that the

mounting pin slides in freely w it h ou t excessive play.

To renew the 'estendblocks' use Fiat tool A.66056

which is suitable for both their removal and installation.

2 Check that the inner and outer bearing outer rings have

no play in their seatings and that the rollers and cages

are not broken, cracked, show signs of overheating

or are worn.

3 Ensure t h a t the o i l seals f i t snugly on the wheel shaft,

also on the joint spacer or shoulder ring and on the

hub seats. If the oil seals should show any signs of wear

then these should be renewed.

4 Inspect the resilient spacer for signs of hair line cracks,

which if not evident the spacer may be used again as

it is not permanently distorted during assembly.

Should, however, new bearings or bearing housings

be fitted it is considered good practice to fit a new

spacer.

Page 90 of 128

CHAPTER 9

THE STEERING SYSTEM

9 : 5 Relay lever and support

9 : 6 Steering rods

9 : 7 Front wheel toe-in

9 : 8 Fault diagnosis 9:1 Description

9 : 2 Steering wheel removal and refitting

9 : 3 Steering box removal and refitting

9 : 4 Steering box dismantling and reassembly

9:1 Description

The steering gear fitted to the new 500 range of

vehicles is of the worm screw and sector type with a

steering ratio of 1:13. The steering gearbox is located on

the front lefthand side of the dash wall on the scuttle as

shown in FIG 9:1. The steering gear comprises a pitman

arm and relay lever pivoting on a pin supported on the

body. A central track rod connects the pitman arm to the

relay lever. T w o track rods connect the pitman arm and

relay lever to the knuckle arms.

9:2 Steering wheel removal and refitting

To remove the steering wheel proceed as follows:

1 Disconnect the battery positive terminal clamp and

remove the horn control from the steering wheel.

2 Remove the cable from the push button seating and the

cable insulation sleeve.

3 Using a suitably sized box spanner or Fiat wrench

A.8279 unscrew the steering wheel to shaft nut as

shown in FIG 9:2.

4 Using the palm of the hands against the back of the

steering wheel rim gently tap the steering wheel

forwards so releasing it from the inner shaft.

F50097 5 Reassembly is the reverse procedure to dismantling.

Care should be taken to ensure that the front wheels

are located in the straight ahead position when the

steering wheel is being replaced otherwise the steering

wheel spokes will not be correctly positioned.

9 : 3 Steering box removal and refitting

To remove the steering box from the vehicle proceed

as follows:

1 From inside the vehicle remove the steering column

clamp bolt 6 (see FIG 9 : 3) after flattening the lock-

washer 7.

2 From the underside of the vehicle remove the t w o

tie rod locking nuts from the pitman arm and then using

Fiat tool A.46006 or a suitable t w o leg puller withdraw

the pins from the seats.

3 Remove the three nuts holding the steering box to the

body panel. Ease out the worm screw from the

steering shaft and lift away the steering box.

4 To refit the steering box is the reverse procedure to

dismantling. The steering box to body mounting nuts

should be tightened to a torque wrench setting of

14 Ib/ft to 18 Ib/ft.

Page 120 of 128

CHAPTER 12

THE BODYWORK

12:1

12:2

12:3

12:4

12:5

12:6

12:7Bodywork finish

Interior and chrome cleaning

Door trim and accessories

Door handles and locks

Removing regulator and door glass

Removing windshield glass

Removing rear side windows12:8

12:9

12:10

12:11

12:12

12:13

12:14Removing rear window glass

Front compartment lid

Engine compartment lid

Folding top

Sun roof

Seats

Interior heater

12:1 Bodywork finish

Large scale repairs to body panels are best left to

expert panel beaters. Even small dents can be tricky, as too

much hammering will stretch the metal and make things

worse instead of better. Filling minor dents and scratches

is probably the best method of restoring the surface. The

touching up of paintwork is well within the powers of

most car owners, particularly as self-spraying cans of

paint in the correct colours are now readily available. It

must be remembered, however, that paint changes colour

w i t h age and it is better to spray a whole wing rather than

try to touch up a small area.

Before spraying it is essential to remove all traces of

wax polish with white spirit. More drastic treatment is

required if silicone polishes have been applied. Use a

primer surfacer or paste stopper according to the amount

of filling required, and when it is dry, rub it down with

400 grade Wet or Dry paper until the surface is smooth

and flush with the surrounding area. Spend time on

getting the best finish as this will control the final effect.

Apply the retouching paint, keeping it wet in the centre

and light and dry round the edges. After a few hours of

drying, use a cutting compound to remove the dry spray

and finish with liquid polish.

F500127

12:2 Interior and chrome cleaning

The cloth upholstery of the seating and the rear

compartment lining must be regularly cleaned to ensure

long life and preserve its attractive appearance. Any dust

or dirt that is blown into the car will settle on the uphol-

stery and will tend to wear the cloth causing an unsightly

appearance. It is recommended that the dust is wiped off

using either a vacuum cleaner or a stiff brush. To remove

ordinary soiling of the upholstery cloth proceed as

follows:

1 Using luke warm water and a neutral soap and a piece

of clean cloth wipe over the upholstery in the direction

of the nap.

2 Repeat the operation using a clean damp cloth and

warm water but no soap.

3 Allow the upholstery cloth to dry, use a stiff brush

against the direction of the upholstery nap to restore

its original fluffy look.

To obtain best results, any stains must be removed as

soon as possible otherwise as time passes they will

become more difficult, if not impossible to remove.

Certain stains require specific solvents and the instruc-

tions must be strictly adhered to.