Front wheel bearing FIAT 500 1970 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1970, Model line: 500, Model: FIAT 500 1970 1.GPages: 128, PDF Size: 9.01 MB

Page 66 of 128

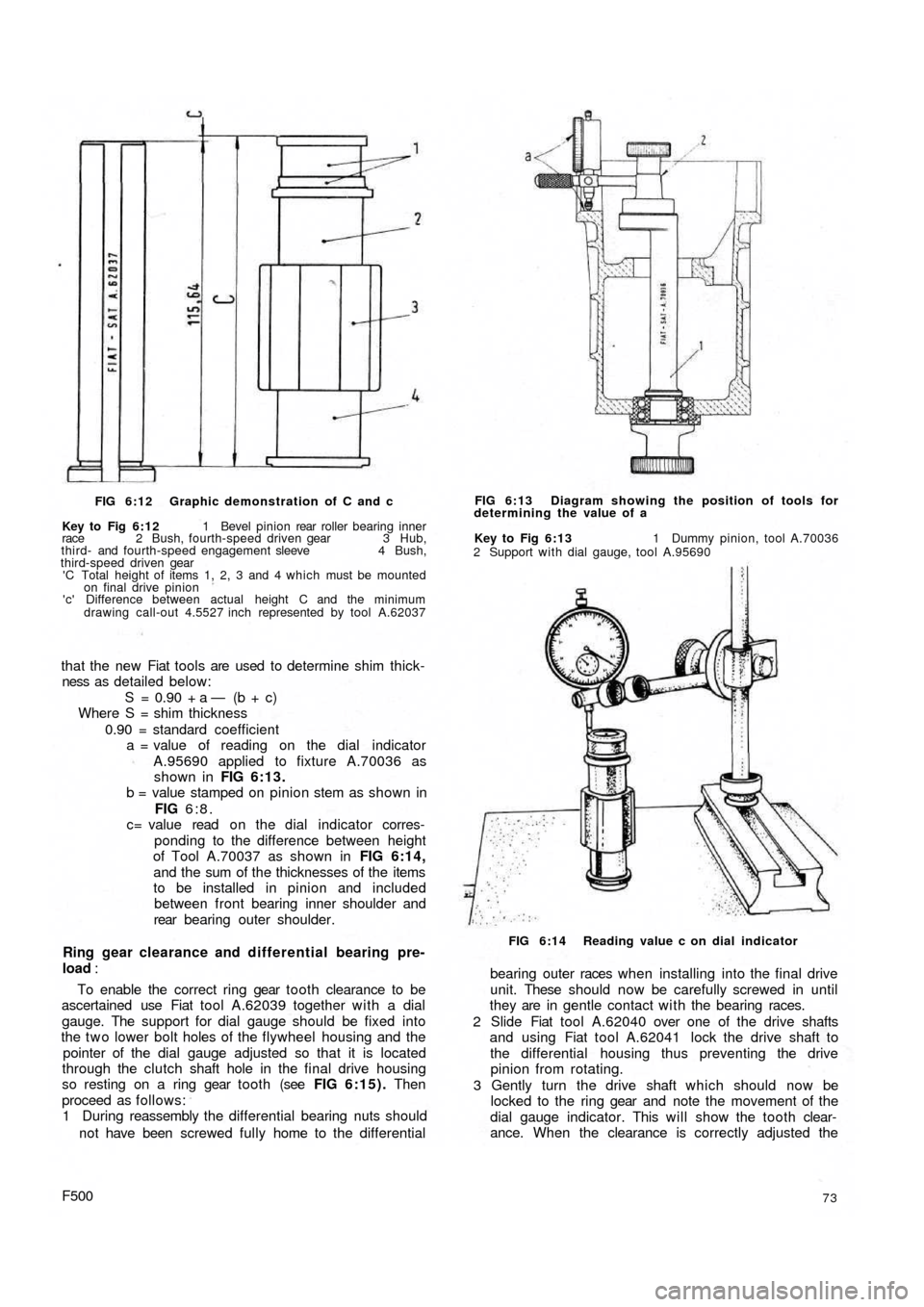

FIG 6:12 Graphic demonstration of C and c

Key to Fig 6:12 1 Bevel pinion rear roller bearing inner

race 2 Bush, fourth-speed driven gear 3 Hub,

third- and fourth-speed engagement sleeve 4 Bush,

third-speed driven gear

'C Total height of items 1, 2, 3 and 4 which must be mounted

on final drive pinion

'c' Difference between actual height C and the minimum

drawing call-out 4.5527 inch represented by tool A.62037

that the new Fiat tools are used to determine shim thick-

ness as detailed below:

S = 0.90 + a — (b + c)

Where S = shim thickness

0.90 = standard coefficient

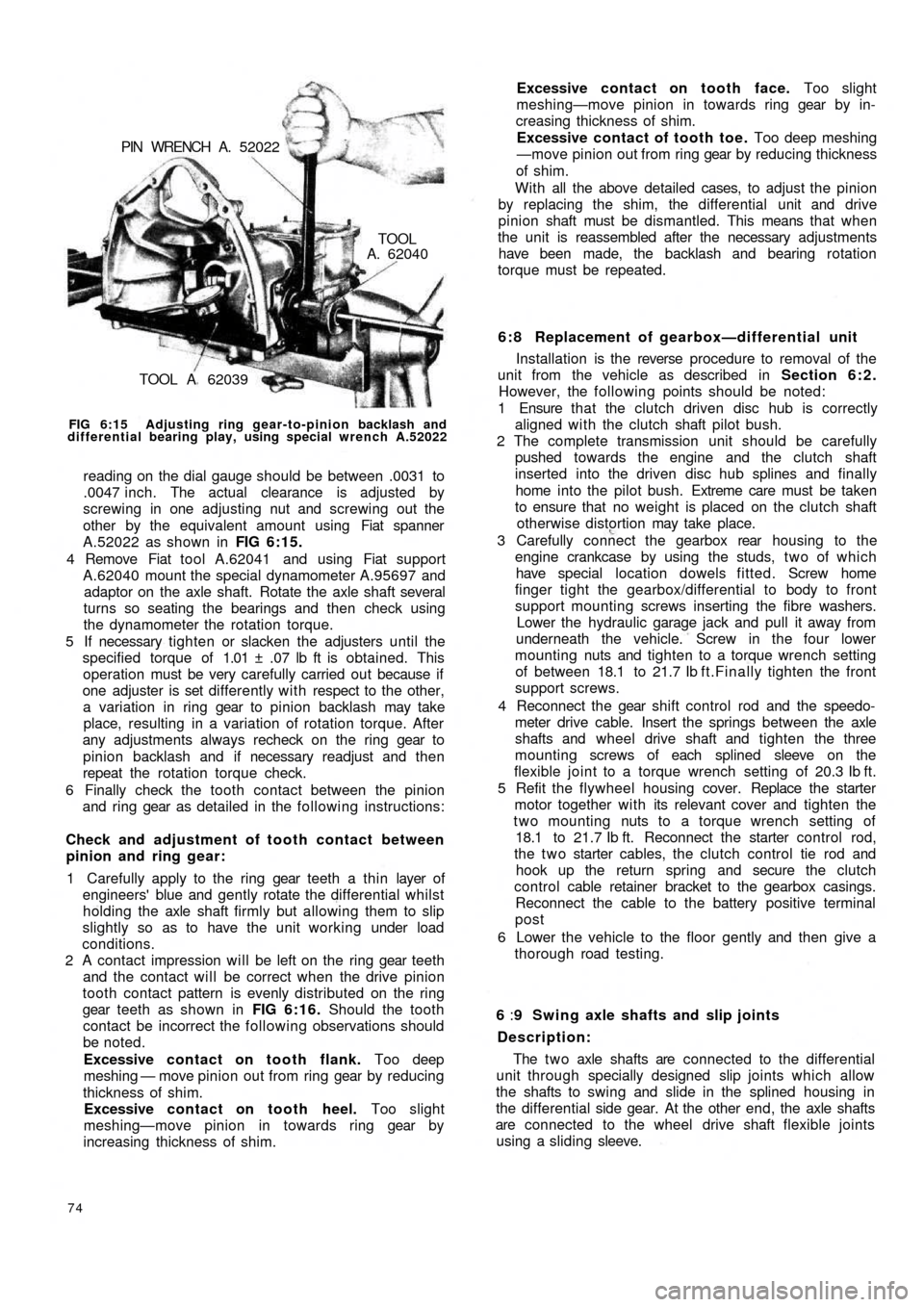

a = value of reading on the dial indicator

A.95690 applied to fixture A.70036 as

shown in FIG 6:13.

b = value stamped on pinion stem as shown in

FIG 6:8.

c= value read o n the dial indicator corres-

ponding to the difference between height

of Tool A.70037 as shown in FIG 6:14,

and the sum of the thicknesses of the items

to be installed in pinion and included

between front bearing inner shoulder and

rear bearing outer shoulder.

Ring gear clearance and differential bearing pre-

load :

To enable the correct ring gear tooth clearance to be

ascertained use Fiat tool A.62039 together with a dial

gauge. The support for dial gauge should be fixed into

the t w o lower bolt holes of the flywheel housing and the

pointer of the dial gauge adjusted so that it is located

through the clutch shaft hole in the final drive housing

so resting on a ring gear tooth (see FIG 6:15). Then

proceed as follows:

1 During reassembly the differential bearing nuts should

not have been screwed fully home to the differential

F50073

bearing outer races w h e n installing into the f i n a l drive

unit. These should now be carefully screwed in until

they are in gentle contact with the bearing races.

2 Slide Fiat tool A.62040 over one of the drive shafts

and using Fiat tool A.62041 lock the drive shaft to

the differential housing thus preventing the drive

pinion from rotating.

3 Gently turn the drive shaft which should now be

locked to the ring gear and note the movement of the

dial gauge indicator. This will show the tooth clear-

ance. When the clearance is correctly adjusted the

FIG 6:14 Reading value c on dial indicator Key to Fig 6:13 1 Dummy pinion, tool A.70036

2 Support with dial gauge, tool A.95690 FIG 6:13 Diagram showing the position of tools for

determining the value of a

Page 67 of 128

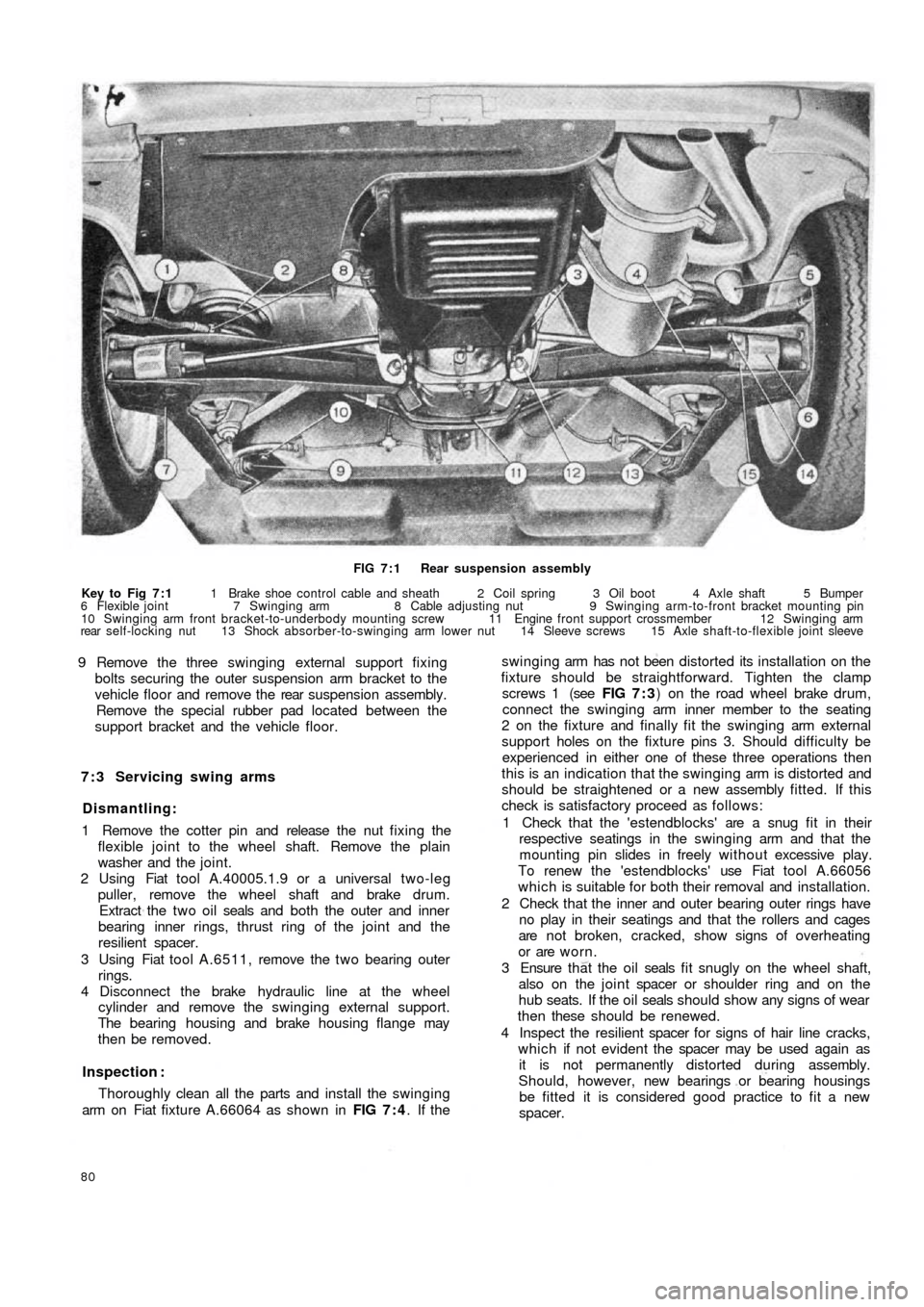

TOOL A 62039

TOOLA. 62040 PIN WRENCH A. 52022

FIG 6:15 Adjusting ring gear-to-pinion backlash and

differential bearing play, using special wrench A.52022

reading on the dial gauge should be between .0031 to

.0047 inch. The actual clearance is adjusted by

screwing in one adjusting nut and screwing out the

other by the equivalent amount using Fiat spanner

A.52022 as shown in FIG 6:15.

4 Remove Fiat tool A.62041 and using Fiat support

A.62040 mount the special dynamometer A.95697 and

adaptor on the axle shaft. Rotate the axle shaft several

turns so seating the bearings and then check using

the dynamometer the rotation torque.

5 If necessary tighten or slacken the adjusters until the

specified torque of 1.01 ± .07 lb ft is obtained. This

operation must be very carefully carried out because if

one adjuster is set differently with respect to the other,

a variation in ring gear to pinion backlash may take

place, resulting in a variation of rotation torque. After

any adjustments always recheck on the ring gear to

pinion backlash and if necessary readjust and then

repeat the rotation torque check.

6 Finally check the tooth contact between the pinion

and ring gear as detailed in the following instructions:

Check and adjustment of tooth contact between

pinion and ring gear:

1 Carefully apply to the ring gear teeth a thin layer of

engineers' blue and gently rotate the differential whilst

holding the axle shaft firmly but allowing them to slip

slightly so as to have the unit working under load

conditions.

2 A contact impression will be left on the ring gear teeth

and the contact will be correct when the drive pinion

tooth contact pattern is evenly distributed on the ring

gear teeth as shown in FIG 6:16. Should the tooth

contact be incorrect the following observations should

be noted.

Excessive contact on tooth flank. Too deep

meshing — move pinion out from ring gear by reducing

thickness of shim.

Excessive contact on tooth heel. Too slight

meshing—move pinion in towards ring gear by

increasing thickness of shim.

74

6 : 8 Replacement of gearbox—differential unit

Installation is the reverse procedure to removal of the

unit from the vehicle as described in Section 6:2.

However, the following points should be noted:

1 Ensure that the clutch driven disc hub is correctly

aligned with the clutch shaft pilot bush.

2 The complete transmission unit should be carefully

pushed towards the engine and the clutch shaft

inserted into the driven disc hub splines and finally

home into the pilot bush. Extreme care must be taken

to ensure that no weight is placed on the clutch shaft

otherwise distortion may take place.

3 Carefully connect the gearbox rear housing to the

engine crankcase by using the studs, t w o of which

have special location dowels fitted. Screw home

finger tight the gearbox/differential to body to front

support mounting screws inserting the fibre washers.

Lower the hydraulic garage jack and pull it away from

underneath the vehicle. Screw in the four lower

mounting nuts and tighten to a torque wrench setting

of between 18.1 to 21.7 Ib f t.Finally tighten the front

support screws.

4 Reconnect the gear shift control rod and the speedo-

meter drive cable. Insert the springs between the axle

shafts and wheel drive shaft and tighten the

three

mounting screws of each splined sleeve on the

flexible joint to a torque wrench setting of 20.3 Ib ft.

5 Refit the flywheel housing cover. Replace the starter

motor together with its relevant cover and tighten the

two mounting nuts to a torque wrench setting of

18.1 to 21.7 Ib ft. Reconnect the starter control rod,

the t w o starter cables, the clutch control tie rod and

hook up the return spring and secure the clutch

control cable retainer bracket to the gearbox casings.

Reconnect the cable to the battery positive terminal

post

6 Lower the vehicle to the floor gently and then give a

thorough road testing.

6 :9 Swing axle shafts and slip joints

Description:

The t w o axle shafts are connected to the differential

unit through specially designed slip joints which allow

the shafts to swing and slide in the splined housing in

the differential side gear. At the other end, the axle shafts

are connected to the wheel drive shaft flexible joints

using a sliding sleeve. Excessive contact on tooth face. Too slight

meshing—move pinion in towards ring gear by in-

creasing thickness of shim.

Excessive contact of tooth toe. Too deep meshing

—move pinion out from ring gear by reducing thickness

of shim.

With all the above detailed cases, to adjust the pinion

by replacing the shim, the differential unit and drive

pinion shaft must be dismantled. This means that when

the unit is reassembled after the necessary adjustments

have been made, the backlash and bearing rotation

torque must be repeated.

Page 73 of 128

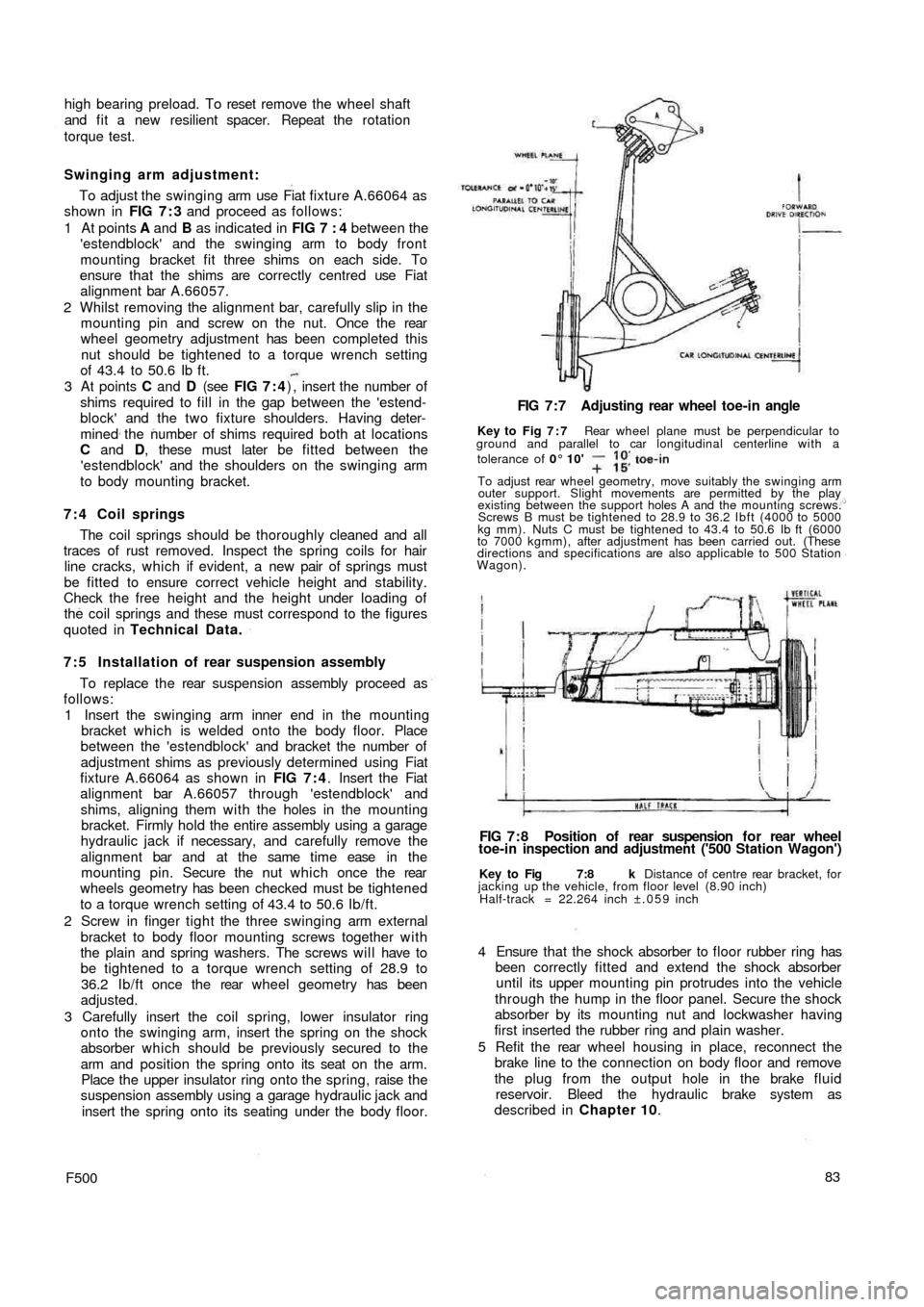

FIG 7 : 1 Rear suspension assembly

Key to Fig 7 : 1 1 Brake shoe control cable and sheath 2 Coil spring 3 Oil boot 4 Axle shaft 5 Bumper

6 Flexible joint 7 Swinging arm 8 Cable adjusting nut 9 Swinging arm-to-front bracket mounting pin

10 Swinging arm front bracket-to-underbody mounting screw 11 Engine front support crossmember 12 Swinging arm

rear self-locking nut 13 Shock absorber-to-swinging arm lower nut 14 Sleeve screws 15 Axle shaft-to-flexible joint sleeve

9 Remove the three swinging external support fixing

bolts securing the outer suspension arm bracket to the

vehicle floor and remove the rear suspension assembly.

Remove the special rubber pad located between the

support bracket and the vehicle floor.

7 : 3 Servicing swing arms

Dismantling:

1 Remove the cotter pin and release the nut fixing the

flexible joint to the wheel shaft. Remove the plain

washer and the joint.

2 Using Fiat tool A.40005.1.9 or a universal two-leg

puller, remove the wheel shaft and brake drum.

Extract the t w o oil seals and both the outer and inner

bearing inner rings, thrust ring of the joint and the

resilient spacer.

3 Using Fiat tool A.6511, remove the t w o bearing outer

rings.

4 Disconnect the brake hydraulic line at the wheel

cylinder and remove the swinging external support.

The bearing housing and brake housing flange may

then be removed.

Inspection :

Thoroughly clean all the parts and install the swinging

arm on Fiat fixture A.66064 as shown in FIG 7 : 4. If the

80

swinging arm has not been distorted its installation on the

fixture should be straightforward. Tighten the clamp

screws 1 (see FIG 7 : 3) on the road wheel brake drum,

connect the swinging arm inner member to the seating

2 on the fixture and finally fit the swinging arm external

support holes on the fixture pins 3. Should difficulty be

experienced in either one of these three operations then

this is an indication that the swinging arm is distorted and

should be straightened or a new assembly fitted. If this

check is satisfactory proceed as follows:

1 Check that the 'estendblocks' are a snug fit in their

respective seatings in the swinging arm and that the

mounting pin slides in freely w it h ou t excessive play.

To renew the 'estendblocks' use Fiat tool A.66056

which is suitable for both their removal and installation.

2 Check that the inner and outer bearing outer rings have

no play in their seatings and that the rollers and cages

are not broken, cracked, show signs of overheating

or are worn.

3 Ensure t h a t the o i l seals f i t snugly on the wheel shaft,

also on the joint spacer or shoulder ring and on the

hub seats. If the oil seals should show any signs of wear

then these should be renewed.

4 Inspect the resilient spacer for signs of hair line cracks,

which if not evident the spacer may be used again as

it is not permanently distorted during assembly.

Should, however, new bearings or bearing housings

be fitted it is considered good practice to fit a new

spacer.

Page 76 of 128

high bearing preload. To reset remove the wheel shaft

and fit a new resilient spacer. Repeat the rotation

torque test.

Swinging arm adjustment:

To adjust the swinging arm use Fiat fixture A.66064 as

shown in FIG 7 : 3 and proceed as follows:

1 At points A and B as indicated in FIG 7 : 4 between the

'estendblock' and the swinging arm to body front

mounting bracket fit three shims on each side. To

ensure that the shims are correctly centred use Fiat

alignment bar A.66057.

2 Whilst removing the alignment bar, carefully slip in the

mounting pin and screw on the nut. Once the rear

wheel geometry adjustment has been completed this

nut should be tightened to a torque wrench setting

of 43.4 to 50.6 Ib ft.

3 At points C and D (see FIG 7 : 4) , insert the number of

shims required to fill in the gap between the 'estend-

block' and the two fixture shoulders. Having deter-

mined the number of shims required both at locations

C and D, these must later be fitted between the

'estendblock' and the shoulders on the swinging arm

to body mounting bracket.

7 : 4 Coil springs

The coil springs should be thoroughly cleaned and all

traces of rust removed. Inspect the spring coils for hair

line cracks, which if evident, a new pair of springs must

be fitted to ensure correct vehicle height and stability.

Check the free

height and the height under loading of

the coil springs and these must correspond to the figures

quoted in Technical Data.

7:5 Installation of rear suspension assembly

To replace the rear suspension assembly proceed as

follows:

1 Insert the swinging arm inner end in the mounting

bracket which is welded onto the body floor. Place

between the 'estendblock' and bracket the number of

adjustment shims as previously determined using Fiat

fixture A.66064 as shown in FIG 7 : 4. Insert the Fiat

alignment bar A.66057 through 'estendblock' and

shims, aligning them with the holes in the mounting

bracket. Firmly hold the entire assembly using a garage

hydraulic jack if necessary, and carefully remove the

alignment bar and at the same time ease in t h e

mounting pin. Secure the nut which once the rear

wheels geometry has been checked must be tightened

to a torque wrench setting of 43.4 to 50.6 Ib/ft.

2 Screw in finger tight the three swinging arm external

bracket to body floor mounting screws together w i t h

the plain and spring washers. The screws will have to

be tightened to a torque wrench setting of 28.9 to

36.2 Ib/ft once the rear wheel geometry has been

adjusted.

3 Carefully insert the coil spring, lower insulator ring

onto the swinging arm, insert the spring on the shock

absorber which should be previously secured to the

arm and position the spring onto its seat on the arm.

Place the upper insulator ring onto the spring, raise the

suspension assembly using a garage hydraulic jack and

insert the spring onto its seating under the body floor.

F50083 4 Ensure that the shock absorber to floor rubber ring has

been correctly fitted and extend the shock absorber

until its upper mounting pin protrudes into the vehicle

through the hump in the floor panel. Secure the shock

absorber by its mounting nut and lockwasher having

first inserted the rubber ring and plain washer.

5 Refit the rear wheel housing in place, reconnect the

brake line to the connection on body floor and remove

the plug from the output hole in the brake fluid

reservoir. Bleed the hydraulic brake system as

described in Chapter 10.

Key to Fig 7:8 k Distance of centre rear bracket, for

jacking up the vehicle, from floor level (8.90 inch)

Half-track = 22.264 inch ±.059 inch

FIG 7 : 8 Position of rear suspension f o r rear wheel

toe-in inspection and adjustment ('500 Station Wagon') FIG 7 : 7 Adjusting rear wheel toe-in angle

Key to Fig 7 : 7 Rear wheel plane must be perpendicular to

ground and parallel to car longitudinal centerline with a

tolerance of 0° 10'

To adjust rear wheel geometry, move suitably the swinging arm

outer support. Slight movements are permitted by the play

existing between the support holes A and the mounting screws.

Screws B must be tightened to 28.9 to 36.2 Ibft (4000 to 5000

kg mm). Nuts C must be tightened to 43.4 to 50.6 Ib ft (6000

to 7000 kgmm), after adjustment has been carried out. (These

directions and specifications are also applicable to 500 Station

Wagon).

Page 79 of 128

A tolerance of —10'.+ 15' is permitted providing

that the value is the same for both rear wheels. It is

important that both rear wheels are set to the same

angle otherwise uneven tyre wear and adverse handl-

ing conditions will result. When the wheel is parallel to

the centre line of the vehicle the pin of bracket

C.696/3 will be .216 inch apart from the pin of the

front suspension swinging arm.

7 Release the swinging arm outer support to body

mounting screws and position arm in such a way as to

obtain the condition as described in Number 6 above.

After the adjustment has been completed tighten

the outer support mounting screws to a torque wrench

setting of 28.9 to 36.2 Ib/ft. Also tighten the two

swinging arm pin nuts C (see FIG 7 : 7) to a torque

wrench setting of 43.4 to 50.6 Ib/ft. Take off the gauge

C.696 w i t h bracket and support C.696/3, and repeat

the check and adjustment operations on the other

wheel. Care must be taken to ensure that bracket

C.696/3 is reversed from the position previously used.

New 500 type 500D, 110F and 110L sedan and

station wagon:

After the rear suspension has been replaced, check

and, if necessary adjust the rear wheel geometry.

1 Inflate the tyres to the normal operating pressures.

2 Lower the car body so that the rear wheels are set at

90 deg. to the floor. This condition is obtained when

the lowermost portion of the sump is 6.61 inches from

the floor level for the new 500D model or the centre

rear bracket for jacking up the rear of t h e vehicle

8.9 inches from the floor level for the 500 Station

Wagon.

3 With the vehicle set to the above conditions check the

wheel geometry. The wheel plane must converge w i t h

the centre line of the vehicle by an angle of 0 deg. 10'

(—10', +15') toeing in at the front.

4 The wheel plane must be 22.343 ± .059 inches from

the centre line of the vehicle for the 500D model.

Whereas for the 500 Station Wagon the distance must

be 22.264 ± .059 inches.

5 To adjust the rear wheel toe-in adjust the positions of

the mounting screws A and B as shown in FIG 7:7.

86

7:7 Modifications

The new 500 Sedan (110F) and late 500 Station

Wagon are fitted with modified wheels side flexible

joints and rear control arm as shown in FIG 7:13.

Together w i t h these modifications a new design rear

coil spring has been fitted details of which are given in

Technical Data.

7 : 8 Fault diagnosis

(a) Irregular or abnormal tyre wear

1 Incorrect tyre pressure

2 Wheels out of balance

3 Wheels off centre

4 Misadjusted brakes

5 Weak or broken coil springs

6 Excessive load

7 Incorrect wheel alignment

(b) Sag on one wheel

1 Incorrect tyre pressure

2 Weak or broken coil spring

3 Wear of shock absorber causing poor dampening

action

(c) Squeaks, thumps or rattles

1 Wheels out of balance

2 Wheels off centre

3 Misadjusted brakes

4 Weak or broken coil springs or spring seats dislodged

5 Wear of shock absorbers causing poor dampening

action

6 Worn rubber bushings in control arms

7 Poor lubrication of wheel bearings

(d) Pull to one side

1 Incorrect tyre pressure

2 Misadjusted brakes

3 Distorted suspension arm

Page 84 of 128

2 Check that the surface of the pin that is in contact with

the camber and castor adjuster shims does not show

any signs of indentation or roughness which could

affect the accuracy of adjustment on reassembly. If

there are any signs of rust or small markings these

should be smoothed out using a file.

3 Inspect the condition of the half arm bushes, the inner

surface of which must not show signs of seizure and

the clearance of the bush to pin must not be greater

than .01 57 inch. Upon initial assembly the fit clearance

is .00059 to .0059 inch. Ensure t h a t the rubber parts

of the bush are not torn, cracked or show signs of

weakness which, if evident, must be renewed.

4 Use Fiat tool A.66058 or a suitably sized drift for

refitting the rubber bushes into the swinging arms.

Upon reassembly it should be observed that the

tightening of the two swinging arms m o u n t i n g nuts 5

(see FIG 8 : 3) , must be carried out whilst keeping

the axis of the swinging arm and the pin hole for the

screws 7 on the same plane otherwise distortion can

occur.

8 : 5 Kingpin housing

1 To remove and replace the 'estendblocks' use Fiat

tool A.66056 as shown in FIG 8 : 8. Ensure t h a t the

'estendblocks' is not worn and that there are no signs

of seizure on its inner surface, or that the rubber has

hardened. Renew if necessary.

2 Check that the kingpin to bush clearance is not

greater than .0079 inch. The clearance when fitted

new is .00063 to .00213 inch. If the clearance is

excessive the t w o bushes must be renewed and also

the kingpin if excessive wear is evident. To remove and

refit the kingpin bushes use Fiat tool A.66016 and

after reassembly the bushes must be accurately

refaced using a reamer set to a diameter of .5912 to

.5922 inch. If considered necessary use Fiat Fixture

C.1004 to check that the kingpin housing has not been

distorted which, if evident, the housing must be

renewed.

3 Whilst the kingpin assembly is being inspected ensure

that the lubrication hole is free to allow the passage of

oil.

4 To prevent incorrect loading of the 'estendblocks' that

is press fitted into the kingpin housing, the housing

to swinging arm pin nut must be tightened with the

parts so arranged that the angle between the swinging

arm plane and the housing axis is approximately

95 deg. as shown in FIG 8:14.

8:6 Steering knuckle and wheel hub

Dismantling:

1 To remove the wheel hub cap use Fiat puller A.46023

as shown in FIG 8 : 9 .

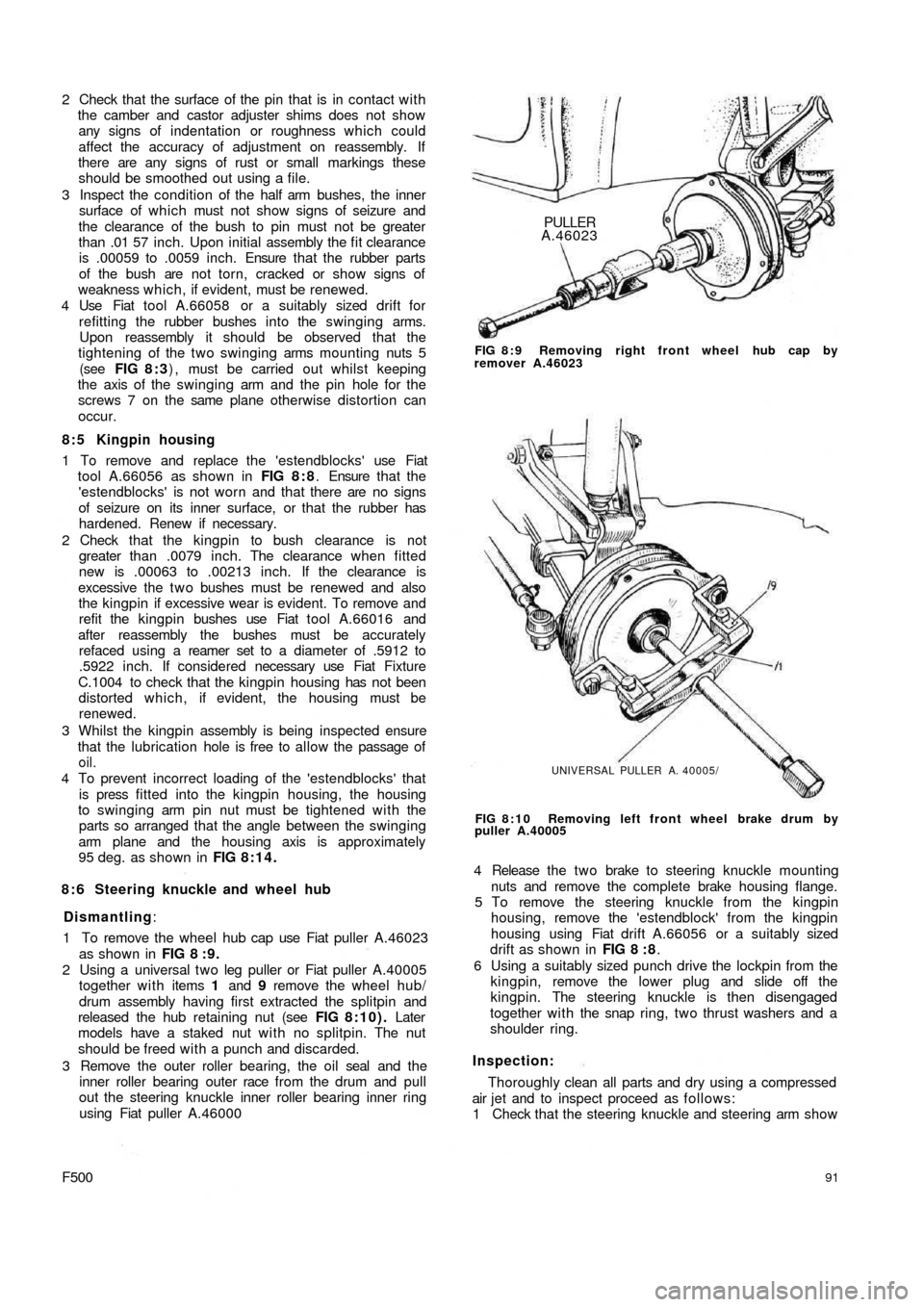

2 Using a universal t w o leg puller or Fiat puller A.40005

together with items 1 and 9 remove the wheel hub/

drum assembly having first extracted the splitpin and

released the hub retaining nut (see FIG 8:10). Later

models have a staked nut w i t h no splitpin. The nut

should be freed with a punch and discarded.

3 Remove the outer roller bearing, the oil seal and the

inner roller bearing outer race from the drum and pull

out the steering knuckle inner roller bearing inner ring

using Fiat puller A.46000

F500PULLER

A.46023

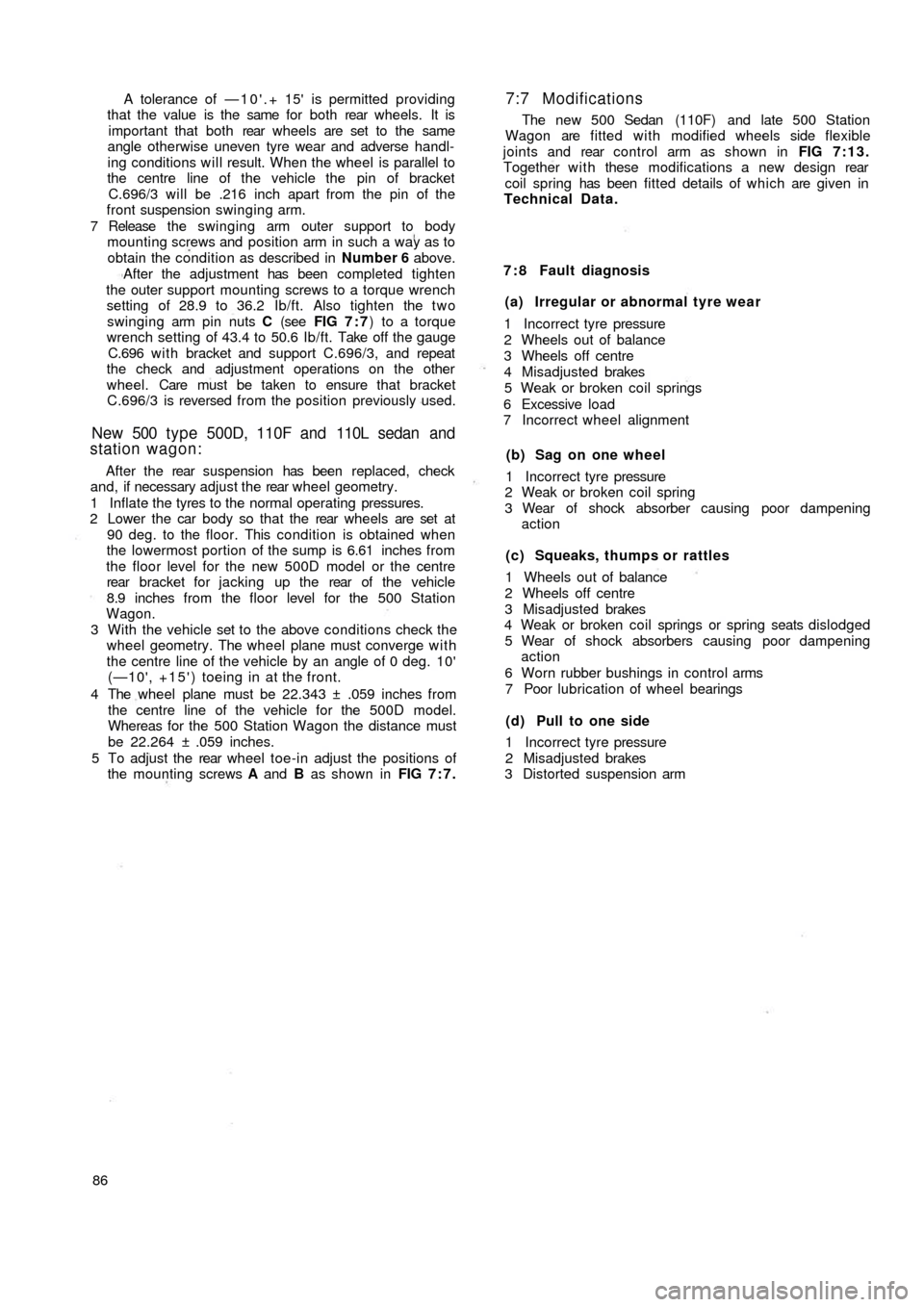

FIG 8 : 9 Removing right front wheel hub cap by

remover A.46023

UNIVERSAL PULLER A. 40005/

FIG 8:10 Removing left front wheel brake drum by

puller A.40005

4 Release the t w o brake to steering knuckle mounting

nuts and remove the complete brake housing flange.

5 To remove the steering knuckle from the kingpin

housing, remove the 'estendblock' from the kingpin

housing using Fiat drift A.66056 or a suitably sized

drift as shown in FIG 8 : 8.

6 Using a suitably sized punch drive the lockpin from the

kingpin, remove the lower plug and slide off the

kingpin. The steering knuckle is then disengaged

together with the snap ring, two thrust washers and a

shoulder ring.

Inspection:

Thoroughly clean all parts and dry using a compressed

air jet and to inspect proceed as follows:

1 Check that the steering knuckle and steering arm show

91

Page 89 of 128

to the body and proceed as follows:

1 If the camber angle requires to be increased (see FIG

8:16) add the same number of shims S on both

screws D and E.

2 If the camber angle requires to be reduced (see FIG

8:16) remove the same number of shims from both

screws D and E.

The addition or removal of shims at the t w o points D

and E permits camber adjustment to be made without

any disturbing of the castor angle.

8:10 Modifications

Checking and adjusting castor and camber angles:

When checking the castor and camber angle the

static loading should be such that the distance between

the semi-elliptic spring mountings G (see FIG 8:16)

and the floor level to be approximately 6.81 inches, also a

distance between the lowermost portion of the sump and

the floor level of approximately 6.14 inch for the Model

500D. For the 500 Station Wagon version the distance

between centre rear bracket for jacking-up the vehicle

and the floor level should be approximately 8.90 inches.

All other front wheel alignment specifications are the

same as for the remaining 500 saloon models.

8:11 Fault diagnosis

(a) Wheel bounce

1 Tyre casing faulty

2 Uneven tyre pressures

3 Wheels out of balance

4 Semi-elliptic mounting spring worn5 Weak or seized shock absorber

6 Wheel rim or tyre misaligned

(b) Suspension noise

1 Lack of lubrication

2 Noisy or inoperative shock absorbers

3 Worn or loose wheel bearings

(c) Pull to one side

1 Low or uneven tyre pressures

2 Incorrect front wheel alignment

3 Suspension arms distorted

4 Inoperative shock absorbers

5 Brakes binding

(d) Excessive t y r e wear

1 Incorrect tyre rotation during servicing periods

2 Incorrect camber angle

3 Incorrect toe-in

4 Incorrect tyre inflation

5 Excessive play at wheel bearings

6 Wheel wobble

7 Stiff suspension arms

8 Brakes out of adjustment

(e) Wheel wobble

1 Uneven tyre pressures

2 Loose or worn wheel bearings

3 Inoperative shock absorbers

4 Loose steering knuckle or kingpin housing

5 Incorrect front wheel alignment

6 Control arm rubber bushings, or kingpin housing and

semi-elliptic spring 'estendblock' worn

96

Page 95 of 128

normal straight-ahead position with the spokes

horizontal. Check that the wheels are in the straight-

ahead position.

2 Load the vehicle to static load conditions or with four

average size passengers.

3 Move the vehicle forwards for a distance of approxi-

mately six yards so that the suspension may settle

correctly.

4 The toe-in measurements should be taken at the same

point of the wheel rim. Measure at A (see FIG 9 : 8)

then back up the car to bring points A to the position B

and remeasure. The value obtained at A should be

equal to or greater than B within .0079 inch.

5 As previously described the steering rods are adjust-

able in length. Loosen the clamps and screw in or out

the adjusting sleeves and before tightening the clamp

ensure that the sleeve slot registers w i t h the clamp

joint. With the clamp fully tightened there should

always be a gap between the joint faces.

6 If the steering gear has been re-installed the correct

front wheel toe-in must be set. Then the relay lever pin

nut must be tightened to a torque wrench setting of 78

to 85 Ib/ft.

9 : 8 Fault diagnosis

(a) Front wheel shimmy

1 Incorrect tyre pressure

2 Incorrect front wheel alignment

3 Loose front wheel bearings

4 Wheels out of balance

5 Loose steering linkage connections

6 Loose steering gear or relay lever support at body

mountings

7 Incorrect fitting of steering worm to worm sector

(b) Hard steering

1 Incorrect tyre pressure

2 Incorrect front wheel alignment

3 Incorrect adjustment of steering worm to worm sector

(c) Hard turning when stationary

1 Incorrect tyre pressure

2 Incorrect adjustment of steering worm to worm sector

102

(d) Pull to one side

1 Incorrect tyre pressure

2 Incorrect front wheel alignment

3 Incorrect front wheel bearing adjustment

4 Distorted kingpin housing or swinging arms

5 Unequal brake adjustment

6 Semi-elliptic spring weak or broken

(e) Rattles

1 Loose steering linkage connections

2 Loose steering gear or relay lever support at body

mountings

3 Semi-elliptic spring weak or broken

4 Lack of lubrication

( f ) Loose steering

1 Incorrect front wheel bearing adjustment

2 Loose steering linkage connections

3 Loose steering gear mountings

4 Incorrect adjustment of steering worm to worm sector

(g) Jerky steering

1 Incorrect front wheel alignment

2 Incorrect front wheel bearing adjustment

3 Wheels out of balance

4 Loose steering linkage connections

5 Loose or incorrect fitting of worm to sector

(h) Side-to-side wander

1 Incorrect tyre pressure

2 Incorrect front wheel alignment

3 Loose steering linkage connections

4 Loose steering gear or relay lever support at body

mountings

5 Incorrect fitting of steering worm to worm sector

6 Distorted kingpin housing or swinging arm

7 Semi-elliptic spring weak or broken

(i) Tyre squeal on turns

1 Incorrect tyre pressure

2 Incorrect wheel alignment

3 Distorted kingpin housing or swinging arms

Page 98 of 128

2 Using Fiat puller A.46023 as shown in FIG 8 : 9

remove the wheel grease cap.

3 Using a universal t w o leg puller or Fiat puller A.40005

together w i t h items 1 and 9 remove the wheel hub/

drum assembly having first extracted the splitpin if

fitted and released the hub retaining nut (see FIG

8:10).

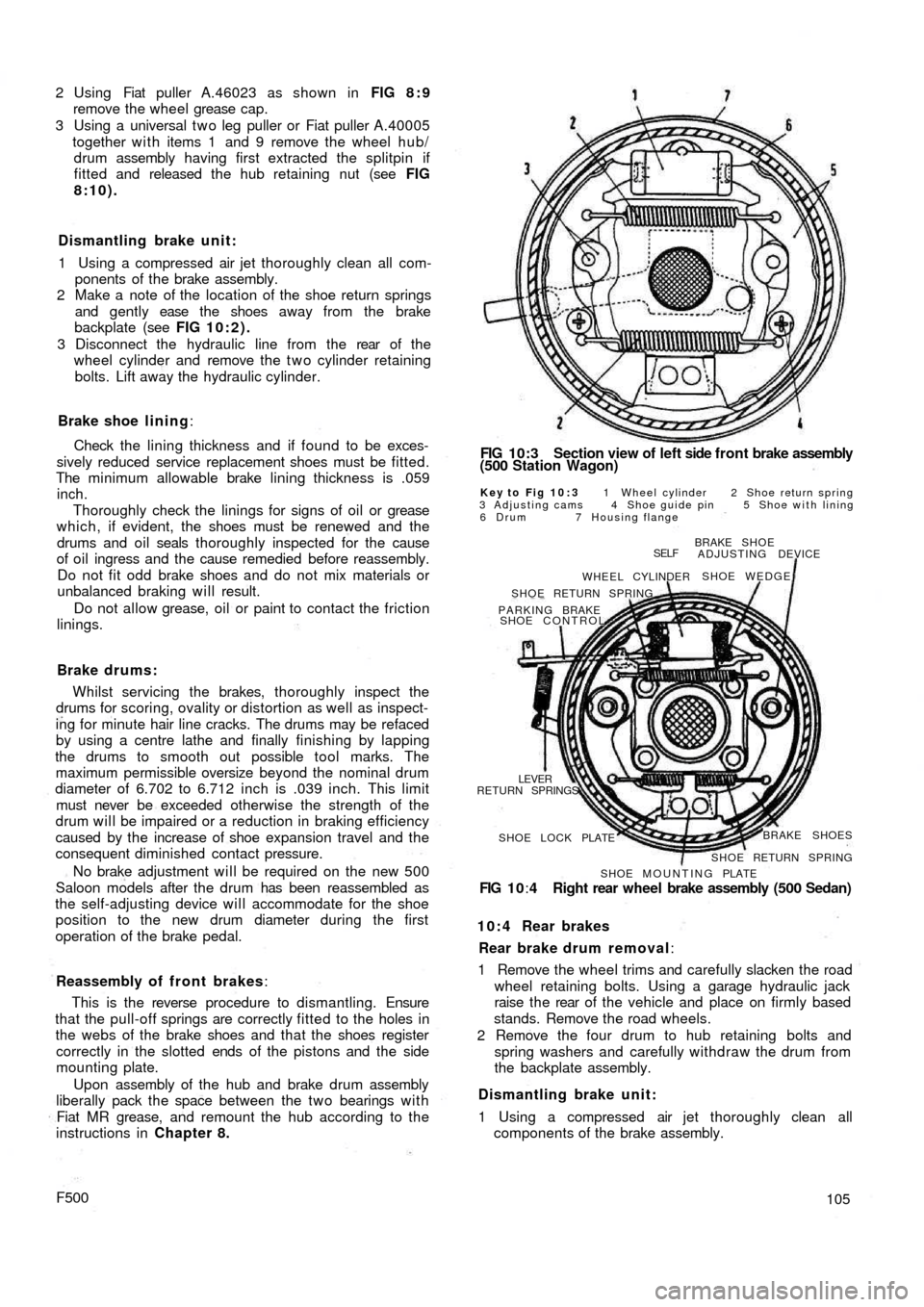

Dismantling brake unit:

1 Using a compressed air jet thoroughly clean all com-

ponents of the brake assembly.

2 Make a note of the location of the shoe return springs

and gently ease the shoes away from the brake

backplate (see FIG 10:2).

3 Disconnect the hydraulic line from the rear of t h e

wheel cylinder and remove the t w o cylinder retaining

bolts. Lift away the hydraulic cylinder.

Brake shoe lining:

Check the lining thickness and if found to be exces-

sively reduced service replacement shoes must be fitted.

The minimum allowable brake lining thickness is .059

inch.

Thoroughly check the linings for signs of oil or grease

which, if evident, the shoes must be renewed and the

drums and oil seals thoroughly inspected for the cause

of oil ingress and the cause remedied before reassembly.

Do not fit odd brake shoes and do not mix materials or

unbalanced braking will result.

Do not allow grease, oil or paint to contact the friction

linings.

Brake drums:

Whilst servicing the brakes, thoroughly inspect the

drums for scoring, ovality or distortion as well as inspect-

ing for minute hair line cracks. The drums may be refaced

by using a centre lathe and finally finishing by lapping

the drums to smooth out possible tool marks. The

maximum permissible oversize beyond the nominal drum

diameter of 6.702 to 6.712 inch is .039 inch. This limit

must never be exceeded otherwise the strength of the

drum will be impaired or a reduction in braking efficiency

caused by the increase of shoe expansion travel and the

consequent diminished contact pressure.

No brake adjustment will be required on the new 500

Saloon models after the drum has been reassembled as

the self-adjusting device will accommodate for the shoe

position to the new drum diameter during the first

operation of the brake pedal.

Reassembly of front brakes:

This is the reverse procedure to dismantling. Ensure

that the pull-off springs are correctly fitted to the holes in

the webs of the brake shoes and that the shoes register

correctly in the slotted ends of the pistons and the

side

mounting plate.

Upon assembly of the hub and brake drum assembly

liberally pack the space between the two bearings w i t h

Fiat MR grease, and remount the hub according to the

instructions in Chapter 8.

F500

FIG 10:3 Section view of left side f r o n t brake assembly

(500 Station Wagon)

Key to Fig 10:3 1 Wheel cylinder 2 Shoe return spring

3 Adjusting cams 4 Shoe guide pin 5 Shoe with lining

6 Drum 7 Housing flange

BRAKE SHOE

ADJUSTING DEVICE

SHOE WEDGE

SELF

WHEEL CYLINDER

SHOE RETURN SPRING

PARKING BRAKE

SHOE CONTROL

RETURN SPRINGS

LEVER

SHOE LOCK PLATEBRAKE SHOES

SHOE RETURN SPRING

SHOE MOUNTING PLATE

FIG 1 0:4 Right rear wheel brake assembly (500 Sedan)

10:4 Rear brakes

Rear brake drum removal:

1 Remove the wheel trims and carefully slacken the road

wheel retaining bolts. Using a garage hydraulic jack

raise the rear of t h e vehicle and place on firmly based

stands. Remove the road wheels.

2 Remove the four drum to hub retaining bolts and

spring washers and carefully withdraw the drum from

the backplate assembly.

Dismantling brake unit:

1 Using a compressed air jet thoroughly clean all

components of the brake assembly.

105