oil level FIAT 500 1970 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1970, Model line: 500, Model: FIAT 500 1970 1.GPages: 128, PDF Size: 9.01 MB

Page 14 of 128

Insert a .0079 ± .00197 inch thick oil paper gasket

between the crankcase and cylinder bottom face and a

.0236 to .0275 inch thick graphitized asbestos gasket

between the cylinder and cylinder head. The compression

of the gaskets on assembly will eliminate any very small

differences between the t w o mating surfaces.

Inspection of tappet seats:

The tappet seats should be checked for scoring and

correct clearance which must not exceed .00315 inch.

Should the clearance be greater than the maximum

specified the seating may be reamed to oversize dimen-

sions as detailed in Technical Data. Tappets are avail-

able in .00197 and .00394 inch diameter oversize.

1 :9 Piston assembly

Inspection:

Before inspection the pistons must be thoroughly

cleaned and the ring grooves and piston head decarbo-

nized. Check for deep score marks and signs of distortion

or fracture especially around the skirt and piston pin areas.

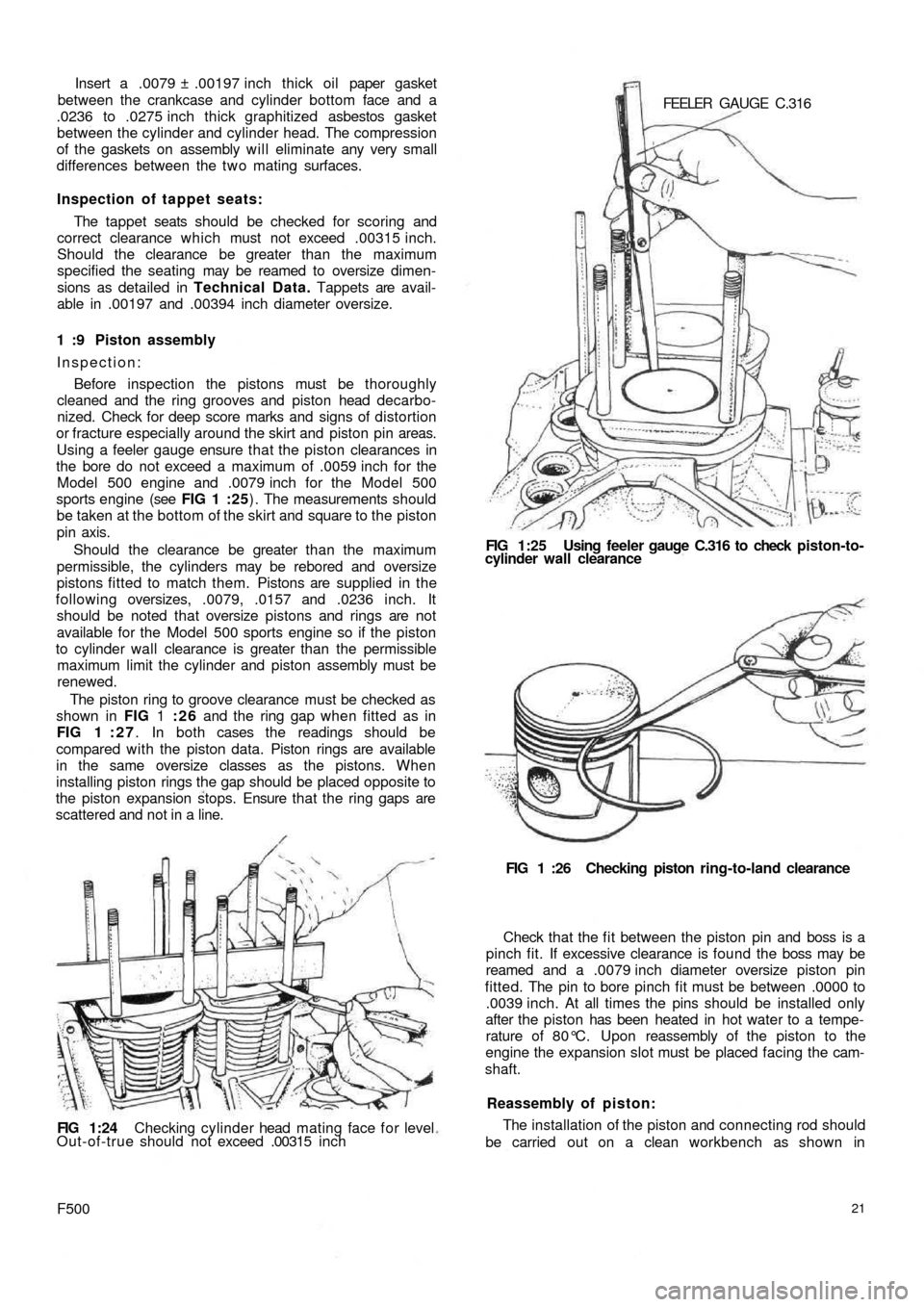

Using a feeler gauge ensure that the piston clearances in

the bore do not exceed a maximum of .0059 inch for the

Model 500 engine and .0079 inch for the Model 500

sports engine (see FIG 1 :25) . The measurements should

be taken at the bottom of the skirt and square to the piston

pin axis.

Should the clearance be greater than the maximum

permissible, the cylinders may be rebored and oversize

pistons fitted to m

atch them. Pistons are supplied in the

following oversizes, .0079, .0157 and .0236 inch. It

should be noted that oversize pistons and rings are not

available for the Model 500 sports engine so if the piston

to cylinder wall clearance is greater than the permissible

maximum limit the cylinder and piston assembly must be

renewed.

The piston ring to groove clearance must be checked as

shown in FIG 1 :26 and the ring gap when fitted as in

FIG 1 : 2 7. In both cases the readings should be

compared with the piston data. Piston rings are available

in the same oversize classes as the pistons. When

installing piston rings the gap should be placed opposite to

the piston expansion stops. Ensure that the ring gaps are

scattered and not in a line.

FIG 1:24 Checking cylinder head mating face f o r level

Out-of-true should not exceed .00315 i n c h

F50021

The installation of the piston and connecting rod should

be carried out on a clean workbench as shown in Reassembly of piston: Check that the f i t between the piston pin and boss is a

pinch fit. If excessive clearance is found the boss may be

reamed and a .0079 inch diameter oversize piston pin

fitted. The pin to bore pinch fit must be between .0000 to

.0039 inch. At all times the pins should be installed only

after the piston has been heated in hot water to a tempe-

rature of 80°C. Upon reassembly of the piston to the

engine the expansion slot must be placed facing the cam-

shaft.FIG 1 :26 Checking piston ring-to-land clearance FEELER GAUGE C.316

FIG 1:25 Using feeler gauge C.316 to check piston-to-

cylinder wall clearance

Page 18 of 128

After the crankshaft has been reground it is important

that all traces of swarf are removed by constant washing

and then drying with a non-fluffy rag.

The clearance between the main bearings and journals

must be checked before installing the crankshaft in the

engine. It should also serve as a recheck after the

crankshaft has been reground.

Measure the maximum main bearing internal

diameter and the minimum journal diameter using

accurate measuring equipment. The clearance must not

exceed .0039 inch otherwise the journals must be

reground and undersize bearings fitted.

Undersize bearings w i t h .0394 inch stock on the

internal diameter are also supplied unmounted. They

must be press fitted in the supports, the recommended

interference fit being .00039 to .00197 inch. After

pressing the bearing into the support, a hole is drilled in

the bearing in line with the location dowel hole in the

support. The hole is finished with a suitable expanding

reamer, such as Fiat U.0334, and the dowel pressed i n ,

noting that the hollow dowel fits in the flywheel end

support.

The next stage is to heat the assembly in an oven or

oil bath for a period of one hour at 150°C (302°F).

When the assembly has cooled to room temperature,

the bearing is reamed in a lathe to match the crankshaft

journal size.

3

Crankshaft oil seals:

Two inner spring rubber oil seals are located, one in a

special seat in the timing gear cover and the other in the

flywheel end of the crankshaft support and provide oil

tightness. These seals are shown in FIGS 1 :3 and 1 :34.

Whenever the engine is dismantled for overhaul these

seals should be carefully inspected for correct seating and

that the inner seal surface is not worn and that the contact

area is perfect both on the crankshaft and on the fan and

generator drive pulley hub.

Clutch shaft pilot bushing:

A self-lubricating bronze bush is fitted in the end of the

crankshaft as shown in FIG 1 :34 and provides a bearing

for the clutch shaft. Should the bush be worn use Fiat

puller A.40006/1 /2 to remove the worn bush. A new bush

should be fitted using a suitably sized drift.

1:12 Flywheel and starter ring gear

The flywheel should be inspected for wear at the clutch

driven plate contact area. It should be flat and have a

smooth finish.

The ring gear teeth should be cheeked for damage

which if evident, the ring gear must be replaced. To facili-

tate the fitting of a new ring gear on the flywheel, the new

ring gear should be heated in an oil bath to a temperature

of 80°C (176°F). Using a press gently ease the

expanded

ring gear over the flywheel and press fully home.

1:13 The oil pump

Sedan :

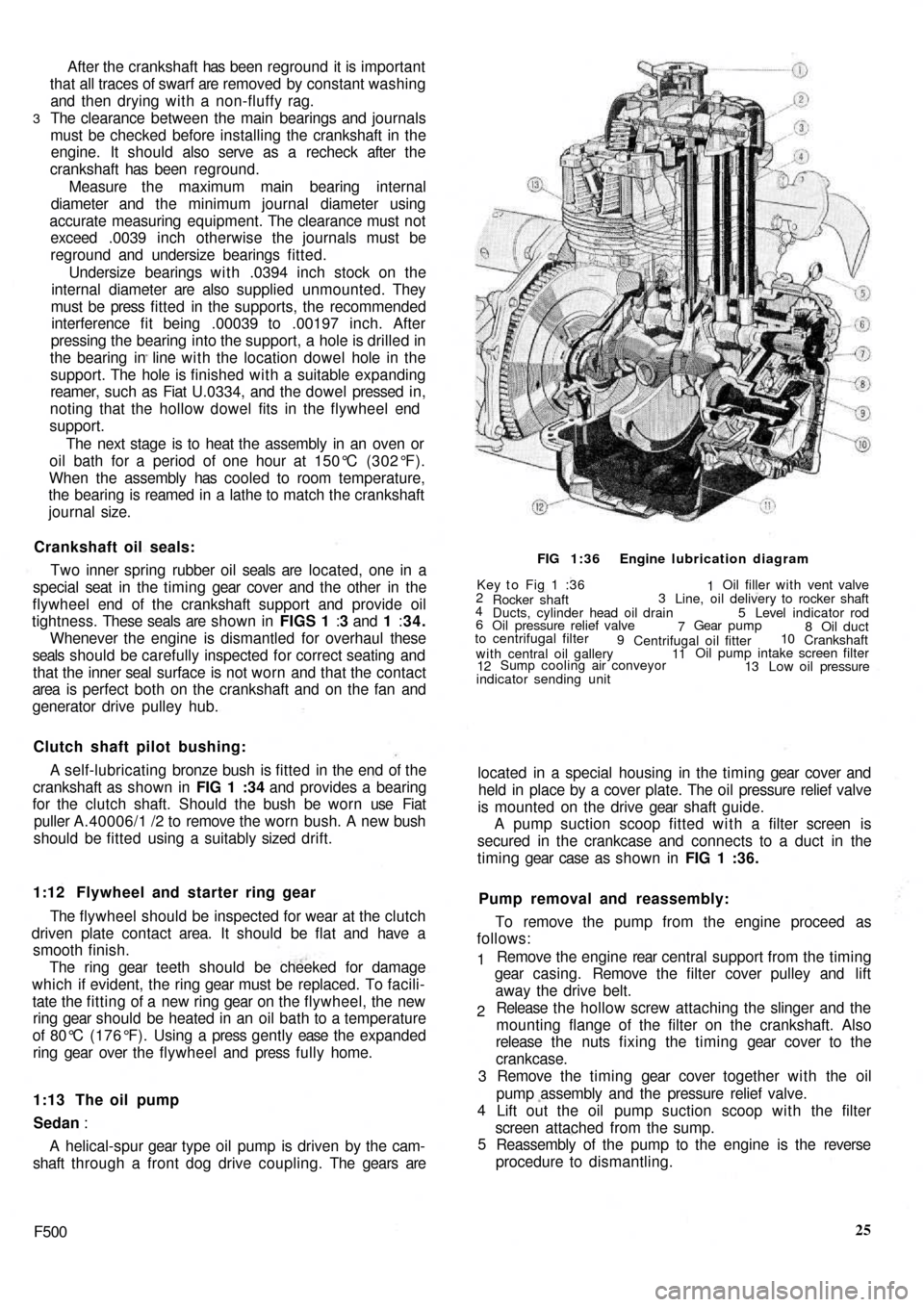

A helical-spur gear type oil pump is driven by the cam-

shaft through a front dog drive coupling. The gears are

F50025 To remove the pump from the engine proceed as

follows:Pump removal and reassembly:

Remove the engine rear central support from the timing

gear casing. Remove the filter cover pulley and lift

away the drive belt.

Release the hollow screw attaching the slinger and the

mounting flange of the filter on the crankshaft. Also

release the nuts fixing the timing gear cover to the

crankcase.

Remove the timing gear cover together with the oil

pump assembly and the pressure relief valve.

Lift out the oil pump suction scoop with the filter

screen attached from the sump.

Reassembly of the pump to the engine is the reverse

procedure to dismantling. 1

2

3

4

5 located in a special housing in the timing gear cover and

held in place by a cover plate. The oil pressure relief valve

is mounted on the drive gear shaft guide.

A pump suction scoop fitted with a filter screen is

secured in the crankcase and connects to a duct in the

timing gear case as s h o w n in FIG 1 :36.

2

4

6Key t o Fig 1 :36

Rocker shaft

Ducts, cylinder head oil drain

Oil pressure relief valve

to centrifugal filter

9

with central oil gallery

12Sump cooling air conveyor

indicator sending unitOil filler with vent valve

Line, oil delivery to rocker shaft

Level indicator rod 31

5

7Gear pump

8 Oil duct

Centrifugal oil fitter

1110

Crankshaft

Oil pump intake screen filter

13 Low oil pressure FIG 1:36 Engine lubrication diagram

Page 26 of 128

4 Mixture too weak

5 Water in fuel system

6 Petrol tank vent blocked

7 Incorrect valve clearance

(c) Engine idles badly

1 Check 1 and 6 in (b)

2 Air leak at manifold joints

3 Slow-running jet blocked or out of adjustment

4 Air leak in carburetter

5 Over-rich mixture

6 Worn piston rings

7 Worn valve stems or guides

8 Weak exhaust valve springs

(d) Engine misfires

1 Check 1, 2, 3, 4, 5, 8, 10, 13, 14, 1 5, 16, 17 in (a);

2, 3, 4 and 7 in (b)

2 Weak or broken valve springs

(e) Engine overheats

1 Generator and fan drive belt too loose

2 Shutter or thermostat seized in closed position

(f) Compression low

1 Check 14 and 15 in (a), 6 and 7 in (c) and 2 in (d)

2 Worn piston ring grooves

3 Scored or worn cylinder bores

(g) Engine lacks power

1 Check 3, 10, 1 1 , 13, 14, 15, 16 and 17 in (a), 2, 3, 4

and 7 in (b) 6 and 7 in (c) and 2 in (d). Also check (e)

and (f)

2 Leaking joint washers

3 Fouled sparking plugs

4 Automatic centrifugal advance not operating

(h) Burnt valves or seats

1 Check 14 and 15 in (a), 7 in (b) and 2 in (d). Alsocheck (e)

2 Excessive carbon around valve seat and head

(j) Sticking valves

1 Check 2 in (d)

2 Bent valve stem

3 Scored valve stem or guide

4 Incorrect valve clearance

(k) Excessive cylinder wear

1 Check 11 in (a) and see Chapter 4

2 Lack of oil

3 Dirty oil

4 Piston rings gummed up or broken

5 Badly fitting piston rings

6 Connecting rods bent

(l) Excessive oil consumption

1 Check 6 and 7 in (c) and check (k)

2 Ring gaps too wide

3 Oil return holes in piston choked with carbon

4 Scored cylinders

5 Oil level too high

6 External oil leaks

7 Ineffective valve stem oil seals

(m) Crankshaft and connecting rod bearing failure

1 Check 2 in (k)

2 Restricted oilways

3 Worn journals or crank pins

4 Loose bearing caps

5 Extremely low oil pressure

6 Bent connecting rod

(n) High fuel consumption (see Chapter 2)

(o) Engine vibration

1 Loose generator bolts

2 Blower blade assembly out-of-balance

3 Incorrect clearance for rear engine mounting rubber

F50033

Page 36 of 128

1

14,5

7,52 9 48 35

76

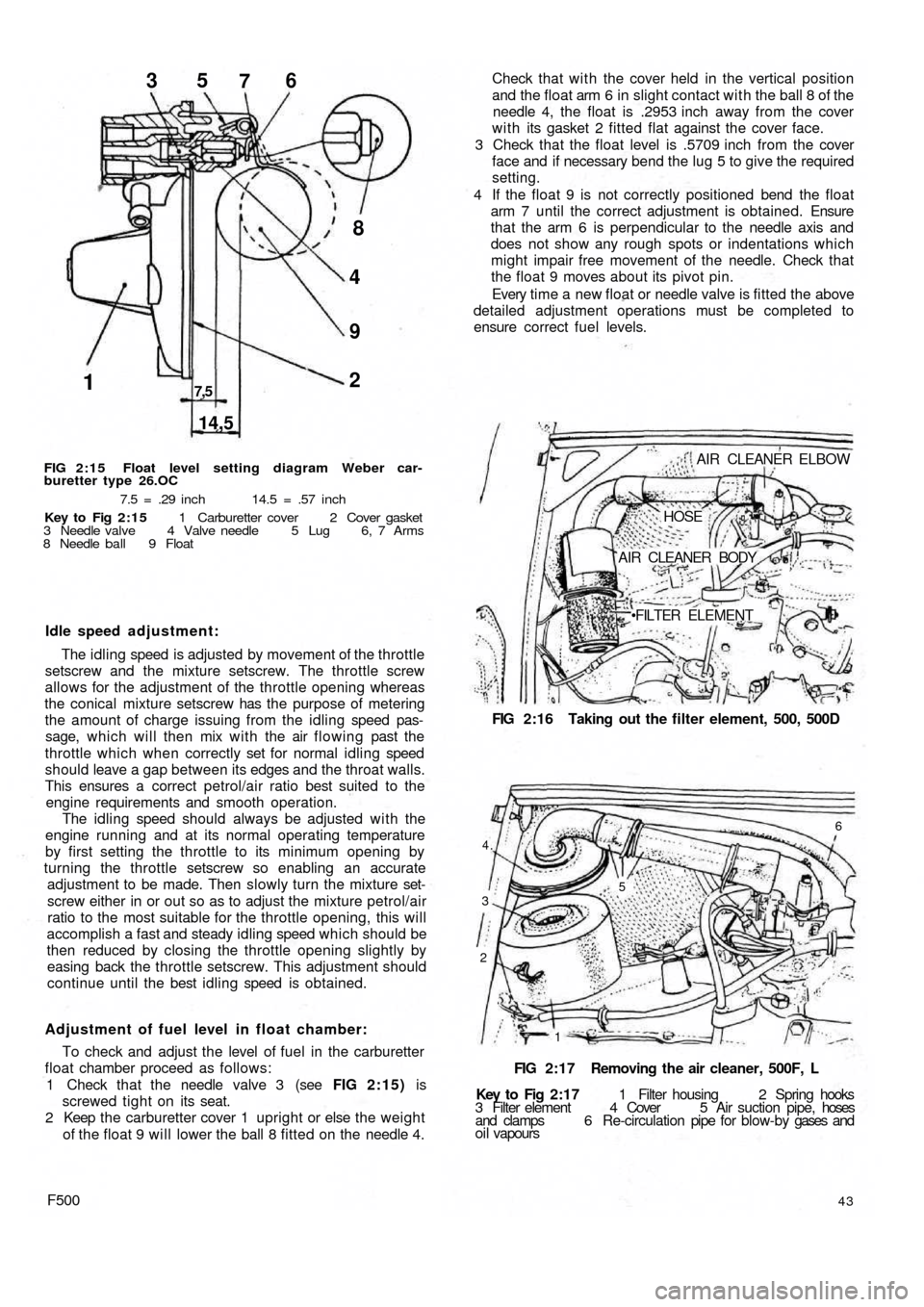

FIG 2:15 Float level setting diagram Weber car-

buretter type 26.OC

7.5 = .29 inch 14.5 = .57 inch

Key to Fig 2:15 1 Carburetter cover 2 Cover gasket

3 Needle valve 4 Valve needle 5 Lug 6, 7 Arms

8 Needle ball 9 Float

Idle speed adjustment:

The idling speed is adjusted by movement of the throttle

setscrew and the mixture setscrew. The throttle screw

allows for the adjustment of the throttle opening whereas

the conical mixture setscrew has the purpose of metering

the amount of charge issuing from the idling speed pas-

sage, which will then mix with the air flowing past the

throttle which when correctly set for normal idling speed

should leave a gap between its edges and the throat walls.

This ensures a correct petrol/air ratio best suited to the

engine requirements and smooth operation.

The idling speed should always be adjusted with the

engine running and at its normal operating temperature

by first setting the throttle to its minimum opening by

turning the throttle setscrew so enabling an accurate

adjustment to be made. Then slowly turn the mixture set-

screw either in or out so as to adjust the mixture petrol/air

ratio to the most suitable for the throttle opening, this will

accomplish a fast and steady idling speed which should be

then reduced by closing the throttle opening slightly by

easing back the throttle setscrew. This adjustment should

continue until the best idling speed is obtained.

Adjustment of fuel level in float chamber:

To check and adjust the level of fuel in the carburetter

float chamber proceed as follows:

1 Check that the needle valve 3 (see FIG 2:15) is

screwed tight on its seat.

2 Keep the carburetter cover 1 upright or else the weight

of the float 9 will lower the ball 8 fitted on the needle 4.

F50043

Key to Fig 2:17 1 Filter housing 2 Spring hooks

3 Filter element 4 Cover 5 Air suction pipe, hoses

and clamps 6 Re-circulation pipe for blow-by gases and

oil vapoursFIG 2:17 Removing the air cleaner, 500F, L

2

1 3

4.

6

5

FIG 2:16 Taking out the filter element, 500, 500D AIR CLEANER ELBOW

HOSE

AIR CLEANER BODY

FILTER ELEMENT Check that with the cover held in the vertical position

and the float arm 6 in slight contact with the ball 8 of the

needle 4, the float is .2953 inch away from the cover

w i t h its gasket 2 fitted flat against the cover face.

3 Check that the float level is .5709 inch from the cover

face and if necessary bend the lug 5 to give the required

setting.

4 If the float 9 is not correctly positioned bend the float

arm 7 until the correct adjustment is obtained. Ensure

that the arm 6 is perpendicular to the needle axis and

does not show any rough spots or indentations which

might impair free movement of the needle. Check that

the float 9 moves about its pivot pin.

Every time a new float or needle valve is fitted the above

detailed adjustment operations must be completed to

ensure correct fuel levels.

Page 71 of 128

although these do not affect the service procedures that

have been previously described.

6:12 Fault diagnosis

(a) Noisy transmission

1 Excessive backlash of gears in mesh due to gear wear

2 Gears, bearings or gear bushings damaged

3 Shafts misaligned or out of centre due to loose mount-

ing nuts

4 Dirt or metal chips in the lubricant

5 Insufficient oil level in transmission case

(b) Transmission jumps out of gear or gear

shifting is irregular

1 Improper shifting

2 Gear shift lever mounting bracket out of adjustment

3 Incorrect assembly or damage of striker rod positioning

balls and springs

4 Striker rod rollers worn or assembled incorrectly

(c) Oil leakage

1 Overfilled transmission case2 Front extension, upper cover and clutch housing nutsloose

3 Speed selector and engagement lever seal at front

extension damaged

4 Faulty bellhousing gasket

5 Gaskets, upper cover-to-case, front extension-to-case,

damaged

6 Damaged axle shaft boot or seal

(d) Transmission shifts hard

1 Defective link of gear shift lever to internal front lever

2 Internal front lever rubber bushing and plates damaged

3 Speed selector and engagement lever control rod

twisted

4 Control rod-to-speed selector and engagement lever

joint damaged

5 Speed selector and engagement lever worn

6 Striker rods binding in casing

7 Sliding sleeves and gears bound in their seats due to

the presence of dirt in splines

8 Improper quality of transmission lubricant

9 Misadjusted clutch linkage and clutch make de-

clutching impossible

78

Page 76 of 128

high bearing preload. To reset remove the wheel shaft

and fit a new resilient spacer. Repeat the rotation

torque test.

Swinging arm adjustment:

To adjust the swinging arm use Fiat fixture A.66064 as

shown in FIG 7 : 3 and proceed as follows:

1 At points A and B as indicated in FIG 7 : 4 between the

'estendblock' and the swinging arm to body front

mounting bracket fit three shims on each side. To

ensure that the shims are correctly centred use Fiat

alignment bar A.66057.

2 Whilst removing the alignment bar, carefully slip in the

mounting pin and screw on the nut. Once the rear

wheel geometry adjustment has been completed this

nut should be tightened to a torque wrench setting

of 43.4 to 50.6 Ib ft.

3 At points C and D (see FIG 7 : 4) , insert the number of

shims required to fill in the gap between the 'estend-

block' and the two fixture shoulders. Having deter-

mined the number of shims required both at locations

C and D, these must later be fitted between the

'estendblock' and the shoulders on the swinging arm

to body mounting bracket.

7 : 4 Coil springs

The coil springs should be thoroughly cleaned and all

traces of rust removed. Inspect the spring coils for hair

line cracks, which if evident, a new pair of springs must

be fitted to ensure correct vehicle height and stability.

Check the free

height and the height under loading of

the coil springs and these must correspond to the figures

quoted in Technical Data.

7:5 Installation of rear suspension assembly

To replace the rear suspension assembly proceed as

follows:

1 Insert the swinging arm inner end in the mounting

bracket which is welded onto the body floor. Place

between the 'estendblock' and bracket the number of

adjustment shims as previously determined using Fiat

fixture A.66064 as shown in FIG 7 : 4. Insert the Fiat

alignment bar A.66057 through 'estendblock' and

shims, aligning them with the holes in the mounting

bracket. Firmly hold the entire assembly using a garage

hydraulic jack if necessary, and carefully remove the

alignment bar and at the same time ease in t h e

mounting pin. Secure the nut which once the rear

wheels geometry has been checked must be tightened

to a torque wrench setting of 43.4 to 50.6 Ib/ft.

2 Screw in finger tight the three swinging arm external

bracket to body floor mounting screws together w i t h

the plain and spring washers. The screws will have to

be tightened to a torque wrench setting of 28.9 to

36.2 Ib/ft once the rear wheel geometry has been

adjusted.

3 Carefully insert the coil spring, lower insulator ring

onto the swinging arm, insert the spring on the shock

absorber which should be previously secured to the

arm and position the spring onto its seat on the arm.

Place the upper insulator ring onto the spring, raise the

suspension assembly using a garage hydraulic jack and

insert the spring onto its seating under the body floor.

F50083 4 Ensure that the shock absorber to floor rubber ring has

been correctly fitted and extend the shock absorber

until its upper mounting pin protrudes into the vehicle

through the hump in the floor panel. Secure the shock

absorber by its mounting nut and lockwasher having

first inserted the rubber ring and plain washer.

5 Refit the rear wheel housing in place, reconnect the

brake line to the connection on body floor and remove

the plug from the output hole in the brake fluid

reservoir. Bleed the hydraulic brake system as

described in Chapter 10.

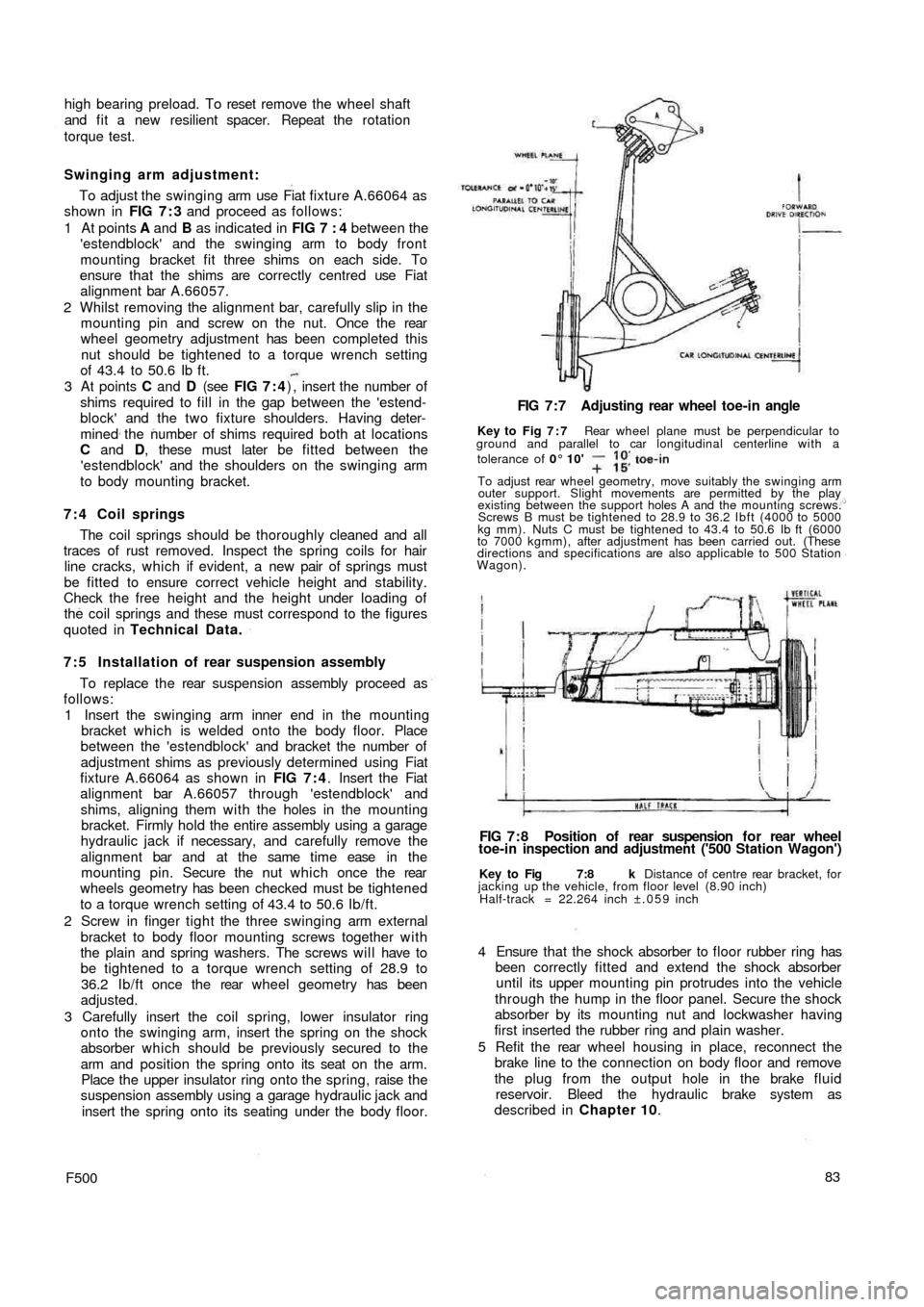

Key to Fig 7:8 k Distance of centre rear bracket, for

jacking up the vehicle, from floor level (8.90 inch)

Half-track = 22.264 inch ±.059 inch

FIG 7 : 8 Position of rear suspension f o r rear wheel

toe-in inspection and adjustment ('500 Station Wagon') FIG 7 : 7 Adjusting rear wheel toe-in angle

Key to Fig 7 : 7 Rear wheel plane must be perpendicular to

ground and parallel to car longitudinal centerline with a

tolerance of 0° 10'

To adjust rear wheel geometry, move suitably the swinging arm

outer support. Slight movements are permitted by the play

existing between the support holes A and the mounting screws.

Screws B must be tightened to 28.9 to 36.2 Ibft (4000 to 5000

kg mm). Nuts C must be tightened to 43.4 to 50.6 Ib ft (6000

to 7000 kgmm), after adjustment has been carried out. (These

directions and specifications are also applicable to 500 Station

Wagon).

Page 79 of 128

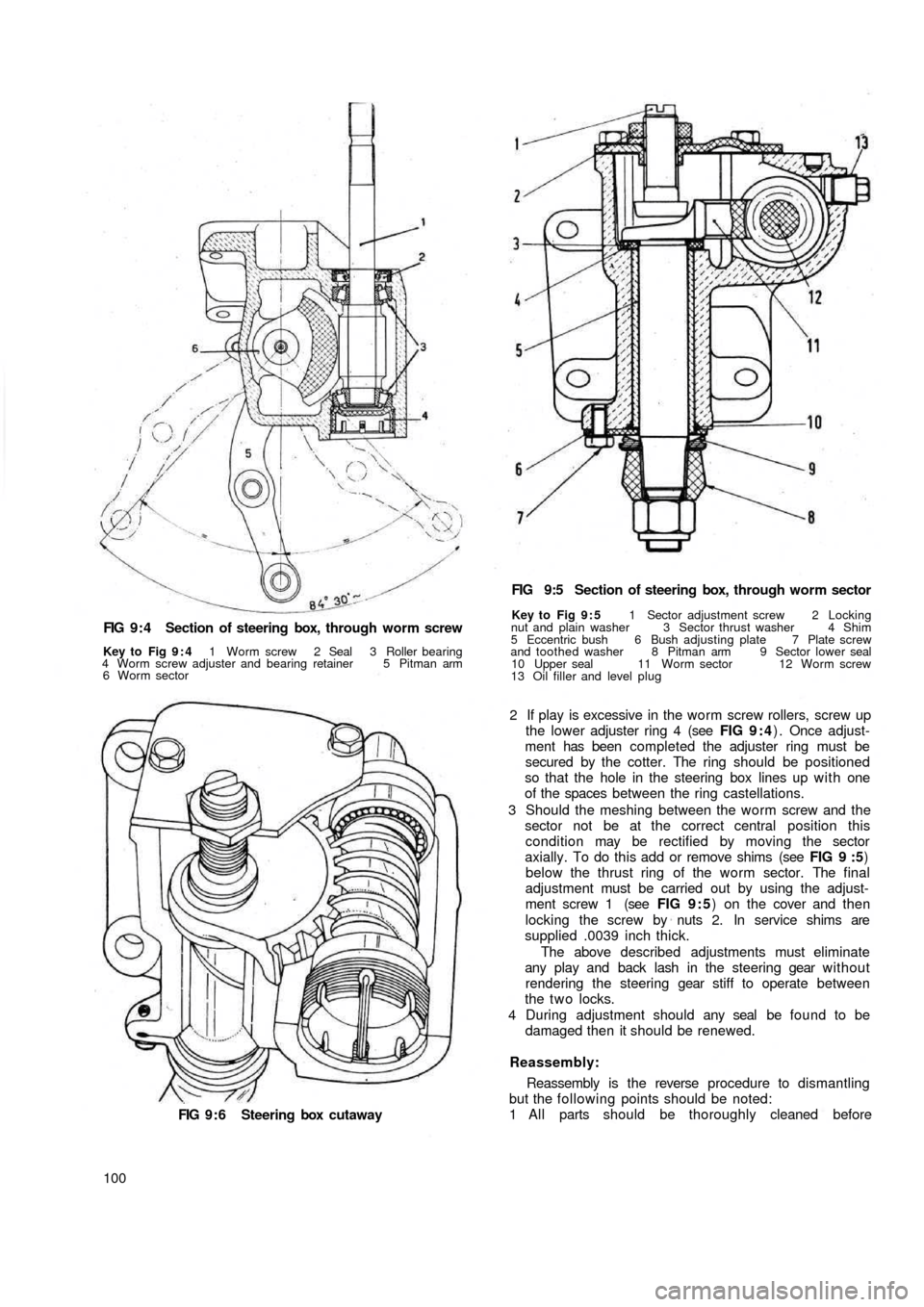

A tolerance of —10'.+ 15' is permitted providing

that the value is the same for both rear wheels. It is

important that both rear wheels are set to the same

angle otherwise uneven tyre wear and adverse handl-

ing conditions will result. When the wheel is parallel to

the centre line of the vehicle the pin of bracket

C.696/3 will be .216 inch apart from the pin of the

front suspension swinging arm.

7 Release the swinging arm outer support to body

mounting screws and position arm in such a way as to

obtain the condition as described in Number 6 above.

After the adjustment has been completed tighten

the outer support mounting screws to a torque wrench

setting of 28.9 to 36.2 Ib/ft. Also tighten the two

swinging arm pin nuts C (see FIG 7 : 7) to a torque

wrench setting of 43.4 to 50.6 Ib/ft. Take off the gauge

C.696 w i t h bracket and support C.696/3, and repeat

the check and adjustment operations on the other

wheel. Care must be taken to ensure that bracket

C.696/3 is reversed from the position previously used.

New 500 type 500D, 110F and 110L sedan and

station wagon:

After the rear suspension has been replaced, check

and, if necessary adjust the rear wheel geometry.

1 Inflate the tyres to the normal operating pressures.

2 Lower the car body so that the rear wheels are set at

90 deg. to the floor. This condition is obtained when

the lowermost portion of the sump is 6.61 inches from

the floor level for the new 500D model or the centre

rear bracket for jacking up the rear of t h e vehicle

8.9 inches from the floor level for the 500 Station

Wagon.

3 With the vehicle set to the above conditions check the

wheel geometry. The wheel plane must converge w i t h

the centre line of the vehicle by an angle of 0 deg. 10'

(—10', +15') toeing in at the front.

4 The wheel plane must be 22.343 ± .059 inches from

the centre line of the vehicle for the 500D model.

Whereas for the 500 Station Wagon the distance must

be 22.264 ± .059 inches.

5 To adjust the rear wheel toe-in adjust the positions of

the mounting screws A and B as shown in FIG 7:7.

86

7:7 Modifications

The new 500 Sedan (110F) and late 500 Station

Wagon are fitted with modified wheels side flexible

joints and rear control arm as shown in FIG 7:13.

Together w i t h these modifications a new design rear

coil spring has been fitted details of which are given in

Technical Data.

7 : 8 Fault diagnosis

(a) Irregular or abnormal tyre wear

1 Incorrect tyre pressure

2 Wheels out of balance

3 Wheels off centre

4 Misadjusted brakes

5 Weak or broken coil springs

6 Excessive load

7 Incorrect wheel alignment

(b) Sag on one wheel

1 Incorrect tyre pressure

2 Weak or broken coil spring

3 Wear of shock absorber causing poor dampening

action

(c) Squeaks, thumps or rattles

1 Wheels out of balance

2 Wheels off centre

3 Misadjusted brakes

4 Weak or broken coil springs or spring seats dislodged

5 Wear of shock absorbers causing poor dampening

action

6 Worn rubber bushings in control arms

7 Poor lubrication of wheel bearings

(d) Pull to one side

1 Incorrect tyre pressure

2 Misadjusted brakes

3 Distorted suspension arm

Page 93 of 128

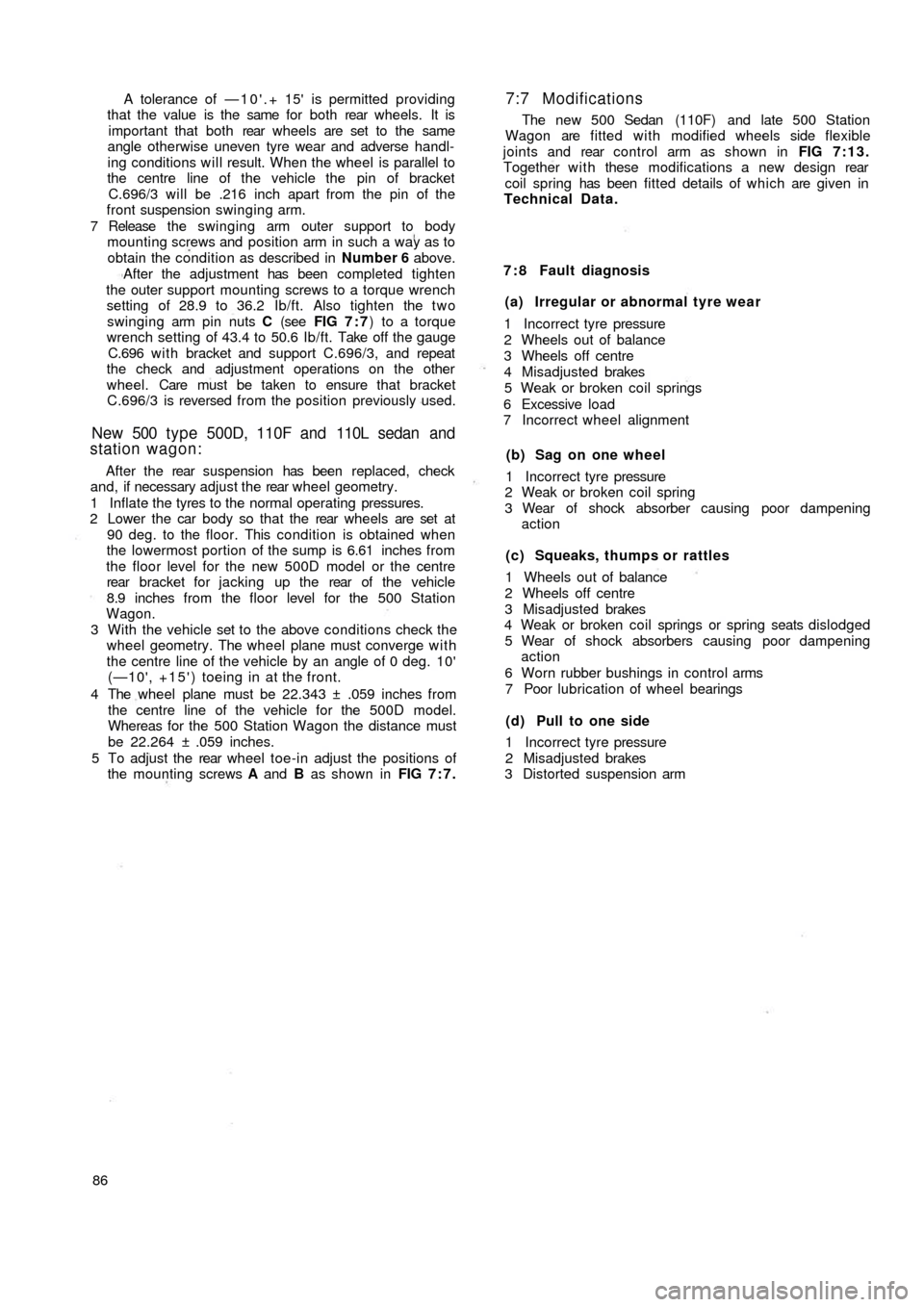

FIG 9 : 4 Section of steering box, through worm screw

Key to Fig 9 : 4 1 Worm screw 2 Seal 3 Roller bearing

4 Worm screw adjuster and bearing retainer 5 Pitman arm

6 Worm sector

FIG 9 : 6 Steering box cutaway

100FIG 9:5 Section of steering box, through worm sector

Key to Fig 9 : 5 1 Sector adjustment screw 2 Locking

nut and plain washer 3 Sector thrust washer 4 Shim

5 Eccentric bush 6 Bush adjusting plate 7 Plate screw

and toothed washer 8 Pitman arm 9 Sector lower seal

10 Upper seal 11 Worm sector 12 Worm screw

13 Oil filler and level plug

2 If play is excessive in the worm screw rollers, screw up

the lower adjuster ring 4 (see FIG 9 : 4) . Once adjust-

ment has been completed the adjuster ring must be

secured by the cotter. The ring should be positioned

so that the hole in the steering box lines up w i t h one

of the spaces between the ring castellations.

3 Should the meshing between the worm screw and the

sector not be at the correct central position this

condition may be rectified by moving the sector

axially. To do this add or remove shims (see FIG 9 :5)

below the thrust ring of the worm sector. The final

adjustment must be carried out by using the adjust-

ment screw 1 (see FIG 9 : 5) on the cover and then

locking the screw by nuts 2. In service shims are

supplied .0039 inch thick.

The above described adjustments must eliminate

any play and back lash in the steering gear without

rendering the steering gear stiff to operate between

the t w o locks.

4 During adjustment should any seal be found to be

damaged then it should be renewed.

Reassembly:

Reassembly is the reverse procedure to dismantling

but the following points should be noted:

1 All parts should be thoroughly cleaned before

Page 94 of 128

reassembling and during assembly liberally lubricated

using Fiat W90/M oil (SAE90 EP).

2 The pitman arm nut should be correctly positioned on

reassembly to the sector shaft and both are marked

with notches or a master tooth on the sector will mate

with a double tooth on the pitman arm which will

prevent incorrect reassembly.

3 The pitman arm nut must be tightened to a torque

wrench setting of 72 Ib/ft.

4 Fill the box up to the level and filler plug with SAE90 EP

gear oil.

Refitting the steering box:

To refit the steering box to the vehicle proceed as

follows:

1 Engage the w o r m screw f r o m the steering shaft by

gently manipulating the steering box.

2 Replace the steering box to body nuts and tighten to a

torque wrench setting of 14 to 18 Ib/ft.

3 Replace the t w o track rod pins in their seatings in the

pitman arm and tighten the self-locking nuts to a

torque wrench setting of 18 to 21 Ib/ft.

4 Replace the steering shaft to worm screw mounting

bolt, lock washer and nut.

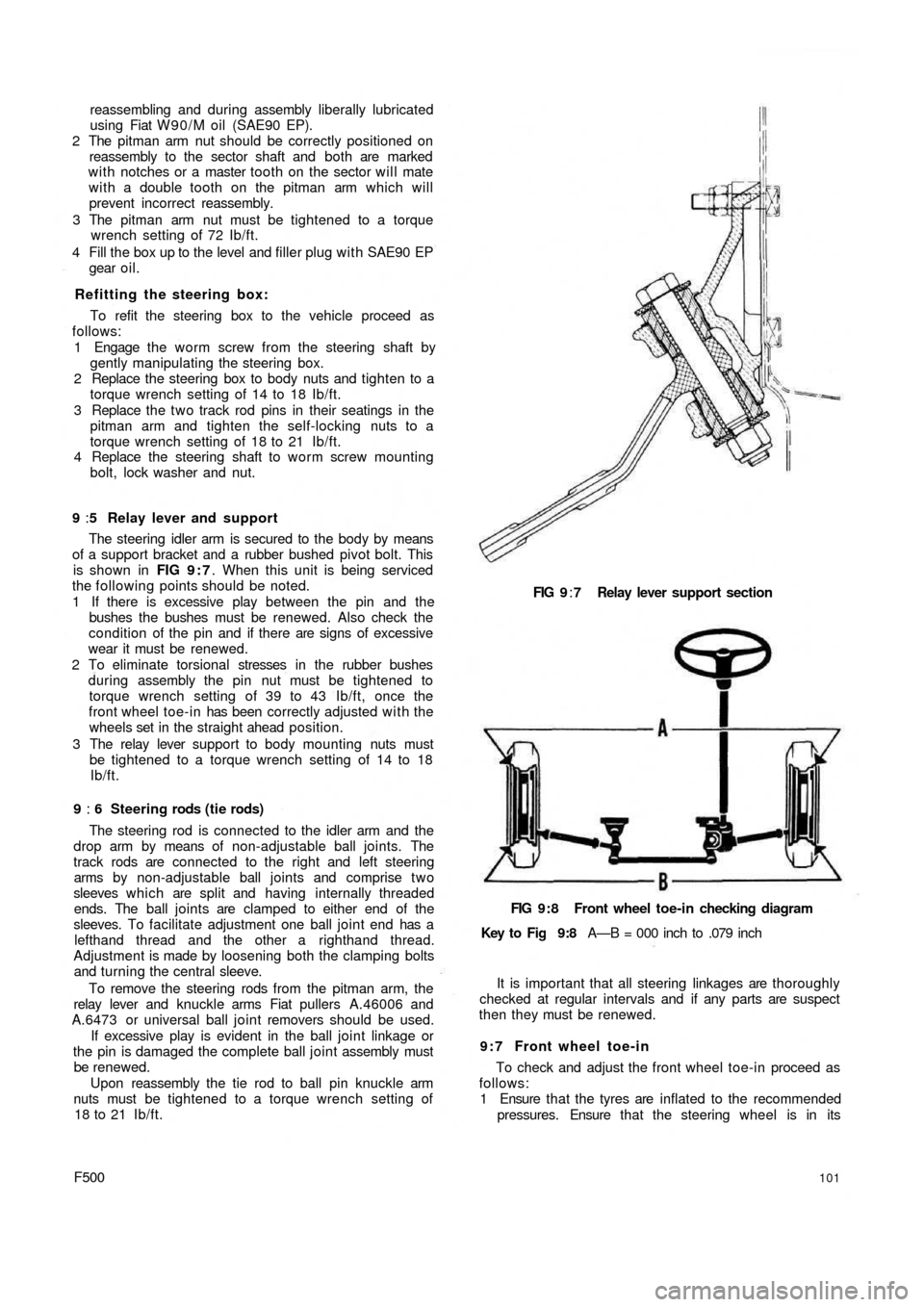

9 :5 Relay lever and support

The steering idler arm is secured to the body by means

of a support bracket and a rubber bushed pivot bolt. This

is shown in FIG 9 : 7. When this unit is being serviced

the following points should be noted.

1 If there is excessive play between the pin and the

bushes the bushes must be renewed. Also check the

condition of the pin and if there are signs of excessive

wear it must be renewed.

2 To eliminate torsional stresses in the rubber bushes

during assembly the pin nut must be tightened to

torque wrench setting of 39 to 43 Ib/ft, once the

front wheel toe-in has been correctly adjusted w i t h the

wheels set in the straight ahead position.

3 The relay lever support to body mounting nuts must

be tightened to a torque wrench setting of 14 to 18

Ib/ft.

9 : 6 Steering rods (tie rods)

The steering rod is connected to the idler arm and the

drop arm by means of non-adjustable ball joints. The

track rods are connected to the right and left steering

arms by non-adjustable ball joints and comprise t w o

sleeves which are split and having internally threaded

ends. The ball joints are clamped to either end of the

sleeves. To facilitate adjustment one ball joint end has a

lefthand thread and the other a righthand thread.

Adjustment is made by loosening both the clamping bolts

and turning the central sleeve.

To remove the steering rods from the pitman arm, the

relay lever and knuckle arms Fiat pullers A.46006 and

A.6473 or universal ball joint removers should be used.

If excessive play is evident in the ball joint linkage or

the pin is damaged the complete ball joint assembly must

be renewed.

Upon reassembly the tie rod to ball pin knuckle arm

nuts must be tightened to a torque wrench setting of

18 to 21 Ib/ft.

F500101

FIG 9:7 Relay lever support section

FIG 9:8 Front wheel toe-in checking diagram

Key to Fig 9:8 A—B = 000 inch to .079 inch

It is important that all steering linkages are thoroughly

checked at regular intervals and if any parts are suspect

then they must be renewed.

9 : 7 Front wheel toe-in

To check and adjust the front wheel toe-in proceed as

follows:

1 Ensure that the tyres are inflated to the recommended

pressures. Ensure that the steering wheel is in its

Page 97 of 128

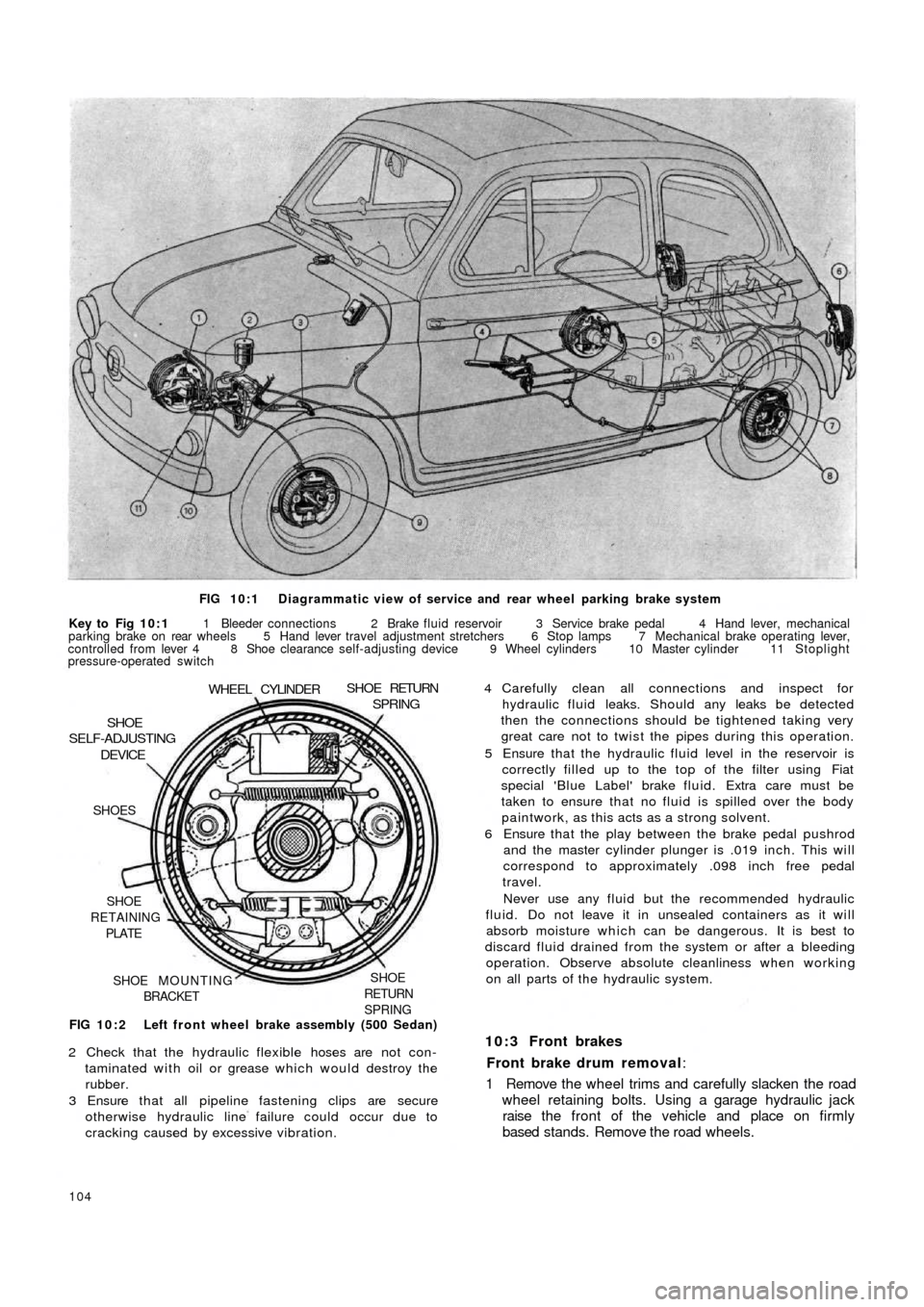

FIG 10:1 Diagrammatic view of service and rear wheel parking brake system

Key to Fig 10:1 1 Bleeder connections 2 Brake fluid reservoir 3 Service brake pedal 4 Hand lever, mechanical

parking brake on rear wheels 5 Hand lever travel adjustment stretchers 6 Stop lamps 7 Mechanical brake operating lever,

controlled from lever 4 8 Shoe clearance self-adjusting device 9 Wheel cylinders 10 Master cylinder 11 Stoplight

pressure-operated switch

FIG 10:2 Left front wheel brake assembly (500 Sedan)

SHOE

RETURN

SPRINGSHOE MOUNTING

BRACKET SHOE

RETAINING

PLATE SHOES

DEVICESHOE

SELF-ADJUSTING

WHEEL CYLINDERSHOE RETURNSPRING

2 Check that the hydraulic flexible hoses are not con-

taminated with oil or grease which would destroy the

rubber.

3 Ensure that all pipeline fastening clips are secure

otherwise hydraulic line failure could occur due to

cracking caused by excessive vibration.

104

4 Carefully clean all connections and inspect for

hydraulic fluid leaks. Should any leaks be detected

then the connections should be tightened taking very

great care not to twist the pipes during this operation.

5 Ensure that the hydraulic fluid level in the reservoir is

correctly filled up to the top of the filter using Fiat

special 'Blue Label' brake fluid. Extra care must be

taken to ensure that no fluid is spilled over the body

paintwork, as this acts as a strong solvent.

6 Ensure that the play between the brake pedal pushrod

and the master cylinder plunger is .019 inch. This will

correspond to approximately .098 inch free pedal

travel.

Never use any fluid but the recommended hydraulic

fluid. Do not leave it in unsealed containers as it will

absorb moisture which can be dangerous. It is best to

discard fluid drained from the system or after a bleeding

operation. Observe absolute cleanliness when working

on all parts of the hydraulic system.

10:3 Front brakes

Front brake drum removal:

1 Remove the wheel trims and carefully slacken the road

wheel retaining bolts. Using a garage hydraulic jack

raise the front of the vehicle and place on firmly

based stands. Remove the road wheels.