wheel FIAT 500 GUCCI 2012 2.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2012, Model line: 500 GUCCI, Model: FIAT 500 GUCCI 2012 2.GPages: 80, PDF Size: 1.87 MB

Page 43 of 80

•Please note that the TPMS is not a substitute for proper tire maintenance, and it is the driver’s

responsibility to maintain correct tire pressure, even if under-inflation has not reached the level

to trigger illumination of the TPMS low tire pressure telltale.

• Your vehicle has also been equipped with a TPMS malfunction indicator to indicate when the

system is not operating properly.The TPMS malfunction indicator is combined with the low tire

pressure telltale.When the system detects a malfunction, the telltale will flash for approximately

one minute and then remain continuously illuminated.This sequence will continue each time the

vehicle is restarted as long as the malfunction exists.

• When the malfunction indicator is illuminated, the system may not be able to detect or signal

low tire pressure as intended.TPMS malfunctions may occur for a variety of reasons, including

the installation of replacement or alternate tires or wheels on the vehicle that prevent the TPMS

from functioning properly.Always check the TPMS malfunction telltale after replacing one or

more tires or wheels on your vehicle, to ensure that the replacement or alternate tires and

wheels allow the TPMS to continue to function properly.

NOTE: Tire pressures change by approximately 1 psi (7 kPa) per 12° F (7° C) of air temperature

change. Keep this in mind when checking tire pressure inside a garage, especially in the Winter.

Example: If garage temperature is 68°F (20°C) and the outside temperature is 32°F (0°C), then

the cold tire inflation pressure should be increased by 3 psi (21 kPa), which equals 1 psi (7 kPa) for

every 12°F (7°C) for this outside temperature condition.

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels.TPMS

pressures and warning have been established for the tire size equipped on your vehicle.

Undesirable system operation or sensor damage may result when using replacement

equipment that is not of the same size, type, and/or style.Aftermarket wheels can cause

sensor damage. Do not use tire sealant from a can, or balance beads if your vehicle is

equipped with a TPMS, as damage to the sensors may result.

BRAKE- Brake Warning Light

• The Brake Warning light illuminates when there is either a system malfunction or the parking

brake is applied. If the light is on and the parking brake is not applied, it indicates a possible brake

hydraulic malfunction, brake booster problem or an Anti-Lock Brake System problem.

• Please have your vehicle serviced immediately.

WARNING!

Driving a vehicle with the red brake light on is dangerous. Part of the brake system may

have failed. It will take longer to stop the vehicle.You could have a collision. Have the

vehicle checked immediately.

WHAT TO DO IN EMERGENCIES

41

Page 47 of 80

4. When the spare is clear, remove the knob orplastic molded nut by rotating it

counter-clockwise.

5. Tilt the retainer at the end of the cable and pull it through the center of the wheel.

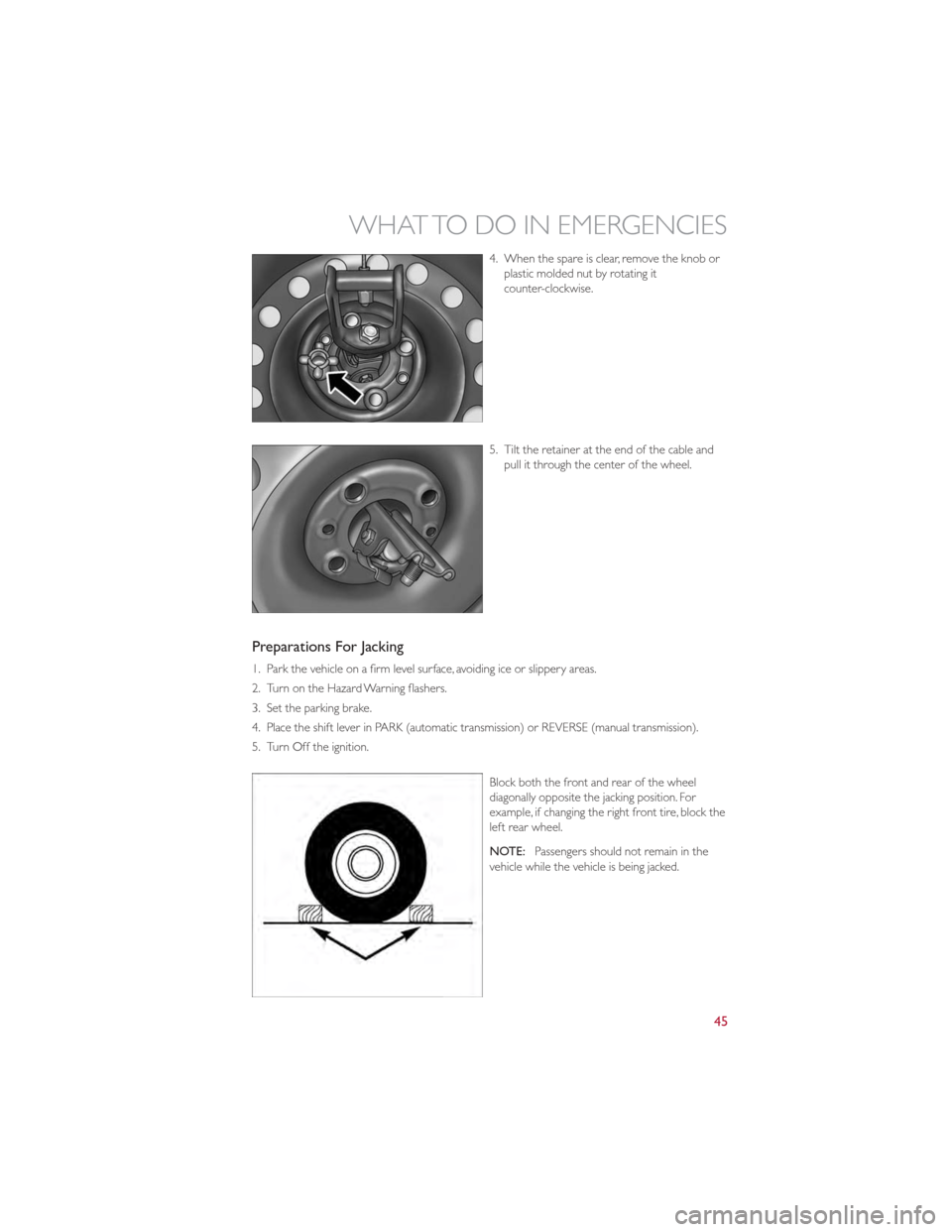

Preparations For Jacking

1. Park the vehicle on a firm level surface, avoiding ice or slippery areas.

2. Turn on the Hazard Warning flashers.

3. Set the parking brake.

4. Place the shift lever in PARK (automatic transmission) or REVERSE (manual transmission).

5. Turn Off the ignition.

Block both the front and rear of the wheel

diagonally opposite the jacking position. For

example, if changing the right front tire, block the

left rear wheel.

NOTE:Passengers should not remain in the

vehicle while the vehicle is being jacked.

WHAT TO DO IN EMERGENCIES

45

Page 48 of 80

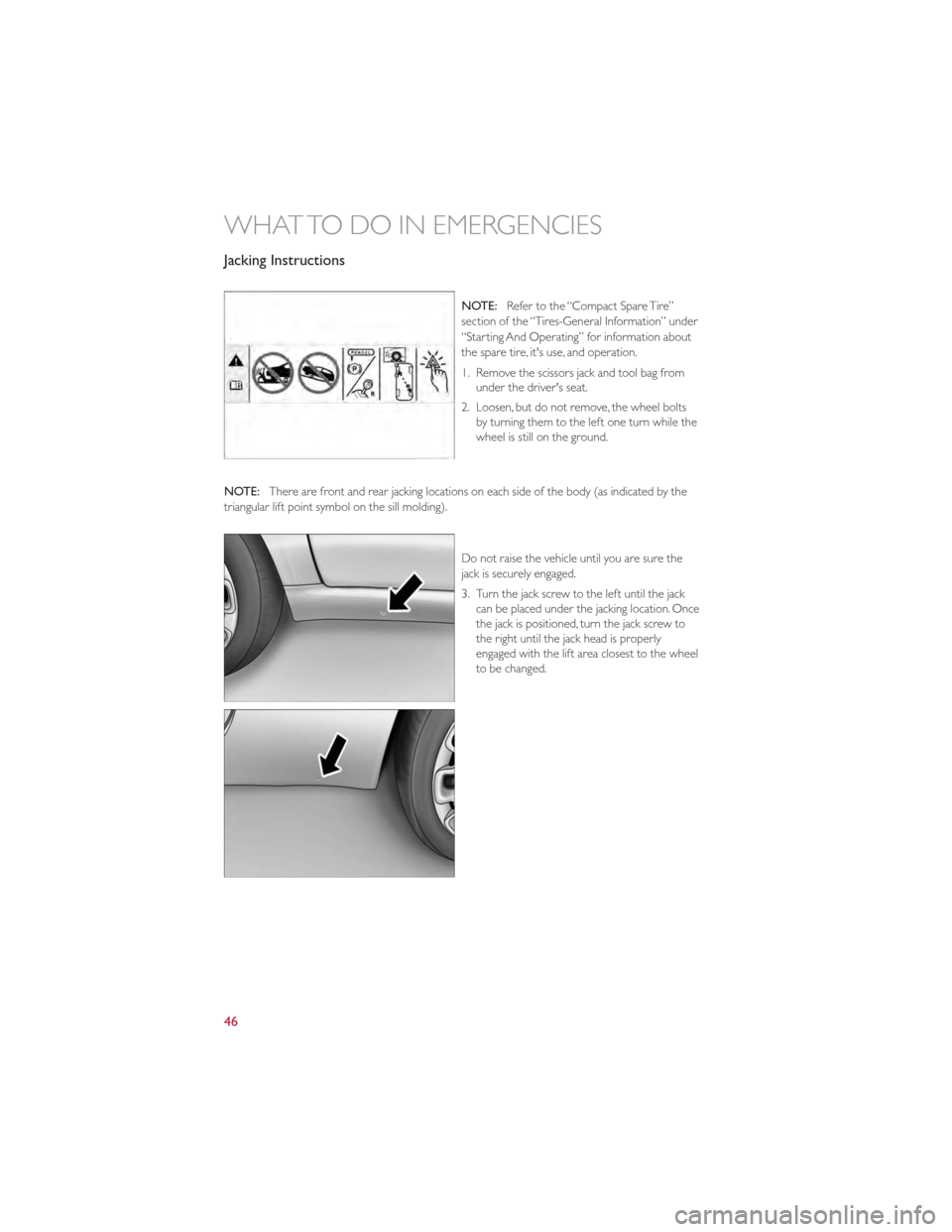

Jacking Instructions

NOTE:Refer to the “Compact Spare Tire”

section of the “Tires-General Information” under

“Starting And Operating” for information about

the spare tire, it's use, and operation.

1. Remove the scissors jack and tool bag from under the driver's seat.

2. Loosen, but do not remove, the wheel bolts by turning them to the left one turn while the

wheel is still on the ground.

NOTE: There are front and rear jacking locations on each side of the body (as indicated by the

triangular lift point symbol on the sill molding).

Do not raise the vehicle until you are sure the

jack is securely engaged.

3. Turn the jack screw to the left until the jackcan be placed under the jacking location. Once

the jack is positioned, turn the jack screw to

the right until the jack head is properly

engaged with the lift area closest to the wheel

to be changed.

WHAT TO DO IN EMERGENCIES

46

Page 49 of 80

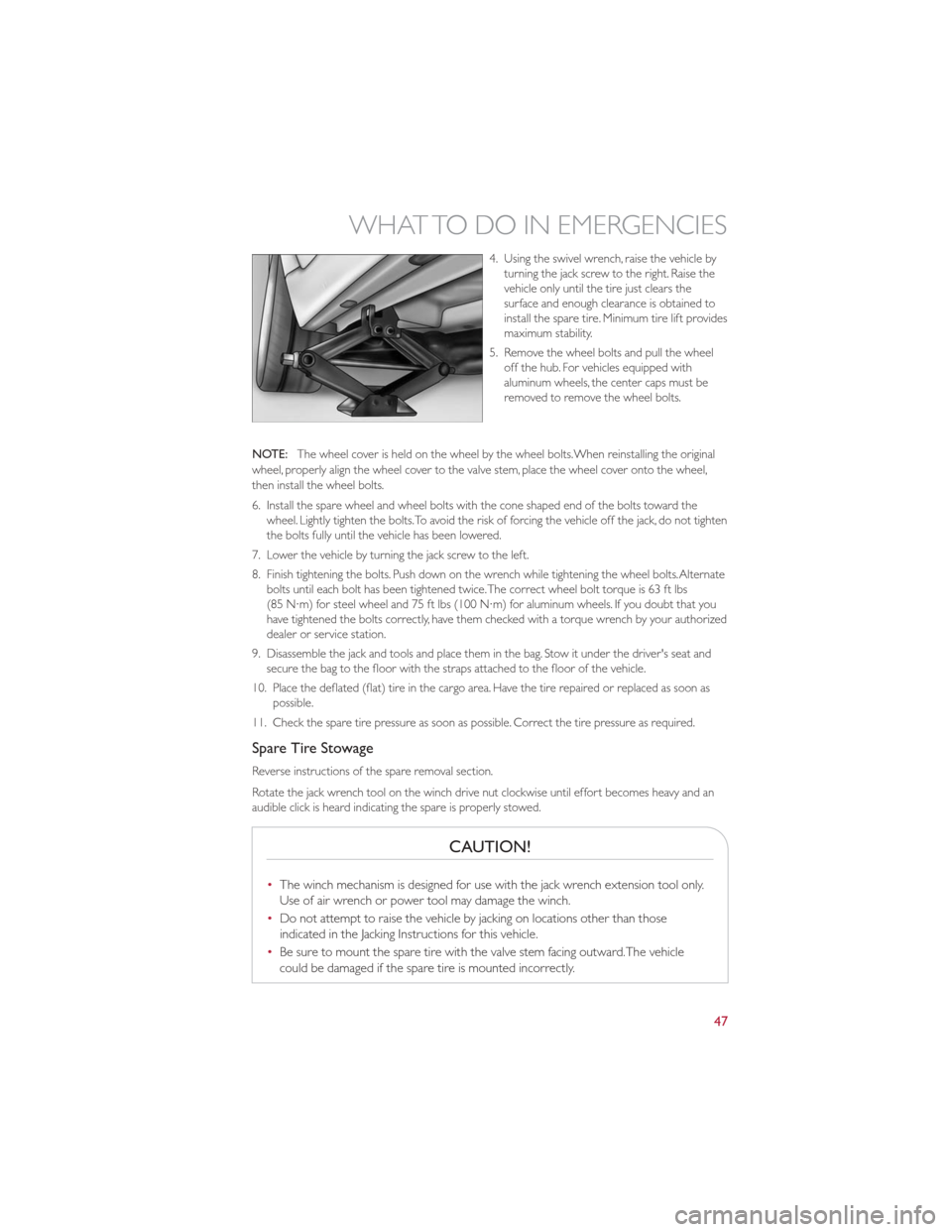

4. Using the swivel wrench, raise the vehicle byturning the jack screw to the right. Raise the

vehicle only until the tire just clears the

surface and enough clearance is obtained to

install the spare tire. Minimum tire lift provides

maximum stability.

5. Remove the wheel bolts and pull the wheel off the hub. For vehicles equipped with

aluminum wheels, the center caps must be

removed to remove the wheel bolts.

NOTE: The wheel cover is held on the wheel by the wheel bolts.When reinstalling the original

wheel, properly align the wheel cover to the valve stem, place the wheel cover onto the wheel,

then install the wheel bolts.

6. Install the spare wheel and wheel bolts with the cone shaped end of the bolts toward the wheel. Lightly tighten the bolts.To avoid the risk of forcing the vehicle off the jack, do not tighten

the bolts fully until the vehicle has been lowered.

7. Lower the vehicle by turning the jack screw to the left.

8. Finish tightening the bolts. Push down on the wrench while tightening the wheel bolts.Alternate bolts until each bolt has been tightened twice.The correct wheel bolt torque is 63 ft lbs

(85 N·m) for steel wheel and 75 ft lbs (100 N·m) for aluminum wheels. If you doubt that you

have tightened the bolts correctly, have them checked with a torque wrench by your authorized

dealer or service station.

9. Disassemble the jack and tools and place them in the bag. Stow it under the driver's seat and secure the bag to the floor with the straps attached to the floor of the vehicle.

10. Place the deflated (flat) tire in the cargo area. Have the tire repaired or replaced as soon as possible.

11. Check the spare tire pressure as soon as possible. Correct the tire pressure as required.

Spare Tire Stowage

Reverse instructions of the spare removal section.

Rotate the jack wrench tool on the winch drive nut clockwise until effort becomes heavy and an

audible click is heard indicating the spare is properly stowed.

CAUTION!

• The winch mechanism is designed for use with the jack wrench extension tool only.

Use of air wrench or power tool may damage the winch.

• Do not attempt to raise the vehicle by jacking on locations other than those

indicated in the Jacking Instructions for this vehicle.

• Be sure to mount the spare tire with the valve stem facing outward.The vehicle

could be damaged if the spare tire is mounted incorrectly.

WHAT TO DO IN EMERGENCIES

47

Page 50 of 80

WARNING!

•Do not attempt to change a tire on the side of the vehicle close to moving traffic.

Pull far enough off the road to avoid the danger of being hit when operating the jack

or changing the wheel.

• Being under a jacked-up vehicle is dangerous.The vehicle could slip off the jack and

fall on you.You could be crushed. Never put any part of your body under a vehicle

that is on a jack.

• Never start or run the engine while the vehicle is on a jack. If you need to get under

a raised vehicle, take it to a service center where it can be raised on a lift.

• The jack is designed to be used as a tool for changing tires only.The jack should not

be used to lift the vehicle for service purposes.The vehicle should be jacked on a

firm level surface only.Avoid ice or slippery areas.

• Carefully follow these tire changing warnings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as possible

before raising the vehicle.

• Turn on the Hazard Warning flashers.

• Block the wheel diagonally opposite the wheel to be raised.

• Set the parking brake firmly and set an automatic transmission in PARK; a manual

transmission in REVERSE.

• Never start or run the engine with the vehicle on a jack.

• Do not let anyone sit in the vehicle when it is on a jack.

• Do not get under the vehicle when it is on a jack.

• Only use the jack in the positions indicated and for lifting this vehicle during a tire

change.

• If working on or near a roadway, be extremely careful of motor traffic.

• To assure that spare tires, flat or inflated, are securely stowed, spares must be stowed

with the valve stem facing the ground.

• Raising the vehicle higher than necessary can make the vehicle less stable. It could slip

off the jack and hurt someone near it. Raise the vehicle only enough to remove the

tire.

• To avoid the risk of forcing the vehicle off the jack, do not fully tighten the wheel

bolts until the vehicle has been lowered. Failure to follow this warning may result in

personal injury.

• To avoid possible personal injury, handle the wheel covers with care to avoid contact

with any sharp edges.

• A loose tire or jack thrown forward in a collision or hard stop could endanger the

occupants of the vehicle.Always stow the jack parts and the spare tire in the places

provided.

WHAT TO DO IN EMERGENCIES

48

Page 52 of 80

•When the TIREFIT sealant is in a liquid form, clean water, and a damp cloth will remove the

material from the vehicle or tire and wheel components. Once the sealant dries, it can easily be

peeled off and properly discarded.

• For optimum performance, make sure the valve stem on the wheel is free of debris before

connecting the TIREFIT kit.

• You can use the TIREFIT air pump to inflate bicycle tires.The kit also comes with two needles,

located in the Accessory Storage Compartment (on the bottom of the air pump) for inflating

sport balls, rafts, or similar inflatable items. However, use only the Air Pump Hose (7) and make

sure the Mode Select Knob (5) is in the Air Mode when inflating such items to avoid injecting

sealant into them.The TIREFIT Sealant is only intended to seal punctures less than

1∕4in (6 mm)

diameter in the tread of your vehicle.

• Do not lift or carry the TIREFIT kit by the hoses.

Sealing A Tire With TIREFIT

(A) Whenever You Stop To Use TIREFIT:

1. Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to

the ground.This will allow the TIREFIT Hoses (6) and (7) to reach the valve stem and keep the

TIREFIT kit flat on the ground.This will provide the best positioning of the kit when injecting the

sealant into the deflated tire and running the air pump. Move the vehicle as necessary to place

the valve stem in this position before proceeding.

3. Place the transmission in PARK (auto transmission) or in Gear (manual transmission) and turn Off the ignition.

4. Set the parking brake.

(B) Setting Up To Use TIREFIT:

1. Turn the Mode Select Knob (5) to the Sealant Mode position.

2. Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of the hose.

3. Place the TIREFIT kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose (6) onto the valve stem.

5. Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE: Do not remove foreign objects (e.g., screws or nails) from the tire.

(C) Injecting TIREFIT Sealant Into The Deflated Tire:

• Always start the engine before turning ON the TIREFIT kit.

NOTE: Manual transmission vehicles must have the parking brake engaged and the shift lever in

NEUTRAL.

• After pressing the Power Button (4), the sealant (white fluid) will flow from the Sealant Bottle

(1) through the Sealant Hose (6) and into the tire.

NOTE: Sealant may leak out through the puncture in the tire.

WHAT TO DO IN EMERGENCIES

50

Page 55 of 80

WARNING!

•Do not attempt to seal a tire on the side of the vehicle closest to traffic. Pull far

enough off the road to avoid the danger of being hit when using the TIREFIT kit.

• Do not use TIREFIT or drive the vehicle under the following circumstances:

− If the puncture in the tire tread is approximately 1/4 in. (6 mm) or larger.

− If the tire has any sidewall damage.

− If the tire has any damage from driving with extremely low tire pressure.

− If the tire has any damage from driving on a flat tire.

− If the wheel has any damage.

− If you are unsure of the condition of the tire or the wheel.

• Keep TIREFIT away from open flames or heat source.

• A loose TIREFIT kit thrown forward in a collision or hard stop could endanger the

occupants of the vehicle.Always stow the TIREFIT kit in the place provided. Failure to

follow these warnings can result in injuries that are serious or fatal to you, your

passengers, and others around you.

• Take care not to allow the contents of TIREFIT to come in contact with hair, eyes, or

clothing.TIREFIT is harmful if inhaled, swallowed, or absorbed through the skin. It

causes skin, eye, and respiratory irritation. Flush immediately with plenty of water if

there is any contact with eyes or skin. Change clothing as soon as possible, if there is

any contact with clothing.

• TIREFIT Sealant solution contains latex. In case of an allergic reaction or rash, consult

a physician immediately. Keep TIREFIT out of reach of children. If swallowed, rinse

mouth immediately with plenty of water and drink plenty of water. Do not induce

vomiting! Consult a physician immediately.

• TIREFIT is not a permanent flat tire repair. Have the tire inspected and repaired or

replaced after using TIREFIT. Do not exceed 55 mph (88 km/h) until the tire is

repaired or replaced. Failure to follow this warning can result in injuries that are

serious or fatal to you, your passengers, and others around you.

JUMP-STARTING PROCEDURE

•If your vehicle has a discharged battery, it can be jump-started using a set of jumper cables and a

battery in another vehicle or by using a portable battery booster pack. Jump-starting can be

dangerous if done improperly so please follow the procedures in this section carefully.

NOTE: When using a portable battery booster pack, follow the manufacturer’s operating

instructions and precautions.

WHAT TO DO IN EMERGENCIES

53

Page 58 of 80

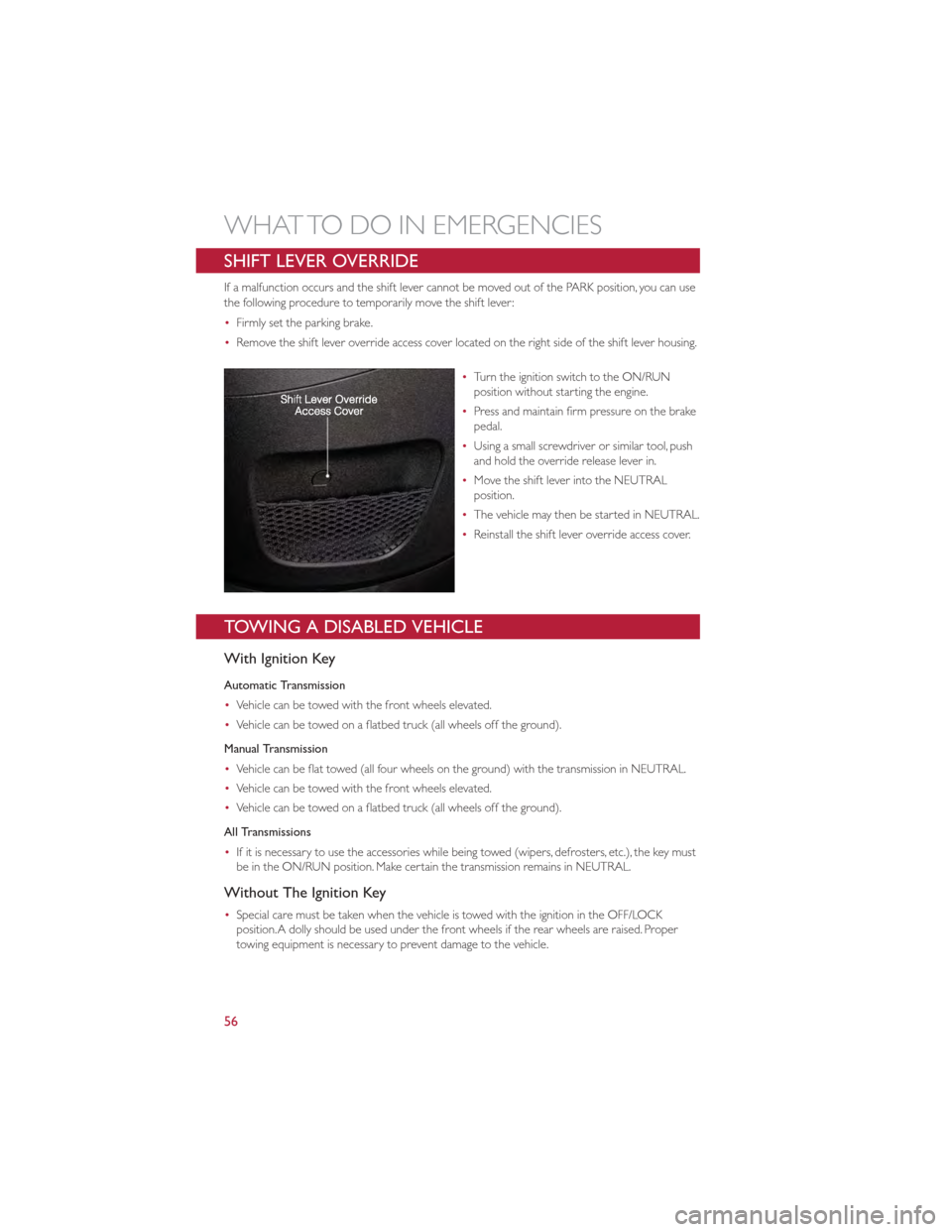

SHIFT LEVER OVERRIDE

If a malfunction occurs and the shift lever cannot be moved out of the PARK position, you can use

the following procedure to temporarily move the shift lever:

•Firmly set the parking brake.

• Remove the shift lever override access cover located on the right side of the shift lever housing.

•Turn the ignition switch to the ON/RUN

position without starting the engine.

• Press and maintain firm pressure on the brake

pedal.

• Using a small screwdriver or similar tool, push

and hold the override release lever in.

• Move the shift lever into the NEUTRAL

position.

• The vehicle may then be started in NEUTRAL.

• Reinstall the shift lever override access cover.

TOWING A DISABLED VEHICLE

With Ignition Key

Automatic Transmission

•Vehicle can be towed with the front wheels elevated.

• Vehicle can be towed on a flatbed truck (all wheels off the ground).

Manual Transmission

• Vehicle can be flat towed (all four wheels on the ground) with the transmission in NEUTRAL.

• Vehicle can be towed with the front wheels elevated.

• Vehicle can be towed on a flatbed truck (all wheels off the ground).

All Transmissions

• If it is necessary to use the accessories while being towed (wipers, defrosters, etc.), the key must

be in the ON/RUN position. Make certain the transmission remains in NEUTRAL.

Without The Ignition Key

•Special care must be taken when the vehicle is towed with the ignition in the OFF/LOCK

position.A dolly should be used under the front wheels if the rear wheels are raised. Proper

towing equipment is necessary to prevent damage to the vehicle.

WHAT TO DO IN EMERGENCIES

56

Page 60 of 80

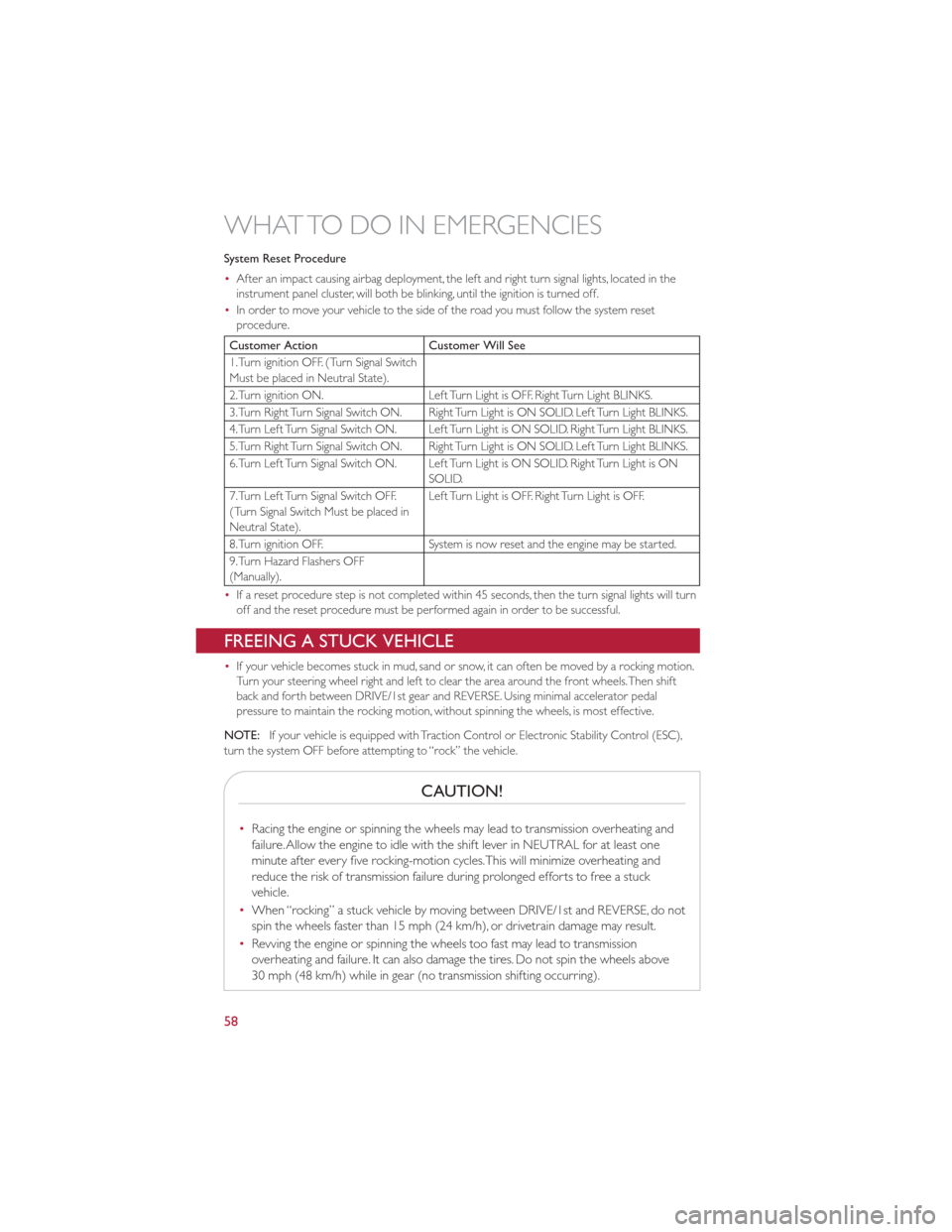

System Reset Procedure

•After an impact causing airbag deployment, the left and right turn signal lights, located in the

instrument panel cluster, will both be blinking, until the ignition is turned off.

• In order to move your vehicle to the side of the road you must follow the system reset

procedure.

Customer Action Customer Will See

1.Turn ignition OFF. (Turn Signal Switch

Must be placed in Neutral State).

2.Turn ignition ON. Left Turn Light is OFF. Right Turn Light BLINKS.

3.Turn Right Turn Signal Switch ON. Right Turn Light is ON SOLID. Left Turn Light BLINKS.

4.Turn Left Turn Signal Switch ON. Left Turn Light is ON SOLID. Right Turn Light BLINKS.

5.Turn Right Turn Signal Switch ON. Right Turn Light is ON SOLID. Left Turn Light BLINKS.

6.Turn Left Turn Signal Switch ON. Left Turn Light is ON SOLID. Right Turn Light is ON SOLID.

7.Turn Left Turn Signal Switch OFF.

(Turn Signal Switch Must be placed in

Neutral State). Left Turn Light is OFF. Right Turn Light is OFF.

8.Turn ignition OFF. System is now reset and the engine may be started.

9.Turn Hazard Flashers OFF

(Manually).

• If a reset procedure step is not completed within 45 seconds, then the turn signal lights will turn

off and the reset procedure must be performed again in order to be successful.

FREEING A STUCK VEHICLE

•If your vehicle becomes stuck in mud, sand or snow, it can often be moved by a rocking motion.

Turn your steering wheel right and left to clear the area around the front wheels.Then shift

back and forth between DRIVE/1st gear and REVERSE. Using minimal accelerator pedal

pressure to maintain the rocking motion, without spinning the wheels, is most effective.

NOTE: If your vehicle is equipped with Traction Control or Electronic Stability Control (ESC),

turn the system OFF before attempting to “rock” the vehicle.

CAUTION!

• Racing the engine or spinning the wheels may lead to transmission overheating and

failure.Allow the engine to idle with the shift lever in NEUTRAL for at least one

minute after every five rocking-motion cycles.This will minimize overheating and

reduce the risk of transmission failure during prolonged efforts to free a stuck

vehicle.

• When “rocking” a stuck vehicle by moving between DRIVE/1st and REVERSE, do not

spin the wheels faster than 15 mph (24 km/h), or drivetrain damage may result.

• Revving the engine or spinning the wheels too fast may lead to transmission

overheating and failure. It can also damage the tires. Do not spin the wheels above

30 mph (48 km/h) while in gear (no transmission shifting occurring).

WHAT TO DO IN EMERGENCIES

58

Page 61 of 80

WARNING!

Fast spinning tires can be dangerous. Forces generated by excessive wheel speeds may

cause damage, or even failure, of the axle and tires.A tire could explode and injure

someone. Do not spin your vehicle's wheels faster than 30 mph (48 km/h) or for

longer than 30 seconds continuously without stopping when you are stuck and do not

let anyone near a spinning wheel, no matter what the speed.

EVENT DATA RECORDER (EDR)

•This vehicle is equipped with an event data recorder (EDR).The main purpose of an EDR is to

record, in certain crash or near crash-like situations, such as an air bag deployment or hitting a

road obstacle, data that will assist in understanding how a vehicle’s systems performed.The EDR

is designed to record data related to vehicle dynamics and safety systems for a short period of

time, typically 30 seconds or less.The EDR in this vehicle is designed to record such data as:

•How various systems in your vehicle were operating;

• Whether or not the driver and passenger safety belts were buckled/fastened;

• How far (if at all) the driver was depressing the accelerator and/or brake pedal; and,

• How fast the vehicle was traveling.

• These data can help provide a better understanding of the circumstances in which crashes and

injuries occur.

NOTE: EDR data are recorded by your vehicle only if a non-trivial crash situation occurs; no data

are recorded by the EDR under normal driving conditions and no personal data (e.g. name, gender,

age, and crash location) are recorded. However, other parties, such as law enforcement, could

combine the EDR data with the type of personally identifying data routinely acquired during a

crash investigation.

• To read data recorded by an EDR, special equipment is required, and access to the vehicle or the

EDR is needed. In addition to the vehicle manufacturer, other parties such as law enforcement,

that have the special equipment, can read the information if they have access to the vehicle or

the EDR.

WHAT TO DO IN EMERGENCIES

59