replace FIAT 500E 2015 2.G Owner's Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: 500E, Model: FIAT 500E 2015 2.GPages: 367, PDF Size: 9.42 MB

Page 287 of 367

(E) After Driving:

Pull over to a safe location. Refer to “Whenever You Stop

to Use Tire Service Kit” before continuing.

1. Push in the Mode Select Knob (5) and turn to the Air

Mode position.

2. Uncoil the power plug and insert the plug into the

vehicle’s 12 Volt power outlet.

3. Uncoil the Air Pump Hose (7) (black in color) and

screw the fitting at the end of hose (7) onto the valve

stem.

4. Check the pressure in the tire by reading the Pressure

Gauge (3).

If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button (4) to turn on Tire Service Kit

and inflate the tire to the pressure indicated on the tire

and loading information label on the driver-side door

opening.

NOTE:If the tire becomes over-inflated, push the Defla-

tion Button to reduce the tire pressure to the recom-

mended inflation pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem,

reinstall the cap on the valve stem and unplug from

12 Volt outlet.

3. Place the Tire Service Kit in its proper storage area in

the vehicle.

4. Have the tire inspected and repaired or replaced at the

earliest opportunity at an authorized dealer or tire

service center.

6

WHAT TO DO IN EMERGENCIES 285

Page 288 of 367

5. Remove the Speed Limit sticker from the instrument

panel after the tire has been repaired.

6. Replace the Sealant Bottle (1) and Sealant Hose (6)

assembly at your authorized dealer as soon as pos-

sible. Refer to (F) “Sealant Bottle and Hose Replace-

ment”.

NOTE:When having the tire serviced, advise the autho-

rized dealer or service center that the tire has been sealed

using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (6) (clear in color).

2. Locate the round Sealant Bottle release button in the

recessed area under the sealant bottle.

3. Push the Sealant Bottle release button. The Sealant

Bottle (1) will pop up. Remove the bottle and dispose

of it accordingly.

4. Clean any remaining sealant from the Tire Service Kit

housing.

5. Position the new Sealant Bottle (1) in the housing so

that the Sealant Hose (6) aligns with the hose slot in

the front of the housing. Push the bottle into the

housing. An audible click will be heard indicating the

bottle is locked into place.

6. Verify that the cap is installed on the fitting at the end

of the Sealant Hose (6) and return the hose to its

storage area (located on the bottom of the air pump).

7. Return the Tire Service Kit to its storage location in the

vehicle.

286 WHAT TO DO IN EMERGENCIES

Page 297 of 367

MAINTAINING YOUR VEHICLE

CONTENTS

!UNDERHOOD COMPARTMENT...........297

!REPLACEMENT PARTS..................298

!DEALER SERVICE......................298

!MAINTENANCE PROCEDURES...........299

▫Power Electronics And Battery Thermal

Management Systems...................300

▫Power Electronics and Battery Thermal

Management Systems — Coolant Level

Check..............................300

▫Power Electronics and Battery Thermal

Management Systems — Cooling Pressure

Caps...............................302

▫Selection Of Coolant...................303

▫Adding Coolant.......................304

▫Power Electronics and Battery Thermal

Management Systems — Drain, Flush And

Refill..............................305

▫Disposal Of Used Power Electronics and Battery

Thermal Management Systems Coolant......305

7

Page 298 of 367

▫Points To Remember...................306

▫Maintenance-Free Battery 12 Volt..........306

▫Air Conditioner Maintenance.............308

▫Body Lubrication.....................309

▫Wiper Blades........................309

▫Adding Washer Fluid..................311

▫Brake System........................312

▫Appearance Care And Protection From

Corrosion...........................314

!FUSES..............................321

▫Interior Fuses........................322

▫Power Distribution Center #1.............325

▫Power Distribution Center (PDC) #2........327

!VEHICLE STORAGE.....................329

!REPLACEMENT BULBS.................329

!BULB REPLACEMENT..................330

▫Headlamps Low Beam and High Beam......330

▫Front Turn Signal, Parking And Daytime

Running Lamps.......................331

▫Front Fog Lamps......................331

▫Front/Rear Side Marker Lamps............332

▫Rear Tail, Stop, Backup And Turn Signal

Lamps.............................332

▫Center High Mounted Stop Lamp (CHMSL) . . .333

!FLUID CAPACITIES....................333

!FLUIDS, LUBES, AND GENUINE PARTS.....334

296 MAINTAINING YOUR VEHICLE

Page 300 of 367

REPLACEMENT PARTS

Use of genuine parts for normal/scheduled maintenance

and repairs is highly recommended to ensure the de-

signed performance. Damage or failures caused by the

use of parts which are not quality-equivalent to genuine

parts for maintenance and repairs will not be covered by

the manufacturer ’s warranty.

DEALER SERVICE

Your authorized dealer has the qualified service person-

nel, special tools, and equipment to perform all service

operations in an expert manner. Service Manuals are

available which include detailed service information for

your vehicle. Refer to these Service Manuals before

attempting any procedure yourself.

NOTE:Intentional tampering with emissions control

systems may void your warranty and could result in civil

penalties being assessed against you.

WARNING!

You can be badly injured working on or around a

motor vehicle. Only do service work for which you

have the knowledge and the proper equipment. If

you have any doubt about your ability to perform a

service job, take your vehicle to a competent me-

chanic.

298 MAINTAINING YOUR VEHICLE

Page 301 of 367

MAINTENANCE PROCEDURES

WARNING!

Your vehicle has both a high voltage DC and AC

system as well as a 12 Volt system. DC and AC high

voltage are both extremely dangerous and can cause

severe burns, electric shock, serious injury or even

death. In order to avoid personal injuries:

•DO NOT TOUCH THE HIGH VOLTAGE CABLES

(ORANGE COLORED) AND/OR THE CONNEC-

TORS.

•Follow all Caution and Warning labels attached to

the High Voltage components.

•Do not remove or replace any of the 500e System

components. All replacement or repairs of 500e

System components should be performed by a

factory-trained technician at an authorized dealer.

The pages that follow contain therequiredmaintenance

services determined by the engineers who designed your

vehicle.

Besides those maintenance items specified in the fixed

maintenance schedule, there are other components which

may require servicing or replacement in the future.

CAUTION!

•Failure to properly maintain your vehicle or per-

form repairs and service when necessary could

result in more costly repairs, damage to other

components or negatively impact vehicle perfor-

mance. Immediately have potential malfunctions

examined by an authorized dealer or qualified

repair center.

(Continued)

7

MAINTAINING YOUR VEHICLE 299

Page 305 of 367

NOTE:

•The pressure caps on the reservoirs are unique and

rated at 5 PSI caps.

•Use only Mopar® replacement parts.

WARNING!

•The warning words “DO NOT OPEN HOT” on the

cooling system pressure cap are a safety precaution.

Never add coolant (antifreeze) when the cooling sys-

tem is overheated. Do not loosen or remove the cap to

cool an overheated cooling system. Heat causes pres-

sure to build up in the cooling system. To prevent

scalding or injury, do not remove the pressure cap

while the system is hot or under pressure.

•Do not use a pressure cap other than the one

specified for your vehicle. Personal injury or ve-

hicle damage may result.

Selection Of Coolant

Refer to “Fluids, Lubricants, and Genuine Parts” in

“Maintaining Your Vehicle” for further information.

CAUTION!

•Mixing of coolant (antifreeze) other than specified

Organic Additive Technology (OAT) coolant (anti-

freeze), may result in cooling system damage and

may decrease corrosion protection. Organic Addi-

tive Technology (OAT) coolant is different and

should not be mixed with Hybrid Organic Additive

Technology (HOAT) coolant (antifreeze). If a non-

OAT coolant (antifreeze) is introduced into the

cooling system in an emergency, it should be re-

placed with the specified coolant (antifreeze) as

soon as possible.

(Continued)

7

MAINTAINING YOUR VEHICLE 303

Page 306 of 367

CAUTION!(Continued)

•Do not use water alone or alcohol-based coolant

(antifreeze) products. Do not use additional rust

inhibitors or antirust products, as they may not be

compatible with the radiator coolant and may plug

the radiator.

•This vehicle has not been designed for use with

propylene glycol-based coolant (antifreeze). Use of

propylene glycol-based coolant (antifreeze) is not

recommended.

Adding Coolant

Your vehicle has been built with cooling systems that allow

extended maintenance intervals. This coolant (antifreeze)

can be used up to ten years or 150,000 miles (240,000 km)

before replacement. To prevent reducing this extended

maintenance period, it is important that you use the same

coolant (antifreeze) throughout the life of your vehicle.

Please review these recommendations for using Organic

Additive Technology (OAT) coolant (antifreeze).

When adding coolant (antifreeze):

•The manufacturer recommends using MOPAR®

Antifreeze/Coolant 10 Year/150,000 Mile Formula

OAT (Organic Additive Technology).

•Mix a minimum solution of 50% OAT coolant (anti-

freeze) and distilled water. Use higher concentrations

(not to exceed 70%) if temperatures below -34ºF (-37ºC)

are anticipated.

•Use only high purity water such as distilled or deion-

ized water when mixing the water and coolant (anti-

freeze) solution. The use of lower quality water will

reduce the amount of corrosion protection in the

cooling systems.

304 MAINTAINING YOUR VEHICLE

Page 309 of 367

WARNING!

•Battery fluid is a corrosive acid solution and can

burn or even blind you. Do not allow battery fluid

to contact your eyes, skin, or clothing. Do not lean

over a battery when attaching clamps. If acid

splashes in eyes or on skin, flush the area imme-

diately with large amounts of water. Refer to

“Jump-Starting Procedures” in “What To Do In

Emergencies” for further information.

•Battery gas is flammable and explosive. Keep

flame or sparks away from the battery. Do not use

a booster battery or any other booster source with

an output greater than 12 Volts. Do not allow cable

clamps to touch each other.

•Battery posts, terminals, and related accessories

contain lead and lead compounds. Wash hands

after handling.

(Continued)

WARNING!(Continued)

•The battery in this vehicle has a vent hose that

should not be disconnected and should only be

replaced with a battery of the same type (vented).

CAUTION!

•It is essential when replacing the cables on the

battery that the positive cable is attached to the

positive post and the negative cable is attached to

the negative post. Battery posts are marked positive

(+) and negative (-) and are identified on the

battery case. Cable clamps should be tight on the

terminal posts and free of corrosion.

(Continued)

7

MAINTAINING YOUR VEHICLE 307

Page 312 of 367

Avoid using the wiper blades to remove frost or ice from

the windshield or rear window. Make sure that they are

not frozen to the glass before turning them on to avoid

damaging the blade. Keep the blade rubber out of contact

with petroleum products.

NOTE:Life expectancy of wiper blades varies depend-

ing on geographical area and frequency of use. Poor

performance of blades may be present with chattering,

marks, water lines or wet spots. If any of these conditions

are present, clean the wiper blades or replace as neces-

sary.

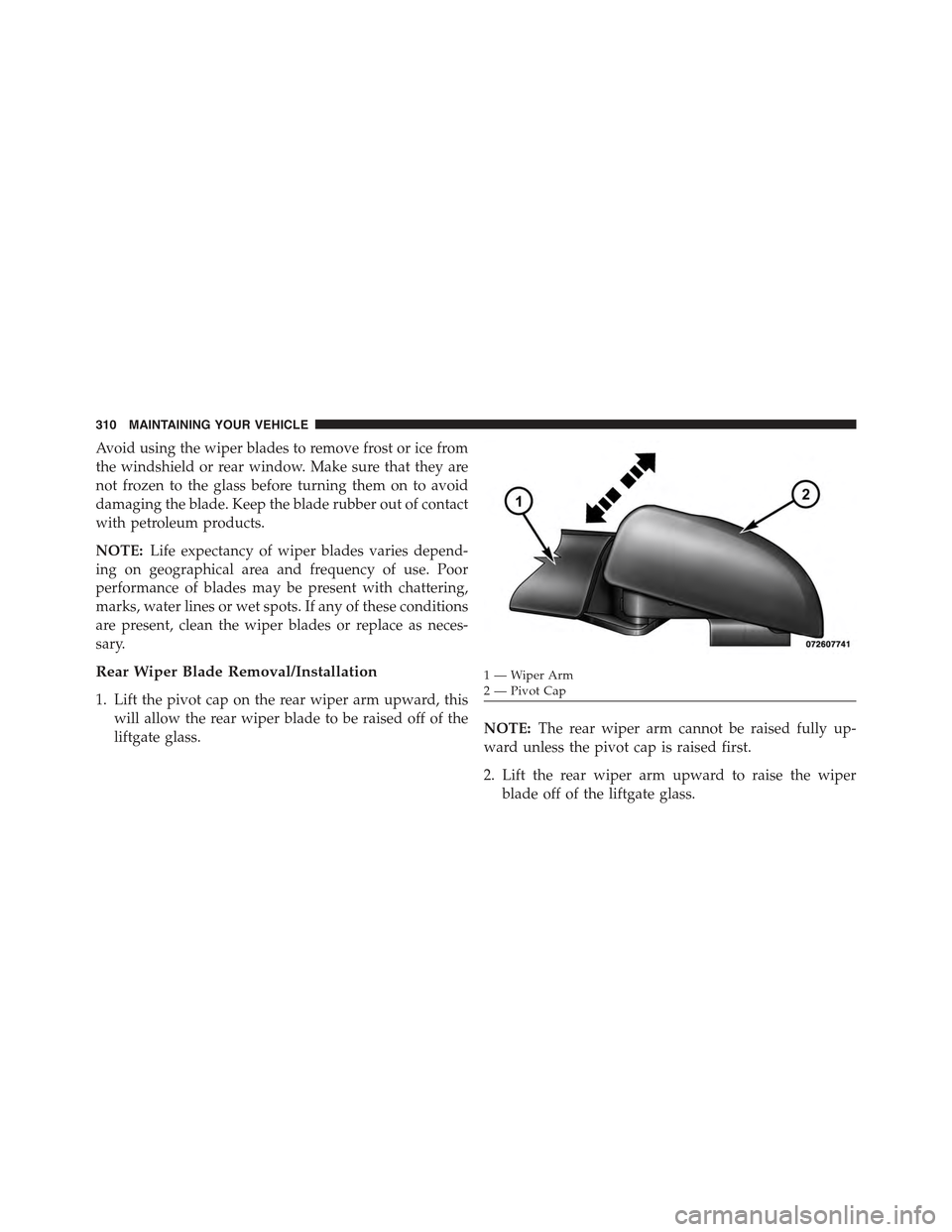

Rear Wiper Blade Removal/Installation

1. Lift the pivot cap on the rear wiper arm upward, this

will allow the rear wiper blade to be raised off of the

liftgate glass.NOTE:The rear wiper arm cannot be raised fully up-

ward unless the pivot cap is raised first.

2. Lift the rear wiper arm upward to raise the wiper

blade off of the liftgate glass.

1—WiperArm2 — Pivot Cap

310 MAINTAINING YOUR VEHICLE