lock FIAT 500E 2017 2.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: 500E, Model: FIAT 500E 2017 2.GPages: 300, PDF Size: 2.58 MB

Page 216 of 300

TPMS Warning

When a system fault is detected, the “Tire Pressure

Monitoring Telltale Light” will flash on and off for 75

seconds and then remain on solid. The system fault will

sound a chime and also display a “Service Tire Pressure

Monitoring System” message in the instrument cluster

for approximately 5 seconds.

If the ignition switch is cycled, this sequence will repeat,

providing the system fault still exists. If the system fault

no longer exists, the “Tire Pressure Monitoring Telltale

Light” will no longer flash, and the “Service TPM

System” message will no longer display.A system fault can occur due to any of the following:

1. Signal interference due to electronic devices or driv-

ing next to facilities emitting the same radio frequen-

cies as the TPM sensors.

2. Installing aftermarket window tinting that contains materials that may block radio wave signals.

3. Accumulation of snow or ice around the wheels or wheel housings.

4. Using tire chains on the vehicle.

5. Using wheels/tires not equipped with TPM sensors.

NOTE:

• The TPMS will not monitor the pressure in a replace-

ment tire installed without a tire pressure sensor.

• If you install a replacement tire in place of a road tire

that has a pressure below the low-pressure warning

limit, upon the next ignition switch cycle, the “Tire

Pressure Monitoring Telltale Light” will remain on

and a chime will sound. In addition, the highlighted

graphic in the instrument cluster will still display a

low pressure text message and a pressure value in a

different color.

Service TPM System Message

214 STARTING AND OPERATING

Page 222 of 300

HAZARD WARNING FLASHERS

The Hazard Warning flasher switch is located on the

instrument panel below the radio.Push the switch to turn on the Hazard Warning

flashers. When the switch is activated, all direc-

tional turn signals will flash on and off to warn oncom-

ing traffic of an emergency. Push the switch a second

time to turn off the Hazard Warning flashers.

Do not use this emergency warning system when the

vehicle is in motion. Use it when your vehicle is

disabled and it is creating a safety hazard for other

motorists.

If it is necessary to leave the vehicle to go for service, the

Hazard Warning flashers will continue to operate with

the ignition key removed and the vehicle locked.

NOTE: With extended use, the Hazard Warning flash-

ers may wear down your battery.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure

that the wheel is properly mounted to the vehicle. Any

time a wheel has been removed and reinstalled on the

vehicle, the lug nuts/bolts should be torqued using a

properly calibrated torque wrench.

Torque Specifications

Lug Nut/Bolt Torque **Lug Nut/ Bolt SizeLug Nut/

Bolt

Socket Size

66 Ft-Lbs (90 N·m)

Steel Wheels Only

74 Ft-Lbs (100 N·m) Aluminum Wheels Only M12 x 1.25 17 mm

**Use only your authorized dealer recommended lug

nuts/bolts and clean or remove any dirt or oil before

tightening.

Inspect the wheel mounting surface prior to mounting

the tire and remove any corrosion or loose particles.

220 WHAT TO DO IN EMERGENCIES

Page 231 of 300

NOTE:If the tire becomes over-inflated, push the

Deflation Button to reduce the tire pressure to the

recommended inflation pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve stem and unplug from

12 Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an authorized dealer or

tire service center.

5. Remove the Speed Limit sticker from the instrument panel after the tire has been repaired.

6. Replace the Sealant Bottle (1) and Sealant Hose (6) assembly at your authorized dealer as soon as pos-

sible. Refer to (F) “Sealant Bottle and Hose Replace-

ment”.

NOTE: When having the tire serviced, advise the

authorized dealer or service center that the tire has been

sealed using the Tire Service Kit.(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (6) (clear in color).

2. Locate the round Sealant Bottle release button in the recessed area under the sealant bottle.

3. Push the Sealant Bottle release button. The Sealant Bottle (1) will pop up. Remove the bottle and dispose

of it accordingly.

4. Clean any remaining sealant from the Tire Service Kit housing.

5. Position the new Sealant Bottle (1) in the housing so that the Sealant Hose (6) aligns with the hose slot in

the front of the housing. Push the bottle into the

housing. An audible click will be heard indicating

the bottle is locked into place.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose (6) and return the hose to its

storage area (located on the bottom of the air pump).

7. Return the Tire Service Kit to its storage location in the vehicle.

6

WHAT TO DO IN EMERGENCIES 229

Page 233 of 300

WARNING!

•Take care to avoid the radiator cooling fan when-

ever the hood is raised. It can start anytime the

ignition switch is ON. You can be injured by

moving fan blades.

•

Remove any metal jewelry such as rings, watch

bands and bracelets that could make an inadvertent

electrical contact. You could be seriously injured.

• Batteries contain sulfuric acid that can burn your

skin or eyes and generate hydrogen gas which is

flammable and explosive. Keep open flames or

sparks away from the battery.

1. Set the parking brake, place the transmission into PARK and turn the ignition to LOCK.

2. Turn off the heater, radio, and all unnecessary elec- trical accessories.

3. Remove the protective cover over the positive (+)

battery post.

4. If using another vehicle to jump-start the battery, park the vehicle within the jumper cables reach, set

the parking brake and make sure the ignition is OFF.

WARNING!

Do not allow vehicles to touch each other as this

could establish a ground connection and personal

injury could result.

Jump-Starting Procedure

WARNING!

Failure to follow this jump-starting procedure

could result in personal injury or property damage

due to battery explosion.

CAUTION!

Failure to follow these procedures could result in

damage to the charging system of the booster ve-

hicle or the discharged vehicle.

Connecting The Jumper Cables

1. Connect the positive (+)end of the jumper cable to

the positive (+)post of the discharged vehicle.

2. Connect the opposite end of the positive (+)jumper

cable to the positive (+)post of the booster battery.

6

WHAT TO DO IN EMERGENCIES 231

Page 236 of 300

WARNING!(Continued)

allow your vehicle to roll away if it is not secured

by the parking brake or other means. Activating the

Manual Park Release on an unsecured vehicle could

lead to serious injury or death for those in or

around the vehicle.

In order to move the vehicle in cases where the trans-

mission will not shift out of PARK (such as a dead

battery), a Manual Park Release is available. If a dead 12

volt battery is the cause of the condition refer to “Jump

Start Procedure — 12 Volt Battery” before performing

the Manual Park Release.

To perform the Manual Park Release follow these steps:

1. To prevent the vehicle from rolling unintentionally, firmly apply the parking brake.

2. If possible, raise the front driver’s side of the vehicle to provide access to the transmission.

3. Working from underneath the vehicle, remove the black rubber plug from the front of the Park module

(a black canister mounted on the front of the trans-

mission). 4. Using a T25 driver bit, rotate the Manual Park

Release shaft (located just behind the rubber plug)

clockwise, at least 20 turns, to release the Park

mechanism. The vehicle is now out of PARK and can

be moved.

5. Reinstall the rubber plug.

6. Release the parking brake only when a driver is in the vehicle, or the vehicle is secured by other means.

The Manual Park Release will be reset automatically

once the vehicle is restarted.

Manual Park Release Location

234 WHAT TO DO IN EMERGENCIES

Page 251 of 300

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should

be lubricated periodically with a lithium based grease,

such as Mopar Spray White Lube to assure quiet, easy

operation and to protect against rust and wear. Prior to

the application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit; after

lubricating excess oil and grease should be removed.

Particular attention should also be given to hood latch-

ing components to ensure proper function. When per-

forming other underhood services, the hood latch,

release mechanism and safety catch should be cleaned

and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the Fall and Spring. Apply a small

amount of a high quality lubricant, such as Mopar Lock

Cylinder Lubricant directly into the lock cylinder.

Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield and rear window periodically with a

sponge or soft cloth and a mild nonabrasive cleaner.This will remove accumulations of salt, waxes, or road

film, and help reduce streaking and smearing.

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always

use washer fluid when using the wipers to remove salt

or dirt from a dry windshield or rear window.

Avoid using the wiper blades to remove frost or ice

from the windshield or rear window. Make sure that

they are not frozen to the glass before turning them on

to avoid damaging the blade. Keep the blade rubber out

of contact with petroleum products.

NOTE:

Life expectancy of wiper blades varies depend-

ing on geographical area and frequency of use. Poor

performance of blades may be present with chattering,

marks, water lines or wet spots. If any of these condi-

tions are present, clean the wiper blades or replace as

necessary.

Rear Wiper Blade Removal/Installation

1. Lift the pivot cap on the rear wiper arm upward, this will allow the rear wiper blade to be raised off of the

liftgate glass.

7

MAINTAINING YOUR VEHICLE 249

Page 262 of 300

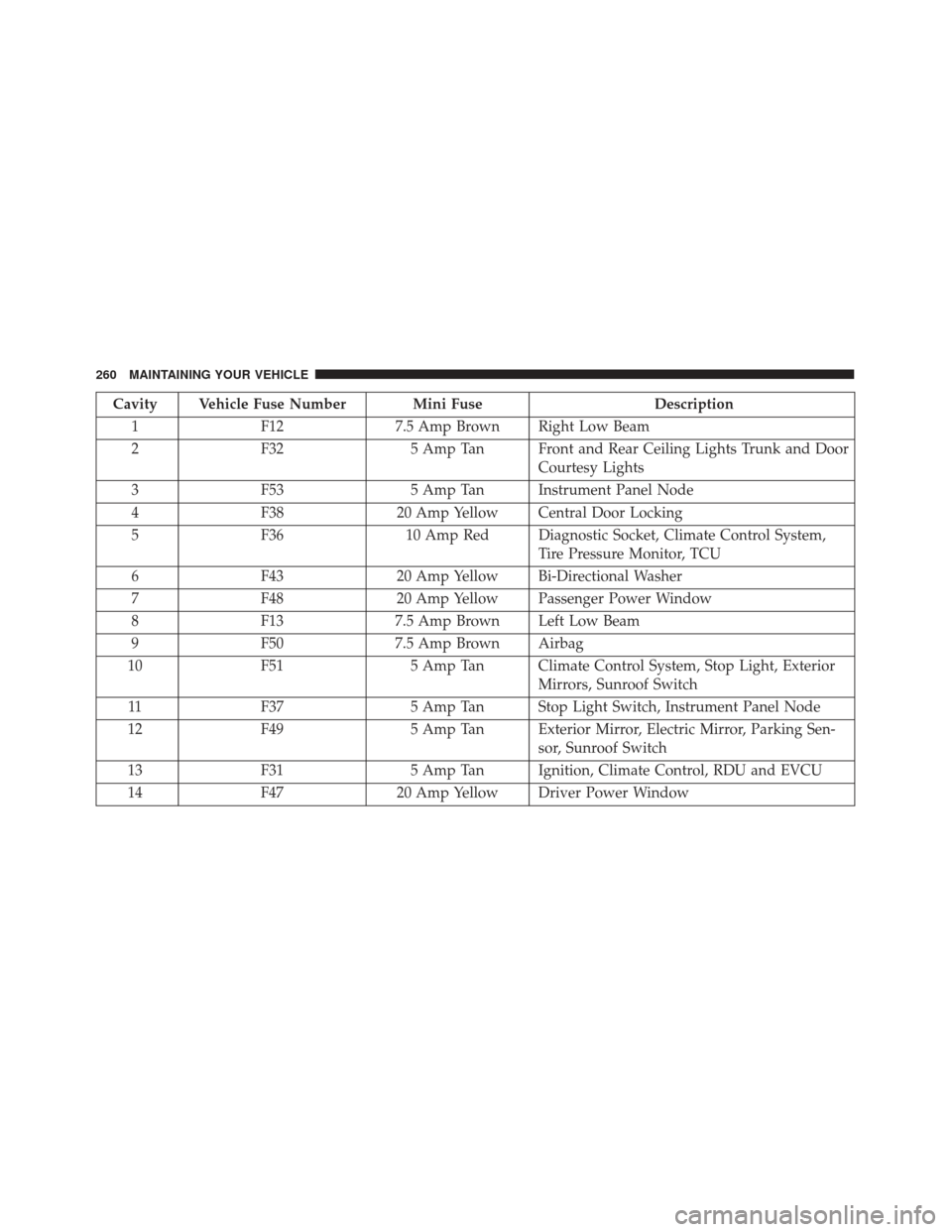

Cavity Vehicle Fuse Number Mini FuseDescription

1 F12 7.5 Amp Brown Right Low Beam

2 F32 5 Amp Tan Front and Rear Ceiling Lights Trunk and Door

Courtesy Lights

3 F53 5 Amp Tan Instrument Panel Node

4 F38 20 Amp Yellow Central Door Locking

5 F36 10 Amp Red Diagnostic Socket, Climate Control System,

Tire Pressure Monitor, TCU

6 F43 20 Amp Yellow Bi-Directional Washer

7 F48 20 Amp Yellow Passenger Power Window

8 F13 7.5 Amp Brown Left Low Beam

9 F50 7.5 Amp Brown Airbag

10 F51 5 Amp Tan Climate Control System, Stop Light, Exterior

Mirrors, Sunroof Switch

11 F37 5 Amp Tan Stop Light Switch, Instrument Panel Node

12 F49 5 Amp Tan Exterior Mirror, Electric Mirror, Parking Sen-

sor, Sunroof Switch

13 F31 5 Amp Tan Ignition, Climate Control, RDU and EVCU

14 F47 20 Amp Yellow Driver Power Window

260 MAINTAINING YOUR VEHICLE

Page 264 of 300

Power Distribution Center #1

The Power Distribution Center #1 is located on the right

side of the underhood compartment. To access the

fuses, remove locking screw and slide cover off.The ID number of the electrical component correspond-

ing to each fuse can be found on the back of the cover.

Cavity

Maxi Fuse Mini Fuse Description

F01 60 Amp Blue –Body Control Module (BCM)

F02 20 Amp Yellow –Audio Amplifier

F03 20 Amp Yellow –Ignition Switch

F04 40 Amp Orange –Brake System Module Pump

F05 70 Amp Tan –Electric Power Steering (EPS)

Front Distribution Unit

262 MAINTAINING YOUR VEHICLE

Page 265 of 300

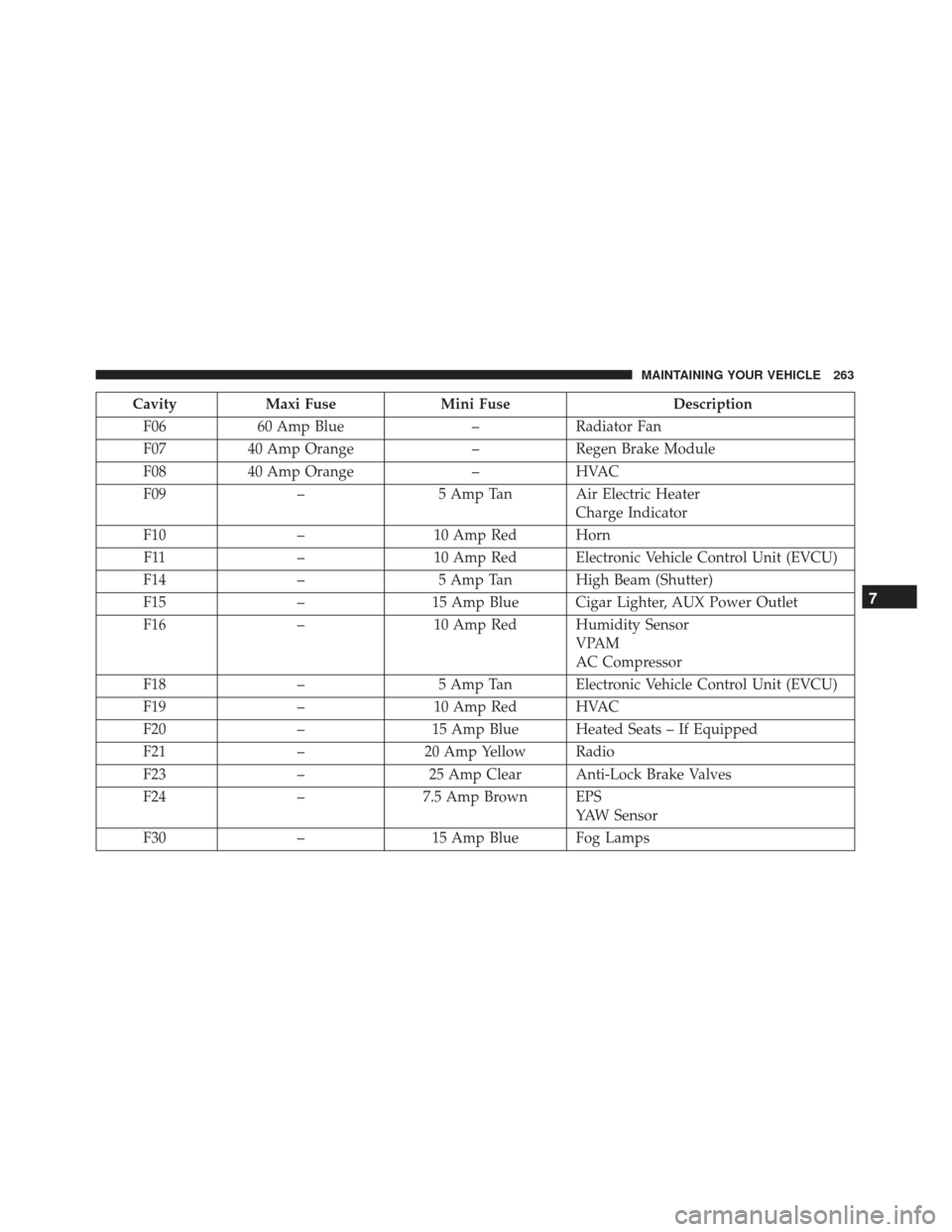

CavityMaxi Fuse Mini Fuse Description

F06 60 Amp Blue –Radiator Fan

F07 40 Amp Orange –Regen Brake Module

F08 40 Amp Orange –HVAC

F09 –5 Amp Tan Air Electric Heater

Charge Indicator

F10 –10 Amp Red Horn

F11 –10 Amp Red Electronic Vehicle Control Unit (EVCU)

F14 –5 Amp Tan High Beam (Shutter)

F15 –15 Amp Blue Cigar Lighter, AUX Power Outlet

F16 –10 Amp Red Humidity Sensor

VPAM

AC Compressor

F18 –5 Amp Tan Electronic Vehicle Control Unit (EVCU)

F19 –10 Amp Red HVAC

F20 –15 Amp Blue Heated Seats – If Equipped

F21 –20 Amp Yellow Radio

F23 –25 Amp Clear Anti-Lock Brake Valves

F24 –7.5 Amp Brown EPS

YAW Sensor

F30 –15 Amp Blue Fog Lamps

7

MAINTAINING YOUR VEHICLE 263

Page 269 of 300

Bulb Number

Center High Mounted Stop Lamp LED (See authorized dealer)

License Plate Lamps LED (See authorized dealer)

NOTE: Numbers refer to commercial bulb types that can be purchased from your authorized dealer.

If a bulb needs to be replaced, visit your authorized dealer or refer to the applicable Service Manual.

BULB REPLACEMENT

Interior Bulbs

Rear Cargo Lamp

1. Using a suitable tool open the light box.

2. Pull the bulb out.

3. Replace the bulb, and reinstall the light box cover.

Exterior Bulbs

NOTE: Lens fogging can occur under certain atmo-

spheric conditions. This will usually clear as atmo-

spheric conditions change to allow the condensation to

change back into a vapor. Turning the lamps on will

usually accelerate the clearing process.

Headlamps Low Beam And High Beam

1. Remove the plastic cap from the back of the head- lamp housing.

2. Rotate the bulb counter-clockwise.

3. Remove the bulb and replace as needed.

4. Install the bulb and rotate clockwise to lock in place.

5. Reinstall the plastic cap.

Front Turn Signal, Parking And Daytime

Running Lamps

1. Turn the steering wheel completely to the left or right.

2. Open the wheel housing access door.

7

MAINTAINING YOUR VEHICLE 267