run flat FIAT 500E 2018 Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2018, Model line: 500E, Model: FIAT 500E 2018Pages: 302, PDF Size: 3.32 MB

Page 114 of 302

seat belts. The Belt Alert feature is active whenever the

ignition switch is in the START or ON/RUN position.

Initial Indication

If the driver is unbuckled when the ignition switch is first

in the START or ON/RUN position, a chime will signal for

a few seconds. If the driver or outboard front seat passen-

ger (if equipped with outboard front passenger seat

BeltAlert) is unbuckled when the ignition switch is first in

the START or ON/RUN position the Seat Belt Reminder

Light will turn on and remain on until both outboard front

seat belts are buckled. The outboard front passenger seat

BeltAlert is not active when an outboard front passenger

seat is unoccupied.

BeltAlert Warning Sequence

The BeltAlert warning sequence is activated when the

vehicle is moving above a specified vehicle speed range

and the driver or outboard front seat passenger is unbuck-

led (if equipped with outboard front passenger seat

BeltAlert) (the outboard front passenger seat BeltAlert is

not active when the outboard front passenger seat is

unoccupied). The BeltAlert warning sequence starts by

blinking the Seat Belt Reminder Light and sounding an

intermittent chime. Once the BeltAlert warning sequence

has completed, the Seat Belt Reminder Light will remain onuntil the seat belts are buckled. The BeltAlert warning

sequence may repeat based on vehicle speed until the

driver and occupied outboard front seat passenger seat

belts are buckled. The driver should instruct all occupants

to buckle their seat belts.

Change of Status

If the driver or outboard front seat passenger (if equipped

with outboard front passenger seat BeltAlert) unbuckles

their seat belt while the vehicle is traveling, the BeltAlert

warning sequence will begin until the seat belts are buck-

led again.

The outboard front passenger seat BeltAlert is not active

when the outboard front passenger seat is unoccupied.

BeltAlert may be triggered when an animal or other items

are placed on the outboard front passenger seat or when

the seat is folded flat (if equipped). It is recommended that

pets be restrained in the rear seat (if equipped) in pet

harnesses or pet carriers that are secured by seat belts, and

cargo is properly stowed.

BeltAlert can be activated or deactivated by an authorized

dealer. FCA US LLC does not recommend deactivating

BeltAlert.

112 SAFETY

Page 123 of 302

•Instrument Panel

• Knee Impact Bolsters

• Driver and Front Passenger Air Bags

• Seat Belt Buckle Switch

• Supplemental Side Air Bags

• Supplemental Knee Air Bags

• Front and Side Impact Sensors

• Seat Belt Pretensioners

• Seat Track Position Sensors

Air Bag Warning Light

The ORC monitors the readiness of the electronic

parts of the air bag system whenever the ignition

switch is in the AVV/START or MAR/ACC/

ON/RUN position. If the ignition switch is in the

STOP/OFF/LOCK position the air bag system is not on

and the air bags will not inflate.

The ORC contains a backup power supply system that may

deploy the air bag system even if the battery loses power or

it becomes disconnected prior to deployment. The ORC turns on the Air Bag Warning Light in the

instrument panel for approximately four to eight seconds

for a self-check when the ignition switch is in the MAR/

ACC/ON/RUN position. After the self-check, the Air Bag

Warning Light will turn off. If the ORC detects a malfunc-

tion in any part of the system, it turns on the Air Bag

Warning Light, either momentarily or continuously. A

single chime will sound to alert you if the light comes on

again after initial startup.

The ORC also includes diagnostics that will illuminate the

instrument panel Air Bag Warning Light if a malfunction is

detected that could affect the air bag system. The diagnos-

tics also record the nature of the malfunction. While the air

bag system is designed to be maintenance free, if any of the

following occurs, have an authorized dealer service the air

bag system immediately.

•

The Air Bag Warning Light does not come on during the

four to eight seconds when the ignition switch is first in

the MAR/ACC/ON/RUN position.

• The Air Bag Warning Light remains on after the four to

eight-second interval.

• The Air Bag Warning Light comes on intermittently or

remains on while driving.

5

SAFETY 121

Page 133 of 302

•Electric power steering

• Brake booster

• Electric park brake

• Automatic transmission gear selector

• Horn

• Front wiper

• Headlamp washer pump

NOTE: After an accident, remember to cycle the ignition

to the STOP (OFF/LOCK) position and remove the key

from the ignition switch to avoid draining the battery.

Carefully check the vehicle for fuel leaks in the engine

compartment and on the ground near the engine compart-

ment and fuel tank before resetting the system and starting

the engine. If there are no fuel leaks or damage to the

vehicle electrical devices (e.g. headlights) after an accident,

reset the system by following the procedure described

below. If you have any doubt, contact an authorized dealer.

Enhanced Accident Response System Reset

Procedure

After an event occurs requiring activation of the Enhanced

Accident Response System, when the system is active, a

“Service Electrical System” message will be displayed on

the instrument cluster. The vehicle is not drivable in this state and must be towed to an authorized dealer immedi-

ately to be inspected and have the Enhanced Accident

Response System reset.

Maintaining Your Air Bag System

WARNING!

•

Modifications to any part of the air bag system could

cause it to fail when you need it. You could be

injured if the air bag system is not there to protect

you. Do not modify the components or wiring, in-

cluding adding any kind of badges or stickers to the

steering wheel hub trim cover or the upper passenger

side of the instrument panel. Do not modify the front

bumper, vehicle body structure, or add aftermarket

side steps or running boards.

• It is dangerous to try to repair any part of the air bag

system yourself. Be sure to tell anyone who works on

your vehicle that it has an air bag system.

• Do not attempt to modify any part of your air bag

system. The air bag may inflate accidentally or may

not function properly if modifications are made.

Take your vehicle to an authorized dealer for any air

bag system service. If your seat, including your trim

(Continued)

5

SAFETY 131

Page 176 of 302

WARNING!

Rapid acceleration on slippery surfaces is dangerous.

Unequal traction can cause sudden pulling of the front

wheels. You could lose control of the vehicle and

possibly have a collision. Accelerate slowly and care-

fully whenever there is likely to be poor traction (ice,

snow, wet, mud, loose sand, etc.).

Traction

When driving on wet or slushy roads, it is possible for a

wedge of water to build up between the tire and road

surface. This is hydroplaning and may cause partial or

complete loss of vehicle control and stopping ability. To

reduce this possibility, the following precautions should be

observed:

•Slow down during rainstorms or when the roads are

slushy.

• Slow down if the road has standing water or puddles.

• Replace the tires when tread wear indicators first be-

come visible.

• Keep tires properly inflated. •

Maintain sufficient distance between your vehicle and

the vehicle in front of you to avoid a collision in a

sudden stop.

Driving Through Water

Driving through water more than a few inches/centimeters

deep will require extra caution to ensure safety and pre-

vent damage to your vehicle.

Flowing/Rising Water

WARNING!

Do not drive on or across a road or path where water is

flowing and/or rising (as in storm run-off). Flowing

water can wear away the road or path’s surface and

cause your vehicle to sink into deeper water. Further-

more, flowing and/or rising water can carry your ve-

hicle away swiftly. Failure to follow this warning may

result in injuries that are serious or fatal to you, your

passengers, and others around you.

174 STARTING AND OPERATING

Page 196 of 302

2. Verify that the valve stem (on the wheel with thedeflated tire) is in a position that is near to the ground.

This will allow the Tire Service Kit Hoses (6) and (7) to

reach the valve stem and keep the Tire Service Kit flat on

the ground. This will provide the best positioning of the

kit when injecting the sealant into the deflated tire and

running the air pump. Move the vehicle as necessary to

place the valve stem in this position before proceeding.

3. Place the transmission in PARK (auto transmission) or in Gear (manual transmission) and place the ignition in the

OFF position.

4. Apply the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Push in the Mode Select Knob (5) and turn to the Sealant Mode position.

2. Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of the hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose (6) onto the valve

stem. 5. Uncoil the Power Plug (8) and insert the plug into the

vehicle’s 12 Volt power outlet.

NOTE: Do not remove foreign objects (e.g., screws or

nails) from the tire.

(C) Injecting Tire Service Kit Sealant Into The

Deflated Tire:

• Always start the vehicle before turning ON the Tire

Service Kit.

NOTE: Manual transmission vehicles must have the park-

ing brake engaged and the gear selector in NEUTRAL.

• After pushing the Power Button (4), the sealant (white

fluid) will flow from the Sealant Bottle (1) through the

Sealant Hose (6) and into the tire.

NOTE: Sealant may leak out through the puncture in the

tire.

If the sealant (white fluid) does not flow within0–10

seconds through the Sealant Hose (6):

1. Push the Power Button (4) to turn Off the Tire Service Kit. Disconnect the Sealant Hose (6) from the valve stem.

Make sure the valve stem is free of debris. Reconnect the

Sealant Hose (6) to the valve stem. Check that the Mode

194 IN CASE OF EMERGENCY

Page 197 of 302

Select Knob (5) is in the Sealant Mode position and not

Air Mode. Push the Power Button (4) to turn On the Tire

Service Kit.

2. Connect the Power Plug (8) to a different 12 Volt power outlet in your vehicle or another vehicle, if available.

Make sure the vehicle is running before turning ON the

Tire Service Kit.

3. The Sealant Bottle (1) may be empty due to previous use. Call for assistance.

NOTE: If the Mode Select Knob (5) is on Air Mode and the

pump is operating, air will dispense from the Air Pump

Hose (7) only, not the Sealant Hose (6).

If the sealant (white fluid) does flow through the Sealant

Hose (6):

1. Continue to operate the pump until sealant is no longer flowing through the hose (typically takes 30 - 70 sec-

onds). As the sealant flows through the Sealant Hose (6),

the Pressure Gauge (3) can read as high as 70 psi (4.8

Bar). The Pressure Gauge (3) will decrease quickly from

approximately 70 psi (4.8 Bar) to the actual tire pressure

when the Sealant Bottle (1) is empty. 2. The pump will start to inject air into the tire immedi-

ately after the Sealant Bottle (1) is empty. Continue to

operate the pump and inflate the tire to the pressure

indicated on the tire pressure label on the driver-side

latch pillar (recommended pressure). Check the tire

pressure by looking at the Pressure Gauge (3).

If the tire does not inflate to at least 26 psi (1.8 Bar)

pressure within 15 minutes:

• The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.

NOTE: If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recommended

inflation pressure before continuing.

If the tire inflates to the recommended pressure or is at

least 26 psi (1.8 Bar) pressure within 15 minutes:

1. Push the Power Button (4) to turn off the Tire Service Kit.

2. Remove the Speed Limit sticker from the top of the Sealant Bottle (1) and place the sticker on the instrument

panel.

7

IN CASE OF EMERGENCY 195

Page 204 of 302

2. Verify that the valve stem (on the wheel with thedeflated tire) is in a position that is near to the ground.

This will allow the Tire Service Kit Hoses (3) and (5) to

reach the valve stem and keep the Tire Service Kit flat on

the ground. This will provide the best positioning of the

kit when injecting the sealant into the deflated tire and

running the air pump. Move the vehicle as necessary to

place the valve stem in this position before proceeding.

3. Place the transmission in PARK (auto transmission) or in Gear (manual transmission) and place the ignition in the

OFF position.

4. Apply the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Push in the Mode Select Knob (2) and turn to the Sealant Mode position.

2. Uncoil the Sealant Hose (3) and then remove the cap from the fitting at the end of the hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose (3) onto the valve

stem. 5. Uncoil the Power Plug (7) and insert the plug into the

vehicle’s 12 Volt power outlet.

NOTE: Do not remove foreign objects (e.g., screws or

nails) from the tire.

(C) Injecting Tire Service Kit Sealant Into The

Deflated Tire:

• Always start the vehicle before turning ON the Tire

Service Kit.

NOTE: Manual transmission vehicles must have the park-

ing brake engaged and the gear selector in NEUTRAL.

• After pushing the Power Button (1), the sealant (white

fluid) will flow from the Sealant Bottle (4) through the

Sealant Hose (3) and into the tire.

NOTE: Sealant may leak out through the puncture in the

tire.

If the sealant (white fluid) does not flow within0–10

seconds through the Sealant Hose (3):

1. Push the Power Button (1) to turn Off the Tire Service Kit. Disconnect the Sealant Hose (3) from the valve stem.

Make sure the valve stem is free of debris. Reconnect the

Sealant Hose (3) to the valve stem. Check that the Mode

202 IN CASE OF EMERGENCY

Page 205 of 302

Select Knob (2) is in the Sealant Mode position and not

Air Mode. Push the Power Button (1) to turn On the Tire

Service Kit.

2. Connect the Power Plug (7) to a different 12 Volt power outlet in your vehicle or another vehicle, if available.

Make sure the vehicle is running before turning ON the

Tire Service Kit.

3. The Sealant Bottle (4) may be empty due to previous use. Call for assistance.

NOTE: If the Mode Select Knob (2) is on Air Mode and the

pump is operating, air will dispense from the Air Pump

Hose (5) only, not the Sealant Hose (3).

If the sealant (white fluid) does flow through the Sealant

Hose (3):

1. Continue to operate the pump until sealant is no longer flowing through the hose (typically takes 30 - 70 sec-

onds). As the sealant flows through the Sealant Hose (3),

the Pressure Gauge (8) can read as high as 70 psi

(4.8 Bar). The Pressure Gauge (8) will decrease quickly

from approximately 70 psi (4.8 Bar) to the actual tire

pressure when the Sealant Bottle (4) is empty. 2. The pump will start to inject air into the tire immedi-

ately after the Sealant Bottle (4) is empty. Continue to

operate the pump and inflate the tire to the pressure

indicated on the tire pressure label on the driver-side

latch pillar (recommended pressure). Check the tire

pressure by looking at the Pressure Gauge (8).

If the tire does not inflate to at least 26 psi (1.8 Bar)

pressure within 15 minutes:

• The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.

NOTE: If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recommended

inflation pressure before continuing.

If the tire inflates to the recommended pressure or is at

least 26 psi (1.8 Bar) pressure within 15 minutes:

1. Push the Power Button (1) to turn off the Tire Service Kit.

2. Remove the Speed Limit sticker from the top of the Sealant Bottle (4) and place the sticker on the instrument

panel.

7

IN CASE OF EMERGENCY 203

Page 213 of 302

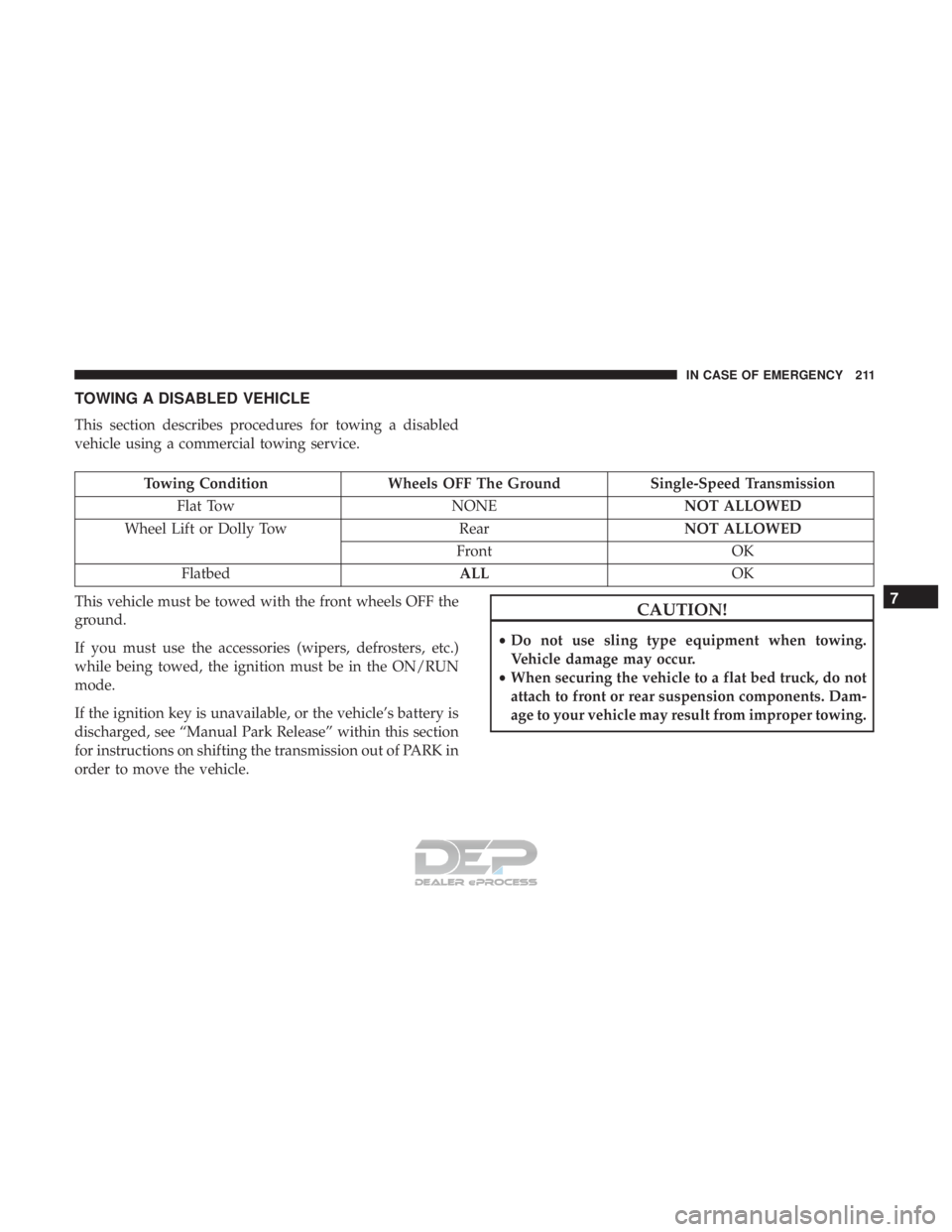

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled

vehicle using a commercial towing service.

Towing ConditionWheels OFF The Ground Single-Speed Transmission

Flat Tow NONENOT ALLOWED

Wheel Lift or Dolly Tow RearNOT ALLOWED

Front OK

Flatbed ALLOK

This vehicle must be towed with the front wheels OFF the

ground.

If you must use the accessories (wipers, defrosters, etc.)

while being towed, the ignition must be in the ON/RUN

mode.

If the ignition key is unavailable, or the vehicle’s battery is

discharged, see “Manual Park Release” within this section

for instructions on shifting the transmission out of PARK in

order to move the vehicle.

CAUTION!

• Do not use sling type equipment when towing.

Vehicle damage may occur.

• When securing the vehicle to a flat bed truck, do not

attach to front or rear suspension components. Dam-

age to your vehicle may result from improper towing.

7

IN CASE OF EMERGENCY 211

Page 240 of 302

pressure should be increased by 3 psi (21 kPa), which

equals 1 psi (7 kPa) for every 12°F (7°C) for this outside

temperature condition.

Tire pressure may increase from 2 to 6 psi (13 to 40 kPa)

during operation. DO NOT reduce this normal pressure

build up or your tire pressure will be too low.

Tire Pressures For High Speed Operation

The manufacturer advocates driving at safe speeds and

within posted speed limits. Where speed limits or condi-

tions are such that the vehicle can be driven at high speeds,

maintaining correct tire inflation pressure is very impor-

tant. Increased tire pressure and reduced vehicle loading

may be required for high-speed vehicle operation. Refer to

an authorized tire dealer or original equipment vehicle

dealer for recommended safe operating speeds, loading

and cold tire inflation pressures.

WARNING!

High speed driving with your vehicle under maximum

load is dangerous. The added strain on your tires could

cause them to fail. You could have a serious collision.

Do not drive a vehicle loaded to the maximum capacity

at continuous speeds above 75 mph (120 km/h).

Radial Ply Tires

WARNING!

Combining radial ply tires with other types of tires on

your vehicle will cause your vehicle to handle poorly.

The instability could cause a collision. Always use

radial ply tires in sets of four. Never combine them

with other types of tires.

Tire Repair

If your tire becomes damaged, it may be repaired if it meets

the following criteria:

• The tire has not been driven on when flat.

• The damage is only on the tread section of your tire

(sidewall damage is not repairable).

• The puncture is no greater thana¼ofaninch (6 mm).

Consult an authorized tire dealer for tire repairs and

additional information.

Damaged Run Flat tires, or Run Flat tires that have

experienced a loss of pressure should be replaced immedi-

ately with another Run Flat tire of identical size and service

description (Load Index and Speed Symbol).

238 SERVICING AND MAINTENANCE