trans FIAT 500L 2014 2.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2014, Model line: 500L, Model: FIAT 500L 2014 2.GPages: 116, PDF Size: 4.53 MB

Page 84 of 116

TIREFIT Usage Precautions

•Replace the TIREFIT Sealant Bottle (1) and Sealant Hose (6) prior to the expiration

date (printed on the bottle label) to assure optimum operation of the system.Refer to

“Sealing a Tire with TIREFIT” section (F) “Sealant Bottle and Hose Replacement.”

•The Sealant Bottle (1) and Sealant Hose (6) are a one tire application use.After each

use, always replace these components immediately at an authorized dealer.

•When the TIREFIT sealant is in a liquid form, clean water, and a damp cloth will re-

move the material from the vehicle or tire and wheel components.Once the sealant

dries, it can easily be peeled off and properly discarded.

•For optimum performance, make sure the valve stem on the wheel is free of debris

before connecting the TIREFIT kit.

•

You can use the TIREFIT air pump to inflate bicycle tires.The kit also comes with two

needles, located in the Accessory Storage Compartment (on the bottom of the air pump)

for inflating sport balls, rafts, or similar inflatable items.However, use only the Air Pump

Hose (7) and make sure the Mode Select Knob (5) is in the Air Mode when inflating such

items to avoid injecting sealant into them.The TIREFIT Sealant is only intended to seal

punctures less than 1/4” (6 mm) diameter in the tread of your vehicle.

•Do not lift or carry the TIREFIT kit by the hoses.

Sealing A Tire With TIREFIT

(A) Whenever You Stop To Use TIREFIT:

1.Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2.Verify that the valve stem (on the wheel with the deflated tire) is in a position that is

near to the ground.This will allow the TIREFIT Hoses (6) and (7) to reach the valve

stem and keep the TIREFIT kit flat on the ground.This will provide the best position-

ing of the kit when injecting the sealant into the deflated tire and running the air

pump.Move the vehicle as necessary to place the valve stem in this position before

proceeding.

3.Place the transmission in PARK (auto transmission) or in Gear (manual transmission)

and cycle the ignition to the OFF position.

4.Set the parking brake.

(B) Setting Up To Use TIREFIT:

1.Turn the Mode Select Knob (5) to the Sealant Mode position.

2.Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of

the hose.

3.Place the TIREFIT kit flat on the ground next to the deflated tire.

4.Remove the cap from the valve stem and then screw the fitting at the end of the

Sealant Hose (6) onto the valve stem.

5.Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

6.Do not remove foreign objects (e.g., screws or nails) from the tire.

WHAT TO DO IN EMERGENCIES

82

Page 85 of 116

(C) Injecting TIREFIT Sealant Into The Deflated Tire:

Always start the engine before turning ON the TIREFIT kit.

NOTE:

Manual transmission vehicles must have the parking brake engaged and the shift lever in

NEUTRAL.

After pressing the Power Button (4), the sealant (white fluid) will flow from the Sealant

Bottle (1) through the Sealant Hose (6) and into the tire.

NOTE:

Sealant may leak out through the puncture in the tire.

If the sealant (white fluid) does not flow within0–10seconds through the Sealant Hose

(6):

1.Press the Power Button (4) to turn Off the TIREFIT kit.Disconnect the Sealant Hose

(6) from the valve stem.Make sure the valve stem is free of debris.Reconnect the

Sealant Hose (6) to the valve stem.Check that the Mode Select Knob (5) is in the

Sealant Mode position and not Air Mode.Press the Power Button (4) to turn On the

TIREFIT kit.

2.Connect the Power Plug (8) to a different 12 Volt power outlet in your vehicle or

another vehicle, if available.Make sure the engine is running before turning ON the

TIREFIT kit.

3.The Sealant Bottle (1) may be empty due to previous use.Call for assistance.

NOTE:

If the Mode Select Knob (5) is on Air Mode and the pump is operating, air will dispense

from the Air Pump Hose (7) only, not the Sealant Hose (6).

If the sealant (white fluid) does flow through the Sealant Hose (6):

1.Continue to operate the pump until sealant is no longer flowing through the hose

(typically takes 30 - 70 seconds).As the sealant flows through the Sealant Hose (6),

the Pressure Gauge (3) can read as high as 70 psi (4.8 Bar).The Pressure Gauge (3)

will decrease quickly from approximately 70 psi (4.8 Bar) to the actual tire pressure

when the Sealant Bottle (1) is empty.

2.The pump will start to inject air into the tire immediately after the Sealant Bottle (1)

is empty.Continue to operate the pump and inflate the tire to the pressure indicated

on the tire pressure label on the driver-side latch pillar (recommended pressure).

Check the tire pressure by looking at the Pressure Gauge (3).

WHAT TO DO IN EMERGENCIES

83

Page 89 of 116

Preparations For Jump-Start

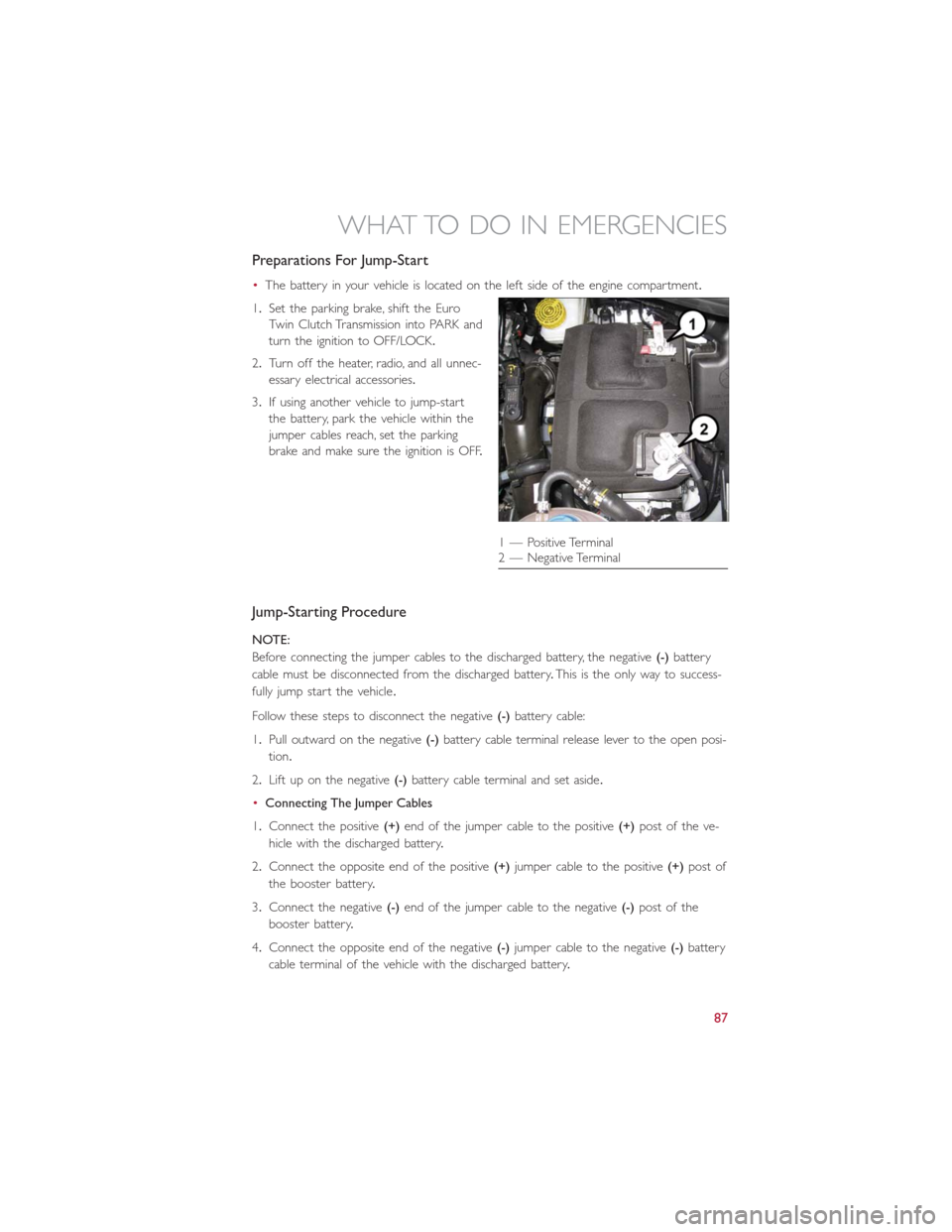

•The battery in your vehicle is located on the left side of the engine compartment.

1.Set the parking brake, shift the Euro

Twin Clutch Transmission into PARK and

turn the ignition to OFF/LOCK.

2.Turn off the heater, radio, and all unnec-

essary electrical accessories.

3.If using another vehicle to jump-start

the battery, park the vehicle within the

jumper cables reach, set the parking

brake and make sure the ignition is OFF.

Jump-Starting Procedure

NOTE:

Before connecting the jumper cables to the discharged battery, the negative(-)battery

cable must be disconnected from the discharged battery.This is the only way to success-

fully jump start the vehicle.

Follow these steps to disconnect the negative(-)battery cable:

1.Pull outward on the negative(-)battery cable terminal release lever to the open posi-

tion.

2.Lift up on the negative(-)battery cable terminal and set aside.

•Connecting The Jumper Cables

1.Connect the positive(+)end of the jumper cable to the positive(+)post of the ve-

hicle with the discharged battery.

2.Connect the opposite end of the positive(+)jumper cable to the positive(+)post of

the booster battery.

3.Connect the negative(-)end of the jumper cable to the negative(-)post of the

booster battery.

4.Connect the opposite end of the negative(-)jumper cable to the negative(-)battery

cable terminal of the vehicle with the discharged battery.

1 — Positive Terminal

2 — Negative Terminal

WHAT TO DO IN EMERGENCIES

87

Page 92 of 116

TOWING A DISABLED VEHICLE

With Ignition Key

Euro Twin Clutch Transmission

•Vehicle can be towed with the front wheels elevated.

•Vehicle can be towed on a flatbed truck (all wheels off the ground).

Manual Transmission

•Vehicle can be flat towed (all four wheels on the ground) with the transmission in

NEUTRAL.

•Vehicle can be towed with the front wheels elevated.

•Vehicle can be towed on a flatbed truck (all wheels off the ground).

NOTE:

If it is necessary to use the accessories while being towed (wipers, defrosters, etc.),

the key must be in the ON/RUN position.Make certain the transmission remains in

NEUTRAL.

All Transmissions

•If it is necessary to use the accessories while being towed (wipers, defrosters, etc.),

the key must be in the ON/RUN position.Make certain the transmission remains in

NEUTRAL.

Without The Ignition Key

•Special care must be taken when the vehicle is towed with the ignition in the OFF/

LOCK position.A dolly should be used under the front wheels if the rear wheels are

raised.Proper towing equipment is necessary to prevent damage to the vehicle.

•Battery power is required to release the brake/transmission interlock system (Euro

Twin Clutch Transmission only).There is a removable plug in the right side of the shift

lever housing that allows you to override the system.Refer to Shift Lever Override in

this guide.

CAUTION!

•Failure to follow these towing methods can cause severe transmission damage.

Such damage is not covered by the New Vehicle Limited Warranty.

•DO NOT flat tow any vehicle equipped with a Euro Twin Clutch Transmission.

Damage to the drivetrain will result.

•If the vehicle being towed requires steering, the ignition switch must be in the

ON/RUN position.

•Do not attempt to use sling-type equipment when towing.When securing the

vehicle to a flatbed truck, do not attach to front or rear suspension components.

Damage to your vehicle may result from improper towing.

WHAT TO DO IN EMERGENCIES

90

Page 93 of 116

FREEING A STUCK VEHICLE

•If your vehicle becomes stuck in mud, sand or snow, it can often be moved by a rock-

ing motion.Turn your steering wheel right and left to clear the area around the front

wheels.Then shift back and forth between DRIVE/2nd gear and REVERSE.Using mini-

mal accelerator pedal pressure to maintain the rocking motion, without spinning the

wheels, is most effective.

NOTE:

If your vehicle is equipped with Traction Control or Electronic Stability Control (ESC),

turn the system OFF before attempting to “rock” the vehicle.

CAUTION!

•Racing the engine or spinning the wheels may lead to transmission overheating and

failure.Allow the engine to idle with the shift lever in NEUTRAL for at least one

minute after every five rocking-motion cycles.This will minimize overheating and

reduce the risk of transmission failure during prolonged efforts to free a stuck

vehicle.

•When “rocking” a stuck vehicle by moving between DRIVE/2nd and REVERSE,

do not spin the wheels faster than 15 mph (24 km/h), or drivetrain damage may

result.

•Revving the engine or spinning the wheels too fast may lead to transmission over-

heating and failure.It can also damage the tires.Do not spin the wheels above

30 mph (48 km/h) while in gear (no transmission shifting occurring).

WARNING!

Fast spinning tires can be dangerous.Forces generated by excessive wheel speeds may

cause damage, or even failure, of the axle and tires.A tire could explode and injure

someone.Do not spin your vehicle's wheels faster than 30 mph (48 km/h) or for

longer than 30 seconds continuously without stopping when you are stuck and do not

let anyone near a spinning wheel, no matter what the speed.

WHAT TO DO IN EMERGENCIES

91

Page 97 of 116

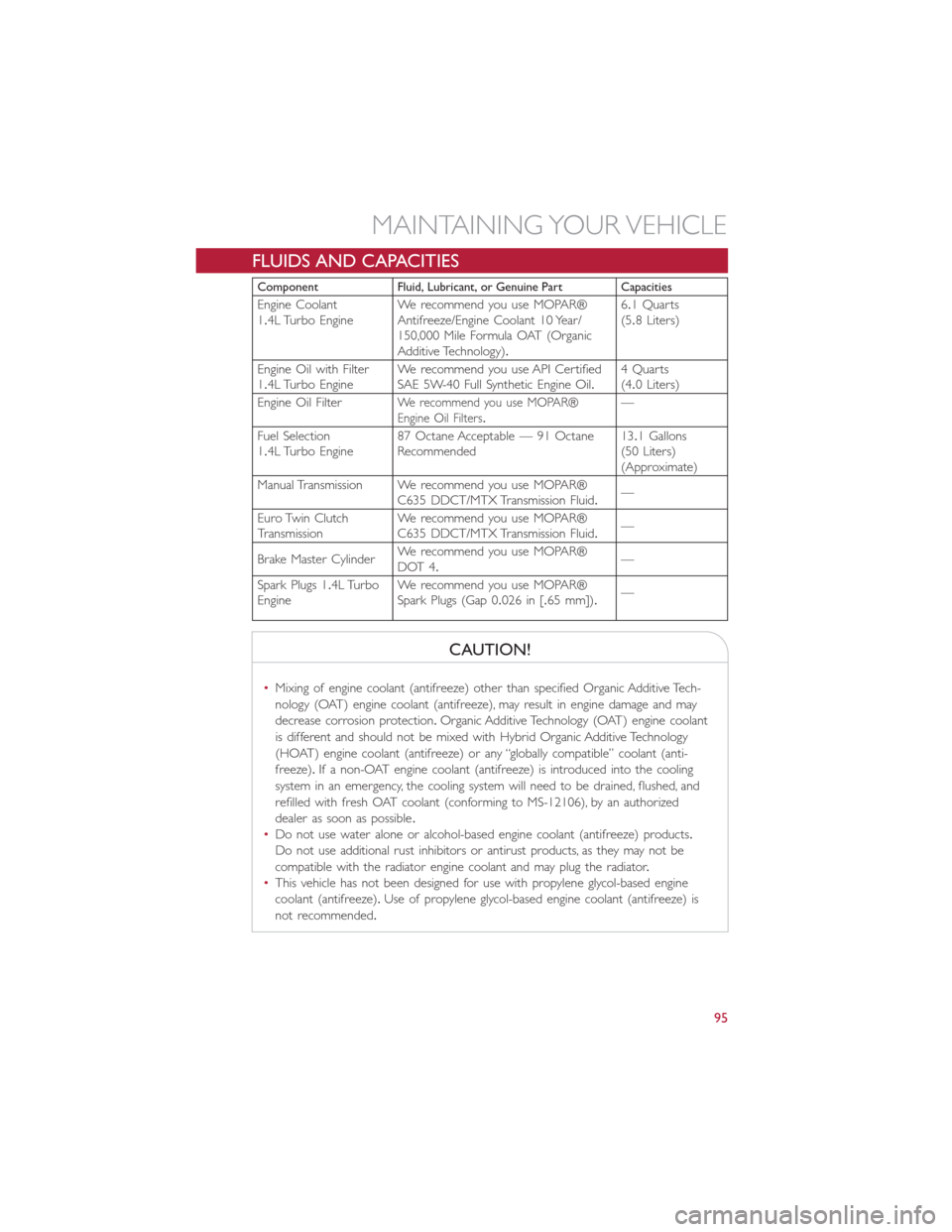

FLUIDS AND CAPACITIES

Component Fluid, Lubricant, or Genuine Part Capacities

Engine Coolant

1.4L Turbo EngineWe recommend you use MOPAR®

Antifreeze/Engine Coolant 10 Year/

150,000 Mile Formula OAT (Organic

Additive Technology).6.1 Quarts

(5.8 Liters)

Engine Oil with Filter

1.4L Turbo EngineWe recommend you use API Certified

SAE 5W-40 Full Synthetic Engine Oil.4 Quarts

(4.0 Liters)

Engine Oil Filter

We recommend you use MOPAR®

Engine Oil Filters.—

Fuel Selection

1.4L Turbo Engine87 Octane Acceptable — 91 Octane

Recommended13.1 Gallons

(50 Liters)

(Approximate)

Manual Transmission We recommend you use MOPAR®

C635 DDCT/MTX Transmission Fluid.—

Euro Twin Clutch

TransmissionWe recommend you use MOPAR®

C635 DDCT/MTX Transmission Fluid.—

Brake Master CylinderWe recommend you use MOPAR®

DOT 4.—

Spark Plugs 1.4L Turbo

EngineWe recommend you use MOPAR®

Spark Plugs (Gap 0.026 in [.65 mm]).—

CAUTION!

•Mixing of engine coolant (antifreeze) other than specified Organic Additive Tech-

nology (OAT) engine coolant (antifreeze), may result in engine damage and may

decrease corrosion protection.Organic Additive Technology (OAT) engine coolant

is different and should not be mixed with Hybrid Organic Additive Technology

(HOAT) engine coolant (antifreeze) or any “globally compatible” coolant (anti-

freeze).If a non-OAT engine coolant (antifreeze) is introduced into the cooling

system in an emergency, the cooling system will need to be drained, flushed, and

refilled with fresh OAT coolant (conforming to MS-12106), by an authorized

dealer as soon as possible.

•Do not use water alone or alcohol-based engine coolant (antifreeze) products.

Do not use additional rust inhibitors or antirust products, as they may not be

compatible with the radiator engine coolant and may plug the radiator.

•This vehicle has not been designed for use with propylene glycol-based engine

coolant (antifreeze).Use of propylene glycol-based engine coolant (antifreeze) is

not recommended.

MAINTAINING YOUR VEHICLE

95

Page 98 of 116

MAINTENANCE SCHEDULE

Your vehicle is equipped with an automatic oil change indicator system.The oil change

indicator system will remind you that it is time to take your vehicle in for scheduled

maintenance.

Based on engine operation conditions, the oil change indicator message will illuminate in

the instrument cluster.This means that service is required for your vehicle.Operating

conditions such as frequent short-trips, trailer tow and extremely hot or cold ambient

temperatures will influence when the “Change Oil” or “Oil Change Required” message is

displayed.Severe Operating Conditions can cause the change oil message to illuminate as

early as 3,500 miles (5,600 km) since last reset.Have your vehicle serviced as soon as

possible, within the next 500 miles (805 km).

Your authorized dealer will reset the oil change indicator message after completing the

scheduled oil change.If a scheduled oil change is performed by someone other than your

authorized dealer, the message can be reset by referring to the steps described under

“Electronic Vehicle Information Center (EVIC)” in “Understanding Your Instrument Panel”

in your Owners Manual on the DVD for further information.

NOTE:

Under no circumstances should oil change intervals exceed 10,000 miles (16,000 km) or

twelve months, whichever comes first.

Severe Duty All Models

Change Engine Oil at 4000 miles (6,500 km) if the vehicle is operated in a dusty and off

road environment.This type of vehicle use is considered Severe Duty

Once A Month Or Before A Long Trip:

•Check engine oil level

•Check windshield washer fluid level

•Check the tire inflation pressures and look for unusual wear or damage

•Check the fluid levels of the coolant reservoir, brake master cylinder reservoir, and

transmission as needed

•Check function of all interior and exterior lights

MAINTAINING YOUR VEHICLE

96

Page 102 of 116

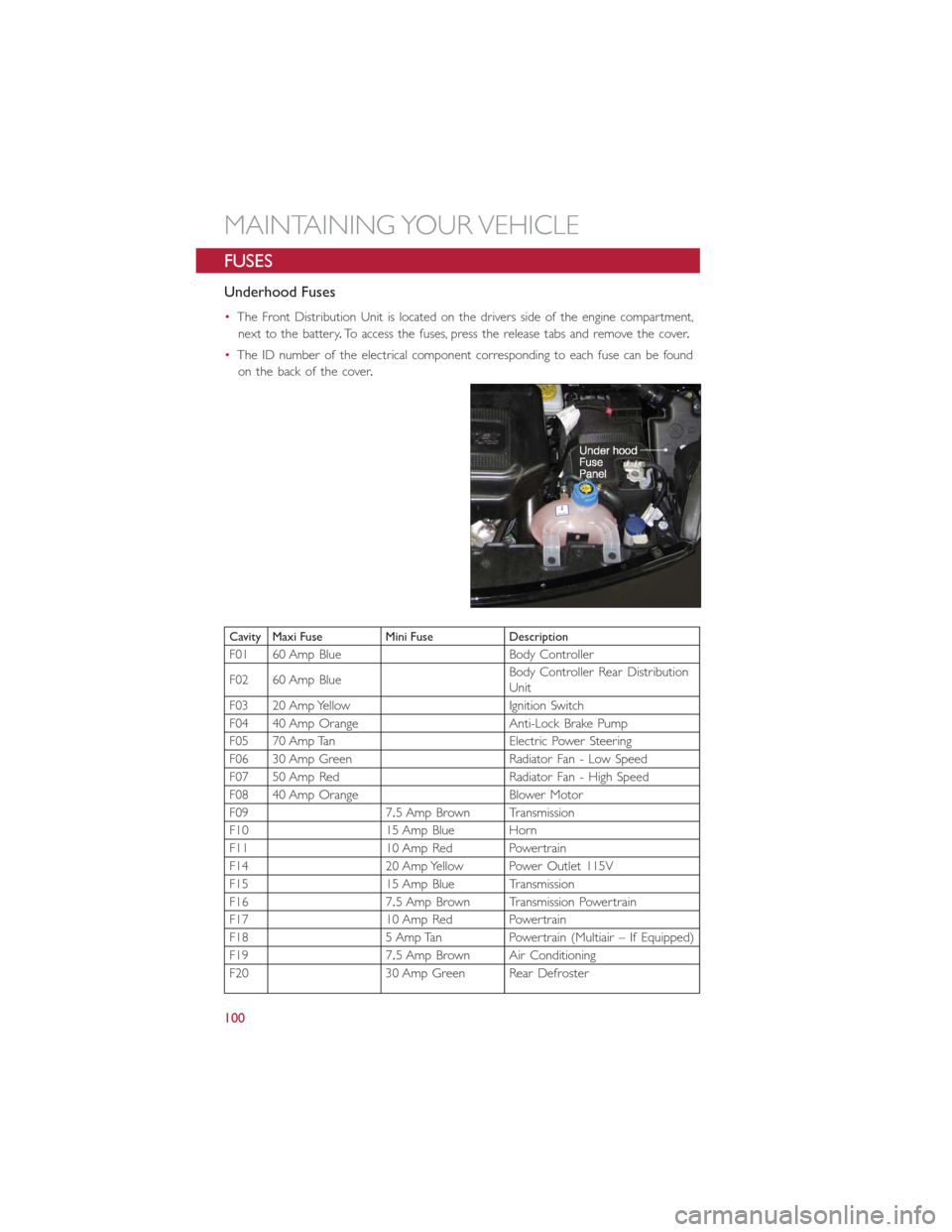

FUSES

Underhood Fuses

•The Front Distribution Unit is located on the drivers side of the engine compartment,

next to the battery.To access the fuses, press the release tabs and remove the cover.

•The ID number of the electrical component corresponding to each fuse can be found

on the back of the cover.

Cavity Maxi Fuse Mini Fuse Description

F01 60 Amp Blue Body Controller

F02 60 Amp BlueBody Controller Rear Distribution

Unit

F03 20 Amp Yellow Ignition Switch

F04 40 Amp Orange Anti-Lock Brake Pump

F05 70 Amp Tan Electric Power Steering

F06 30 Amp Green Radiator Fan - Low Speed

F07 50 Amp Red Radiator Fan - High Speed

F08 40 Amp Orange Blower Motor

F09 7.5 Amp Brown Transmission

F10 15 Amp Blue Horn

F11 10 Amp Red Powertrain

F14 20 Amp Yellow Power Outlet 115V

F15 15 Amp Blue Transmission

F16 7.5 Amp Brown Transmission Powertrain

F17 10 Amp Red Powertrain

F18 5 Amp Tan Powertrain (Multiair – If Equipped)

F19 7.5 Amp Brown Air Conditioning

F20 30 Amp Green Rear Defroster

MAINTAINING YOUR VEHICLE

100

Page 103 of 116

Cavity Maxi Fuse Mini Fuse Description

F21 15 Amp Blue Fuel Pump

F23 20 Amp Yellow Anti-Lock Brake Valves

F24 7.5 Amp Brown Stability Control System

F30 5 Amp Tan After Run Pump

F81 70 Amp Tan PTC (Secondary)

F82 40 Amp Orange Transmission

F83 40 Amp Orange PTC (Primary)

F84 7.5 Amp Brown Transmission

F85 15 Amp Blue Front Power Outlet 12V

F86 15 Amp Blue Rear Power Outlet 12V

F88 7.5 Amp Brown Heated Mirrors

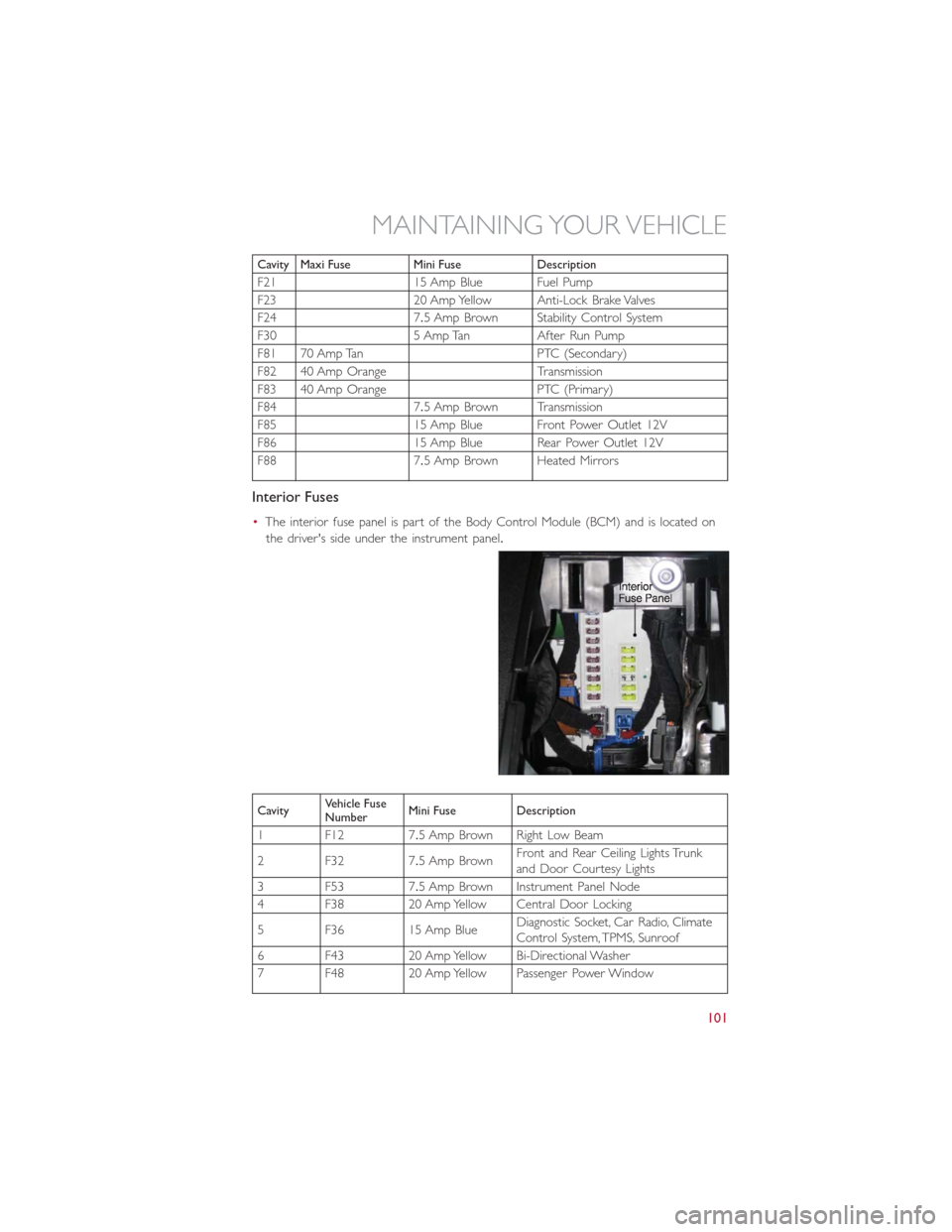

Interior Fuses

•The interior fuse panel is part of the Body Control Module (BCM) and is located on

the driver's side under the instrument panel.

CavityVehicle Fuse

NumberMini Fuse Description

1 F12 7.5 Amp Brown Right Low Beam

2 F32 7.5 Amp BrownFront and Rear Ceiling Lights Trunk

and Door Courtesy Lights

3 F53 7.5 Amp Brown Instrument Panel Node

4 F38 20 Amp Yellow Central Door Locking

5 F36 15 Amp BlueDiagnostic Socket, Car Radio, Climate

Control System, TPMS, Sunroof

6 F43 20 Amp Yellow Bi-Directional Washer

7 F48 20 Amp Yellow Passenger Power Window

MAINTAINING YOUR VEHICLE

101

Page 108 of 116

REPORTING SAFETY DEFECTS IN THE UNITED STATES

If you believe that your vehicle has a defect that could cause a collision or cause injury or

death, you should immediately inform the National Highway Traffic Safety Administration

(NHTSA) in addition to notifying the manufacturer.

If NHTSA receives similar complaints, it may open an investigation, and if it finds that a

safety defect exists in a group of vehicles, it may order a recall and remedy campaign.

However, NHTSA cannot become involved in individual problems between you, your

authorized dealer and the manufacturer.

To contact NHTSA, you may either call the Auto Safety Hotline toll free at

1–888–327–4236 (TTY: 1–800–424–9153), or go to http://www.safercar.gov; or

write to: Administrator, NHTSA, 1200 New Jersey Avenue, SE., West Building,

Washington, D.C.20590.You can also obtain other information about motor vehicle

safety from http://www.safercar.gov.

In Canada

If you believe that your vehicle has a safety defect, you should contact the Customer

Service Department immediately.Canadian customers who wish to report a safety defect

to the Canadian government should contact Transport Canada, Motor Vehicle Defect

Investigations and Recalls at 1-800-333-0510 or go to http://www.tc.gc.ca/eng/roadsafety/

safedrivers-childsafety-index-53.htm

French Canadian customers who wish to report a safety defect to the Canadian govern-

ment should contact Transport Canada, Motor Vehicle Defect Investigations and Recalls at

1-800-333-0510 or go to http://www.tc.gc.ca/securiteroutiere/

CONSUMER ASSISTANCE

106