service FIAT 500L 2015 2.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: 500L, Model: FIAT 500L 2015 2.GPages: 148, PDF Size: 3.77 MB

Page 94 of 148

ROADSIDE ASSISTANCE

•If your FIAT 500L requires jump start assistance, out of gas/fuel delivery, tire service,

lockout service or towing due to a defect covered under the Basic Limited Warranty,

dial toll-free 1-888-242-6342 or 1-800-363-4869 for Canadian Residents.See your

Warranty booklet for further details.

•Provide your name, vehicle identification number and license plate number.

•Provide your location, including telephone number, from which you are calling.

•Briefly describe the nature of the problem and answer a few simple questions.

•You will be given the name of the service provider and an estimated time of arrival.If

you feel you are in an “unsafe situation,” please let us know.With your consent, we will

contact local police or safety authorities.

INSTRUMENT CLUSTER WARNING LIGHTS

- Low Fuel Warning Light

This warning light indicates when the fuel level reaches approximately 2.0 gal (7.8 L).This

light will turn on and a single chime will sound.

Charging System Light

This light shows the status of the electrical charging system.If the charging system light

remains on, it means that the vehicle is experiencing a problem with the charging system.

We recommend you do not continue driving if the charging system light is on.Have the

vehicle serviced immediately.

Oil Pressure Warning Light

This light indicates low engine oil pressure.If the light turns on while driving, stop the

vehicle and shut off the engine as soon as possible.A chime will sound when this light

turns on.

We recommend you do not operate the vehicle or engine damage will occur.Have the

vehicle serviced immediately.

Anti-Lock Brake (ABS) Light

This light monitors the Anti-Lock Brake System (ABS).

If the light is not on during starting, stays on or turns on while driving, we recommend

you contact the nearest authorized dealer and have the vehicle serviced immediately.

Air Bag Warning Light

If the light is not on during starting, stays on, or turns on while driving, have the vehicle

serviced by an authorized dealer immediately.

WHAT TO DO IN EMERGENCIES

92

Page 96 of 148

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels.TPMS pres-

sures and warning have been established for the tire size equipped on your vehicle.

Undesirable system operation or sensor damage may result when using replacement

equipment that is not of the same size, type, and/or style.Aftermarket wheels can cause

sensor damage.Do not use tire sealant from a can, or balance beads if your vehicle is

equipped with a TPMS, as damage to the sensors may result.

- Engine Temperature Warning Light

This light warns of an overheated engine condition.

If the light turns on or flashes continuously while driving, safely pull over and stop the

vehicle.If the A/C system is on, turn it off.Also, shift the transmission into NEUTRAL and

idle the vehicle.If the temperature reading does not return to normal, turn the engine

off immediately.

We recommend that you do not operate the vehicle or engine damage will occur.Have

the vehicle serviced immediately.

WARNING!

A hot engine cooling system is dangerous.You or others could be badly burned by

steam or boiling coolant.

- Seat Belt Reminder Light

When the ignition switch is first turned to the ON/RUN position, this light will turn on

for four to eight seconds as a bulb check.During the bulb check, if the driver's seat belt

is unbuckled, a chime will sound.After the bulb check or when driving, if the driver or

front passenger seat belt remains unbuckled, the Seat Belt Indicator Light will flash or

remain on continuously.Refer to “Seat Belt Systems” in “Things To Know Before Starting”

in your Owner’s Manual on the DVD for further information.

Brake Warning Light

This light monitors various brake functions, including brake fluid level and parking brake

application.If the brake light turns on, it may indicate that the parking brake is applied,

that the brake fluid level is low, or that there is a problem with the anti-lock brake sys-

tem reservoir.

If the light remains on when the parking brake has been disengaged, and the fluid level is

at the full mark on the master cylinder reservoir, it indicates a possible brake hydraulic

system malfunction or that a problem with the Brake Booster has been detected by the

WHAT TO DO IN EMERGENCIES

94

Page 97 of 148

Anti-Lock Brake System (ABS)/Electronic Stability Control (ESC) system.In this case, the

light will remain on until the condition has been corrected.If the problem is related to

the brake booster, the ABS pump will run when applying the brake, and a brake pedal

pulsation may be felt during each stop.

The dual brake system provides a reserve braking capacity in the event of a failure to a

portion of the hydraulic system.A leak in either half of the dual brake system is indicated

by the Brake Warning Light, which will turn on when the brake fluid level in the master

cylinder has dropped below a specified level.The light will remain on until the cause is

corrected.

Vehicles equipped with the Anti-Lock Brake System (ABS) are also equipped with Elec-

tronic Brake Force Distribution (EBD).In the event of an EBD failure, the Brake Warning

Light will turn on along with the ABS Light.Immediate repair to the ABS system is re-

quired.

Operation of the Brake Warning Light can be checked by turning the ignition switch from

the OFF position to the ON/RUN position.The light should illuminate for approximately

two seconds.The light should then turn off unless the parking brake is applied or a brake

fault is detected.If the light does not illuminate, have the light inspected by an authorized

dealer.

The light also will turn on when the parking brake is applied with the ignition switch in

the ON/RUN position.

NOTE:

This light shows only that the parking brake is applied.It does not show the degree of

brake application.

WARNING!

Driving a vehicle with the red brake light on is dangerous.Part of the brake system

may have failed.It will take longer to stop the vehicle.You could have a collision.Have

the vehicle checked immediately.

- Malfunction Indicator Light (MIL)

Certain conditions, such as a loose or missing gas cap, poor fuel quality, etc., may illumi-

nate the MIL after engine start.The vehicle should be serviced if the light stays on

through several typical driving cycles.In most situations, the vehicle will drive normally and

not require towing.

If the MIL flashes when the engine is running, serious conditions may exist that could lead

to immediate loss of power or severe catalytic converter damage.We recommend you

do not operate the vehicle.Have the vehicle serviced immediately.

WHAT TO DO IN EMERGENCIES

95

Page 98 of 148

- Electronic Stability Control (ESC) Activation / Malfunction

Indicator Light

The “ESC Activation/Malfunction Indicator Light” in the instrument cluster will come on

for four seconds when the ignition switch is turned to the ON/RUN position.If the “ESC

Activation/Malfunction Indicator Light” comes on continuously with the engine running, a

malfunction has been detected in the ESC system.If this light remains on, see your au-

thorized dealer as soon as possible to have the problem diagnosed and corrected.

NOTE:

•The “ESC Off Indicator Light” and the “ESC Activation/Malfunction Indicator Light”

come on momentarily each time the ignition switch is turned to ON/RUN.

•Each time the ignition is turned to ON/RUN, the ESC system will be ON even if it

was turned off previously.

•ESC Activation/Malfunction Light can blink during a ESC or TC intervention.

- Generic Warning Light

The Generic Warning Light will illuminate if any of the following conditions occur: Oil

Change Request, Engine Oil Pressure Sensor Failure, External Light Failure, Fuel Cut-Off

Not Available, Parking Sensor Failure, DST System Failure.

Electronic Throttle Control (ETC) Indicator Light

This light informs you of a problem with the system.

If a problem is detected, the light will come on while the engine is running.Cycle the

ignition when the vehicle has completely stopped and the shift lever is placed in the

PARK position; the light should turn off.

If the light remains lit with the engine running, your vehicle will usually be drivable.How-

ever, see an authorized dealer immediately.If the light is flashing when the engine is run-

ning, immediate service is required, and you may experience reduced performance, an

elevated/rough idle or engine stall, and your vehicle may require towing.

INSTRUMENT CLUSTER INDICATOR LIGHTS

Turn Signal Indicator

The arrows will flash with the exterior turn signals when the turn signal lever is oper-

ated.A tone will chime, and a EVIC message will appear if either turn signal is left on for

more than 1 mile (1.6 km).

NOTE:

If either indicator flashes at a rapid rate, check for a defective outside light bulb.

High Beam Indicator

Indicates that headlights are on high beam.

WHAT TO DO IN EMERGENCIES

96

Page 100 of 148

Change Engine Oil

•Your vehicle is equipped with an engine oil change indicator system.The “Change En-

gine Oil” message will flash in the EVIC display for approximately 10 seconds after a

single chime has sounded to indicate the next scheduled oil change interval.The engine

oil change indicator system is duty cycle based, which means the engine oil change in-

terval may fluctuate, dependent upon your personal driving style.

•Unless reset, this message will continue to display each time you turn the ignition

switch to the ON/RUN position.To turn off the message temporarily, press and re-

lease theMENUbutton.To reset the oil change indicator system (after performing the

scheduled maintenance), refer to the following procedure:

1.Turn the ignition switch to the ON position.(do not start the engine).

2.Fully depress the accelerator pedal slowly, three times within 10 seconds.

3.Turn the ignition switch to the OFF/LOCK position.

NOTE:

If the indicator message illuminates when you start the vehicle, the oil change indicator

system did not reset.If necessary, repeat this procedure.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can reduce the potential for overheating by taking

the appropriate action:

•On the highways — slow down.

•In city traffic — while stopped, shift transmission into NEUTRAL, but do not increase

engine idle speed.

NOTE:

There are steps that you can take to slow down an overheat condition:

•If your air conditioner (A/C) is on, turn it off.The A/C system adds heat to the engine

cooling system and turning the A/C off can help remove this heat.

•You can also turn the Temperature control to maximum heat, the Mode control to

floor and the Fan control to high.This allows the heater core to act as a supplement

to the radiator and aids in removing heat from the engine cooling system.

•If the temperature reading does not return to normal, turn the engine off immediately.

•We recommend that you do not operate the vehicle or engine damage will occur.

Have the vehicle serviced immediately.

WHAT TO DO IN EMERGENCIES

98

Page 101 of 148

CAUTION!

Driving with a hot cooling system could damage your vehicle.If the temperature gauge

reads hot, pull over and stop the vehicle.Idle the vehicle with the air conditioner

turned off until the pointer drops back into the normal range.If the pointer remains

on hot, turn the engine off immediately and call for service.

WARNING!

You or others can be badly burned by hot engine coolant (antifreeze) or steam from

your radiator.If you see or hear steam coming from under the hood, do not open the

hood until the radiator has had time to cool.Never try to open a cooling system pres-

sure cap when the radiator or coolant bottle is hot.

JACKING AND TIRE CHANGING

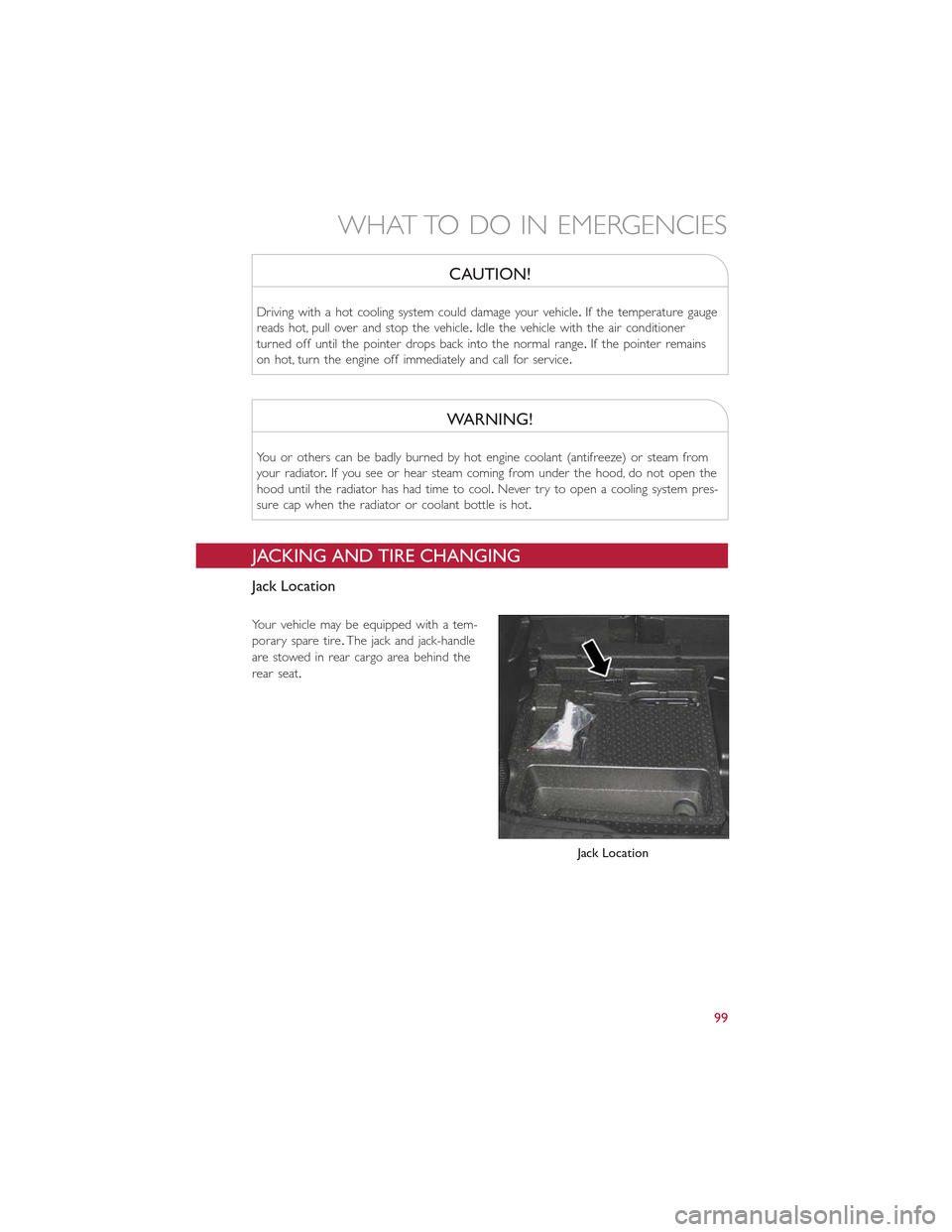

Jack Location

Your vehicle may be equipped with a tem-

porary spare tire.The jack and jack-handle

are stowed in rear cargo area behind the

rear seat.

Jack Location

WHAT TO DO IN EMERGENCIES

99

Page 106 of 148

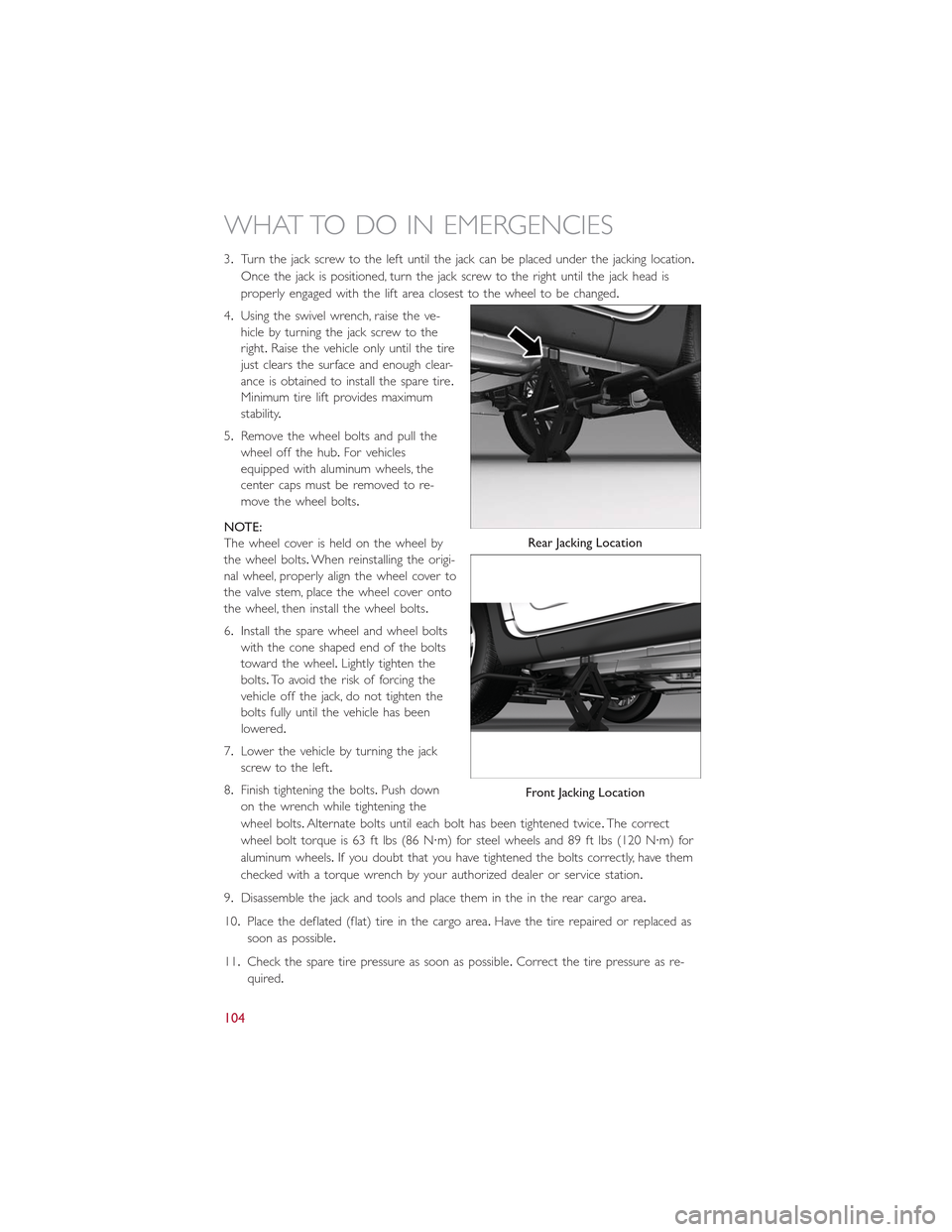

3.Turn the jack screw to the left until the jack can be placed under the jacking location.

Once the jack is positioned, turn the jack screw to the right until the jack head is

properly engaged with the lift area closest to the wheel to be changed.

4.Using the swivel wrench, raise the ve-

hicle by turning the jack screw to the

right.Raise the vehicle only until the tire

just clears the surface and enough clear-

ance is obtained to install the spare tire.

Minimum tire lift provides maximum

stability.

5.Remove the wheel bolts and pull the

wheel off the hub.For vehicles

equipped with aluminum wheels, the

center caps must be removed to re-

move the wheel bolts.

NOTE:

The wheel cover is held on the wheel by

the wheel bolts.When reinstalling the origi-

nal wheel, properly align the wheel cover to

the valve stem, place the wheel cover onto

the wheel, then install the wheel bolts.

6.Install the spare wheel and wheel bolts

with the cone shaped end of the bolts

toward the wheel.Lightly tighten the

bolts.To avoid the risk of forcing the

vehicle off the jack, do not tighten the

bolts fully until the vehicle has been

lowered.

7.Lower the vehicle by turning the jack

screw to the left.

8.Finish tightening the bolts.Push down

on the wrench while tightening the

wheel bolts.Alternate bolts until each bolt has been tightened twice.The correct

wheel bolt torque is 63 ft lbs (86 N·m) for steel wheels and 89 ft lbs (120 N·m) for

aluminum wheels.If you doubt that you have tightened the bolts correctly, have them

checked with a torque wrench by your authorized dealer or service station.

9.Disassemble the jack and tools and place them in the in the rear cargo area.

10.Place the deflated (flat) tire in the cargo area.Have the tire repaired or replaced as

soon as possible.

11.Check the spare tire pressure as soon as possible.Correct the tire pressure as re-

quired.

Rear Jacking Location

Front Jacking Location

WHAT TO DO IN EMERGENCIES

104

Page 108 of 148

WARNING!

•Do not attempt to change a tire on the side of the vehicle close to moving traffic.

Pull far enough off the road to avoid the danger of being hit when operating the

jack or changing the wheel.

•Being under a jacked-up vehicle is dangerous.The vehicle could slip off the jack

and fall on you.You could be crushed.Never put any part of your body under a

vehicle that is on a jack.

•Never start or run the engine while the vehicle is on a jack.if you need to get

under a raised vehicle, take it to a authorized dealer where it can be raised on a

lift.

•The jack is designed to use as a tool for changing tires only.The jack should not be

used to lift the vehicle for service purposes.The vehicle should be jacked on a

firm, level surface only.Avoid ice or slippery areas.

•After using the jack and tools, always reinstall them in the original carrier and loca-

tion.While driving you may experience abrupt stopping, rapid acceleration, or

sharp turns.A loose jack, tools, bracket or other objects in the vehicle may move

around with force, resulting in serious injury.

•Carefully follow these tire changing warnings to help prevent personal injury or

damage to your vehicle:

•Always park on a firm, level surface as far from the edge of the roadway as pos-

sible before raising the vehicle.

•Turn on the Hazard Warning flasher.

•Block the wheel diagonally opposite the wheel to be raised.

•Set the parking brake firmly and set an automatic transmission in PARK; a manual

transmission in REVERSE.

•Do not let anyone sit in the vehicle when it is on a jack.

•Do not get under the vehicle when it is on a jack.

•Only use the jack in the positions indicated and for lifting this vehicle during a tire

change.

•If working on or near a roadway, be extremely careful of motor traffic.

•To assure that spare tires, flat or inflated, are securely stowed, spares must be

stowed with the valve stem facing the ground.

•Raising the vehicle higher than necessary can make the vehicle unstable and cause

a collision.It could slip off the jack and hurt someone near it.Raise the vehicle

only enough to remove the tire.

•A loose tire or jack thrown forward in a collision or hard stop could injure some-

one in the vehicle.Always stow the jack parts and the extra tire and wheel in the

places provided.

WHAT TO DO IN EMERGENCIES

106

Page 109 of 148

TIRE SERVICE KIT

Your vehicle may be equipped with a Tire Service Kit.

Small punctures up to 1/4” (6 mm) in the tire tread can be sealed with the Tire Service

Kit.Foreign objects (e.g., screws or nails) should not be removed from the tire.The Tire

Service Kit can be used in outside temperatures down to approximately -4°F (-20°C).

This kit will provide a temporary tire seal, allowing you to drive your vehicle up to 100

miles (160 km) with a maximum speed of 55 mph (90 km/h).

Tire Service Kit Storage

The Tire Service Kit is located in the rear trunk area on the left side.

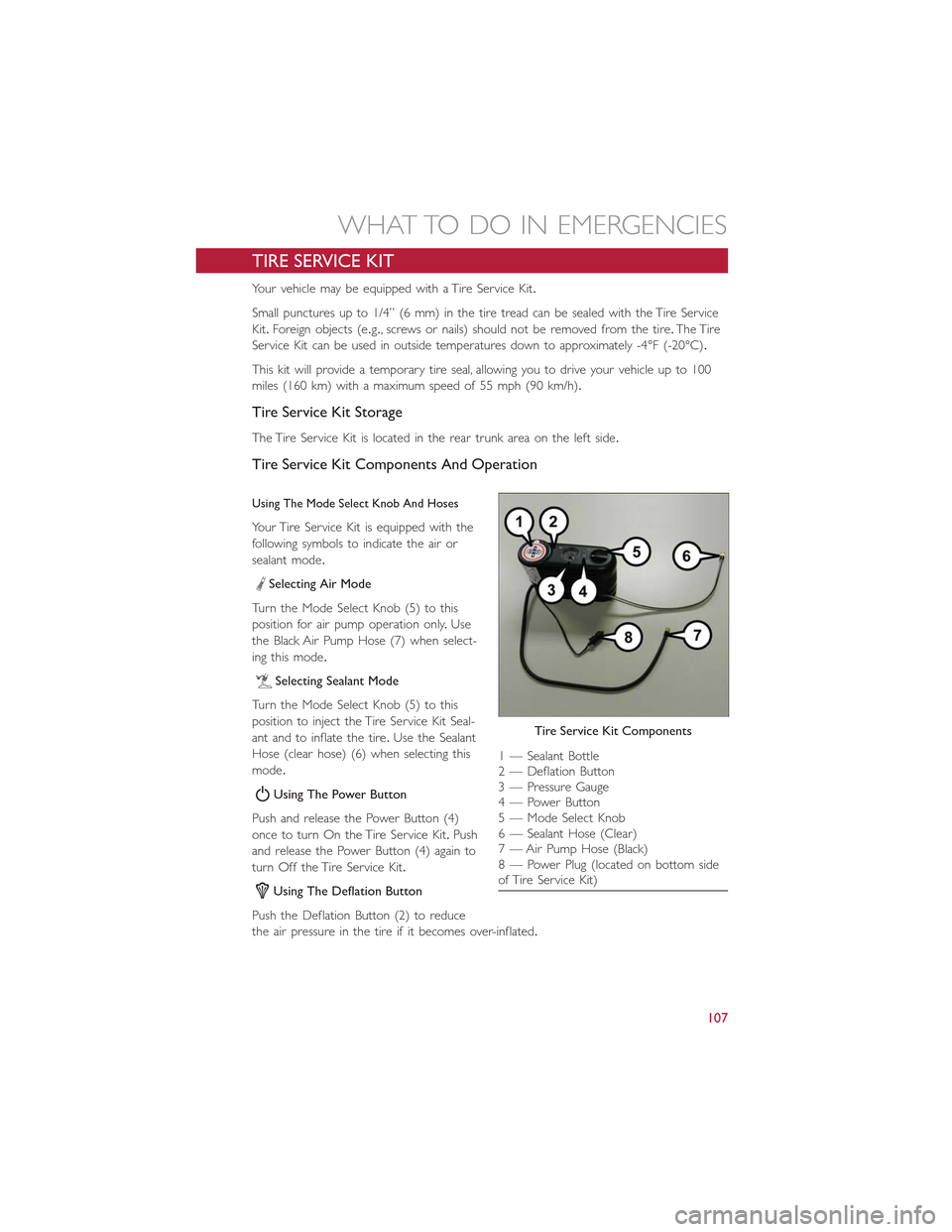

Tire Service Kit Components And Operation

Using The Mode Select Knob And Hoses

Your Tire Service Kit is equipped with the

following symbols to indicate the air or

sealant mode.

Selecting Air Mode

Turn the Mode Select Knob (5) to this

position for air pump operation only.Use

the Black Air Pump Hose (7) when select-

ing this mode.

Selecting Sealant Mode

Turn the Mode Select Knob (5) to this

position to inject the Tire Service Kit Seal-

ant and to inflate the tire.Use the Sealant

Hose (clear hose) (6) when selecting this

mode.

Using The Power Button

Push and release the Power Button (4)

once to turn On the Tire Service Kit.Push

and release the Power Button (4) again to

turn Off the Tire Service Kit.

Using The Deflation Button

Push the Deflation Button (2) to reduce

the air pressure in the tire if it becomes over-inflated.

Tire Service Kit Components

1 — Sealant Bottle2 — Deflation Button3 — Pressure Gauge4 — Power Button5 — Mode Select Knob6 — Sealant Hose (Clear)7 — Air Pump Hose (Black)8 — Power Plug (located on bottom sideof Tire Service Kit)

WHAT TO DO IN EMERGENCIES

107

Page 110 of 148

Tire Service Kit Usage Precautions

•Replace the Tire Service Kit Sealant Bottle (1) and Sealant Hose (6) prior to the expi-

ration date (printed on the bottle label) to assure optimum operation of the system.

Refer to “Sealing A Tire With Tire Service Kit” section (F) “Sealant Bottle and Hose

Replacement.”

•The Sealant Bottle (1) and Sealant Hose (6) are a one tire application use.After each

use, always replace these components immediately at an authorized dealer.

•When the Tire Service Kit sealant is in a liquid form, clean water, and a damp cloth will

remove the material from the vehicle or tire and wheel components.Once the sealant

dries, it can easily be peeled off and properly discarded.

•For optimum performance, make sure the valve stem on the wheel is free of debris

before connecting the Tire Service Kit.

•You can use the Tire Service Kit air pump to inflate bicycle tires.The kit also comes

with two needles, located in the Accessory Storage Compartment (on the bottom of

the air pump) for inflating sport balls, rafts, or similar inflatable items.However, use

only the Air Pump Hose (7) and make sure the Mode Select Knob (5) is in the Air

Mode when inflating such items to avoid injecting sealant into them.The Tire Service

Kit Sealant is only intended to seal punctures less than 1/4 inch (6 mm) diameter in

the tread of your vehicle.

•Do not lift or carry the Tire Service Kit by the hoses.

Sealing A Tire With Tire Service Kit

(A) Whenever You Stop To Use Tire Service Kit:

1.Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2.Verify that the valve stem (on the wheel with the deflated tire) is in a position that is

near to the ground.This will allow the Tire Service Kit Hoses (6) and (7) to reach the

valve stem and keep the Tire Service Kit flat on the ground.This will provide the best

positioning of the kit when injecting the sealant into the deflated tire and running the

air pump.Move the vehicle as necessary to place the valve stem in this position be-

fore proceeding.

3.Place the transmission in PARK (auto transmission) or in Gear (manual transmission)

and cycle the ignition to the OFF position.

4.Set the parking brake.

(B) Setting Up To Use Tire Service Kit:

1.Turn the Mode Select Knob (5) to the Sealant Mode position.

2.Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of

the hose.

3.Place the Tire Service Kit flat on the ground next to the deflated tire.

4.Remove the cap from the valve stem and then screw the fitting at the end of the

Sealant Hose (6) onto the valve stem.

WHAT TO DO IN EMERGENCIES

108