recommended oil FIAT 500L 2015 2.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: 500L, Model: FIAT 500L 2015 2.GPages: 148, PDF Size: 3.77 MB

Page 111 of 148

5.Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

6.Do not remove foreign objects (e.g., screws or nails) from the tire.

(C) Injecting Tire Service Kit Sealant Into The Deflated Tire:

Always start the engine before turning ON the Tire Service Kit.

NOTE:

Manual transmission vehicles must have the parking brake engaged and the shift lever in

NEUTRAL.

After pushing the Power Button (4), the sealant (white fluid) will flow from the Sealant

Bottle (1) through the Sealant Hose (6) and into the tire.

NOTE:

Sealant may leak out through the puncture in the tire.

If the sealant (white fluid) does not flow within 0 – 10seconds through the Sealant Hose

(6):

1.Push the Power Button (4) to turn Off the Tire Service Kit.Disconnect the Sealant

Hose (6) from the valve stem.Make sure the valve stem is free of debris.Reconnect

the Sealant Hose (6) to the valve stem.Check that the Mode Select Knob (5) is in

the Sealant Mode position and not Air Mode.Push the Power Button (4) to turn On

the Tire Service Kit.

2.Connect the Power Plug (8) to a different 12 Volt power outlet in your vehicle or

another vehicle, if available.Make sure the engine is running before turning ON the

Tire Service Kit.

3.The Sealant Bottle (1) may be empty due to previous use.Call for assistance.

NOTE:

If the Mode Select Knob (5) is on Air Mode and the pump is operating, air will dispense

from the Air Pump Hose (7) only, not the Sealant Hose (6).

If the sealant (white fluid) does flow through the Sealant Hose (6):

1.Continue to operate the pump until sealant is no longer flowing through the hose

(typically takes 30 - 70 seconds).As the sealant flows through the Sealant Hose (6),

the Pressure Gauge (3) can read as high as 70 psi (4.8 Bar).The Pressure Gauge (3)

will decrease quickly from approximately 70 psi (4.8 Bar) to the actual tire pressure

when the Sealant Bottle (1) is empty.

2.The pump will start to inject air into the tire immediately after the Sealant Bottle (1)

is empty.Continue to operate the pump and inflate the tire to the pressure indicated

on the tire pressure label on the driver-side latch pillar (recommended pressure).

Check the tire pressure by looking at the Pressure Gauge (3).

WHAT TO DO IN EMERGENCIES

109

Page 112 of 148

If the tire does not inflate to at least 26 psi (1.8 Bar) pressure within 15 minutes:

The tire is too badly damaged.Do not attempt to drive the vehicle further.Call for assis-

tance.

NOTE:

If the tire becomes over-inflated, push the Deflation Button to reduce the tire pressure

to the recommended inflation pressure before continuing.

If the tire inflates to the recommended pressure or is at least 26 psi (1.8 Bar) pressure

within 15 minutes:

1.Push the Power Button (4) to turn off the Tire Service Kit.

2.Remove the Speed Limit sticker from the top of the Sealant Bottle (1) and place the

sticker on the instrument panel.

3.Immediately disconnect the Sealant Hose (6) from the valve stem, reinstall the cap on

the fitting at the end of the hose, and place the Tire Service Kit in the vehicle storage

location.Quickly proceed to (D) “Drive Vehicle.”

(D) Drive Vehicle:

Immediately after injecting sealant and inflating the tire, drive the vehicle 5 miles (8 km)

or 10 minutes to ensure distribution of the Tire Service Kit Sealant within the tire.Do

not exceed 55 mph (88 km/h).

(E) After Driving:

Pull over to a safe location.Refer to “Whenever You Stop to Use Tire Service Kit” before

continuing.

1.Turn the Mode Select Knob (5) to the Air Mode position.

2.Uncoil the Air Pump Hose (7) (black in color) and screw the fitting at the end of

hose (7) onto the valve stem.

3.Uncoil the power plug and insert the plug into the vehicles 12 Volt power outlet.

4.Check the pressure in the tire by reading the Pressure Gauge (3).

If tire pressure is less than 19 psi (1.3 Bar), the tire is too badly damaged. Do not at-

tempt to drive the vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1.Push the Power Button (4) to turn on Tire Service Kit and inflate the tire to the pres-

sure indicated on the tire and loading information label on the driver-side door open-

ing.

2.Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve

stem and unplug from 12 Volt outlet.

3.Place the Tire Service Kit in its proper storage area in the vehicle.

4.Have the tire inspected and repaired or replaced at the earliest opportunity at an

authorized dealer or tire service center.

WHAT TO DO IN EMERGENCIES

110

Page 113 of 148

5.Remove the Speed Limit sticker from the instrument panel after the tire has been

repaired.

6.Replace the Sealant Bottle (1) and Sealant Hose (6) assembly at your authorized

dealer as soon as possible.Refer to “(F) Sealant Bottle and Hose Replacement.”

NOTE:

•If the tire becomes over-inflated, push the Deflation Button to reduce the tire pressure

to the recommended inflation pressure before continuing.

•When having the tire serviced, advise the authorized dealer or service center that the

tire has been sealed using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1.Uncoil the Sealant Hose (6) (clear in color).

2.Locate the round Sealant Bottle release button in the recessed area under the sealant

bottle.

3.Push the Sealant Bottle release button.The Sealant Bottle (1) will pop up.Remove the

bottle and dispose of it accordingly.

4.Clean any remaining sealant from the Tire Service Kit housing.

5.Position the new Sealant Bottle (1) in the housing so that the Sealant Hose (6) aligns

with the hose slot in the front of the housing.Push the bottle into the housing.An

audible click will be heard indicating the bottle is locked into place.

6.Verify that the cap is installed on the fitting at the end of the Sealant Hose (6) and

return the hose to its storage area (located on the bottom of the air pump).

7.Return the Tire Service Kit to its storage location in the vehicle.

NOTE:

•The metal end fitting from Power Plug (8) may get hot after use, so it should be

handled carefully.

•Failure to reinstall the cap on the fitting at the end of the Sealant Hose (6) can result

in sealant contacting your skin, clothing, and the vehicle’s interior.It can also result in

sealant contacting internal Tire Service Kit components which may cause permanent

damage to the kit.

WHAT TO DO IN EMERGENCIES

111

Page 126 of 148

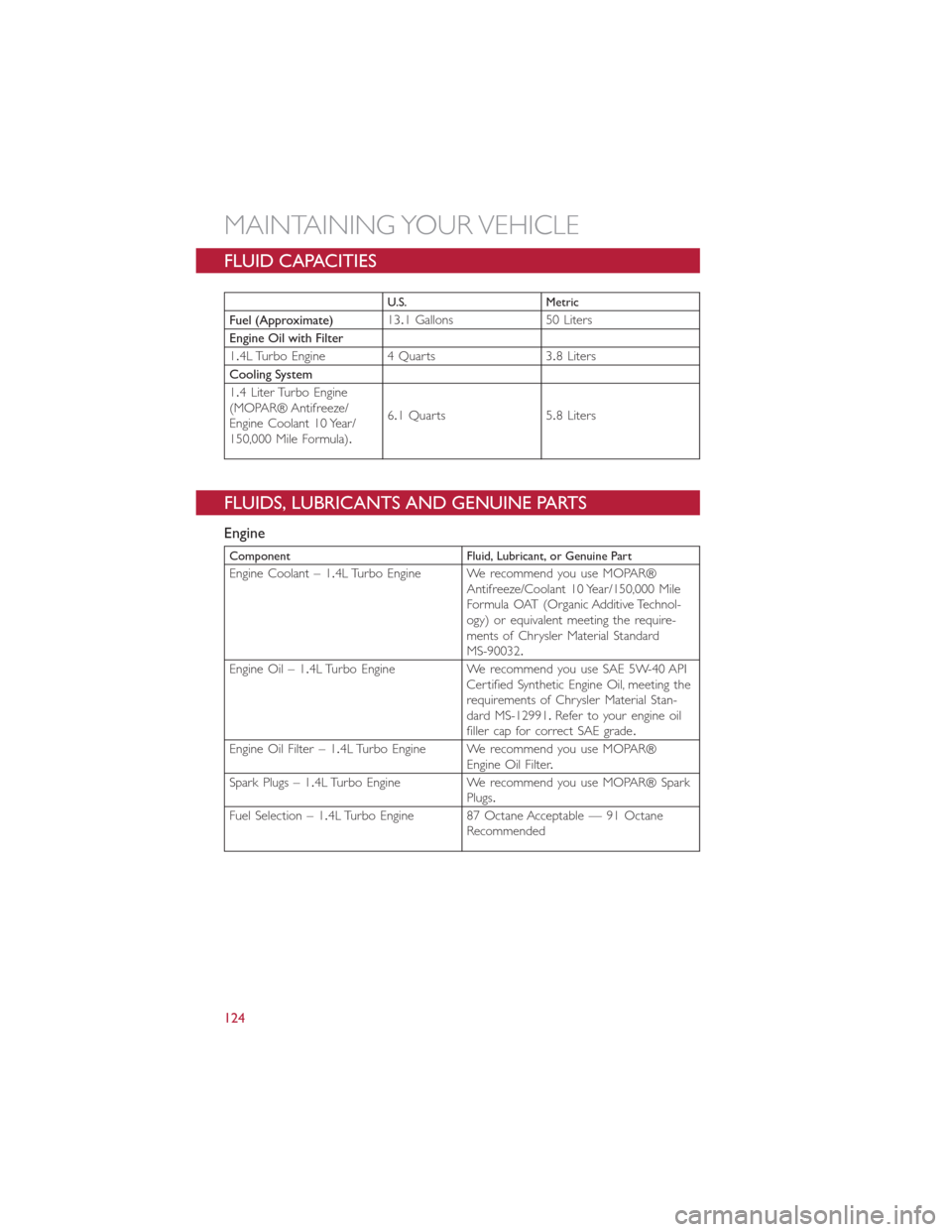

FLUID CAPACITIES

U.S. Metric

Fuel (Approximate)13.1 Gallons 50 Liters

Engine Oil with Filter

1.4L Turbo Engine 4 Quarts 3.8 Liters

Cooling System

1.4 Liter Turbo Engine(MOPAR® Antifreeze/Engine Coolant 10 Year/150,000 Mile Formula).

6.1Quarts 5.8 Liters

FLUIDS, LUBRICANTS AND GENUINE PARTS

Engine

Component Fluid, Lubricant, or Genuine Part

Engine Coolant – 1.4L Turbo Engine We recommend you use MOPAR®Antifreeze/Coolant 10 Year/150,000 MileFormula OAT (Organic Additive Technol-ogy) or equivalent meeting the require-ments of Chrysler Material StandardMS-90032.

Engine Oil – 1.4L Turbo Engine We recommend you use SAE 5W-40 APICertified Synthetic Engine Oil, meeting therequirements of Chrysler Material Stan-dard MS-12991.Refer to your engine oilfiller cap for correct SAE grade.

Engine Oil Filter – 1.4L Turbo Engine We recommend you use MOPAR®Engine Oil Filter.

Spark Plugs – 1.4L Turbo Engine We recommend you use MOPAR® SparkPlugs.

Fuel Selection – 1.4L Turbo Engine 87 Octane Acceptable — 91 OctaneRecommended

MAINTAINING YOUR VEHICLE

124

Page 127 of 148

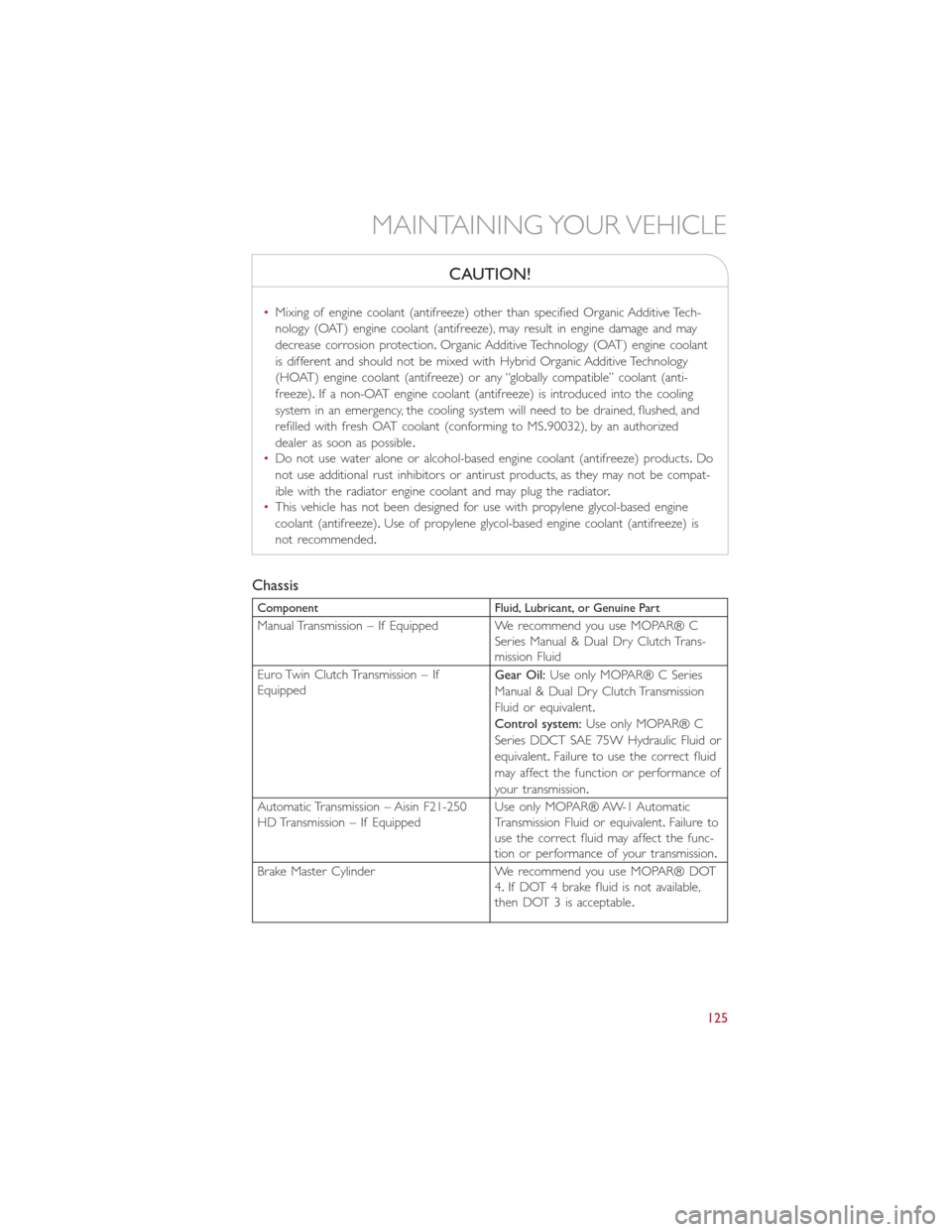

CAUTION!

•Mixing of engine coolant (antifreeze) other than specified Organic Additive Tech-

nology (OAT) engine coolant (antifreeze), may result in engine damage and may

decrease corrosion protection.Organic Additive Technology (OAT) engine coolant

is different and should not be mixed with Hybrid Organic Additive Technology

(HOAT) engine coolant (antifreeze) or any “globally compatible” coolant (anti-

freeze).If a non-OAT engine coolant (antifreeze) is introduced into the cooling

system in an emergency, the cooling system will need to be drained, flushed, and

refilled with fresh OAT coolant (conforming to MS.90032), by an authorized

dealer as soon as possible.

•Do not use water alone or alcohol-based engine coolant (antifreeze) products.Do

not use additional rust inhibitors or antirust products, as they may not be compat-

ible with the radiator engine coolant and may plug the radiator.

•This vehicle has not been designed for use with propylene glycol-based engine

coolant (antifreeze).Use of propylene glycol-based engine coolant (antifreeze) is

not recommended.

Chassis

Component Fluid, Lubricant, or Genuine Part

Manual Transmission – If Equipped We recommend you use MOPAR® CSeries Manual & Dual Dry Clutch Trans-mission Fluid

Euro Twin Clutch Transmission – IfEquippedGear Oil:Use only MOPAR® C Series

Manual & Dual Dry Clutch Transmission

Fluid or equivalent.

Control system:Use only MOPAR® C

Series DDCT SAE 75W Hydraulic Fluid or

equivalent.Failure to use the correct fluid

may affect the function or performance of

your transmission.

Automatic Transmission – Aisin F21-250HD Transmission – If EquippedUse only MOPAR® AW-1 AutomaticTransmission Fluid or equivalent.Failure touse the correct fluid may affect the func-tion or performance of your transmission.

Brake Master Cylinder We recommend you use MOPAR® DOT4.If DOT 4 brake fluid is not available,then DOT 3 is acceptable.

MAINTAINING YOUR VEHICLE

125