lock FIAT 500L 2017 2.G Manual PDF

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: 500L, Model: FIAT 500L 2017 2.GPages: 370, PDF Size: 3.56 MB

Page 286 of 370

NOTE:There are front and rear jacking locations on

each side of the body (as indicated by the traingular lift

point symbols on the sill molding).

4. Place the jack underneath the lift area that is closest to the flat tire. Turn the jack screw clockwise to firmly

engage the jack saddle with the lift area of the sill

flange, centering the jack saddle between the locating

notches on the sill flange.

5. Raise the vehicle just enough to remove the flat tire and install the spare tire.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

6. Remove the wheel bolts and tire.

7. Mount the spare tire.

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if

the spare tire is mounted incorrectly.

NOTE: •For vehicles so equipped, do not attempt to install

a center cap or wheel cover on the compact spare.

• Refer to “Compact Spare Tire” and to “Limited-Use

Spare” under “Tires—General Information” in

“Starting and Operating” for additional warnings,

cautions, and information about the spare tire, its

use, and operation.Rear Jacking Location

284 WHAT TO DO IN EMERGENCIES

Page 287 of 370

8. Install the wheel bolts with the threaded end of thewheel bolt toward the wheel. Lightly tighten the

wheel bolts.

WARNING!

•To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in personal injury.

• To avoid possible personal injury, handle the

wheel covers with care to avoid contact with any

sharp edges.

9. Lower the vehicle to the ground by turning the jack handle counterclockwise.

10. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened twice.

Refer to Torque Specifications in this section for

proper lug nut torque. If in doubt about the correct

tightness, have them checked with a torque wrench

by your authorized dealer or at a service station. 11. Stow the jack, tools and flat tire.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the

vehicle. Always stow the jack parts and the spare

tire in the places provided. Have the deflated (flat)

tire repaired or replaced immediately.

Spare Tire Stowage

Rotate the jack wrench tool on the winch drive nut

clockwise (the flat tire must not be connected to the

winch) until effort becomes heavy and an audible click

is heard indicating the winch is properly stowed.

Cover the flat tire with the Emergency Spare Tire Bag

and stow the flat tire into the trunk.

CAUTION!

The winch mechanism is designed for use with the

jack wrench extension tool only. Use of air wrench

or power tool may damage the winch.

6

WHAT TO DO IN EMERGENCIES 285

Page 295 of 370

If the ignition key is unavailable, or the battery is

discharged, refer to “Gear Selector Override” in this

section for instructions on shifting the transmission out

of PARK in order to move the vehicle.

CAUTION!

•DO NOT flat tow any vehicle equipped with an

automatic transmission. Damage to the drivetrain

will result. If these vehicles require towing, make

sure all drive wheels are OFF the ground.

• Towing this vehicle in violation of the above

requirements can cause severe transmission dam-

age. Damage from improper towing is not covered

under the New Vehicle Limited Warranty.

IGNITION KEY REMOVAL OVERRIDE

This vehicle is equipped with a Key Ignition Park

Interlock which requires the transmission to be in PARK

before the ignition switch can be turned to the LOCK/

OFF (key removal) position. To remove the key manu-

ally, proceed as follows:

1. Firmly apply the parking brake 2. Remove the Allen Key located in the rear cargo area,

in the tool bag (if equipped) or on the left side in the

cargo box.

3. Unlock the steering column, pull the tilt/telescoping control handle down.

4. Pull the steering wheel outward until it is in the end of the travel position, then lock the steering column

in position, push the control handle up until fully

engaged.

5. Using the Allen key, undo the lower steering column cover screws, and remove the lower cover.

Lower Steering Column Screw Locations

6

WHAT TO DO IN EMERGENCIES 293

Page 311 of 370

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should

be lubricated periodically with a lithium based grease,

such as MOPAR Spray White Lube to assure quiet, easy

operation and to protect against rust and wear. Prior to

the application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit; after

lubricating excess oil and grease should be removed.

Particular attention should also be given to hood latch-

ing components to ensure proper function. When per-

forming other underhood services, the hood latch,

release mechanism and safety catch should be cleaned

and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the Fall and Spring. Apply a small

amount of a high quality lubricant, such as MOPAR

Lock Cylinder Lubricant directly into the lock cylinder.

Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield and rear window periodically with a

sponge or soft cloth and a mild nonabrasive cleaner.

This will remove accumulations of salt, waxes, or road

film, and help reduce streaking and smearing.

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always

use washer fluid when using the wipers to remove salt

or dirt from a dry windshield or rear window.

Avoid using the wiper blades to remove frost or ice

from the windshield or rear window. Make sure that

they are not frozen to the glass before turning them on

to avoid damaging the blade. Keep the wiper blade out

of contact with petroleum products such as engine oil,

gasoline, etc.

NOTE:Life expectancy of wiper blades varies depend-

ing on geographical area and frequency of use. Poor

performance of blades may be present with chattering,

marks, water lines or wet spots. If any of these condi-

tions are present, clean the wiper blades or replace as

necessary.

7

MAINTAINING YOUR VEHICLE 309

Page 330 of 370

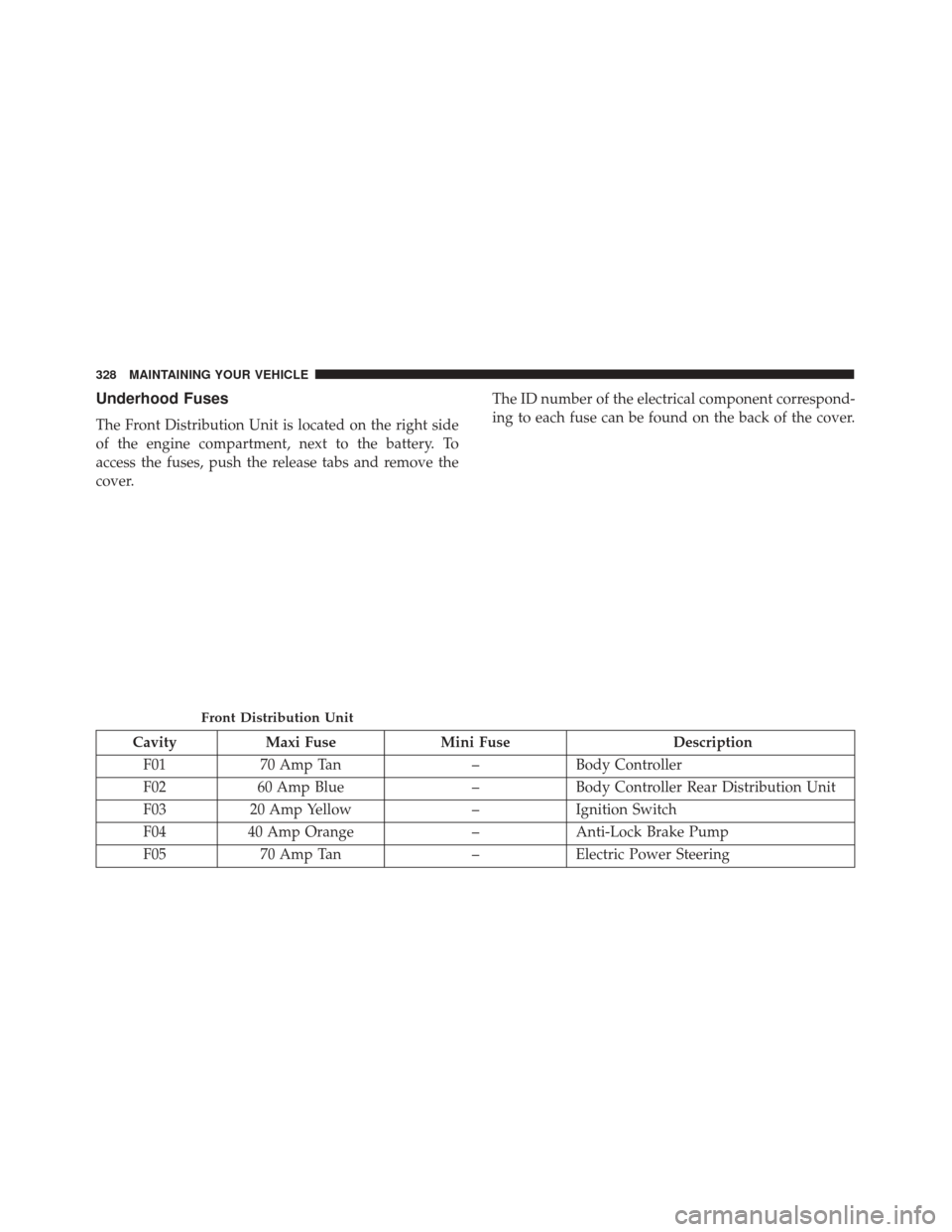

Underhood Fuses

The Front Distribution Unit is located on the right side

of the engine compartment, next to the battery. To

access the fuses, push the release tabs and remove the

cover.The ID number of the electrical component correspond-

ing to each fuse can be found on the back of the cover.

Cavity

Maxi Fuse Mini Fuse Description

F01 70 Amp Tan –Body Controller

F02 60 Amp Blue –Body Controller Rear Distribution Unit

F03 20 Amp Yellow –Ignition Switch

F04 40 Amp Orange –Anti-Lock Brake Pump

F05 70 Amp Tan –Electric Power Steering

Front Distribution Unit

328 MAINTAINING YOUR VEHICLE

Page 331 of 370

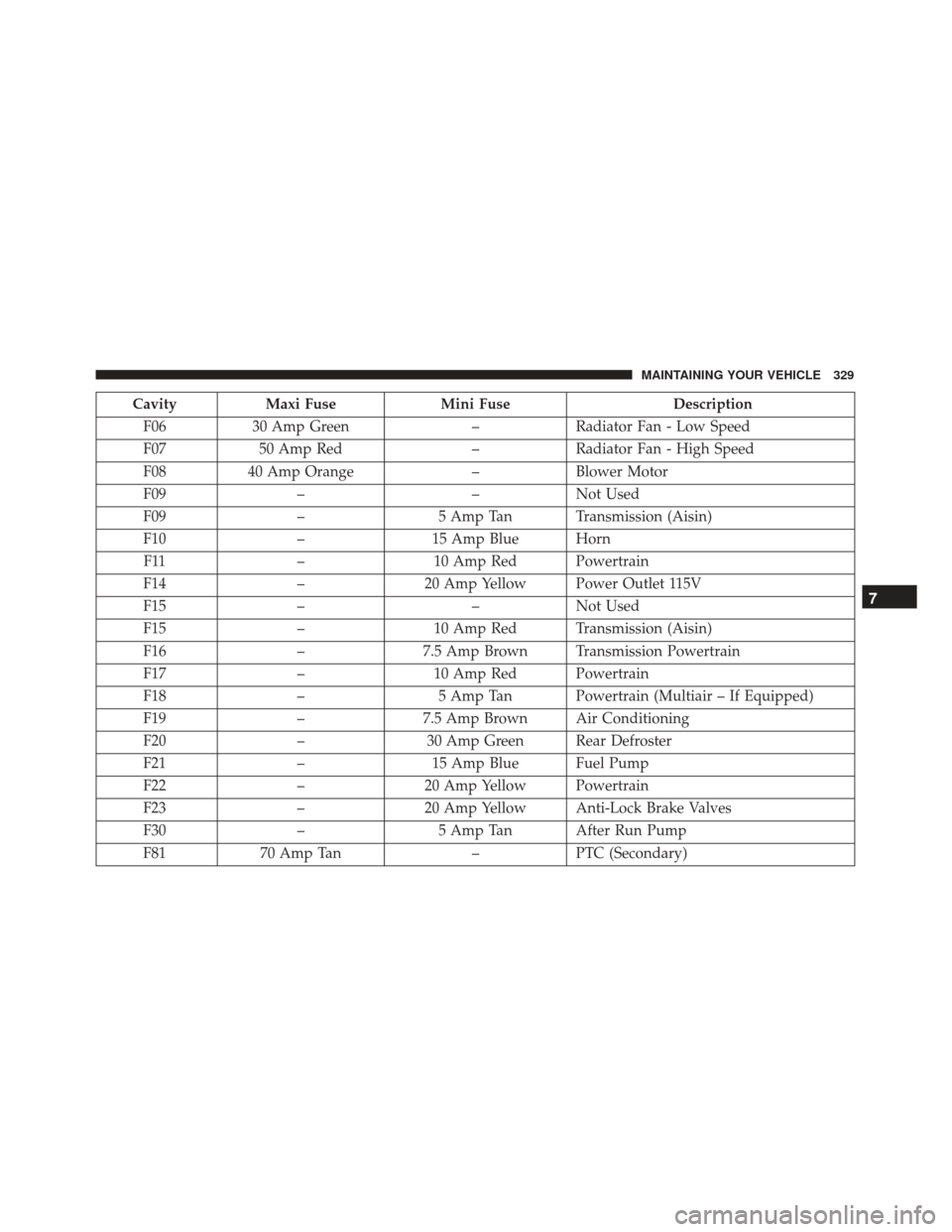

CavityMaxi Fuse Mini Fuse Description

F06 30 Amp Green –Radiator Fan - Low Speed

F07 50 Amp Red –Radiator Fan - High Speed

F08 40 Amp Orange –Blower Motor

F09 – –Not Used

F09 –5 Amp Tan Transmission (Aisin)

F10 –15 Amp Blue Horn

F11 –10 Amp Red Powertrain

F14 –20 Amp Yellow Power Outlet 115V

F15 – –Not Used

F15 –10 Amp Red Transmission (Aisin)

F16 –7.5 Amp Brown Transmission Powertrain

F17 –10 Amp Red Powertrain

F18 –5 Amp Tan Powertrain (Multiair – If Equipped)

F19 –7.5 Amp Brown Air Conditioning

F20 –30 Amp Green Rear Defroster

F21 –15 Amp Blue Fuel Pump

F22 –20 Amp Yellow Powertrain

F23 –20 Amp Yellow Anti-Lock Brake Valves

F30 –5 Amp Tan After Run Pump

F81 70 Amp Tan –PTC (Secondary)

7

MAINTAINING YOUR VEHICLE 329

Page 334 of 370

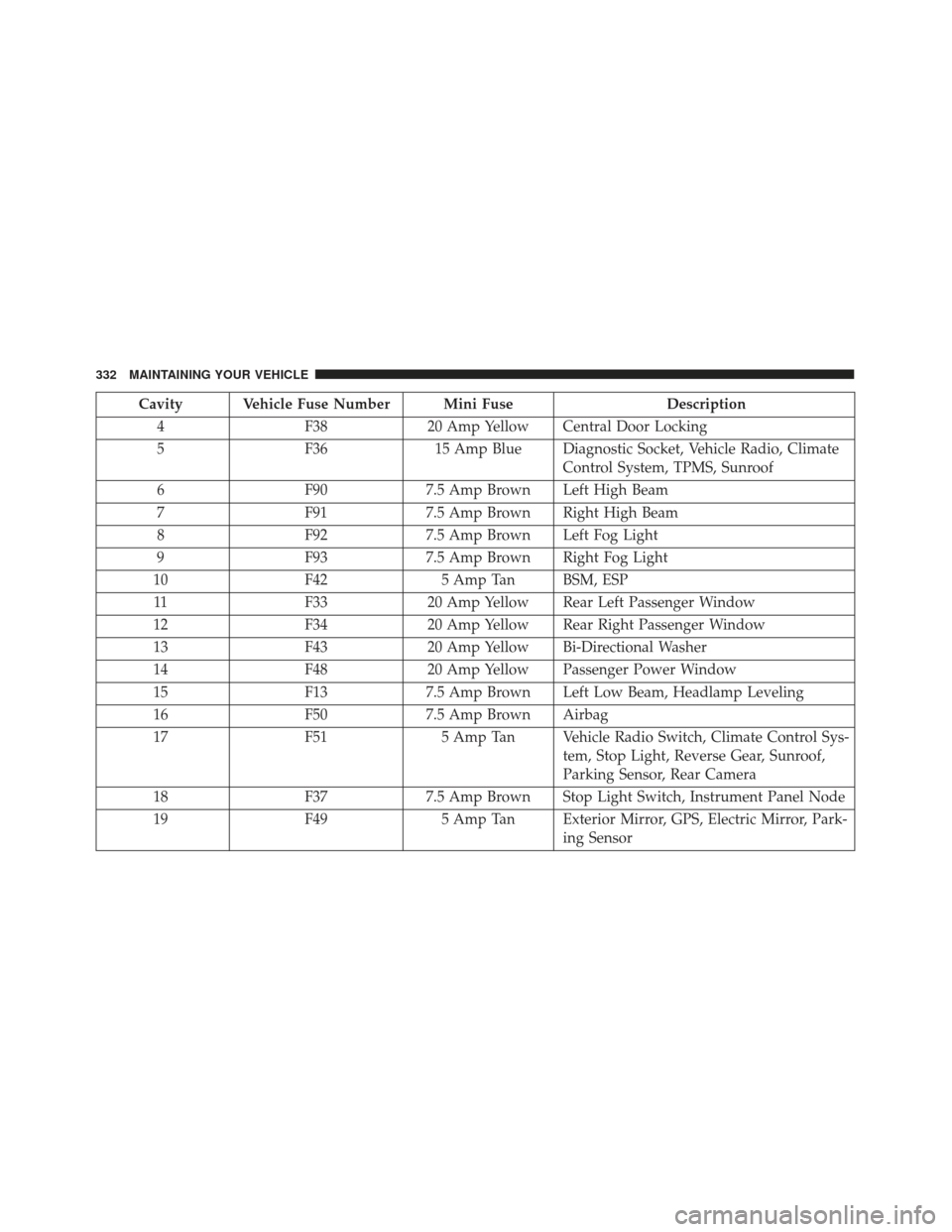

Cavity Vehicle Fuse Number Mini FuseDescription

4 F3820 Amp Yellow Central Door Locking

5 F3615 Amp Blue Diagnostic Socket, Vehicle Radio, Climate

Control System, TPMS, Sunroof

6 F907.5 Amp Brown Left High Beam

7 F917.5 Amp Brown Right High Beam

8 F927.5 Amp Brown Left Fog Light

9 F937.5 Amp Brown Right Fog Light

10 F425 Amp Tan BSM, ESP

11 F3320 Amp Yellow Rear Left Passenger Window

12 F3420 Amp Yellow Rear Right Passenger Window

13 F4320 Amp Yellow Bi-Directional Washer

14 F4820 Amp Yellow Passenger Power Window

15 F137.5 Amp Brown Left Low Beam, Headlamp Leveling

16 F507.5 Amp Brown Airbag

17 F515 Amp Tan Vehicle Radio Switch, Climate Control Sys-

tem, Stop Light, Reverse Gear, Sunroof,

Parking Sensor, Rear Camera

18 F377.5 Amp Brown Stop Light Switch, Instrument Panel Node

19 F495 Amp Tan Exterior Mirror, GPS, Electric Mirror, Park-

ing Sensor

332 MAINTAINING YOUR VEHICLE

Page 338 of 370

BULB REPLACEMENT

NOTE:Lens fogging can occur under certain atmo-

spheric conditions. This will usually clear as atmo-

spheric conditions change to allow the condensation to

change back into a vapor. Turning the lamps on will

usually accelerate the clearing process.

Headlamps Low Beam And High Beam

1. Remove the plastic sealing cap from the back of the headlamp housing by turning it counterclockwise.

2. Rotate the bulb counterclockwise. 3. Remove the bulb when all the tabs are aligned with

the openings in the metal holder.

Headlamp Sealing Cap Removal

Bulb Removal Procedure

336 MAINTAINING YOUR VEHICLE

Page 339 of 370

4. Disconnect the electrical connector from the bulb. 5. Install the new bulb and rotate clockwise to lock inplace.

Electrical Connector Removal

New Bulb Installation

7

MAINTAINING YOUR VEHICLE 337

Page 340 of 370

6. Reinstall the plastic cap.

Front Turn Signal, Parking And Daytime

Running Lamps

1. Turn front wheels inboard to access upper cover inwheel liner.

2. Open the upper cover on the front of the wheel liner.

3. Remove the cap from the back of the lower headlamp housing. 4. Rotate the bulb counterclockwise and remove.

5. Install the bulb into socket, and rotate bulb/socket

clockwise into lamp locking it in place.

6. Reinstall the plastic cap and close the cover on the wheel liner.

Front Fog Lamps

To replace the front fog lights, see your authorized

dealer.

Front, Rear Roof Lamps

1. Remove two screw and remove the lamp assembly.

2. Remove the socket bulb by turning counterclock-wise.

3. Remove bulb and replace as needed.

4. Reinstall the bulb socket and rotate clockwise to lock in place.

5. Reinstall lamp.Headlamp Sealing Cap Installation

338 MAINTAINING YOUR VEHICLE