brake FIAT 500L LIVING 2015 2.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: 500L LIVING, Model: FIAT 500L LIVING 2015 2.GPages: 224, PDF Size: 5.92 MB

Page 104 of 224

OPERATION WITH A

TRAILERSensor operation is deactivated

automatically when the trailer's electric

cable plug is fitted into the car's tow

hook socket.

The sensors are automatically

reactivated when the trailer's cable plug

is removed.IMPORTANT

INFORMATIONWhen parking, take the utmost care

over obstacles that may be above

or below the sensors.

Under certain circumstances, objects

close to the vehicle are not detected by

the system and could therefore cause

damage to the car or be damaged

themselves.

Some conditions may influence the

performance of the parking sensors:

❒the presence of ice, snow, mud

or think paint on the sensor surface

may cause reduced sensitivity of the

sensor itself and therefore reduce

the system performance.

❒mechanical interference (e.g. washing

the car, rain, strong wind, hail) may

cause the sensor to detect a

non-existent obstacle ("echo

interference");❒the presence of ultrasonic systems

(e.g. pneumatic brake systems of

trucks or pneumatic drills) near the car

could alter the signals sent by the

sensor;

❒the variation in sensor position,

caused by variation in ride (due

to suspension component wear),

changing tyres, overloaded car, or

tuning that lowers the car, for example,

may affect parking sensor system

performance.

WARNING

110)Parking and other dangerous

manoeuvres are, however, always the

driver’s responsibility. While carrying out

these manoeuvres, always make sure that

no people (especially children) or animals

are in the area concerned. The parking

sensors are an aid for the driver, but the

driver must never allow their attention

to lapse during potentially dangerous

manoeuvres, even those executed at low

speeds.

WARNING

59)The sensors must be free from mud,

dirt, snow or ice in order for the system to

operate correctly. Be careful not to scratch

or damage the sensors while cleaning

them. Avoid using dry, rough or hard

cloths. The sensors should be washed

using clean water with the addition of car

shampoo if necessary. When using special

washing equipment such as high pressure

jets or steam cleaning, clean the sensors

very quickly keeping the jet more than

10 cm away. Also, do not apply stickers to

the sensors.

102

STARTING AND DRIVING

9-1-2015 12:9 Pagina 102

Page 105 of 224

REAR VIEW CAMERA

111)

60)

DESCRIPTIONThe camera is located on the tailgate

fig. 98.Camera activation/deactivationUse the "Settings" menu of the

Uconnect™system. When the camera

is activated, whenever reverse is

engaged, the display of the

Uconnect™system shows the image

of the vehicle's rear area.

SYMBOLS AND

MESSAGES ON THE

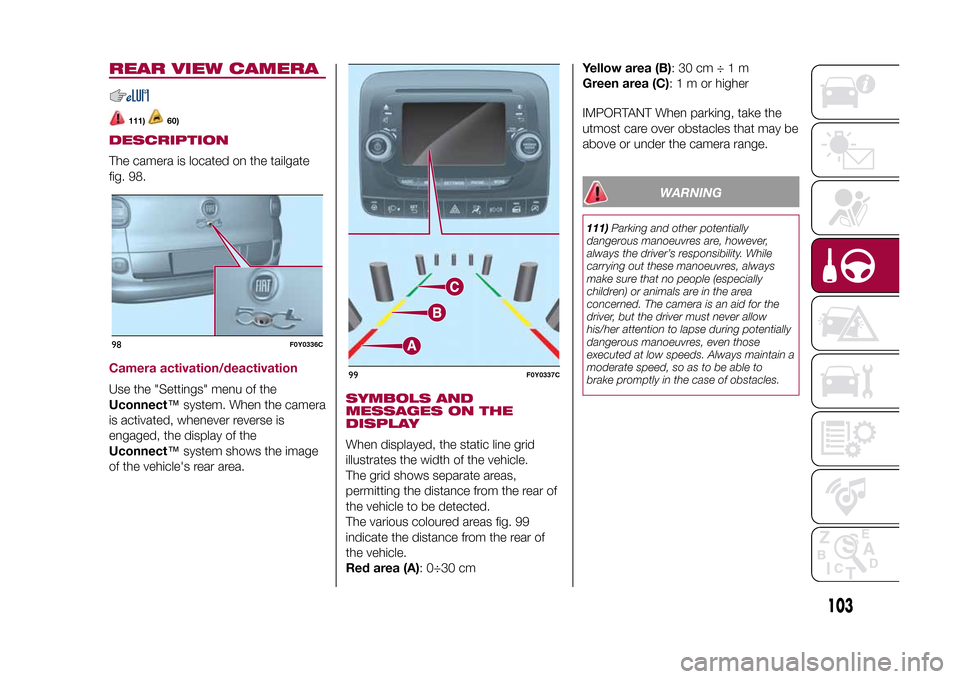

DISPLAYWhen displayed, the static line grid

illustrates the width of the vehicle.

The grid shows separate areas,

permitting the distance from the rear of

the vehicle to be detected.

The various coloured areas fig. 99

indicate the distance from the rear of

the vehicle.

Red area (A): 0÷30 cmYellow area (B):30cm÷1m

Green area (C):1morhigher

IMPORTANT When parking, take the

utmost care over obstacles that may be

above or under the camera range.

WARNING

111)Parking and other potentially

dangerous manoeuvres are, however,

always the driver’s responsibility. While

carrying out these manoeuvres, always

make sure that no people (especially

children) or animals are in the area

concerned. The camera is an aid for the

driver, but the driver must never allow

his/her attention to lapse during potentially

dangerous manoeuvres, even those

executed at low speeds. Always maintain a

moderate speed, so as to be able to

brake promptly in the case of obstacles.

98

F0Y0336C

99

F0Y0337C

103

9-1-2015 12:9 Pagina 103

Page 106 of 224

WARNING

60)It is extremely important, for correct

operation, that the camera is always kept

clean and free from mud, dirt, snow or ice.

Be careful not to scratch or damage the

camera while cleaning it. Avoid using

dry, rough or hard cloths. The camera

must be washed using clean water, with

the addition of car shampoo if necessary.

In washing stations which use steam or

high-pressure jets, clean the camera

quickly, keeping the nozzle more than 10

cm away. Do not apply stickers to the

camera.

TOWING TRAILERS

112) 113) 114)

INSTALLING A TOW

HOOKThe towing device should be fastened

to the body by specialised personnel

according to any additional and/or

integrative information supplied by the

Manufacturer of the device.

The towing device must meet current

regulations with reference to Directive

94/20/EC and subsequent

amendments.

For any version the towing device used

must be right for the towable weight

of the vehicle on which it is to be

installed.

For the electrical connection a standard

connector should be used which is

generally placed on a special bracket

normally fastened to the towing device,

and a special ECU for external trailer

light control must be installed on the

vehicle.

Seven or thirteen pin 12 V DC

connections should be used (CUNA/

UNI and ISO/DIN Standards). Follow

any instructions provided by the vehicle

manufacturer and/or the towing device

manufacturer.

IMPORTANTFor towing caravans or trailers the car

must be fitted with a type-approved

tow hook and an adequate electrical

system. Installation must be carried out

by a specialist.

Install any specific and/or additional

rear view mirrors as specified by the

Highway Code.

Remember that when towing a trailer,

steep hills are harder to climb, braking

distances increase and overtaking

takes longer depending on the overall

weight of the trail.

Engage a low gear when driving

downhill, rather than constantly using

the brake.

The weight of the trailer on the car's

tow hook will reduce the load capacity

of the car by the same amount. To

make sure that the maximum towable

weight is not exceeded (given in the car

registration document) account should

be taken of the fully laden trailer,

including accessories and luggage.

Respect the speed limits specific to

each country for vehicles towing

trailers. In any case, the top speed

must not exceed 100 km/h.

Any electric brake or other device

(winch etc.) should be powered directly

by the battery through a cable with a

cross-section of no less than 2.5 mm

2.

104

STARTING AND DRIVING

9-1-2015 12:9 Pagina 104

Page 107 of 224

In addition to the electrical branches,

the car's electrical system can be

connected only to the supply cable for

an electric brake and to the cable for an

internal trailer light, though not more

than 15 W. To connect, use the preset

control unit with a battery cable with

cross-section no less than 2.5 mm

2.

IMPORTANT The use of auxiliary loads

other than external lights (electric brake,

winch, etc.) must occur with engine

running.

IMPORTANT To install a tow hook

contact a Fiat Dealership.

WARNING

112)The ABS with which the vehicle is

equipped will not control the braking

system of the trailer. Take particular care

when travelling on slippery roads.

113)Never modify the braking system of

the vehicle to control the trailer brake. The

trailer braking system must be fully

independent of the vehicle’s hydraulic

system.

114)After fitting, fixing screw holes must

be sealed to prevent an exhaust gas inlet.

REFUELLING THE

VEHICLE

115) 116) 117)

61)

During refuelling, switch the engine off,

engage the handbrake, turn the ignition

key to STOP and do not smoke.PETROL ENGINESUse unleaded petrol only, with octane

number (RON) no lower than 95.DIESEL ENGINESOnly use Diesel for motor vehicles (EN

590 specification).

When using or parking the car for a

long time in the mountains or cold

areas, it is advisable to refuel using

locally available diesel. In this case, it is

also advisable to keep the tank over

50% full.REFUELLING

PROCEDURE

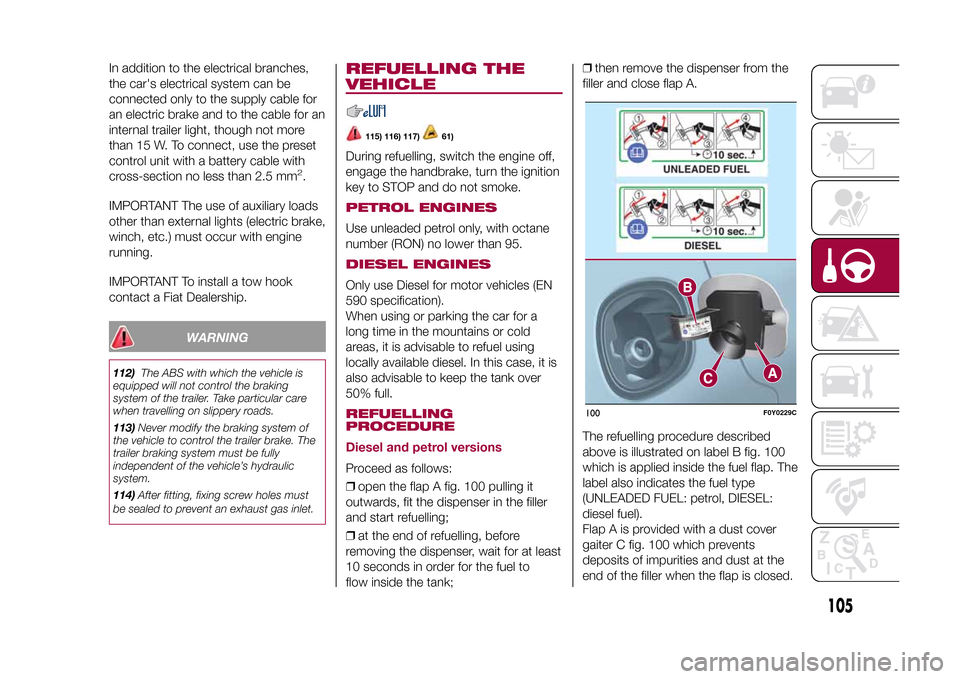

Diesel and petrol versionsProceed as follows:

❒open the flap A fig. 100 pulling it

outwards, fit the dispenser in the filler

and start refuelling;

❒at the end of refuelling, before

removing the dispenser, wait for at least

10 seconds in order for the fuel to

flow inside the tank;❒then remove the dispenser from the

filler and close flap A.

The refuelling procedure described

above is illustrated on label B fig. 100

which is applied inside the fuel flap. The

label also indicates the fuel type

(UNLEADED FUEL: petrol, DIESEL:

diesel fuel).

Flap A is provided with a dust cover

gaiter C fig. 100 which prevents

deposits of impurities and dust at the

end of the filler when the flap is closed.

100

F0Y0229C

105

9-1-2015 12:9 Pagina 105

Page 111 of 224

HAZARD WARNING

LIGHTSCONTROLPress button fig. 104 to switch the

lights on/off. When the hazard warning

lights are on, the

and

warning

lights flash.

Emergency brakingIn the event of emergency braking the

hazard warning lights switch on

automatically as well as warning lights

and

in the instrument panel.

The lights switch off automatically when

emergency braking ceases.

CHANGING A WHEEL

118) 119) 120) 121) 122)

63)

JACKPlease note that:

❒the jack weight is 1,76 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired and in

the event of a fault it must be replaced

by another original one;

❒no tool other than its cranking device

may be fitted on the jack.WHEEL REPLACEMENT

PROCEDUREProceed as follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground should be flat if possible,

and sufficiently firm;

❒switch off the engine, pull up the

handbrake and engage the 1

stgear or

reverse. Wear the reflective safety

jacket (compulsory by law) before

getting out of the vehicle;

❒500L versions: open the tailgate and

lift the carpet;❒500L LIVING versions: open the

tailgate, lift the load platform of

the "Cargo Magic Space" holding it with

one hand and then take the toolbox.

❒500L versions: using the wrench

A fig. 105 located in the tool box,

loosen the locking device, take the tool

box B and place it close to the wheel

to be replaced. Then take the

space-saver wheel C;

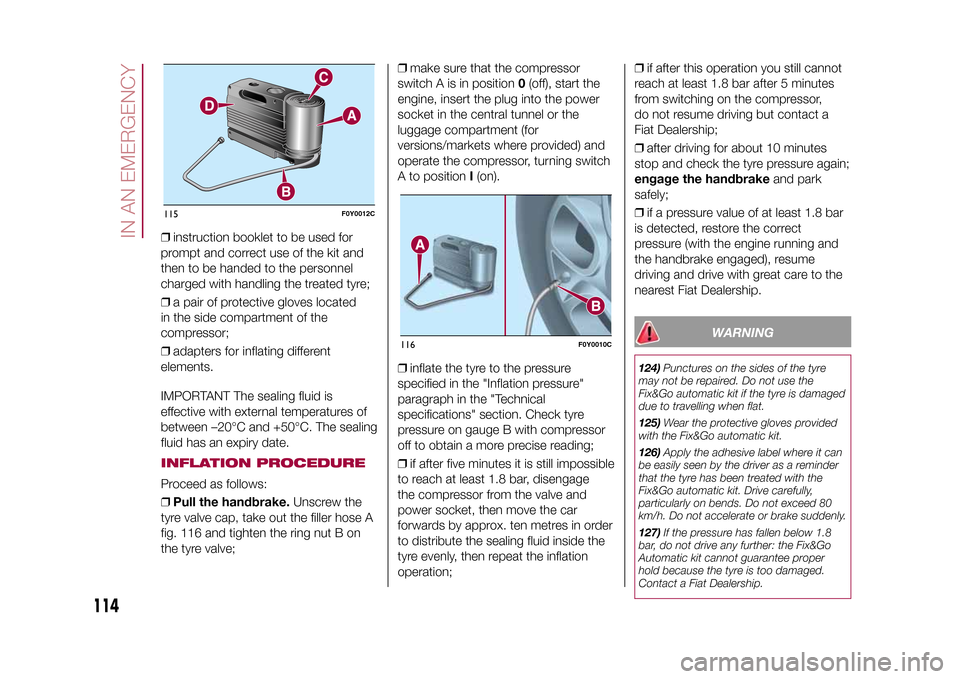

❒500L LIVING versions: lift the flap A

fig. 106 located on the luggage

compartment mat, take spanner B from

the tool bag and fit it on device C.

Rotate spanner B anticlockwise in order

to undo the space-saver wheel support

locking bolt, allowing the latter to be

lowered, and use the spanner to take

the wheel out of the vehicle;

❒500L LIVING versions: rotate the

device D fig. 107 and release the

space-saver wheel from the mounting

E;

104

F0Y0037C

105

F0Y0096C

109

9-1-2015 12:9 Pagina 109

Page 116 of 224

❒instruction booklet to be used for

prompt and correct use of the kit and

then to be handed to the personnel

charged with handling the treated tyre;

❒a pair of protective gloves located

in the side compartment of the

compressor;

❒adapters for inflating different

elements.

IMPORTANT The sealing fluid is

effective with external temperatures of

between –20°C and +50°C. The sealing

fluid has an expiry date.INFLATION PROCEDUREProceed as follows:

❒Pull the handbrake.Unscrew the

tyre valve cap, take out the filler hose A

fig. 116 and tighten the ring nut B on

the tyre valve;❒make sure that the compressor

switch A is in position0(off), start the

engine, insert the plug into the power

socket in the central tunnel or the

luggage compartment (for

versions/markets where provided) and

operate the compressor, turning switch

A to positionI(on).

❒inflate the tyre to the pressure

specified in the "Inflation pressure"

paragraph in the "Technical

specifications" section. Check tyre

pressure on gauge B with compressor

off to obtain a more precise reading;

❒if after five minutes it is still impossible

to reach at least 1.8 bar, disengage

the compressor from the valve and

power socket, then move the car

forwards by approx. ten metres in order

to distribute the sealing fluid inside the

tyre evenly, then repeat the inflation

operation;❒if after this operation you still cannot

reach at least 1.8 bar after 5 minutes

from switching on the compressor,

do not resume driving but contact a

Fiat Dealership;

❒after driving for about 10 minutes

stop and check the tyre pressure again;

engage the handbrakeand park

safely;

❒if a pressure value of at least 1.8 bar

is detected, restore the correct

pressure (with the engine running and

the handbrake engaged), resume

driving and drive with great care to the

nearest Fiat Dealership.

WARNING

124)Punctures on the sides of the tyre

may not be repaired. Do not use the

Fix&Go automatic kit if the tyre is damaged

due to travelling when flat.

125)Wear the protective gloves provided

with the Fix&Go automatic kit.

126)Apply the adhesive label where it can

be easily seen by the driver as a reminder

that the tyre has been treated with the

Fix&Go automatic kit. Drive carefully,

particularly on bends. Do not exceed 80

km/h. Do not accelerate or brake suddenly.

127)If the pressure has fallen below 1.8

bar, do not drive any further: the Fix&Go

Automatic kit cannot guarantee proper

hold because the tyre is too damaged.

Contact a Fiat Dealership.

115

F0Y0012C

116

F0Y0010C

114

IN AN EMERGENCY

9-1-2015 12:9 Pagina 114

Page 119 of 224

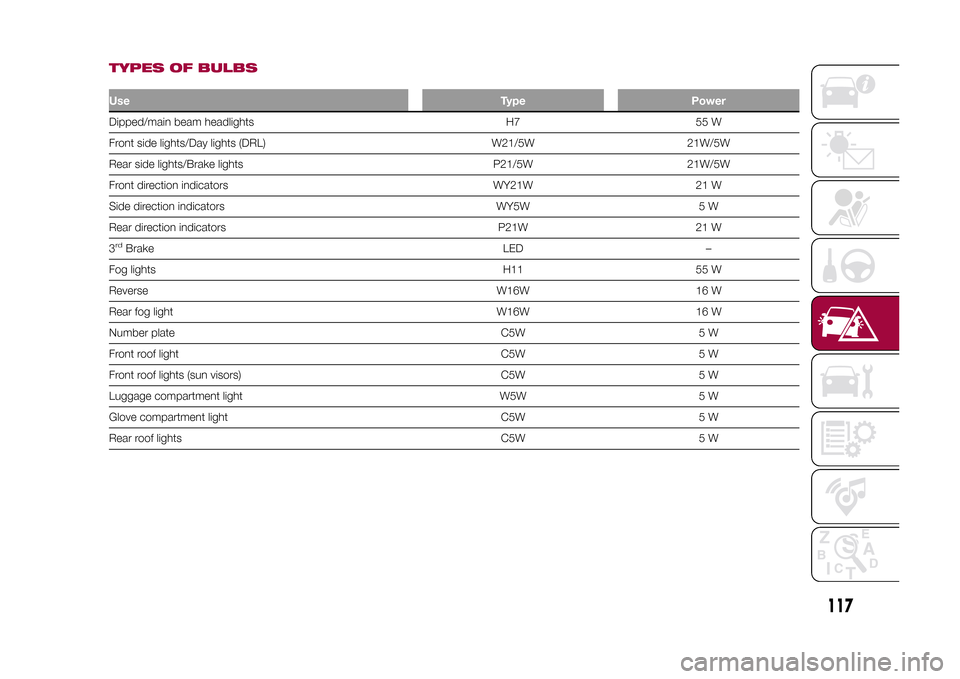

TYPES OF BULBSUseType PowerDipped/main beam headlights H7 55 W

Front side lights/Day lights (DRL) W21/5W 21W/5W

Rear side lights/Brake lights P21/5W 21W/5W

Front direction indicators WY21W 21 W

Side direction indicators WY5W 5 W

Rear direction indicators P21W 21 W

3rdBrake LED –

Fog lights H11 55 W

Reverse W16W 16 W

Rear fog light W16W 16 W

Number plate C5W 5 W

Front roof light C5W 5 W

Front roof lights (sun visors) C5W 5 W

Luggage compartment light W5W 5 W

Glove compartment light C5W 5 W

Rear roof lights C5W 5 W

117

9-1-2015 12:9 Pagina 117

Page 122 of 224

❒refit the cluster making sure that the

internal catch B fig. 125 clips into

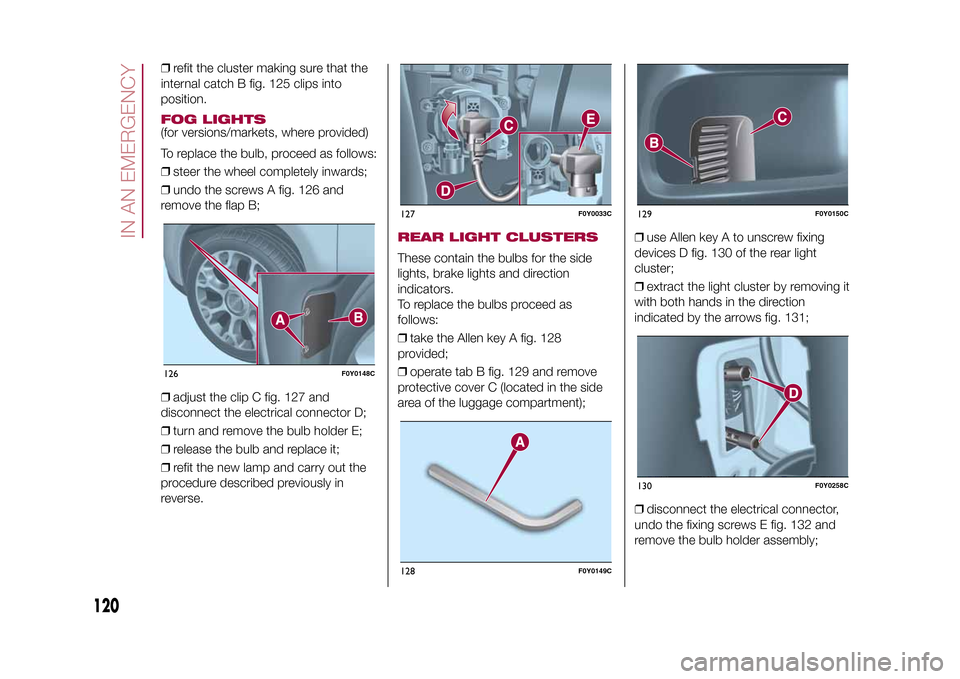

position.FOG LIGHTS(for versions/markets, where provided)

To replace the bulb, proceed as follows:

❒steer the wheel completely inwards;

❒undo the screws A fig. 126 and

remove the flap B;

❒adjust the clip C fig. 127 and

disconnect the electrical connector D;

❒turn and remove the bulb holder E;

❒release the bulb and replace it;

❒refit the new lamp and carry out the

procedure described previously in

reverse.

REAR LIGHT CLUSTERSThese contain the bulbs for the side

lights, brake lights and direction

indicators.

To replace the bulbs proceed as

follows:

❒take the Allen key A fig. 128

provided;

❒operate tab B fig. 129 and remove

protective cover C (located in the side

area of the luggage compartment);❒use Allen key A to unscrew fixing

devices D fig. 130 of the rear light

cluster;

❒extract the light cluster by removing it

with both hands in the direction

indicated by the arrows fig. 131;

❒disconnect the electrical connector,

undo the fixing screws E fig. 132 and

remove the bulb holder assembly;

126

F0Y0148C

127

F0Y0033C

128

F0Y0149C

129

F0Y0150C

130

F0Y0258C

120

IN AN EMERGENCY

9-1-2015 12:9 Pagina 120

Page 123 of 224

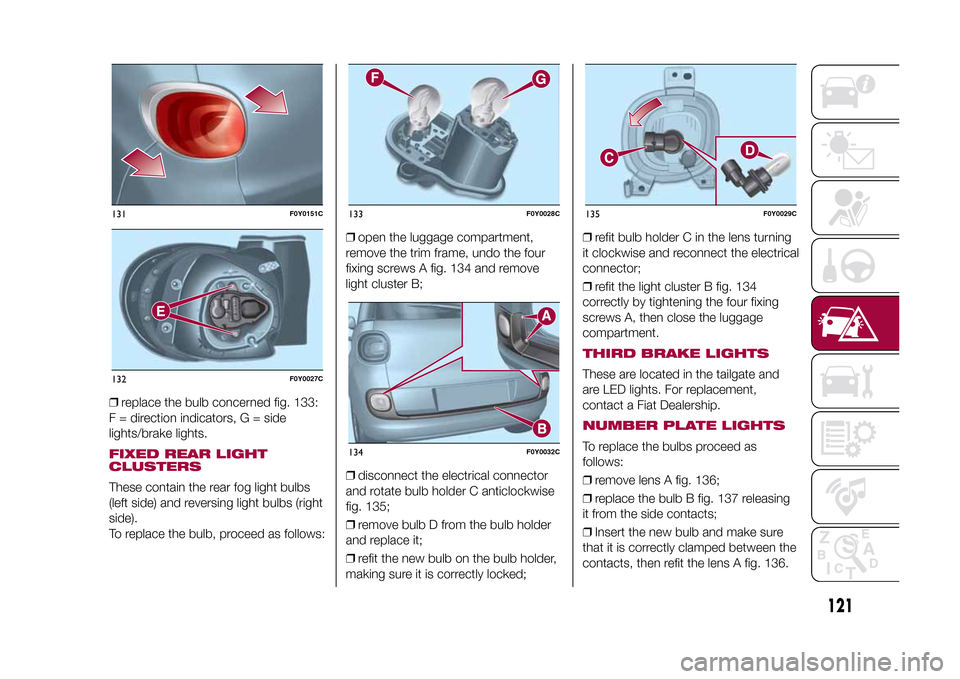

❒replace the bulb concerned fig. 133:

F = direction indicators, G = side

lights/brake lights.FIXED REAR LIGHT

CLUSTERSThese contain the rear fog light bulbs

(left side) and reversing light bulbs (right

side).

To replace the bulb, proceed as follows:❒open the luggage compartment,

remove the trim frame, undo the four

fixing screws A fig. 134 and remove

light cluster B;

❒disconnect the electrical connector

and rotate bulb holder C anticlockwise

fig. 135;

❒remove bulb D from the bulb holder

and replace it;

❒refit the new bulb on the bulb holder,

making sure it is correctly locked;❒refit bulb holder C in the lens turning

it clockwise and reconnect the electrical

connector;

❒refit the light cluster B fig. 134

correctly by tightening the four fixing

screws A, then close the luggage

compartment.

THIRD BRAKE LIGHTSThese are located in the tailgate and

are LED lights. For replacement,

contact a Fiat Dealership.NUMBER PLATE LIGHTSTo replace the bulbs proceed as

follows:

❒remove lens A fig. 136;

❒replace the bulb B fig. 137 releasing

it from the side contacts;

❒Insert the new bulb and make sure

that it is correctly clamped between the

contacts, then refit the lens A fig. 136.

131

F0Y0151C

132

F0Y0027C

133

F0Y0028C

134

F0Y0032C

135

F0Y0029C

121

9-1-2015 12:9 Pagina 121

Page 130 of 224

JUMP STARTINGIf the battery is flat, a jump starting can

be performed using the battery and

the cables of another vehicle, or using a

booster battery.IMPORTANTWhen a booster battery is used, comply

with the utilisation and precaution

instructions specified by the producer.

Do not use the booster battery or

any other source of external supply with

a voltage above 12 V: the battery, the

starter, the alternator and the electrical

system of the vehicle could be

damaged.

Do not attempt jump starting if the

battery is frozen. The battery could

break and explode!PREPARATION TO JUMP

STARTING

140) 141) 142)

68)

IMPORTANT The positive terminal (+) of

the battery is shielded by a protective

cover. Lift the cover to access the

positive terminal.

Proceed as follows:

❒engage the handbrake, move the

Dualogic gear lever to P (Park) or,

for versions with manual gearbox, to

neutral and bring the ignition key to

STOP;❒switch off all the other electrical

devices in the vehicle;

❒if another vehicle is ready for jump

starting, park the vehicle within the

reach of the cables to be used for

starting, operate the handbrake and

make sure that the ignition is

deactivated.

IMPORTANT Avoid contact between

the two vehicles since this could cause

a connection to earth and may result

in serious injury to any people nearby.

PROCEDURE FOR JUMP

STARTINGIMPORTANT If the procedure below is

carried out incorrectly, it can cause

severe injury to people or damage the

recharging system of one or both

vehicles. Carefully follow the

instructions given below.Cable connectionProceed as follows to carry out a jump

starting:

❒connect one end of the cable used

for positive (+) to the positive terminal

(+) of the vehicle with flat battery;

❒connect the other end of the cable

used for positive (+) to the positive

terminal (+) of the auxiliary battery;❒connect one end of the cable used

for negative (–) to the negative terminal

(–) of the auxiliary battery;

❒connect the other end of the cable

used for negative (–) to an engine earth

(the visible metal part of the vehicle

engine with flat battery) away from the

battery and the fuel injection system;

❒start the vehicle engine with the

auxiliary battery, let it run for a

few minutes at idling. Start the engine

of the vehicle with flat battery.

Cable disconnectionOnce the engine has been started,

remove the cables proceeding as

follows:

❒disconnect the end of the cable used

for negative (–) from the engine earth

of the vehicle with flat battery;

❒disconnect the other end of the cable

used for negative (–) from the negative

terminal (–) of the auxiliary battery;

❒disconnect the end of the cable used

for positive (+) from the positive terminal

(+) of the auxiliary battery;

❒disconnect one end of the cable

used for positive (+) from the positive

terminal (+) of the vehicle with flat

battery.

128

IN AN EMERGENCY

9-1-2015 12:9 Pagina 128