light FIAT 500L LIVING 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2018, Model line: 500L LIVING, Model: FIAT 500L LIVING 2018Pages: 268, PDF Size: 4.87 MB

Page 115 of 268

Turning off

To deactivate “Traction +” mode and go

back to “Normal” mode, turn the ring

leftwards and hold this position for half

a second. In this case, the LED related

to “Normal” mode will light up and

the indication that “Traction +” mode

has been deactivated will appear on the

display.

IMPORTANT If “Traction +” or “Normal”

modes are selected when the engine

is stopped, the mode will be maintained

when starting again.IMPORTANT In “Traction +” mode, the

Start&Stop system is temporarily

deactivated (LED on the Start&Stop

system button on). To reactivate the

Start&Stop system with “Traction +”

mode on, press the Start&Stop button

located on the dashboard. The

Start&Stop system will be activated

again when “Traction +” mode is

deactivated.

IMPORTANT The City Brake Control -

“Collision Mitigation” system is

temporarily deactivated when “Traction

+” mode is deactivated. Temporary

deactivation of the system is indicated

by the warning light

on the

instrument panel (together with a

message on the display). The City

Brake Control - “Collision Mitigation”

system will be activated again when

“Traction +” mode is deactivated.

“GRAVITY CONTROL” FUNCTION

This driving function aims at maintaining

a constant speed when driving

downhill on a steel gradient. Noise and

vibrations from the wheel sides (brakes)

are normal when the function is active.IMPORTANT The function can only be

selected with “Traction +” mode active,

engine running, handbrake released

and driver side door correctly closed.

Activation

To activate the function, go to a speed

slower than 25 km/h.

After reaching the desired speed,

release the accelerator and brake

pedals completely. If you want to

increase/decrease the speed, press the

accelerator and brake pedals again.

Activation

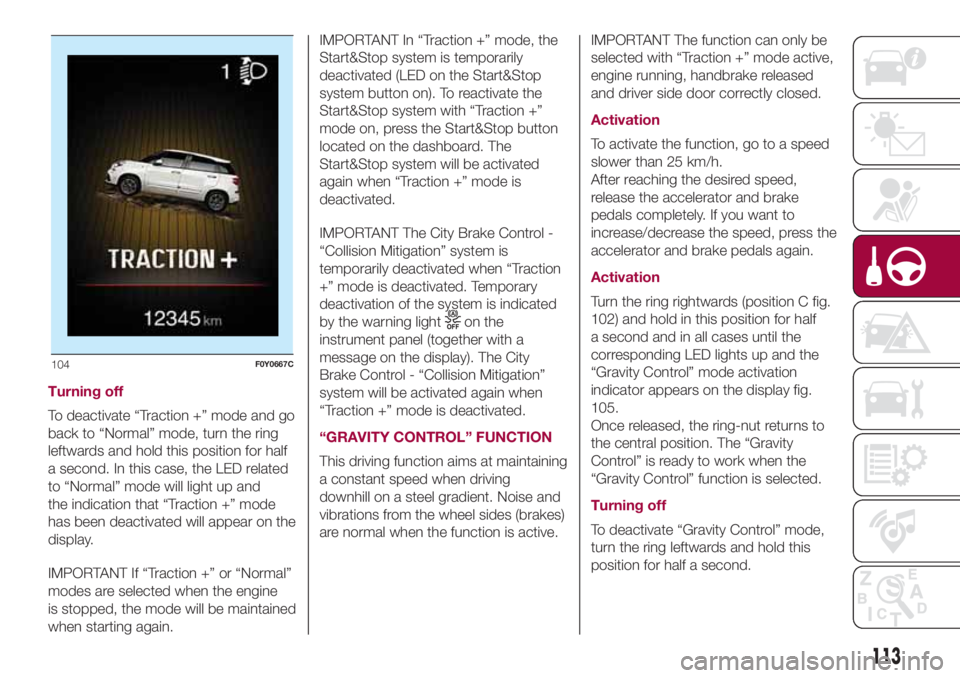

Turn the ring rightwards (position C fig.

102) and hold in this position for half

a second and in all cases until the

corresponding LED lights up and the

“Gravity Control” mode activation

indicator appears on the display fig.

105.

Once released, the ring-nut returns to

the central position. The “Gravity

Control” is ready to work when the

“Gravity Control” function is selected.

Turning off

To deactivate “Gravity Control” mode,

turn the ring leftwards and hold this

position for half a second.

104F0Y0667C

113

Page 116 of 268

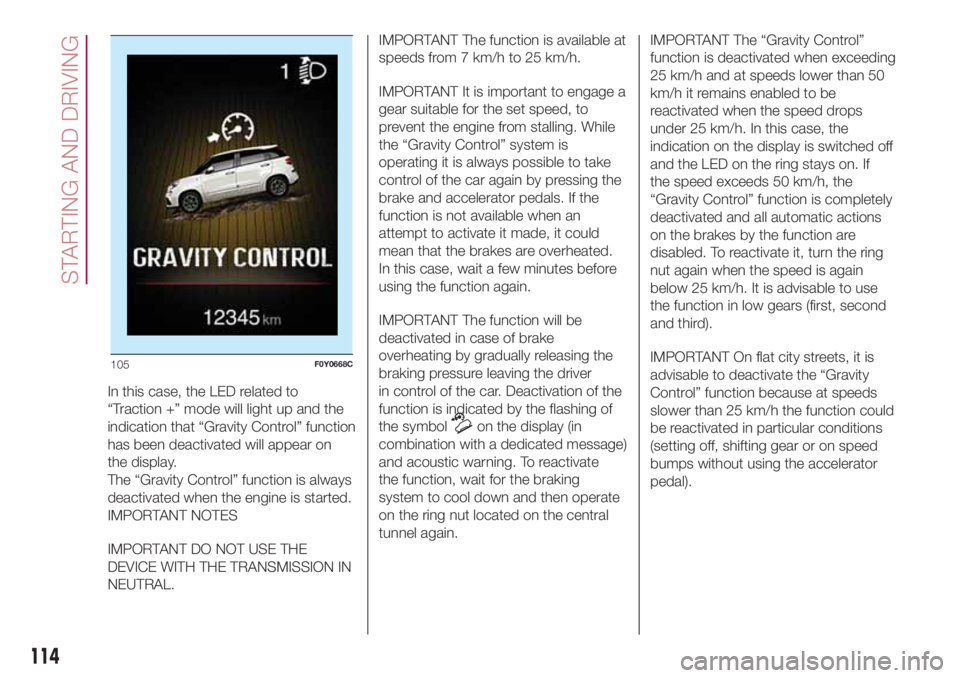

In this case, the LED related to

“Traction +” mode will light up and the

indication that “Gravity Control” function

has been deactivated will appear on

the display.

The “Gravity Control” function is always

deactivated when the engine is started.

IMPORTANT NOTES

IMPORTANT DO NOT USE THE

DEVICE WITH THE TRANSMISSION IN

NEUTRAL.IMPORTANT The function is available at

speeds from 7 km/h to 25 km/h.

IMPORTANT It is important to engage a

gear suitable for the set speed, to

prevent the engine from stalling. While

the “Gravity Control” system is

operating it is always possible to take

control of the car again by pressing the

brake and accelerator pedals. If the

function is not available when an

attempt to activate it made, it could

mean that the brakes are overheated.

In this case, wait a few minutes before

using the function again.

IMPORTANT The function will be

deactivated in case of brake

overheating by gradually releasing the

braking pressure leaving the driver

in control of the car. Deactivation of the

function is indicated by the flashing of

the symbol

on the display (in

combination with a dedicated message)

and acoustic warning. To reactivate

the function, wait for the braking

system to cool down and then operate

on the ring nut located on the central

tunnel again.IMPORTANT The “Gravity Control”

function is deactivated when exceeding

25 km/h and at speeds lower than 50

km/h it remains enabled to be

reactivated when the speed drops

under 25 km/h. In this case, the

indication on the display is switched off

and the LED on the ring stays on. If

the speed exceeds 50 km/h, the

“Gravity Control” function is completely

deactivated and all automatic actions

on the brakes by the function are

disabled. To reactivate it, turn the ring

nut again when the speed is again

below 25 km/h. It is advisable to use

the function in low gears (first, second

and third).

IMPORTANT On flat city streets, it is

advisable to deactivate the “Gravity

Control” function because at speeds

slower than 25 km/h the function could

be reactivated in particular conditions

(setting off, shifting gear or on speed

bumps without using the accelerator

pedal).

105F0Y0668C

114

STARTING AND DRIVING

Page 119 of 268

SYMBOLS AND

MESSAGES ON THE

DISPLAY

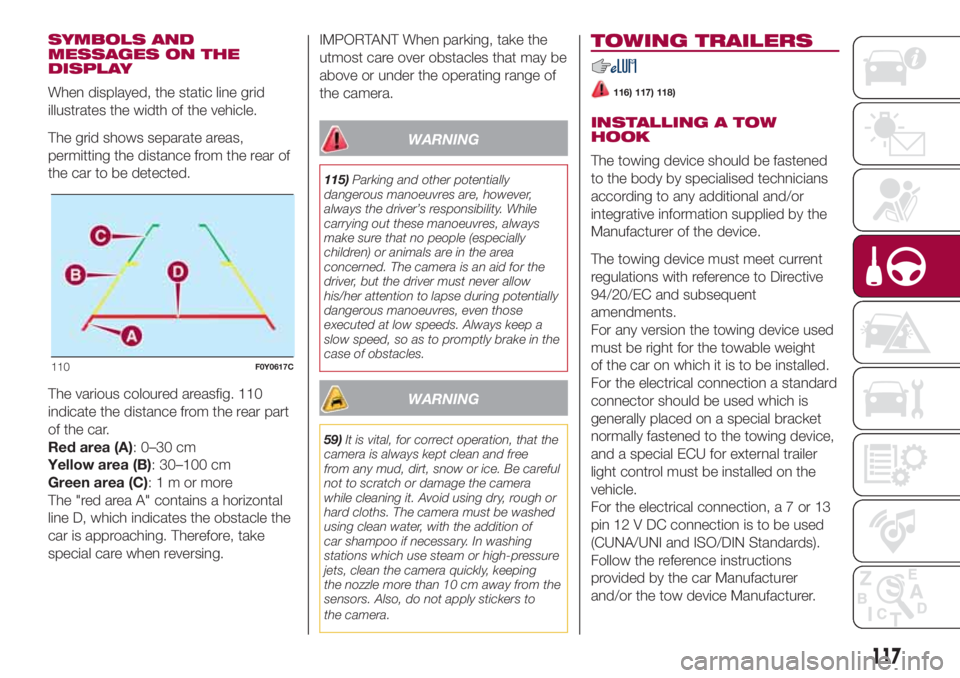

When displayed, the static line grid

illustrates the width of the vehicle.

The grid shows separate areas,

permitting the distance from the rear of

the car to be detected.

The various coloured areasfig. 110

indicate the distance from the rear part

of the car.

Red area (A): 0–30 cm

Yellow area (B): 30–100 cm

Green area (C):1mormore

The "red area A" contains a horizontal

line D, which indicates the obstacle the

car is approaching. Therefore, take

special care when reversing.IMPORTANT When parking, take the

utmost care over obstacles that may be

above or under the operating range of

the camera.

WARNING

115)Parking and other potentially

dangerous manoeuvres are, however,

always the driver’s responsibility. While

carrying out these manoeuvres, always

make sure that no people (especially

children) or animals are in the area

concerned. The camera is an aid for the

driver, but the driver must never allow

his/her attention to lapse during potentially

dangerous manoeuvres, even those

executed at low speeds. Always keep a

slow speed, so as to promptly brake in the

case of obstacles.

WARNING

59)It is vital, for correct operation, that the

camera is always kept clean and free

from any mud, dirt, snow or ice. Be careful

not to scratch or damage the camera

while cleaning it. Avoid using dry, rough or

hard cloths. The camera must be washed

using clean water, with the addition of

car shampoo if necessary. In washing

stations which use steam or high-pressure

jets, clean the camera quickly, keeping

the nozzle more than 10 cm away from the

sensors. Also, do not apply stickers to

the camera.

TOWING TRAILERS

116) 117) 118)

INSTALLING A TOW

HOOK

The towing device should be fastened

to the body by specialised technicians

according to any additional and/or

integrative information supplied by the

Manufacturer of the device.

The towing device must meet current

regulations with reference to Directive

94/20/EC and subsequent

amendments.

For any version the towing device used

must be right for the towable weight

of the car on which it is to be installed.

For the electrical connection a standard

connector should be used which is

generally placed on a special bracket

normally fastened to the towing device,

and a special ECU for external trailer

light control must be installed on the

vehicle.

For the electrical connection,a7or13

pin 12 V DC connection is to be used

(CUNA/UNI and ISO/DIN Standards).

Follow the reference instructions

provided by the car Manufacturer

and/or the tow device Manufacturer.

110F0Y0617C

117

Page 120 of 268

IMPORTANT NOTES

For towing caravans or trailers the car

must be fitted with an approved tow

hook and an adequate electrical

system. Installation must be carried out

by specialised technicians.

Install any specific and/or additional

door mirrors as specified by the

Highway Code.

Remember that, when towing a trailer,

steep hills are harder to climb, braking

distances increase and overtaking

takes longer depending on the overall

weight of the trailer.

Engage a low gear when driving

downhill, rather than constantly using

the brake.

The weight the trailer exerts on the car

tow hook reduces the car's loading

capacity by the same amount. To make

sure that the maximum towable weight

is not exceeded (given in the vehicle

registration document) account should

be taken of the fully laden trailer,

including accessories and luggage.

Do not exceed the speed limits specific

to each country you are driving in, in

the case of vehicles towing trailers.

In any case, the top speed must not

exceed 100 km/h.Any electric brake (or electric winch,

etc.) should be supplied directly by the

battery through a cable with a section

of at least 2.5 mm

2.

In addition to the electrical branches,

the car electrical system can only

be connected to the supply cable for an

electric brake and to the cable for an

internal light for the trailer, not

exceeding 15 W. For connections, use

the preset control unit with a battery

cable with section not less than 2.5

mm

2.

IMPORTANT The use of auxiliary loads

other than external lights (electric brake,

winch, etc.) must take place with

engine running.

IMPORTANT To install a tow hook

contact a Fiat Dealership.

WARNING

116)The ABS with which the car is

equipped will not control the braking

system of the trailer. Particular caution is

required on slippery roads.

117)Never modify the braking system of

the vehicle to control the trailer brake. The

trailer braking system must be fully

independent of the vehicle’s hydraulic

system.

118)After fitting, screw holes must be

sealed to prevent a exhaust gas inlet.

REFUELLING THE

VEHICLE

119) 120) 121)60)

Before refuelling, make sure that the

fuel type is correct. During refuelling

procedure, switch off the engine,

engage handbrake, rotate the ignition

key to STOP and do not smoke.

PETROL ENGINES

Only use unleaded petrol with a number

of octanes (R.O.N.) not lower than 95

(EN228 specification).

DIESEL ENGINES

Only use Diesel for motor vehicles

(EN590 specification).

When using or parking the car for a

long time in the mountains or cold

areas, it is advisable to refuel using

locally available Diesel. In this case, it is

also advisable to keep the tank over

50% full.

REFUELLING

PROCEDURE

Diesel and petrol versions

Proceed as follows:

open the flap A fig. 111 pulling

outwards, insert the nozzle in the filler

and refuel;

118

STARTING AND DRIVING

Page 124 of 268

IN AN EMERGENCY

A punctured tyre or a burnt-out bulb?

At times, a problem may interfere

with our journey.

The pages on emergencies can help

you to deal with critical situations

independently and with calm.

In an emergency we recommend that

you call the freephone number found in

the Warranty Booklet.

It is also possible to call the national or

international universal freephone

number to search for the nearest

Dealership.HAZARD WARNING LIGHTS...........123

REPLACING A WHEEL ...................123

“FIX&GO AUTOMATIC” KIT .............127

REPLACING A BULB ......................130

REPLACING FUSES........................137

JUMP STARTING ............................143

FUEL CUT-OFF SYSTEM ................145

TOWING THE VEHICLE ..................145

122

IN AN EMERGENCY

Page 125 of 268

HAZARD WARNING

LIGHTS

CONTROL

Press the button fig. 119 to switch the

lights on/off. When the hazard warning

lights are on, the

andwarning

lights flash.

Emergency braking

In the event of emergency braking the

hazard warning lights switch on

automatically as well as warning lights

andin the instrument panel.

The lights switch off automatically when

emergency braking ceases.

REPLACING A

WHEEL

122) 123) 124) 125) 128) 127) 126)62)

JACK

Please note that:

the jack weight is 1,76 kg;

the jack requires no adjustment;

the jack cannot be repaired and in

the event of a fault it must be replaced

by another genuine one;

no tool other than its cranking

device may be fitted on the jack.

Maintenance

prevent any dirt from depositing on

the "worm screw";

keep the "worm screw" lubricated;

never modify the jack.

Conditions for non-use

temperatures below −40°C;

on sandy or muddy ground;

on uneven ground;

on steep roads;

in extreme weather conditions:

thunderstorms, typhoons, hurricanes,

blizzards, storms, etc...

in direct contact with the engine or

for repairs under the car;

on boats.WHEEL REPLACEMENT

PROCEDURE

Proceed as follows:

stop the car in a position that is not

dangerous for oncoming traffic where

you can change the wheel safely. The

car must be stopped in a lay-by,

car-park or parking or service area, and

the ground must be as level as possible

and sufficiently compact;

switch off the engine, pull up the

handbrake and engage the 1stgear or

reverse. Make sure that any passengers

get out of the car and go to a safe

place where they will not obstruct traffic

or be exposed to the risk of injury.

Wear the reflective safety jacket

(compulsory by law) before getting out

of the car;

500L versions: open the luggage

compartment and lift up the mat;

500L WAGON versions: open the

luggage compartment and lift up the

"Cargo Magic Space" load platform,

holding it with one hand while you take

out the tool bag.

500L versions: using the wrench A

fig. 120 located in the tool box, loosen

the locking device, take the tool box

B and place it close to the wheel to be

replaced. Then take the space-saver

wheel C;

119F0Y0649C

123

Page 128 of 268

With third row of rear seats not

folded: remove the luggage-covering

curtain (which must be positioned

in front of second row of seats) then

place the punctured tyre in the luggage

compartment, positioning it as shown

in fig. 129 (wheel hub facing the inside

of the passenger compartment in

order to prevent the wheel from falling

when closing the tailgate).

REFITTING THE

STANDARD WHEEL

Versions with steel wheels

make sure the contact surfaces

between standard wheel and hub are

clean and free from impurities so that

the fixing stud bolts will not come

loose;

fit the standard wheel inserting the 5

stud bolts into the holes;

press-fit the wheel cap, aligning the

special splining (on the cap) with the

inflation valve;

using the spanner provided, tighten

the fixing stud bolts;

lower the car and remove the jack;

using the spanner provided, fully

tighten the stud bolts in the sequence

shown previously.

Versions with alloy rims

insert the wheel on the hub and

using the spanner provided tighten the

stud bolts;

lower the car and remove the jack;

using the spanner provided, fully

tighten the 5 stud bolts in the sequence

shown;

reinstall the hub cap, taking care to

position the three plastic pins in the

dedicated seats on the wheel. Slightly

press the cap to prevent any damage

to the plastic pins.

IMPORTANT If it is not fitted correctly,

the hub cap may detach when the

vehicle is running.

At the end of the operation

Proceed as follows:

stow the space-saver wheel in the

compartment provided in the boot;

place the jack and the other tools in

their container;

arrange the container and tools on

the space-saver wheel;

correctly reposition the luggage

compartment mat.

WARNING

122)The space-saver wheel (for

versions/markets where provided) is

specific to your car, do not use it on other

models, or use the space-saver wheel

of other models on your car. The

space-saver wheel must only be used in

the event of an emergency. Never use it for

more than strictly necessary and never

exceed 80 km/h. On the space-saver

wheel there is an orange label,

summarising the main warnings regarding

space-saver wheel usage restrictions.

Never remove or cover the label. The label

contains the following indications in four

languages: "Warning! For temporary use

only! 80 km/h max.! Replace with standard

wheel as soon as possible. Never cover

this indication." Never apply a wheel cap

on a space-saver wheel.

123)Alert other drivers that the car is

stationary in compliance with local

regulations: hazard warning lights, warning

triangle, etc. Any passengers on board

should leave the car, especially if it is

heavily laden. Passengers should stay

away from on-coming traffic while the

wheel is being changed.

129F0Y0368C

126

IN AN EMERGENCY

Page 132 of 268

WARNING

63)The sealant is effective with external

temperatures of between -40°C and

+55°C. The sealant has an expiry date. It is

possible to repair tyres which have been

damaged on tread up to a diameter of

6 mm. Show the cartridge and the label to

the personnel charged with handling the

tyre treated with the tyre repair kit.

WARNING

2)Dispose of the bottle and the sealant

liquid properly. Have the sealing fluid and

the bottle disposed of in compliance

with national and local regulations.

REPLACING A BULB

132) 133)64) 65)

GENERAL

INSTRUCTIONS

Before replacing a bulb check the

contacts for oxidation.

Burnt bulbs must be replaced by

others of the same type and power.

After replacing a headlight bulb,

always check that alignment of the light

beam is correct.

when a light is not working, check

that the corresponding fuse is intact

before replacing a bulb. For the location

of fuses, refer to the paragraph

"Replacing fuses" in this chapter.IMPORTANT When the weather is cold

or damp or after heavy rain or washing,

the surface of headlights or rear lights

may steam up and/or form drops of

condensation on the inside. This is

a natural phenomenon due to the

difference in temperature and humidity

between the inside and the outside

of the glass which does not indicate a

fault and does not compromise the

normal operation of lighting devices.

The mist disappears quickly when the

lights are turned on, starting from

the centre of the diffuser, extending

progressively towards the edges.

130

IN AN EMERGENCY

Page 133 of 268

TYPES OF BULBS

UseType Power

Dipped/main beam headlights H7 55W

Daytime running lights (DRL) LED + bulb W21W 21W

Front side lights LED –

Rear side lights/Brake lights P21/5W 21W/5W

Front direction indicators PY21W 21W

Side direction indicators WY5W 5W

Rear direction indicators P21W 21W

Third brake light LED –

Fog lights H11 55W

Reversing light W16W 16W

Rear fog light W16W 16W

Number plate C5W 5W

Front ceiling light C5W 5W

Front roof lights (sun visors) C5W 5W

Luggage compartment light W5W 5W

Glove compartment light C5W 5W

Rear ceiling lights C5W 5W

131

Page 134 of 268

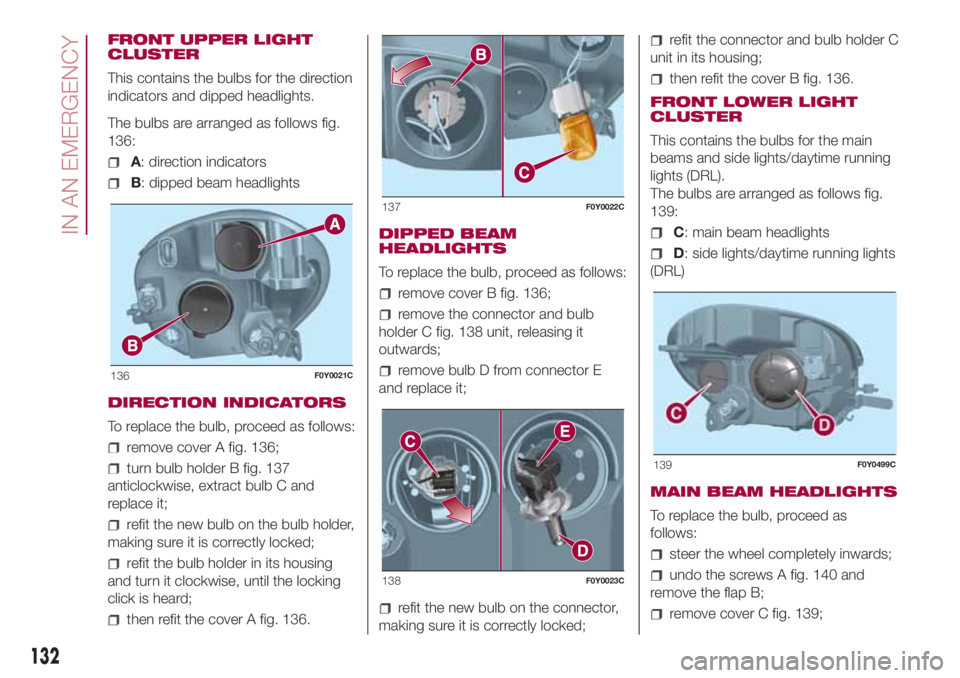

FRONT UPPER LIGHT

CLUSTER

This contains the bulbs for the direction

indicators and dipped headlights.

The bulbs are arranged as follows fig.

136:

A: direction indicators

B: dipped beam headlights

DIRECTION INDICATORS

To replace the bulb, proceed as follows:

remove cover A fig. 136;

turn bulb holder B fig. 137

anticlockwise, extract bulb C and

replace it;

refit the new bulb on the bulb holder,

making sure it is correctly locked;

refit the bulb holder in its housing

and turn it clockwise, until the locking

click is heard;

then refit the cover A fig. 136.DIPPED BEAM

HEADLIGHTS

To replace the bulb, proceed as follows:

remove cover B fig. 136;

remove the connector and bulb

holder C fig. 138 unit, releasing it

outwards;

remove bulb D from connector E

and replace it;

refit the new bulb on the connector,

making sure it is correctly locked;

refit the connector and bulb holder C

unit in its housing;

then refit the cover B fig. 136.

FRONT LOWER LIGHT

CLUSTER

This contains the bulbs for the main

beams and side lights/daytime running

lights (DRL).

The bulbs are arranged as follows fig.

139:

C: main beam headlights

D: side lights/daytime running lights

(DRL)

MAIN BEAM HEADLIGHTS

To replace the bulb, proceed as

follows:

steer the wheel completely inwards;

undo the screws A fig. 140 and

remove the flap B;

remove cover C fig. 139;

136F0Y0021C

137F0Y0022C

138F0Y0023C

139F0Y0499C

132

IN AN EMERGENCY