ECU FIAT 500X 2015 2.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: 500X, Model: FIAT 500X 2015 2.GPages: 240, PDF Size: 10.72 MB

Page 119 of 240

TOWING TRAILERSIMPORTANT

120) 121)

For towing caravans or trailers the

vehicle must be fitted with an approved

tow hook and an adequate electrical

system. Should aftermarket installation

be requested, this must be carried

out by specialists.

Install any specific and/or additional

door mirrors as specified by the

Highway Code.

Remember that when towing a trailer,

steep hills are harder to climb, braking

distances increase and overtaking

takes longer depending on the overall

weight of the trailer. Engage a low gear

when driving downhill, rather than

constantly using the brake. The weight

the trailer exerts on the vehicle tow

hook reduces the vehicle's loading

capacity by the same amount. To make

sure that the maximum towable weight

is not exceeded (given in the vehicle

registration document) account should

be taken of the fully laden trailer,

including accessories and luggage.

Do not exceed the speed limits specific

to each country you are driving in, in

the case of vehicles towing trailers.

In any case, the top speed must not

exceed 100 km/h.Any electric brake must be powered

directly by the battery through a cable

with a cross-section of no less than 2.5

mm

2. In addition to the electrical

branches, the vehicle electrical system

can only be connected to the supply

cable for an electric brake and to the

cable for an internal light for the trailer,

not exceeding 15 W. For connections,

use the preset control unit with a

battery cable with section not less than

2.5 mm

2. The use of auxiliary loads

other than external lights (e.g. electric

brake) must take place with engine

running.

INSTALLING A TOW

HOOKThe towing device should be fastened

to the body by specialised personnel

according to any additional and/or

integrative information supplied by the

Manufacturer of the device. It must also

meet current regulations with reference

to Directive 94/20/EC and subsequent

amendments.

For any version the towing device used

must be right for the towable weight

of the vehicle on which it is to be

installed.For the electrical connection a standard

connector should be used which is

generally placed on a special bracket

normally fastened to the towing device,

and a special ECU for external trailer

light control must be installed on the

vehicle. 7 or 13-pin 12 V DC

connections should be used (CUNA/

UNI and ISO/DIN Standards). Follow

any instructions provided by the vehicle

manufacturer and/or the towing device

manufacturer.

117

15-12-2014 8:23 Pagina 117

Page 120 of 240

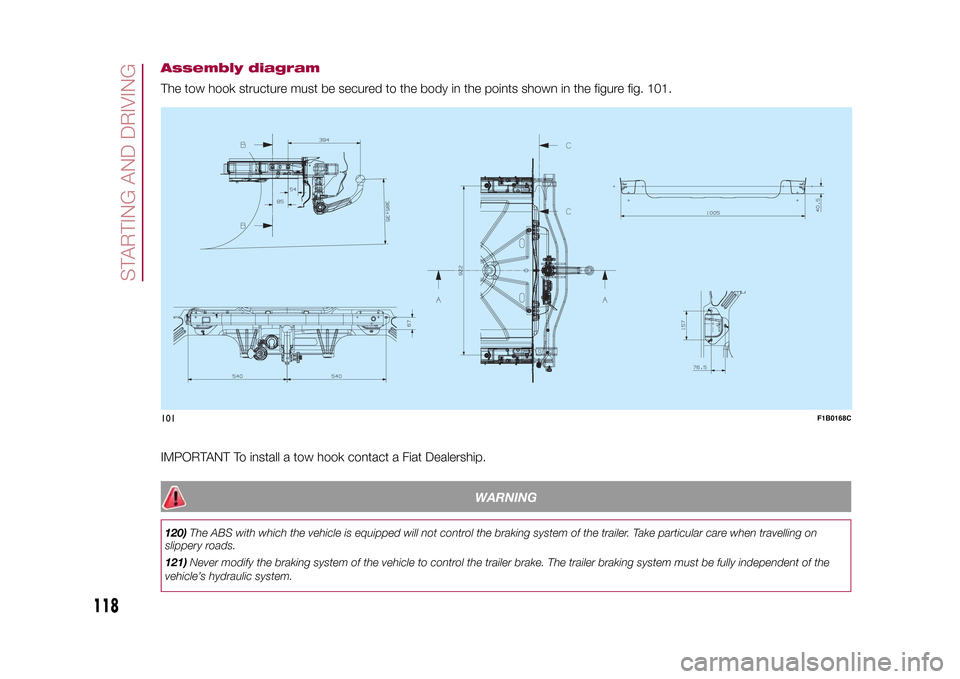

Assembly diagramThe tow hook structure must be secured to the body in the points shown in the figure fig. 101.

.

IMPORTANT To install a tow hook contact a Fiat Dealership.

WARNING

120)The ABS with which the vehicle is equipped will not control the braking system of the trailer. Take particular care when travelling on

slippery roads.

121)Never modify the braking system of the vehicle to control the trailer brake. The trailer braking system must be fully independent of the

vehicle’s hydraulic system.101

F1B0168C

118

STARTING AND DRIVING

15-12-2014 8:23 Pagina 118

Page 131 of 240

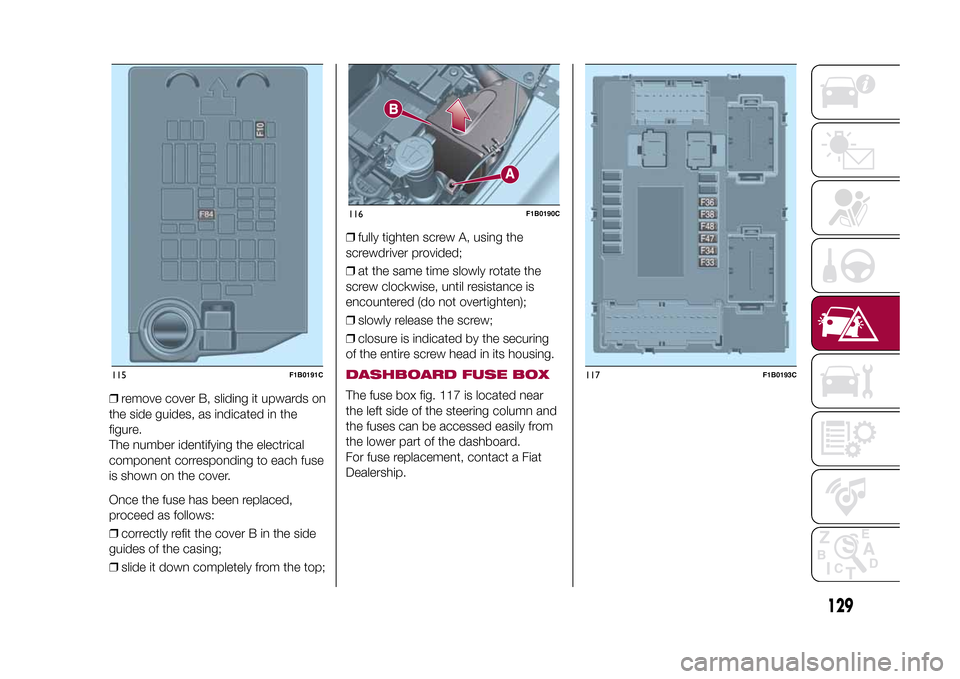

❒remove cover B, sliding it upwards on

the side guides, as indicated in the

figure.

The number identifying the electrical

component corresponding to each fuse

is shown on the cover.

Once the fuse has been replaced,

proceed as follows:

❒correctly refit the cover B in the side

guides of the casing;

❒slide it down completely from the top;❒fully tighten screw A, using the

screwdriver provided;

❒at the same time slowly rotate the

screw clockwise, until resistance is

encountered (do not overtighten);

❒slowly release the screw;

❒closure is indicated by the securing

of the entire screw head in its housing.

DASHBOARD FUSE BOXThe fuse box fig. 117 is located near

the left side of the steering column and

the fuses can be accessed easily from

the lower part of the dashboard.

For fuse replacement, contact a Fiat

Dealership.

115

F1B0191C

116

F1B0190C

117

F1B0193C

129

15-12-2014 8:23 Pagina 129

Page 135 of 240

CHANGING A WHEELJACKPlease note that:

❒the weight of the jack is 2.8 kg;

❒The jack requires no adjustment;

❒the jack cannot be repaired and in

the event of a fault it must be replaced

by another original one;

❒No tool other than its cranking device

may be fitted on the jack.CHANGING PROCEDURE

132) 133) 134) 135) 136) 137) 138) 139)

Proceed as follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground should be flat if possible,

and sufficiently firm;

❒stop the engine, engage the hazard

warning lights and the electric parking

brake;

❒engage first gear or reverse or, for

versions with automatic transmission,

move the lever to position P (Park);

❒wear the reflective safety jacket

(compulsory by law in certain countries)

before getting out of the vehicle;❒open the boot and position the

reconfigurable load platform in

an inclined position (see "Boot" in the

"Knowing your vehicle" chapter);

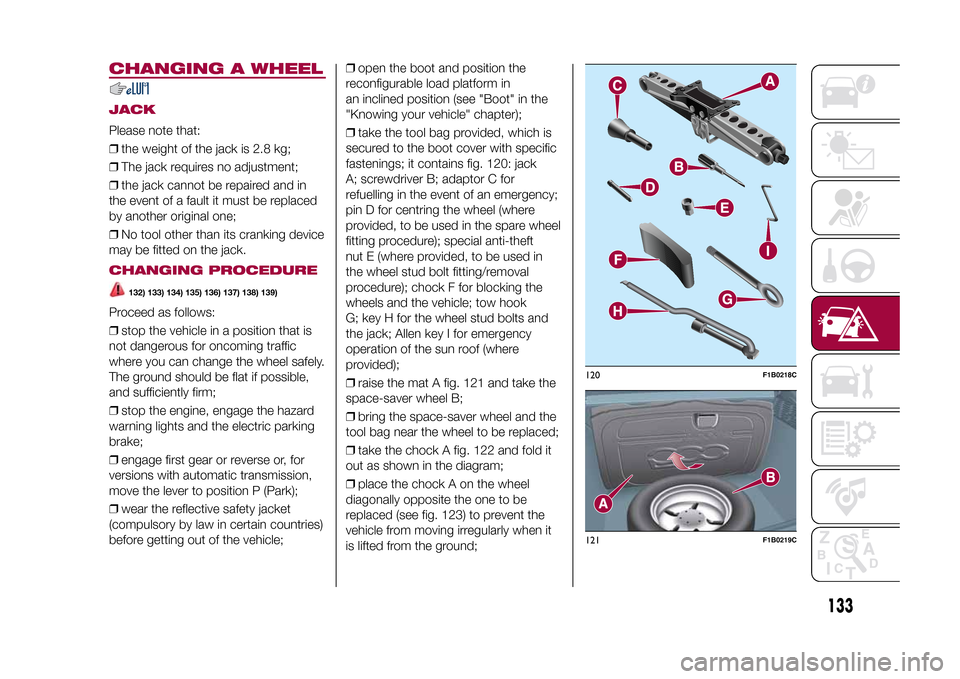

❒take the tool bag provided, which is

secured to the boot cover with specific

fastenings; it contains fig. 120: jack

A; screwdriver B; adaptor C for

refuelling in the event of an emergency;

pin D for centring the wheel (where

provided, to be used in the spare wheel

fitting procedure); special anti-theft

nut E (where provided, to be used in

the wheel stud bolt fitting/removal

procedure); chock F for blocking the

wheels and the vehicle; tow hook

G; key H for the wheel stud bolts and

the jack; Allen key I for emergency

operation of the sun roof (where

provided);

❒raise the mat A fig. 121 and take the

space-saver wheel B;

❒bring the space-saver wheel and the

tool bag near the wheel to be replaced;

❒take the chock A fig. 122 and fold it

out as shown in the diagram;

❒place the chock A on the wheel

diagonally opposite the one to be

replaced (see fig. 123) to prevent the

vehicle from moving irregularly when it

is lifted from the ground;

120

F1B0218C

121

F1B0219C

133

15-12-2014 8:23 Pagina 133

Page 139 of 240

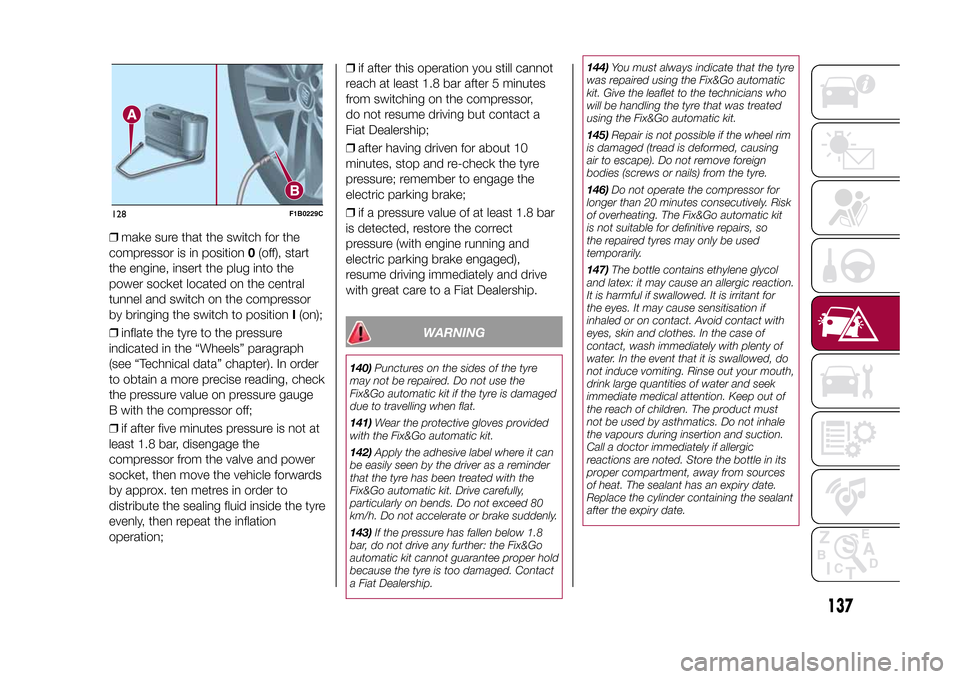

❒make sure that the switch for the

compressor is in position0(off), start

the engine, insert the plug into the

power socket located on the central

tunnel and switch on the compressor

by bringing the switch to positionI(on);

❒inflate the tyre to the pressure

indicated in the “Wheels” paragraph

(see “Technical data” chapter). In order

to obtain a more precise reading, check

the pressure value on pressure gauge

B with the compressor off;

❒if after five minutes pressure is not at

least 1.8 bar, disengage the

compressor from the valve and power

socket, then move the vehicle forwards

by approx. ten metres in order to

distribute the sealing fluid inside the tyre

evenly, then repeat the inflation

operation;❒if after this operation you still cannot

reach at least 1.8 bar after 5 minutes

from switching on the compressor,

do not resume driving but contact a

Fiat Dealership;

❒after having driven for about 10

minutes, stop and re-check the tyre

pressure; remember to engage the

electric parking brake;

❒if a pressure value of at least 1.8 bar

is detected, restore the correct

pressure (with engine running and

electric parking brake engaged),

resume driving immediately and drive

with great care to a Fiat Dealership.

WARNING

140)Punctures on the sides of the tyre

may not be repaired. Do not use the

Fix&Go automatic kit if the tyre is damaged

due to travelling when flat.

141)Wear the protective gloves provided

with the Fix&Go automatic kit.

142)Apply the adhesive label where it can

be easily seen by the driver as a reminder

that the tyre has been treated with the

Fix&Go automatic kit. Drive carefully,

particularly on bends. Do not exceed 80

km/h. Do not accelerate or brake suddenly.

143)If the pressure has fallen below 1.8

bar, do not drive any further: the Fix&Go

automatic kit cannot guarantee proper hold

because the tyre is too damaged. Contact

a Fiat Dealership.144)You must always indicate that the tyre

was repaired using the Fix&Go automatic

kit. Give the leaflet to the technicians who

will be handling the tyre that was treated

using the Fix&Go automatic kit.

145)Repair is not possible if the wheel rim

is damaged (tread is deformed, causing

air to escape). Do not remove foreign

bodies (screws or nails) from the tyre.

146)Do not operate the compressor for

longer than 20 minutes consecutively. Risk

of overheating. The Fix&Go automatic kit

is not suitable for definitive repairs, so

the repaired tyres may only be used

temporarily.

147)The bottle contains ethylene glycol

and latex: it may cause an allergic reaction.

It is harmful if swallowed. It is irritant for

the eyes. It may cause sensitisation if

inhaled or on contact. Avoid contact with

eyes, skin and clothes. In the case of

contact, wash immediately with plenty of

water. In the event that it is swallowed, do

not induce vomiting. Rinse out your mouth,

drink large quantities of water and seek

immediate medical attention. Keep out of

the reach of children. The product must

not be used by asthmatics. Do not inhale

the vapours during insertion and suction.

Call a doctor immediately if allergic

reactions are noted. Store the bottle in its

proper compartment, away from sources

of heat. The sealant has an expiry date.

Replace the cylinder containing the sealant

after the expiry date.

128

F1B0229C

137

15-12-2014 8:23 Pagina 137

Page 165 of 240

BATTERY

RECHARGINGIMPORTANTIMPORTANT The battery recharging

procedure is given as information only.

To carry out this operation contact a

Fiat Dealership.

IMPORTANT After setting the ignition

device to STOP and having closed the

driver side door, wait at least one

minute before disconnecting the

electrical supply from the battery. When

reconnecting the electrical supply to

the battery, make sure that the ignition

device is in the STOP position and

the driver side door is closed.

IMPORTANT Charging should be slow

at a low ampere rating for

approximately 24 hours. Charging for a

longer time may damage the battery.IMPORTANT The cables of the

electrical system must be correctly

reconnected to the battery, i.e. the

positive cable (+) to the positive

terminal and the negative cable (–) to

the negative terminal. The battery

terminals are marked with the positive

(+) and negative (–) symbols, and are

shown on the battery cover. The battery

terminals must also be corrosion-free

and firmly secured to the terminals. If a

"quick-type" battery charger is used

with the battery fitted on the vehicle,

before connecting it disconnect both

cables of the battery itself. Do not use a

"quick-type" battery charger to provide

the starting voltage.

VERSIONS WITHOUT

START&STOP SYSTEMTo recharge, proceed as follows:

❒disconnect the terminal from the

negative battery pole;

❒connect the charger cables to the

battery terminals, observing the polarity;

❒turn on the charger;

❒when it is recharged, turn the charger

off before disconnecting it from the

battery;

❒reconnect the negative battery

terminal.

VERSIONS WITH

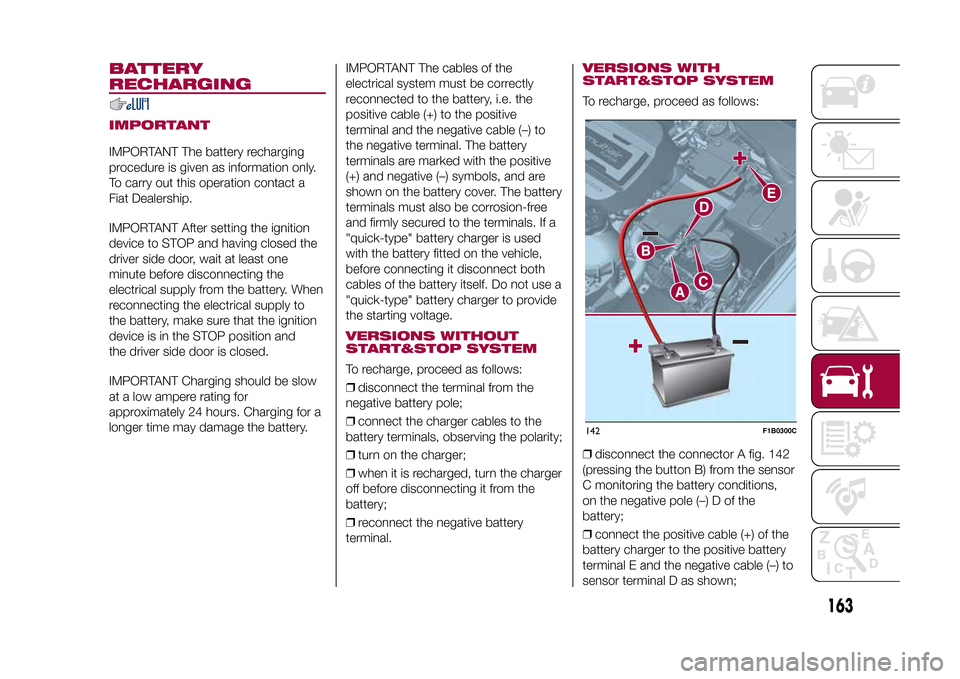

START&STOP SYSTEMTo recharge, proceed as follows:

❒disconnect the connector A fig. 142

(pressing the button B) from the sensor

C monitoring the battery conditions,

on the negative pole (–) D of the

battery;

❒connect the positive cable (+) of the

battery charger to the positive battery

terminal E and the negative cable (–) to

sensor terminal D as shown;142

F1B0300C

163

15-12-2014 8:23 Pagina 163