warning light FIAT 500X 2022 Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2022, Model line: 500X, Model: FIAT 500X 2022Pages: 312, PDF Size: 13.26 MB

Page 231 of 312

IN CASE OF EMERGENCY229

REFUELING IN EMERGENCY

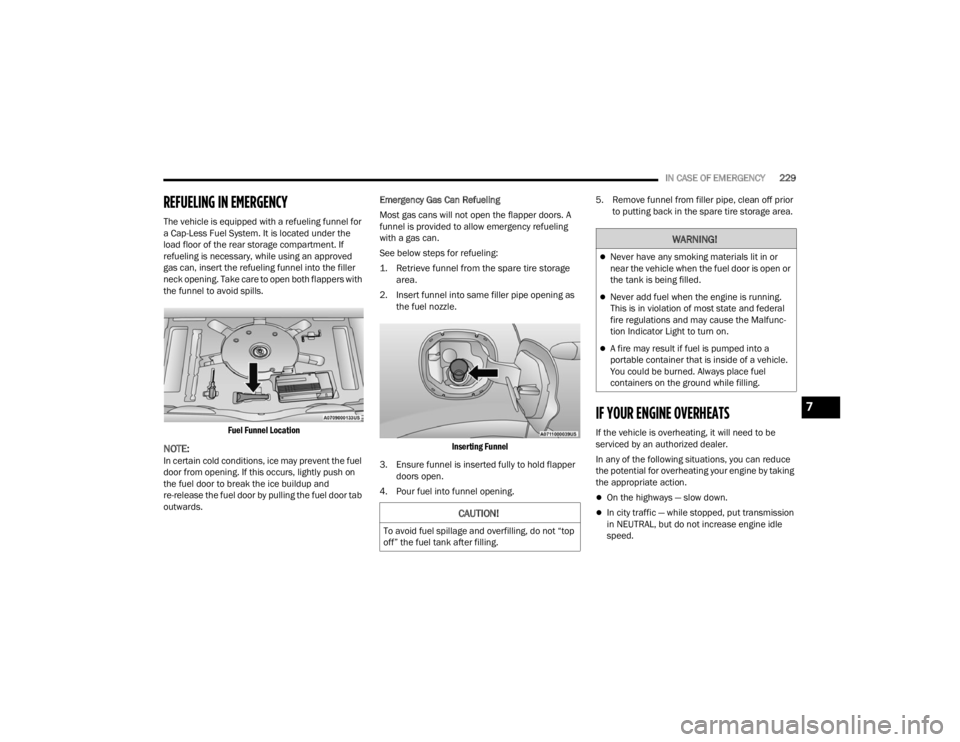

The vehicle is equipped with a refueling funnel for

a Cap-Less Fuel System. It is located under the

load floor of the rear storage compartment. If

refueling is necessary, while using an approved

gas can, insert the refueling funnel into the filler

neck opening. Take care to open both flappers with

the funnel to avoid spills.

Fuel Funnel Location

NOTE:In certain cold conditions, ice may prevent the fuel

door from opening. If this occurs, lightly push on

the fuel door to break the ice buildup and

re-release the fuel door by pulling the fuel door tab

outwards. Emergency Gas Can Refueling

Most gas cans will not open the flapper doors. A

funnel is provided to allow emergency refueling

with a gas can.

See below steps for refueling:

1. Retrieve funnel from the spare tire storage

area.

2. Insert funnel into same filler pipe opening as the fuel nozzle.

Inserting Funnel

3. Ensure funnel is inserted fully to hold flapper doors open.

4. Pour fuel into funnel opening. 5. Remove funnel from filler pipe, clean off prior

to putting back in the spare tire storage area.

IF YOUR ENGINE OVERHEATS

If the vehicle is overheating, it will need to be

serviced by an authorized dealer.

In any of the following situations, you can reduce

the potential for overheating your engine by taking

the appropriate action.

On the highways — slow down.

In city traffic — while stopped, put transmission

in NEUTRAL, but do not increase engine idle

speed.CAUTION!

To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

WARNING!

Never have any smoking materials lit in or

near the vehicle when the fuel door is open or

the tank is being filled.

Never add fuel when the engine is running.

This is in violation of most state and federal

fire regulations and may cause the Malfunc -

tion Indicator Light to turn on.

A fire may result if fuel is pumped into a

portable container that is inside of a vehicle.

You could be burned. Always place fuel

containers on the ground while filling.

7

22_FD_OM_EN_USC_t.book Page 229

Page 239 of 312

SERVICING AND MAINTENANCE237

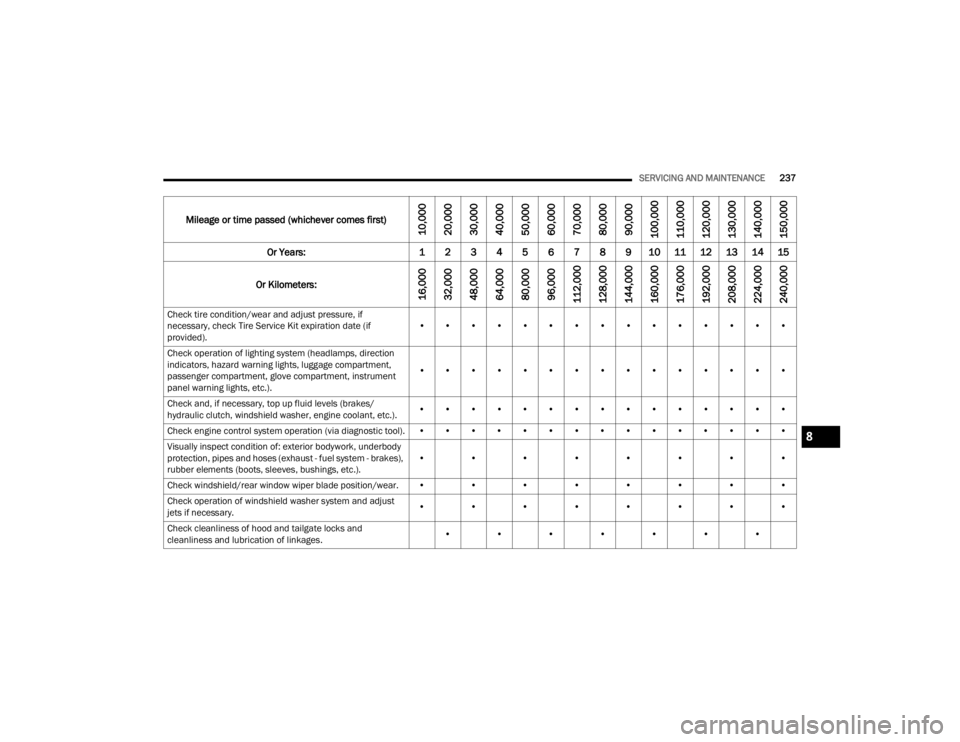

Mileage or time passed (whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Check tire condition/wear and adjust pressure, if

necessary, check Tire Service Kit expiration date (if

provided). • • • • • • • • • • • • • • •

Check operation of lighting system (headlamps, direction

indicators, hazard warning lights, luggage compartment,

passenger compartment, glove compartment, instrument

panel warning lights, etc.). • • • • • • • • • • • • • • •

Check and, if necessary, top up fluid levels (brakes/

hydraulic clutch, windshield washer, engine coolant, etc.). • • • • • • • • • • • • • • •

Check engine control system operation (via diagnostic tool). • • • • • • • • • • • • • • •

Visually inspect condition of: exterior bodywork, underbody

protection, pipes and hoses (exhaust - fuel system - brakes),

rubber elements (boots, sleeves, bushings, etc.). • • • • • • • •

Check windshield/rear window wiper blade position/wear. • • • • • • • •

Check operation of windshield washer system and adjust

jets if necessary. • • • • • • • •

Check cleanliness of hood and tailgate locks and

cleanliness and lubrication of linkages. • • • • • • •

8

22_FD_OM_EN_USC_t.book Page 237

Page 241 of 312

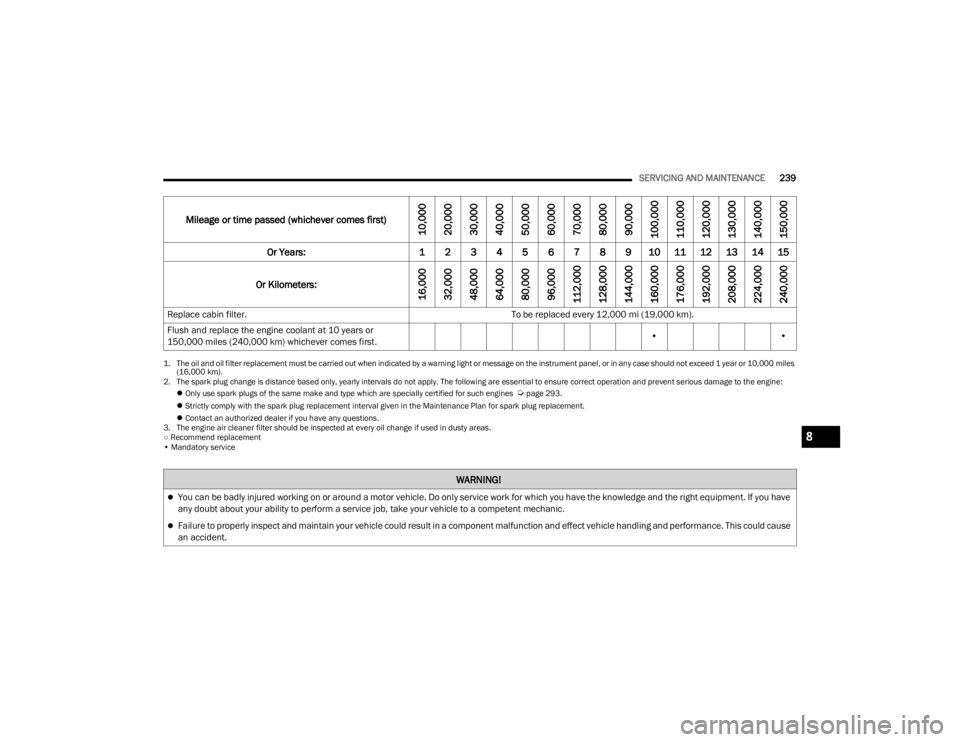

SERVICING AND MAINTENANCE239

Replace cabin filter. To be replaced every 12,000 mi (19,000 km).

Flush and replace the engine coolant at 10 years or

150,000 miles (240,000 km) whichever comes first. •

•

1. The oil and oil filter replacement must be carried out when indicated by a warning light or message on the instrument panel, or in any case should not exceed 1 year or 10,000 miles

(16,000 km).

2. The spark plug change is distance based only, yearly intervals do not apply. The following are essential to ensure correct operation and prevent serious damage to the engine:

Only use spark plugs of the same make and type which are specially certified for such engines

Úpage 293.

Strictly comply with the spark plug replacement interval given in the Maintenance Plan for spark plug replacement.

Contact an authorized dealer if you have any questions.

3. The engine air cleaner filter should be inspected at every oil change if used in dusty areas.

○ Recommend replacement

• Mandatory service

Mileage or time passed (whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

WARNING!

You can be badly injured working on or around a motor vehicle. Do only service work for which you have the knowledge and the right equipment. If you have

any doubt about your ability to perform a service job, take your vehicle to a competent mechanic.

Failure to properly inspect and maintain your vehicle could result in a component malfunction and effect vehicle handling and performance. This could cause

an accident.

8

22_FD_OM_EN_USC_t.book Page 239

Page 252 of 312

250SERVICING AND MAINTENANCE

(Continued)

If frequent engine coolant additions are

required, the cooling system should be pressure

tested for leaks.

Maintain engine coolant concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corro-

sion protection of your engine which contains

aluminum components.

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces -

sary, install ONLY the correct type thermostat.

Other designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically Ú page 236.

Brake Master Cylinder

The fluid level in the master cylinder should be

checked when performing under hood services, or

immediately if the “Brake Warning Light” is on.

Be sure to clean the top of the master cylinder area

before removing the cap. If necessary, add fluid to

bring the fluid level up to the requirements

described on the brake fluid reservoir. Fluid level

can be expected to fall as the brake pads wear. The

brake fluid level should be checked when the pads

are replaced. However, low fluid level may be

caused by a leak and a checkup may be needed.

Use only manufacturer's recommended brake fluid

Úpage 293.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. You

would not have your full braking capacity in an

emergency.

WARNING!

Use only manufacturer’s recommended brake

fluid Ú page 293. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in a open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

22_FD_OM_EN_USC_t.book Page 250

Page 260 of 312

258SERVICING AND MAINTENANCE

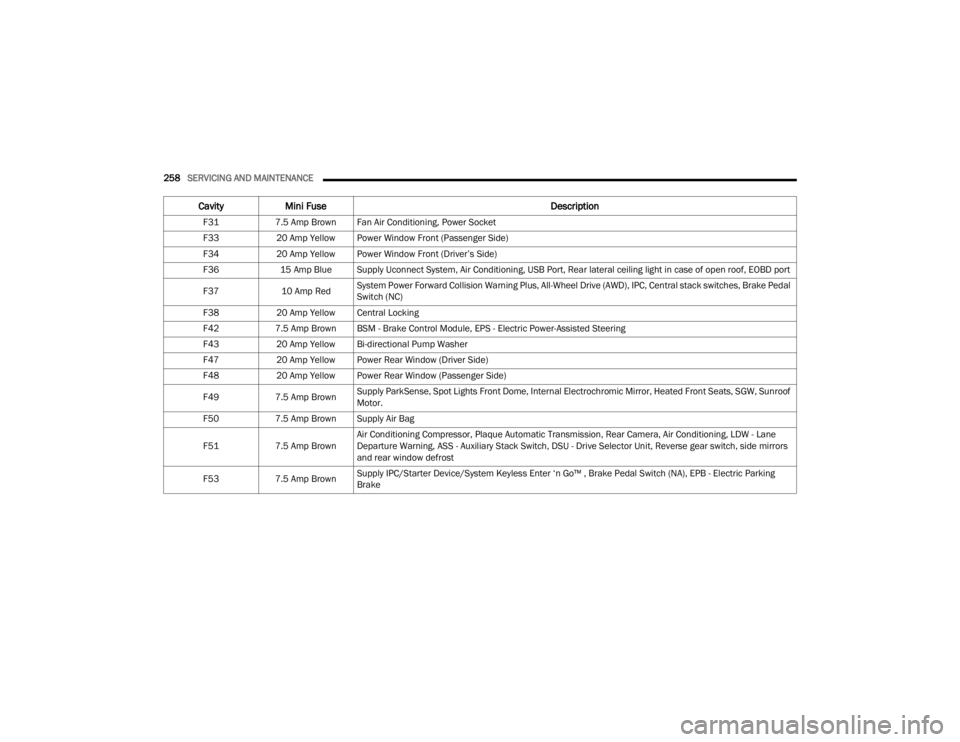

CavityMini Fuse Description

F317.5 Amp Brown Fan Air Conditioning, Power Socket

F33 20 Amp Yellow Power Window Front (Passenger Side)

F34 20 Amp Yellow Power Window Front (Driver’s Side)

F36 15 Amp Blue Supply Uconnect System, Air Conditioning, USB Port, Rear lateral ceiling light in case of open roof, EOBD port

F37 10 Amp RedSystem Power Forward Collision Warning Plus, All-Wheel Drive (AWD), IPC, Central stack switches, Brake Pedal

Switch (NC)

F38 20 Amp Yellow Central Locking

F42 7.5 Amp Brown BSM - Brake Control Module, EPS - Electric Power-Assisted Steering

F43 20 Amp Yellow Bi-directional Pump Washer

F47 20 Amp Yellow Power Rear Window (Driver Side)

F48 20 Amp Yellow Power Rear Window (Passenger Side)

F49 7.5 Amp Brown Supply ParkSense, Spot Lights Front Dome, Internal Electrochromic Mirror, Heated Front Seats, SGW, Sunroof

Motor.

F50 7.5 Amp Brown Supply Air Bag

F51 7.5 Amp Brown Air Conditioning Compressor, Plaque Automatic Transmission, Rear Camera, Air Conditioning, LDW - Lane

Departure Warning, ASS - Auxiliary Stack Switch, DSU - Drive Selector Unit, Reverse gear switch, side mirrors

and rear window defrost

F53 7.5 Amp Brown Supply IPC/Starter Device/System Keyless Enter ‘n Go™ , Brake Pedal Switch (NA), EPB - Electric Parking

Brake

22_FD_OM_EN_USC_t.book Page 258

Page 264 of 312

262SERVICING AND MAINTENANCE

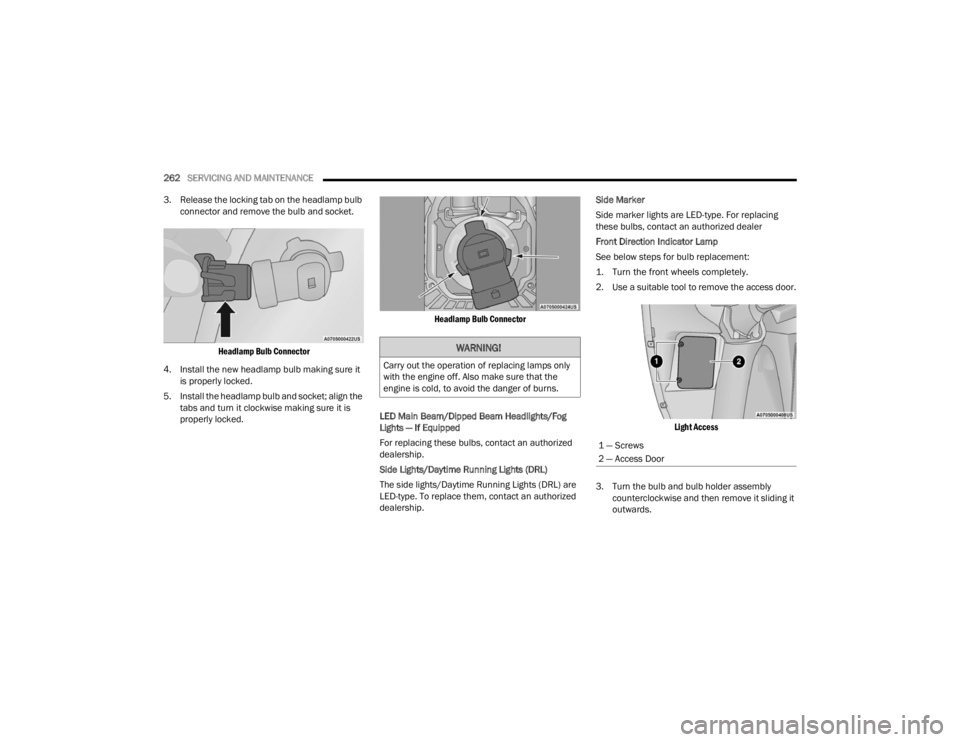

3. Release the locking tab on the headlamp bulb connector and remove the bulb and socket.

Headlamp Bulb Connector

4. Install the new headlamp bulb making sure it is properly locked.

5. Install the headlamp bulb and socket; align the tabs and turn it clockwise making sure it is

properly locked.

Headlamp Bulb Connector

LED Main Beam/Dipped Beam Headlights/Fog

Lights — If Equipped

For replacing these bulbs, contact an authorized

dealership.

Side Lights/Daytime Running Lights (DRL)

The side lights/Daytime Running Lights (DRL) are

LED-type. To replace them, contact an authorized

dealership. Side Marker

Side marker lights are LED-type. For replacing

these bulbs, contact an authorized dealer

Front Direction Indicator Lamp

See below steps for bulb replacement:

1. Turn the front wheels completely.

2. Use a suitable tool to remove the access door.

Light Access

3. Turn the bulb and bulb holder assembly counterclockwise and then remove it sliding it

outwards.

WARNING!

Carry out the operation of replacing lamps only

with the engine off. Also make sure that the

engine is cold, to avoid the danger of burns.

1 — Screws

2 — Access Door

22_FD_OM_EN_USC_t.book Page 262

Page 270 of 312

268SERVICING AND MAINTENANCE

(Continued)

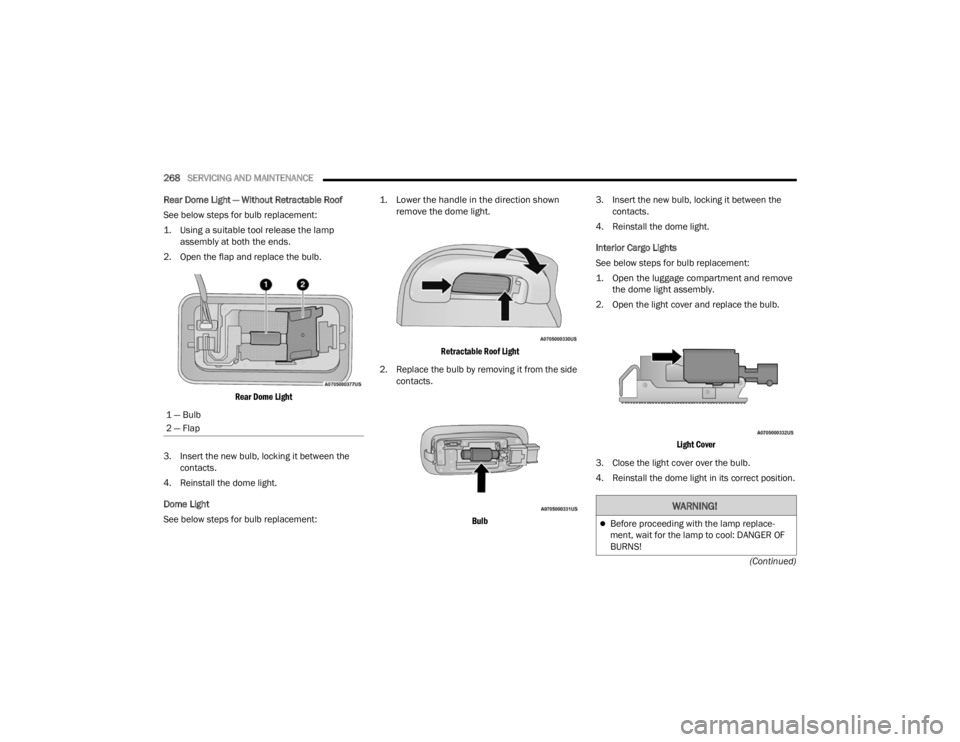

Rear Dome Light — Without Retractable Roof

See below steps for bulb replacement:

1. Using a suitable tool release the lamp

assembly at both the ends.

2. Open the flap and replace the bulb.

Rear Dome Light

3. Insert the new bulb, locking it between the contacts.

4. Reinstall the dome light.

Dome Light

See below steps for bulb replacement:

1. Lower the handle in the direction shown

remove the dome light.

Retractable Roof Light

2. Replace the bulb by removing it from the side contacts.

Bulb

3. Insert the new bulb, locking it between the

contacts.

4. Reinstall the dome light.

Interior Cargo Lights

See below steps for bulb replacement:

1. Open the luggage compartment and remove the dome light assembly.

2. Open the light cover and replace the bulb.

Light Cover

3. Close the light cover over the bulb.

4. Reinstall the dome light in its correct position.

1 — Bulb

2 — Flap

WARNING!

Before proceeding with the lamp replace

-

ment, wait for the lamp to cool: DANGER OF

BURNS!

22_FD_OM_EN_USC_t.book Page 268

Page 271 of 312

SERVICING AND MAINTENANCE269

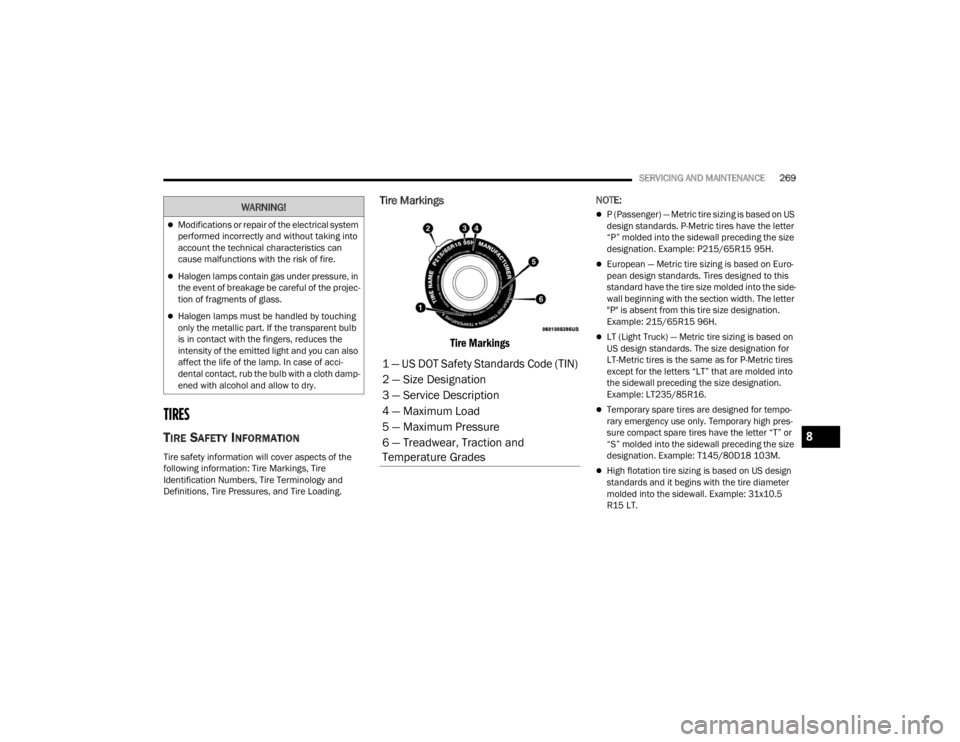

TIRES

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on US

design standards. P-Metric tires have the letter

“P” molded into the sidewall preceding the size

designation. Example: P215/65R15 95H.

European — Metric tire sizing is based on Euro -

pean design standards. Tires designed to this

standard have the tire size molded into the side -

wall beginning with the section width. The letter

"P" is absent from this tire size designation.

Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based on

US design standards. The size designation for

LT-Metric tires is the same as for P-Metric tires

except for the letters “LT” that are molded into

the sidewall preceding the size designation.

Example: LT235/85R16.

Temporary spare tires are designed for tempo -

rary emergency use only. Temporary high pres -

sure compact spare tires have the letter “T” or

“S” molded into the sidewall preceding the size

designation. Example: T145/80D18 103M.

High flotation tire sizing is based on US design

standards and it begins with the tire diameter

molded into the sidewall. Example: 31x10.5

R15 LT.

Modifications or repair of the electrical system

performed incorrectly and without taking into

account the technical characteristics can

cause malfunctions with the risk of fire.

Halogen lamps contain gas under pressure, in

the event of breakage be careful of the projec -

tion of fragments of glass.

Halogen lamps must be handled by touching

only the metallic part. If the transparent bulb

is in contact with the fingers, reduces the

intensity of the emitted light and you can also

affect the life of the lamp. In case of acci -

dental contact, rub the bulb with a cloth damp -

ened with alcohol and allow to dry.

WARNING!

1 — US DOT Safety Standards Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and

Temperature Grades

8

22_FD_OM_EN_USC_t.book Page 269

Page 281 of 312

SERVICING AND MAINTENANCE279

Keep dismounted tires in a cool, dry place with as

little exposure to light as possible. Protect tires

from contact with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance of

many characteristics. They should be inspected

regularly for wear and correct cold tire inflation

pressures. The manufacturer strongly

recommends that you use tires equivalent to the

originals in size, quality and performance when

replacement is needed Ú page 278. Refer to the

Tire and Loading Information placard or the

Vehicle Certification Label for the size designation

of your tire. The Load Index and Speed Symbol for

your tire will be found on the original equipment

tire sidewall.

See the Tire Sizing Chart example for more

information relating to the Load Index and Speed

Symbol of a tire Ú page 270.

It is recommended to replace the two front tires or

two rear tires as a pair. Replacing just one tire can

seriously affect your vehicle’s handling. If you ever

replace a wheel, make sure that the wheel’s

specifications match those of the original wheels.

It is recommended you contact an authorized tire

dealer or original equipment dealer with any

questions you may have on tire specifications or capability. Failure to use equivalent replacement

tires may adversely affect the safety, handling, and

ride of your vehicle.

TIRE TYPES

All Season Tires — If Equipped

All Season tires provide traction for all seasons

(Spring, Summer, Autumn, and Winter). Traction

levels may vary between different all season tires.

All season tires can be identified by the M+S, M&S,

M/S or MS designation on the tire sidewall. Use all

season tires only in sets of four; failure to do so

may adversely affect the safety and handling of

your vehicle.

Summer Or Three Season Tires —

If Equipped

Summer tires provide traction in both wet and dry

conditions, and are not intended to be driven in

snow or on ice. If your vehicle is equipped with

Summer tires, be aware these tires are not

designed for Winter or cold driving conditions.

Install Winter tires on your vehicle when ambient

temperatures are less than 40°F (5°C) or if roads

are covered with ice or snow. For more

information, contact an authorized dealer.

WARNING!

Do not use a tire, wheel size, load rating, or

speed rating other than that specified for your

vehicle. Some combinations of unapproved

tires and wheels may change suspension

dimensions and performance characteristics,

resulting in changes to steering, handling, and

braking of your vehicle. This can cause unpre

-

dictable handling and stress to steering and

suspension components. You could lose

control and have a collision resulting in

serious injury or death. Use only the tire and

wheel sizes with load ratings approved for

your vehicle.

Never use a tire with a smaller load index or

capacity, other than what was originally

equipped on your vehicle. Using a tire with a

smaller load index could result in tire over -

loading and failure. You could lose control and

have a collision.

Failure to equip your vehicle with tires having

adequate speed capability can result in

sudden tire failure and loss of vehicle control.

CAUTION!

Replacing original tires with tires of a different

size may result in false speedometer and

odometer readings.

8

22_FD_OM_EN_USC_t.book Page 279

Page 291 of 312

289

TECHNICAL SPECIFICATIONS

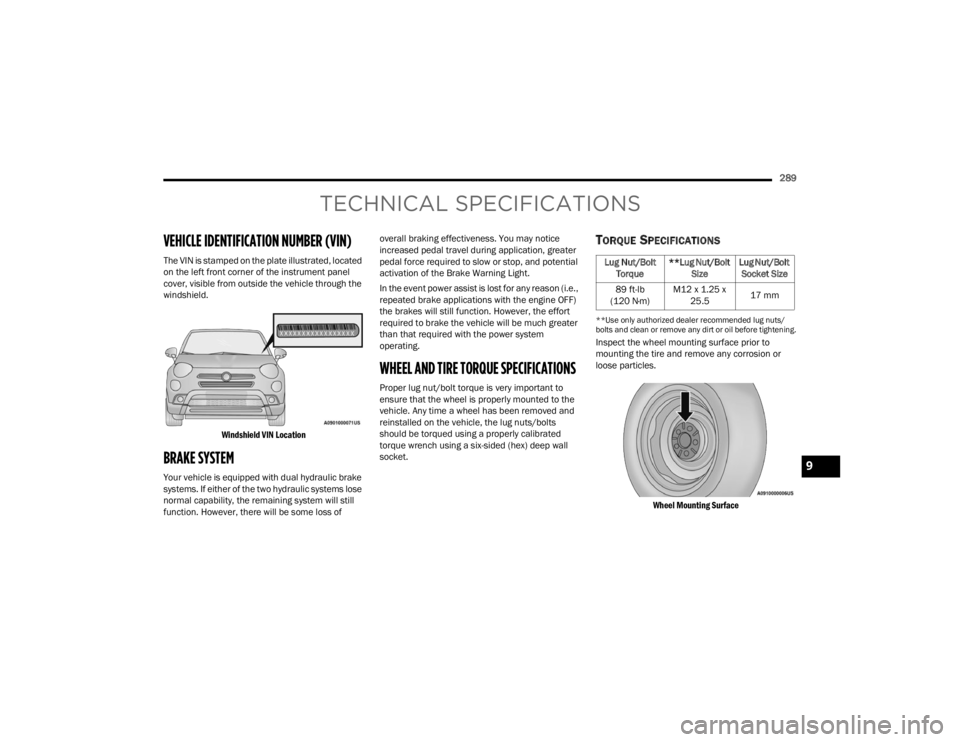

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is stamped on the plate illustrated, located

on the left front corner of the instrument panel

cover, visible from outside the vehicle through the

windshield.

Windshield VIN Location

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic brake

systems. If either of the two hydraulic systems lose

normal capability, the remaining system will still

function. However, there will be some loss of overall braking effectiveness. You may notice

increased pedal travel during application, greater

pedal force required to slow or stop, and potential

activation of the Brake Warning Light.

In the event power assist is lost for any reason (i.e.,

repeated brake applications with the engine OFF)

the brakes will still function. However, the effort

required to brake the vehicle will be much greater

than that required with the power system

operating.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to the

vehicle. Any time a wheel has been removed and

reinstalled on the vehicle, the lug nuts/bolts

should be torqued using a properly calibrated

torque wrench using a six-sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Lug Nut/Bolt Torque **Lug Nut/Bolt

Size Lug Nut/Bolt

Socket Size

89 ft-lb

(120 N·m) M12 x 1.25 x

25.5 17 mm

9

22_FD_OM_EN_USC_t.book Page 289