wheel bolts FIAT BARCHETTA 2003 1.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2003, Model line: BARCHETTA, Model: FIAT BARCHETTA 2003 1.GPages: 170, PDF Size: 3.55 MB

Page 87 of 170

86

Observe the instructions on this and

the following pages to use the jack and

space-saver spare wheel correctly.

BUMP STARTING IF A TYRE

IS PUNCTURED

General instructions

Do not bump start by

pushing, towing or coast-

ing downhill. This way of

starting could cause a rush of fu-

el into the catalytic exhaust pipe

and damage it beyond repair.

Signal the presence of the

stopped vehicle according

to the laws in force (e.g. hazard

lights, reflecting triangle, etc.).

Any passengers on board should

leave the vehicle, especially if it is

heavily laden. Passengers should

stay away from oncoming traffic

while the wheel is being changed.

If the wheel is being changed on a

steep or badly surfaced road, place

wedges or other suitable material

under the wheels to stop the vehi-

cle.

WARNING

Remember that if the en-

gine is not running, the

brake booster will not work. You

therefore have to use considerably

more effort on the brake pedal.

WARNING

The space-saver spare

wheel is vehicle-specific.

Never use the wheel on other mod-

els. Never use other model spare

wheels on your vehicle.

If you change the type of wheels

(alloy rims instead of steel rims) you

will have to change the entire set of

fastening bolts with another set of

suitably sized bolts.

Only use the spare-saver wheel for

emergencies.

With the spare wheel do not exceed

80 kph.

An orange sticker is attached to the

spare wheel giving the main in-

structions for its use and limitations.

The sticker must never be re-

moved or covered.

Do not fit the hub cap to the

spare wheel.

WARNING

Page 89 of 170

88

CHANGING A WHEEL

Please note:

– the jack weighs 1.85 kg;

– the jack requires no adjustments;

– the jack cannot be repaired. If it

breaks it must be replaced with a new

jack;

– no other tool, part from the han-

dle shown in this chapter can be fitted

to the jack.

Change the wheel as follows:

1)Stop the vehicle so that it is not

a hazard for other road users or your-

self when changing the wheel. The

ground should be as flat and firm as

possible.2)Stop the engine and engage the

handbrake.

3)Engage first gear or reverse.

4)Lift the boot carpet.

5)Unscrew the locking device A-

fig. 2. Lift out the tool kit and place

it near the wheel to be changed and

take out the space-saver spare wheel.6)Loosen the bolts on the wheel to

be replaced by approximately half a

turn. If alloy rims are fitted, shake the

car to facilitate removing the rim from

the wheel hub.

7)Turn the jack handle so the jack

opens partially.

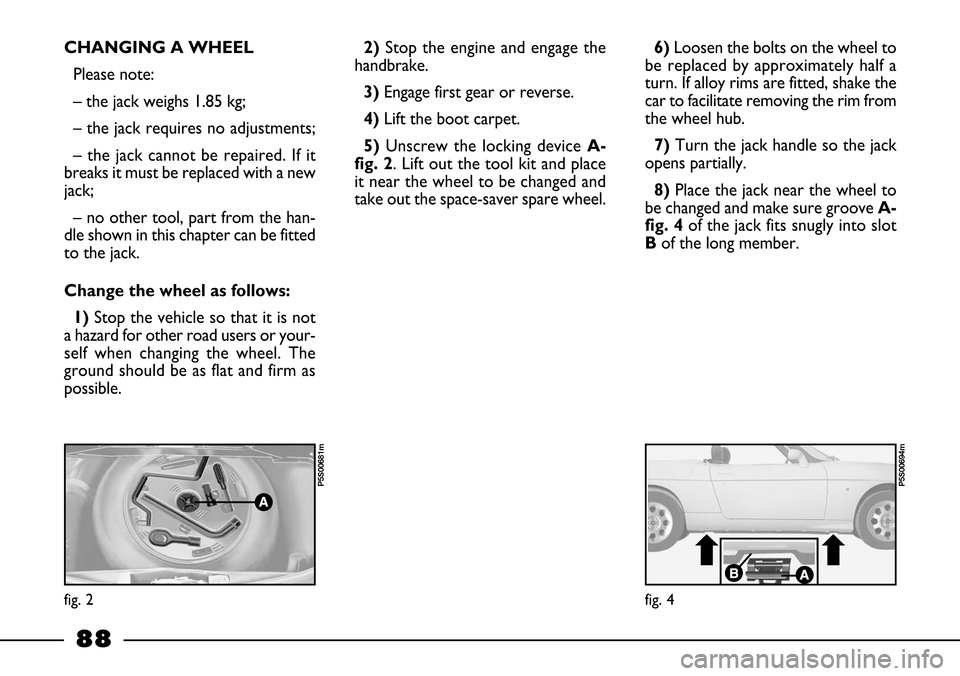

8)Place the jack near the wheel to

be changed and make sure groove A-

fig. 4of the jack fits snugly into slot

Bof the long member.

fig. 2

P5S00681m

fig. 4

P5S00694m

Page 90 of 170

89

Depending on whether the normal

wheels are fitted with steel or light al-

loy rims, the spare wheel (always

made of steel) differs in order to be

compatible with the wheel bolts which

are specific for each of the two types

of rim.

If the type of wheel to be used is to

be changed (alloy rims in place of steel

rims and vice-versa) the bolts must al-

so be changed and a specific spare

wheel adopted.

Keep the bolts and the spare wheel

as they are essential if the original

wheels are to be refitted at some time

in the future. 9) Warn anyone nearby that the ve-

hicle is about to be lifted. They must

stay clear and not touch the vehicle

until it is back on the ground.

10) Turn the jack handle and raise

the car until the wheel is a few cen-

timetres above the ground.

The jack handle must turn freely,

without touching the ground to avoid

scraping your hands. Do not touch the

moving parts of the jack as they can

cause injuries. If you dirty your hands

with grease, clean them carefully.

11) Fully unscrew the 4 bolts, re-

move the wheel and, where provided

recover the wheel hub cap.

12)Make sure the surfaces of the

space-saver spare wheel that come in-

to contact with the hub are clean and

free from any impurities which could

result in the wheel bolts working

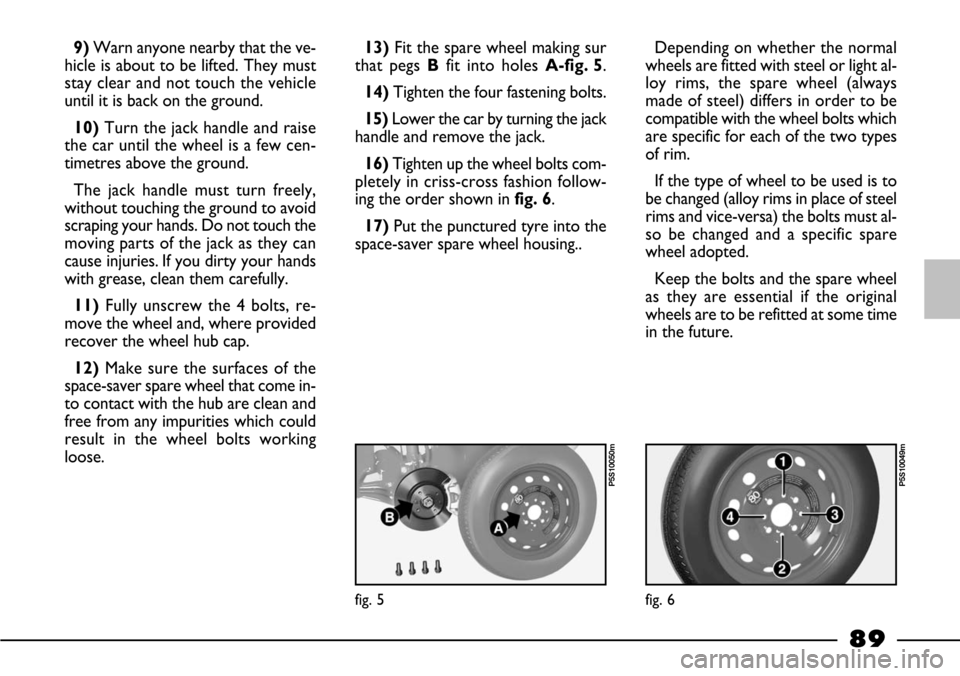

loose.13)Fit the spare wheel making sur

that pegs Bfit into holes A-fig. 5.

14) Tighten the four fastening bolts.

15) Lower the car by turning the jack

handle and remove the jack.

16)Tighten up the wheel bolts com-

pletely in criss-cross fashion follow-

ing the order shown in fig. 6.

17) Put the punctured tyre into the

space-saver spare wheel housing..

fig. 5

P5S10050m

fig. 6

P5S10049m

Page 91 of 170

90

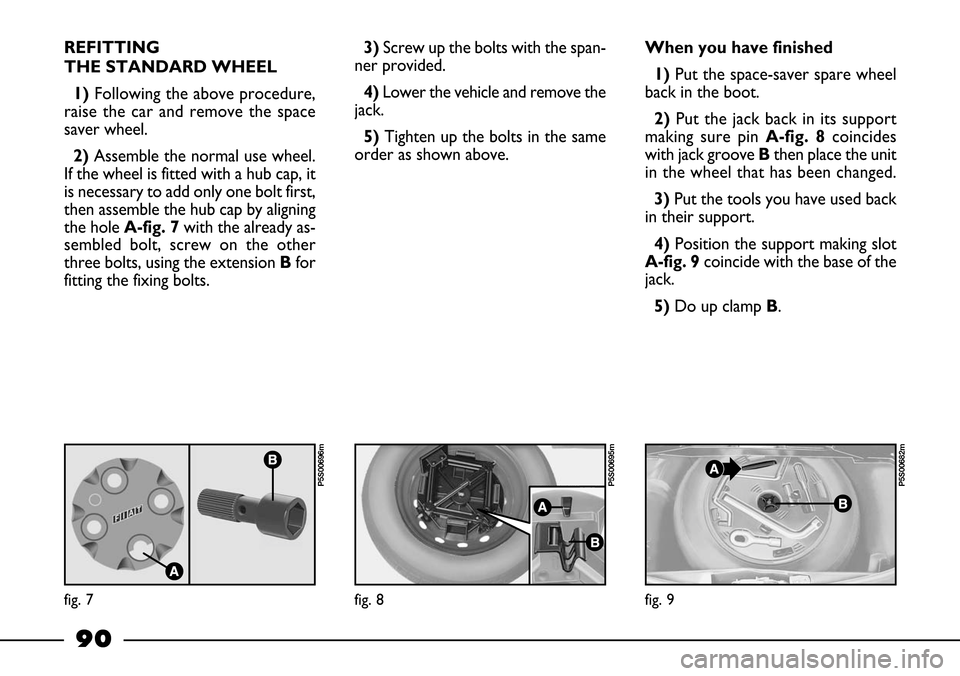

3)Screw up the bolts with the span-

ner provided.

4) Lower the vehicle and remove the

jack.

5)Tighten up the bolts in the same

order as shown above.When you have finished

1)Put the space-saver spare wheel

back in the boot.

2) Put the jack back in its support

making sure pin A-fig. 8coincides

with jack groove Bthen place the unit

in the wheel that has been changed.

3) Put the tools you have used back

in their support.

4)Position the support making slot

A-fig. 9coincide with the base of the

jack.

5)Do up clamp B. REFITTING

THE STANDARD WHEEL

1) Following the above procedure,

raise the car and remove the space

saver wheel.

2)Assemble the normal use wheel.

If the wheel is fitted with a hub cap, it

is necessary to add only one bolt first,

then assemble the hub cap by aligning

the hole A-fig. 7with the already as-

sembled bolt, screw on the other

three bolts, using the extension Bfor

fitting the fixing bolts.

fig. 7

P5S00696m

fig. 8

P5S00695m

fig. 9

P5S00682m

Page 142 of 170

141

WHEELS

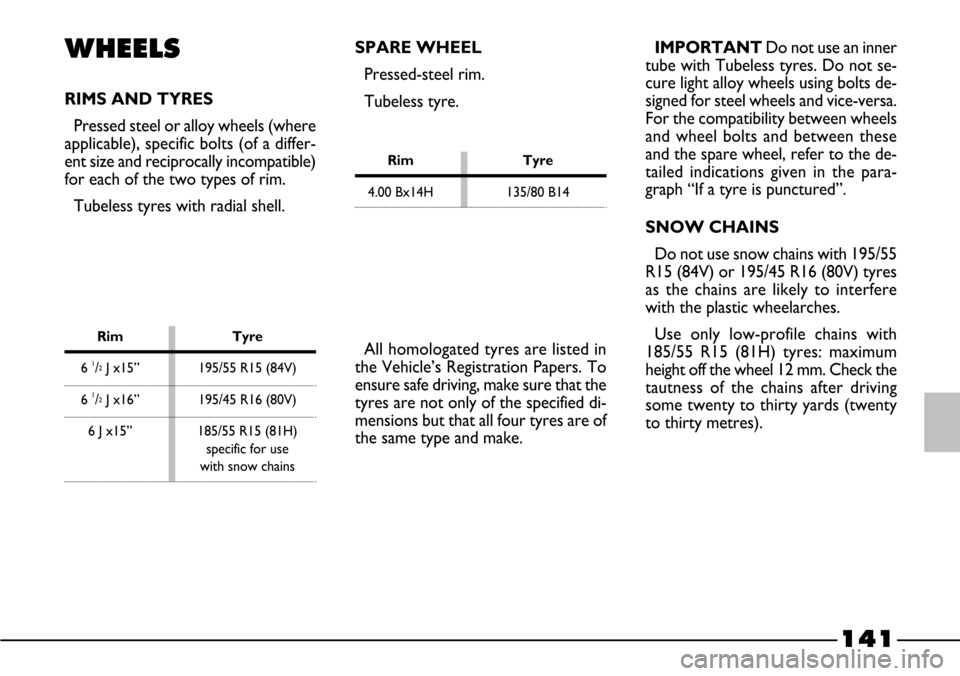

RIMS AND TYRES

Pressed steel or alloy wheels (where

applicable), specific bolts (of a differ-

ent size and reciprocally incompatible)

for each of the two types of rim.

Tubeless tyres with radial shell.IMPORTANT Do not use an inner

tube with Tubeless tyres. Do not se-

cure light alloy wheels using bolts de-

signed for steel wheels and vice-versa.

For the compatibility between wheels

and wheel bolts and between these

and the spare wheel, refer to the de-

tailed indications given in the para-

graph “If a tyre is punctured”.

SNOW CHAINS

Do not use snow chains with 195/55

R15 (84V) or 195/45 R16 (80V) tyres

as the chains are likely to interfere

with the plastic wheelarches.

Use only low-profile chains with

185/55 R15 (81H) tyres: maximum

height off the wheel 12 mm. Check the

tautness of the chains after driving

some twenty to thirty yards (twenty

to thirty metres).

Rim Tyre

6 1/2J x15” 195/55 R15 (84V)

6 1/2J x16” 195/45 R16 (80V)

6 J x15” 185/55 R15 (81H)

specific for use

with snow chains

SPARE WHEEL

Pressed-steel rim.

Tubeless tyre.

All homologated tyres are listed in

the Vehicle’s Registration Papers. To

ensure safe driving, make sure that the

tyres are not only of the specified di-

mensions but that all four tyres are of

the same type and make.

Rim Tyre

4.00 Bx14H 135/80 B14

Page 154 of 170

153

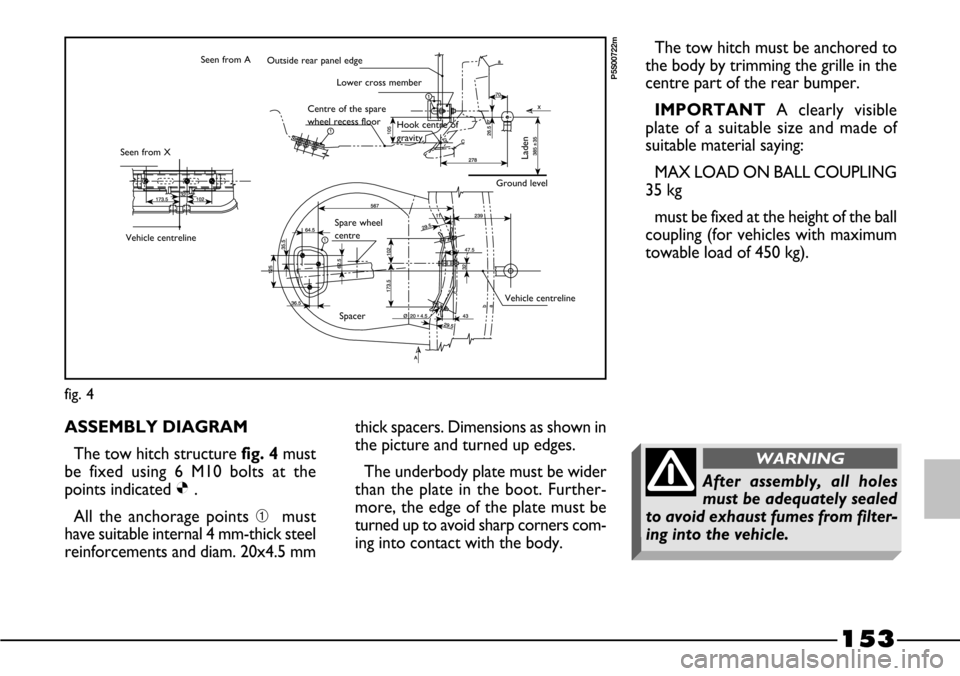

ASSEMBLY DIAGRAM

The tow hitch structure fig. 4must

be fixed using 6 M10 bolts at the

points indicated Ø.

All the anchorage points ➀must

have suitable internal 4 mm-thick steel

reinforcements and diam. 20x4.5 mmthick spacers. Dimensions as shown in

the picture and turned up edges.

The underbody plate must be wider

than the plate in the boot. Further-

more, the edge of the plate must be

turned up to avoid sharp corners com-

ing into contact with the body.

fig. 4

P5S00722m

The tow hitch must be anchored to

the body by trimming the grille in the

centre part of the rear bumper.

IMPORTANTA clearly visible

plate of a suitable size and made of

suitable material saying:

MAX LOAD ON BALL COUPLING

35 kg

must be fixed at the height of the ball

coupling (for vehicles with maximum

towable load of 450 kg).Outside rear panel edge

Lower cross member

Laden

Ground level Hook centre of

gravity Centre of the spare

wheel recess floor

Seen from X

Vehicle centreline

Vehicle centreline

Spacer Spare wheel

centre Seen from A

After assembly, all holes

must be adequately sealed

to avoid exhaust fumes from filter-

ing into the vehicle.

WARNING