wiper fluid FIAT BARCHETTA 2003 1.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2003, Model line: BARCHETTA, Model: FIAT BARCHETTA 2003 1.GPages: 170, PDF Size: 3.55 MB

Page 11 of 170

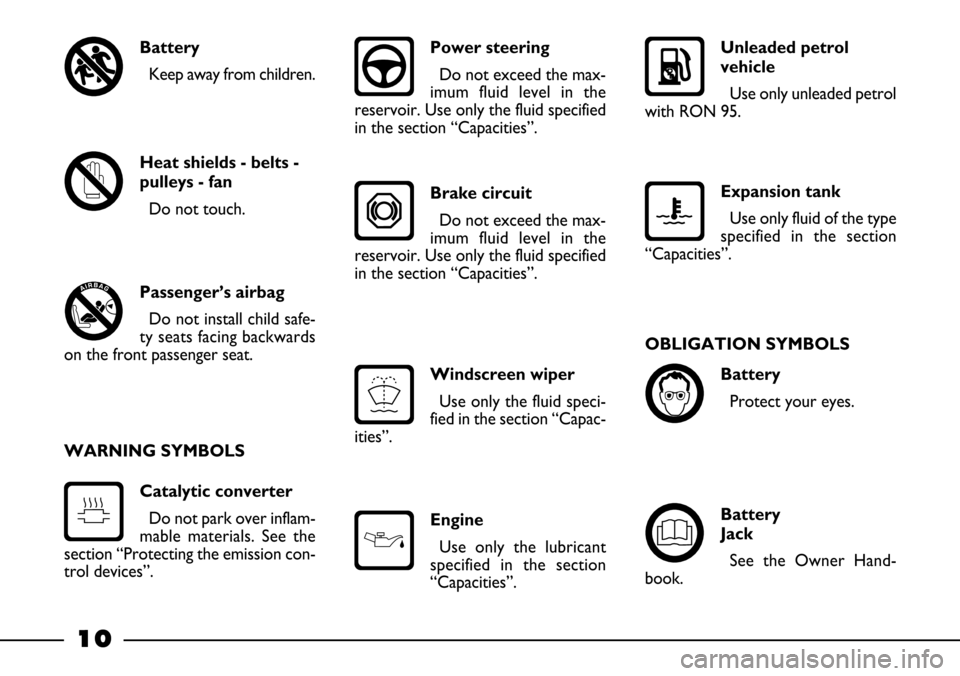

Unleaded petrol

vehicle

Use only unleaded petrol

with RON 95.

Expansion tank

Use only fluid of the type

specified in the section

“Capacities”.

Battery

Jack

See the Owner Hand-

book.Battery

Protect your eyes.

Engine

Use only the lubricant

specified in the section

“Capacities”. Windscreen wiper

Use only the fluid speci-

fied in the section “Capac-

ities”.Brake circuit

Do not exceed the max-

imum fluid level in the

reservoir. Use only the fluid specified

in the section “Capacities”.

Catalytic converter

Do not park over inflam-

mable materials. See the

section “Protecting the emission con-

trol devices”.Power steering

Do not exceed the max-

imum fluid level in the

reservoir. Use only the fluid specified

in the section “Capacities”.

Passenger’s airbag

Do not install child safe-

ty seats facing backwards

on the front passenger seat.Heat shields - belts -

pulleys - fan

Do not touch. Battery

Keep away from children.

10

WARNING SYMBOLSOBLIGATION SYMBOLS

Page 112 of 170

111

CAR MAINTENANCE

The Fiat barchetta is brand new throughout, even

in its service schedule. For example: the first service

schedule coupon is to be used at 20,000 km making the

traditional check at 1,500 km unnecessary. You should

however remember that your car needs routine main-

tenance such as systematic checking of the fluid level

and tyre pressure, and any necessary topping up.

You should nonetheless bear in mind that proper car

maintenance is certainly the best way to keep your car

in tip-top condition for years to come and safeguard its

safety features, its environmentally-friendly nature and

its low running costs.

Also remember that following the servicing regula-

tions marked with the symbol ∑as specified might be

essential to ensuring the warranty remains valid.SCHEDULED SERVICING ............................................... 112

SERVICE SCHEDULE ......................................................... 113

ANNUAL INSPECTION SCHEDULE ........................... 115

ADDITIONAL OPERATIONS ........................................ 115

CHECKING FLUID LEVELS ............................................. 117

AIR CLEANER ..................................................................... 122

POLLEN FILTER .................................................................. 123

BATTERY .............................................................................. 123

ELECTRONIC CONTROL UNITS ............................... 125

SPARK PLUGS ..................................................................... 126

WHEELS AND TYRES ...................................................... 126

RUBBER TUBING .............................................................. 128

WINDSCREEN WIPER ..................................................... 128

MANUAL CLIMATE CONTROL SYSTEM ................. 130

BODYWORK ...................................................................... 130

HOOD ................................................................................... 133

INTERIORS ........................................................................... 133

Page 116 of 170

115

ANNUAL

INSPECTION

SCHEDULE

The following annual inspection

schedule is required for cars travelling

less than 20,000 km a year (e.g. ap-

proximately 10,000 km). The schedule

includes the following operations:

– Check tyre condition and wear and

adjust pressure, if required (including

spare-saver spare wheel).

– Check operation of lights (head-

lights, direction indicators, hazard

lights, boot light, passenger compart-

ment ceiling light, glove compartment

light, instrument panel lights, etc.).

– Check windscreen wiper/washer

and adjust nozzles.

– Check position wear of windscreen

window wiper blades.

ADDITIONAL

OPERATIONS

Every 1,000 kmor before long

trips, check and top up as necessary:

– coolant level

– brake fluid level

– power steering fluid level

– electrolyte level

– windscreen washer liquid level

– tyre condition and pressure.

We advise you to use FL Selenia

products, which have been designed

and produced expressly for the Fiat

vehicles (see the table “Capacities” giv-

en in the “Technical specifications”

section).

Every 3,000 km check and top up

as necessary: engine oil level. – Check rear brake pad conditions

and wear.

– Inspect conditions of. engine, gear-

box, transmission, piping (exhaust - fu-

el feed - brakes), rubber parts (boots

- sleeves - bushings - etc.), brake and

fuel line hoses.

– Check battery charge status.

– Check conditions of various con-

trol belts.

– Check and top up fluid levels (en-

gine coolant, brakes, windscreen

washer, battery, etc.).

– Change engine oil.

– Replace engine oil filter.

– Replace pollen filter (where fitted).

Page 129 of 170

128

RUBBER TUBING

Follow the Service Schedule careful-

ly in the case of the braking, power

steering and fuel supply systems' rub-

ber hoses. Ozone, high temperatures

and long absence of liquid in the sys-

tem can in fact cause the hardening

and cracking of the hoses with possi-

ble losses of fluid. A careful check is

therefore essential.

WINDSCREEN

WIPER

BLADES

Periodically clean the rubber part

with suitable liquid; TUTELA PRO-

FESSIONAL SC 35is recommend-

ed.

Change the blades if the rubber edge

is warped or worn out. You should in

any case change them approximately

once a year. To ensure the front and rear tyres all

wear evenly, you are advised to change

the tyres over every 10-15 thousand

kilometres (6-10 thousand miles)

keeping them on the same side of the

car so as not to reverse the direction

of rotation.

Do not change the tyres

over in criss-cross fashion

by moving a tyre from the left hand

side of the car to the right and vice

versa.

WARNING

Travelling with worn wiper

blades is dangerous be-

cause it reduces visibility in bad

weather.

WARNING

Page 130 of 170

129

Some simple steps can reduce po-

tential damage to the blades:

– If the temperature falls to below

zero, make sure the rubber blade is

not frozen to the windscreen. If nec-

essary, free it with a de-icing com-

pound.

– Remove any snow that has settled

on the glass: besides saving the blades

you will avoid straining the electric

windscreen wiper motor and causing

it to overheat.

– Do not operate the windscreen

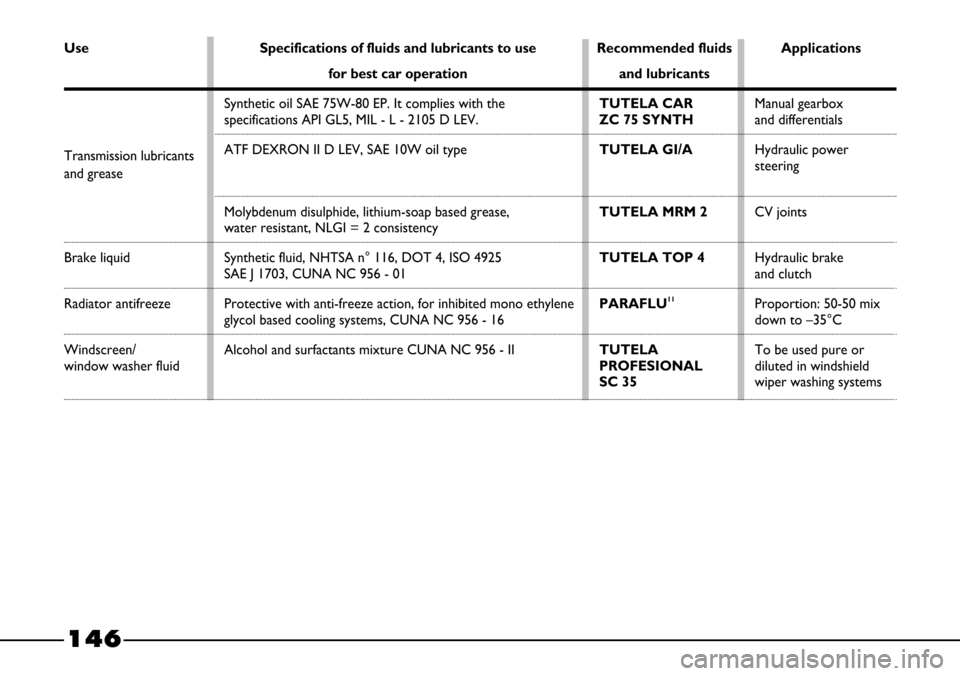

wipers on dry glass.SPRAY NOZZLES

If there is no jet of liquid, first make

sure that there is liquid in the reser-

voir: see “Checking fluid levels” in this

chapter.

Then make sure that the holes in the

nozzles fig. 12 are not clogged up.

Use a pin for this if necessary.

The jets of the windscreen washer

are directed by adjusting the nozzles

in such a way that the jets are direct-

ed at the highest point reached by the

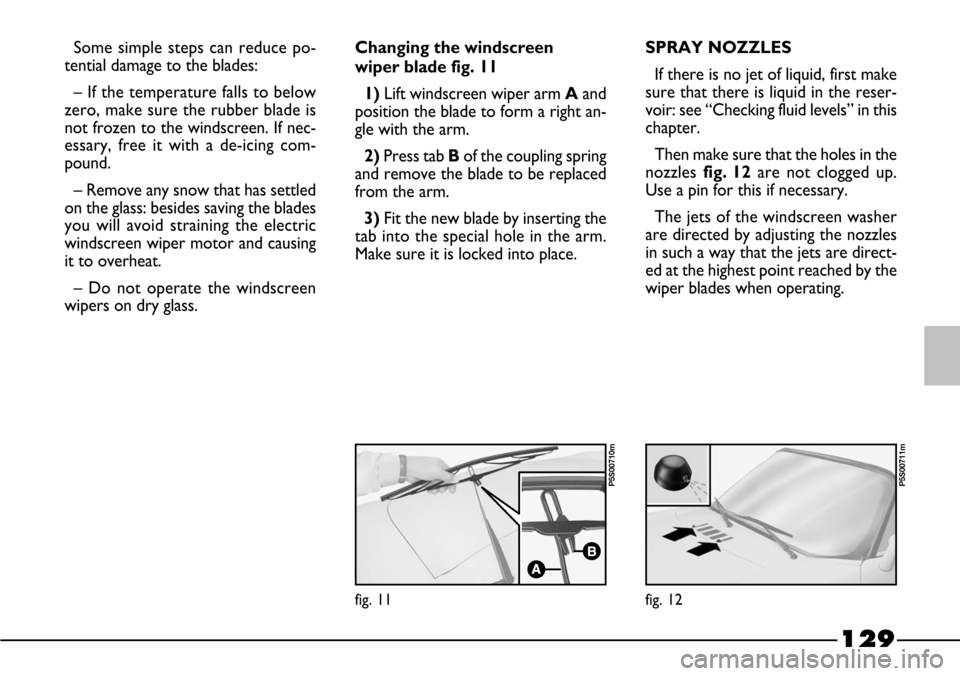

wiper blades when operating. Changing the windscreen

wiper blade fig. 11

1)Lift windscreen wiper armAand

position the blade to form a right an-

gle with the arm.

2) Press tab Bof the coupling spring

and remove the blade to be replaced

from the arm.

3)Fit the new blade by inserting the

tab into the special hole in the arm.

Make sure it is locked into place.

fig. 12

P5S00711m

fig. 11

P5S00710m

Page 147 of 170

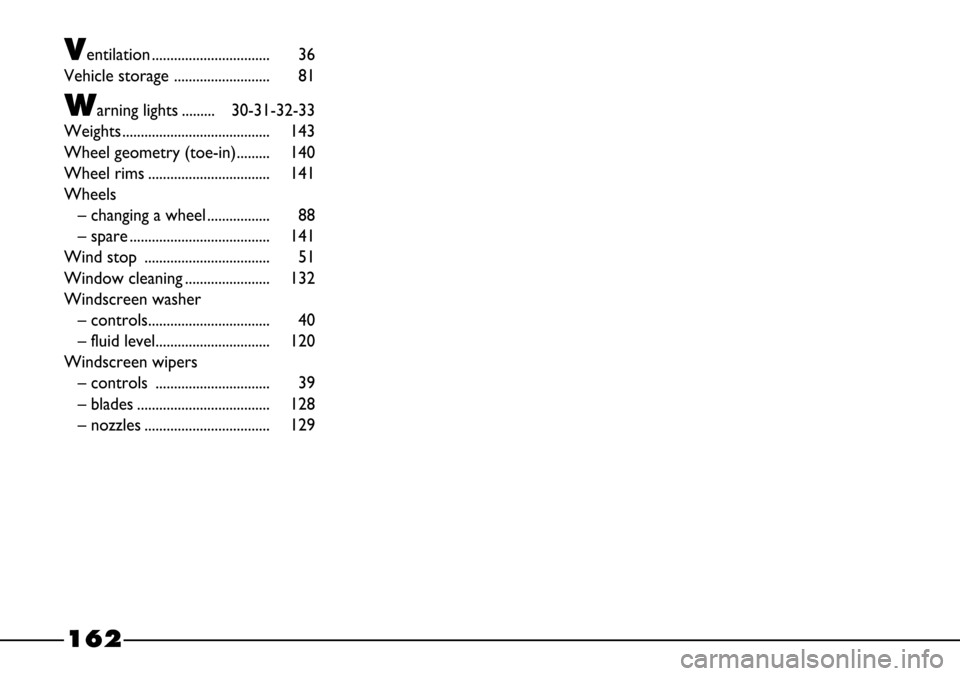

Transmission lubricants

and grease

146

Specifications of fluids and lubricants to use

for best car operation

Synthetic oil SAE 75W-80 EP. It complies with the

specifications API GL5, MIL - L - 2105 D LEV.

ATF DEXRON II D LEV, SAE 10W oil type

Molybdenum disulphide, lithium-soap based grease,

water resistant, NLGI = 2 consistency

Synthetic fluid, NHTSA n° 116, DOT 4, ISO 4925

SAE J 1703, CUNA NC 956 - 01

Protective with anti-freeze action, for inhibited mono ethylene

glycol based cooling systems, CUNA NC 956 - 16

Alcohol and surfactants mixture CUNA NC 956 - IIRecommended fluids

and lubricants

TUTELA CAR

ZC 75 SYNTH

TUTELA GI/A

TUTELA MRM 2

TUTELA TOP 4

PARAFLU

11

TUTELA

PROFESIONAL

SC 35Applications

Manual gearbox

and differentials

Hydraulic power

steering

CV joints

Hydraulic brake

and clutch

Proportion: 50-50 mix

down to –35°C

To be used pure or

diluted in windshield

wiper washing systems Use

Brake liquid

Radiator antifreeze

Windscreen/

window washer fluid

Page 163 of 170

162

Ventilation ................................ 36

Vehicle storage .......................... 81

Warning lights ......... 30-31-32-33

Weights ........................................ 143

Wheel geometry (toe-in)......... 140

Wheel rims ................................. 141

Wheels

– changing a wheel ................. 88

– spare ...................................... 141

Wind stop .................................. 51

Window cleaning ....................... 132

Windscreen washer

– controls................................. 40

– fluid level............................... 120

Windscreen wipers

– controls ............................... 39

– blades .................................... 128

– nozzles .................................. 129