FIAT DOBLO COMBI 2016 2.G Owners Manual

Manufacturer: FIAT, Model Year: 2016, Model line: DOBLO COMBI, Model: FIAT DOBLO COMBI 2016 2.GPages: 298, PDF Size: 25.92 MB

Page 161 of 298

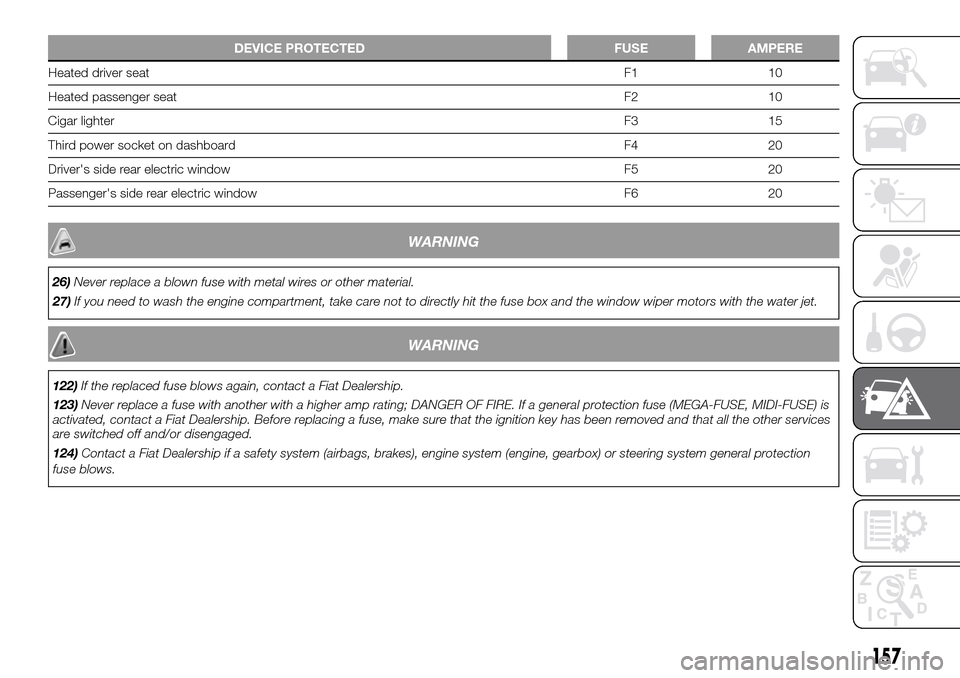

DEVICE PROTECTED FUSE AMPERE

Heated driver seatF1 10

Heated passenger seatF2 10

Cigar lighterF3 15

Third power socket on dashboard F4 20

Driver's side rear electric window F5 20

Passenger's side rear electric window F6 20

WARNING

26)Never replace a blown fuse with metal wires or other material.

27)If you need to wash the engine compartment, take care not to directly hit the fuse box and the window wiper motors with the water jet.

WARNING

122)If the replaced fuse blows again, contact a Fiat Dealership.

123)Never replace a fuse with another with a higher amp rating; DANGER OF FIRE. If a general protection fuse (MEGA-FUSE, MIDI-FUSE) is

activated, contact a Fiat Dealership. Before replacing a fuse, make sure that the ignition key has been removed and that all the other services

are switched off and/or disengaged.

124)Contact a Fiat Dealership if a safety system (airbags, brakes), engine system (engine, gearbox) or steering system general protection

fuse blows.

157

Page 162 of 298

CHANGING A WHEEL

The vehicle is originally equipped with

the Fix&Go automatic quick tyre repair

kit (see instructions in the next section).

As an alternative, the vehicle may

have a normal-sized spare wheel.

Wheel changing and correct use of the

jack and spare wheel call for some

precautions, as listed below.

125) 126) 127) 128)

Note for one-way tyres

One-way tyres have a few arrows on

the side indicating the rotation direction.

If a wheel is changed (when punctured,

for example) the direction of the arrows

on the spare wheel tyre may not

coincide with the rotation direction of

the wheel to be replaced.

In these conditions, too, the tyre still

maintains its safety features.

Anyway, it is recommended to have the

wheel repaired and refitted as soon as

possible, as the best performance is

achieved when the rotation direction of

all tyres coincides with the one

indicated by the arrows.

Please note that:

the jack weight is 4 kg;

the jack requires no adjustment;

the jack cannot be repaired and in

the event of a fault it must be replaced

by another original one;

no tool other than its cranking

device may be fitted on the jack.

To change a wheel, proceed as follows:

stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground should be flat if possible,

and sufficiently firm;

stop the engine and pull the

handbrake;

engage first gear or reverse;

wear the reflective safety jacket

(compulsory by law in certain countries)

before getting out of the vehicle;

indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

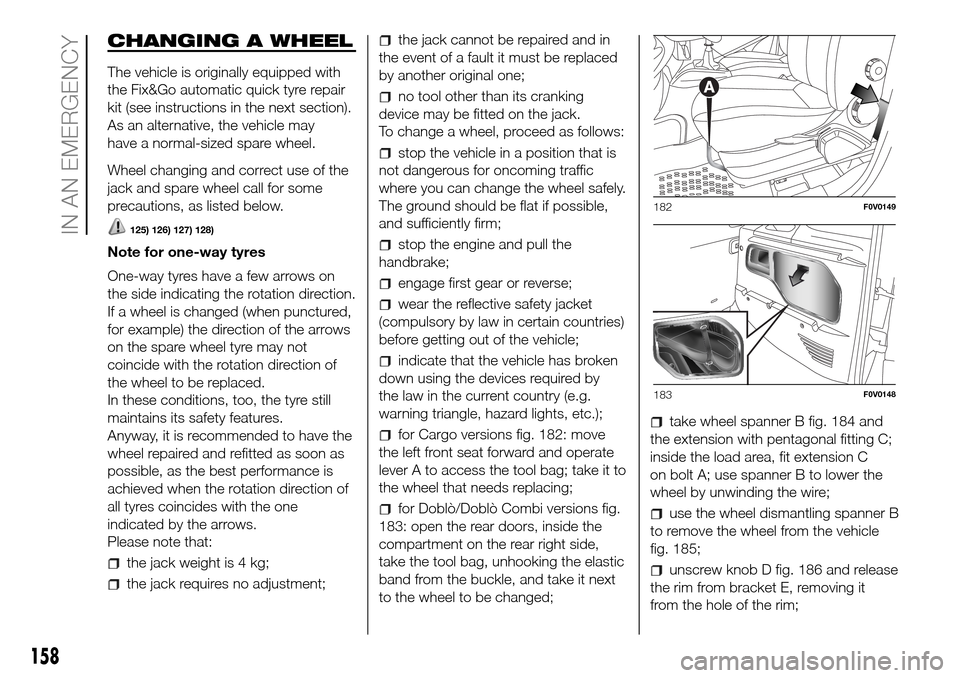

for Cargo versions fig. 182: move

the left front seat forward and operate

lever A to access the tool bag; take it to

the wheel that needs replacing;

for Doblò/Doblò Combi versions fig.

183: open the rear doors, inside the

compartment on the rear right side,

take the tool bag, unhooking the elastic

band from the buckle, and take it next

to the wheel to be changed;

take wheel spanner B fig. 184 and

the extension with pentagonal fitting C;

inside the load area, fit extension C

on bolt A; use spanner B to lower the

wheel by unwinding the wire;

use the wheel dismantling spanner B

to remove the wheel from the vehicle

fig. 185;

unscrew knob D fig. 186 and release

the rim from bracket E, removing it

from the hole of the rim;

182F0V0149

183F0V0148

158

IN AN EMERGENCY

Page 163 of 298

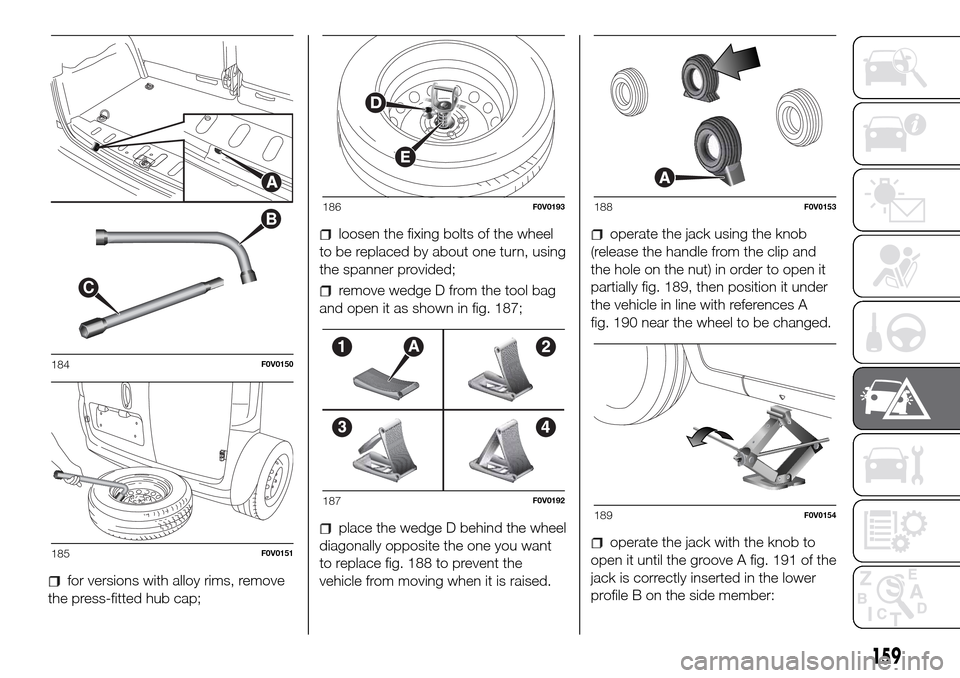

for versions with alloy rims, remove

the press-fitted hub cap;

loosen the fixing bolts of the wheel

to be replaced by about one turn, using

the spanner provided;

remove wedge D from the tool bag

and open it as shown in fig. 187;

place the wedge D behind the wheel

diagonally opposite the one you want

to replace fig. 188 to prevent the

vehicle from moving when it is raised.

operate the jack using the knob

(release the handle from the clip and

the hole on the nut) in order to open it

partially fig. 189, then position it under

the vehicle in line with references A

fig. 190 near the wheel to be changed.

operate the jack with the knob to

open it until the groove A fig. 191 of the

jack is correctly inserted in the lower

profile B on the side member:

B

C

184F0V0150

185F0V0151

186F0V0193

187F0V0192

188F0V0153

189F0V0154

159

Page 164 of 298

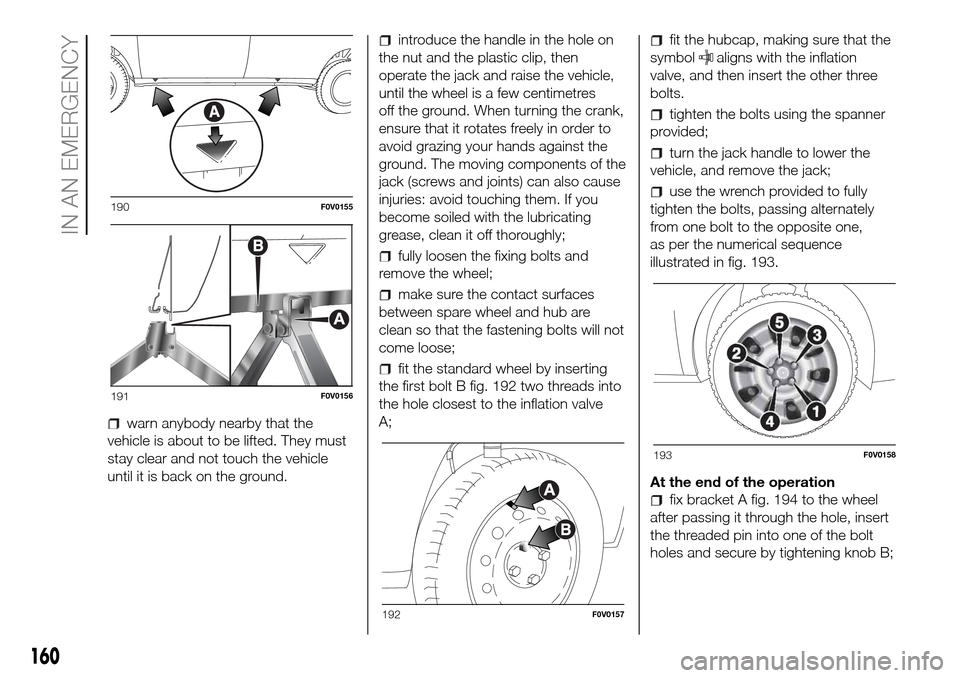

warn anybody nearby that the

vehicle is about to be lifted. They must

stay clear and not touch the vehicle

until it is back on the ground.

introduce the handle in the hole on

the nut and the plastic clip, then

operate the jack and raise the vehicle,

until the wheel is a few centimetres

off the ground. When turning the crank,

ensure that it rotates freely in order to

avoid grazing your hands against the

ground. The moving components of the

jack (screws and joints) can also cause

injuries: avoid touching them. If you

become soiled with the lubricating

grease, clean it off thoroughly;

fully loosen the fixing bolts and

remove the wheel;

make sure the contact surfaces

between spare wheel and hub are

clean so that the fastening bolts will not

come loose;

fit the standard wheel by inserting

the first bolt B fig. 192 two threads into

the hole closest to the inflation valve

A;

fit the hubcap, making sure that the

symbol

aligns with the inflation

valve, and then insert the other three

bolts.

tighten the bolts using the spanner

provided;

turn the jack handle to lower the

vehicle, and remove the jack;

use the wrench provided to fully

tighten the bolts, passing alternately

from one bolt to the opposite one,

as per the numerical sequence

illustrated in fig. 193.

At the end of the operation

fix bracket A fig. 194 to the wheel

after passing it through the hole, insert

the threaded pin into one of the bolt

holes and secure by tightening knob B;

190F0V0155

191F0V0156

192F0V0157

193F0V0158

160

IN AN EMERGENCY

Page 165 of 298

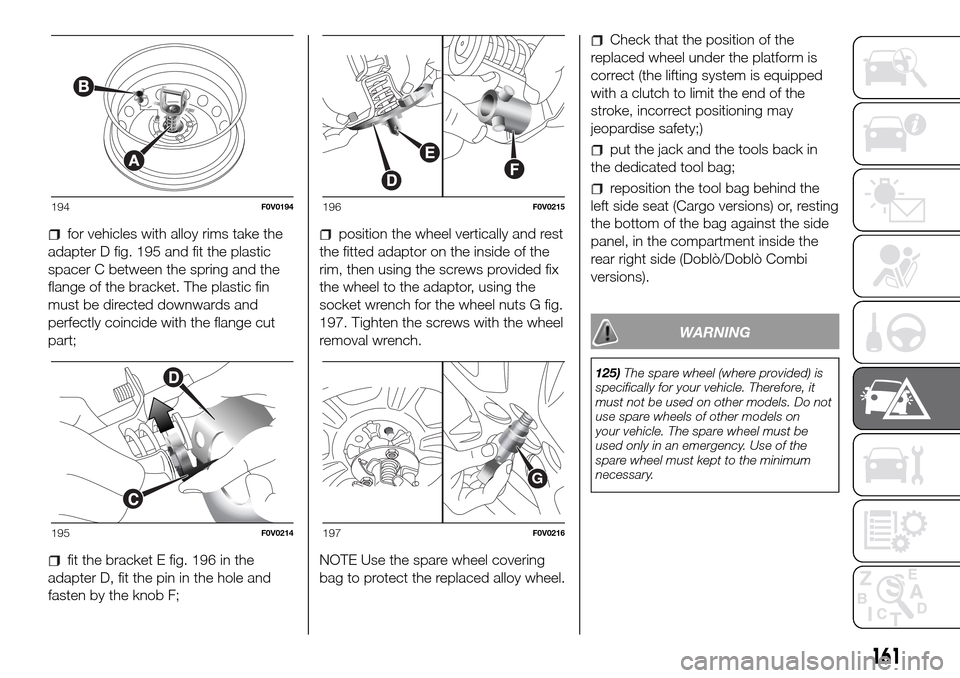

for vehicles with alloy rims take the

adapter D fig. 195 and fit the plastic

spacer C between the spring and the

flange of the bracket. The plastic fin

must be directed downwards and

perfectly coincide with the flange cut

part;

fit the bracket E fig. 196 in the

adapter D, fit the pin in the hole and

fasten by the knob F;

position the wheel vertically and rest

the fitted adaptor on the inside of the

rim, then using the screws provided fix

the wheel to the adaptor, using the

socket wrench for the wheel nuts G fig.

197. Tighten the screws with the wheel

removal wrench.

NOTE Use the spare wheel covering

bag to protect the replaced alloy wheel.

Check that the position of the

replaced wheel under the platform is

correct (the lifting system is equipped

with a clutch to limit the end of the

stroke, incorrect positioning may

jeopardise safety;)

put the jack and the tools back in

the dedicated tool bag;

reposition the tool bag behind the

left side seat (Cargo versions) or, resting

the bottom of the bag against the side

panel, in the compartment inside the

rear right side (Doblò/Doblò Combi

versions).

WARNING

125)The spare wheel (where provided) is

specifically for your vehicle. Therefore, it

must not be used on other models. Do not

use spare wheels of other models on

your vehicle. The spare wheel must be

used only in an emergency. Use of the

spare wheel must kept to the minimum

necessary.

194F0V0194

195F0V0214

196F0V0215

G

197F0V0216

161

Page 166 of 298

126)Use your hazard lights, warning

triangle, etc. to show that your vehicle is

stationary according to the regulations

in force. Passengers should get out of the

vehicle, particularly if it is heavily loaded,

and wait for the wheel to be changed away

from the traffic. If you are on a slope or

uneven surface, place wedges or other

suitable objects under the wheels to secure

the vehicle. Have the wheel repaired and

refitted as soon as possible. Do not apply

grease to the bolt threads before

assembly: they might spontaneously

unscrew.

127)Use the jack only to replace wheels

on the vehicle with which it is supplied

or on other vehicles of the same model.

Never use the jack for other purposes,

such as lifting other models. Never use the

jack to carry out repairs under the vehicle.

Incorrect positioning of the jack may cause

the lifted vehicle to fall. Do not use the

jack for loads higher than those shown on

the label.

128)Incorrect hub cap assembly may

cause it to come off when the vehicle is

moving. Never tamper with the inflation

valve. Never introduce tools of any kind

between rim and tyre. Check tyre and

spare wheel pressures regularly, referring to

the values shown in the "Technical

specifications" section.FIX&GO AUTOMATIC

KIT

(where provided)

DESCRIPTION

28)

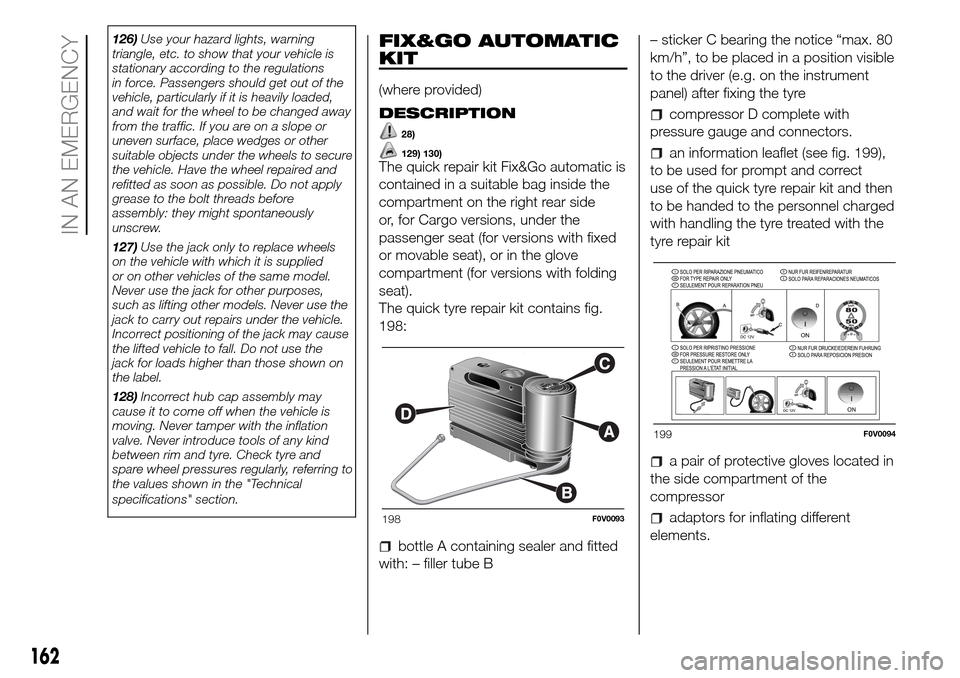

129) 130)The quick repair kit Fix&Go automatic is

contained in a suitable bag inside the

compartment on the right rear side

or, for Cargo versions, under the

passenger seat (for versions with fixed

or movable seat), or in the glove

compartment (for versions with folding

seat).

The quick tyre repair kit contains fig.

198:

bottle A containing sealer and fitted

with: – filler tube B– sticker C bearing the notice “max. 80

km/h”, to be placed in a position visible

to the driver (e.g. on the instrument

panel) after fixing the tyre

compressor D complete with

pressure gauge and connectors.

an information leaflet (see fig. 199),

to be used for prompt and correct

use of the quick tyre repair kit and then

to be handed to the personnel charged

with handling the tyre treated with the

tyre repair kit

a pair of protective gloves located in

the side compartment of the

compressor

adaptors for inflating different

elements.198F0V0093

199F0V0094

162

IN AN EMERGENCY

Page 167 of 298

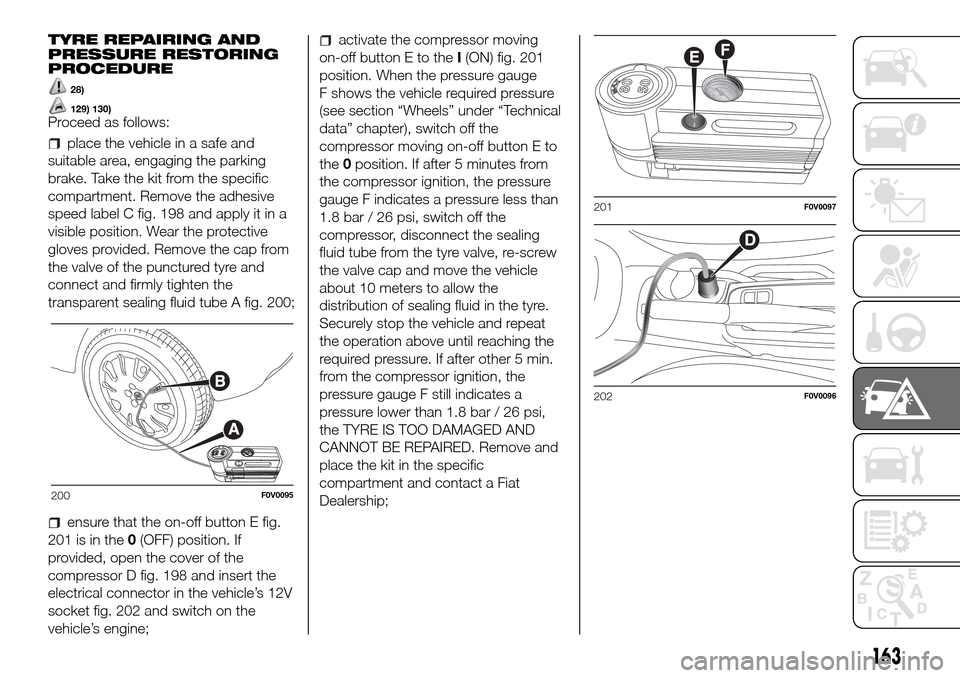

TYRE REPAIRING AND

PRESSURE RESTORING

PROCEDURE

28)

129) 130)Proceed as follows:

place the vehicle in a safe and

suitable area, engaging the parking

brake. Take the kit from the specific

compartment. Remove the adhesive

speed label C fig. 198 and apply it in a

visible position. Wear the protective

gloves provided. Remove the cap from

the valve of the punctured tyre and

connect and firmly tighten the

transparent sealing fluid tube A fig. 200;

ensure that the on-off button E fig.

201 is in the0(OFF) position. If

provided, open the cover of the

compressor D fig. 198 and insert the

electrical connector in the vehicle’s 12V

socket fig. 202 and switch on the

vehicle’s engine;

activate the compressor moving

on-off button E to theI(ON) fig. 201

position. When the pressure gauge

F shows the vehicle required pressure

(see section “Wheels” under “Technical

data” chapter), switch off the

compressor moving on-off button E to

the0position. If after 5 minutes from

the compressor ignition, the pressure

gauge F indicates a pressure less than

1.8 bar / 26 psi, switch off the

compressor, disconnect the sealing

fluid tube from the tyre valve, re-screw

the valve cap and move the vehicle

about 10 meters to allow the

distribution of sealing fluid in the tyre.

Securely stop the vehicle and repeat

the operation above until reaching the

required pressure. If after other 5 min.

from the compressor ignition, the

pressure gauge F still indicates a

pressure lower than 1.8 bar / 26 psi,

the TYRE IS TOO DAMAGED AND

CANNOT BE REPAIRED. Remove and

place the kit in the specific

compartment and contact a Fiat

Dealership;

200F0V0095

201F0V0097

202F0V0096

163

Page 168 of 298

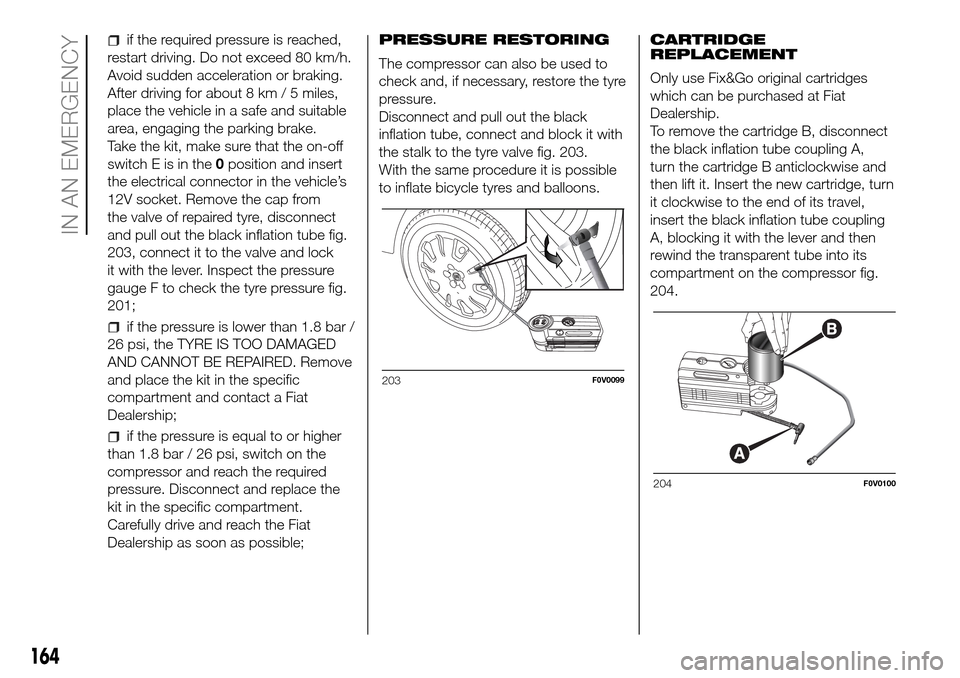

if the required pressure is reached,

restart driving. Do not exceed 80 km/h.

Avoid sudden acceleration or braking.

After driving for about 8 km / 5 miles,

place the vehicle in a safe and suitable

area, engaging the parking brake.

Take the kit, make sure that the on-off

switch E is in the0position and insert

the electrical connector in the vehicle’s

12V socket. Remove the cap from

the valve of repaired tyre, disconnect

and pull out the black inflation tube fig.

203, connect it to the valve and lock

it with the lever. Inspect the pressure

gauge F to check the tyre pressure fig.

201;

if the pressure is lower than 1.8 bar /

26 psi, the TYRE IS TOO DAMAGED

AND CANNOT BE REPAIRED. Remove

and place the kit in the specific

compartment and contact a Fiat

Dealership;

if the pressure is equal to or higher

than 1.8 bar / 26 psi, switch on the

compressor and reach the required

pressure. Disconnect and replace the

kit in the specific compartment.

Carefully drive and reach the Fiat

Dealership as soon as possible;PRESSURE RESTORING

The compressor can also be used to

check and, if necessary, restore the tyre

pressure.

Disconnect and pull out the black

inflation tube, connect and block it with

the stalk to the tyre valve fig. 203.

With the same procedure it is possible

to inflate bicycle tyres and balloons.CARTRIDGE

REPLACEMENT

Only use Fix&Go original cartridges

which can be purchased at Fiat

Dealership.

To remove the cartridge B, disconnect

the black inflation tube coupling A,

turn the cartridge B anticlockwise and

then lift it. Insert the new cartridge, turn

it clockwise to the end of its travel,

insert the black inflation tube coupling

A, blocking it with the lever and then

rewind the transparent tube into its

compartment on the compressor fig.

204.

203F0V0099

204F0V0100

164

IN AN EMERGENCY

Page 169 of 298

WARNING

28)The label on the Fix&Go kit’s packaging

gives the information required by the laws

in force. To ensure that the Fix&Go kit is

safe and effective, it is essential to comply

with all the instructions given on the label.

Carefully read the label before use, avoid

improper use. Fix&Go is subject to

expiration and must be replaced

periodically. The kit should be used by

adults and cannot be used by children.

WARNING

129)Show the package and the label to

the personnel charged with handling

the tyre treated with the tyre repair kit.

130)Fix&Go provides a temporary repair,

therefore the tyre must be examined and

repaired by a specialist as soon as

possible. The sealing fluid is effective at

temperatures between -40°C and +50°C. It

is possible to repair tyres which have

been damaged on tread up to a diameter

of 4mm; however, tyres damaged on

their side cannot be repaired. Before using

Fix&Go kit, ensure that the tyre isn't

excessively damaged and that the rim is in

good condition, otherwise do not use it

and contact a Fiat Dealership. Do not

remove foreign bodies from the tyre. Do

not let the compressor turned on for more

than 20 consecutive minutes - overheating

hazard.

EMERGENCY

STARTING

Go to a Fiat Dealership immediately if

warning light

stays on constantly on

the instrument panel.

JUMP STARTING

If the battery is flat, it is possible to start

the engine using an auxiliary battery

with the same capacity or a little higher

than the flat one.

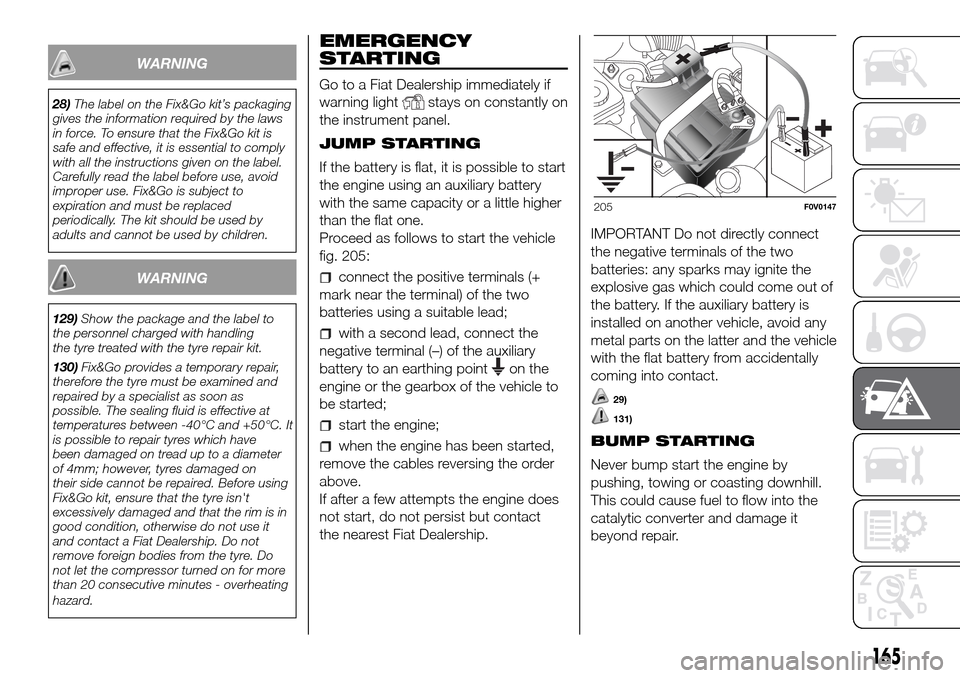

Proceed as follows to start the vehicle

fig. 205:

connect the positive terminals (+

mark near the terminal) of the two

batteries using a suitable lead;

with a second lead, connect the

negative terminal (–) of the auxiliary

battery to an earthing point

on the

engine or the gearbox of the vehicle to

be started;

start the engine;

when the engine has been started,

remove the cables reversing the order

above.

If after a few attempts the engine does

not start, do not persist but contact

the nearest Fiat Dealership.IMPORTANT Do not directly connect

the negative terminals of the two

batteries: any sparks may ignite the

explosive gas which could come out of

the battery. If the auxiliary battery is

installed on another vehicle, avoid any

metal parts on the latter and the vehicle

with the flat battery from accidentally

coming into contact.

29)

131)

BUMP STARTING

Never bump start the engine by

pushing, towing or coasting downhill.

This could cause fuel to flow into the

catalytic converter and damage it

beyond repair.

205F0V0147

165

Page 170 of 298

IMPORTANT Remember that the brake

booster and the electric power steering

system are not active until the engine

is started, so you will need to apply

much more force to the brake pedal or

steering wheel.

WARNING

29)Never use a fast battery-charger for

emergency starting of the engine as this

could damage the electronic systems

of your vehicle, particularly the ignition and

fuel supply control units.

WARNING

131)This procedure must be performed by

qualified personnel as incorrect actions

may cause high-intensity electrical

discharge. Furthermore, battery fluid is

poisonous and corrosive: avoid contact

with skin and eyes. Keep naked flames

away from the battery. No smoking. Do not

cause sparks.

FUEL CUT-OFF

SYSTEM

This intervenes in the case of an impact

causing:

the fuel supply cut-off with the

engine consequently switching off;

the automatic unlocking of the

doors;

the switching on of the interior lights;

switching on of the hazard warning

lights (to deactivate the lights press

the dedicated button on the

dashboard).

132)When the system has been triggered,

the message “Fuel cut off, see

handbook” is displayed on some

versions.

Check carefully for fuel leaks, for

instance in the engine compartment,

under the vehicle or near the tank area.

After a collision, turn the ignition key

to STOP to prevent the battery from

running down.

The following procedure should be

carried out to restore the correct

operation of the vehicle:

turn the ignition key to the MAR

position;

activate the right direction indicator;

deactivate the right direction

indicator;

activate the left direction indicator;

deactivate the left direction indicator;

activate the right direction indicator;

deactivate the right direction

indicator;

activate the left direction indicator;

deactivate the left direction indicator;

turn the ignition key to the OFF

position.

WARNING

132)If, after an impact, you smell fuel or

notice leaks from the fuel supply system,

do not reactivate the system to avoid

the risk of fire.

166

IN AN EMERGENCY