technical data FIAT DUCATO 2009 3.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2009, Model line: DUCATO, Model: FIAT DUCATO 2009 3.GPages: 282, PDF Size: 4.55 MB

Page 29 of 282

28

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

Day

YearMonth

Deutsch

Français

English

Español

Italiano

Nederland

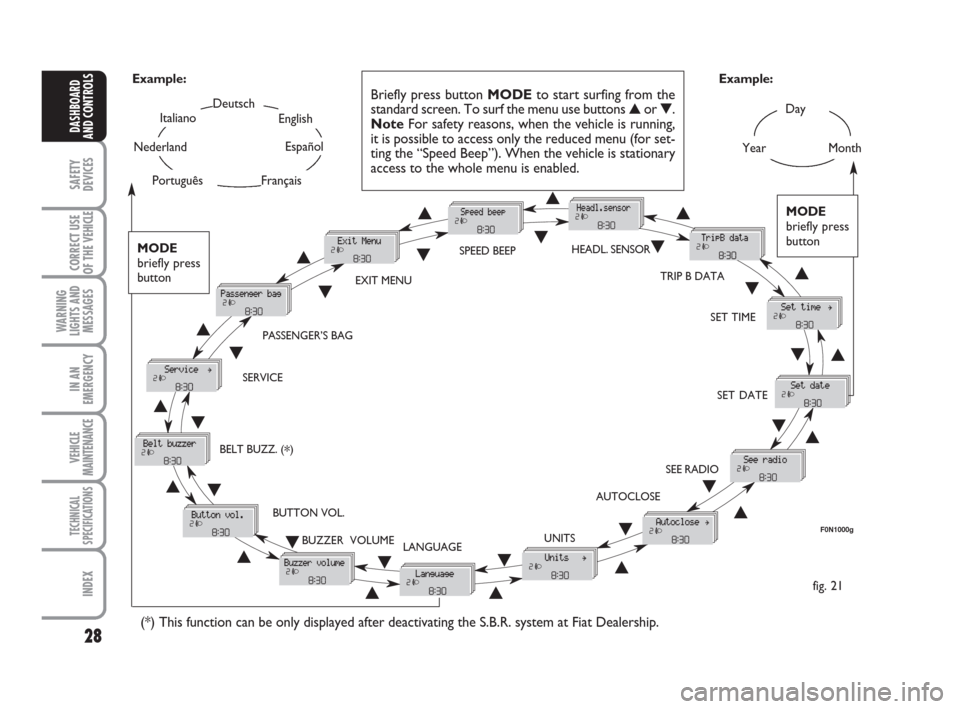

Português Example:

fig. 21 Example:

Briefly press button MODEto start surfing from the

standard screen. To surf the menu use buttons ▲or ▼.

NoteFor safety reasons, when the vehicle is running,

it is possible to access only the reduced menu (for set-

ting the “Speed Beep”). When the vehicle is stationary

access to the whole menu is enabled.

F0N1000g

MODE

briefly press

button

▲

▼

EXIT MENUSPEED BEEPHEADL. SENSOR

SET TIME

SET DATE

SEE RADIO

AUTOCLOSE

UNITS

LANGUAGE BUZZER VOLUME BUTTON VOL. SERVICEPASSENGER’S BAG

(*) This function can be only displayed after deactivating the S.B.R. system at Fiat Dealership.

TRIP B DATA

MODE

briefly press

button

▲

▼▲

▼▲

▼

▲

▼

▲ ▼

▲ ▼ ▲

▼

▲

▼

▲

▼

▲▼

▲▼

▲▼

▲▼▲ ▼

BELT BUZZ. (*)

Page 30 of 282

29

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

– briefly press button MODE to go back

to the menu screen or press the button

for long to go back to the standard screen

without storing settings.

To cancel the setting, proceed as follows:

– briefly press button MODE: (On) will

flash on the display;

– press button ▼: (Off) will flash on the

display;

– briefly press button MODEto go back

to the menu screen or press the button

for long to go back to the standard screen

without storing settings.

Headlight sensor sensitivity

adjustment (where provided)

With this function it is possible to adjust

the light sensor sensitivity according to 3

levels.

To set the required sensitivity level pro-

ceed as follows:

– briefly press button MODE, the previ-

ously set sensitivity “level” will flash on the

display; Speed limit (Speed Beep)

With this function it is possible to set the

vehicle speed limit (km/h or mph); when

this limit is exceeded the driver is imme-

diately alerted (see section “Warning lights

and messages”).

To set the speed limit, proceed as follows:

– briefly press button MODE, the display

will show the wording (Speed Beep);

– press button ▲or ▼to select speed

limit activation (On) or deactivation (Off);

– if the function has been activated (On),

press buttons ▲or ▼to select the re-

quired speed limit and then press MODE

to confirm.

NoteThe possible setting is between 30 and

200 km/h, or between 20 and 125 mph de-

pending on the unit set previously (see para-

graph “Setting the distance unit (Units)”) de-

scribed later. Every press on button

▲/ ▼increases/decreases by 5 units. Keeping the

button ▲/ ▼pressed obtains the automat-

ic fast increase or decrease. When you are

near the required setting complete adjust-

ment by single presses.

– press button ▲or ▼for setting;

– briefly press button MODEto go back

to the menu screen or press the button

for long to go back to the standard screen

without storing settings.

Trip B On/Off (tripB data)

Through this option it is possible to acti-

vate (On) or deactivate (Off) the Trip B

(partial trip).

For further information see “Trip com-

puter”.

For activation / deactivation, proceed as

follows:

– briefly press button MODE: (On) or

(Off) will flash on the display (according to

previous setting);

– press button ▲or ▼for setting;

– briefly press button MODEto go back

to the menu screen or press the button

for long to go back to the standard screen

without storing settings.

Page 93 of 282

92

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

IMPORTANT

Do not use abrasive detergents or sol-

vents to clean the device. To clean its ex-

ternal surface, use a wet cloth or special

products for cleaning synthetic materials.

The multimeter is installed and sealed with

lead by authorised personnel: access to

the device and relevant power and record-

ing cables is forbidden.

The vehicle owner is responsible for gov-

erning the instrument use. The inspection

must be carried out at least every two

years and will include a test to confirm

correct operation.

After the inspection, check that the plate

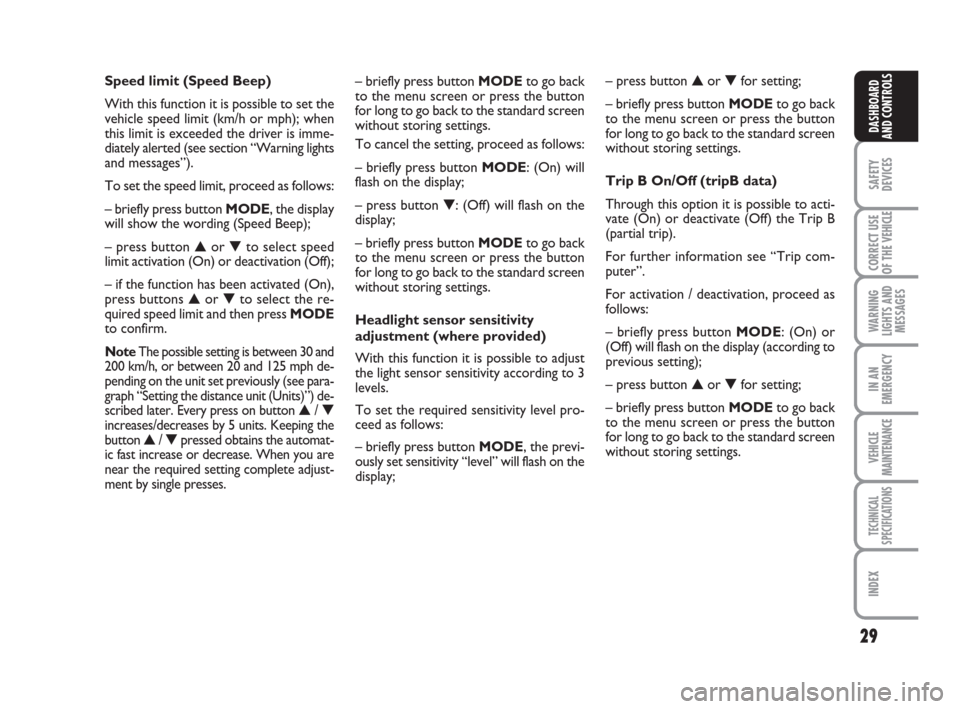

is updated with specified data.SPEED BLOCK

(where provided)

The vehicle is available with a speed re-

striction function that can be set, by the

user, at one of 4 pre-set levels: 90, 100,

110, 130 km/h. To activate/deactivate this

function, go to a Fiat Dealership. After the

operation a label will be stuck on the

windscreen containing the maximum set

speed.

WARNING The speedometer may show

a top speed that is higher than the actual

one set by the Dealership as provided for

by legislation.

DOORS

CENTRAL DOOR

LOCKING/UNLOCKING SYSTEM

Locking from the outside

With the doors closed, press the button

Øon the remote control fig. 107or fit

and turn clockwise the metal insert into

the driver’s door lock.

Door locking is only possible if all the

doors are closed. Opening one or more

doors by pressing the button

Øon the re-

mote control fig. 107, will make the di-

rection indicators and the button led A-

fig. 110flash quickly for about 3 seconds.

With this function active, buttons Aand

B fig. 110are disabled.

fig. 107F0N0800m

Pressing twice briefly the button Øon the

remote control fig. 107will engage the

dead lock device (see paragraph “Dead

lock device”).

Door unlocking from the outside

Briefly press button

Qfig. 107or Ëfig.

108, according to versions, to obtain re-

mote door unlocking, timed ceiling light

turning on, directions indicator double

fig. 108F0N0801m

Page 113 of 282

112

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

During normal service the

diesel particulate filter (DPF)

reaches high temperatures. Do not

therefore park the car over inflam-

mable materials (grass, dry leaves,

pine needles, etc.): fire hazard.

WARNING

PROTECTING

THE ENVIRONMENT

The devices for curtailing diesel fuel en-

gine emissions are the following:

❒oxidising catalytic converter;

❒exhaust gas recirculation system

(E.G.R.);

❒diesel particulate filter (DPF).

During normal service the

catalyst reaches high tem-

peratures. Do not therefore park the

car over inflammable materials (grass,

dry leaves, pine needles, etc.): fire

hazard.

WARNING

DIESEL PARTICULATE FILTER

(DPF)

The Diesel Particulate Filter is a mechan-

ical filter, integral with the exhaust system,

that physically traps particulates present

in the exhaust gases of Diesel engines.

The diesel particular filter has been adopt-

ed to eliminate almost totally particulates

in compliance with current / future law

regulations.

During normal use of the car, the engine

control unit records a set of data (e.g.:

travel time, type of route, temperatures,

etc.) and it will then calculate how much

particulates has been trapped by the filter.

Since this filter physically traps particulates,

it shall be cleaned (reclaimed) at regular

intervals by burning carbon particles.

Reclaiming procedure is controlled auto-

matically by the engine control unit ac-

cording to the filter conditions and the

conditions of use of the car.During reclaiming the following phenomena

could take place: idling slight increase, fan ac-

tivation, slight smoke increase, high exhaust

temperatures. These situations shall not be

considered as faults and they do not affect

car performance and environment.

If the dedicated message is displayed, refer to

section “Warning lights and messages”.

Page 120 of 282

HOW TO KEEP THE SEAT

BELTS ALWAYS IN EFFICIENT

CONDITIONS

Observe the following:

❒always use the belt with the tap taut

and never twisted; make sure that it

is free to run without impediments;

❒after a serious accident, replace the

belt being worn at that time, even if it

does not appear damaged. Always re-

place the seat belts if pretensioners

have been activated;

❒to clean the belts, wash by hand with

neutral soap, rinse and leave to dry in

the shade. Never use strong deter-

gents, bleach or dyes or other chem-

ical substance that might weaken the

fibres;

❒prevent the reels from getting wet:

their correct operation is only guar-

anteed if water does not get inside;

❒replace the seat belt when showing

significant wear or cut signs.For optimal protection in the event of a

crash, all passengers must be seated and

wearing adequate restraint systems.

This is even more important for children.

This prescription is compulsory in all EC

countries according to EC Directive

2003/20/EC.

Compared with adults, their head is pro-

portionally larger and heavier than the rest

of the body, while the muscles and bone

structure are not completely developed.

Therefore, correct restraint systems are

necessary, other than adult seat belts. The

results of research on the best child re-

straint systems are contained in the Euro-

pean Standard EEC-R44. This Standard en-

forces the use of restraint systems classi-

fied in five groups:Group 0 0-10 kg in weight

Group 0+ 0-13 kg in weight

Group 1 9-18 kg in weight

Group 2 15-25 kg in weight

Group 3 22-36 kg in weight

As it may be noted, the groups overlap

partly and in fact, in commerce it is pos-

sible to find devices that cover more than

one weight group.

All restraint devices must bear the certi-

fication data, together with the control

brand, on a solidly fixed label which must

absolutely never be removed.

Over 1.50 m in height, from the point of

view of restraint systems, children are

considered as adults and wear the seat

belts normally.

119

CORRECT USE

OF THE

VEHICLE

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CARRYING CHILDREN SAFELY

Page 142 of 282

141

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE VEHICLE

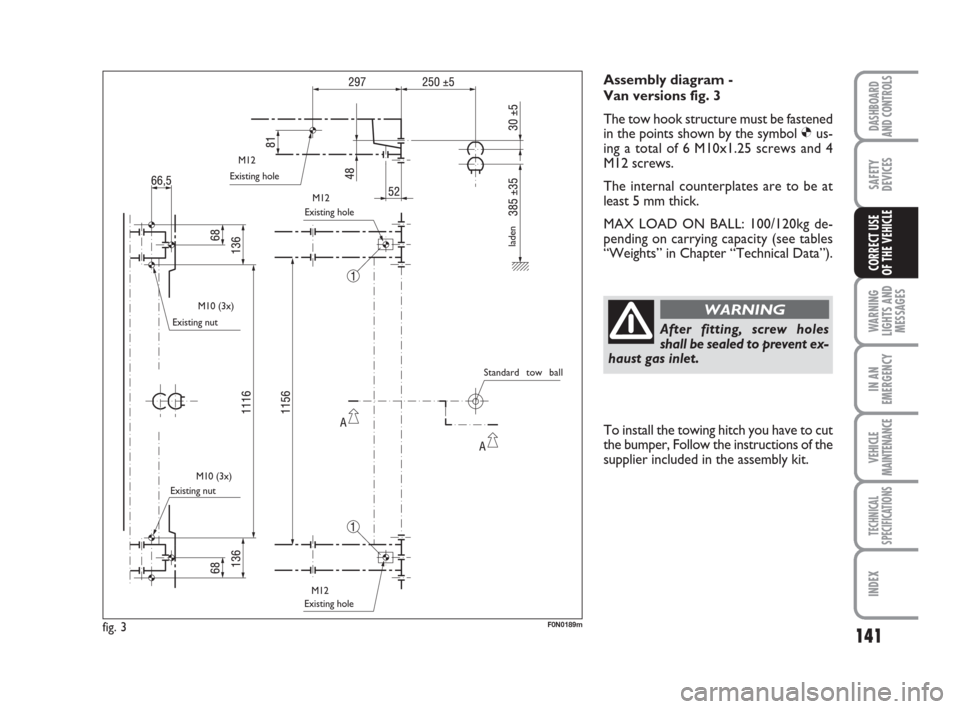

Assembly diagram -

Van versions fig. 3

The tow hook structure must be fastened

in the points shown by the symbol Øus-

ing a total of 6 M10x1.25 screws and 4

M12 screws.

The internal counterplates are to be at

least 5 mm thick.

MAX LOAD ON BALL: 100/120kg de-

pending on carrying capacity (see tables

“Weights” in Chapter “Technical Data”).

After fitting, screw holes

shall be sealed to prevent ex-

haust gas inlet.

WARNING

fig. 3F0N0189m

Existing hole

Existing nut

Existing nutExisting hole

Existing hole

laden

Standard tow ball M12

M12

M10 (3x)

M10 (3x)

M12

To install the towing hitch you have to cut

the bumper, Follow the instructions of the

supplier included in the assembly kit.

Page 143 of 282

142

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE VEHICLE

fig. 4F0N0250m

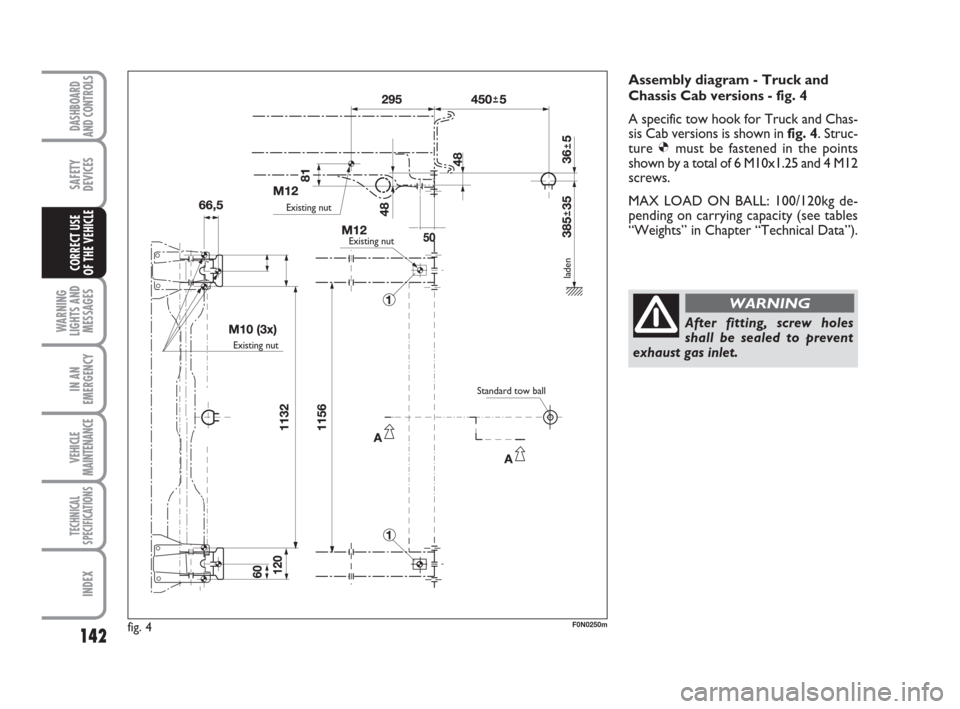

Assembly diagram - Truck and

Chassis Cab versions - fig. 4

A specific tow hook for Truck and Chas-

sis Cab versions is shown infig. 4. Struc-

ture Ømust be fastened in the points

shown by a total of 6 M10x1.25 and 4 M12

screws.

MAX LOAD ON BALL: 100/120kg de-

pending on carrying capacity (see tables

“Weights” in Chapter “Technical Data”).

After fitting, screw holes

shall be sealed to prevent

exhaust gas inlet.

WARNING

Existing nut

Existing nut

Existing nut

Standard tow ball

laden

Page 167 of 282

166

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

❒insert the pin E-fig. 14in the near-

est 12V current socket and start the

engine. Turn the selector D-fig. 13

anti-clockwise to the repair position.

Activate the kit by pressing the

on/off switch. Inflate the tyre to the

pressure specified in the “Inflation

pressure” paragraph, in the “Technical

Data” chapter.For a more accurate reading, it is

advisable to check the pressure

reading on the pressure gauge F-

fig. 13with the compressor off and

without moving the centre selector

from the repair position;

❒if a pressure of at least 3 bar is not

reached within 10 minutes, detach

the transparent filler pipe from the

valve and switch off the 12V current

pin, then move the vehicle about 10

metres forward to distribute the

sealant liquid inside the tyre and

repeat the inflation operation;

❒if, in this case too, within 10 minutes

of turning the compressor on, a

pressure of at least 3 bar is not

reached, do not start driving again

because the tyre is too damaged and

the quick repair kit is not sufficient in

this situation and it is necessary to

go to a Fiat Dealership;

❒if the tyre reaches the pressure spec-

ified in “Inflation pressure” pressure

in the “Technical Data” chapter,

start driving immediately;

fig. 13F0N0827m

fig. 14F0N0182m

Apply the adhesive label in a

position clearly visible by the

driver as a reminder that the tyre has

been treated with the quick repair

kit. Drive carefully, particularly on

bends. Do not exceed 80 km/h. Do

not accelerate or brake suddenly.

WARNING

❒after driving for about 10 minutes,

stop and check the tyre pressure

again; remember to engage the

handbrake;

❒if, on the other hand, a pressure of at

least 3 bar is reached, restore the cor-

rect pressure recommended in the

“Tyre inflation” paragraph in the

“Technical Data” chapter (with engine

running and handbrake on) and

resume driving;

Stop if the pressure has

dropped to less than 3 bar:

The automatic Fix & Go fast repair

kit cannot work properly if the tyre

is excessively damaged. Go to a Fiat

Dealership.

WARNING

Page 168 of 282

167

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

❒drive with the utmost care to the

nearest Fiat Dealership.

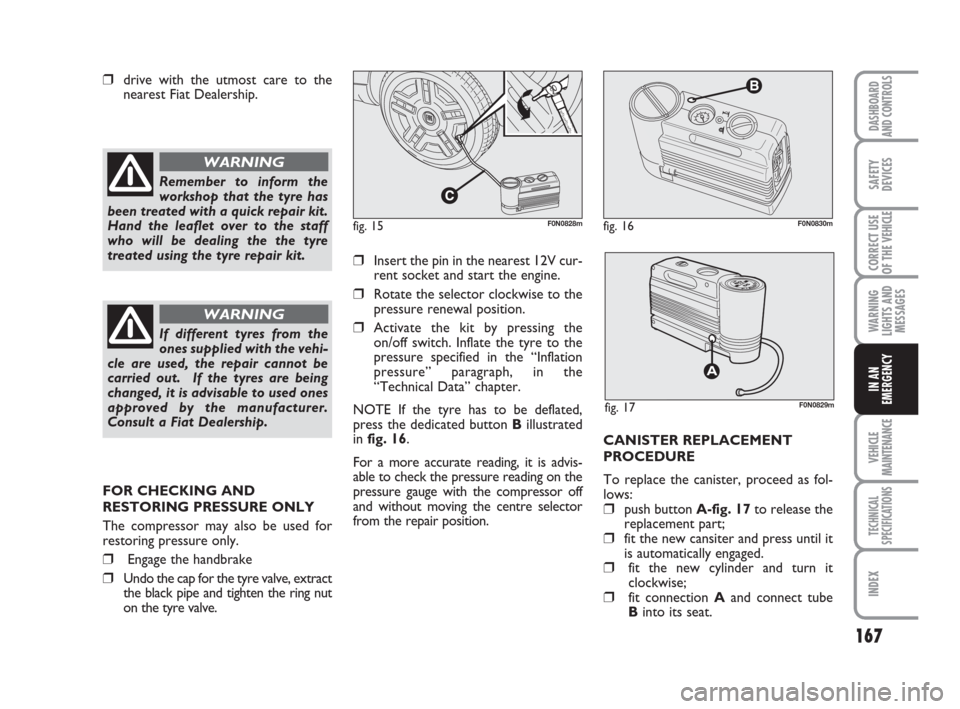

FOR CHECKING AND

RESTORING PRESSURE ONLY

The compressor may also be used for

restoring pressure only.

❒Engage the handbrake

❒Undo the cap for the tyre valve, extract

the black pipe and tighten the ring nut

on the tyre valve.

❒Insert the pin in the nearest 12V cur-

rent socket and start the engine.

❒Rotate the selector clockwise to the

pressure renewal position.

❒Activate the kit by pressing the

on/off switch. Inflate the tyre to the

pressure specified in the “Inflation

pressure” paragraph, in the

“Technical Data” chapter.

NOTE If the tyre has to be deflated,

press the dedicated button Billustrated

in fig. 16.

For a more accurate reading, it is advis-

able to check the pressure reading on the

pressure gauge with the compressor off

and without moving the centre selector

from the repair position.CANISTER REPLACEMENT

PROCEDURE

To replace the canister, proceed as fol-

lows:

❒push button A-fig. 17to release the

replacement part;

❒fit the new cansiter and press until it

is automatically engaged.

❒fit the new cylinder and turn it

clockwise;

❒fit connection Aand connect tube

Binto its seat.

Remember to inform the

workshop that the tyre has

been treated with a quick repair kit.

Hand the leaflet over to the staff

who will be dealing the the tyre

treated using the tyre repair kit.

WARNING

If different tyres from the

ones supplied with the vehi-

cle are used, the repair cannot be

carried out. If the tyres are being

changed, it is advisable to used ones

approved by the manufacturer.

Consult a Fiat Dealership.

WARNING

fig. 16

B

F0N0830m

fig. 17F0N0829m

fig. 15F0N0828m

Page 212 of 282

211

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IDENTIFICATION DATA ................................................. 212

ENGINE CODES - BODYWORK VERSIONS .............. 214

ENGINE .................................................................................. 216

FUEL FEED ............................................................................. 217

TRANSMISSION .................................................................. 217

BRAKES................................................................................... 218

SUSPENSIONS....................................................................... 218

STEERING............................................................................... 218

WHEELS.................................................................................. 219

DIMENSIONS......................................................................... 223

PERFORMANCE................................................................... 229

WEIGHTS............................................................................... 230

CAPACITIES .......................................................................... 261

FLUIDS AND LUBRICANTS.............................................. 262

FUEL CONSUMPTION....................................................... 264

CO

2EMISSIONS .................................................................. 265

RADIO FREQUENCY REMOTE CONTROL:

MINISTERIAL CERTIFICATIONS .................................... 266

TT T

E E

C C

H H

N N

I I

C C

A A

L L

S S

P P

E E

C C

I I

F F

I I

C C

A A

T T

I I

O O

N N

S S