Slope FIAT DUCATO 2015 3.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: DUCATO, Model: FIAT DUCATO 2015 3.GPages: 387, PDF Size: 20.76 MB

Page 87 of 387

HILL HOLDER SYSTEM

This system is an integral part of the

ESC system and facilitates starting on

slopes.

It is automatically activated in the

following conditions:

❒uphill: vehicle stationary on a road

with a gradient higher than 5%,

engine running, brake pressed and

gearbox in neutral or gear (other than

reverse) engaged;

❒downhill: vehicle stationary on a road

with a gradient higher than 5%,

engine running, brake pressed and

reverse gear engaged.

When setting off, the ESC system

control unit maintains the braking

pressure on the wheels until the torque

necessary for starting is reached, or

in any case for a maximum of 2

seconds, allowing your right foot to be

moved easily from the brake pedal to

the accelerator.

When two seconds have elapsed,

without starting, the system is

automatically deactivated, gradually

releasing the braking pressure. During

this release stage, the typical brake

disengagement noise indicating that the

vehicle is going to move imminently

will be heard.IMPORTANT The Hill Holder system is

not a parking brake; therefore, never

leave the vehicle without having

engaged the handbrake, turned the

engine off and engaged first gear,

so that it is parked in safe conditions

(for further information read the

"Parking" paragraph in the "Starting

and driving" chapter).

ASR (AntiSlip

Regulation) SYSTEM

It is an integral part of the ESC system.

It automatically operates in the event

of one or both drive wheels slipping,

loss of grip on wet roads (aquaplaning)

and acceleration on slippery, snowy

or icy roads, etc.

Depending on the slipping conditions,

two different control systems are

activated:

❒if the slipping involves both drive

wheels, the ASR intervenes reducing

the power transmitted by the engine;

❒if the slipping only involves one of the

drive wheels, it intervenes

automatically braking the wheel that

is slipping.

62)

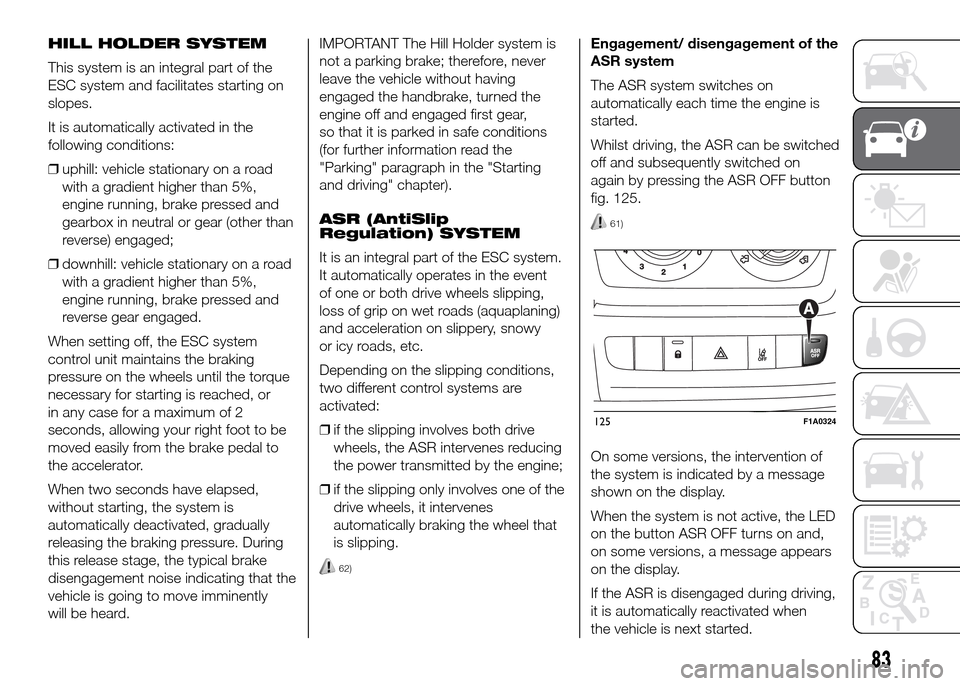

Engagement/ disengagement of the

ASR system

The ASR system switches on

automatically each time the engine is

started.

Whilst driving, the ASR can be switched

off and subsequently switched on

again by pressing the ASR OFF button

fig. 125.

61)

On some versions, the intervention of

the system is indicated by a message

shown on the display.

When the system is not active, the LED

on the button ASR OFF turns on and,

on some versions, a message appears

on the display.

If the ASR is disengaged during driving,

it is automatically reactivated when

the vehicle is next started.

125F1A0324

83

Page 164 of 387

SEAT BELTS

USING THE SEAT BELTS

The belt should be worn keeping the

torso straight and rested against the

backrest.

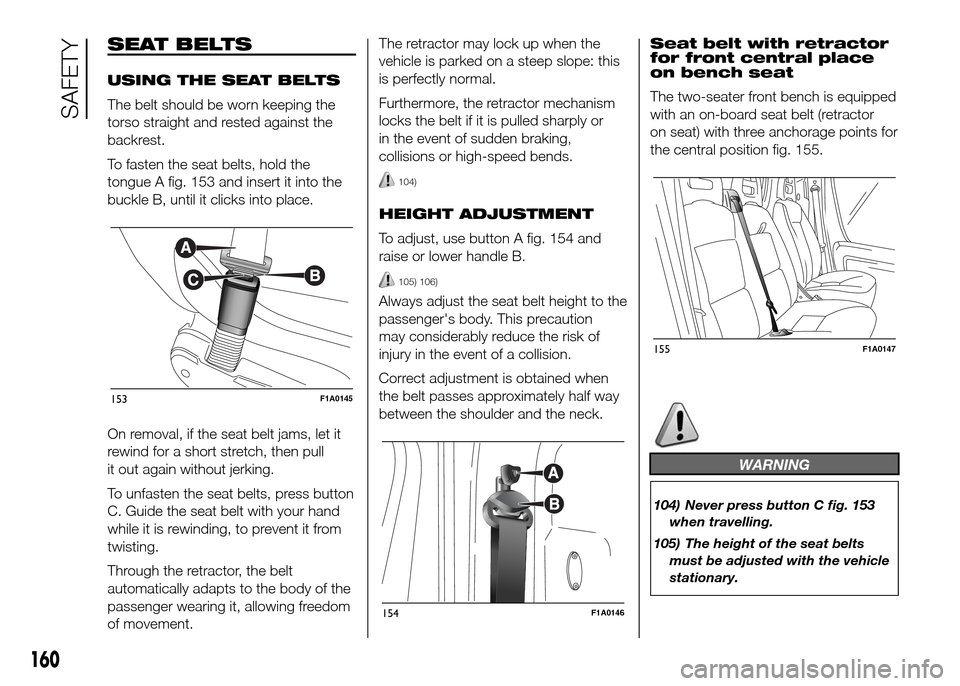

To fasten the seat belts, hold the

tongue A fig. 153 and insert it into the

buckle B, until it clicks into place.

On removal, if the seat belt jams, let it

rewind for a short stretch, then pull

it out again without jerking.

To unfasten the seat belts, press button

C. Guide the seat belt with your hand

while it is rewinding, to prevent it from

twisting.

Through the retractor, the belt

automatically adapts to the body of the

passenger wearing it, allowing freedom

of movement.The retractor may lock up when the

vehicle is parked on a steep slope: this

is perfectly normal.

Furthermore, the retractor mechanism

locks the belt if it is pulled sharply or

in the event of sudden braking,

collisions or high-speed bends.

104)

HEIGHT ADJUSTMENT

To adjust, use button A fig. 154 and

raise or lower handle B.

105) 106)

Always adjust the seat belt height to the

passenger's body. This precaution

may considerably reduce the risk of

injury in the event of a collision.

Correct adjustment is obtained when

the belt passes approximately half way

between the shoulder and the neck.Seat belt with retractor

for front central place

on bench seat

The two-seater front bench is equipped

with an on-board seat belt (retractor

on seat) with three anchorage points for

the central position fig. 155.

WARNING

104) Never press button C fig. 153

when travelling.

105) The height of the seat belts

must be adjusted with the vehicle

stationary.

153F1A0145

154F1A0146

155F1A0147

160

SAFETY

Page 189 of 387

30) Remember that the brake servo

and power steering are not

operational until the engine has

been started, so you need to apply

much more force than usual to

the brake pedal and steering

wheel.

31) Never start the engine by

pushing, towing or driving

downhill. This could cause fuel to

flow into the catalytic converter

and damage it beyond repair.

32) A quick burst on the accelerator

before turning off the engine

serves absolutely no practical

purpose; it wastes fuel and is

especially damaging to

turbocharged engines.

33) In some cases, when the engine

switches off, the fan could

activate for max. 120 seconds.

WARNING

134) It is dangerous to run the

engine in enclosed areas. The

engine takes in oxygen and

releases carbon dioxide, carbon

monoxide and other toxic gases.

PARKING

Proceed as follows:

❒stop the engine and engage the

handbrake;

❒engage a gear (on a slope, engage

first gear if the car is facing uphill or

reverse if it is facing downhill) and

leave the wheels steered.

If the vehicle is parked on a steep

slope, it is advisable to block the

wheels with a wedge or stone.

Do not leave the key in the ignition as

this drains the battery. Always remove

the key when you leave the car.

135)

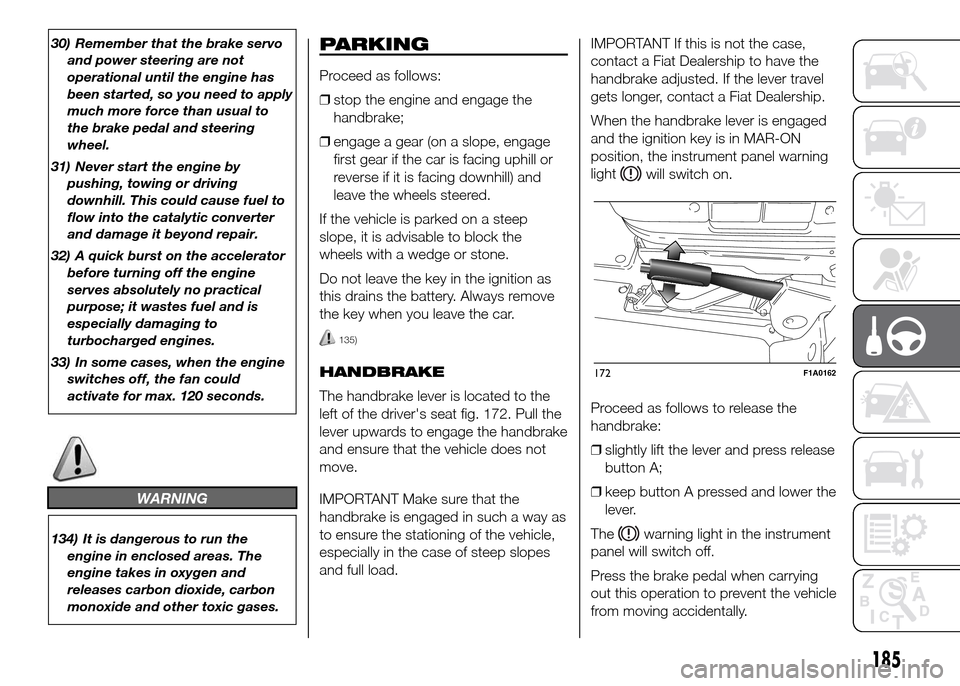

HANDBRAKE

The handbrake lever is located to the

left of the driver's seat fig. 172. Pull the

lever upwards to engage the handbrake

and ensure that the vehicle does not

move.

IMPORTANT Make sure that the

handbrake is engaged in such a way as

to ensure the stationing of the vehicle,

especially in the case of steep slopes

and full load.IMPORTANT If this is not the case,

contact a Fiat Dealership to have the

handbrake adjusted. If the lever travel

gets longer, contact a Fiat Dealership.

When the handbrake lever is engaged

and the ignition key is in MAR-ON

position, the instrument panel warning

light

will switch on.

Proceed as follows to release the

handbrake:

❒slightly lift the lever and press release

button A;

❒keep button A pressed and lower the

lever.

The

warning light in the instrument

panel will switch off.

Press the brake pedal when carrying

out this operation to prevent the vehicle

from moving accidentally.

172F1A0162

185

Page 207 of 387

WARNING

145) This procedure must be

performed by qualified personnel

as incorrect actions may cause

high-intensity electrical discharge.

Furthermore, battery fluid is

poisonous and corrosive: avoid

contact with skin and eyes. Keep

naked flames and lighted

cigarettes away from the battery

and do not cause sparks.

REPLACING A

WHEEL

GENERAL

INSTRUCTIONS

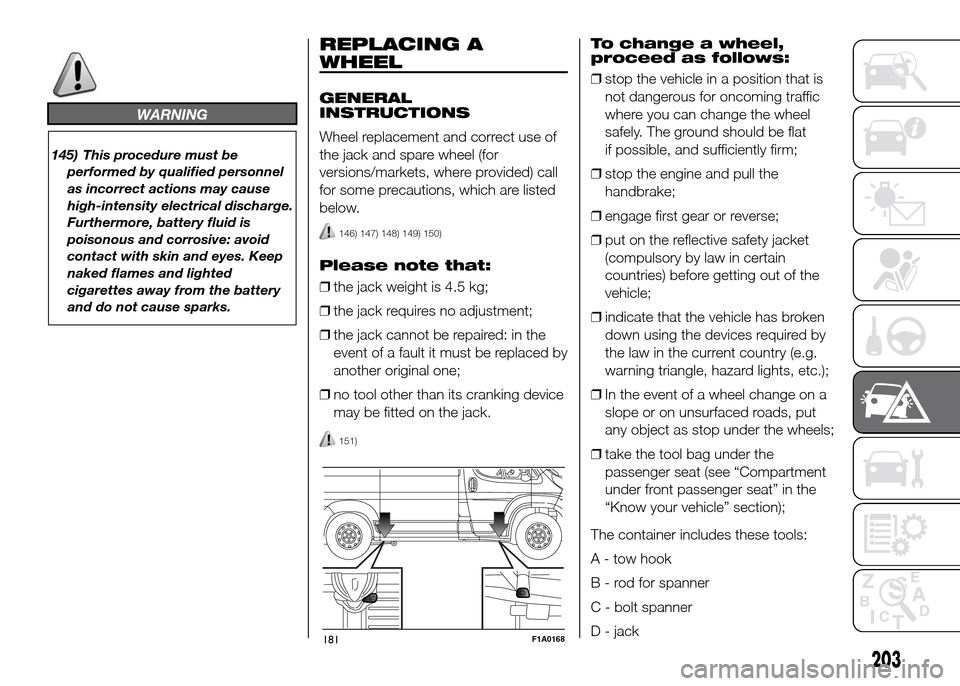

Wheel replacement and correct use of

the jack and spare wheel (for

versions/markets, where provided) call

for some precautions, which are listed

below.

146) 147) 148) 149) 150)

Please note that:

❒the jack weight is 4.5 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired: in the

event of a fault it must be replaced by

another original one;

❒no tool other than its cranking device

may be fitted on the jack.

151)

To change a wheel,

proceed as follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel

safely. The ground should be flat

if possible, and sufficiently firm;

❒stop the engine and pull the

handbrake;

❒engage first gear or reverse;

❒put on the reflective safety jacket

(compulsory by law in certain

countries) before getting out of the

vehicle;

❒indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

❒In the event of a wheel change on a

slope or on unsurfaced roads, put

any object as stop under the wheels;

❒take the tool bag under the

passenger seat (see “Compartment

under front passenger seat” in the

“Know your vehicle” section);

The container includes these tools:

A - tow hook

B - rod for spanner

C - bolt spanner

D - jack

181F1A0168

203

Page 211 of 387

❒introduce the assembled tool fig. 186

with the suitable extension B fig. 185

on the screw A fig. 185 of the spare

wheel housing manoeuvring device

and turn clockwise to lift the spare

wheel back up until it is fully

supported in its housing under the

platform, checking that the

attachment reference D fig. 188

appears in the window on the device;

❒Check the correct position of the

replaced wheel under the platform

(the lifting system is equipped with a

clutch to limit the end of the stroke).

Incorrect positioning may jeopardise

safety;

❒place the removal tools back in the

tool bag / compartment;

❒place the tool box / compartment in

its housing under the passenger

seat.

156) 157)

WARNING

146) Use your hazard lights, warning

triangle, etc. to show that your

vehicle is stationary according to

the regulations in force.

Passengers should get out of the

vehicle, particularly if it is heavily

loaded, and wait for the wheel

to be changed away from the

traffic. Apply the handbrake. in

the event of a wheel change on a

slope or on unsurfaced roads,

put any object as stop under the

wheels.147) The spare wheel supplied (for

versions/markets, where

provided) is specific for your

vehicle. Therefore, it must not be

used on other models. Do not

use spare wheels of other models

on your vehicle. The wheel bolts

are specific for your vehicle: do

not use them on different models

and do not use bolts from other

models on your car.

148) Have the wheel repaired and

refitted as soon as possible. Do

not apply grease to the bolt

threads before fitting: they could

come unscrewed.

149) Use the jack only to replace

wheels on the vehicle with which

it is supplied or on other vehicles

of the same model. Never use

the jack for other purposes, such

as lifting other car models. Never

use the jack to carry out repairs

under the vehicle. Incorrect

positioning of the jack may cause

the lifted vehicle to fall. Do not

use the jack for loads higher than

those shown on the label.

150) Never tamper with the inflation

valve. Never introduce tools of any

kind between rim and tyre. Check

tyre and spare wheel pressure

regularly, referring to the values

shown in the "Technical

specifications" section.

194F1A0385

207