ECU FIAT DUCATO BASE CAMPER 2014 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2014, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2014Pages: 367, PDF Size: 20.39 MB

Page 25 of 367

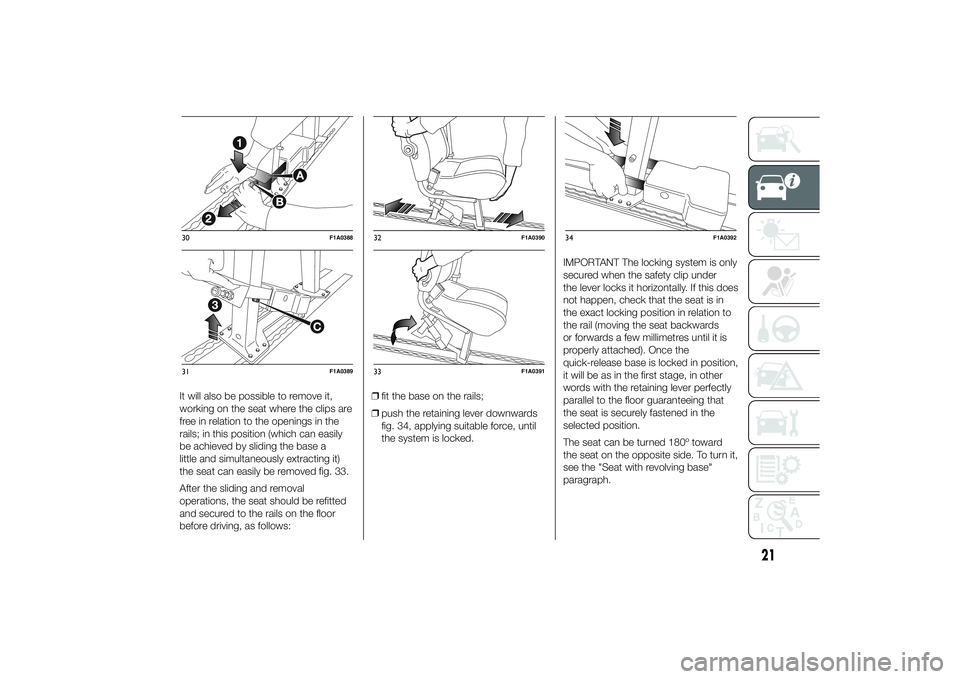

It will also be possible to remove it,

working on the seat where the clips are

free in relation to the openings in the

rails; in this position (which can easily

be achieved by sliding the base a

little and simultaneously extracting it)

the seat can easily be removed fig. 33.

After the sliding and removal

operations, the seat should be refitted

and secured to the rails on the floor

before driving, as follows:❒fit the base on the rails;

❒push the retaining lever downwards

fig. 34, applying suitable force, until

the system is locked.IMPORTANT The locking system is only

secured when the safety clip under

the lever locks it horizontally. If this does

not happen, check that the seat is in

the exact locking position in relation to

the rail (moving the seat backwards

or forwards a few millimetres until it is

properly attached). Once the

quick-release base is locked in position,

it will be as in the first stage, in other

words with the retaining lever perfectly

parallel to the floor guaranteeing that

the seat is securely fastened in the

selected position.

The seat can be turned 180º toward

the seat on the opposite side. To turn it,

see the "Seat with revolving base"

paragraph.30

F1A0388

31

F1A0389

32

F1A0390

33

F1A0391

34

F1A0392

21

Page 94 of 367

IMPORTANT When parking, take the

utmost care over obstacles that may be

above or under the camera range.

WARNING

77) The responsibility for parking

and other manoeuvres is always

and in any case charged to the

driver. While carrying out these

manoeuvres, always make sure

that no people (especially

children) or animals are in the

area concerned. The camera is an

aid for the driver, but the driver

must never allow his/her attention

to lapse during potentially

dangerous manoeuvres, even

those executed at low speeds.

Always keep a slow speed, so as

to promptly brake in the case

of obstacles.

IMPORTANT

8) It is vital, for correct operation,

that the camera is always kept

clean and free from mud, dirt,

snow or ice. Be careful not to

scratch or damage the camera

while cleaning it. Avoid using dry,

rough or hard cloths. The camera

must be washed using clean

water, with the addition of car

shampoo if necessary. In washing

stations which use steam or

high-pressure jets, clean the

camera quickly, keeping the

nozzle more than 10 cm away

from the sensors. Do not apply

stickers to the camera.

TRAFFIC SIGN

RECOGNITION(for versions/markets, where provided)

74) 79) 80) 81)9) 10) 11) 12) 13) 14) 15)

The system automatically detects the

recognisable traffic signs: speed limits,

no overtaking signs and signs indicating

the end of such prohibitions.

The camera is fitted behind the internal

rear view mirror. The sensor always

checks the traffic signs indicating the

current speed limit and possible no

overtaking signs.

IMPORTANT The system is designed to

read signs complying with the

specifications of the Vienna convention.

USE OF THE TRAFFIC

SIGN RECOGNITION

System switching on

and off

The system can be activated/

deactivated using the display menu.

Refer to the "Display" paragraph in the

"Knowing the instrument panel"

chapter.

Note: the system condition and settings

do not change throughout the different

on-off cycles.

90

KNOW YOUR VEHICLE

Page 98 of 367

❒Objects close to the vehicle, in

certain circumstances are not

detected and could therefore cause

damage to the vehicle or be

damaged.

The following conditions may influence

the performance of the parking

assistance system:

❒Reduced sensor sensitivity and a

reduction in the parking assistance

system performance could be due to

the presence on the surface of the

sensor of: ice, snow, mud, thick

paint.

❒The sensor may detect a non-

existent obstacle (echo noise) due to

mechanical noises, for example

when washing the vehicle, in case of

rain, strong wind, hail.

❒The signals sent by the sensors can

also be altered by the presence of

ultrasonic systems (e.g. pneumatic

brake systems or pneumatic drills)

near the vehicle.❒The performance of the parking

assistance system may also be

affected by the position of the

sensors. For example by a change in

the ride setting (caused by the wear

of the shock absorbers, suspension),

changing the tyres, overloading the

vehicle and carrying out specific

tuning operations that require the

vehicle to be lowered.

❒Detection of obstacles in the upper

part of the vehicle (particularly in the

case of vans or chassis cabs) may

not be guaranteed because the

system detects obstacles that could

strike the lower part of the vehicle.

IMPORTANT

16) The sensor must be clean of

mud, dirt, snow or ice in order for

the system to operate correctly.

Be careful not to scratch or

damage the sensors while

cleaning them. Avoid using dry,

rough or hard cloths. The sensors

must be washed using clean

water, with the addition of car

shampoo if necessary.

WARNING

82) The responsibility for parking

and other dangerous manoeuvres

always and in every case lies

with the driver. While carrying out

these manoeuvres, always make

sure that no people (especially

children) or animals are in the

area concerned. The parking

sensors are used to assist the

driver, who must never allow his

attention to lapse during

potentially dangerous

manoeuvres, even those executed

at low speeds.

94

KNOW YOUR VEHICLE

Page 158 of 367

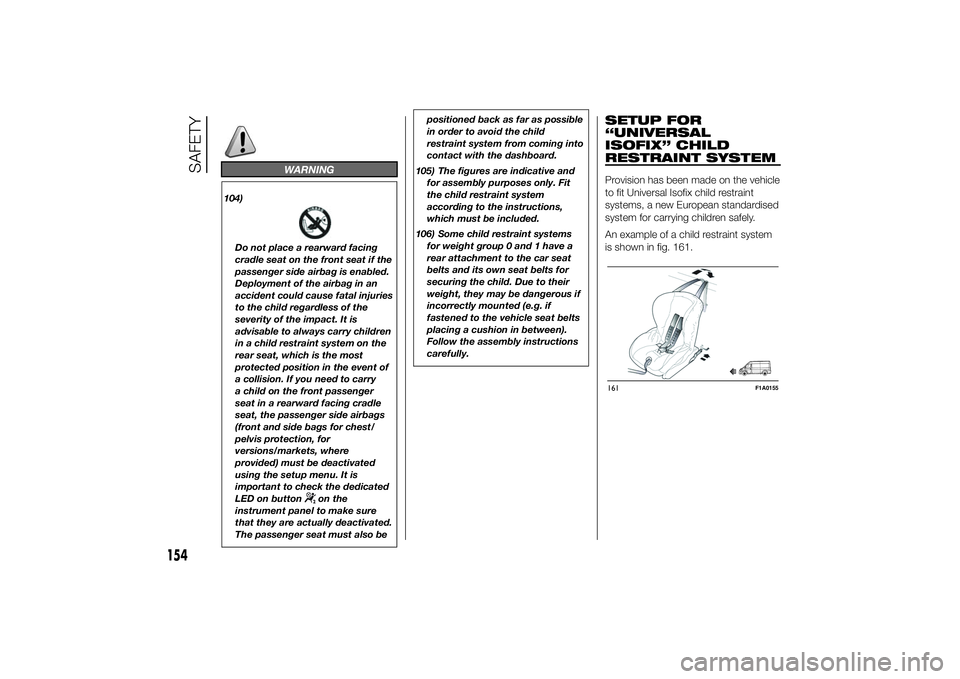

WARNING

104)Do not place a rearward facing

cradle seat on the front seat if the

passenger side airbag is enabled.

Deployment of the airbag in an

accident could cause fatal injuries

to the child regardless of the

severity of the impact. It is

advisable to always carry children

in a child restraint system on the

rear seat, which is the most

protected position in the event of

a collision. If you need to carry

a child on the front passenger

seat in a rearward facing cradle

seat, the passenger side airbags

(front and side bags for chest/

pelvis protection, for

versions/markets, where

provided) must be deactivated

using the setup menu. It is

important to check the dedicated

LED on button

on the

instrument panel to make sure

that they are actually deactivated.

The passenger seat must also bepositioned back as far as possible

in order to avoid the child

restraint system from coming into

contact with the dashboard.

105) The figures are indicative and

for assembly purposes only. Fit

the child restraint system

according to the instructions,

which must be included.

106) Some child restraint systems

for weight group 0 and 1 have a

rear attachment to the car seat

belts and its own seat belts for

securing the child. Due to their

weight, they may be dangerous if

incorrectly mounted (e.g. if

fastened to the vehicle seat belts

placing a cushion in between).

Follow the assembly instructions

carefully.

SETUP FOR

“UNIVERSAL

ISOFIX” CHILD

RESTRAINT SYSTEMProvision has been made on the vehicle

to fit Universal Isofix child restraint

systems, a new European standardised

system for carrying children safely.

An example of a child restraint system

is shown in fig. 161.161

F1A0155

154

SAFETY

Page 159 of 367

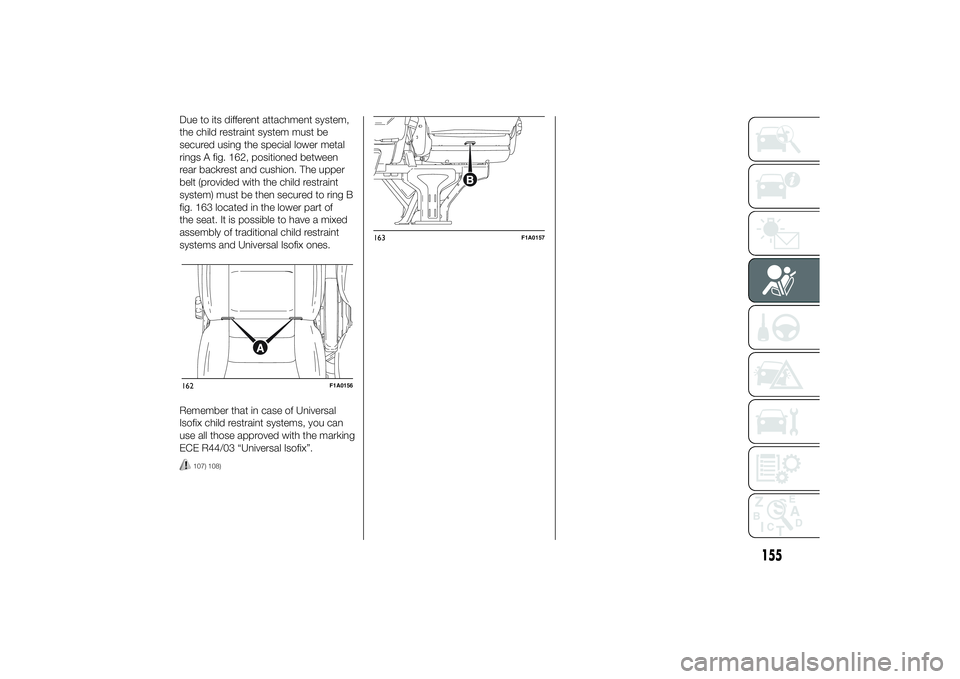

Due to its different attachment system,

the child restraint system must be

secured using the special lower metal

rings A fig. 162, positioned between

rear backrest and cushion. The upper

belt (provided with the child restraint

system) must be then secured to ring B

fig. 163 located in the lower part of

the seat. It is possible to have a mixed

assembly of traditional child restraint

systems and Universal Isofix ones.

Remember that in case of Universal

Isofix child restraint systems, you can

use all those approved with the marking

ECE R44/03 “Universal Isofix”.

107) 108)

162

F1A0156

163

F1A0157

155

Page 179 of 367

LOADING ADVICEThe Fiat Ducato version used by you

has been designed and type approved

on the basis of certain maximum

weights (see "Weights" table in the

"Technical Data" chapter): kerb weight,

payload, total weight, maximum weight

on front axle, maximum weight on

rear axle, towable weight.

IMPORTANT The maximum permitted

load on the floor fastenings is 500

kg; the maximum permitted load on the

side panel is 150 kg.

IMPORTANT For versions with right and

left side flaps, it is advisable to

reposition the release lever in the closed

position before lowering the sides.

35)128) 129) 130)

In addition to these general

precautions, some simple precautions

can improve driving safety, travelling

comfort and vehicle durability:

❒distribute the load evenly over the

platform: if it is necessary to

concentrate it in a single area,

choose an area mid-way between

both axles;❒lastly, remember that the vehicle’s

dynamic behaviour is affected by

the weight transported: in particular,

the stopping distances are longer,

especially at high speed.

IMPORTANT

35) Each of these must be strictly

observed and MUST NEVER BE

EXCEEDED in any case. In

particular, ensure that you never

exceed the maximum permitted

weights on the front and rear

axles when arranging the load on

the vehicle (particularly if the

vehicle is equipped with a specific

trim level).

WARNING

128) Irregular trajectories and abrupt

braking may cause sudden

movements of the load with

consequent situations of hazard

for the driver and passengers:

before setting off, secure the load

tightly using the appropriate

hooks on the floor and use steel

cables, ropes or chains strong

enough to hold the items to be

secured.

129) If a vehicle is parked on a very

steep gradient or with a side

gradient, opening the rear door or

side door could cause any

unsecured items to emerge

suddenly.

130) If you wish to carry a reserve of

petrol in a can, observe the legal

restrictions and only use a can

that is type-approved and

properly secured to the load

anchorage eyebolts. Anyway, by

doing so, you increase the risk

of fire in the event of an accident

with your vehicle.

175

Page 182 of 367

TOWING TRAILERSIMPORTANT

INFORMATION

The vehicle must be provided with a

type-approved tow hook and adequate

electrical system to tow caravans or

trailers. Installation should be carried

out by specialised personnel who

will issue the required papers for

travelling on roads.

Install any specific and/or additional

door mirrors as specified by the

Highway Code.

Remember that when towing a trailer,

steep hills are harder to climb, the

braking spaces increase and overtaking

takes longer depending on the overall

weight.

Engage a low gear when driving

downhill, rather than constantly using

the brake.

The weight of the trailer on the vehicle

tow hook will reduce the loading

capacity of the vehicle by the same

amount. Consider the weight of the

trailer fully laden, including accessories

and luggage, to make sure you do

not exceed the maximum towable

weight (shown on the vehicle

registration document).Do not exceed the speed limits specific

to each country you are driving in, in

the case of vehicles towing trailers.

In any case, the top speed must not

exceed 100 km/h.

You are advised to fit a suitable

stabiliser to the trailer drawbar.

In the vehicles equipped with parking

sensors, after fitting the tow hook

malfunctioning warnings may be

displayed, as some parts (tow bar, ball

tow hook) may be within the sensor

detection range. In this case the

detection range must be adjusted or

the parking assistance function must be

deactivated.

131) 132)

INSTALLING THE TOW

HOOK

The towing device should be fastened

to the body by specialised personnel

according to any additional and/or

integrative information supplied by the

Manufacturer of the device.

The towing device must meet current

regulations with reference to Directive

94/20/EC and subsequent

amendments.

For any version the towing device used

must match the towable weight of the

vehicle on which it is to be installed.

For the electric connection a standard

connector should be used which is

generally placed on a special bracket

normally fastened to the towing device,

and a special ECU for external trailer

light control must be installed on the

vehicle. For the electrical connection, 7

or 13 pin 12 V DC connections are to

be used (CUNA/UNI and ISO/DIN

Standards). Follow the instructions

provided by the vehicle manufacturer

and/or the tow hitch manufacturer.

An electric brake (or electric winch)

should be supplied directly by the

battery through a cable with a cross

section of no less than 2.5 mm

2.

178

STARTING AND DRIVING

Page 187 of 367

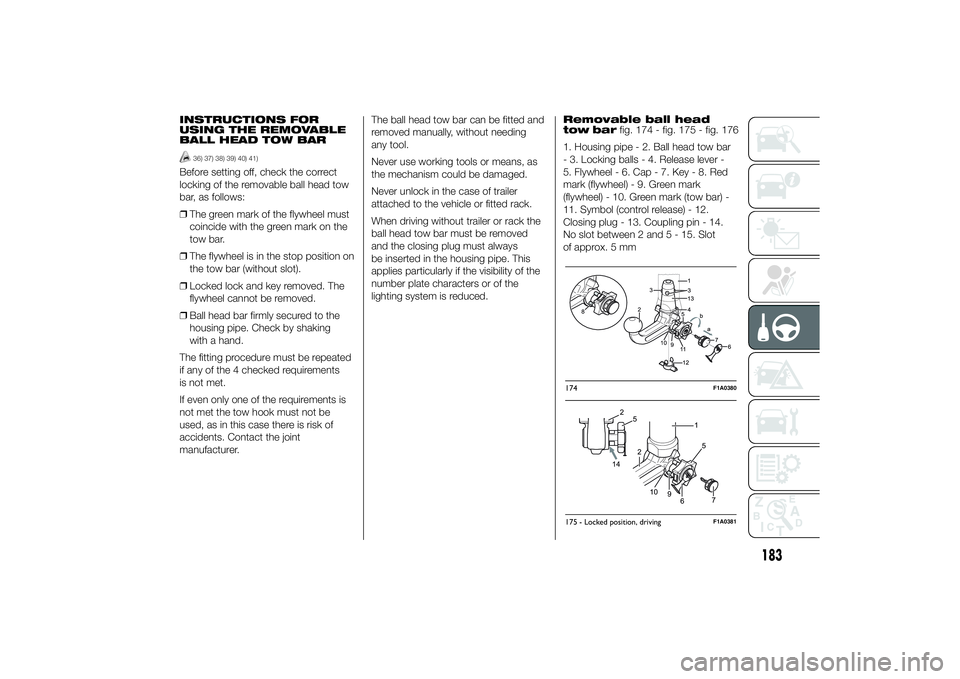

INSTRUCTIONS FOR

USING THE REMOVABLE

BALL HEAD TOW BAR

36) 37) 38) 39) 40) 41)

Before setting off, check the correct

locking of the removable ball head tow

bar, as follows:

❒The green mark of the flywheel must

coincide with the green mark on the

tow bar.

❒The flywheel is in the stop position on

the tow bar (without slot).

❒Locked lock and key removed. The

flywheel cannot be removed.

❒Ball head bar firmly secured to the

housing pipe. Check by shaking

with a hand.

The fitting procedure must be repeated

if any of the 4 checked requirements

is not met.

If even only one of the requirements is

not met the tow hook must not be

used, as in this case there is risk of

accidents. Contact the joint

manufacturer.The ball head tow bar can be fitted and

removed manually, without needing

any tool.

Never use working tools or means, as

the mechanism could be damaged.

Never unlock in the case of trailer

attached to the vehicle or fitted rack.

When driving without trailer or rack the

ball head tow bar must be removed

and the closing plug must always

be inserted in the housing pipe. This

applies particularly if the visibility of the

number plate characters or of the

lighting system is reduced.Removable ball head

tow barfig. 174 - fig. 175 - fig. 176

1. Housing pipe - 2. Ball head tow bar

- 3. Locking balls - 4. Release lever -

5. Flywheel - 6. Cap - 7. Key - 8. Red

mark (flywheel) - 9. Green mark

(flywheel) - 10. Green mark (tow bar) -

11. Symbol (control release) - 12.

Closing plug - 13. Coupling pin - 14.

No slot between 2 and 5 - 15. Slot

of approx. 5 mm

174

F1A0380

175 - Locked position, driving

F1A0381

183

Page 199 of 367

138) The spare wheel supplied (for

versions/markets, where

provided) is specific for your

vehicle. Therefore, it must not be

used on other models. Do not

use spare wheels of other models

on your vehicle. The wheel bolts

are specific for your vehicle: do

not use them on different models

and do not use bolts from other

models on your car.

139) Have the wheel repaired and

refitted as soon as possible. Do

not apply grease to the bolt

threads before fitting: they could

come unscrewed.

140) Use the jack only to replace

wheels on the vehicle with which

it is supplied or on other vehicles

of the same model. Never use

the jack for other purposes, such

as lifting other car models. Never

use the jack to carry out repairs

under the vehicle. Incorrect

positioning of the jack may cause

the lifted vehicle to fall. Do not

use the jack for loads higher than

those shown on the label.

141) Never tamper with the inflation

valve. Never introduce tools of any

kind between rim and tyre. Check

tyre and spare wheel pressure

regularly, referring to the values

shown in the "Technical

specifications" section.142) No tools other than the crank

provided should be used with

the spare wheel lifting device; it

should be operated by hand only.

143) On versions equipped with

self-levelling air suspension, never

introduce the head or hands in

the wheel arch: the vehicle could

raise or lower automatically

depending on possible load or

temperature changes.

144) The device should only be

operated by hand, without using

any type of tool other than the

crank provided, like pneumatic or

electrical screwers.

145) The moving components of the

jack (screw and joints) can also

cause injuries: do not touch them.

If you come into contact with

lubricating grease, clean yourself

thoroughly.146) At the end of the operation of

raising/locking the spare wheel,

after having checked the correct

positioning of the wheel under the

platform (white notch inside the

window on the device), the key

must be extracted, taking care not

to turn it in the wrong direction

to facilitate the extraction of the

key itself, to prevent the

attachment device from being

released and the wheel assembly

not being securely retained fig.

188.

147) Each time the spare wheel is

moved, check that it is correctly

positioned in its housing under

the platform. If it is not correctly

positioned, this could adversely

affect safety.

195

Page 203 of 367

WARNING

148) Give the instruction booklet to

the tyre repair workshop

personnel.

149) Punctures on the sides of the

tyre cannot be repaired. Do not

use the quick tyre repair kit if the

damage is due to running with flat

tyre.

150) If the wheel rim has been

damaged (bent so as to cause air

to leak), the wheel cannot be

repaired. Do not remove the

foreign body (screws or nails)

from the tyre.

151) Do not use the compressor for

more than 20 consecutive

minutes. Risk of overheating.

Tyres repaired with the quick tyre

repair kit must only be used

temporarily, as the kit is not

suitable for a definitive repair.152) The bottle contains ethylene

glycol. It contains latex that might

cause allergic reactions. It is

harmful if swallowed. It is irritant

for the eyes. It may cause

sensitisation if inhaled or on

contact. Avoid contact with eyes,

skin and clothes. In the event of

contact, wash immediately with

plenty of water. Do not induce

vomiting if swallowed. Rinse your

mouth and drink plenty of water.

Call a doctor immediately. Keep

out of the reach of children. The

product must not be used by

asthmatics. Do not breathe in the

vapours during insertion and

suction. Call a doctor immediately

if allergic reactions are noted.

Store the bottle in its proper

compartment, away from sources

of heat. The sealant has an expiry

date. Replace the bottle if the

sealant has expired.

153) Wear the protective gloves

provided together with the quick

tyre repair kit.

154) affix the adhesive label in an

easy-to-see position for the driver

as a reminder that the tyre has

been treated with the quick tyre

repair kit. Drive carefully,

particularly on bends. Do not

exceed 80 km/h. Do not

accelerate or brake suddenly.155) If the pressure falls below 3

bars, do not drive any further: the

Fix & Go automatic quick tyre

repair kit cannot guarantee proper

hold because the tyre is too much

damaged. Contact a Fiat

Dealership.

156) You must inform the dealership

that the tyre has been repaired

using the quick tyre repair kit.

Give the booklet to the personnel

who will be handling the tyre

treated with the repair kit.

157) If different tyres from the ones

supplied with the vehicle are

used, it may not be possible to

carry out the repair. If the tyres

are replaced, it is advisable to use

those approved by the

manufacturer. Consult a Fiat

Dealership.

199