brakes FIAT DUCATO BASE CAMPER 2014 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2014, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2014Pages: 367, PDF Size: 20.39 MB

Page 81 of 367

On some versions, the intervention of

the system is indicated by a message

shown on the display.

When the system is not active, the LED

on the button ASR OFF turns on and,

on some versions, a message appears

on the display.

If the ASR is disengaged during driving,

it is automatically reactivated when

the vehicle is next started.

When travelling on snowy roads with

snow chains, it may be helpful to turn

the ASR off: in fact, in these conditions,

the driving wheels slipping when

moving off gives you better traction.HBA SYSTEM

(Hydraulic Brake Assist)

The HBA system is designed to

improve the vehicle’s braking capacity

during emergency braking. The system

detects emergency braking by

monitoring the speed and strength with

which the brake pedal is pressed,

thereby applying the optimal brake

pressure.

This can reduce the braking distance:

the HBA system therefore completes

the ABS.

Maximum assistance from the HBA

system is obtained by pressing the

brake pedal very quickly. In addition,

the brake pedal must be pressed

continuously during braking, avoiding

intermittent presses, to benefit from the

system.

Do not reduce pressure on the brake

pedal until braking is not necessary

anymore.

The HBA system is deactivated when

the brake pedal is released.

59) 60) 61)

ERM ELECTRONIC ROLLOVER

MITIGATION SYSTEM

(Electronic Rollover Mitigation)

The system monitors the tendency of

the wheels to rise from the ground if the

driver performs extreme manoeuvres

like quick steering to avoid an obstacle,

especially in poor road conditions.

If these conditions occur, the system

intervenes on the brakes and engine

power to reduce the possibility that the

wheels are raised from the ground.

It is not possible to avoid the tendency

to roll over if this is due to reasons

such as driving on high side gradients,

collision with objects or other vehicles.

62)

HILL DESCENT CONTROL

(HDC) SYSTEM

It is an integral part of the ESC and is

aimed at keeping the vehicle at a

constant speed during a descent,

operating autonomously on the brakes

in various ways at the same time. In this

way the vehicle stability and completely

safe driving are guaranteed, above all

in poor grip conditions and/or steep

descents.

124

F1A0324

77

Page 82 of 367

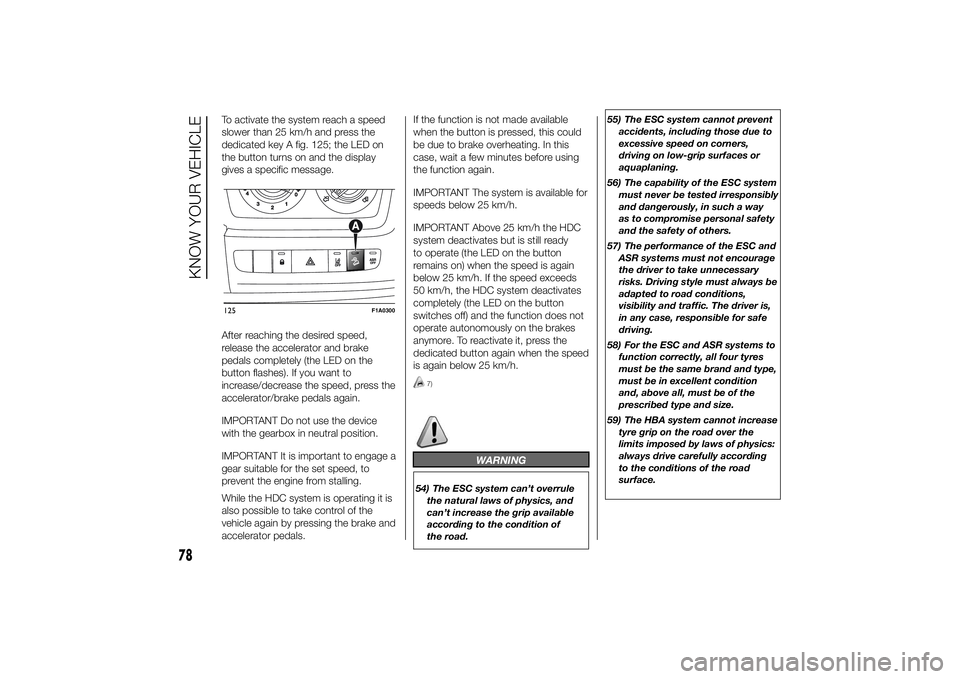

To activate the system reach a speed

slower than 25 km/h and press the

dedicated key A fig. 125; the LED on

the button turns on and the display

gives a specific message.

After reaching the desired speed,

release the accelerator and brake

pedals completely (the LED on the

button flashes). If you want to

increase/decrease the speed, press the

accelerator/brake pedals again.

IMPORTANT Do not use the device

with the gearbox in neutral position.

IMPORTANT It is important to engage a

gear suitable for the set speed, to

prevent the engine from stalling.

While the HDC system is operating it is

also possible to take control of the

vehicle again by pressing the brake and

accelerator pedals.If the function is not made available

when the button is pressed, this could

be due to brake overheating. In this

case, wait a few minutes before using

the function again.

IMPORTANT The system is available for

speeds below 25 km/h.

IMPORTANT Above 25 km/h the HDC

system deactivates but is still ready

to operate (the LED on the button

remains on) when the speed is again

below 25 km/h. If the speed exceeds

50 km/h, the HDC system deactivates

completely (the LED on the button

switches off) and the function does not

operate autonomously on the brakes

anymore. To reactivate it, press the

dedicated button again when the speed

is again below 25 km/h.

7)

WARNING

54) The ESC system can’t overrule

the natural laws of physics, and

can’t increase the grip available

according to the condition of

the road.55) The ESC system cannot prevent

accidents, including those due to

excessive speed on corners,

driving on low-grip surfaces or

aquaplaning.

56) The capability of the ESC system

must never be tested irresponsibly

and dangerously, in such a way

as to compromise personal safety

and the safety of others.

57) The performance of the ESC and

ASR systems must not encourage

the driver to take unnecessary

risks. Driving style must always be

adapted to road conditions,

visibility and traffic. The driver is,

in any case, responsible for safe

driving.

58) For the ESC and ASR systems to

function correctly, all four tyres

must be the same brand and type,

must be in excellent condition

and, above all, must be of the

prescribed type and size.

59) The HBA system cannot increase

tyre grip on the road over the

limits imposed by laws of physics:

always drive carefully according

to the conditions of the road

surface.

125

F1A0300

78

KNOW YOUR VEHICLE

Page 83 of 367

60) The HBA system cannot prevent

accidents, including those due to

excessive speed on bends,

travelling on low-grip surfaces or

aquaplaning.

61) The HBA system is an aid for the

driver, who must always pay full

attention while driving. The

responsibility always rests with

the driver. The features of the

HBA system must never be tested

in imprudent or dangerous ways,

with the possibility of putting

the safety of the driver, occupants

or other road users at risk.

62) The performance of a vehicle

with ERM must never be tested

in imprudent or dangerous ways,

with the possibility of putting

the safety of the driver or other

people at risk.

IMPORTANT

7) Prolonged use of the system may

overheat the braking system. If

the brakes overheat, the HDC

system, when active, will be

gradually deactivated after

suitably informing the driver (the

LED on the button turns off): it

can be reactivated only when the

brakes have cooled sufficiently.

The distance that can be covered

depends on the temperature of

the brakes and therefore on the

gradient, load and speed of the

vehicle.

TRACTION PLUS

SYSTEM(for versions/markets, where provided)

Traction Plus is a driving aid, useful

for setting off in poor grip conditions on

non-homogeneous road surfaces

(snow/asphalt, ice/asphalt, mud/

asphalt, etc.), which allows the drive

force to be distributed adequately

on the engine axle when one of the two

drive wheels slips.

Traction Plus acts by braking the wheel

with poor grip (or slipping more than

the others), thereby transferring the

drive force to that which has greater

grip on the ground.

This function can be activated manually

by pressing button A on the dashboard

fig. 126 and operates under 50 km/h.

When this speed is exceeded, it is

automatically deactivated (the LED on

the button is still on) and it is

reactivated again when the speed falls

below 30 km/h.

63) 64)

79

Page 104 of 367

WARNING

87) Take care when fitting additional

spoilers, alloy wheels or non-

standard wheel hubs: they could

reduce the ventilation of the

brakes and affect efficiency

during sharp, repeated braking or

on long descents. Make sure

that nothing obstructs the pedal

stroke (mats, etc.)

REFUELLING THE

VEHICLE

IN BRIEF

Refuel the vehicle exclusively with

diesel for motor vehicles in

compliance with European

specification EN590.

Stop the engine before refuelling.

OPERATION AT LOW

TEMPERATURES

If the outside temperature is very low,

diesel thickens due to the formation

of paraffin clots with consequent

defective operation of the fuel supply

system.

In order to avoid these problems,

different types of diesel are distributed

according to the season: summer type,

winter type and arctic type (cold/

mountain areas). If refuelling with diesel

fuel whose specifications are not

suitable for the current temperature, it is

advisable to mix TUTELA DIESEL ART

additive in the proportions shown on

the container. Pour the additive into the

tank before the diesel fuel.

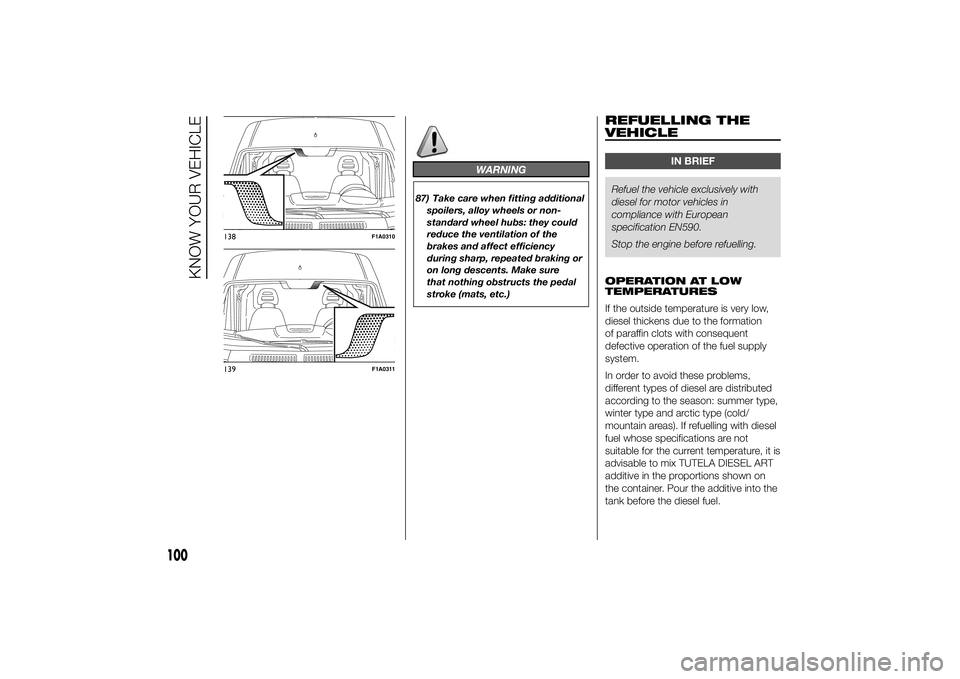

138

F1A0310

139

F1A0311

100

KNOW YOUR VEHICLE

Page 183 of 367

IMPORTANT Electric brakes or other

devices must be used with engine

running.

In addition to the electrical branches,

the vehicle's electric system can only

be connected to the supply cable for an

electric brake and to the cable for an

internal light, though not above 15

W. For connections use the preset

control unit with battery cable no less

than 2.5 mm

2.

IMPORTANT The trailer tow hook

contributes to the length of the vehicle.

When installing on long wheelbase

versions, it is only possible to install

removable tow hooks because the total

vehicle length limit of 6 metres is

exceeded.

If no trailer is fitted, the hook must be

removed from the attachment base and

it must not exceed the vehicle's

original length.IMPORTANT If you wish to leave the

tow hook fitted without towing a trailer,

it is advisable to contact a Fiat

Dealership for the relevant system

update operations because the tow

hook could be detected as an obstacle

by the central sensors.Installation diagram for

Van versions fig. 172

The tow hook structure must be

fastened in the points shown by the

symbol Ø using a total of 6 M10x1.25

screws and 4 M12 screws.

The internal back plates must be at

least 5 mm thick. MAX LOAD ON

BALL: 100/120 kg according to the

payload (see “Weights” table in the

“Technical data” section).

133)

To install a tow hook, the bumpers

must be trimmed as described in the

supplier's installation kit.

Installation diagram for

Truck and Chassis Cab

versions fig. 173

Another tow hook specific to Truck and

Chassis Cab versions in shown in fig.

173.

The structure Ø must be fixed in the

points indicated using a total of 6

M10x1.25 screws and 4 M12 screws.

MAX LOAD ON BALL: 100/120 kg

according to the payload (see

“Weights” table in the “Technical data”

section).

134)

179

Page 229 of 367

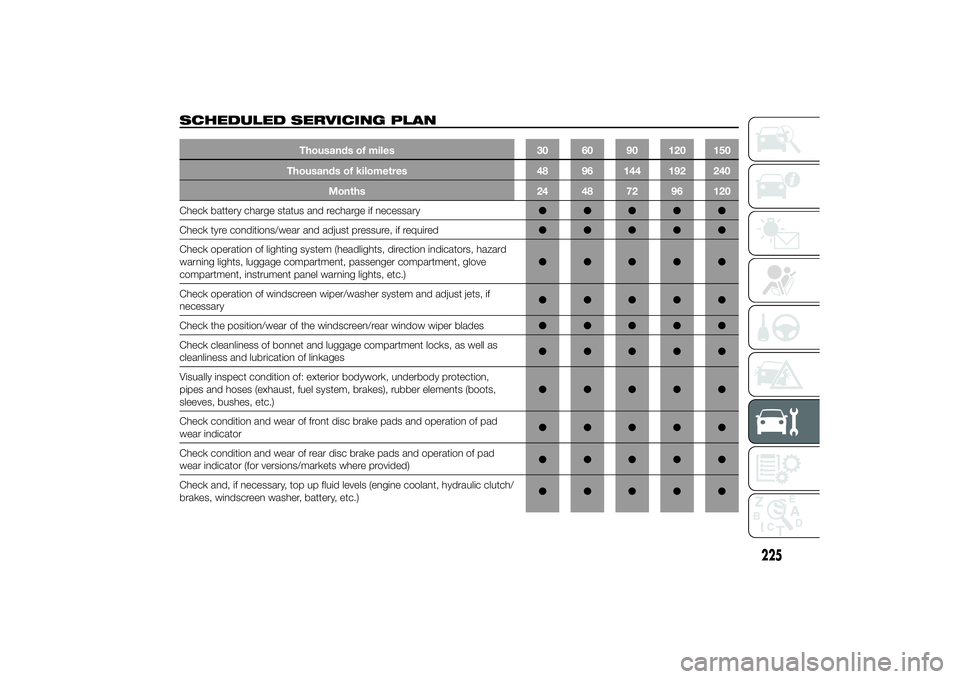

SCHEDULED SERVICING PLAN

Thousands of miles 30 60 90 120 150

Thousands of kilometres 48 96 144 192 240

Months 24 48 72 96 120

Check battery charge status and recharge if necessary●●●●●

Check tyre conditions/wear and adjust pressure, if required●●●●●

Check operation of lighting system (headlights, direction indicators, hazard

warning lights, luggage compartment, passenger compartment, glove

compartment, instrument panel warning lights, etc.)●●●●●

Check operation of windscreen wiper/washer system and adjust jets, if

necessary●●●●●

Check the position/wear of the windscreen/rear window wiper blades●●●●●

Check cleanliness of bonnet and luggage compartment locks, as well as

cleanliness and lubrication of linkages●●●●●

Visually inspect condition of: exterior bodywork, underbody protection,

pipes and hoses (exhaust, fuel system, brakes), rubber elements (boots,

sleeves, bushes, etc.)●●●●●

Check condition and wear of front disc brake pads and operation of pad

wear indicator●●●●●

Check condition and wear of rear disc brake pads and operation of pad

wear indicator (for versions/markets where provided)●●●●●

Check and, if necessary, top up fluid levels (engine coolant, hydraulic clutch/

brakes, windscreen washer, battery, etc.)●●●●●

225

Page 232 of 367

PERIODIC CHECKSBefore long journeys, check and, if

necessary, restore:

❒engine coolant level;

❒brake fluid level;

❒windscreen washer fluid level;

❒tyre inflation pressure and condition;

❒operation of lighting system

(headlamps, direction indicators,

hazard warning lights, etc.);

❒operation of screen washer/wiper

system and positioning/wear of

windscreen/rear window wiper

blades.

To ensure that the vehicle is always

efficient and well maintained, it is

advisable to make sure that you carry

out the above operations regularly

(approximately every 1000 km and

every 3000 km for checking and

topping up engine oil is advisable).

DEMANDING

VEHICLE USEIf the vehicle is mostly used in one of

the following conditions:

❒towing a trailer or caravan;

❒dusty roads;

❒short, repeated journeys (less than

7-8 km) at sub-zero outside

temperatures;

❒engine often idling or driving long

distances at low speeds or long

periods of inactivity;

the following checks must be carried

out more often than indicated in the

Scheduled Servicing Plan:

❒check front disc brake pad

conditions and wear;

❒check cleanliness of bonnet and boot

locks, cleanliness and lubrication of

linkage;

❒visually inspect conditions of: engine,

gearbox, transmission, pipes and

hoses (exhaust - fuel system -

brakes) and rubber elements (boots -

sleeves - bushes - etc.);

❒check battery charge and battery

fluid level (electrolyte);

❒visually inspect condition of the

accessory drive belts;❒check and, if necessary, change

engine oil and replace oil filter.

❒check and, if necessary, replace

pollen filter.

228

SERVICING AND MAINTENANCE

Page 253 of 367

TECHNICAL SPECIFICATIONS

Everything you may find useful for

understanding how your vehicle

is made and works is contained in this

chapter and illustrated with data, tables

and graphics. For the enthusiasts and

the technician, but also just for those

who want to know every detail of their

vehicle.IDENTIFICATION DATA....................250

ENGINE CODES - BODYWORK

VERSION ........................................252

ENGINE ..........................................254

POWER SUPPLY ............................255

TRANSMISSION .............................256

SUSPENSION .................................257

BRAKES .........................................258

STEERING ......................................259

WHEELS .........................................260

DIMENSIONS ..................................264

PERFORMANCE .............................274

WEIGHTS........................................276

SUPPLIES .......................................316

FLUIDS AND LUBRICANTS ............318

FUEL CONSUMPTION ....................321

CO2 EMISSIONS ............................332

OFFICIAL TYPE APPROVALS .........342

PRESCRIPTIONS FOR HANDLING

THE VEHICLE AT THE END OF ITS

LIFE ................................................346

249

Page 262 of 367

BRAKES

Front service brakes Rear service brakes Parking brakeself-ventilated discs discscontrolled by hand lever, working on rear

brakes

IMPORTANT Water, ice and salt spread on the roads may deposit on the brake discs reducing braking efficiency the first time

the brakes are applied.

258

TECHNICAL SPECIFICATIONS

Page 323 of 367

UseFluid and lubricant features for a correct use

of the carGenuine fluids and

lubricantsApplicationsLubricants and

greases for drive

transmissionSAE 75W- 80 grade synthetic lubricant.

Classification FIAT 9.55550-MZ2..TUTELA

TRANSMISSION

EXPERYA

Contractual Technical

Reference No. F178.B06Manual gearbox and

differential

Synthetic base lubricant SAE 75W-85 grade

Classification FIAT 9.55550-MZ3TUTELA

TRANSMISSION

GEARTECH

Contractual Technical

Reference No. F704.C08Manual gearbox and

differential

Molybdenum disulphide grease, for use at high

temperatures.

FIAT 9.55580 classification. Consistency NLGI

1-2TUTELA ALL STAR

Contractual Technical

Reference No. F702.G07Wheel side constant

velocity joints

Grease for constant velocity joints with low friction

coefficient.

FIAT 9.55580 classification. Consistency NLGI

0-1TUTELA STAR 700

Contractual Technical

Reference No. F701.C07Differential-side

constant velocity joints

Lubricant for power steering

Exceeds "ATF DEXRON III" specifications

Classification FIAT 9.55550-AG2.TUTELA

TRANSMISSION GI/E

Contractual Technical

Reference No. F001.C94Hydraulic power

steering

Brake fluidSynthetic fluid for brake and clutch systems

Exceeds specifications: FMVSS no. 116 DOT 4,

ISO 4925, SAE J 1704

Classification FIAT 9.55597.TUTELA TOP 4

Contractual Technical

Reference No. F001.A93Hydraulic brakes and

clutch controls

319