tow FIAT DUCATO BASE CAMPER 2015 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2015Pages: 367, PDF Size: 19.73 MB

Page 201 of 367

IN AN EMERGENCY

A punctured tyre or a burnt-out

bulb?

At times, a problem may interfere

with our journey.

The pages on emergencies can

help you to deal with critical

situations independently and with

calm.

In an emergency we recommend

that you call the freephone number

found in the Warranty Booklet.

It is also possible to call the 00 800

3428 0000 freephone number to

search the nearest Fiat Dealership.STARTING THE ENGINE .................198

REPLACING A WHEEL ...................199

FIX & GO AUTOMATIC QUICK

TYRE REPAIR KIT ...........................204

CHANGING A BULB .......................208

REPLACING AN EXTERIOR BULB ..211

CHANGING AN INTERIOR BULB ....216

REPLACING FUSES........................217

BATTERY RECHARGING ................225

LIFTING THE VEHICLE....................226

TOWING THE VEHICLE ..................226

197

Page 202 of 367

STARTING THE

ENGINE

Go to a Fiat Dealership immediately

if warning light

stays on

constantly on the instrument panel.

JUMP STARTING

If the battery is flat, it is possible to

start the engine using an auxiliary

battery with the same capacity or a

little higher than the flat one.

It is advisable to contact a Fiat

Dealership to check/replace the

battery.

140)

Proceed as follows to start the

vehicle:

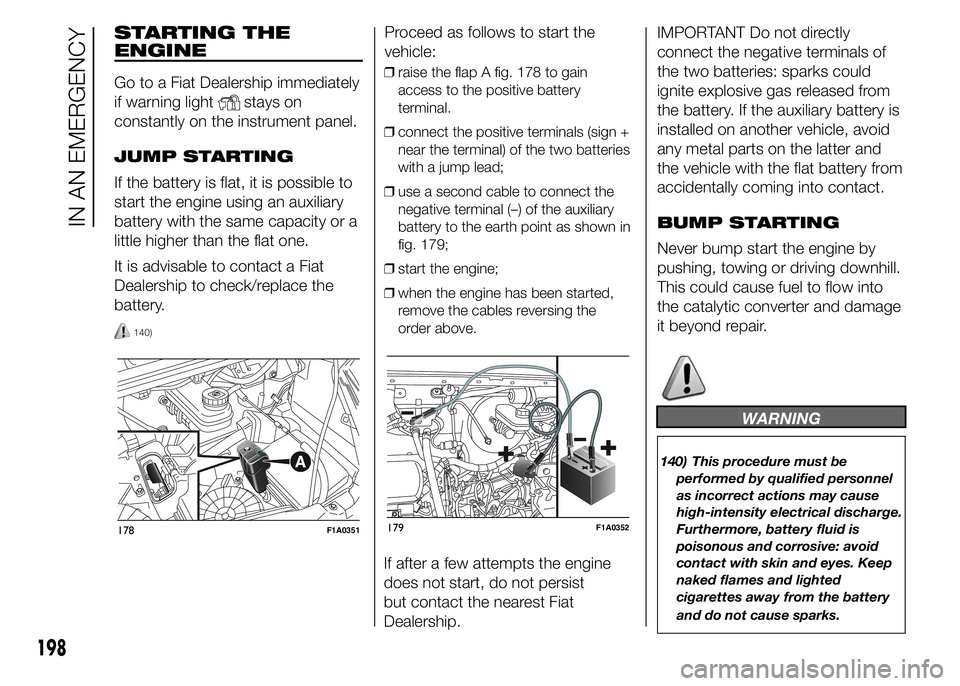

❒raise the flap A fig. 178 to gain

access to the positive battery

terminal.

❒connect the positive terminals (sign +

near the terminal) of the two batteries

with a jump lead;

❒use a second cable to connect the

negative terminal (–) of the auxiliary

battery to the earth point as shown in

fig. 179;

❒start the engine;

❒when the engine has been started,

remove the cables reversing the

order above.

If after a few attempts the engine

does not start, do not persist

but contact the nearest Fiat

Dealership.IMPORTANT Do not directly

connect the negative terminals of

the two batteries: sparks could

ignite explosive gas released from

the battery. If the auxiliary battery is

installed on another vehicle, avoid

any metal parts on the latter and

the vehicle with the flat battery from

accidentally coming into contact.

BUMP STARTING

Never bump start the engine by

pushing, towing or driving downhill.

This could cause fuel to flow into

the catalytic converter and damage

it beyond repair.

WARNING

140) This procedure must be

performed by qualified personnel

as incorrect actions may cause

high-intensity electrical discharge.

Furthermore, battery fluid is

poisonous and corrosive: avoid

contact with skin and eyes. Keep

naked flames and lighted

cigarettes away from the battery

and do not cause sparks.

178F1A0351179F1A0352

198

IN AN EMERGENCY

Page 203 of 367

REPLACING A

WHEEL

GENERAL

INSTRUCTIONS

Wheel replacement and correct use

of the jack and spare wheel (for

versions/markets, where provided)

call for some precautions, which

are listed below.

141) 142) 143) 144) 145)

Please note that:

❒the jack weight is 4.5 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired: in the

event of a fault it must be replaced by

another original one;

❒no tool other than its cranking device

may be fitted on the jack.

146)

To change a wheel,

proceed as follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel

safely. The ground should be flat

if possible, and sufficiently firm;❒stop the engine and pull the

handbrake;

❒engage first gear or reverse;

❒put on the reflective safety jacket

(compulsory by law in certain

countries) before getting out of the

vehicle;

❒indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

❒In the event of a wheel change on a

slope or on unsurfaced roads, put

any object as stop under the wheels;

❒take the tool bag under the

passenger seat (see “Compartment

under front passenger seat” in the

“Know your vehicle” section);

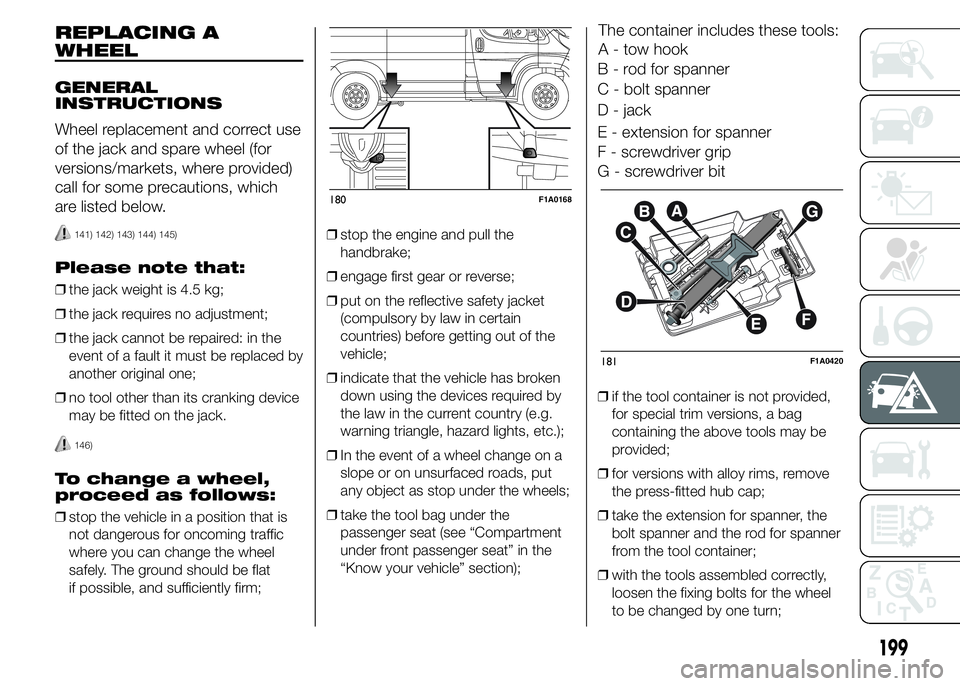

The container includes these tools:

A - tow hook

B - rod for spanner

C - bolt spanner

D - jack

E - extension for spanner

F - screwdriver grip

G - screwdriver bit

❒if the tool container is not provided,

for special trim versions, a bag

containing the above tools may be

provided;

❒for versions with alloy rims, remove

the press-fitted hub cap;

❒take the extension for spanner, the

bolt spanner and the rod for spanner

from the tool container;

❒with the tools assembled correctly,

loosen the fixing bolts for the wheel

to be changed by one turn;

180F1A0168

181F1A0420

199

Page 230 of 367

170) Do not attempt to charge a

frozen battery: it must be thawed

first, otherwise it may explode.

If freezing has occurred, the

battery should be checked by

skilled personnel to make sure

that the internal elements are not

damaged and that the body is

not cracked, with the risk of

leaking poisonous and corrosive

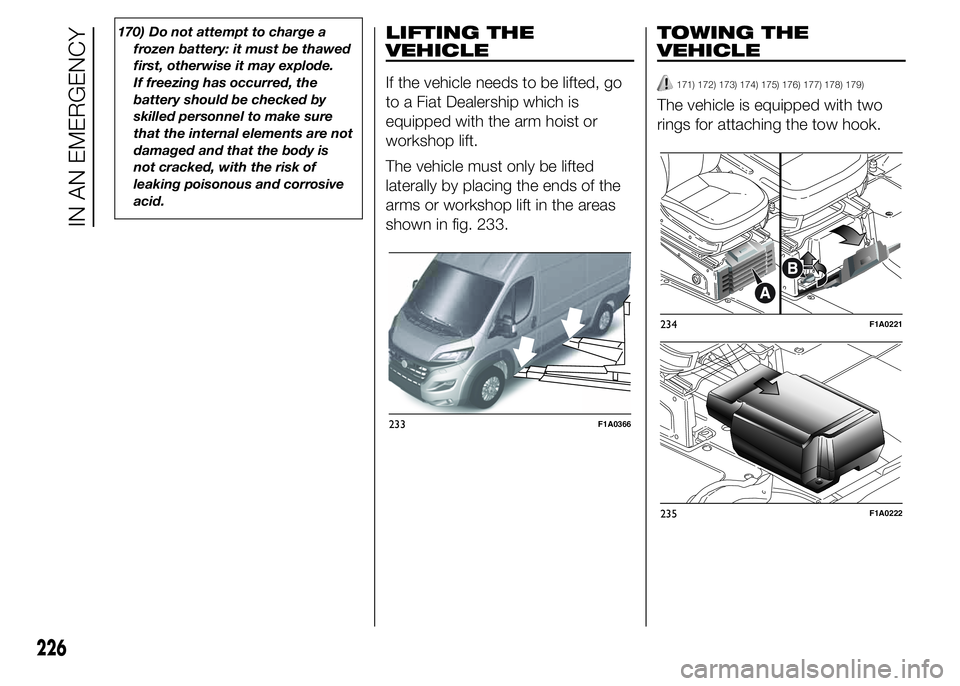

acid.LIFTING THE

VEHICLE

If the vehicle needs to be lifted, go

to a Fiat Dealership which is

equipped with the arm hoist or

workshop lift.

The vehicle must only be lifted

laterally by placing the ends of the

arms or workshop lift in the areas

shown in fig. 233.

TOWING THE

VEHICLE

171) 172) 173) 174) 175) 176) 177) 178) 179)

The vehicle is equipped with two

rings for attaching the tow hook.

233F1A0366

234F1A0221

235F1A0222

226

IN AN EMERGENCY

Page 231 of 367

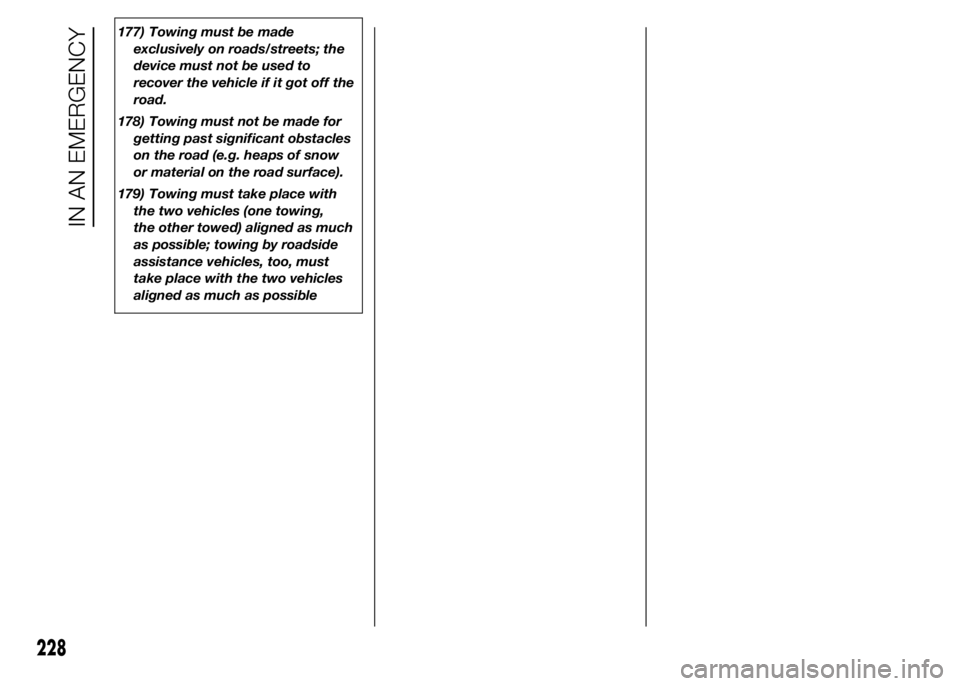

The front ring is located in the tool

box beneath the passenger side

seat. On versions with Fix&Go

kit and without spare wheel, the

tool box is available only on request

for versions/markets where

provided.In the absence of the tool box the

vehicle front tow hook is housed

in the on-board documentation

container, together with the Owner

Handbook.

To use it, proceed as follows:

❒Open the flap A and remove it as

illustrated in fig. 234;

❒turn retaining knob B fig. 234

anticlockwise and remove it to allow

the box fig. 235 to come out;

❒take the screwdriver provided from

the box and prise up at the point

shown to raise the cap C fig. 237;

❒take the tow ring D from the box and

screw it onto the threaded pin fig.

237.

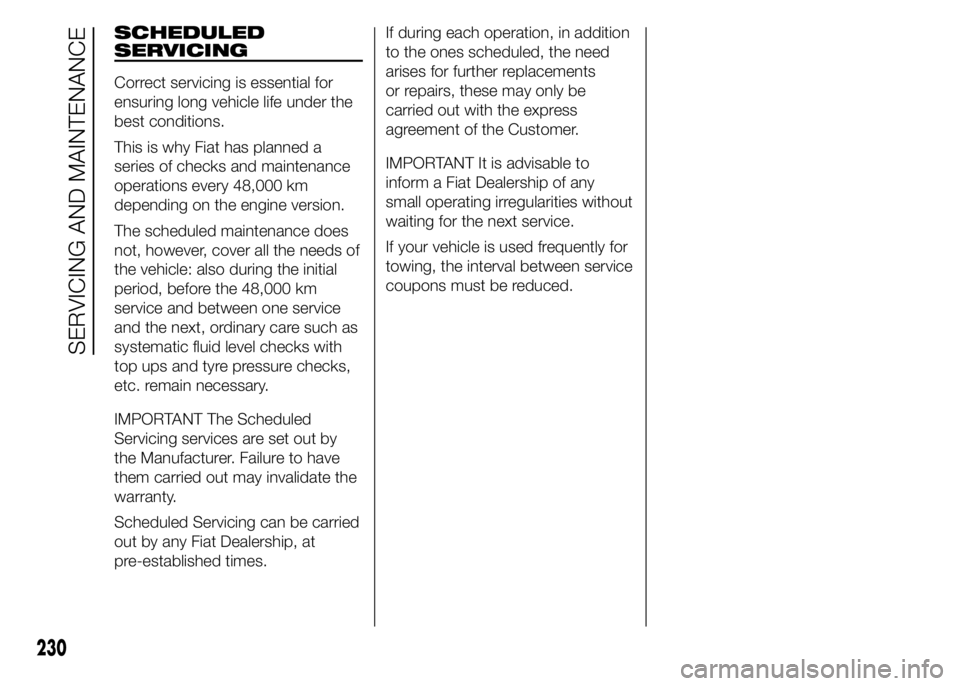

The rear ring B fig. 238 is located at

the point shown in the diagram.

WARNING

171) Screw on the tow hook and

check that it stops at the end

of travel position.

172) Before towing, switch off the

steering lock (see "Starting

device" paragraph under the

"Knowing your car" section).

173) Remember that the brake servo

and the electric power steering

are not available during towing

operations. Significantly greater

force must be exerted on the

brake pedal and on the steering

wheel to operate them.

174) Do not use flexible cables for

towing and avoid jerking. During

towing operations, make sure that

the fastened joint does not

damage adjoining components.

175) When towing the vehicle

comply with the specific rules of

the Highway Code regarding

the towing device and the

behaviour on the road.

176) Do not start the engine while

towing the vehicle.

236F1A0344

237F1A0223

238F1A0224

227

Page 232 of 367

177) Towing must be made

exclusively on roads/streets; the

device must not be used to

recover the vehicle if it got off the

road.

178) Towing must not be made for

getting past significant obstacles

on the road (e.g. heaps of snow

or material on the road surface).

179) Towing must take place with

the two vehicles (one towing,

the other towed) aligned as much

as possible; towing by roadside

assistance vehicles, too, must

take place with the two vehicles

aligned as much as possible

228

IN AN EMERGENCY

Page 234 of 367

SCHEDULED

SERVICING

Correct servicing is essential for

ensuring long vehicle life under the

best conditions.

This is why Fiat has planned a

series of checks and maintenance

operations every 48,000 km

depending on the engine version.

The scheduled maintenance does

not, however, cover all the needs of

the vehicle: also during the initial

period, before the 48,000 km

service and between one service

and the next, ordinary care such as

systematic fluid level checks with

top ups and tyre pressure checks,

etc. remain necessary.

IMPORTANT The Scheduled

Servicing services are set out by

the Manufacturer. Failure to have

them carried out may invalidate the

warranty.

Scheduled Servicing can be carried

out by any Fiat Dealership, at

pre-established times.If during each operation, in addition

to the ones scheduled, the need

arises for further replacements

or repairs, these may only be

carried out with the express

agreement of the Customer.

IMPORTANT It is advisable to

inform a Fiat Dealership of any

small operating irregularities without

waiting for the next service.

If your vehicle is used frequently for

towing, the interval between service

coupons must be reduced.

230

SERVICING AND MAINTENANCE

Page 237 of 367

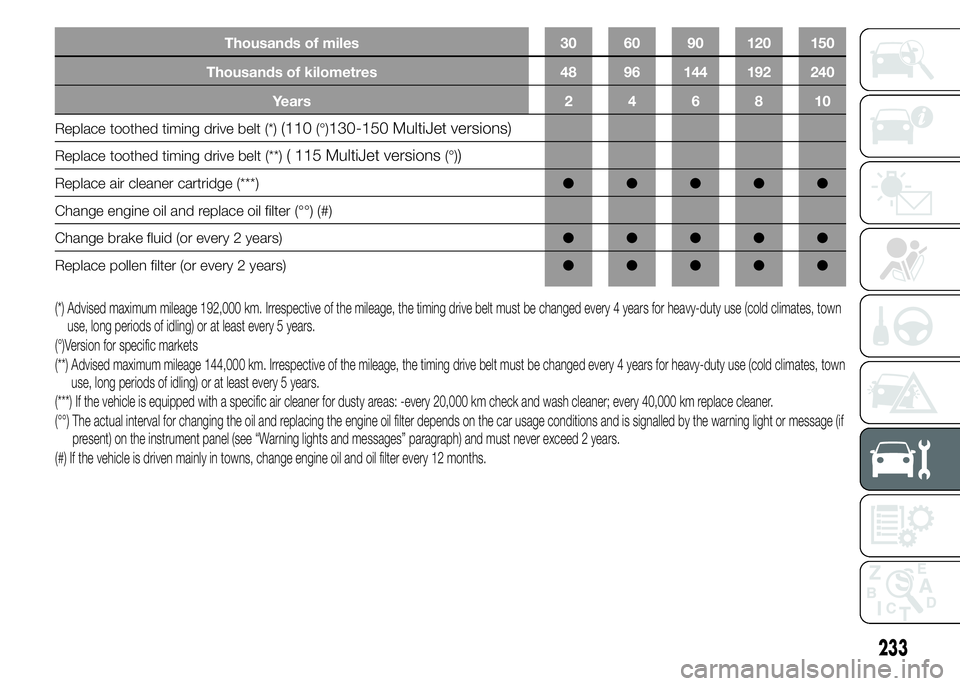

Thousands of miles 30 60 90 120 150

Thousands of kilometres 48 96 144 192 240

Years246810

Replace toothed timing drive belt (*)(110(°)130-150 MultiJet versions)

Replace toothed timing drive belt (**)( 115 MultiJet versions(°))

Replace air cleaner cartridge (***)●●●●●

Change engine oil and replace oil filter (°°) (#)

Change brake fluid (or every 2 years)●●●●●

Replace pollen filter (or every 2 years)●●●●●

(*) Advised maximum mileage 192,000 km. Irrespective of the mileage, the timing drive belt must be changed every 4 years for heavy-duty use (cold climates, town

use, long periods of idling) or at least every 5 years.

(°)Version for specific markets

(**) Advised maximum mileage 144,000 km. Irrespective of the mileage, the timing drive belt must be changed every 4 years for heavy-duty use (cold climates, town

use, long periods of idling) or at least every 5 years.

(***) If the vehicle is equipped with a specific air cleaner for dusty areas: -every 20,000 km check and wash cleaner; every 40,000 km replace cleaner.

(°°) The actual interval for changing the oil and replacing the engine oil filter depends on the car usage conditions and is signalled by the warning light or message (if

present) on the instrument panel (see “Warning lights and messages” paragraph) and must never exceed 2 years.

(#) If the vehicle is driven mainly in towns, change engine oil and oil filter every 12 months.

233

Page 238 of 367

PERIODIC CHECKS

Before long journeys, check and, if

necessary, restore:

❒engine coolant level;

❒brake fluid level;

❒windscreen washer fluid level;

❒tyre inflation pressure and condition;

❒operation of lighting system

(headlamps, direction indicators,

hazard warning lights, etc.);

❒operation of screen washer/wiper

system and positioning/wear of

windscreen/rear window wiper

blades.

To ensure that the vehicle is always

efficient and well maintained, it is

advisable to make sure that you

carry out the above operations

regularly (approximately every 1000

km and every 3000 km for

checking and topping up engine oil

is advisable).

DEMANDING

VEHICLE USE

If the vehicle is mostly used in one

of the following conditions:

❒towing a trailer or caravan;

❒dusty roads;

❒short, repeated journeys (less than

7-8 km) at sub-zero outside

temperatures;

❒engine often idling or driving long

distances at low speeds or long

periods of inactivity;

the following checks must be

carried out more often than

indicated in the Scheduled

Servicing Plan:

❒check front disc brake pad

conditions and wear;

❒check cleanliness of bonnet and boot

locks, cleanliness and lubrication of

linkage;❒visually inspect conditions of: engine,

gearbox, transmission, pipes and

hoses (exhaust - fuel system -

brakes) and rubber elements (boots -

sleeves - bushes - etc.);

❒check battery charge and battery

fluid level (electrolyte);

❒visually inspect condition of the

accessory drive belts;

❒check and, if necessary, change

engine oil and replace oil filter.

❒check and, if necessary, replace

pollen filter.

234

SERVICING AND MAINTENANCE

Page 284 of 367

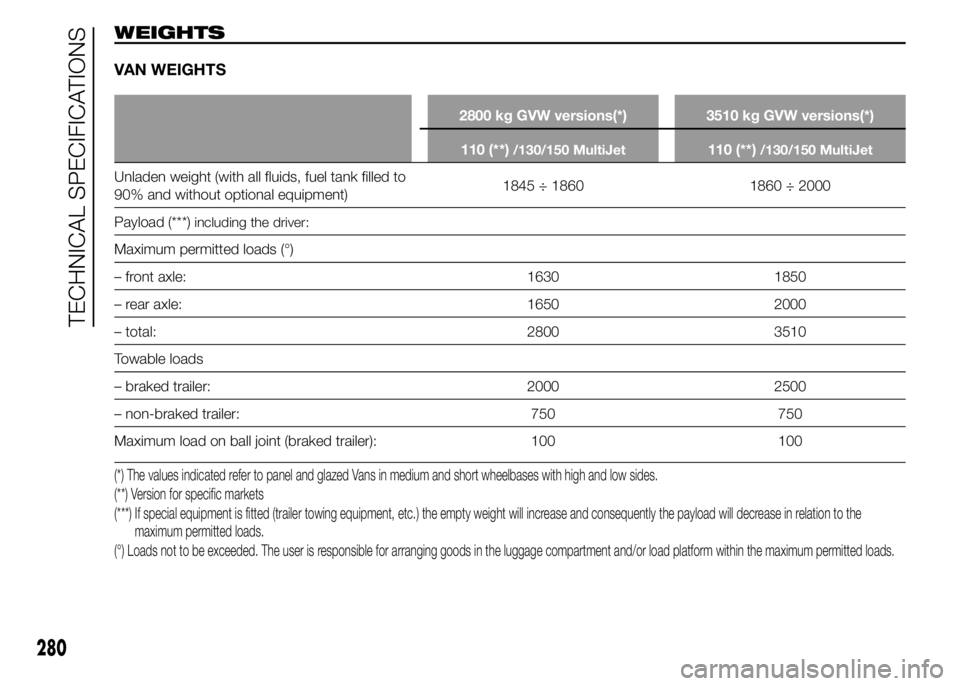

WEIGHTS

VAN WEIGHTS

2800 kg GVW versions(*) 3510 kg GVW versions(*)

110 (**)

/130/150 MultiJet110 (**)/130/150 MultiJet

Unladen weight (with all fluids, fuel tank filled to

90% and without optional equipment)1845 ÷ 1860 1860 ÷ 2000

Payload (***)

including the driver:

Maximum permitted loads (°)

– front axle: 1630 1850

– rear axle: 1650 2000

– total: 2800 3510

Towable loads

– braked trailer: 2000 2500

– non-braked trailer: 750 750

Maximum load on ball joint (braked trailer): 100 100

(*) The values indicated refer to panel and glazed Vans in medium and short wheelbases with high and low sides.

(**) Version for specific markets

(***) If special equipment is fitted (trailer towing equipment, etc.) the empty weight will increase and consequently the payload will decrease in relation to the

maximum permitted loads.

(°) Loads not to be exceeded. The user is responsible for arranging goods in the luggage compartment and/or load platform within the maximum permittedloads.

280

TECHNICAL SPECIFICATIONS