lock FIAT DUCATO BASE CAMPER 2015 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2015Pages: 367, PDF Size: 19.73 MB

Page 218 of 367

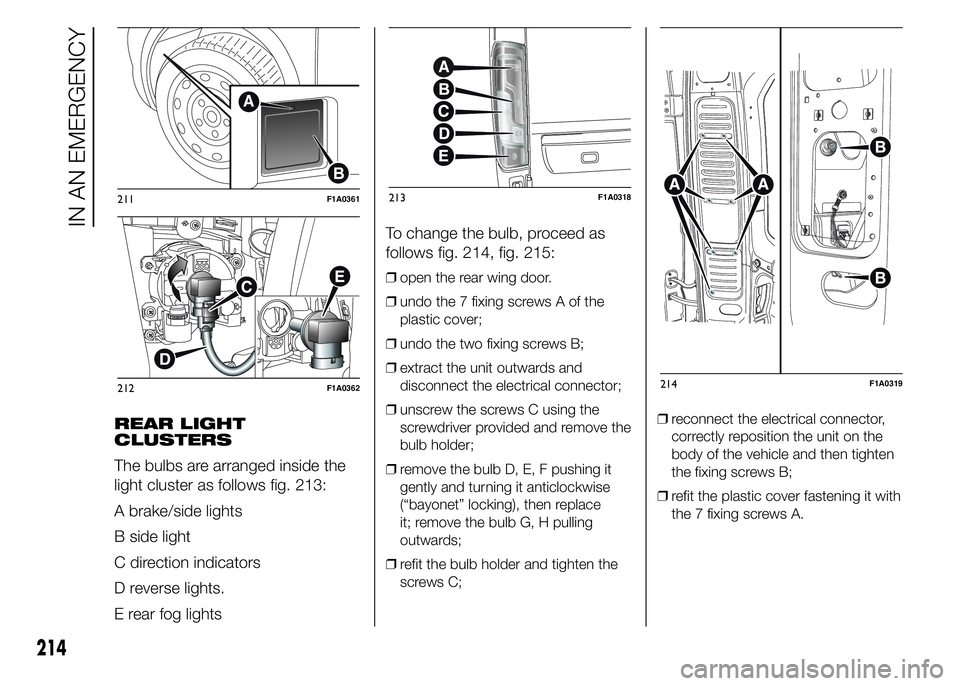

REAR LIGHT

CLUSTERS

The bulbs are arranged inside the

light cluster as follows fig. 213:

A brake/side lights

B side light

C direction indicators

D reverse lights.

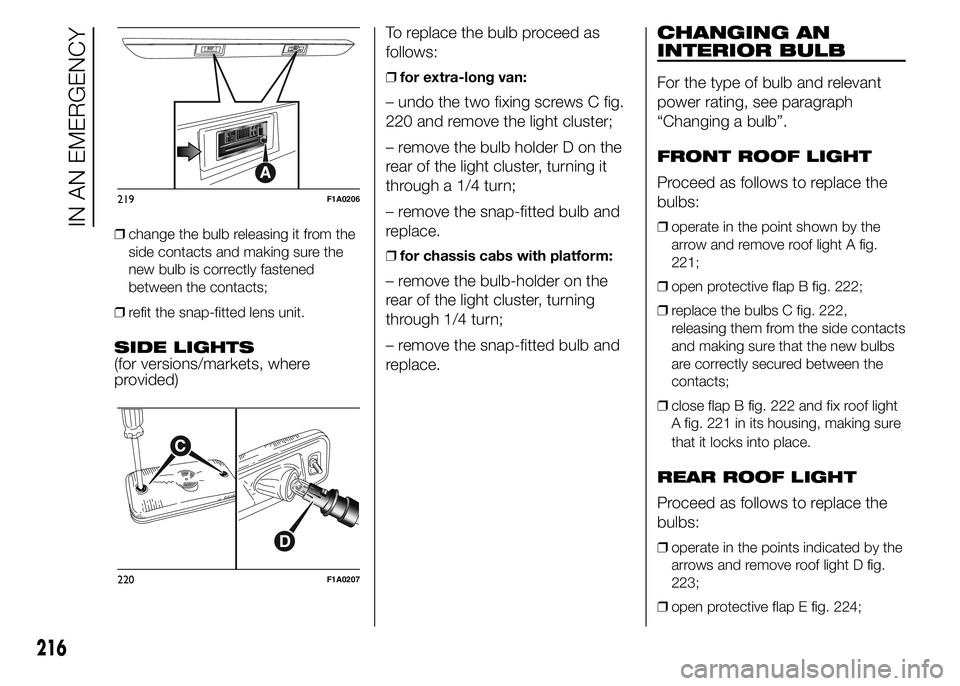

E rear fog lightsTo change the bulb, proceed as

follows fig. 214, fig. 215:

❒open the rear wing door.

❒undo the 7 fixing screws A of the

plastic cover;

❒undo the two fixing screws B;

❒extract the unit outwards and

disconnect the electrical connector;

❒unscrew the screws C using the

screwdriver provided and remove the

bulb holder;

❒remove the bulb D, E, F pushing it

gently and turning it anticlockwise

(“bayonet” locking), then replace

it; remove the bulb G, H pulling

outwards;

❒refit the bulb holder and tighten the

screws C;❒reconnect the electrical connector,

correctly reposition the unit on the

body of the vehicle and then tighten

the fixing screws B;

❒refit the plastic cover fastening it with

the 7 fixing screws A.

211F1A0361

212F1A0362

213F1A0318

214F1A0319

214

IN AN EMERGENCY

Page 220 of 367

❒change the bulb releasing it from the

side contacts and making sure the

new bulb is correctly fastened

between the contacts;

❒refit the snap-fitted lens unit.

SIDE LIGHTS

(for versions/markets, where

provided)To replace the bulb proceed as

follows:

❒for extra-long van:

– undo the two fixing screws C fig.

220 and remove the light cluster;

– remove the bulb holder D on the

rear of the light cluster, turning it

through a 1/4 turn;

– remove the snap-fitted bulb and

replace.

❒for chassis cabs with platform:

– remove the bulb-holder on the

rear of the light cluster, turning

through 1/4 turn;

– remove the snap-fitted bulb and

replace.

CHANGING AN

INTERIOR BULB

For the type of bulb and relevant

power rating, see paragraph

“Changing a bulb”.

FRONT ROOF LIGHT

Proceed as follows to replace the

bulbs:

❒operate in the point shown by the

arrow and remove roof light A fig.

221;

❒open protective flap B fig. 222;

❒replace the bulbs C fig. 222,

releasing them from the side contacts

and making sure that the new bulbs

are correctly secured between the

contacts;

❒close flap B fig. 222 and fix roof light

A fig. 221 in its housing, making sure

that it locks into place.

REAR ROOF LIGHT

Proceed as follows to replace the

bulbs:

❒operate in the points indicated by the

arrows and remove roof light D fig.

223;

❒open protective flap E fig. 224;

219F1A0206

220F1A0207

216

IN AN EMERGENCY

Page 221 of 367

❒replace bulb F fig. 224, releasing it

from the side contacts and making

sure that the new bulb is correctly

locked between these contacts;

❒close protective flap E fig. 224 and

refit roof light D fig. 223 in its

housing, making sure that it locks

into place.

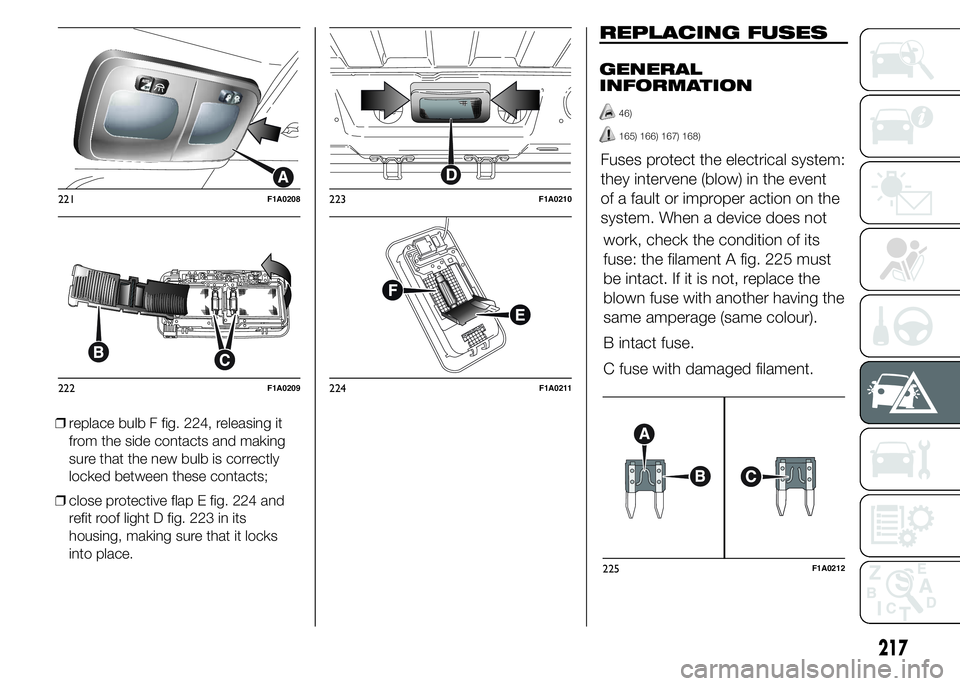

REPLACING FUSES

GENERAL

INFORMATION

46)

165) 166) 167) 168)

Fuses protect the electrical system:

they intervene (blow) in the event

of a fault or improper action on the

system. When a device does not

work, check the condition of its

fuse: the filament A fig. 225 must

be intact. If it is not, replace the

blown fuse with another having the

same amperage (same colour).

B intact fuse.

C fuse with damaged filament.

221F1A0208

222F1A0209

223F1A0210

224F1A0211

225F1A0212

217

Page 223 of 367

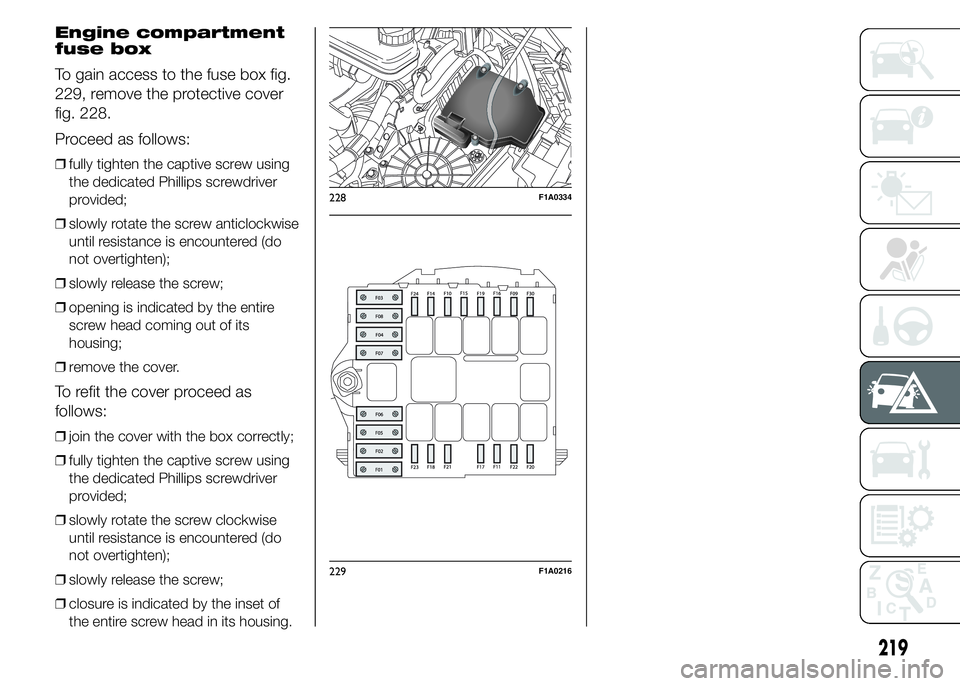

Engine compartment

fuse box

To gain access to the fuse box fig.

229, remove the protective cover

fig. 228.

Proceed as follows:

❒fully tighten the captive screw using

the dedicated Phillips screwdriver

provided;

❒slowly rotate the screw anticlockwise

until resistance is encountered (do

not overtighten);

❒slowly release the screw;

❒opening is indicated by the entire

screw head coming out of its

housing;

❒remove the cover.

To refit the cover proceed as

follows:

❒join the cover with the box correctly;

❒fully tighten the captive screw using

the dedicated Phillips screwdriver

provided;

❒slowly rotate the screw clockwise

until resistance is encountered (do

not overtighten);

❒slowly release the screw;

❒closure is indicated by the inset of

the entire screw head in its housing.

228F1A0334

229F1A0216

219

Page 225 of 367

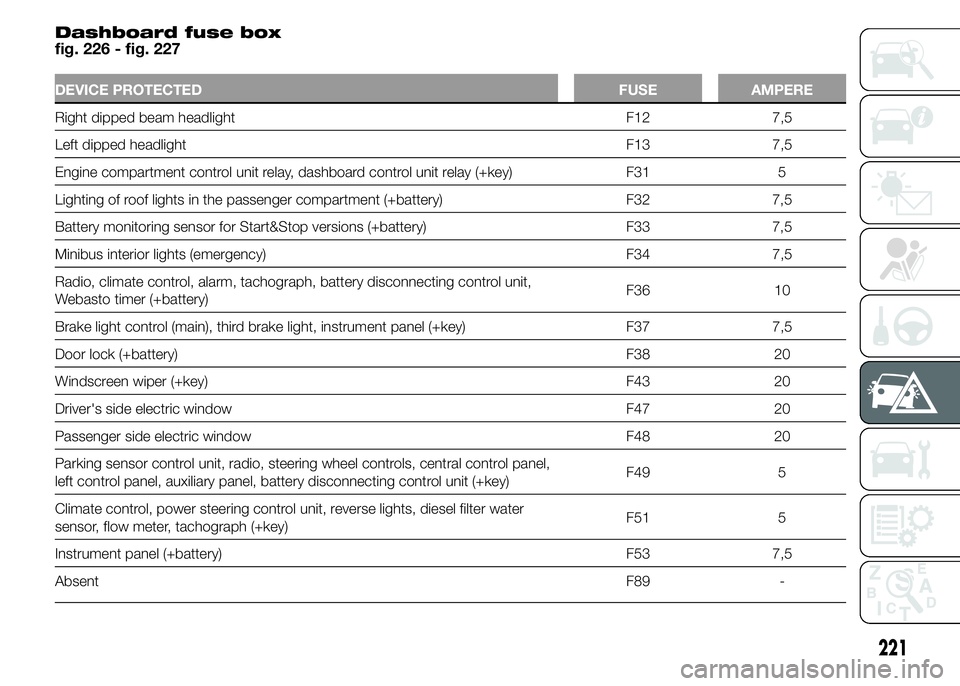

Dashboard fuse box

fig. 226 - fig. 227

DEVICE PROTECTED FUSE AMPERE

Right dipped beam headlight F12 7,5

Left dipped headlight F13 7,5

Engine compartment control unit relay, dashboard control unit relay (+key) F31 5

Lighting of roof lights in the passenger compartment (+battery) F32 7,5

Battery monitoring sensor for Start&Stop versions (+battery) F33 7,5

Minibus interior lights (emergency) F34 7,5

Radio, climate control, alarm, tachograph, battery disconnecting control unit,

Webasto timer (+battery)F36 10

Brake light control (main), third brake light, instrument panel (+key) F37 7,5

Door lock (+battery) F38 20

Windscreen wiper (+key) F43 20

Driver's side electric window F47 20

Passenger side electric window F48 20

Parking sensor control unit, radio, steering wheel controls, central control panel,

left control panel, auxiliary panel, battery disconnecting control unit (+key)F49 5

Climate control, power steering control unit, reverse lights, diesel filter water

sensor, flow meter, tachograph (+key)F51 5

Instrument panel (+battery) F53 7,5

AbsentF89 -

221

Page 231 of 367

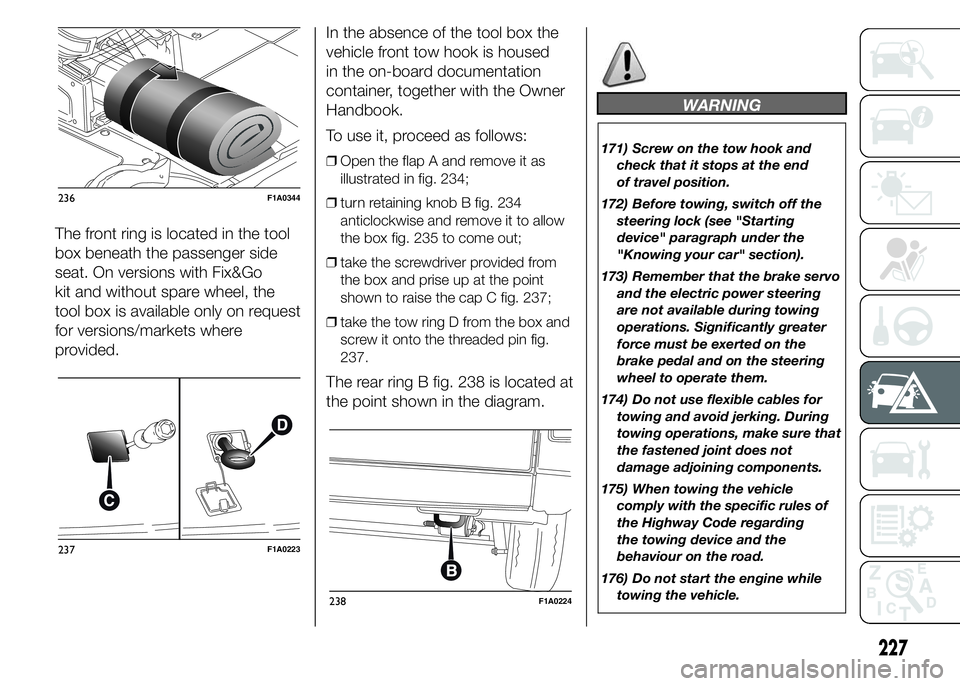

The front ring is located in the tool

box beneath the passenger side

seat. On versions with Fix&Go

kit and without spare wheel, the

tool box is available only on request

for versions/markets where

provided.In the absence of the tool box the

vehicle front tow hook is housed

in the on-board documentation

container, together with the Owner

Handbook.

To use it, proceed as follows:

❒Open the flap A and remove it as

illustrated in fig. 234;

❒turn retaining knob B fig. 234

anticlockwise and remove it to allow

the box fig. 235 to come out;

❒take the screwdriver provided from

the box and prise up at the point

shown to raise the cap C fig. 237;

❒take the tow ring D from the box and

screw it onto the threaded pin fig.

237.

The rear ring B fig. 238 is located at

the point shown in the diagram.

WARNING

171) Screw on the tow hook and

check that it stops at the end

of travel position.

172) Before towing, switch off the

steering lock (see "Starting

device" paragraph under the

"Knowing your car" section).

173) Remember that the brake servo

and the electric power steering

are not available during towing

operations. Significantly greater

force must be exerted on the

brake pedal and on the steering

wheel to operate them.

174) Do not use flexible cables for

towing and avoid jerking. During

towing operations, make sure that

the fastened joint does not

damage adjoining components.

175) When towing the vehicle

comply with the specific rules of

the Highway Code regarding

the towing device and the

behaviour on the road.

176) Do not start the engine while

towing the vehicle.

236F1A0344

237F1A0223

238F1A0224

227

Page 235 of 367

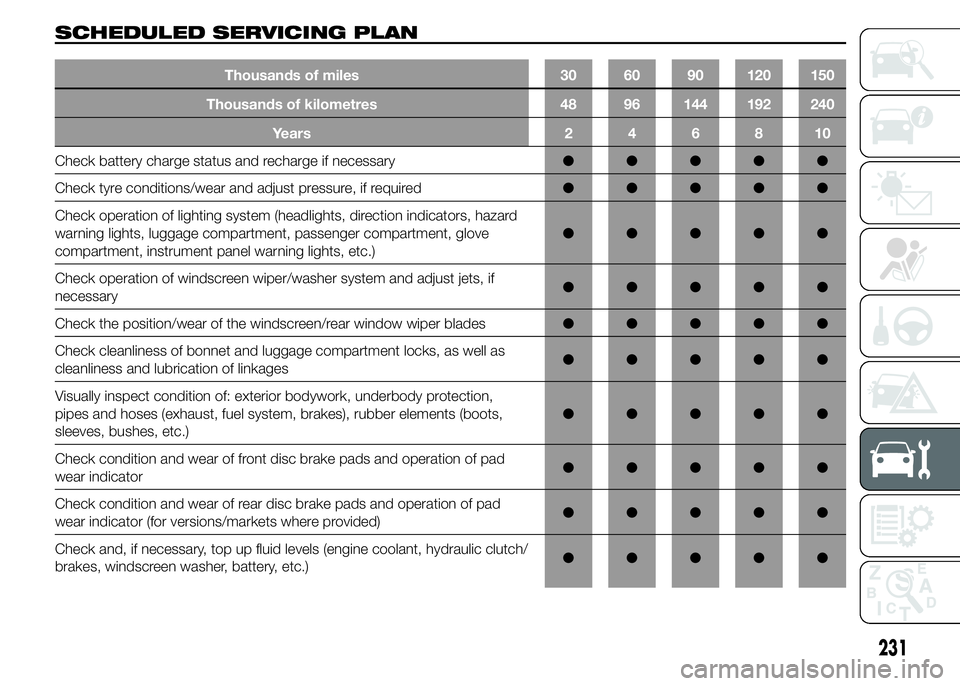

SCHEDULED SERVICING PLAN

Thousands of miles 30 60 90 120 150

Thousands of kilometres 48 96 144 192 240

Years246810

Check battery charge status and recharge if necessary●●●●●

Check tyre conditions/wear and adjust pressure, if required●●●●●

Check operation of lighting system (headlights, direction indicators, hazard

warning lights, luggage compartment, passenger compartment, glove

compartment, instrument panel warning lights, etc.)●●●●●

Check operation of windscreen wiper/washer system and adjust jets, if

necessary●●●●●

Check the position/wear of the windscreen/rear window wiper blades●●●●●

Check cleanliness of bonnet and luggage compartment locks, as well as

cleanliness and lubrication of linkages●●●●●

Visually inspect condition of: exterior bodywork, underbody protection,

pipes and hoses (exhaust, fuel system, brakes), rubber elements (boots,

sleeves, bushes, etc.)●●●●●

Check condition and wear of front disc brake pads and operation of pad

wear indicator●●●●●

Check condition and wear of rear disc brake pads and operation of pad

wear indicator (for versions/markets where provided)●●●●●

Check and, if necessary, top up fluid levels (engine coolant, hydraulic clutch/

brakes, windscreen washer, battery, etc.)●●●●●

231

Page 238 of 367

PERIODIC CHECKS

Before long journeys, check and, if

necessary, restore:

❒engine coolant level;

❒brake fluid level;

❒windscreen washer fluid level;

❒tyre inflation pressure and condition;

❒operation of lighting system

(headlamps, direction indicators,

hazard warning lights, etc.);

❒operation of screen washer/wiper

system and positioning/wear of

windscreen/rear window wiper

blades.

To ensure that the vehicle is always

efficient and well maintained, it is

advisable to make sure that you

carry out the above operations

regularly (approximately every 1000

km and every 3000 km for

checking and topping up engine oil

is advisable).

DEMANDING

VEHICLE USE

If the vehicle is mostly used in one

of the following conditions:

❒towing a trailer or caravan;

❒dusty roads;

❒short, repeated journeys (less than

7-8 km) at sub-zero outside

temperatures;

❒engine often idling or driving long

distances at low speeds or long

periods of inactivity;

the following checks must be

carried out more often than

indicated in the Scheduled

Servicing Plan:

❒check front disc brake pad

conditions and wear;

❒check cleanliness of bonnet and boot

locks, cleanliness and lubrication of

linkage;❒visually inspect conditions of: engine,

gearbox, transmission, pipes and

hoses (exhaust - fuel system -

brakes) and rubber elements (boots -

sleeves - bushes - etc.);

❒check battery charge and battery

fluid level (electrolyte);

❒visually inspect condition of the

accessory drive belts;

❒check and, if necessary, change

engine oil and replace oil filter.

❒check and, if necessary, replace

pollen filter.

234

SERVICING AND MAINTENANCE

Page 242 of 367

ENGINE OIL

48)

Check the oil level a few minutes

(about 5) after the engine has

stopped, with the vehicle parked on

level ground.

The oil level must be between the

MIN and MAX marks on the

dipstick B fig. 239 - fig. 240 - fig.

241.

The range between the MIN and

MAX marks corresponds to about 1

litre of oil.

If the oil level is near or under the

MIN mark, add oil through the filler

A fig. 239 - fig. 240 - fig. 241,

until it reaches the MAX mark.

The oil level must never exceed the

MAX mark.

Engine oil

consumption

The maximum engine oil

consumption is usually 400 grams

every 1000 km.

When the vehicle is new, the engine

needs to be run in, therefore the

engine oil consumption can only be

considered stabilised after the first

5,000–6,000 km.IMPORTANT The oil consumption

depends on driving style and the

conditions under which the vehicle

is used.

IMPORTANT After adding or

changing the oil, let the engine run

for a few seconds and wait a few

minutes after switching it off before

checking the level.

IMPORTANT Always top up using

engine oil of the same

specifications as that already in the

engine.

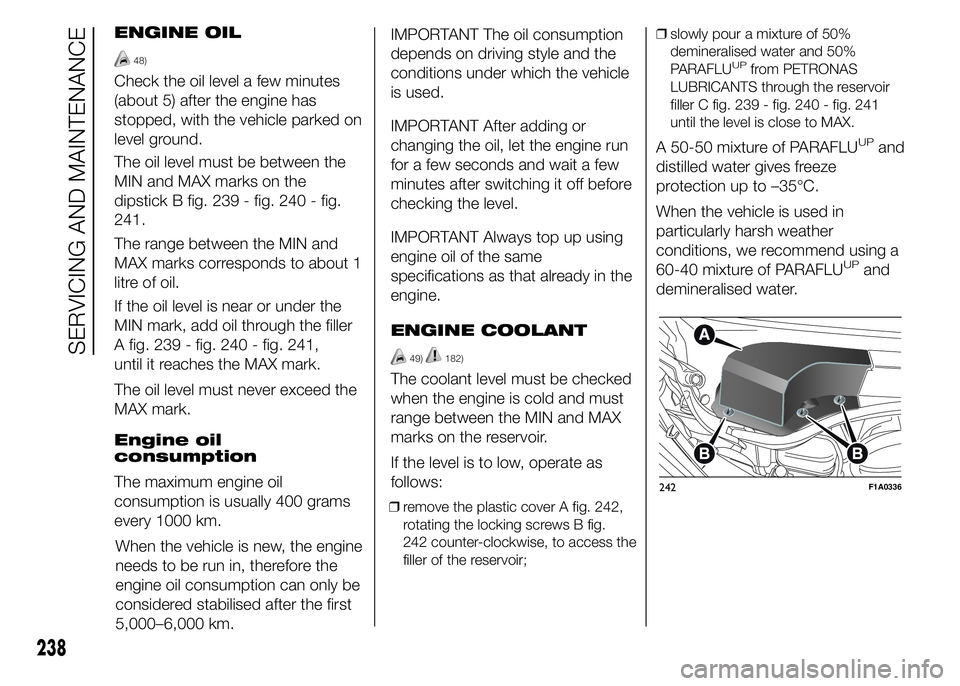

ENGINE COOLANT

49)182)

The coolant level must be checked

when the engine is cold and must

range between the MIN and MAX

marks on the reservoir.

If the level is to low, operate as

follows:

❒remove the plastic cover A fig. 242,

rotating the locking screws B fig.

242 counter-clockwise, to access the

filler of the reservoir;❒slowly pour a mixture of 50%

demineralised water and 50%

PARAFLU

UPfrom PETRONAS

LUBRICANTS through the reservoir

filler C fig. 239 - fig. 240 - fig. 241

until the level is close to MAX.

A 50-50 mixture of PARAFLUUPand

distilled water gives freeze

protection up to –35°C.

When the vehicle is used in

particularly harsh weather

conditions, we recommend using a

60-40 mixture of PARAFLU

UPand

demineralised water.

242F1A0336

238

SERVICING AND MAINTENANCE

Page 243 of 367

POWER STEERING

FLUID

188)

3)

51)

Check that the liquid contained in

the tank is at the maximum level.

This operation must be carried out

with the vehicle level and with

the engine off and cold.

Proceed as follows:

❒remove the plastic cover A fig. 242,

rotating the locking screws B fig.

242 counter-clockwise, to access the

filler of the reservoir;

❒check that the fluid level is up to the

MAX mark on the dipstick attached

to the fuel cap F fig. 239 - fig. 240

- fig. 241 (use the level shown on the

20°C side of the dipstick to check

when cold).

If the level of the fluid in the tank is

lower than the specified level,

top up using only one of the

products indicated in the "Fluid and

lubricants" table in the "Technical

specifications" section, proceeding

as follows:

❒Start the engine and wait for the fluid

level in the tank to stabilise.❒With the engine running, turn the

steering wheel from right to left

fully several times.

❒Top up the fuel to the MAX level and

then retighten the cap.

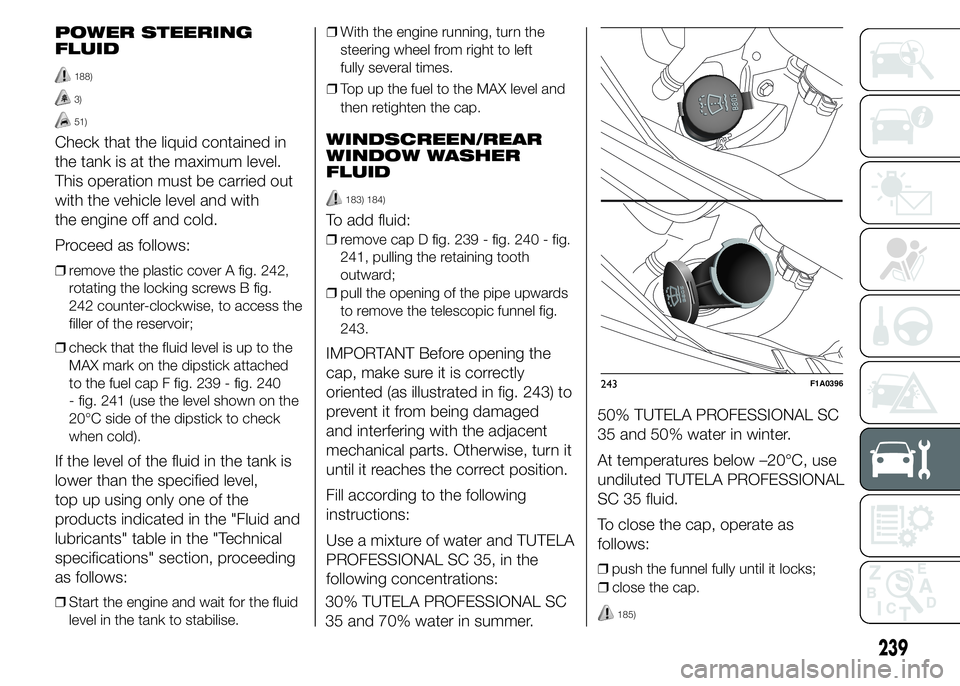

WINDSCREEN/REAR

WINDOW WASHER

FLUID

183) 184)

To add fluid:

❒remove cap D fig. 239 - fig. 240 - fig.

241, pulling the retaining tooth

outward;

❒pull the opening of the pipe upwards

to remove the telescopic funnel fig.

243.

IMPORTANT Before opening the

cap, make sure it is correctly

oriented (as illustrated in fig. 243) to

prevent it from being damaged

and interfering with the adjacent

mechanical parts. Otherwise, turn it

until it reaches the correct position.

Fill according to the following

instructions:

Use a mixture of water and TUTELA

PROFESSIONAL SC 35, in the

following concentrations:

30% TUTELA PROFESSIONAL SC

35 and 70% water in summer.50% TUTELA PROFESSIONAL SC

35 and 50% water in winter.

At temperatures below –20°C, use

undiluted TUTELA PROFESSIONAL

SC 35 fluid.

To close the cap, operate as

follows:

❒push the funnel fully until it locks;

243F1A0396

239

❒close the cap.

185)