spare wheel FIAT DUCATO BASE CAMPER 2015 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2015Pages: 367, PDF Size: 19.73 MB

Page 95 of 367

IMPORTANT

INFORMATION

WARNING

69) The TPMS is optimised for the

original tyres and wheels

provided. TPMS pressures and

alerts have been defined

according to the size of the tyres

mounted on the vehicle. Using

equipment with different size,

type or kind may cause irregular

system operation or sensor

damage. Non-original spare

wheels can damage the sensor.

Do not use tyre sealant or

balancing weights if the vehicle is

equipped with TPMS as these

may damage the sensors.

70) If the system signals a pressure

decrease on a specific tyre, it is

recommended to check the

pressure on all four tyres.

71) TPMS does not relieve the driver

from the obligation to check the

tyre pressure every month; it is

not even to be considered a

replacing system for maintenance

or a safety system.72) Tyre pressure must be checked

with tyres cold. Should it become

necessary for whatever reason

to check pressure with warm

tyres, do not reduce pressure

even if it is higher than the

prescribed value, but repeat the

check when tyres are cold.

73) The TPMS cannot indicate

sudden tyre pressure drops (for

example when a tyre bursts).

In this case, stop the car, braking

with caution and avoiding abrupt

steering.

74) The system only warns that the

tyre pressure is low: it is not able

to inflate them.

75) An insufficient tyre inflation

increases fuel consumption,

reduces the tread duration and

may affect the capacity of driving

safely.

76) Always refit the valve stem cap

after inspecting or adjusting tyre

pressure. This prevents dampness

or dirt from entering the valve

stem and thus the pressure

control sensor from being

damaged.77) The tyre repair kit (Fix&Go)

provided with the car (for

versions/markets, where

provided) is compatible with the

TPMS sensors; using sealants not

equivalent with that in the original

kit may adversely affect its

operation. If sealants not

equivalent with the original one

are used, it is recommended to

have the TPMS sensor operation

checked by a qualified repair

centre.

91

Page 203 of 367

REPLACING A

WHEEL

GENERAL

INSTRUCTIONS

Wheel replacement and correct use

of the jack and spare wheel (for

versions/markets, where provided)

call for some precautions, which

are listed below.

141) 142) 143) 144) 145)

Please note that:

❒the jack weight is 4.5 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired: in the

event of a fault it must be replaced by

another original one;

❒no tool other than its cranking device

may be fitted on the jack.

146)

To change a wheel,

proceed as follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel

safely. The ground should be flat

if possible, and sufficiently firm;❒stop the engine and pull the

handbrake;

❒engage first gear or reverse;

❒put on the reflective safety jacket

(compulsory by law in certain

countries) before getting out of the

vehicle;

❒indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

❒In the event of a wheel change on a

slope or on unsurfaced roads, put

any object as stop under the wheels;

❒take the tool bag under the

passenger seat (see “Compartment

under front passenger seat” in the

“Know your vehicle” section);

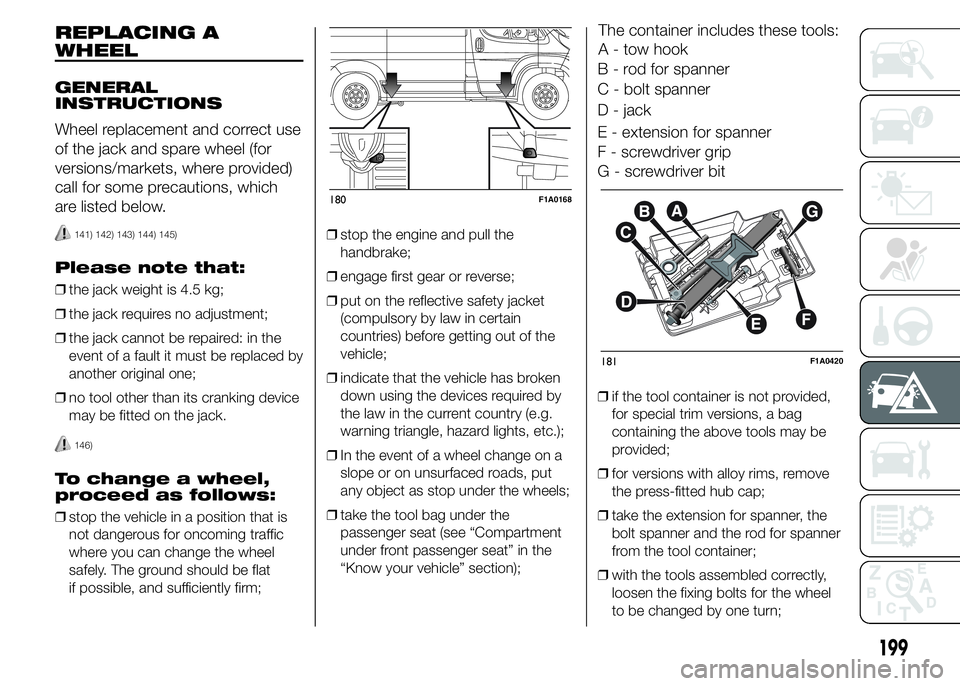

The container includes these tools:

A - tow hook

B - rod for spanner

C - bolt spanner

D - jack

E - extension for spanner

F - screwdriver grip

G - screwdriver bit

❒if the tool container is not provided,

for special trim versions, a bag

containing the above tools may be

provided;

❒for versions with alloy rims, remove

the press-fitted hub cap;

❒take the extension for spanner, the

bolt spanner and the rod for spanner

from the tool container;

❒with the tools assembled correctly,

loosen the fixing bolts for the wheel

to be changed by one turn;

180F1A0168

181F1A0420

199

Page 204 of 367

❒turn the ring nut to partly extend the

jack;

❒arrange the jack near the lift support

closest to the wheel to be replaced

at the points shown in fig. 180.

For short wheelbase versions with

retractable footboard, the jack must

be positioned at the lift point shown

in fig. 182 aligned (45°) so that it

does not interfere with the retractable

footboard;

❒warn all bystanders that the vehicle is

about to be lifted. They must stay

clear and not touch the vehicle until it

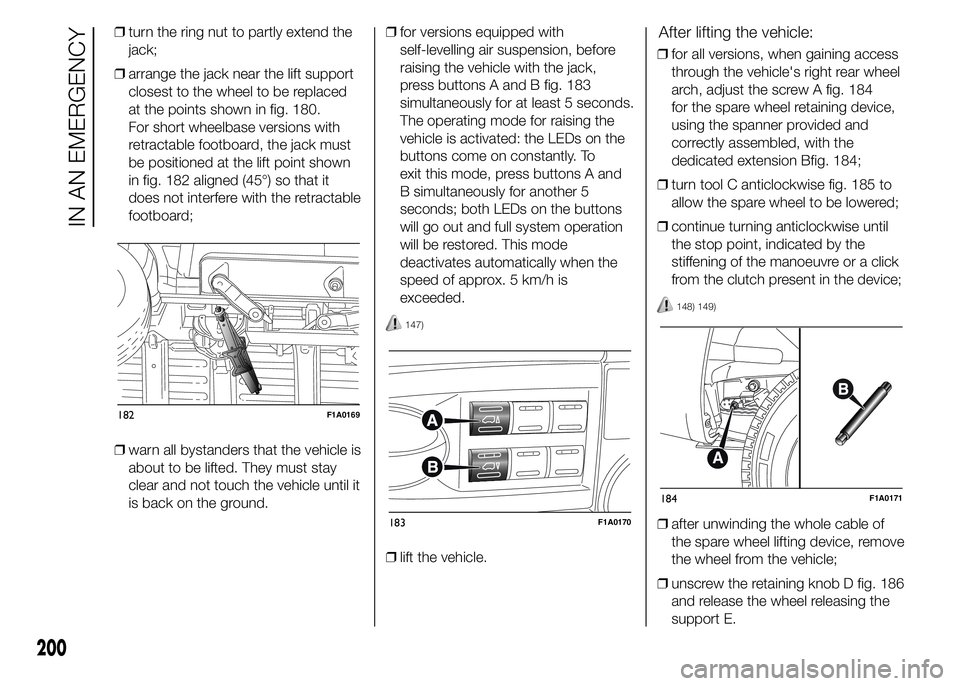

is back on the ground.❒for versions equipped with

self-levelling air suspension, before

raising the vehicle with the jack,

press buttons A and B fig. 183

simultaneously for at least 5 seconds.

The operating mode for raising the

vehicle is activated: the LEDs on the

buttons come on constantly. To

exit this mode, press buttons A and

B simultaneously for another 5

seconds; both LEDs on the buttons

will go out and full system operation

will be restored. This mode

deactivates automatically when the

speed of approx. 5 km/h is

exceeded.

147)

❒lift the vehicle.

After lifting the vehicle:

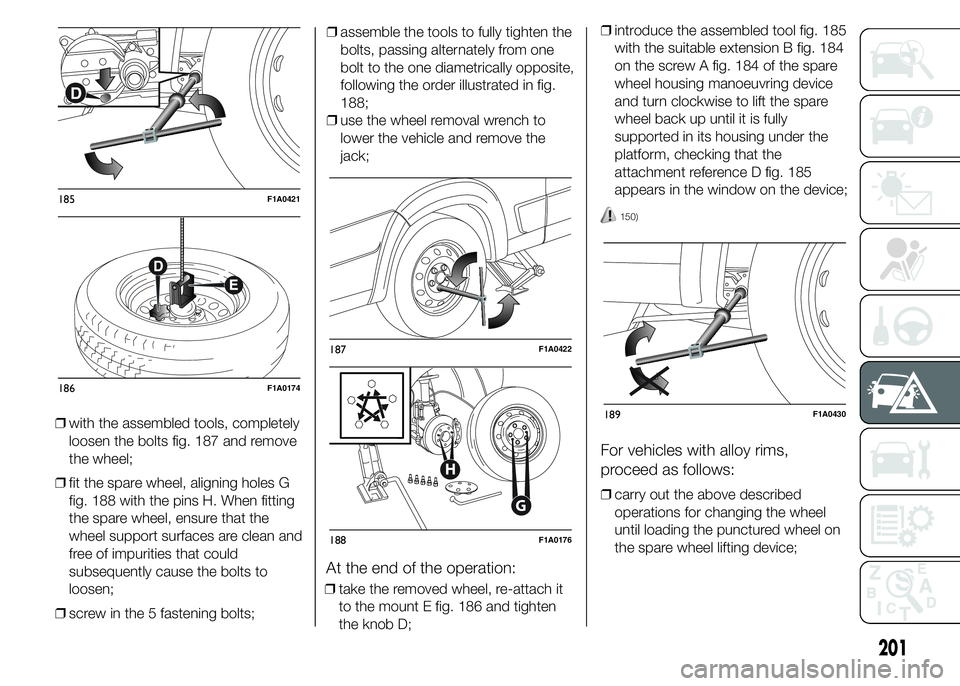

❒for all versions, when gaining access

through the vehicle's right rear wheel

arch, adjust the screw A fig. 184

for the spare wheel retaining device,

using the spanner provided and

correctly assembled, with the

dedicated extension Bfig. 184;

❒turn tool C anticlockwise fig. 185 to

allow the spare wheel to be lowered;

❒continue turning anticlockwise until

the stop point, indicated by the

stiffening of the manoeuvre or a click

from the clutch present in the device;

148) 149)

❒after unwinding the whole cable of

the spare wheel lifting device, remove

the wheel from the vehicle;

❒unscrew the retaining knob D fig. 186

and release the wheel releasing the

support E.

182F1A0169

183F1A0170

184F1A0171

200

IN AN EMERGENCY

Page 205 of 367

❒with the assembled tools, completely

loosen the bolts fig. 187 and remove

the wheel;

❒fit the spare wheel, aligning holes G

fig. 188 with the pins H. When fitting

the spare wheel, ensure that the

wheel support surfaces are clean and

free of impurities that could

subsequently cause the bolts to

loosen;

❒screw in the 5 fastening bolts;❒assemble the tools to fully tighten the

bolts, passing alternately from one

bolt to the one diametrically opposite,

following the order illustrated in fig.

188;

❒use the wheel removal wrench to

lower the vehicle and remove the

jack;

At the end of the operation:

❒take the removed wheel, re-attach it

to the mount E fig. 186 and tighten

the knob D;❒introduce the assembled tool fig. 185

with the suitable extension B fig. 184

on the screw A fig. 184 of the spare

wheel housing manoeuvring device

and turn clockwise to lift the spare

wheel back up until it is fully

supported in its housing under the

platform, checking that the

attachment reference D fig. 185

appears in the window on the device;

150)

For vehicles with alloy rims,

proceed as follows:

❒carry out the above described

operations for changing the wheel

until loading the punctured wheel on

the spare wheel lifting device;

185F1A0421

186F1A0174

187F1A0422

G

H

188F1A0176

189F1A0430

201

Page 206 of 367

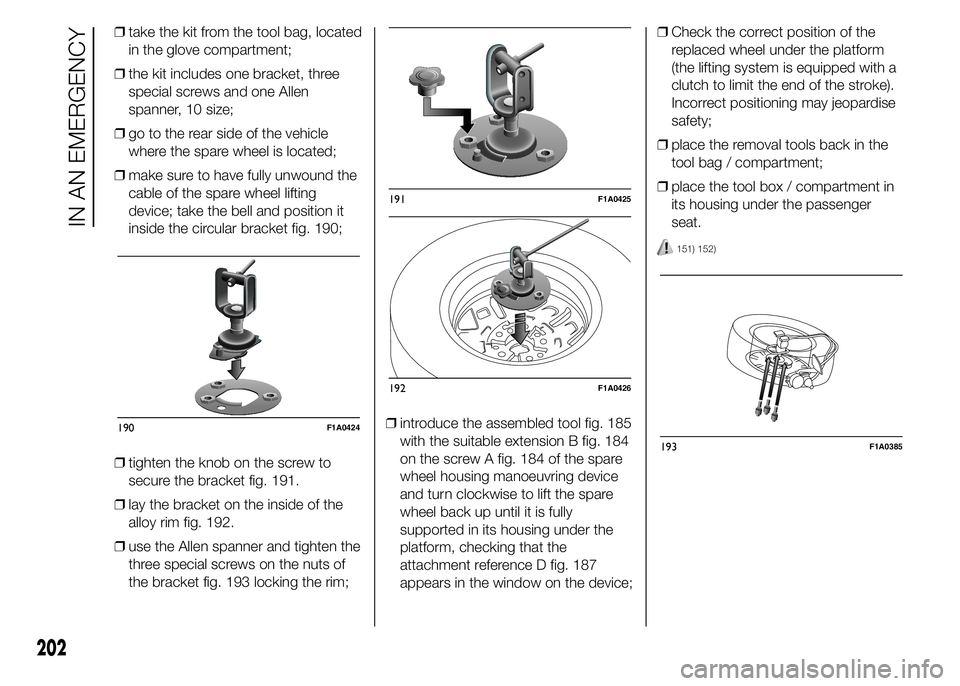

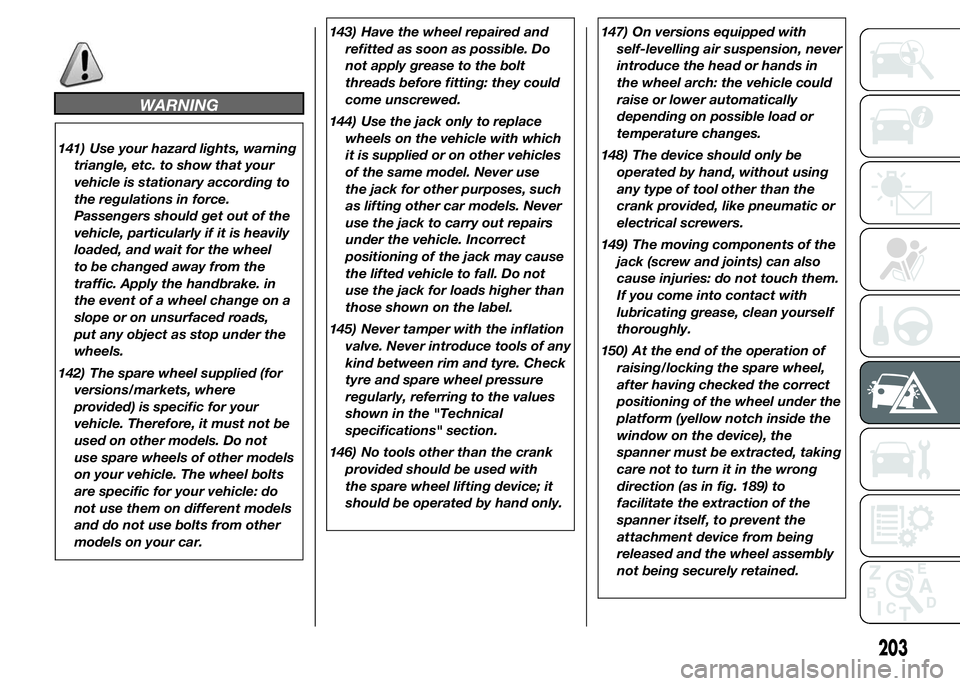

❒take the kit from the tool bag, located

in the glove compartment;

❒the kit includes one bracket, three

special screws and one Allen

spanner, 10 size;

❒go to the rear side of the vehicle

where the spare wheel is located;

❒make sure to have fully unwound the

cable of the spare wheel lifting

device; take the bell and position it

inside the circular bracket fig. 190;

❒tighten the knob on the screw to

secure the bracket fig. 191.

❒lay the bracket on the inside of the

alloy rim fig. 192.

❒use the Allen spanner and tighten the

three special screws on the nuts of

the bracket fig. 193 locking the rim;❒introduce the assembled tool fig. 185

with the suitable extension B fig. 184

on the screw A fig. 184 of the spare

wheel housing manoeuvring device

and turn clockwise to lift the spare

wheel back up until it is fully

supported in its housing under the

platform, checking that the

attachment reference D fig. 187

appears in the window on the device;❒Check the correct position of the

replaced wheel under the platform

(the lifting system is equipped with a

clutch to limit the end of the stroke).

Incorrect positioning may jeopardise

safety;

❒place the removal tools back in the

tool bag / compartment;

❒place the tool box / compartment in

its housing under the passenger

seat.

151) 152)

190F1A0424

191F1A0425

192F1A0426

193F1A0385

202

IN AN EMERGENCY

Page 207 of 367

WARNING

141) Use your hazard lights, warning

triangle, etc. to show that your

vehicle is stationary according to

the regulations in force.

Passengers should get out of the

vehicle, particularly if it is heavily

loaded, and wait for the wheel

to be changed away from the

traffic. Apply the handbrake. in

the event of a wheel change on a

slope or on unsurfaced roads,

put any object as stop under the

wheels.

142) The spare wheel supplied (for

versions/markets, where

provided) is specific for your

vehicle. Therefore, it must not be

used on other models. Do not

use spare wheels of other models

on your vehicle. The wheel bolts

are specific for your vehicle: do

not use them on different models

and do not use bolts from other

models on your car.143) Have the wheel repaired and

refitted as soon as possible. Do

not apply grease to the bolt

threads before fitting: they could

come unscrewed.

144) Use the jack only to replace

wheels on the vehicle with which

it is supplied or on other vehicles

of the same model. Never use

the jack for other purposes, such

as lifting other car models. Never

use the jack to carry out repairs

under the vehicle. Incorrect

positioning of the jack may cause

the lifted vehicle to fall. Do not

use the jack for loads higher than

those shown on the label.

145) Never tamper with the inflation

valve. Never introduce tools of any

kind between rim and tyre. Check

tyre and spare wheel pressure

regularly, referring to the values

shown in the "Technical

specifications" section.

146) No tools other than the crank

provided should be used with

the spare wheel lifting device; it

should be operated by hand only.147) On versions equipped with

self-levelling air suspension, never

introduce the head or hands in

the wheel arch: the vehicle could

raise or lower automatically

depending on possible load or

temperature changes.

148) The device should only be

operated by hand, without using

any type of tool other than the

crank provided, like pneumatic or

electrical screwers.

149) The moving components of the

jack (screw and joints) can also

cause injuries: do not touch them.

If you come into contact with

lubricating grease, clean yourself

thoroughly.

150) At the end of the operation of

raising/locking the spare wheel,

after having checked the correct

positioning of the wheel under the

platform (yellow notch inside the

window on the device), the

spanner must be extracted, taking

care not to turn it in the wrong

direction (as in fig. 189) to

facilitate the extraction of the

spanner itself, to prevent the

attachment device from being

released and the wheel assembly

not being securely retained.

203

Page 208 of 367

151) Each time the spare wheel is

moved, check that it is correctly

positioned in its housing under

the platform. If it is not correctly

positioned, this could adversely

affect safety.

152) The spare wheel lifting device

is equipped with a clutch safety

system for its own protection; this

could activated if an excessive

load is applied on the

maneuvering screw.FIX&GO

AUTOMATIC QUICK

TYRE REPAIR KIT

(for versions/markets, where

provided)

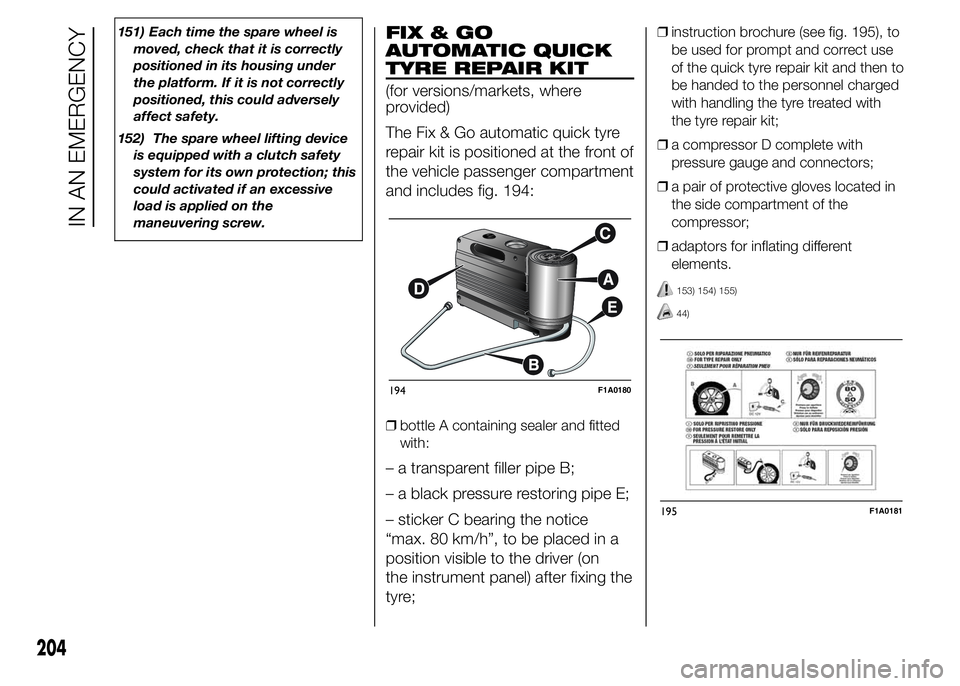

The Fix & Go automatic quick tyre

repair kit is positioned at the front of

the vehicle passenger compartment

and includes fig. 194:

❒bottle A containing sealer and fitted

with:

– a transparent filler pipe B;

– a black pressure restoring pipe E;

– sticker C bearing the notice

“max. 80 km/h”, to be placed in a

position visible to the driver (on

the instrument panel) after fixing the

tyre;

❒instruction brochure (see fig. 195), to

be used for prompt and correct use

of the quick tyre repair kit and then to

be handed to the personnel charged

with handling the tyre treated with

the tyre repair kit;

❒a compressor D complete with

pressure gauge and connectors;

❒a pair of protective gloves located in

the side compartment of the

compressor;

❒adaptors for inflating different

elements.

153) 154) 155)

44)

194F1A0180

195F1A0181

204

IN AN EMERGENCY

Page 231 of 367

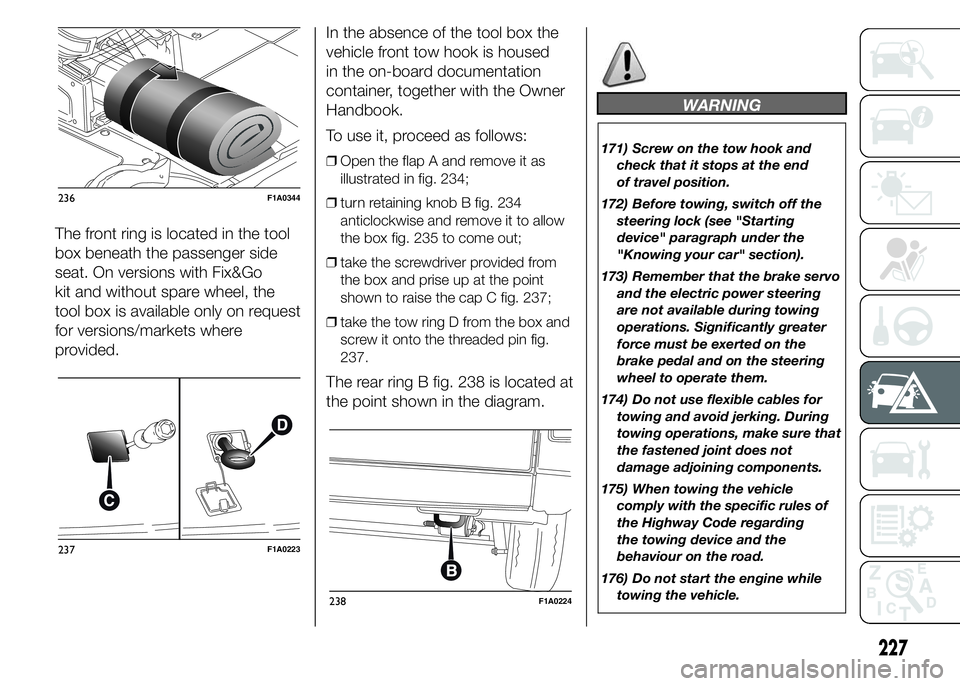

The front ring is located in the tool

box beneath the passenger side

seat. On versions with Fix&Go

kit and without spare wheel, the

tool box is available only on request

for versions/markets where

provided.In the absence of the tool box the

vehicle front tow hook is housed

in the on-board documentation

container, together with the Owner

Handbook.

To use it, proceed as follows:

❒Open the flap A and remove it as

illustrated in fig. 234;

❒turn retaining knob B fig. 234

anticlockwise and remove it to allow

the box fig. 235 to come out;

❒take the screwdriver provided from

the box and prise up at the point

shown to raise the cap C fig. 237;

❒take the tow ring D from the box and

screw it onto the threaded pin fig.

237.

The rear ring B fig. 238 is located at

the point shown in the diagram.

WARNING

171) Screw on the tow hook and

check that it stops at the end

of travel position.

172) Before towing, switch off the

steering lock (see "Starting

device" paragraph under the

"Knowing your car" section).

173) Remember that the brake servo

and the electric power steering

are not available during towing

operations. Significantly greater

force must be exerted on the

brake pedal and on the steering

wheel to operate them.

174) Do not use flexible cables for

towing and avoid jerking. During

towing operations, make sure that

the fastened joint does not

damage adjoining components.

175) When towing the vehicle

comply with the specific rules of

the Highway Code regarding

the towing device and the

behaviour on the road.

176) Do not start the engine while

towing the vehicle.

236F1A0344

237F1A0223

238F1A0224

227

Page 249 of 367

WHEELS AND TYRES

Check the pressure of each tyre,

including the space-saver wheel,

approximately every two weeks and

before long journeys: the pressure

should be checked with the tyre

rested and cold.

It is normal for the pressure to

increase when the vehicle is used;

for the correct tyre inflation

pressure, see “Wheels” in the

“Technical specifications” section.

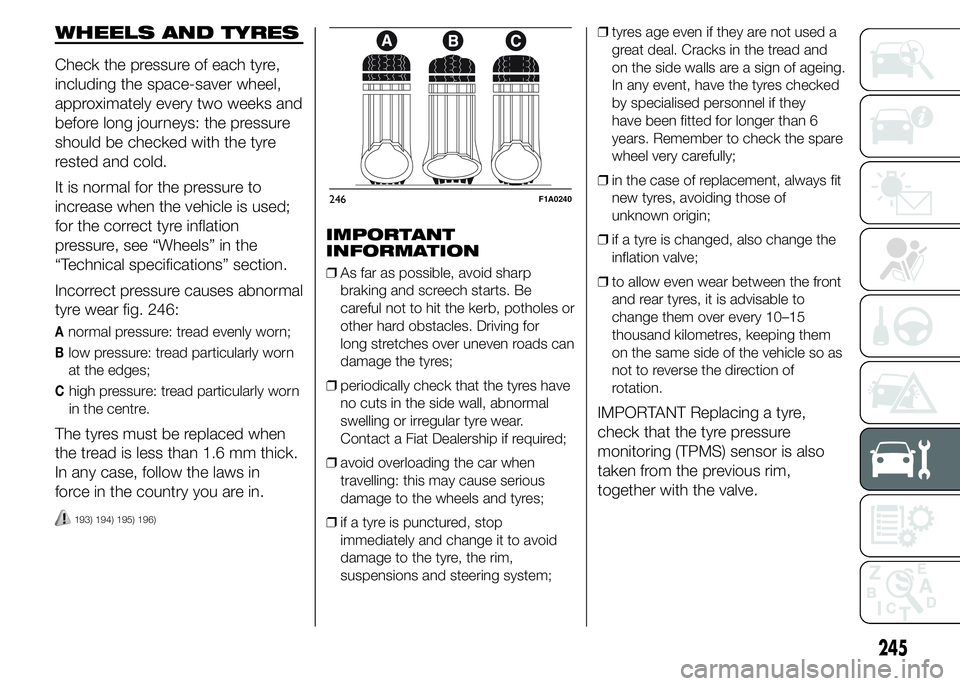

Incorrect pressure causes abnormal

tyre wear fig. 246:

Anormal pressure: tread evenly worn;

Blow pressure: tread particularly worn

at the edges;

Chigh pressure: tread particularly worn

in the centre.

The tyres must be replaced when

the tread is less than 1.6 mm thick.

In any case, follow the laws in

force in the country you are in.

193) 194) 195) 196)

IMPORTANT

INFORMATION

❒As far as possible, avoid sharp

braking and screech starts. Be

careful not to hit the kerb, potholes or

other hard obstacles. Driving for

long stretches over uneven roads can

damage the tyres;

❒periodically check that the tyres have

no cuts in the side wall, abnormal

swelling or irregular tyre wear.

Contact a Fiat Dealership if required;

❒avoid overloading the car when

travelling: this may cause serious

damage to the wheels and tyres;

❒if a tyre is punctured, stop

immediately and change it to avoid

damage to the tyre, the rim,

suspensions and steering system;❒tyres age even if they are not used a

great deal. Cracks in the tread and

on the side walls are a sign of ageing.

In any event, have the tyres checked

by specialised personnel if they

have been fitted for longer than 6

years. Remember to check the spare

wheel very carefully;

❒in the case of replacement, always fit

new tyres, avoiding those of

unknown origin;

❒if a tyre is changed, also change the

inflation valve;

❒to allow even wear between the front

and rear tyres, it is advisable to

change them over every 10–15

thousand kilometres, keeping them

on the same side of the vehicle so as

not to reverse the direction of

rotation.

IMPORTANT Replacing a tyre,

check that the tyre pressure

monitoring (TPMS) sensor is also

taken from the previous rim,

together with the valve.

246F1A0240

245

Page 252 of 367

BODYWORK

PROTECTION AGAINST

ATMOSPHERIC

AGENTS

The main causes of corrosion are

the following:

❒atmospheric pollution;

❒salty air and humidity (coastal areas,

or hot humid climates);

❒seasonal environmental conditions.

The abrasive action of wind-borne

atmospheric dust and sand, as well

as mud and gravel raised by other

vehicles is also not to be

underestimated.

On your vehicle, Fiat has

implemented the best

manufacturing technologies to

effectively protect the bodywork

against corrosion.

These include:

❒painting products and systems which

give the vehicle particular resistance

to corrosion and abrasion;

❒Use of galvanised (or pretreated)

steel sheets, with high resistance

to corrosion;❒spraying the underbody, engine

compartment, wheelhouse internal

parts and other parts with highly

protective wax products;

❒spraying of plastic parts, with a

protective function in the more

exposed points: underdoor, inner

wing, edges, etc;

❒use of “open” boxed sections to

prevent condensation and pockets of

moisture from triggering rust inside.

VEHICLE BODY AND

UNDERBODY

WARRANTY

Your vehicle is covered by warranty

against perforation due to corrosion

of any original element of the

structure or body.

For the general terms of this

warranty, refer to the Warranty

Booklet.

ADVICE FOR

PRESERVING THE

BODYWORK

Paintwork

Paintwork does not only serve an

aesthetic purpose, but also

protects the underlying sheet metal.Touch up abrasions and scratches

immediately to prevent rust

formation. Only use genuine spare

paint products for touch-ups (see

“Bodywork paint identification

plate” in the “Technical

Specifications” section).

Normal maintenance of paintwork

consists in washing the car: the

frequency depends on the

conditions and environment where

the car is used.

For example, it is advisable to wash

the vehicle more often in areas

with high levels of environmental

pollution or on roads spread with

salt.

To correctly wash the vehicle,

proceed as follows:

❒wash the bodywork using a low

pressure jet of water;

❒wipe a sponge with a slightly soapy

solution over the bodywork,

frequently rinsing the sponge;

248

SERVICING AND MAINTENANCE

❒rinse well with water and dry with a

jet of air or a chamois leather.