clock FIAT DUCATO BASE CAMPER 2016 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2016Pages: 387, PDF Size: 20.76 MB

Page 115 of 387

❒if during the topping up, the level of

AdBlue in the bottle does not drop,

it means that you have reached

the full tank, therefore proceed pulling

the bottle towards you in order to

re-lock the safety valve of the bottle

and unscrew the bottle from the

filler (fig. 142, ref. 3);

❒after removing the bottle remount

cap C fig. 141 on the filler neck

UREA, turning it clockwise until it

stops;

❒turn the key in the pawl starter in the

ON position (no need to start the

engine);

❒wait for the signal on the instrument

panel to power off before moving the

vehicle, the warning light may stay

on for a few seconds to half a

minute. In case of motor start-up and

movement of the vehicle, the

warning sign will remain on for a

longer period of time, but there are

no problems on the engine

functionality;

❒If topping up is done with the UREA

tank empty, you have to wait two

minutes before starting the vehicle;NoteThe driving conditions (altitude,

vehicle speed, load, etc.) determine the

quantity of UREA used by the vehicle.

In order to use the additive for Diesel

Emissions (UREA) correctly, see "Fluids

and lubricants" in the "Technical data".

IMPORTANT

❒Exceeding the maximum filling

level of the tank UREA, it can

cause damage to the tank and

spilling UREA. Please avoid

topping up after filling the tank.

❒DO NOT EXCEED THE MAXIMUM

LEVEL. The UREA freezes at

under -11 ° C. Although the

system is designed to operate

below the freezing point of the

UREA, it is advisable not to fill the

tank beyond the maximum level

because if the UREA freezes

the system can be damaged.

❒If the UREA is spilled on painted

surfaces or aluminium,

immediately clean the area with

water and use absorbent material

to collect the fluid that has been

spilled on the ground.

❒Do not try to start the engine if

UREA was accidentally added

to the diesel fuel tank, this can

result in serious engine damage,

contact Dealership.❒Use AdBlue only according to DIN

70 070 and ISO 22241-1. Other

fluids may cause damage to the

system: also exhaust emissions

would no longer comply with

the law. The distribution

companies are responsible for

the compliance of their product.

Observe the precautions of

storage and maintenance, in

order to preserve the initial

qualities. The manufacturer of the

vehicle does not recognize any

guarantee in case of

malfunctions and damage caused

to the vehicle due to the use of

urea (AdBlue) not in accordance

with regulations.

❒Any introduction of diesel fuel

inside the tank AdBlue, causes

irreversible damage to the

pumping unit circuit AdBlue.

❒Do not add additives to AdBlue.

Do not dilute AdBlue with tap

water as this may damage the

system of purification of exhaust

gases.

111

Page 127 of 387

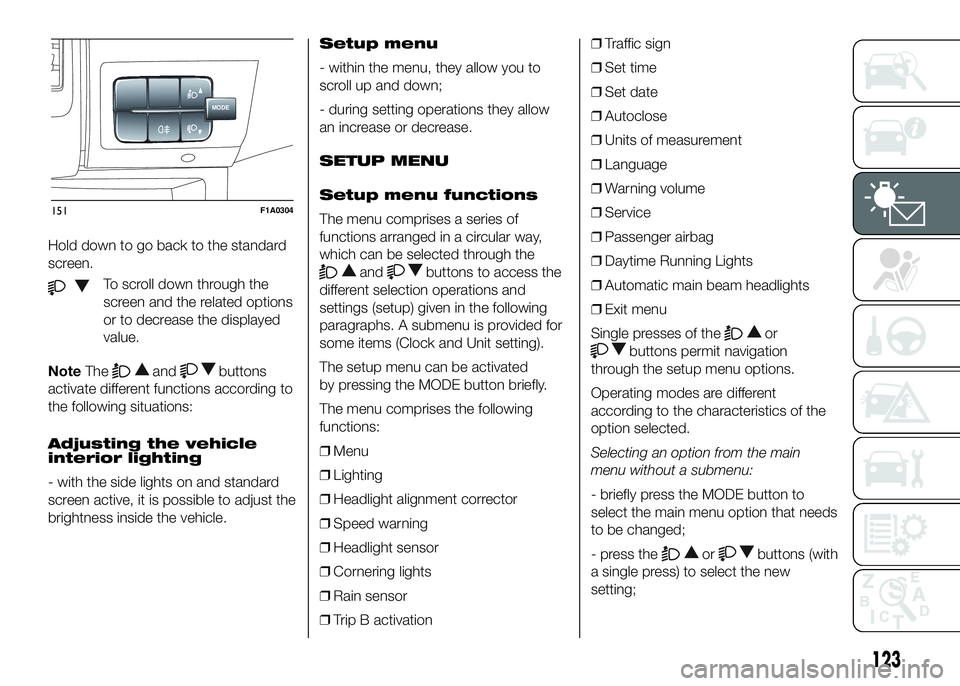

Hold down to go back to the standard

screen.

To scroll down through the

screen and the related options

or to decrease the displayed

value.

NoteThe

andbuttons

activate different functions according to

the following situations:

Adjusting the vehicle

interior lighting

- with the side lights on and standard

screen active, it is possible to adjust the

brightness inside the vehicle.Setup menu

- within the menu, they allow you to

scroll up and down;

- during setting operations they allow

an increase or decrease.

SETUP MENU

Setup menu functions

The menu comprises a series of

functions arranged in a circular way,

which can be selected through the

andbuttons to access the

different selection operations and

settings (setup) given in the following

paragraphs. A submenu is provided for

some items (Clock and Unit setting).

The setup menu can be activated

by pressing the MODE button briefly.

The menu comprises the following

functions:

❒Menu

❒Lighting

❒Headlight alignment corrector

❒Speed warning

❒Headlight sensor

❒Cornering lights

❒Rain sensor

❒Trip B activation❒Traffic sign

❒Set time

❒Set date

❒Autoclose

❒Units of measurement

❒Language

❒Warning volume

❒Service

❒Passenger airbag

❒Daytime Running Lights

❒Automatic main beam headlights

❒Exit menu

Single presses of the

or

buttons permit navigation

through the setup menu options.

Operating modes are different

according to the characteristics of the

option selected.

Selecting an option from the main

menu without a submenu:

- briefly press the MODE button to

select the main menu option that needs

to be changed;

- press the

orbuttons (with

a single press) to select the new

setting;

MODE

151F1A0304

123

Page 128 of 387

- briefly press the MODE button to

store the new setting and at the same

time go back to the previously selected

menu option.

Selecting an option from the main

menu with a submenu:

- briefly press the MODE button to

display the first submenu option;

- press the

orbuttons (with

a single press) to scroll through all

submenu options;

- briefly press the MODE button to

select the displayed submenu option

and to open the relevant settings menu;

- press the

orbuttons

(with a single press) to choose the new

setting for this submenu option;

- briefly press the MODE button to

store the setting and return to the

previously selected submenu option.

Selecting “Date” and “Set Clock”:

- briefly press the MODE button to

select the first value to be changed (e.g.

hours / minutes or year / month / day);

- press the

orbuttons (with

a single press) to select the new

setting;- briefly press the MODE button to

store the new setting and go to the

next settings menu option. If this is the

last one, the system brings you back

to the previously selected menu option.

Press the button MODE for long:

- to exit the set-up menu if you are in

the main menu;

- to exit the main menu if you are in

another point of the menu (e.g.: at

submenu option setting level, at

submenu level or at main menu option

setting level);

- to save only the changes stored by

the user (and confirmed by pressing the

MODE button).

The setup menu environment is timed;

when the menu is exited due to expiry

of the time allowed, only the changes

already stored by the user (confirmed

beforehand by a brief press of the

MODE button) will be saved.

From the standard screen, briefly press

button MODE to start navigation.

Press theorbuttons to

navigate within the menu.NoteOnly the reduced menu can be

accessed while the vehicle is moving

for safety reasons ("Speed Beep"

setting). Stop the vehicle to access the

full menu.

Lighting

(Passenger compartment light

adjustment)

(only with side lights on)

This function is used to set the

brightness of the instrument panel,

uconnect™system controls (for

versions/markets where provided) and

automatic climate control system

controls (for versions/markets where

provided) to 8 levels.

Proceed as follows to adjust the light

intensity:

❒briefly press the MODE button. The

level set previously flashes on the

display;

❒press button

orto set

the required brightness level;

❒briefly press the MODE button to

return to the menu screen or hold the

button down to return to the

standard screen without storing.

124

KNOWING THE INSTRUMENT PANEL

Page 131 of 387

- press theorbutton to

select;

- press the MODE button briefly to

return to the menu screen or hold the

button down to return to the standard

screen without storing.

Setting the clock (Set

time)

This function allows you to set the clock

through two submenus: “Time” and

“Format”.

To carry out the adjustment, proceed as

follows:

- briefly press the MODE button and

two submenus, "Time" and "Format",

will be displayed;

- press the

orbutton to

switch between the two submenus;

- once you have selected the submenu

to be changed, press button MODE

briefly;

- if you enter the "Time" submenu,

pressing the MODE button briefly

makes the "hours" flash on the display;

- press the

orbutton to

adjust;

- briefly press the MODE button: the

"minutes" starts to flash on the display;- press the

orbutton to

adjust;

– if you enter the "Format" submenu,

pressing the MODE button briefly

makes the display format flash on the

display;

- press the

orbutton to

select "24h" or "12h" mode.

When you have made the adjustment,

briefly press the MODE button to go

back to the submenu screen or hold

the button down to go back to the main

menu screen without storing.

- press the MODE button again to

return to the standard screen or to the

main menu according to where you

are in the menu.

Setting the date (Set

Date)

This function allows updating of the

date (day - month - year).

Proceed as follows to update:

- briefly press the MODE button: the

day starts flashing on the display (dd);

- press the

orbutton to

adjust;

- briefly press the MODE button: the

month starts flashing on the display

(mm);- press the

orbutton to

adjust;

- briefly press the MODE button: the

year starts flashing on the display

(yyyy);

- press the button

orfor

setting.

NoteThe setting will increase or

decrease by one unit each time the

orbutton is pressed.

Keeping the button pressed causes an

automatic rapid value increase/

decrease. Complete the adjustment

with single presses of the button when

you approach the desired value.

- press the MODE button briefly to

return to the menu screen or hold the

button down to return to the standard

screen without storing.

Automatic central

locking with vehicle

moving (Autoclose)

After activation (On), this function allows

the automatic locking of the doors

when the speed exceeds 20 km/h.

Proceed as follows to activate (On) or

deactivate (Off) this function:

- briefly press the MODE button to

display a submenu;

127

Page 209 of 387

After lifting the vehicle:

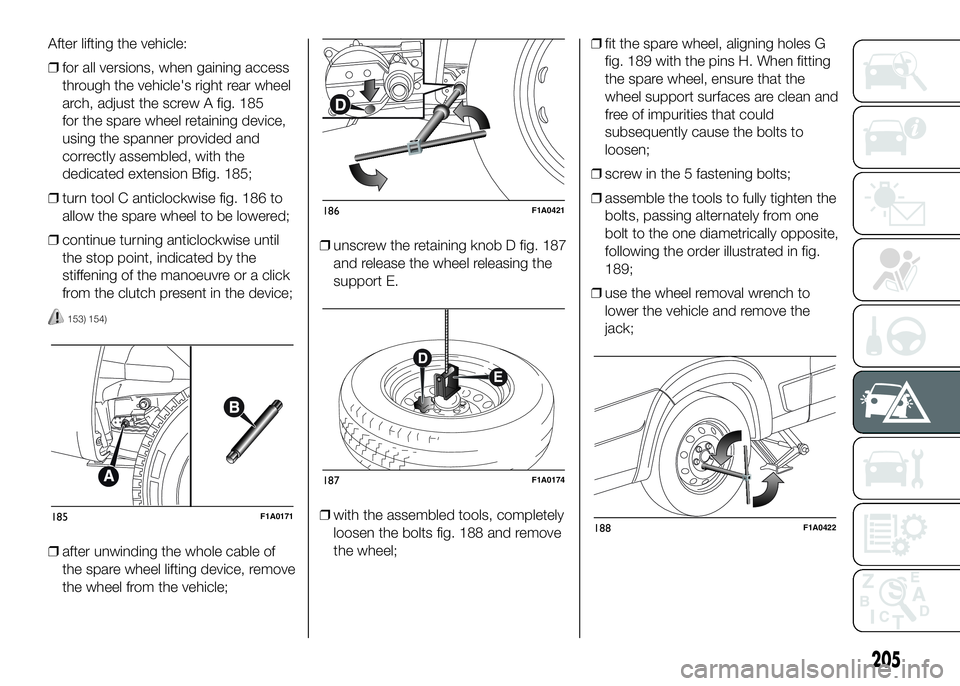

❒for all versions, when gaining access

through the vehicle's right rear wheel

arch, adjust the screw A fig. 185

for the spare wheel retaining device,

using the spanner provided and

correctly assembled, with the

dedicated extension Bfig. 185;

❒turn tool C anticlockwise fig. 186 to

allow the spare wheel to be lowered;

❒continue turning anticlockwise until

the stop point, indicated by the

stiffening of the manoeuvre or a click

from the clutch present in the device;

153) 154)

❒after unwinding the whole cable of

the spare wheel lifting device, remove

the wheel from the vehicle;❒unscrew the retaining knob D fig. 187

and release the wheel releasing the

support E.

❒with the assembled tools, completely

loosen the bolts fig. 188 and remove

the wheel;❒fit the spare wheel, aligning holes G

fig. 189 with the pins H. When fitting

the spare wheel, ensure that the

wheel support surfaces are clean and

free of impurities that could

subsequently cause the bolts to

loosen;

❒screw in the 5 fastening bolts;

❒assemble the tools to fully tighten the

bolts, passing alternately from one

bolt to the one diametrically opposite,

following the order illustrated in fig.

189;

❒use the wheel removal wrench to

lower the vehicle and remove the

jack;

185F1A0171

186F1A0421

187F1A0174

188F1A0422

205

Page 210 of 387

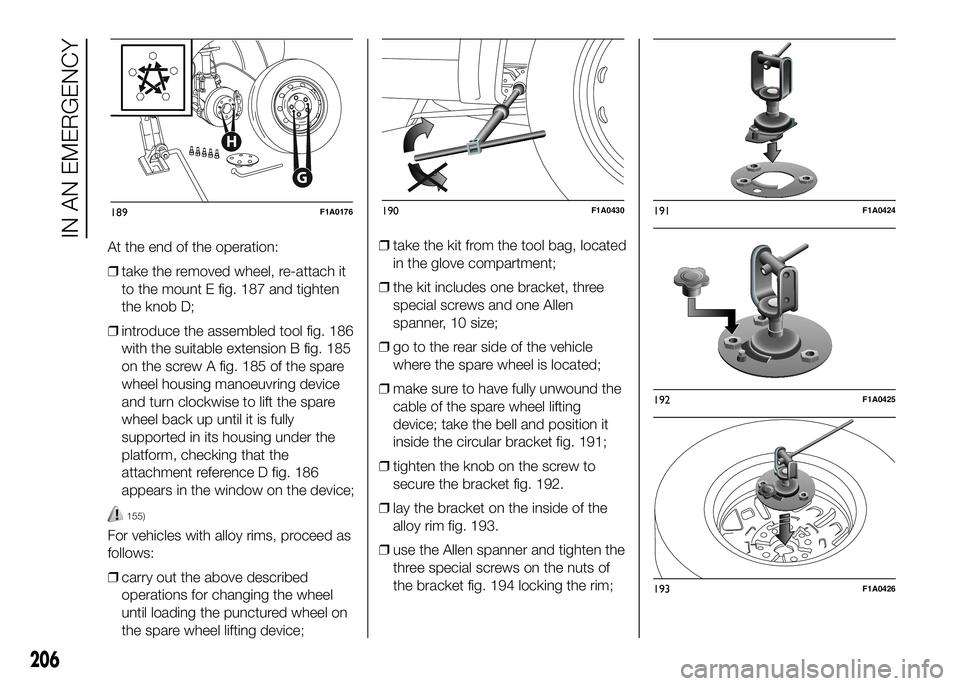

At the end of the operation:

❒take the removed wheel, re-attach it

to the mount E fig. 187 and tighten

the knob D;

❒introduce the assembled tool fig. 186

with the suitable extension B fig. 185

on the screw A fig. 185 of the spare

wheel housing manoeuvring device

and turn clockwise to lift the spare

wheel back up until it is fully

supported in its housing under the

platform, checking that the

attachment reference D fig. 186

appears in the window on the device;

155)

For vehicles with alloy rims, proceed as

follows:

❒carry out the above described

operations for changing the wheel

until loading the punctured wheel on

the spare wheel lifting device;❒take the kit from the tool bag, located

in the glove compartment;

❒the kit includes one bracket, three

special screws and one Allen

spanner, 10 size;

❒go to the rear side of the vehicle

where the spare wheel is located;

❒make sure to have fully unwound the

cable of the spare wheel lifting

device; take the bell and position it

inside the circular bracket fig. 191;

❒tighten the knob on the screw to

secure the bracket fig. 192.

❒lay the bracket on the inside of the

alloy rim fig. 193.

❒use the Allen spanner and tighten the

three special screws on the nuts of

the bracket fig. 194 locking the rim;

G

H

189F1A0176190F1A0430191F1A0424

192F1A0425

193F1A0426

206

IN AN EMERGENCY

Page 211 of 387

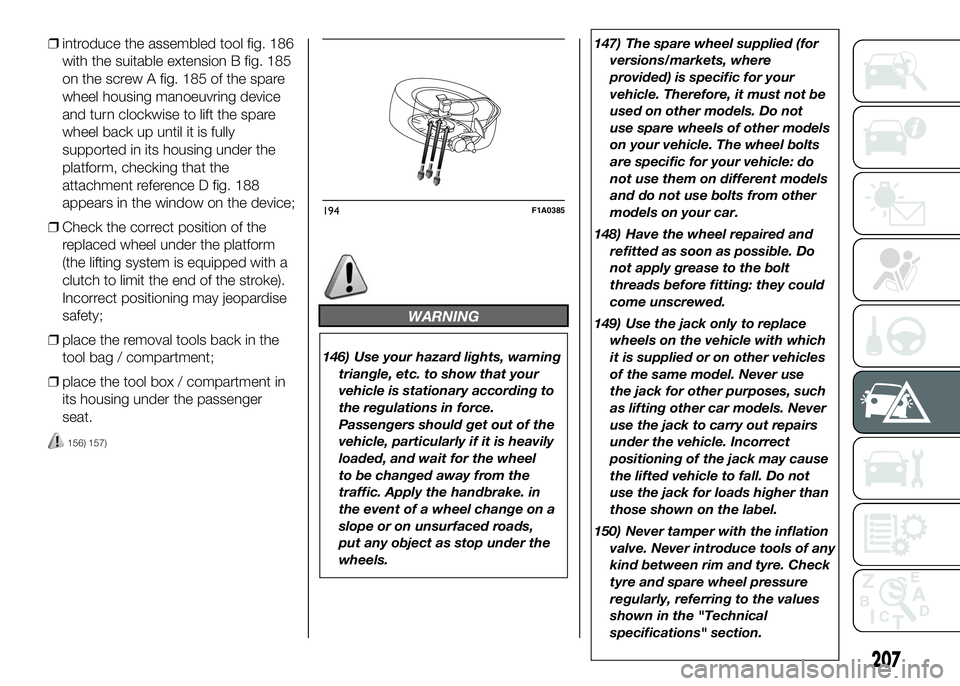

❒introduce the assembled tool fig. 186

with the suitable extension B fig. 185

on the screw A fig. 185 of the spare

wheel housing manoeuvring device

and turn clockwise to lift the spare

wheel back up until it is fully

supported in its housing under the

platform, checking that the

attachment reference D fig. 188

appears in the window on the device;

❒Check the correct position of the

replaced wheel under the platform

(the lifting system is equipped with a

clutch to limit the end of the stroke).

Incorrect positioning may jeopardise

safety;

❒place the removal tools back in the

tool bag / compartment;

❒place the tool box / compartment in

its housing under the passenger

seat.

156) 157)

WARNING

146) Use your hazard lights, warning

triangle, etc. to show that your

vehicle is stationary according to

the regulations in force.

Passengers should get out of the

vehicle, particularly if it is heavily

loaded, and wait for the wheel

to be changed away from the

traffic. Apply the handbrake. in

the event of a wheel change on a

slope or on unsurfaced roads,

put any object as stop under the

wheels.147) The spare wheel supplied (for

versions/markets, where

provided) is specific for your

vehicle. Therefore, it must not be

used on other models. Do not

use spare wheels of other models

on your vehicle. The wheel bolts

are specific for your vehicle: do

not use them on different models

and do not use bolts from other

models on your car.

148) Have the wheel repaired and

refitted as soon as possible. Do

not apply grease to the bolt

threads before fitting: they could

come unscrewed.

149) Use the jack only to replace

wheels on the vehicle with which

it is supplied or on other vehicles

of the same model. Never use

the jack for other purposes, such

as lifting other car models. Never

use the jack to carry out repairs

under the vehicle. Incorrect

positioning of the jack may cause

the lifted vehicle to fall. Do not

use the jack for loads higher than

those shown on the label.

150) Never tamper with the inflation

valve. Never introduce tools of any

kind between rim and tyre. Check

tyre and spare wheel pressure

regularly, referring to the values

shown in the "Technical

specifications" section.

194F1A0385

207

Page 213 of 387

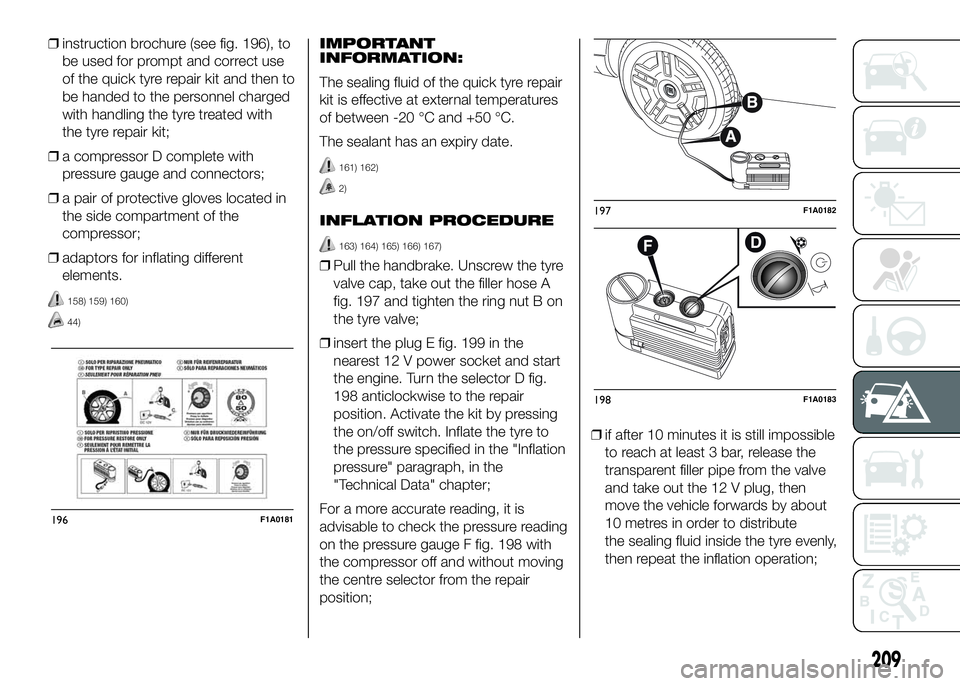

❒instruction brochure (see fig. 196), to

be used for prompt and correct use

of the quick tyre repair kit and then to

be handed to the personnel charged

with handling the tyre treated with

the tyre repair kit;

❒a compressor D complete with

pressure gauge and connectors;

❒a pair of protective gloves located in

the side compartment of the

compressor;

❒adaptors for inflating different

elements.

158) 159) 160)

44)

IMPORTANT

INFORMATION:

The sealing fluid of the quick tyre repair

kit is effective at external temperatures

of between -20 °C and +50 °C.

The sealant has an expiry date.

161) 162)

2)

INFLATION PROCEDURE

163) 164) 165) 166) 167)

❒Pull the handbrake. Unscrew the tyre

valve cap, take out the filler hose A

fig. 197 and tighten the ring nut B on

the tyre valve;

❒insert the plug E fig. 199 in the

nearest 12 V power socket and start

the engine. Turn the selector D fig.

198 anticlockwise to the repair

position. Activate the kit by pressing

the on/off switch. Inflate the tyre to

the pressure specified in the "Inflation

pressure" paragraph, in the

"Technical Data" chapter;

For a more accurate reading, it is

advisable to check the pressure reading

on the pressure gauge F fig. 198 with

the compressor off and without moving

the centre selector from the repair

position;❒if after 10 minutes it is still impossible

to reach at least 3 bar, release the

transparent filler pipe from the valve

and take out the 12 V plug, then

move the vehicle forwards by about

10 metres in order to distribute

the sealing fluid inside the tyre evenly,

then repeat the inflation operation;

196F1A0181

197F1A0182

198F1A0183

209

Page 214 of 387

❒if after this operation you still cannot

reach at least 3 bar after 10 minutes,

do not resume driving because the

tyre is too damaged and the quick

tyre repair kit cannot guarantee

suitable sealing. Contact a Fiat

Dealership;

❒if the tyre reaches the pressure

specified in “Inflation pressure”

paragraph in the "Technical Data"

section, start driving immediately;

❒after having driven for about

10 minutes, stop and recheck the

tyre pressure; remember to apply the

handbrake;❒if a pressure value of at least 3 bar is

detected, restore the correct

pressure prescribed in the paragraph

“Inflation pressure” in “Technical

specification” (with the engine

running and the handbrake

engaged), resume driving and drive

with care to nearest Fiat Dealership.

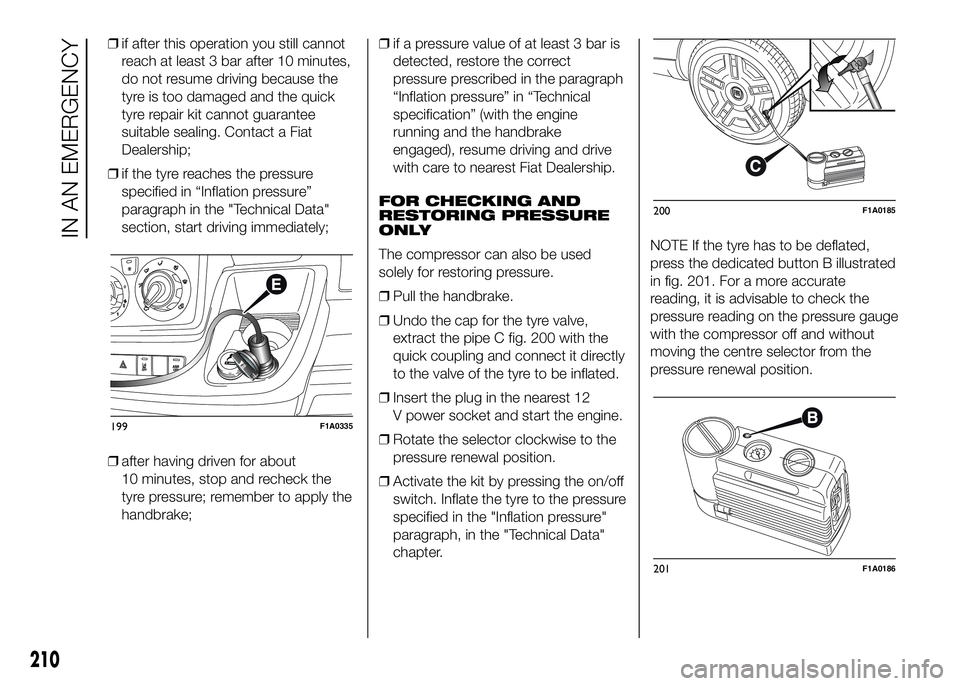

FOR CHECKING AND

RESTORING PRESSURE

ONLY

The compressor can also be used

solely for restoring pressure.

❒Pull the handbrake.

❒Undo the cap for the tyre valve,

extract the pipe C fig. 200 with the

quick coupling and connect it directly

to the valve of the tyre to be inflated.

❒Insert the plug in the nearest 12

V power socket and start the engine.

❒Rotate the selector clockwise to the

pressure renewal position.

❒Activate the kit by pressing the on/off

switch. Inflate the tyre to the pressure

specified in the "Inflation pressure"

paragraph, in the "Technical Data"

chapter.NOTE If the tyre has to be deflated,

press the dedicated button B illustrated

in fig. 201. For a more accurate

reading, it is advisable to check the

pressure reading on the pressure gauge

with the compressor off and without

moving the centre selector from the

pressure renewal position.

199F1A0335

200F1A0185

201F1A0186

210

IN AN EMERGENCY

Page 218 of 387

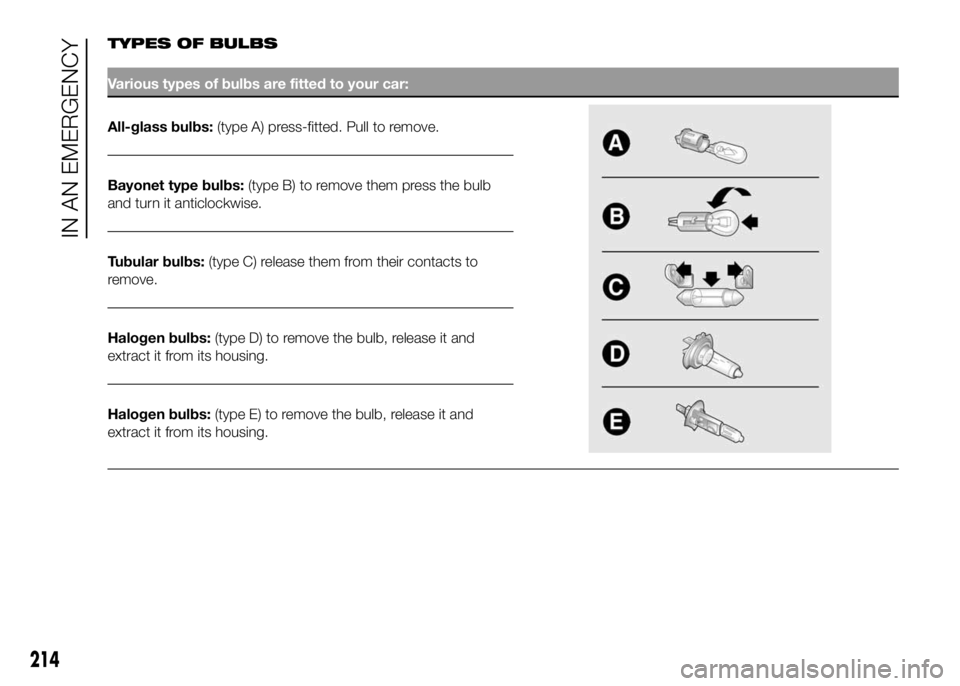

TYPES OF BULBS

Various types of bulbs are fitted to your car:

All-glass bulbs:(typeA) press-fitted. Pull to remove.

Bayonet type bulbs:(type B) to remove them press the bulb

and turn it anticlockwise.

Tubular bulbs:(type C) release them from their contacts to

remove.

Halogen bulbs:(type D) to remove the bulb, release it and

extract it from its housing.

Halogen bulbs:(type E) to remove the bulb, release it and

extract it from its housing.

214

IN AN EMERGENCY