technical data FIAT DUCATO BASE CAMPER 2017 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2017Pages: 296, PDF Size: 14.44 MB

Page 3 of 296

Dear Customer,

We would like to congratulate and thank you for choosing a Fiat Ducato.

We have written this handbook to help you get to know all the features of your vehicle and use it in the best possible way.

Here you will find information, advice and important warnings regarding vehicle use and how to achieve the best performance from the

technical features of your Fiat Ducato.

You are advised to read it right through before taking to the road for the first time, to become familiar with the controls and above all

with those concerning brakes, steering and transmission; at the same time, you can understand the vehicle behaviour on different road

surfaces.

This document also provides a description of special features and tips, as well as essential information for the safe driving, care and

servicing of your Fiat Ducato over time.

After reading it, you are advised to keep the handbook inside the vehicle, for an easy reference and for making sure it remains on

board the vehicle should it be sold.

In the attached Warranty Booklet you will also find a description of the Services that Fiat offers to its customers, the Warranty

Certificate and the detail of the terms and conditions for maintaining its validity.

We are sure that these will help you to get in touch with and appreciate your new vehicle and the service provided by the people at

Fiat.

Enjoy reading. Happy motoring!

IMPORTANT

This Owner Handbook describes all Fiat Ducato versions. As a consequence, you should only consider the information

related to the trim level, engine and version that you have purchased. All data contained in this publication are purely

indicative. FCA Italy S.p.A. can modify the specifications of the vehicle model described in this publication at any time, for

technical or marketing purposes. For further information, contact a Fiat Dealership.

Page 7 of 296

KNOWING YOUR VEHICLE

KNOWING THE INSTRUMENT PANEL

SAFETY

STARTING AND DRIVING

IN AN EMERGENCY

SERVICING AND CARE

TECHNICAL DATA

MULTIMEDIA

INDEX

5

Page 129 of 296

wait for the warning on the

instrument panel to switch off before

moving the vehicle, the warning light

may stay on for a few seconds to half a

minute. In case of motor start-up and

movement of the vehicle, the warning

light will remain on for a longer period of

time, but there are no problems on the

engine functionality. If topping up is

done with the UREA tank empty, you

have to wait two minutes before

starting the vehicle.

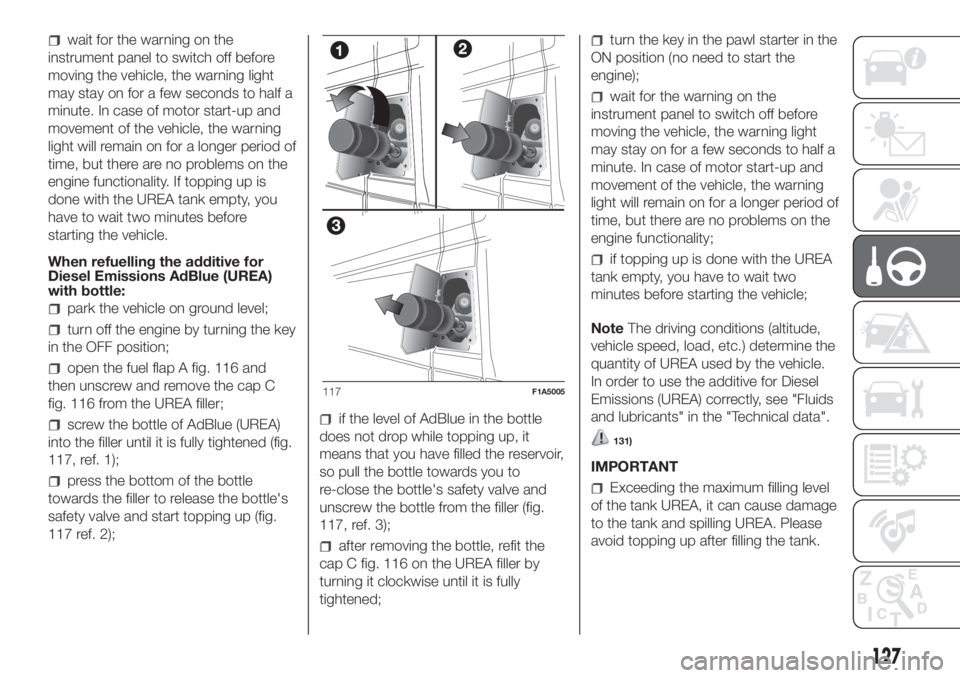

When refuelling the additive for

Diesel Emissions AdBlue (UREA)

with bottle:

park the vehicle on ground level;

turn off the engine by turning the key

in the OFF position;

open the fuel flap A fig. 116 and

then unscrew and remove the cap C

fig. 116 from the UREA filler;

screw the bottle of AdBlue (UREA)

into the filler until it is fully tightened (fig.

117, ref. 1);

press the bottom of the bottle

towards the filler to release the bottle's

safety valve and start topping up (fig.

117 ref. 2);

if the level of AdBlue in the bottle

does not drop while topping up, it

means that you have filled the reservoir,

so pull the bottle towards you to

re-close the bottle's safety valve and

unscrew the bottle from the filler (fig.

117, ref. 3);

after removing the bottle, refit the

cap C fig. 116 on the UREA filler by

turning it clockwise until it is fully

tightened;

turn the key in the pawl starter in the

ON position (no need to start the

engine);

wait for the warning on the

instrument panel to switch off before

moving the vehicle, the warning light

may stay on for a few seconds to half a

minute. In case of motor start-up and

movement of the vehicle, the warning

light will remain on for a longer period of

time, but there are no problems on the

engine functionality;

if topping up is done with the UREA

tank empty, you have to wait two

minutes before starting the vehicle;

NoteThe driving conditions (altitude,

vehicle speed, load, etc.) determine the

quantity of UREA used by the vehicle.

In order to use the additive for Diesel

Emissions (UREA) correctly, see "Fluids

and lubricants" in the "Technical data".

131)

IMPORTANT

Exceeding the maximum filling level

of the tank UREA, it can cause damage

to the tank and spilling UREA. Please

avoid topping up after filling the tank.

117F1A5005

127

Page 135 of 296

LOADING ADVICE

The Fiat Ducato version used by you

has been designed and type approved

on the basis of certain maximum

weights (see "Weights" table in the

"Technical Data" chapter): kerb weight,

payload, total weight, maximum weight

on front axle, maximum weight on

rear axle, towable weight.

IMPORTANT The maximum permitted

load on the floor fastenings is 500

kg; the maximum permitted load on the

side panel is 150 kg.

IMPORTANT For versions with right and

left side flaps, it is advisable to

reposition the release lever in the closed

position before lowering the sides.

133) 134) 135)

39)In addition to these general

precautions, some simple precautions

can improve driving safety, travelling

comfort and vehicle durability:

distribute the load evenly over the

platform: if it is necessary to

concentrate it in a single area, choose

an area mid-way between both axles;

lastly, remember that the vehicle’s

dynamic behaviour is affected by the

weight transported: in particular, the

stopping distances are longer,

especially at high speed.

WARNING

133)Bumpy roads and abrupt braking may

cause unexpected load shifting with

consequently hazardous situations for the

driver and passengers: before setting

off, secure the load tightly using the

partition and appropriate hooks, steel

cables, ropes or chains strong enough to

hold the items to be secured.

134)Even when the car is stopped on a

steep hill or side slope, opening the rear or

side doors could cause unsecured goods

to fall out.

135)If you wish to carry a reserve of petrol

in a can, observe the legal restrictions

and only use a can that is type-approved

and properly secured to the load

anchorage eyebolts. In the event of a

collision the fire risk is increased all the

same.

WARNING

39)Each of these must be strictly

observed and MUST NEVER BE

EXCEEDED in any case. In particular,

ensure that you never exceed the

maximum permitted weights on the front

and rear axles when arranging the load on

the vehicle (particularly if the vehicle is

equipped with a specific trim level).

133

Page 138 of 296

In addition to the electrical branches,

the vehicle's electric system can only

be connected to the supply cable for an

electric brake and to the cable for an

internal light, though not above 15

W. For connections use the preset

control unit with battery cable no less

than 2.5 mm

2.

IMPORTANT The trailer tow hook

contributes to the length of the vehicle.

When installing on long wheelbase

versions, it is only possible to install

removable tow hooks because the total

vehicle length limit of 6 metres is

exceeded.

If no trailer is fitted, the hook must be

removed from the attachment base and

it must not exceed the vehicle's

original length.

IMPORTANT If you wish to leave the

tow hook fitted without towing a trailer,

it is advisable to contact a Fiat

Dealership for the relevant system

update operations because the tow

hook could be detected as an obstacle

by the central sensors.Installation diagram for Van

versions fig. 121

The tow hook structure must be

fastened in the points shown by the

symbol Ø using a total of 6 M10x1.25

screws and 4 M12 screws.

The internal back plates must be at

least 5 mm thick. MAX LOAD ON

BALL: 100/120 kg depending on the

payload (see the “Weights” table in the

“Technical Data” chapter).

138)

To install a tow hook, the bumpers

must be trimmed as described in the

supplier's installation kit.

Installation diagram for Truck and

Chassis Cab versions fig. 122

Another tow hook specific to Truck and

Chassis Cab versions is shown in fig.

122.

The structure Ø must be fixed in the

points indicated using a total of 6

M10x1.25 screws and 4 M12 screws.MAX LOAD ON BALL: 100/120 kg

depending on the payload (see the

“Weights” table in the “Technical Data”

chapter).

WARNING

136)The ABS with which the vehicle may

be equipped will not control the braking

system of the trailer. Particular caution

is required on slippery roads.

137)Never modify the braking system of

the vehicle to control the trailer brake. The

trailer braking system must be fully

independent from the hydraulic system of

the vehicle.

138)After fitting, screw holes must be

sealed to prevent a exhaust gas inlet.

.

136

STARTING AND DRIVING

Page 177 of 296

information leaflet (see fig. 172), to

be used for prompt and correct use

of the quick tyre repair kit and then to

be given to the personnel that must

handle the tyre treated with the tyre

repair kit;

compressor D complete with

pressure gauge and connectors;

a pair of protective gloves located in

the side compartment of the

compressor;

adaptors for inflating different

elements.

157) 158) 159)

48)

IMPORTANT

INFORMATION:

The sealing fluid of the quick repair kit is

effective at external temperatures of

between –20 °C and +50 °C.

The sealing fluid has an expiry date.

160) 161)

3)

INFLATION PROCEDURE

162) 163) 164) 165) 166)

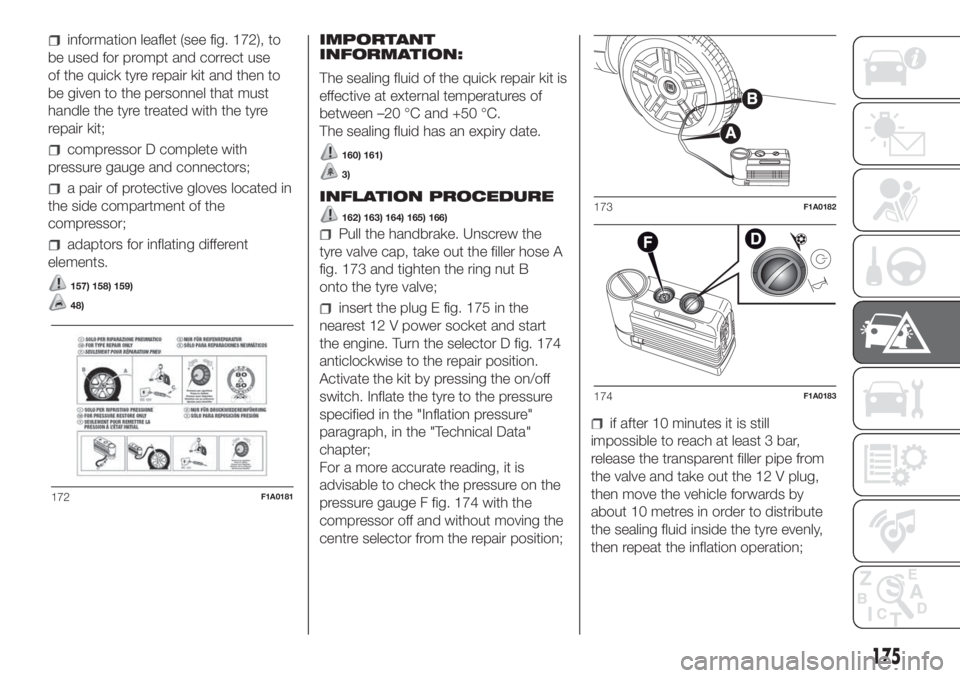

Pull the handbrake. Unscrew the

tyre valve cap, take out the filler hose A

fig. 173 and tighten the ring nut B

onto the tyre valve;

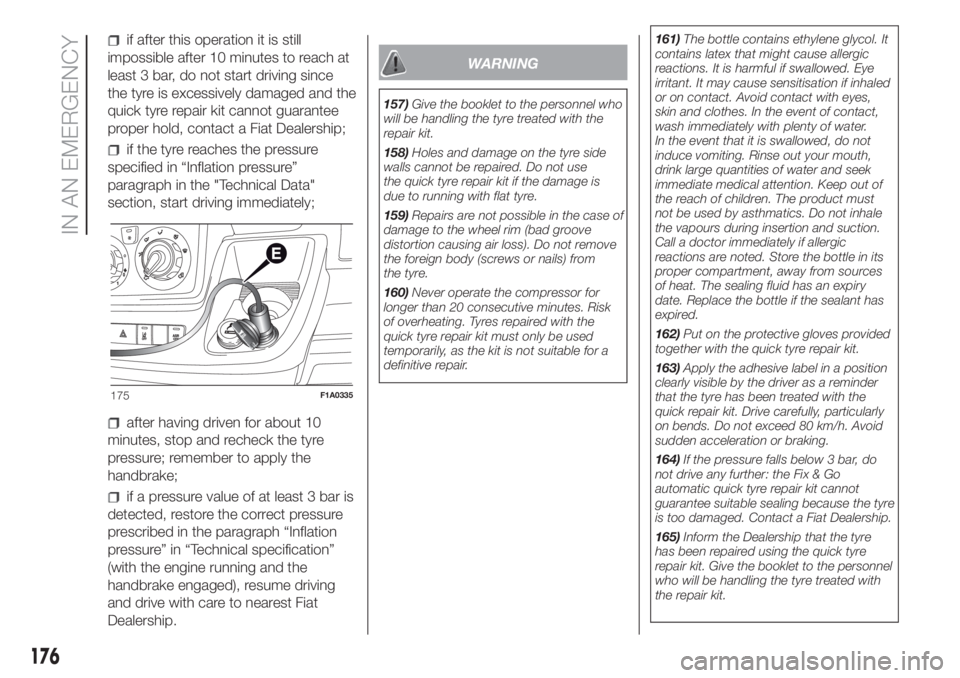

insert the plug E fig. 175 in the

nearest 12 V power socket and start

the engine. Turn the selector D fig. 174

anticlockwise to the repair position.

Activate the kit by pressing the on/off

switch. Inflate the tyre to the pressure

specified in the "Inflation pressure"

paragraph, in the "Technical Data"

chapter;

For a more accurate reading, it is

advisable to check the pressure on the

pressure gauge F fig. 174 with the

compressor off and without moving the

centre selector from the repair position;

if after 10 minutes it is still

impossible to reach at least 3 bar,

release the transparent filler pipe from

the valve and take out the 12 V plug,

then move the vehicle forwards by

about 10 metres in order to distribute

the sealing fluid inside the tyre evenly,

then repeat the inflation operation;

172F1A0181

173F1A0182

174F1A0183

175

Page 178 of 296

if after this operation it is still

impossible after 10 minutes to reach at

least 3 bar, do not start driving since

the tyre is excessively damaged and the

quick tyre repair kit cannot guarantee

proper hold, contact a Fiat Dealership;

if the tyre reaches the pressure

specified in “Inflation pressure”

paragraph in the "Technical Data"

section, start driving immediately;

after having driven for about 10

minutes, stop and recheck the tyre

pressure; remember to apply the

handbrake;

if a pressure value of at least 3 bar is

detected, restore the correct pressure

prescribed in the paragraph “Inflation

pressure” in “Technical specification”

(with the engine running and the

handbrake engaged), resume driving

and drive with care to nearest Fiat

Dealership.

WARNING

157)Give the booklet to the personnel who

will be handling the tyre treated with the

repair kit.

158)Holes and damage on the tyre side

walls cannot be repaired. Do not use

the quick tyre repair kit if the damage is

due to running with flat tyre.

159)Repairs are not possible in the case of

damage to the wheel rim (bad groove

distortion causing air loss). Do not remove

the foreign body (screws or nails) from

the tyre.

160)Never operate the compressor for

longer than 20 consecutive minutes. Risk

of overheating. Tyres repaired with the

quick tyre repair kit must only be used

temporarily, as the kit is not suitable for a

definitive repair.161)The bottle contains ethylene glycol. It

contains latex that might cause allergic

reactions. It is harmful if swallowed. Eye

irritant. It may cause sensitisation if inhaled

or on contact. Avoid contact with eyes,

skin and clothes. In the event of contact,

wash immediately with plenty of water.

In the event that it is swallowed, do not

induce vomiting. Rinse out your mouth,

drink large quantities of water and seek

immediate medical attention. Keep out of

the reach of children. The product must

not be used by asthmatics. Do not inhale

the vapours during insertion and suction.

Call a doctor immediately if allergic

reactions are noted. Store the bottle in its

proper compartment, away from sources

of heat. The sealing fluid has an expiry

date. Replace the bottle if the sealant has

expired.

162)Put on the protective gloves provided

together with the quick tyre repair kit.

163)Apply the adhesive label in a position

clearly visible by the driver as a reminder

that the tyre has been treated with the

quick repair kit. Drive carefully, particularly

on bends. Do not exceed 80 km/h. Avoid

sudden acceleration or braking.

164)If the pressure falls below 3 bar, do

not drive any further: the Fix & Go

automatic quick tyre repair kit cannot

guarantee suitable sealing because the tyre

is too damaged. Contact a Fiat Dealership.

165)Inform the Dealership that the tyre

has been repaired using the quick tyre

repair kit. Give the booklet to the personnel

who will be handling the tyre treated with

the repair kit.

175F1A0335

176

IN AN EMERGENCY

Page 210 of 296

TECHNICAL DATA

Everything you may find useful for

understanding how your vehicle

is made and works is contained in this

chapter and illustrated with data, tables

and graphics. For the enthusiasts and

the technician, but also just for those

who want to know every detail of their

vehicle.IDENTIFICATION DATA....................209

ENGINE CODES - BODYWORK

VERSION ........................................211

ENGINE ..........................................213

STEERING SYSTEM .......................216

WHEELS .........................................217

DIMENSIONS ..................................222

PERFORMANCE .............................232

WEIGHTS AND LOADS...................234

REFUELLING ..................................237

FLUIDS AND LUBRICANTS ............242

FUEL CONSUMPTION ....................245

CO2 EMISSIONS ...........................252

208

TECHNICAL DATA

Page 212 of 296

ENGINE MARKING

It is stamped on the cylinder block and

includes the type and the engine serial

number.

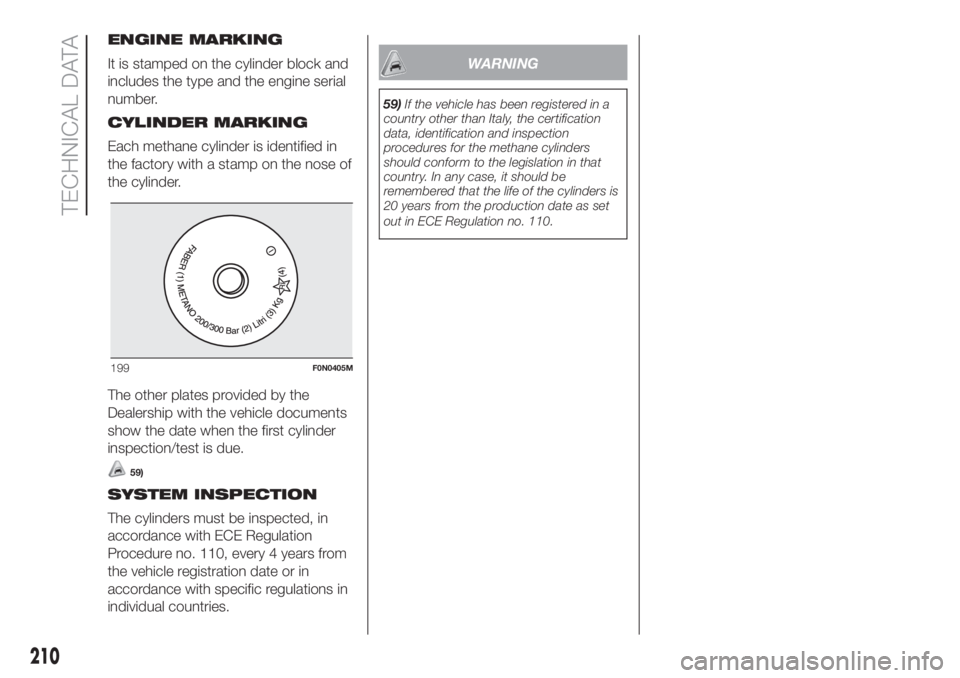

CYLINDER MARKING

Each methane cylinder is identified in

the factory with a stamp on the nose of

the cylinder.

The other plates provided by the

Dealership with the vehicle documents

show the date when the first cylinder

inspection/test is due.

59)

SYSTEM INSPECTION

The cylinders must be inspected, in

accordance with ECE Regulation

Procedure no. 110, every 4 years from

the vehicle registration date or in

accordance with specific regulations in

individual countries.

WARNING

59)If the vehicle has been registered in a

country other than Italy, the certification

data, identification and inspection

procedures for the methane cylinders

should conform to the legislation in that

country. In any case, it should be

remembered that the life of the cylinders is

20 years from the production date as set

out in ECE Regulation no. 110.

199F0N0405M

210

TECHNICAL DATA

Page 214 of 296

WHEELBASE

AShort wheelbase

BMedium wheelbase

CLong wheelbase

DMedium-long wheelbase

UAll wheelbases (incomplete vehicles)

BODY

ACab chassis

BChassis without cab

CPlatform chassis cab

DBox truck

EPrimary school bus

FVa n

GLong cab tipper

HLong cab chassis

MMinibus

PPanorama

RCombinato 6/9-seater

212

TECHNICAL DATA