wheel size FIAT DUCATO BASE CAMPER 2017 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2017Pages: 296, PDF Size: 14.44 MB

Page 86 of 296

HILL DESCENT CONTROL

(HDC) SYSTEM

It is an integral part of the ESC and is

aimed at keeping the vehicle at a

constant speed during a descent,

operating autonomously on the brakes

in various ways at the same time. In this

way the vehicle stability and completely

safe driving are guaranteed, above all

in poor grip conditions and/or steep

descents.

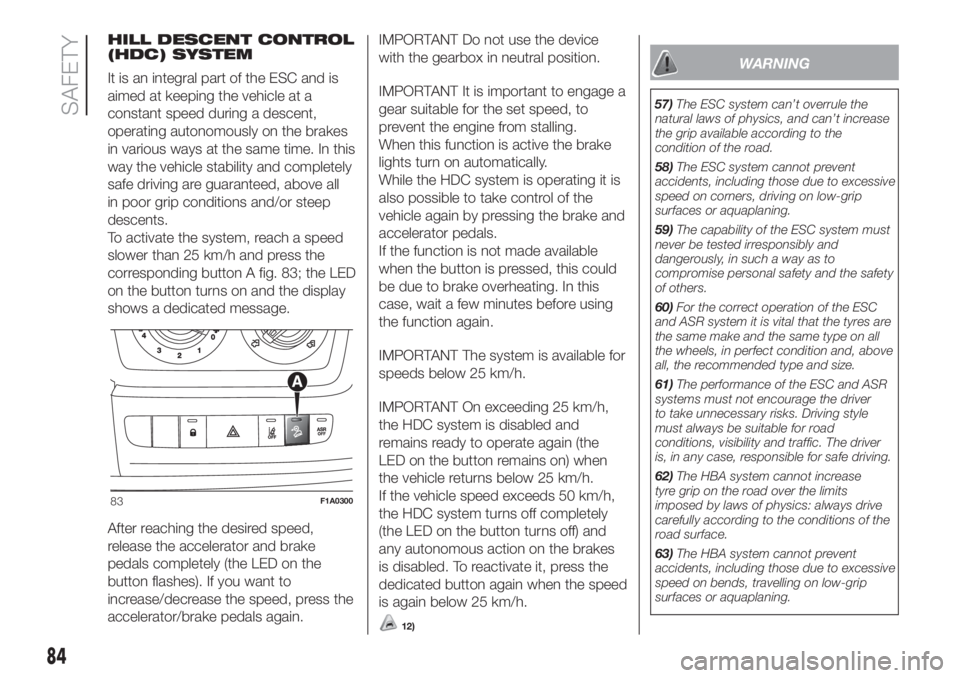

To activate the system, reach a speed

slower than 25 km/h and press the

corresponding button A fig. 83; the LED

on the button turns on and the display

shows a dedicated message.

After reaching the desired speed,

release the accelerator and brake

pedals completely (the LED on the

button flashes). If you want to

increase/decrease the speed, press the

accelerator/brake pedals again.IMPORTANT Do not use the device

with the gearbox in neutral position.

IMPORTANT It is important to engage a

gear suitable for the set speed, to

prevent the engine from stalling.

When this function is active the brake

lights turn on automatically.

While the HDC system is operating it is

also possible to take control of the

vehicle again by pressing the brake and

accelerator pedals.

If the function is not made available

when the button is pressed, this could

be due to brake overheating. In this

case, wait a few minutes before using

the function again.

IMPORTANT The system is available for

speeds below 25 km/h.

IMPORTANT On exceeding 25 km/h,

the HDC system is disabled and

remains ready to operate again (the

LED on the button remains on) when

the vehicle returns below 25 km/h.

If the vehicle speed exceeds 50 km/h,

the HDC system turns off completely

(the LED on the button turns off) and

any autonomous action on the brakes

is disabled. To reactivate it, press the

dedicated button again when the speed

is again below 25 km/h.

12)

WARNING

57)The ESC system can’t overrule the

natural laws of physics, and can’t increase

the grip available according to the

condition of the road.

58)The ESC system cannot prevent

accidents, including those due to excessive

speed on corners, driving on low-grip

surfaces or aquaplaning.

59)The capability of the ESC system must

never be tested irresponsibly and

dangerously, in such a way as to

compromise personal safety and the safety

of others.

60)For the correct operation of the ESC

and ASR system it is vital that the tyres are

the same make and the same type on all

the wheels, in perfect condition and, above

all, the recommended type and size.

61)The performance of the ESC and ASR

systems must not encourage the driver

to take unnecessary risks. Driving style

must always be suitable for road

conditions, visibility and traffic. The driver

is, in any case, responsible for safe driving.

62)The HBA system cannot increase

tyre grip on the road over the limits

imposed by laws of physics: always drive

carefully according to the conditions of the

road surface.

63)The HBA system cannot prevent

accidents, including those due to excessive

speed on bends, travelling on low-grip

surfaces or aquaplaning.

83F1A0300

84

SAFETY

Page 90 of 296

WARNING

68)The TPMS is optimised for the original

tyres and wheels provided. TPMS

pressures and alerts have been defined

according to the size of the tyres mounted

on the vehicle. Using equipment with

different size, type or kind may cause

irregular system operation or sensor

damage. Non-original spare wheels can

damage the sensor. Do not use tyre

sealant or balancing weights if the vehicle

is equipped with TPMS as these may

damage the sensors.

69)If the system signals a pressure

decrease on a specific tyre, it is

recommended to check the pressure on all

four tyres.

70)The TPMS does not relieve the driver

from the obligation to check the tyre

pressure every month; it is not even to be

considered a replacing system for

maintenance or a safety system.

71)Tyre pressure must be checked with

tyres cold. Should it become necessary for

whatever reason to check pressure with

warm tyres, do not reduce pressure even

though it is higher than the prescribed

value, but repeat the check when tyres are

cold.

72)The TPMS cannot indicate sudden tyre

pressure drops (for example when a tyre

bursts). In this case, stop the vehicle,

braking with caution and avoiding abrupt

steering.73)The system only warns that the tyre

pressure is low: it is not able to inflate

them.

74)Insufficient tyre inflation increases fuel

consumption, reduces the tread duration

and may affect your ability to drive the

vehicle safely.

75)Always refit the valve stem cap after

inspecting or adjusting tyre pressure. This

prevents dampness or dirt from entering

the valve stem and thus the pressure

control sensor from being damaged.

76)The tyre repair kit (Fix&Go) provided

with the vehicle (for versions/markets,

where provided) is compatible with the

TPMS sensors; using sealants not

equivalent with that in the original kit may

adversely affect its operation. If sealants

not equivalent with the original one are

used, it is recommended to have the

TPMS sensors checked by a qualified

repair centre.

88

SAFETY

Page 174 of 296

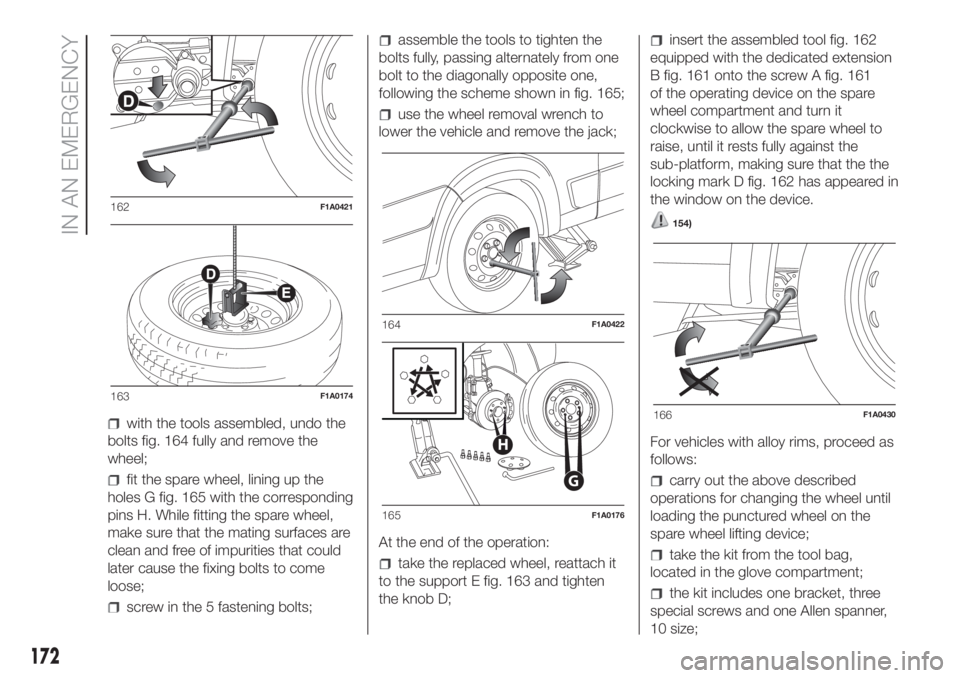

with the tools assembled, undo the

bolts fig. 164 fully and remove the

wheel;

fit the spare wheel, lining up the

holes G fig. 165 with the corresponding

pins H. While fitting the spare wheel,

make sure that the mating surfaces are

clean and free of impurities that could

later cause the fixing bolts to come

loose;

screw in the 5 fastening bolts;

assemble the tools to tighten the

bolts fully, passing alternately from one

bolt to the diagonally opposite one,

following the scheme shown in fig. 165;

use the wheel removal wrench to

lower the vehicle and remove the jack;

At the end of the operation:

take the replaced wheel, reattach it

to the support E fig. 163 and tighten

the knob D;

insert the assembled tool fig. 162

equipped with the dedicated extension

B fig. 161 onto the screw A fig. 161

of the operating device on the spare

wheel compartment and turn it

clockwise to allow the spare wheel to

raise, until it rests fully against the

sub-platform, making sure that the the

locking mark D fig. 162 has appeared in

the window on the device.

154)

For vehicles with alloy rims, proceed as

follows:

carry out the above described

operations for changing the wheel until

loading the punctured wheel on the

spare wheel lifting device;

take the kit from the tool bag,

located in the glove compartment;

the kit includes one bracket, three

special screws and one Allen spanner,

10 size;

162F1A0421

163F1A0174

164F1A0422

G

H

165F1A0176

166F1A0430

172

IN AN EMERGENCY