boot FIAT FIORINO 2012 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2012, Model line: FIORINO, Model: FIAT FIORINO 2012Pages: 210, PDF Size: 4.9 MB

Page 5 of 210

4

SAFETY

STARTING

AND DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLSDASHBOARD........................................................................ 5

INSTRUMENT PANEL ......................................................... 6

SYMBOLS ............................................................................... 7

THE FIAT CODE SYSTEM ................................................. 7

THE KEYS .............................................................................. 8

ALARM ................................................................................... 11

IGNITION DEVICE ............................................................. 13

INSTRUMENTS .................................................................... 14

DIGITAL DISPLAY ............................................................... 16

MULTIFUNCTIONAL DISPLAY ...................................... 21

TRIP COMPUTER ................................................................ 30

SEATS ...................................................................................... 33

PARTITIONS .......................................................................... 36

HEAD RESTRAINTS............................................................. 38

STEERING WHEEL .............................................................. 39

REARVIEW MIRRORS......................................................... 39

HEATING AND CLIMATE CONTROL SYSTEM ........ 41

HEATING AND VENTILATION ...................................... 43

MANUAL CLIMATE CONTROL SYSTEM .................... 46

EXTERNAL LIGHTS ............................................................ 49WINDOW WASHING....................................................... 51

CEILING LIGHTS.................................................................. 52

CONTROLS ........................................................................... 55

INTERIOR FITTINGS........................................................... 56

DOORS .................................................................................. 59

WINDOW WINDERS ....................................................... 63

BOOT ...................................................................................... 64

BONNET................................................................................. 68

ROOF RACK/SKI RACK .................................................... 69

HEADLIGHTS........................................................................ 70

ABS SYSTEM ......................................................................... 71

ESP SYSTEM............................................................................ 72

TRACTION PLUS SYSTEM ............................................... 75

EOBD SYSTEM ..................................................................... 76

SPEED BLOCK ..................................................................... 76

PARKING SENSORS ........................................................... 77

SOUND SYSTEM.................................................................. 79

ELECTRICAL/ELECTRONIC DEVICES

INSTALLATION.................................................................... 80

VEHICLE REFUELLING........................................................ 80

ENVIRONMENTAL PROTECTION................................. 82

D D

A A

S S

H H

B B

O O

A A

R R

D D

A A

N N

D D

C C

O O

N N

T T

R R

O O

L L

S S

001-035 Fiorino GB 1ed:001-035 Fiorino GB 1ed 2-12-2009 16:13 Pagina 4

Page 12 of 210

11

SAFETY

STARTING

AND DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

ALARM

(for versions/markets, where provided)

In addition to all the remote control func-

tions described above, an alarm has been

installed, which is controlled by a receiv-

er unit located under the dashboard near

the fuse box.

ALARM TRIPPING

The alarm trips in the following cases:

❒when one of the doors or bonnet is

opened illegitimately (perimeter pro-

tection);

❒when the ignition system is started up

(ignition key rotated to MAR);

❒when the battery cables are cut;

❒when someone is moving inside the

passenger compartment (volumetric

protection);

❒when the vehicle is unusually lift-

ed/tilted.

Depending on the markets where the ve-

hicle is sold, alarm tripping causes either

a siren or direction indicators to go on

(for approx. 26 seconds). Alarm tripping

and the number of cycles depend on the

sales market.Provision has been made for a maximum

number of acoustic/visual cycles, after

which the system resumes its standard

control function.

Volumetric and anti-lift protections are

disabled by pressing the control button in-

stalled on the front dashboard (see para-

graph “Anti-lift protections).

IMPORTANT The engine stop function is

guaranteed by the Fiat CODE, which is au-

tomatically activated when the ignition key

is extracted from the starter device.

ENABLING THE ALARM

Keep the doors and bonnets closed and

either turn the ignition key to STOPor

remove it. Direct the key with the remote

control towards the vehicle and press but-

ton

Á, then release it.

Excluding some versions for specific mar-

kets, the system produces a sound warn-

ing (beep) and enables door locking.

Before the alarm is enabled, a self-test is

run. If a failure is detected, the system pro-

duces a new acoustic signal and shows a

message on the display (see section

“Warning lights and messages”). If this is the case, disable the alarm by

pressing button Æ, check correct locking

of the doors, bonnet and boot, and enable

the alarm again by pressing button

Á.

If a door or the bonnet is not correctly

closed, it will be excluded from the test-

ing by the alarm system.

If the alarm produces an acoustic signal

even when the doors, bonnet and boot

are correctly closed, a failure has occurred

in system operation. Go to a Fiat Dealer-

ship.

IMPORTANT If the central door locking

system is engaged using the metal insert

of the key, the alarm is not enabled.

IMPORTANT Originally, the alarm is con-

figured in compliance with the regulations

existing in the different countries.

001-035 Fiorino GB 1ed:001-035 Fiorino GB 1ed 2-12-2009 16:14 Pagina 11

Page 65 of 210

64

SAFETY

STARTING

AND DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

BOOT

EMERGENCY OPENING

FROM INSIDE

In case of emergency the boot can be

opened from inside the vehicle as de-

scribed below.

❒Open the side sliding door and lower

the backrest of the rear seat all the way

down so as to gain access to the load-

ing compartment (Combi versions).

or

❒Open the side sliding door (Cargo ver-

sions).

❒Use handle A-fig. 79positioned on the

inside of the right-hand swing-door.

❒Open the left-hand swing-door using

the supplied handle (see the instruc-

tions provided in paragraph “Doors” of

this section).

fig. 79F0T0060m

Never exceed the maximum

allowed load in the boot (see

section “Technical Specifications”).

Make sure that the objects are well

arranged in the boot so that they will

not be projected forwards following

sudden braking.

WARNING

If you travel in areas with

few filling stations and you

want to transport fuel in a spare tank,

respect applicable laws and exclu-

sively use a type-approved suitably

secured tank. However, the risks in

case of collision increase.

WARNING

036-082 Fiorino GB 1ed:036-082 Fiorino GB 1ed 30-11-2009 15:47 Pagina 64

Page 67 of 210

66

SAFETY

STARTING

AND DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

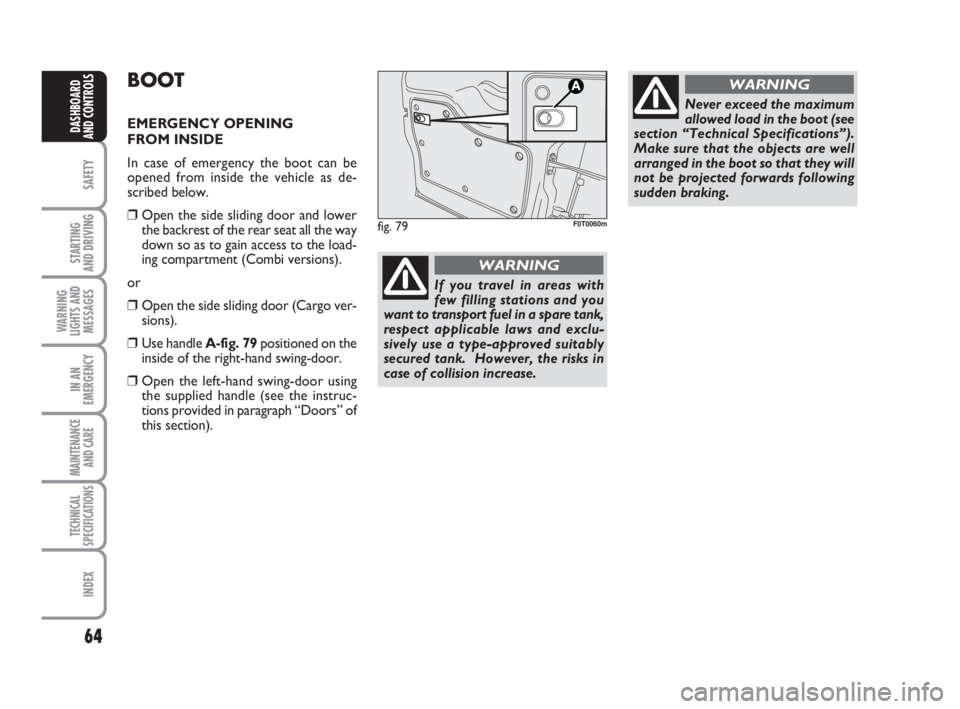

EXPANDING THE BOOT

Proceed as follows:

❒open the rear doors and remove the

rear parcel shelf (see description in pre-

vious paragraph);

❒lower the rear seat head restraints all

the way down;❒move the seat belt sideways and check

that it is stretched and presents no

twisting;

❒raise lever A-fig. 84retaining the back-

rest and fold it forwards to create an

even load compartment. The raising of

the lever is shown by a “red band” B;Versions with one-piece rear seat

To extend the luggage compartment fur-

ther, pull the tab A-fig. 85behind the rear

seat backrest and fold the seat and back-

rest forwards fig. 86.

Versions with split rear seat

To extend the luggage compartment fur-

ther, pull the tabs Aand B-fig. 87behind

the rear seat backrests and fold the seats

and backrests forwards fig. 88.

NoteThe one-piece and split seats have

circlips on the rear edge of the cushion for

attaching the seat to the front seat head

restraint rods when it is folded over.

fig. 84

AB

F0T0064m

fig. 85F0T0065m

fig. 86F0T0066m

fig. 87

AB

F0T0289m

fig. 88F0T0290m

036-082 Fiorino GB 1ed:036-082 Fiorino GB 1ed 30-11-2009 15:47 Pagina 66

Page 68 of 210

67

SAFETY

STARTING

AND DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

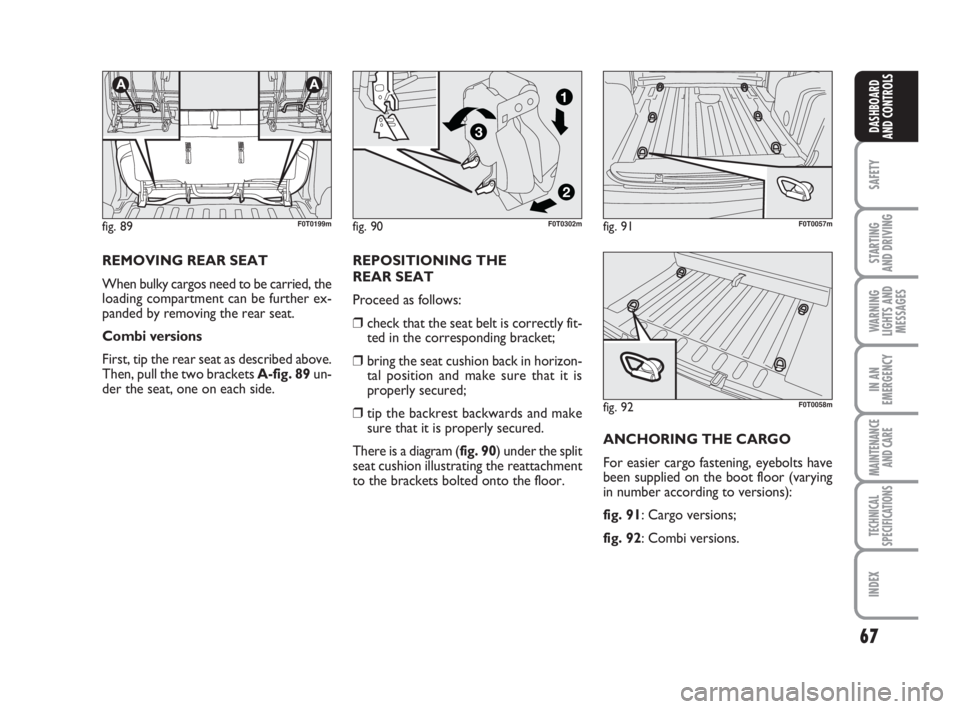

REMOVING REAR SEAT

When bulky cargos need to be carried, the

loading compartment can be further ex-

panded by removing the rear seat.

Combi versions

First, tip the rear seat as described above.

Then, pull the two brackets A-fig. 89un-

der the seat, one on each side.REPOSITIONING THE

REAR SEAT

Proceed as follows:

❒check that the seat belt is correctly fit-

ted in the corresponding bracket;

❒bring the seat cushion back in horizon-

tal position and make sure that it is

properly secured;

❒tip the backrest backwards and make

sure that it is properly secured.

There is a diagram (fig. 90) under the split

seat cushion illustrating the reattachment

to the brackets bolted onto the floor.

fig. 89

AA

F0T0199mfig. 91F0T0057m

fig. 92F0T0058m

ANCHORING THE CARGO

For easier cargo fastening, eyebolts have

been supplied on the boot floor (varying

in number according to versions):

fig. 91: Cargo versions;

fig. 92: Combi versions.

fig. 90

2

3

1

F0T0302m

036-082 Fiorino GB 1ed:036-082 Fiorino GB 1ed 30-11-2009 15:47 Pagina 67

Page 70 of 210

69

SAFETY

STARTING

AND DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

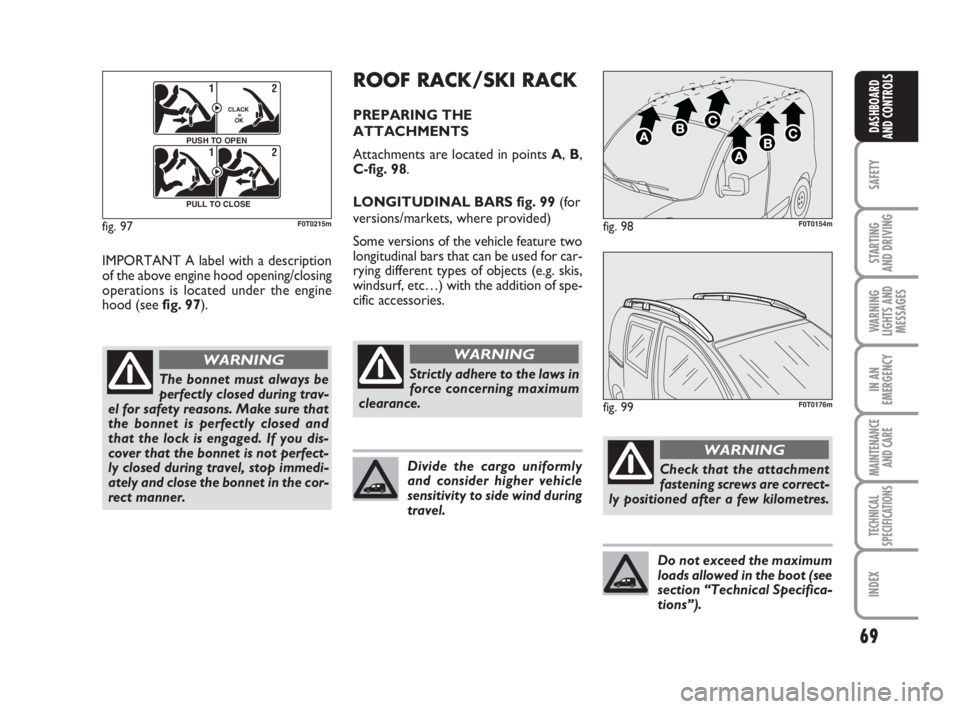

IMPORTANT A label with a description

of the above engine hood opening/closing

operations is located under the engine

hood (see fig. 97).

The bonnet must always be

perfectly closed during trav-

el for safety reasons. Make sure that

the bonnet is perfectly closed and

that the lock is engaged. If you dis-

cover that the bonnet is not perfect-

ly closed during travel, stop immedi-

ately and close the bonnet in the cor-

rect manner.

WARNING

fig. 97

F0Q0603m

12

CLACK

=

OK

PUSH TO OPEN12

PULL TO CLOSE

F0T0215mfig. 98F0T0154m

fig. 99F0T0176m

Strictly adhere to the laws in

force concerning maximum

clearance.

WARNING

Check that the attachment

fastening screws are correct-

ly positioned after a few kilometres.

WARNING

Divide the cargo uniformly

and consider higher vehicle

sensitivity to side wind during

travel.

Do not exceed the maximum

loads allowed in the boot (see

section “Technical Specifica-

tions”).

ROOF RACK/SKI RACK

PREPARING THE

ATTACHMENTS

Attachments are located in points A,B,

C-fig. 98.

LONGITUDINAL BARS fig. 99 (for

versions/markets, where provided)

Some versions of the vehicle feature two

longitudinal bars that can be used for car-

rying different types of objects (e.g. skis,

windsurf, etc…) with the addition of spe-

cific accessories.

036-082 Fiorino GB 1ed:036-082 Fiorino GB 1ed 30-11-2009 15:47 Pagina 69

Page 71 of 210

70

SAFETY

STARTING

AND DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

HEADLIGHTS

DIRECTING THE BEAM

Correct direction of the headlights is es-

sential for the comfort and safety of the

driver and the other road users. To en-

sure the best visibility conditions during

travel with the headlights on the vehicle

must have beams aimed correctly. Con-

tact the Fiat Dealership to have the head-

lights checked and properly adjusted.

HEADLIGHT AIMING DEVICE

This device works with the key at MAR

and the dipped beam headlights on.

The vehicle slants backwards when it is

loaded, raising the beam. The beams must

therefore be directed again in this case.FOG LIGHT AIMING DEVICE

(for versions/markets, where provided)

Contact the Fiat Dealership to have the

fog lights checked and properly adjusted.

REGULATING THE BEAMS

ABROAD

Dipped beams factory adjustment depends

on the country where the vehicle is pur-

chased. In countries driving on the left, the

beams are aimed by affixing a purposeful-

ly studied adhesive film in order not to

dazzle the vehicles travelling in the oppo-

site direction. This adhesive film is pro-

vided in Lineaccessori Fiat and is available

at the Fiat Dealership. Headlight aiming device regulation

To adjust, press buttons Òand

fig. 100

on the control panel.

The display located on the instrument pan-

el provides a visual indication of the posi-

tions during adjustment operations.

Position 0 - one or two passengers on

front seats.

Position 1 - five passengers.

Position 2 - five passengers + loaded

boot.

Position 3 - driver + maximum admitted

cargo in the boot.

IMPORTANT Check beam aiming when-

ever the weight of the load carried

changes.

fig. 100F0T0037m

036-082 Fiorino GB 1ed:036-082 Fiorino GB 1ed 30-11-2009 15:47 Pagina 70

Page 107 of 210

106

SAFETY

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARDAND CONTROLS

STARTING

AND DRIVING

CONTAINING

RUNNING COSTS

Here are some useful tips to save fuel and

minimize polluting emissions of CO

2and

other pollutants (nitric oxide, unburnt hy-

drocarbons, fine dusts etc…).GENERAL REMARKS

Vehicle maintenance

Have checks and adjustments carried out

in accordance with the “Scheduled Service

Plan”.

Tyres

Check tyre pressure regularly at least

once every four weeks: excessively low

pressure will increase consumption be-

cause rolling resistance will be higher.

Unnecessary loads

Do not travel with an overloaded boot.

The weight of the vehicle (especially when

driving in town) and its trim greatly affect

fuel consumption and stability.

Roof rack/ski rack

Remove the roof rack or the ski rack from

the roof after use. These accessories de-

crease aerodynamic penetration of the ve-

hicle and have a negative effect on fuel

consumption. It is better to use a trailer

to transport particularly bulky objects.Electric devices

Use electric devices only for the amount

of time needed. The rear heated window,

additional headlights, windscreen wipers

and heater fan need a considerable

amount of energy, therefore increasing fu-

el consumption (up to +25% in the urban

cycle).

Climate control

The climate control system leads to high-

er fuel consumption (up to +20% on av-

erage): use air vents only when the ex-

ternal temperature allows it.

Spoilers

The use of non-certified spoilers may ad-

versely affect air drag and fuel consump-

tion levels.

101-110 Fiorino GB 1ed:101-110 Fiorino GB 1ed 30-11-2009 16:14 Pagina 106

Page 130 of 210

129

SAFETY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARDAND CONTROLS

STARTING

AND DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

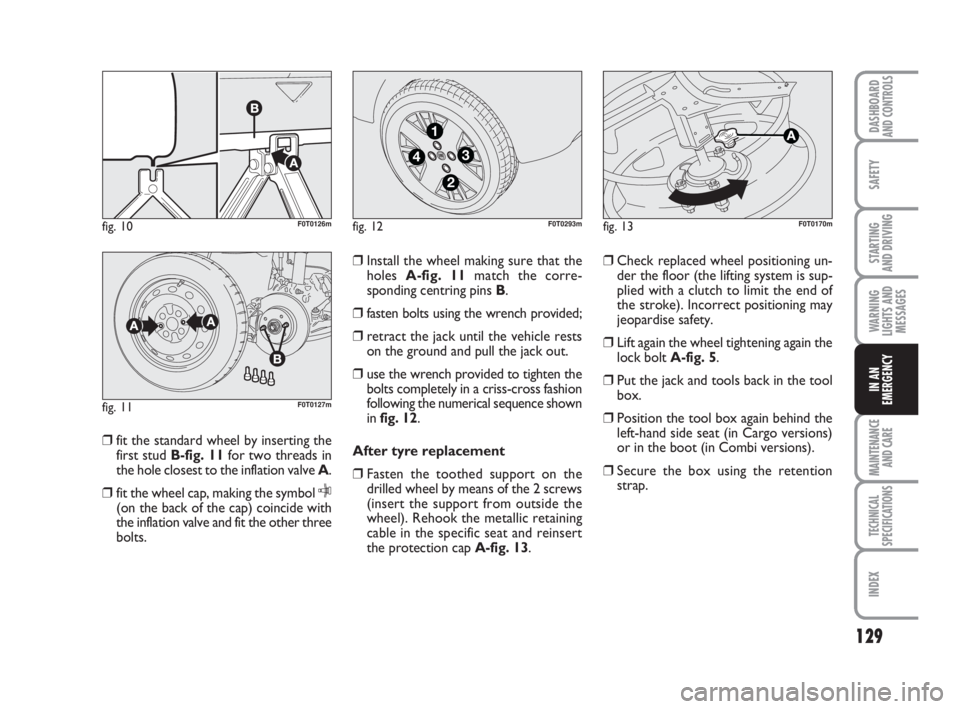

❒fit the standard wheel by inserting the

first stud B-fig. 11for two threads in

the hole closest to the inflation valve A.

❒fit the wheel cap, making the symbol

C(on the back of the cap) coincide with

the inflation valve and fit the other three

bolts.❒Install the wheel making sure that the

holes A-fig. 11match the corre-

sponding centring pins B.

❒fasten bolts using the wrench provided;

❒retract the jack until the vehicle rests

on the ground and pull the jack out.

❒use the wrench provided to tighten the

bolts completely in a criss-cross fashion

following the numerical sequence shown

in fig. 12.

After tyre replacement

❒Fasten the toothed support on the

drilled wheel by means of the 2 screws

(insert the support from outside the

wheel). Rehook the metallic retaining

cable in the specific seat and reinsert

the protection cap A-fig. 13.❒Check replaced wheel positioning un-

der the floor (the lifting system is sup-

plied with a clutch to limit the end of

the stroke). Incorrect positioning may

jeopardise safety.

❒Lift again the wheel tightening again the

lock boltA-fig. 5.

❒Put the jack and tools back in the tool

box.

❒Position the tool box again behind the

left-hand side seat (in Cargo versions)

or in the boot (in Combi versions).

❒Secure the box using the retention

strap.

fig. 10F0T0126m

fig. 11F0T0127m

fig. 12

4

1

3

2

F0T0293mfig. 13F0T0170m

123-154 Fiorino GB 1ed:123-154 Fiorino GB 1ed 3-12-2009 15:33 Pagina 129

Page 131 of 210

130

SAFETY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARDAND CONTROLS

STARTING

AND DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

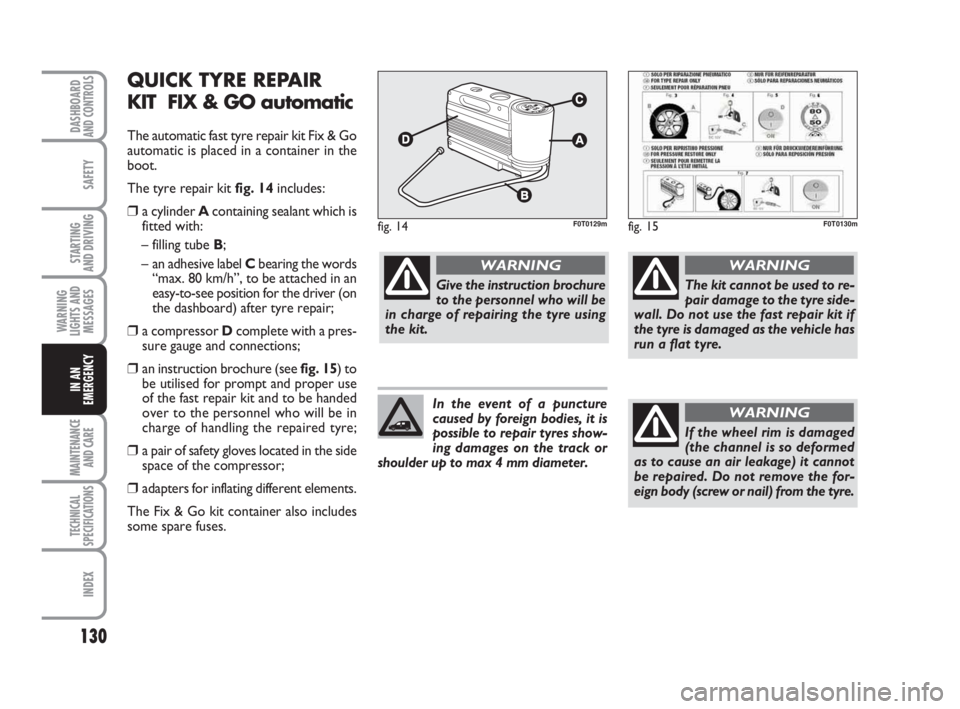

QUICK TYRE REPAIR

KIT FIX & GO automatic

The automatic fast tyre repair kit Fix & Go

automatic is placed in a container in the

boot.

The tyre repair kit fig. 14includes:

❒a cylinder A containing sealant which is

fitted with:

– filling tube B;

– an adhesive label Cbearing the words

“max. 80 km/h”, to be attached in an

easy-to-see position for the driver (on

the dashboard) after tyre repair;

❒a compressor Dcomplete with a pres-

sure gauge and connections;

❒an instruction brochure (see fig. 15) to

be utilised for prompt and proper use

of the fast repair kit and to be handed

over to the personnel who will be in

charge of handling the repaired tyre;

❒a pair of safety gloves located in the side

space of the compressor;

❒adapters for inflating different elements.

The Fix & Go kit container also includes

some spare fuses.

fig. 14F0T0129mfig. 15F0T0130m

Give the instruction brochure

to the personnel who will be

in charge of repairing the tyre using

the kit.

WARNING

The kit cannot be used to re-

pair damage to the tyre side-

wall. Do not use the fast repair kit if

the tyre is damaged as the vehicle has

run a flat tyre.

WARNING

If the wheel rim is damaged

(the channel is so deformed

as to cause an air leakage) it cannot

be repaired. Do not remove the for-

eign body (screw or nail) from the tyre.

WARNINGIn the event of a puncture

caused by foreign bodies, it is

possible to repair tyres show-

ing damages on the track or

shoulder up to max 4 mm diameter.

123-154 Fiorino GB 1ed:123-154 Fiorino GB 1ed 3-12-2009 15:33 Pagina 130