clock FIAT FREEMONT 2012 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2012, Model line: FREEMONT, Model: FIAT FREEMONT 2012Pages: 332, PDF Size: 5.61 MB

Page 242 of 332

The winch mechanism is designed for use

with the jack-handle only. Use of an air

wrench or other power tools is not rec-

ommended and it can damage the winch.

3. Pull the spare tire out from underneath the vehicle and raise it upright so the tire's tread is on the

ground.

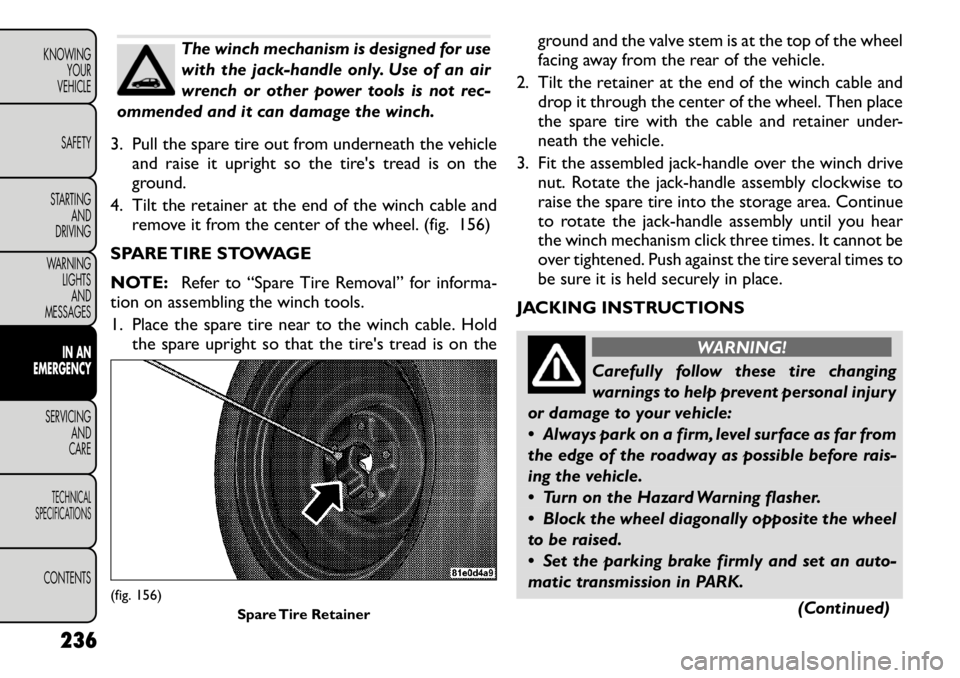

4. Tilt the retainer at the end of the winch cable and remove it from the center of the wheel. (fig. 156)

SPARE TIRE STOWAGE

NOTE: Refer to “Spare Tire Removal” for informa-

tion on assembling the winch tools.

1. Place the spare tire near to the winch cable. Hold

the spare upright so that the tire's tread is on the ground and the valve stem is at the top of the wheel

facing away from the rear of the vehicle.

2. Tilt the retainer at the end of the winch cable and drop it through the center of the wheel. Then place

the spare tire with the cable and retainer under-

neath the vehicle.

3. Fit the assembled jack-handle over the winch drive nut. Rotate the jack-handle assembly clockwise to

raise the spare tire into the storage area. Continue

to rotate the jack-handle assembly until you hear

the winch mechanism click three times. It cannot be

over tightened. Push against the tire several times to

be sure it is held securely in place.

JACKING INSTRUCTIONS

WARNING!

Carefully follow these tire changing

warnings to help prevent personal injury

or damage to your vehicle:

Always park on a firm, level surface as far from

the edge of the roadway as possible before rais-

ing the vehicle.

Turn on the Hazard Warning flasher.

Block the wheel diagonally opposite the wheel

to be raised.

Set the parking brake firmly and set an auto-

matic transmission in PARK.

(Continued)

(fig. 156)Spare Tire Retainer

236

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 243 of 332

(Continued)

Never start or run the engine with the vehicle

on a jack.

Do not let anyone sit in the vehicle when it is on

a jack.

Do not get under the vehicle when it is on a

jack.

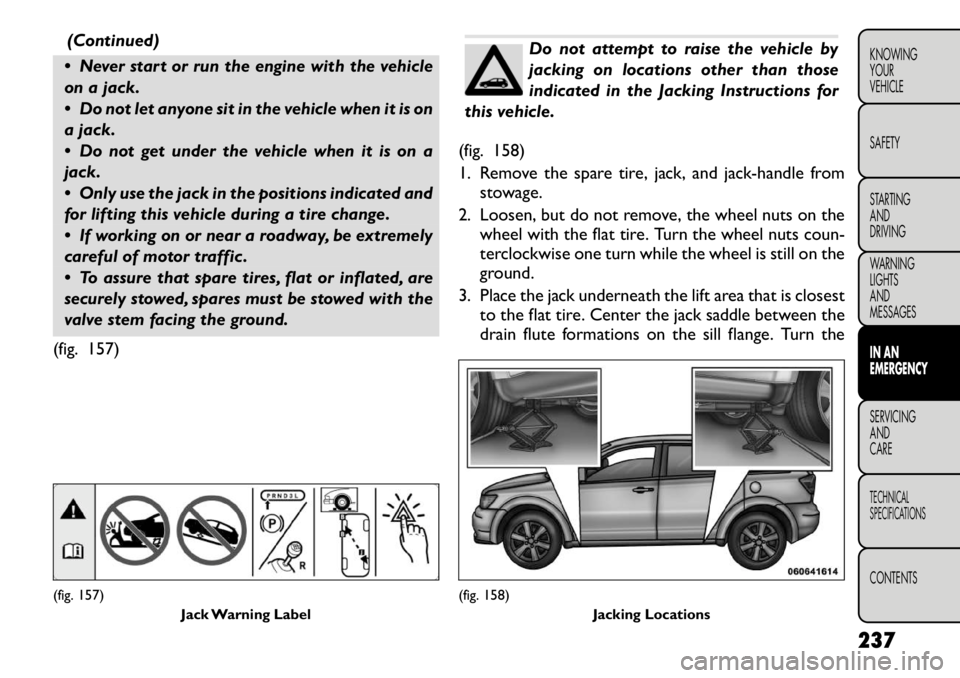

Only use the jack in the positions indicated and

for lifting this vehicle during a tire change.

If working on or near a roadway, be extremely

careful of motor traffic .

To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with the

valve stem facing the ground.

(fig. 157)

Do not attempt to raise the vehicle by

jacking on locations other than those

indicated in the Jacking Instructions for

this vehicle.

(fig. 158)

1. Remove the spare tire, jack, and jack-handle from stowage.

2. Loosen, but do not remove, the wheel nuts on the wheel with the flat tire. Turn the wheel nuts coun-

terclockwise one turn while the wheel is still on the

ground.

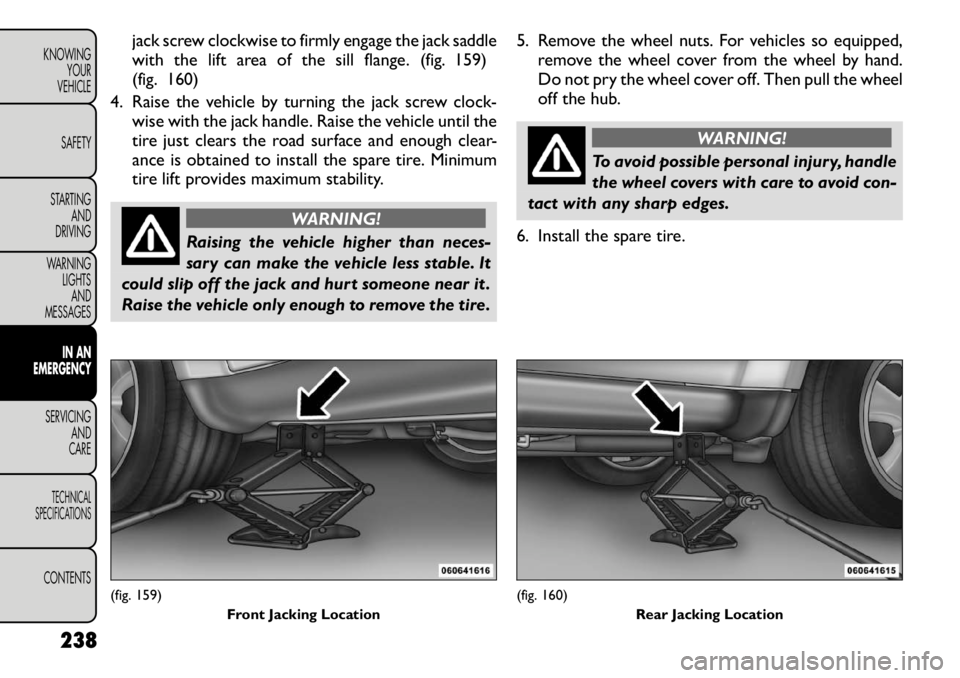

3. Place the jack underneath the lift area that is closest to the flat tire. Center the jack saddle between the

drain flute formations on the sill flange. Turn the

(fig. 157)

Jack Warning Label

(fig. 158) Jacking Locations

237

KNOWING

YOURVEHICLE SAFETY

STARTING ANDDRIVING

WARNING LIGHTSAND

MESSAGESIN AN

EMERGENCYSERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 244 of 332

jack screw clockwise to firmly engage the jack saddle

with the lift area of the sill flange. (fig. 159)

(fig. 160)

4. Raise the vehicle by turning the jack screw clock- wise with the jack handle. Raise the vehicle until the

tire just clears the road surface and enough clear-

ance is obtained to install the spare tire. Minimum

tire lift provides maximum stability.

WARNING!

Raising the vehicle higher than neces-

sary can make the vehicle less stable. It

could slip off the jack and hurt someone near it .

Raise the vehicle only enough to remove the tire. 5. Remove the wheel nuts. For vehicles so equipped,

remove the wheel cover from the wheel by hand.

Do not pry the wheel cover off. Then pull the wheel

off the hub.

WARNING!

To avoid possible personal injury, handle

the wheel covers with care to avoid con-

tact with any sharp edges.

6. Install the spare tire.

(fig. 159) Front Jacking Location

(fig. 160) Rear Jacking Location

238

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 245 of 332

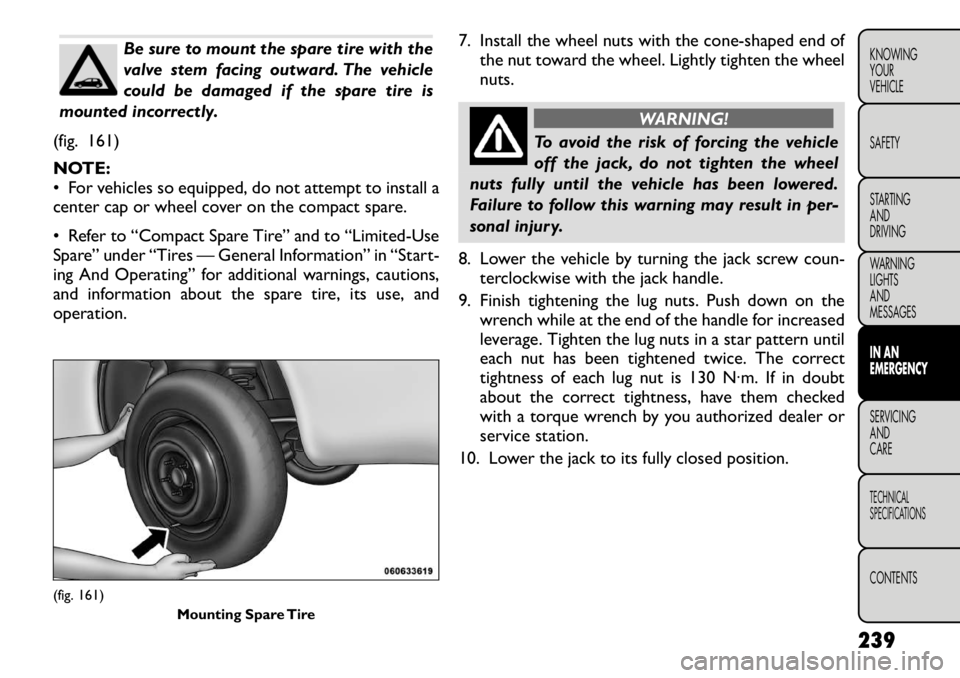

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.

(fig. 161)

NOTE:

• For vehicles so equipped, do not attempt to install a

center cap or wheel cover on the compact spare.

• Refer to “Compact Spare Tire” and to “Limited-Use

Spare” under “Tires — General Information” in “Start-

ing And Operating” for additional warnings, cautions,

and information about the spare tire, its use, andoperation. 7. Install the wheel nuts with the cone-shaped end of

the nut toward the wheel. Lightly tighten the wheel

nuts.

WARNING!

To avoid the risk of forcing the vehicle

off the jack, do not tighten the wheel

nuts fully until the vehicle has been lowered.

Failure to follow this warning may result in per-

sonal injury.

8. Lower the vehicle by turning the jack screw coun- terclockwise with the jack handle.

9. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. The correct

tightness of each lug nut is 130 N

Page 246 of 332

WARNING!

A loose tire or jack, thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places provided.

Have the deflated (flat) tire repaired or replaced

immediately.

11. Place the deflated (flat) tire in the cargo area. Do

not stow the deflated tire in the spare tire

stowage location. Have the deflated (flat) tire

repaired or replaced as soon as possible.

12. To stow the winch cable and retainer, fit the assembled jack-handle over the winch drive nut.

Rotate the jack-handle assembly clockwise until

you hear the winch mechanism click three times. It

cannot be over tightened.

13. Stow the jack-handle and jack.

14. Check the tire pressure as soon as possible. Adjust the tire pressure as required.

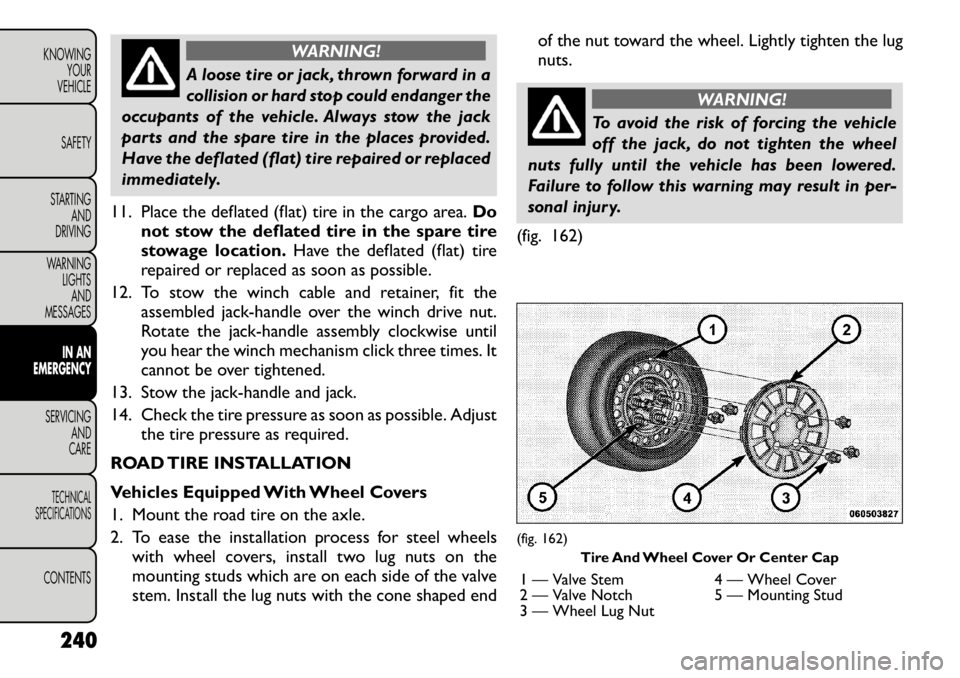

ROAD TIRE INSTALLATION

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lug nuts on the

mounting studs which are on each side of the valve

stem. Install the lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the lug

nuts.

WARNING!

To avoid the risk of forcing the vehicle

off the jack, do not tighten the wheel

nuts fully until the vehicle has been lowered.

Failure to follow this warning may result in per-

sonal injury.

(fig. 162)

(fig. 162) Tire And Wheel Cover Or Center Cap

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Mounting Stud

3 — Wheel Lug Nut

240

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 247 of 332

3. Align the valve notch in the wheel cover with thevalve stem on the wheel. Install the cover by hand,

snapping the cover over the two lug nuts. Do not

use a hammer or excessive force to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the

lug nuts.

WARNING!

To avoid the risk of forcing the vehicle

off the jack, do not tighten the wheel

nuts fully until the vehicle has been lowered.

Failure to follow this warning may result in per-

sonal injury.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. The correct

tightness of each lug nut is 130 N

Page 255 of 332

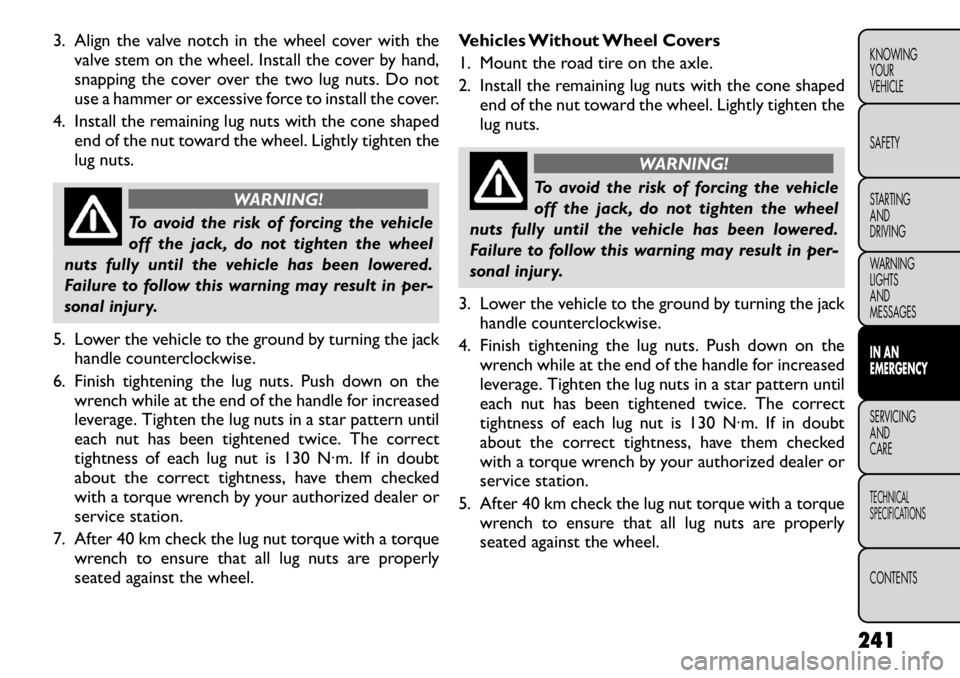

BULB REPLACEMENT

LOW BEAM/HIGH BEAM/FRONT TURN

SIGNAL AND FRONT POSITION LAMP

1. Open the hood.

NOTE:It may be necessary to remove the air cleaner

filter housing and position the Totally Integrated Power

Module (TIPM) aside to replace certain lamps in the left

headlamp housing.

2. Rotate the applicable bulb and connector assembly

1∕4turn counterclockwise and remove the assembly

from the headlamp housing. (fig. 165) 3. Disconnect the bulb from the harness connector

and then connect the replacement bulb.

Do not touch the new bulb with your

fingers. Oil contamination will severely

shorten bulb life. If the bulb comes in

contact with any oily surface, clean the bulb with

rubbing alcohol.

4. Install the bulb and connector assembly into the headlamp housing and rotate it

1∕4turn clockwise to

lock it in place.

FRONT FOG LAMP

NOTE: Turn the steering wheel to the right if replac-

ing the left front fog lamp or to the left if replacing the

right front fog lamp to allow for easier access to the

front of the wheel well.

1. Remove the fasteners retaining the front lower wheel well access panel and remove the access panel.

2. Remove the electrical connector from the fog lamp housing. (fig. 166)

3. Firmly grasp the bulb by the two side latches and squeeze them together to unlock the bulb from the

back of the front fog lamp housing.

4. Pull the bulb straight out from the keyed opening in the housing.

(fig. 165)

1 — Front Turn Signal Lamp Bulb

2 — Low Beam Headlamp Bulb

3 — Front Position Bulb

4 — High Beam Headlamp Bulb

249

KNOWING

YOURVEHICLE SAFETY

STARTING ANDDRIVING

WARNING LIGHTSAND

MESSAGESIN AN

EMERGENCYSERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 258 of 332

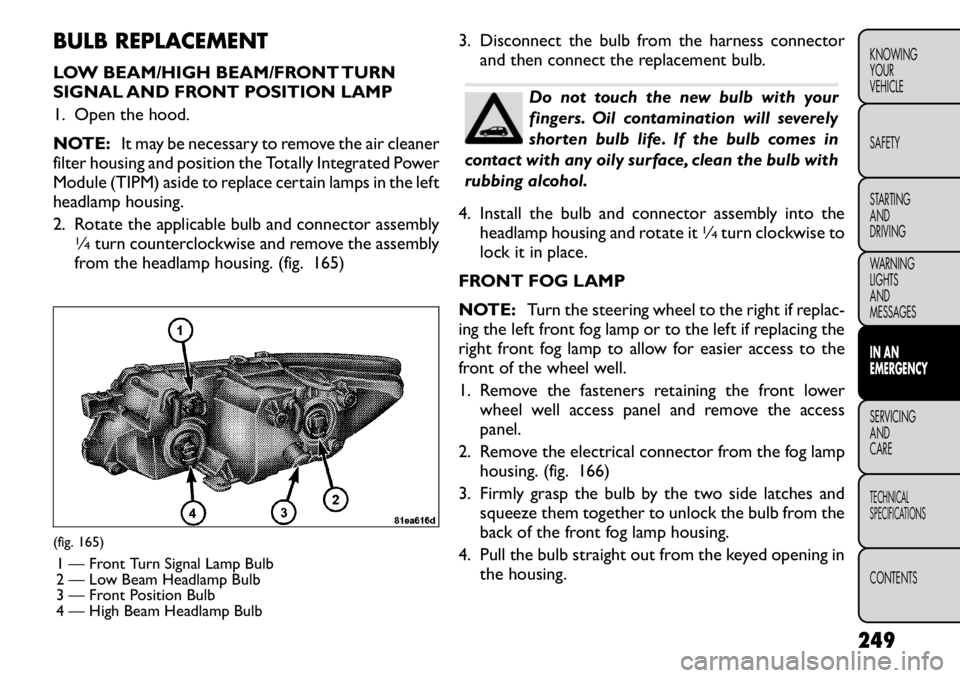

2. Remove the two fasteners from the inboard side ofthe taillamp housing. (fig. 170)

3. Carefully insert a trim stick (plastic flat-blade tool) between the body panel and the outboard side of

the taillamp housing with one hand and grasp the

flange on the inboard side of the taillamp housing

with the other hand. Use the trim stick and hand

pressure together to disengage the taillamp housing

from the vehicle.

4. Rotate the applicable bulb's electrical connector

1∕4

turn counterclockwise and remove it from the tail-

lamp housing.

5. Remove the bulb from the connector socket and install the replacement bulb.

6. Install the bulb and connector assembly into the taillamp housing and rotate the connector

1∕4turn

clockwise to lock it in place. 7. Reinstall the taillamp housing and fasteners.

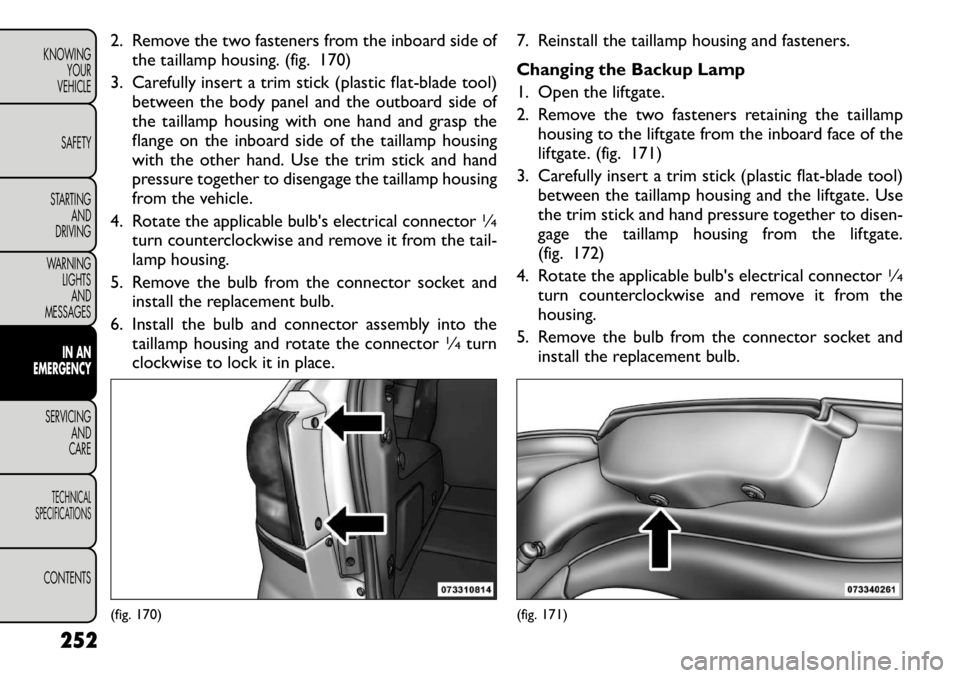

Changing the Backup Lamp

1. Open the liftgate.

2. Remove the two fasteners retaining the taillamp

housing to the liftgate from the inboard face of the

liftgate. (fig. 171)

3. Carefully insert a trim stick (plastic flat-blade tool) between the taillamp housing and the liftgate. Use

the trim stick and hand pressure together to disen-

gage the taillamp housing from the liftgate.

(fig. 172)

4. Rotate the applicable bulb's electrical connector

1∕4

turn counterclockwise and remove it from thehousing.

5. Remove the bulb from the connector socket and install the replacement bulb.

(fig. 170)

(fig. 171)

252

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 259 of 332

6. Install the bulb and connector assembly into thehousing and rotate the connector

1∕4turn clockwise

to lock it in place.

7. Reinstall the taillamp housing and fasteners.

LICENSE PLATE LAMP

1. Push the small locking tab sticking out of the end of the lens toward the side of the vehicle and hold it in

that position.

2. Insert a small flat-blade tool between the end of the lens with the locking tab and the surrounding hous-

ing and then pivot the tool to separate the lens from

the housing.

3. Hold the lens with one hand and rotate the bulb's electrical connector

1∕4turn counterclockwise with

the other hand and then separate the bulb and

connector assembly from the lens. 4. Remove the bulb from the connector socket and

install the replacement bulb.

5. Install the bulb and connector assembly into the lens and rotate the connector

1∕4turn clockwise to

lock it in place.

6. Insert the end of the lens without the locking tab into the housing on the liftgate and then push the

opposite end of the lens into the housing, making

sure it locks in the housing.

(fig. 172)

253

KNOWING

YOURVEHICLE SAFETY

STARTING ANDDRIVING

WARNING LIGHTSAND

MESSAGESIN AN

EMERGENCYSERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS