brake FIAT IDEA 2008 1.G Owner's Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2008, Model line: IDEA, Model: FIAT IDEA 2008 1.GPages: 210, PDF Size: 3.64 MB

Page 161 of 210

160

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

TOW RING HOOKING

Proceed as follows:

❒take the tow ring Bfrom its support;

❒tighten the ring on the rear fig. 48 or

front threaded pin fig. 49.

fig. 48F0H0204mfig. 49F0H0205m

Before starting to tow, turn

the ignition key to MAR and

then to STOP. Do not remove the

key. If the key is removed, the steer-

ing lock engages automatically which

prevents the wheels being turned.

WARNING

While the car is being towed

with the engine off, remem-

ber that the brake pedal and steering

will require more effort as you no

longer have the benefit of the brake

booster and the electrical power

steering. Do not use flexible cables to

tow. Avoid jerking. Whilst towing, en-

sure that the coupling to the car does

not damage the surrounding compo-

nents. When towing the car, you must

comply with the specific traffic reg-

ulations regarding the tow hitch and

how to tow on the road.

WARNING

Do not start the engine

when towing the car.

WARNING

133-160 idea GB 1 ed 10-07-2008 8:30 Pagina 160

Page 164 of 210

163

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

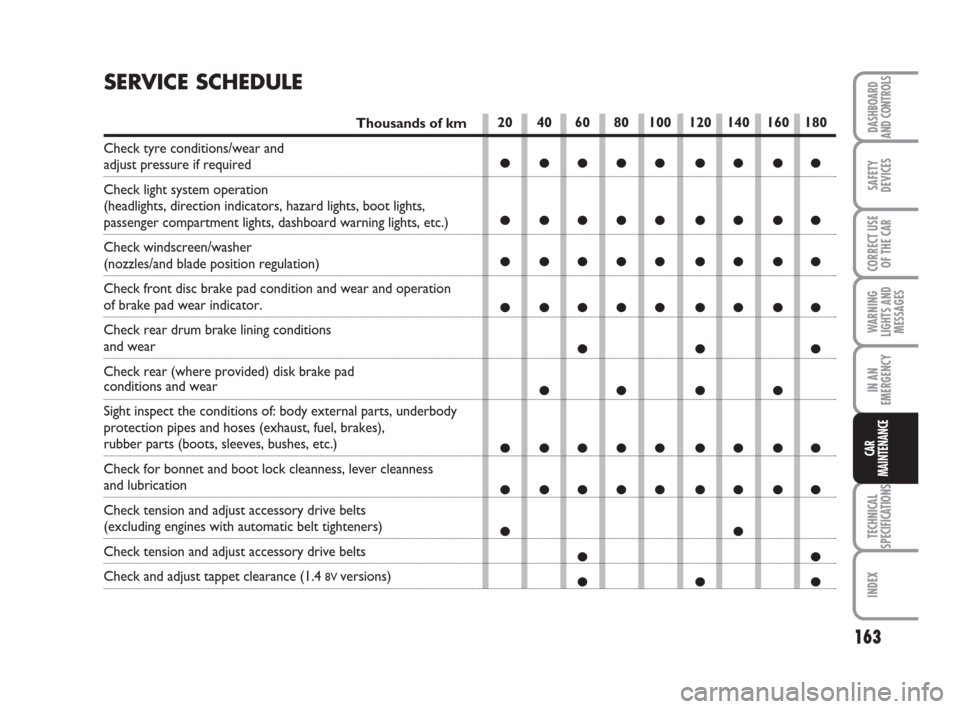

SERVICE SCHEDULE

Thousands of km

Check tyre conditions/wear and

adjust pressure if required

Check light system operation

(headlights, direction indicators, hazard lights, boot lights,

passenger compartment lights, dashboard warning lights, etc.)

Check windscreen/washer

(nozzles/and blade position regulation)

Check front disc brake pad condition and wear and operation

of brake pad wear indicator.

Check rear drum brake lining conditions

and wear

Check rear (where provided) disk brake pad

conditions and wear

Sight inspect the conditions of: body external parts, underbody

protection pipes and hoses (exhaust, fuel, brakes),

rubber parts (boots, sleeves, bushes, etc.)

Check for bonnet and boot lock cleanness, lever cleanness

and lubrication

Check tension and adjust accessory drive belts

(excluding engines with automatic belt tighteners)

Check tension and adjust accessory drive belts

Check and adjust tappet clearance (1.4 8V versions)

20 40 60 80 100 120 140 160 180

●●●●● ●●●●

●●●●● ●●●●

●●●●● ●●●●

●●●●● ●●●●

●●●

●● ● ●

●●●●● ●●●●

●●●●● ●●●●

●●

●●

●●●

161-180 idea GB 1 ed 10-07-2008 8:30 Pagina 163

Page 165 of 210

164

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

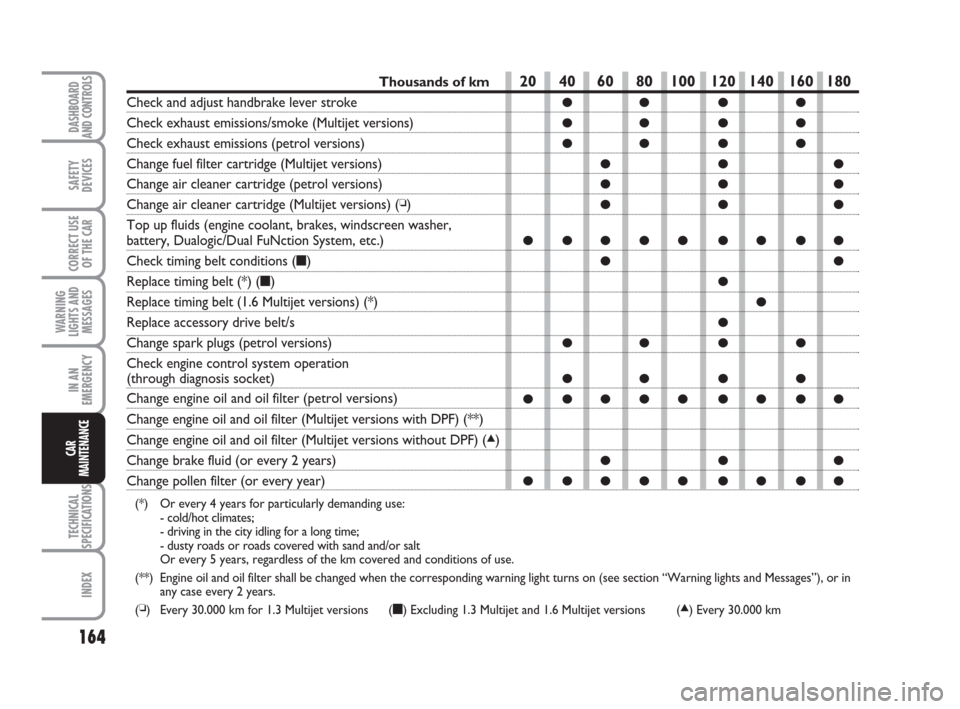

Thousands of km

Check and adjust handbrake lever stroke

Check exhaust emissions/smoke (Multijet versions)

Check exhaust emissions (petrol versions)

Change fuel filter cartridge (Multijet versions)

Change air cleaner cartridge (petrol versions)

Change air cleaner cartridge (Multijet versions) (❏)

Top up fluids (engine coolant, brakes, windscreen washer,

battery, Dualogic/Dual FuNction System, etc.)

Check timing belt conditions (■)

Replace timing belt (*) (■)

Replace timing belt (1.6 Multijet versions) (*)

Replace accessory drive belt/s

Change spark plugs (petrol versions)

Check engine control system operation

(through diagnosis socket)

Change engine oil and oil filter (petrol versions)

Change engine oil and oil filter (Multijet versions with DPF) (**)

Change engine oil and oil filter (Multijet versions without DPF) (▲)

Change brake fluid (or every 2 years)

Change pollen filter (or every year)

(*) Or every 4 years for particularly demanding use:

- cold/hot climates;

- driving in the city idling for a long time;

- dusty roads or roads covered with sand and/or salt

Or every 5 years, regardless of the km covered and conditions of use.

(**) Engine oil and oil filter shall be changed when the corresponding warning light turns on (see section “Warning lights and Messages”), or in

any case every 2 years.

(

❏) Every 30.000 km for 1.3 Multijet versions (■) Excluding 1.3 Multijet and 1.6 Multijet versions (▲) Every 30.000 km

20 40 60 80 100 120 140 160 180

●● ● ●

●● ● ●

●● ● ●

●●●

●●●

●●●

●●●●● ●●●●

●●

●

●

●

●● ● ●

●● ● ●

●●●●● ●●●●

●●●

●●●●● ●●●●

161-180 idea GB 1 ed 10-07-2008 8:30 Pagina 164

Page 166 of 210

165

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

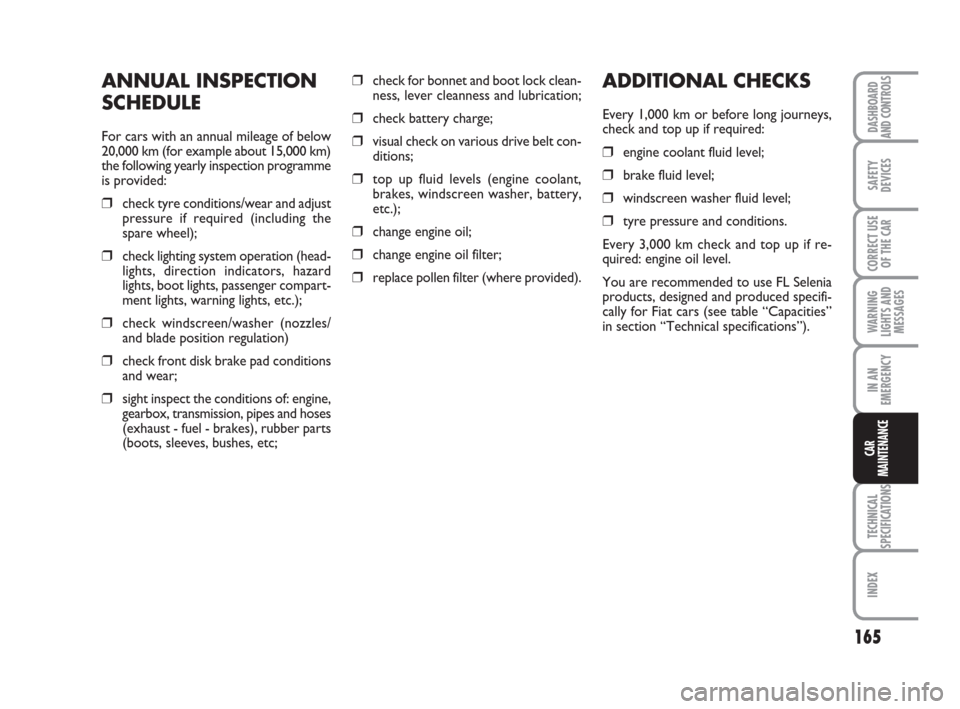

ANNUAL INSPECTION

SCHEDULE

For cars with an annual mileage of below

20,000 km (for example about 15,000 km)

the following yearly inspection programme

is provided:

❒check tyre conditions/wear and adjust

pressure if required (including the

spare wheel);

❒check lighting system operation (head-

lights, direction indicators, hazard

lights, boot lights, passenger compart-

ment lights, warning lights, etc.);

❒check windscreen/washer (nozzles/

and blade position regulation)

❒check front disk brake pad conditions

and wear;

❒sight inspect the conditions of: engine,

gearbox, transmission, pipes and hoses

(exhaust - fuel - brakes), rubber parts

(boots, sleeves, bushes, etc;

❒check for bonnet and boot lock clean-

ness, lever cleanness and lubrication;

❒check battery charge;

❒visual check on various drive belt con-

ditions;

❒top up fluid levels (engine coolant,

brakes, windscreen washer, battery,

etc.);

❒change engine oil;

❒change engine oil filter;

❒replace pollen filter (where provided).

ADDITIONAL CHECKS

Every 1,000 km or before long journeys,

check and top up if required:

❒engine coolant fluid level;

❒brake fluid level;

❒windscreen washer fluid level;

❒tyre pressure and conditions.

Every 3,000 km check and top up if re-

quired: engine oil level.

You are recommended to use FL Selenia

products, designed and produced specifi-

cally for Fiat cars (see table “Capacities”

in section “Technical specifications”).

161-180 idea GB 1 ed 10-07-2008 8:30 Pagina 165

Page 168 of 210

167

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

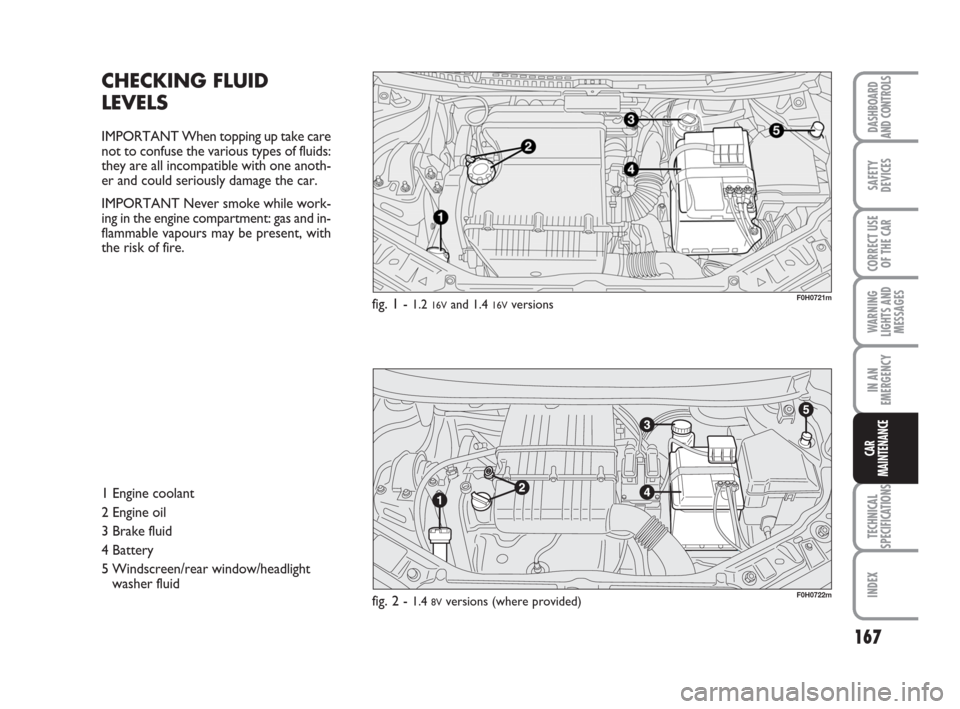

CHECKING FLUID

LEVELS

IMPORTANT When topping up take care

not to confuse the various types of fluids:

they are all incompatible with one anoth-

er and could seriously damage the car.

IMPORTANT Never smoke while work-

ing in the engine compartment: gas and in-

flammable vapours may be present, with

the risk of fire.

F0H0721mfig. 1 - 1.2 16Vand 1.4 16Vversions

F0H0722mfig. 2 - 1.4 8Vversions (where provided)

1 Engine coolant

2 Engine oil

3 Brake fluid

4 Battery

5 Windscreen/rear window/headlight

washer fluid

161-180 idea GB 1 ed 10-07-2008 8:30 Pagina 167

Page 169 of 210

168

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

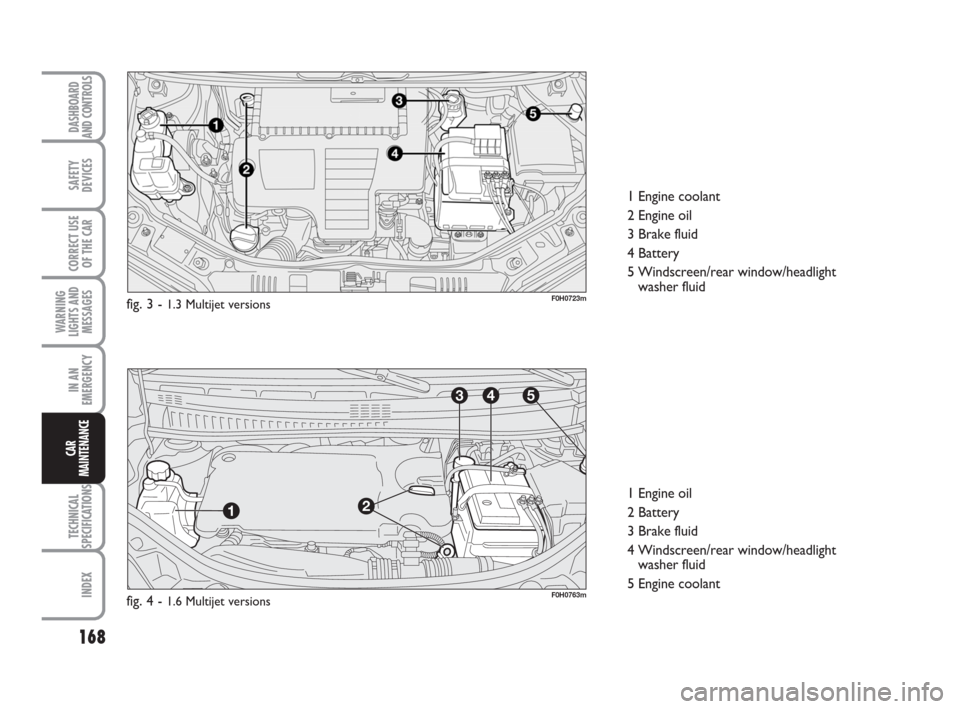

F0H0723mfig. 3 - 1.3 Multijet versions

3

12

45

F0H0763mfig. 4 - 1.6 Multijet versions

1 Engine coolant

2 Engine oil

3 Brake fluid

4 Battery

5 Windscreen/rear window/headlight

washer fluid

1 Engine oil

2 Battery

3 Brake fluid

4 Windscreen/rear window/headlight

washer fluid

5 Engine coolant

161-180 idea GB 1 ed 10-07-2008 8:30 Pagina 168

Page 173 of 210

172

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

BRAKE FLUID fig. 12

Unscrew cap: check that the fluid level in

the reservoir is at maximum.

Fluid level in the reservoir shall not exceed

the MAXmark.

If fluid has to be added, it is suggested to

use the brake fluid in table “Fluids and lu-

bricants” (see chapter “Technical charac-

teristics”).

NOTE Clean accurately the tank cap and

the surrounding surface.

At plug opening, pay maximum attention

in order to prevent any impurities from

entering the tank.

For topping up, always use a funnel with

integrated filter with mesh equal to or

lower than 0.12 mm.

IMPORTANT Brake fluid absorbs mois-

ture, for this reason, if the vehicle is main-

ly used in areas with a high degree of at-

mospheric humidity, the fluid should be

replaced at more frequent intervals than

specified in the “Service schedule”.

fig. 12F0H0213m

Brake fluid is poisonous and

highly corrosive. In the event

of accidental contact, wash the parts

involved immediately with neutral

soap and water, then rinse thor-

oughly. Call the doctor immediately

if the fluid is swallowed.

WARNING

Symbol πon the container

indicates synthetic brake flu-

id, distinguishing it from the mineral

kind. Using mineral fluids irreversibly

damages the special braking system

rubber seals.

WARNINGMake sure that the highly

corrosive brake fluid does not

drip onto the paintwork. If it

does, wash it off immediate-

ly with water.

161-180 idea GB 1 ed 10-07-2008 8:30 Pagina 172

Page 177 of 210

176

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

RUBBER HOSES

As far as the brake system and fuel rubber

hoses are concerned, carefully follow the

“Service schedule” in this section.

Indeed ozone, high temperatures and pro-

longed lack of fluid in the system may

cause hardening and cracking of the hoses,

with possible leaks. Careful control is

therefore necessary.

WINDSCREEN/

REAR WINDOW

WIPERS

BLADES

Periodically clean the rubber part using

special products; TUTELA PROFES-

SIONAL SC 35 is recommended.

If the rubber blades are bent or worn they

should be replaced. In any case they

should be changed once a year.

A few simple notions can reduce the pos-

sibility of damage to the blades:

❒if the temperature fall below zero,

make sure that ice has not frozen the

rubber against glass. If necessary, thaw

using an antifreeze product;

❒remove any snow from the glass: in ad-

dition to protecting the blades, this

prevents effort on the motor and

overheating;

❒do not operate the windscreen and

rear window wipers on dry glass.

Driving with worn wiper

blades is a serious hazard,

because visibility is reduced in bad

weather.

WARNING

Changing the windscreen wiper

blades fig. 14

Proceed as follows:

❒raise the windscreen wiper arm Aand

position the blade so that it forms an

angle of 90° with the arm;

❒press tab Bof the coupling spring and

remove the blade to be replaced from

the arm A;

❒fit the new blade by inserting the tab

into the special slot in the arm. Make

sure it is properly locked into place.

161-180 idea GB 1 ed 10-07-2008 8:30 Pagina 176

Page 182 of 210

181

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

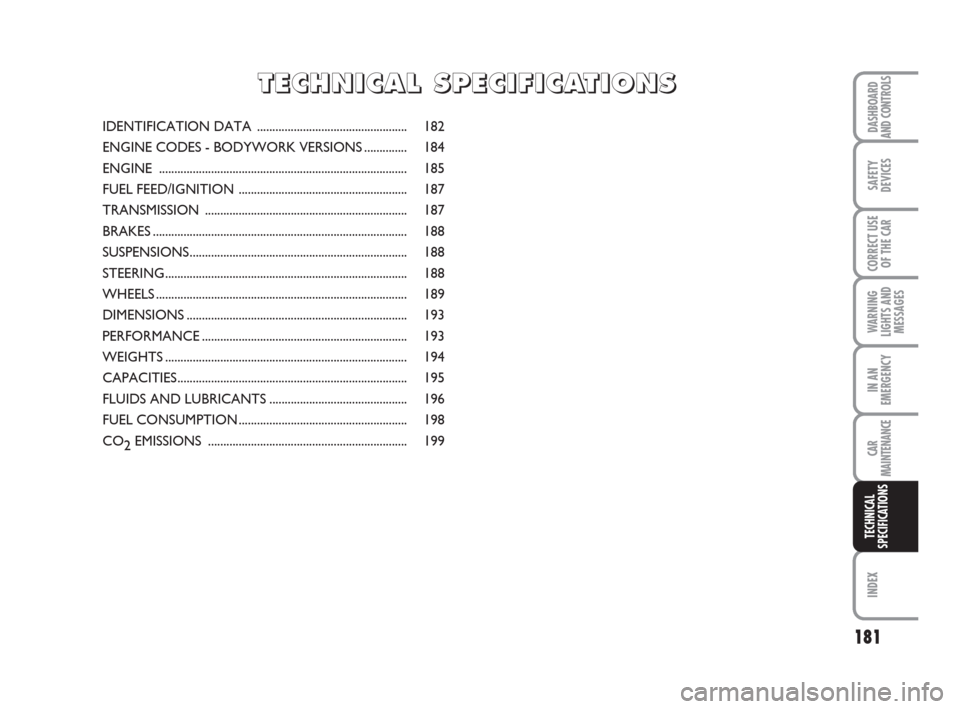

IDENTIFICATION DATA ................................................. 182

ENGINE CODES - BODYWORK VERSIONS .............. 184

ENGINE ................................................................................. 185

FUEL FEED/IGNITION ....................................................... 187

TRANSMISSION .................................................................. 187

BRAKES ................................................................................... 188

SUSPENSIONS ....................................................................... 188

STEERING............................................................................... 188

WHEELS .................................................................................. 189

DIMENSIONS ........................................................................ 193

PERFORMANCE ................................................................... 193

WEIGHTS ............................................................................... 194

CAPACITIES........................................................................... 195

FLUIDS AND LUBRICANTS ............................................. 196

FUEL CONSUMPTION ....................................................... 198

CO

2EMISSIONS ................................................................. 199

TT T

E E

C C

H H

N N

I I

C C

A A

L L

S S

P P

E E

C C

I I

F F

I I

C C

A A

T T

I I

O O

N N

S S

181-199 idea GB 1 ed 13-10-2008 12:12 Pagina 181

Page 189 of 210

188

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

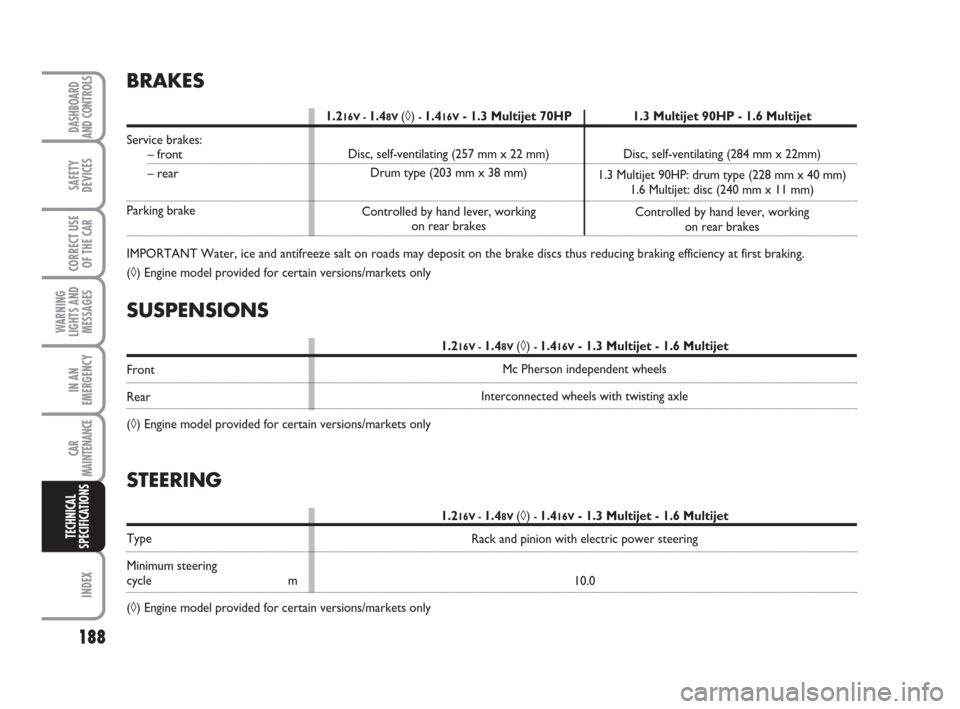

SUSPENSIONS

Front

Rear

(◊) Engine model provided for certain versions/markets only1.2

16V - 1.48V (◊) - 1.416V- 1.3 Multijet - 1.6 Multijet

Mc Pherson independent wheels

Interconnected wheels with twisting axle

STEERING

Type

Minimum steering

cycle m

(◊) Engine model provided for certain versions/markets only1.2

16V - 1.48V (◊) - 1.416V- 1.3 Multijet - 1.6 Multijet

Rack and pinion with electric power steering

10.0

BRAKES

Service brakes:– front

– rear

Parking brake

IMPORTANT Water, ice and antifreeze salt on roads may deposit on the brake discs thus reducing braking efficiency at first braking.

(◊) Engine model provided for certain versions/markets only1.2

16V - 1.48V (◊) - 1.416V- 1.3 Multijet 70HP

Disc, self-ventilating (257 mm x 22 mm)

Drum type (203 mm x 38 mm)

Controlled by hand lever, working

on rear brakes1.3 Multijet 90HP - 1.6 Multijet

Disc, self-ventilating (284 mm x 22mm)

1.3 Multijet 90HP: drum type (228 mm x 40 mm)

1.6 Multijet: disc (240 mm x 11 mm)

Controlled by hand lever, working

on rear brakes

181-199 idea GB 1 ed 13-10-2008 12:12 Pagina 188