right side FIAT MAREA 2000 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2000, Model line: MAREA, Model: FIAT MAREA 2000 1.GPages: 330

Page 115 of 330

Marea-Marea Weekend

2000 range (j§)

1

4F029XJ02

Engine

Fuel feed system

10.

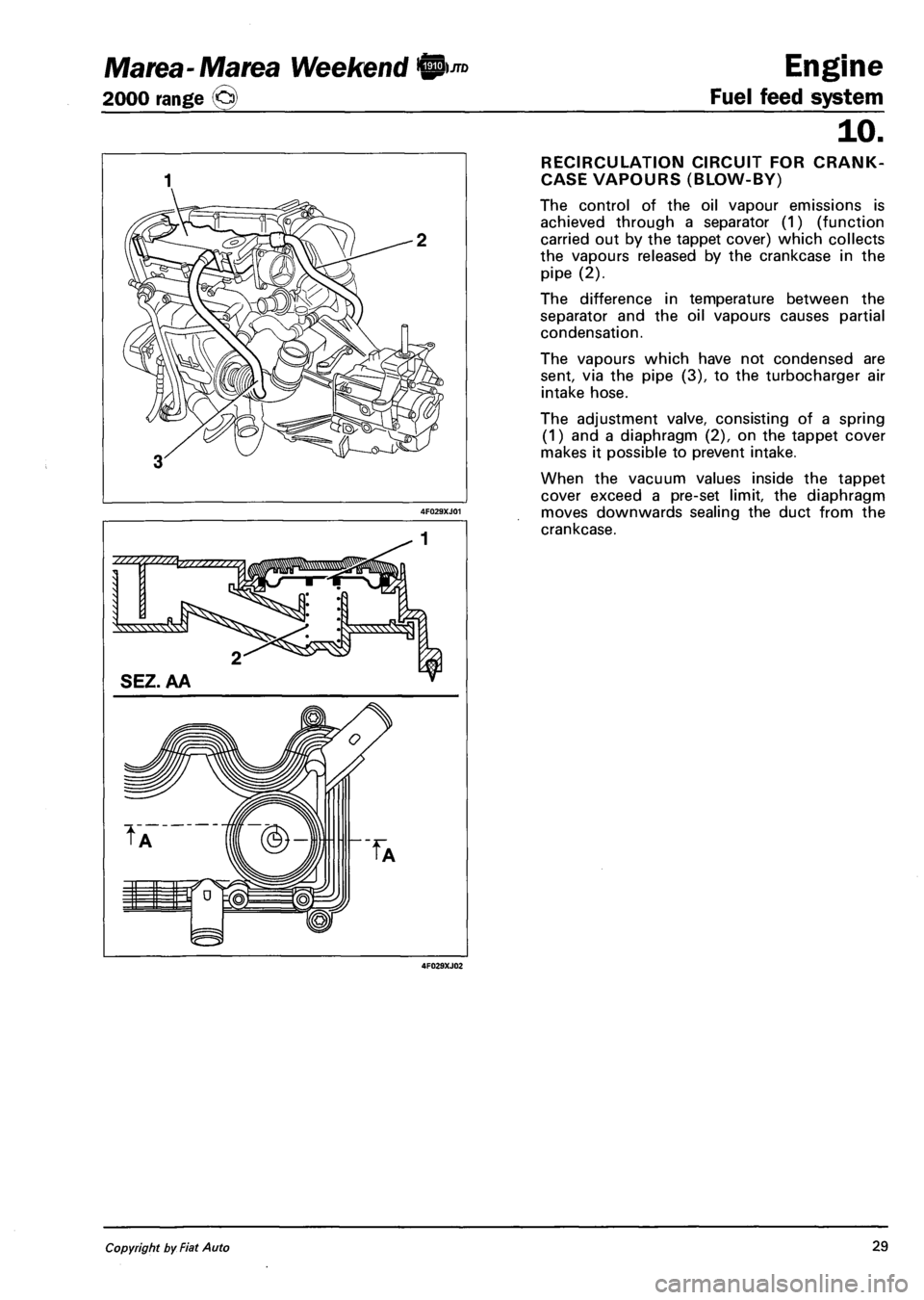

RECIRCULATION CIRCUIT FOR CRANK-

CASE VAPOURS (BLOW-BY)

The control of the oil vapour emissions is

achieved through a separator (1) (function

carried out by the tappet cover) which collects

the vapours released by the crankcase in the

pipe (2).

The difference in temperature between the

separator and the oil vapours causes partial

condensation.

The vapours which have not condensed are

sent, via the pipe (3), to the turbocharger air

intake hose.

The adjustment valve, consisting of a spring

(1) and a diaphragm (2), on the tappet cover

makes it possible to prevent intake.

When the vacuum values inside the tappet

cover exceed a pre-set limit, the diaphragm

moves downwards sealing the duct from the

crankcase.

Copyright by Fiat Auto 29

Page 123 of 330

Marea-Marea Weekend H nD Engine

2000 range (Q) Fuel feed system

10.

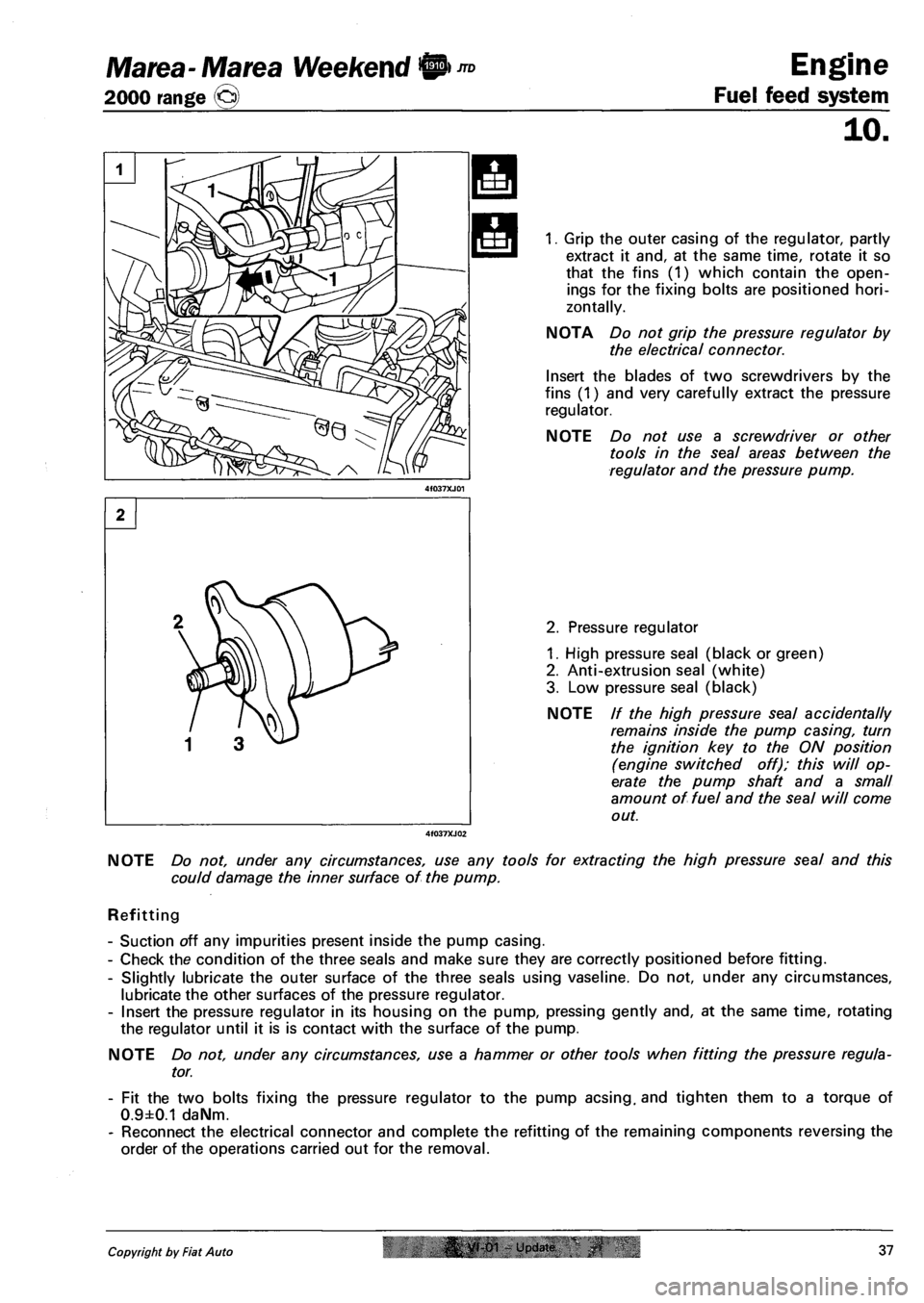

1. Grip the outer casing of the regulator, partly

extract it and, at the same time, rotate it so

that the fins (1) which contain the open

ings for the fixing bolts are positioned hori

zontally.

NOTA Do not grip the pressure regulator by

the electrical connector.

Insert the blades of two screwdrivers by the

fins (1) and very carefully extract the pressure

regulator.

NOTE Do not use a screwdriver or other

tools in the seal areas between the

regulator and the pressure pump.

2. Pressure regulator

1. High pressure seal (black or green)

2. Anti-extrusion seal (white)

3. Low pressure seal (black)

NOTE // the high pressure seal accidentally

remains inside the pump casing, turn

the ignition key to the ON position

(engine switched off); this will op

erate the pump shaft and a small

amount of fuel and the seal will come

out.

NOTE Do not, under any circumstances, use any tools for extracting the high pressure seal and this

could damage the inner surface of the pump.

Refitting

- Suction off any impurities present inside the pump casing.

- Check the condition of the three seals and make sure they are correctly positioned before fitting.

- Slightly lubricate the outer surface of the three seals using vaseline. Do not, under any circumstances,

lubricate the other surfaces of the pressure regulator.

- Insert the pressure regulator in its housing on the pump, pressing gently and, at the same time, rotating

the regulator until it is is contact with the surface of the pump.

NOTE Do not, under any circumstances, use a hammer or other tools when fitting the pressure regula

tor.

- Fit the two bolts fixing the pressure regulator to the pump acsing. and tighten them to a torque of

0.9±0.1 daNm.

- Reconnect the electrical connector and complete the refitting of the remaining components reversing the

order of the operations carried out for the removal.

Copyright by Fiat Auto |& yt-01 - Update 37

Page 126 of 330

Marea- Marea Weekend

2000 range ©

Auxiliary Units

Climate control

50

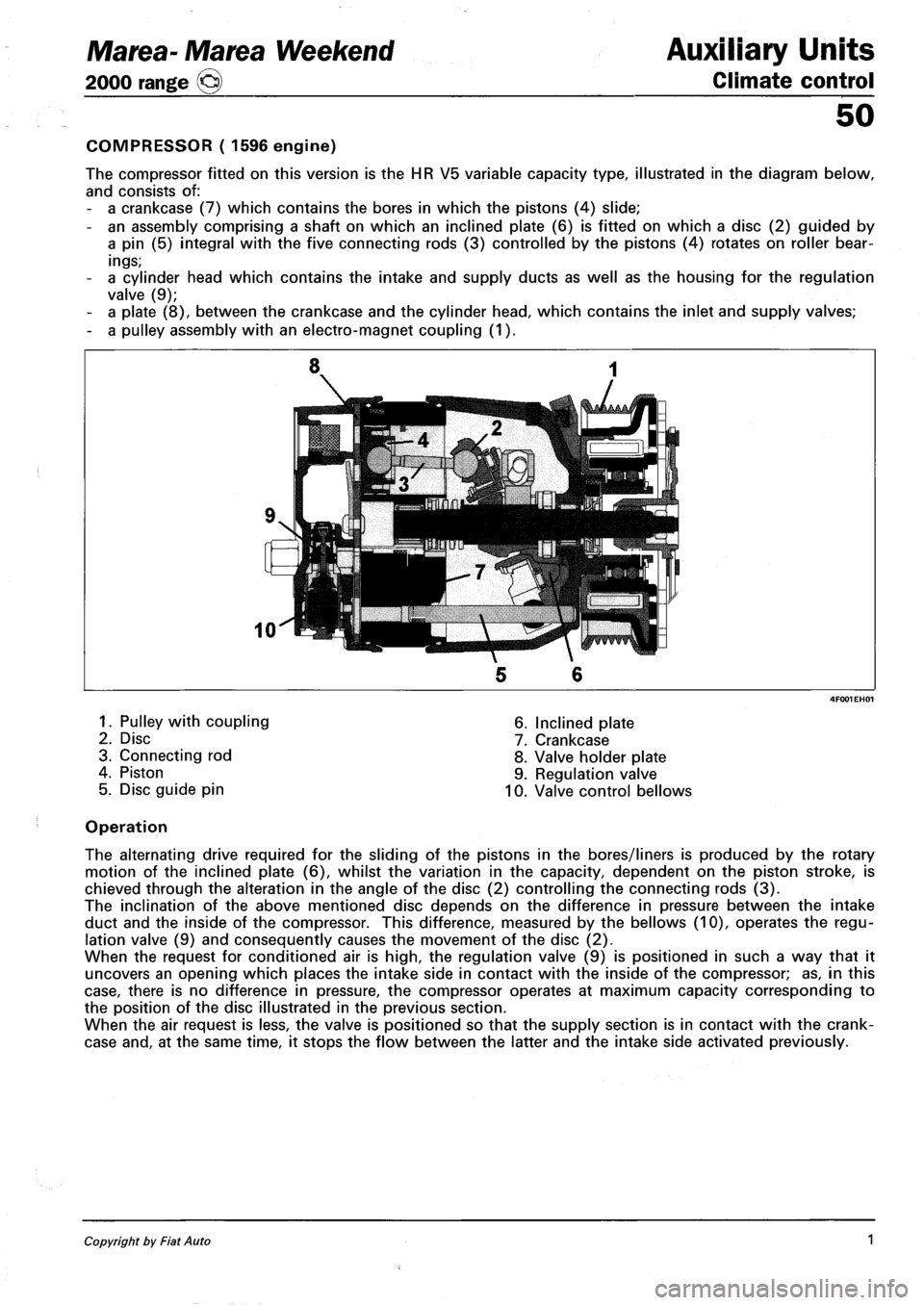

COMPRESSOR ( 1596 engine)

The compressor fitted on this version is the HR V5 variable capacity type, illustrated in the diagram below,

and consists of:

- a crankcase (7) which contains the bores in which the pistons (4) slide;

- an assembly comprising a shaft on which an inclined plate (6) is fitted on which a disc (2) guided by

a pin (5) integral with the five connecting rods (3) controlled by the pistons (4) rotates on roller bear

ings;

- a cylinder head which contains the intake and supply ducts as well as the housing for the regulation

valve (9);

- a plate (8), between the crankcase and the cylinder head, which contains the inlet and supply valves;

- a pulley assembly with an electro-magnet coupling (1).

1. Pulley with coupling

2. Disc

3. Connecting rod

4. Piston

5. Disc guide pin

6. Inclined plate

7. Crankcase

8. Valve holder plate

9. Regulation valve

10. Valve control bellows

Operation

The alternating drive required for the sliding of the pistons in the bores/liners is produced by the rotary

motion of the inclined plate (6), whilst the variation in the capacity, dependent on the piston stroke, is

chieved through the alteration in the angle of the disc (2) controlling the connecting rods (3).

The inclination of the above mentioned disc depends on the difference in pressure between the intake

duct and the inside of the compressor. This difference, measured by the bellows (10), operates the regu

lation valve (9) and consequently causes the movement of the disc (2).

When the request for conditioned air is high, the regulation valve (9) is positioned in such a way that it

uncovers an opening which places the intake side in contact with the inside of the compressor; as, in this

case, there is no difference in pressure, the compressor operates at maximum capacity corresponding to

the position of the disc illustrated in the previous section.

When the air request is less, the valve is positioned so that the supply section is in contact with the crank

case and, at the same time, it stops the flow between the latter and the intake side activated previously.

Copyright by Fiat Auto 1

Page 128 of 330

Marea-Marea Weekend

2000 range ©)

Auxiliary Units

Climate control

50

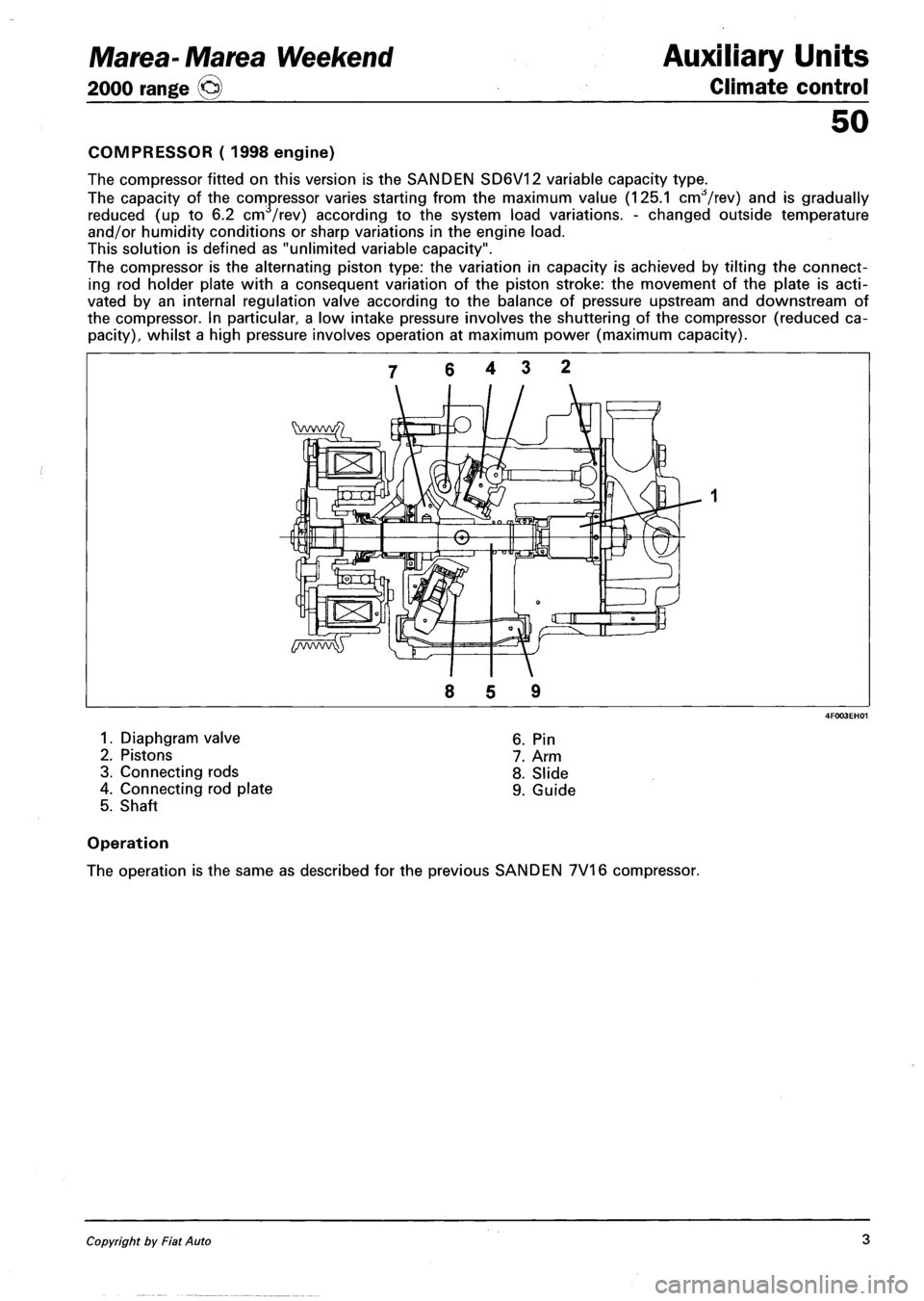

COMPRESSOR ( 1998 engine)

The compressor fitted on this version is the SANDEN SD6V12 variable capacity type.

The capacity of the compressor varies starting from the maximum value (125.1 cnrfVrev) and is gradually

reduced (up to 6.2 cm /rev) according to the system load variations. - changed outside temperature

and/or humidity conditions or sharp variations in the engine load.

This solution is defined as "unlimited variable capacity".

The compressor is the alternating piston type: the variation in capacity is achieved by tilting the connect

ing rod holder plate with a consequent variation of the piston stroke: the movement of the plate is acti

vated by an internal regulation valve according to the balance of pressure upstream and downstream of

the compressor. In particular a low intake pressure involves the shuttering of the compressor (reduced ca

pacity), whilst a high pressure involves operation at maximum power (maximum capacity).

1. Diaphgram valve

2. Pistons

3. Connecting rods

4. Connecting rod plate

5. Shaft

6. Pin

7. Arm

8. Slide

9. Guide

Operation

The operation is the same as described for the previous SANDEN 7V16 compressor.

Copyright by Fiat Auto 3

Page 131 of 330

Marea- Marea Weekend

2000 range ©

Electrical equipment

Protection and security devices

55.

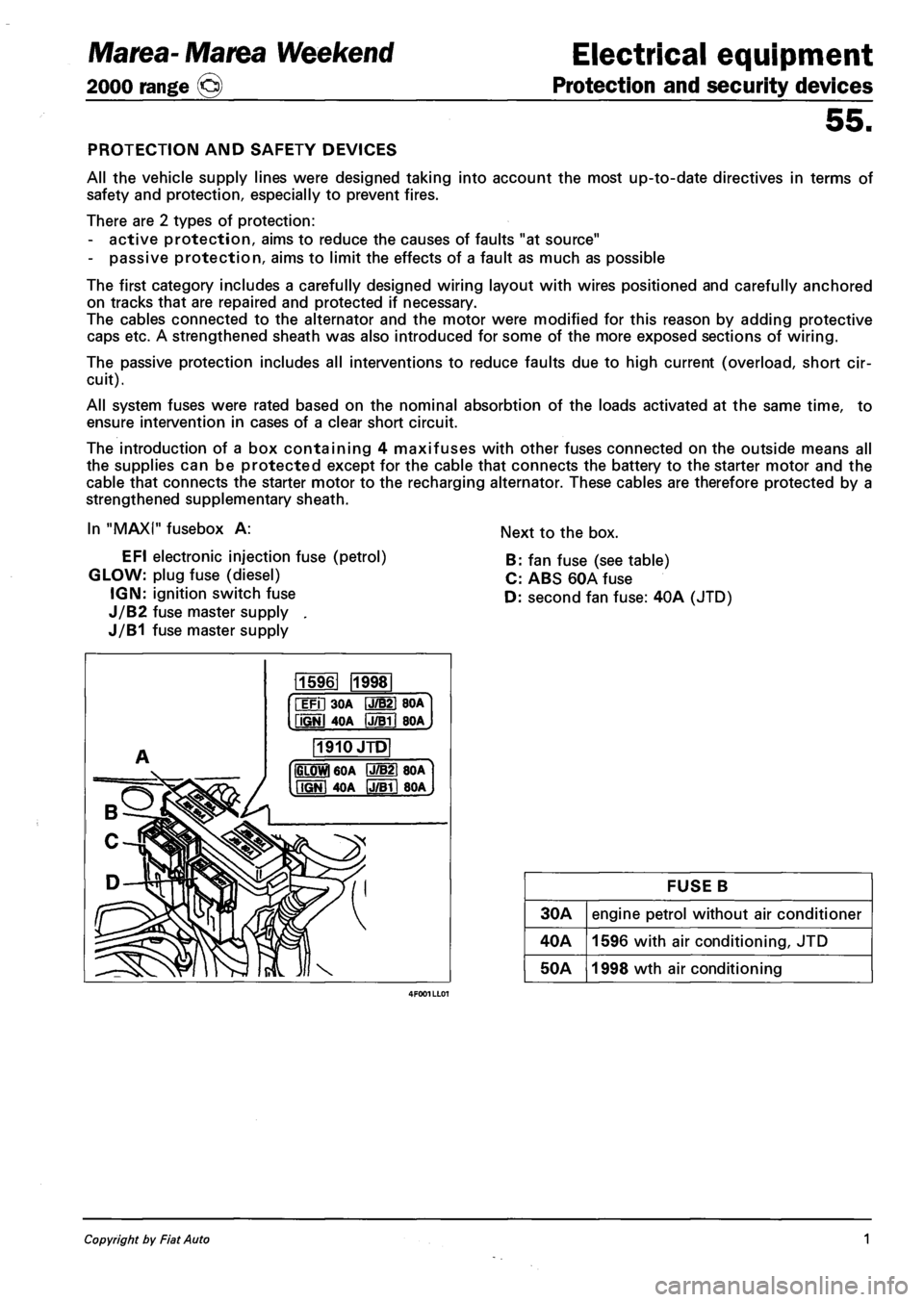

PROTECTION AND SAFETY DEVICES

All the vehicle supply lines were designed taking into account the most up-to-date directives in terms of

safety and protection, especially to prevent fires.

There are 2 types of protection:

- active protection, aims to reduce the causes of faults "at source"

- passive protection, aims to limit the effects of a fault as much as possible

The first category includes a carefully designed wiring layout with wires positioned and carefully anchored

on tracks that are repaired and protected if necessary.

The cables connected to the alternator and the motor were modified for this reason by adding protective

caps etc. A strengthened sheath was also introduced for some of the more exposed sections of wiring.

The passive protection includes all interventions to reduce faults due to high current (overload, short cir

cuit).

All system fuses were rated based on the nominal absorbtion of the loads activated at the same time, to

ensure intervention in cases of a clear short circuit.

The introduction of a box containing 4 maxifuses with other fuses connected on the outside means all

the supplies can be protected except for the cable that connects the battery to the starter motor and the

cable that connects the starter motor to the recharging alternator. These cables are therefore protected by a

strengthened supplementary sheath.

In "MAXI" fusebox A:

EFI electronic injection fuse (petrol)

GLOW: plug fuse (diesel)

IGN: ignition switch fuse

J/B2 fuse master supply .

J/B1 fuse master supply

Next to the box.

B: fan fuse (see table)

C: ABS 60A fuse

D: second fan fuse: 40A (JTD)

115961 1998

iFil 30A IJ/B21 BOA

fiGNl 4OA IJTBTI BOA

1910JTD

IGLOWl 60A P7B21 80A

MGNI 40A IJ/Bll 80A

FUSE B

30A engine petrol without air conditioner

40A 1596 with air conditioning, JTD

50A 1998 wth air conditioning

Copyright by Fiat Auto 1

Page 135 of 330

Marea-Marea Weekend

2000 range Q

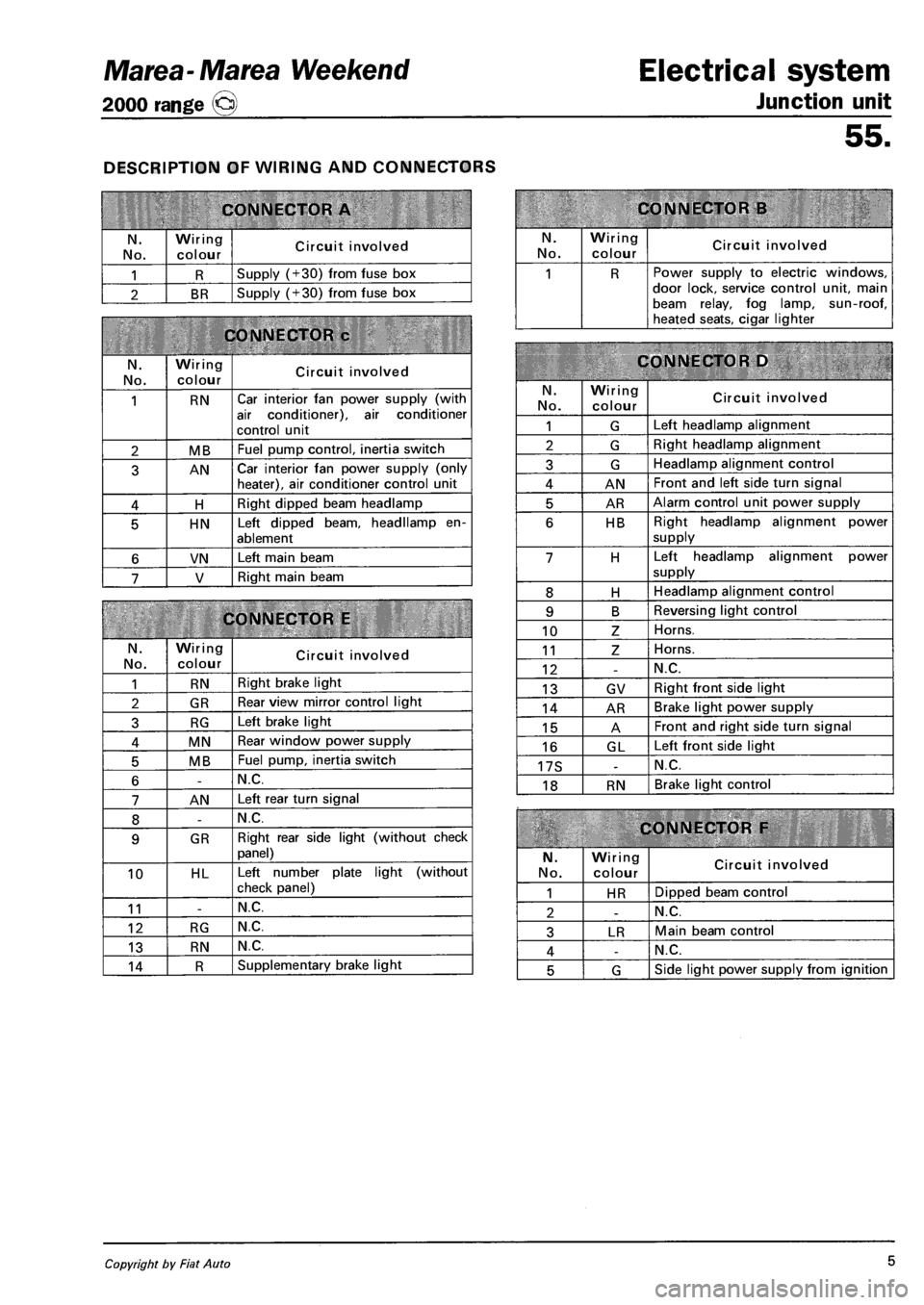

DESCRIPTION OF WIRING AND CONNECTORS

CONNECTOR A

N.

No.

Wiring

colour Circuit involved

1 R Supply (+30) from fuse box

2 BR Supply (+30) from fuse box

CONNECTOR c

N. No.

Wiring colour Circuit involved

1 RN Car interior fan power supply (with

air conditioner), air conditioner

control unit

2 MB Fuel pump control, inertia switch

3 AN Car interior fan power supply (only heater), air conditioner control unit

4 H Right dipped beam headlamp

5 HN Left dipped beam, headllamp en

ablement

6 VN Left main beam

7 V Right main beam

CONNECTOR E

N.

No.

Wiring colour Circuit involved

1 RN Right brake light

2 GR Rear view mirror control light

3 RG Left brake light

4 MN Rear window power supply

5 MB Fuel pump, inertia switch

6 -N.C.

7 AN Left rear turn signal

8 -N.C.

9 GR Right rear side light (without check

panel)

10 HL Left number plate light (without

check panel)

11 -N.C.

12 RG N.C.

13 RN N.C.

14 R Supplementary brake light

Electrical system

Junction unit

55.

CONNECTOR B

N. No.

Wiring

colour Circuit involved

1 R Power supply to electric windows, door lock, service control unit, main beam relay, fog lamp, sun-roof, heated seats, cigar lighter

CONNECTOR D

N.

No.

Wiring colour Circuit involved

1 G Left headlamp alignment

2 G Right headlamp alignment

3 G Headlamp alignment control

4 AN Front and left side turn signal

5 AR Alarm control unit power supply

6 HB Right headlamp alignment power

supply

7 H Left headlamp alignment power

supply

8 H Headlamp alignment control

9 B Reversing light control

10 Z Horns.

11 Z Horns.

12 -N.C.

13 GV Right front side light

14 AR Brake light power supply

15 A Front and right side turn signal

16 GL Left front side light

17S -N.C.

18 RN Brake light control

CONNECTOR F

N.

No.

Wiring colour Circuit involved

1 HR Dipped beam control

2 -N.C.

3 LR Main beam control

4 -N.C.

5 G Side light power supply from ignition

Copyright by Fiat Auto 5

Page 136 of 330

Electrical system

Junction unit

Marea- Marea Weekend

2000 range ©

55. 55.

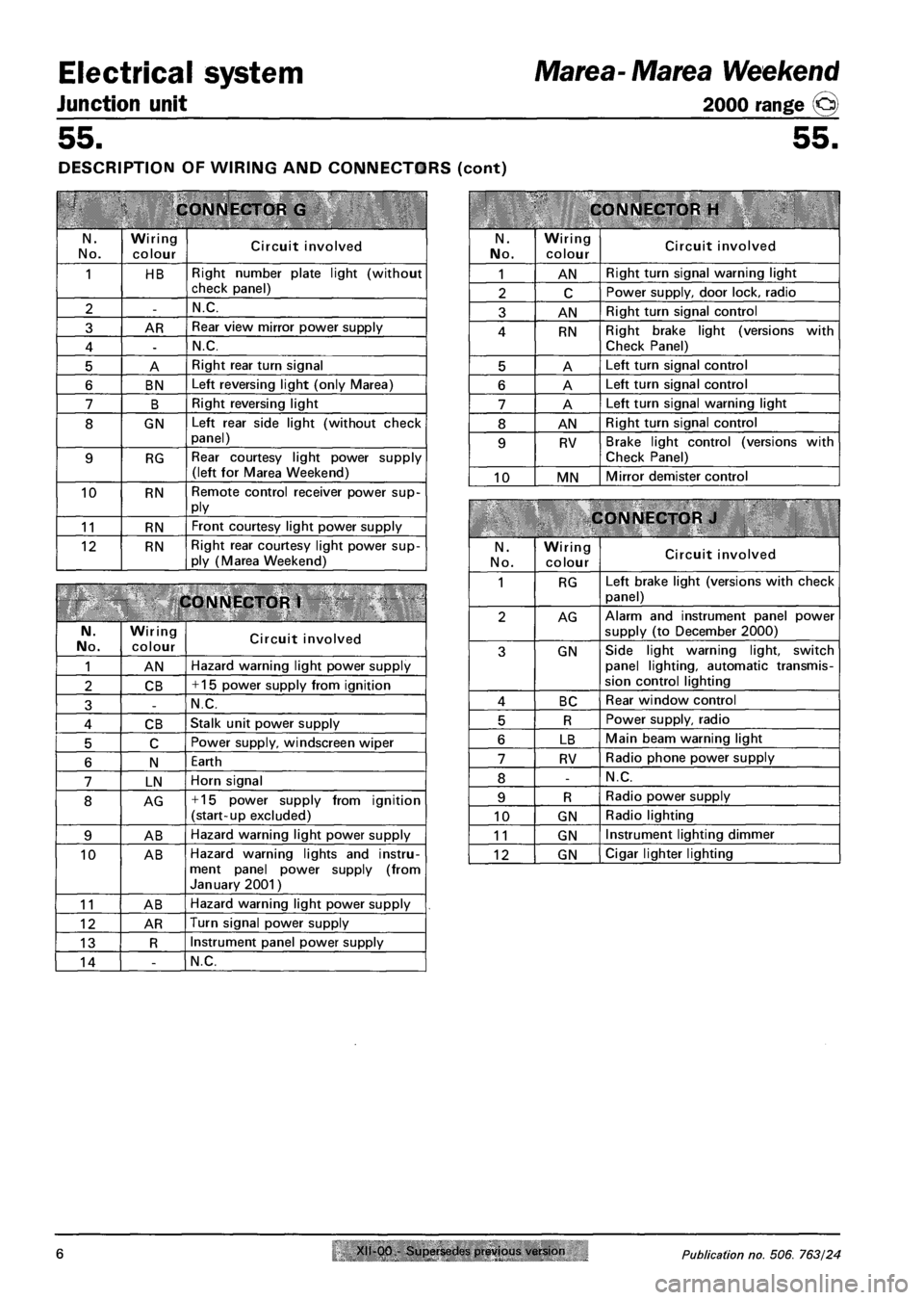

DESCRIPTION OF WIRING AND CONNECTORS (cont)

CONNECTOR G

N.

No.

Wiring

colour Circuit involved

1 HB Right number plate light (without check panel)

2 -N.C.

3 AR Rear view mirror power supply

4 -N.C.

5 A Right rear turn signal

6 BN Left reversing light (only Marea)

7 B Right reversing light

8 GN Left rear side light (without check panel)

9 RG Rear courtesy light power supply (left for Marea Weekend)

10 RN Remote control receiver power supply

11 RN Front courtesy light power supply

12 RN Right rear courtesy light power supply (Marea Weekend)

CONNECTOR 1

N. No. Wiring

colour Circuit involved

1 AN Hazard warning light power supply

2 CB + 15 power supply from ignition

3 -N.C.

4 CB Stalk unit power supply

5 C Power supply, windscreen wiper

6 N Earth

7 LN Horn signal

8 AG + 15 power supply from ignition (start-up excluded)

9 AB Hazard warning light power supply

10 AB Hazard warning lights and instrument panel power supply (from January 2001)

11 AB Hazard warning light power supply

12 AR Turn signal power supply

13 R Instrument panel power supply

14 -N.C.

CONNECTOR H

N.

No.

Wiring

colour Circuit involved

1 AN Right turn signal warning light

2 C Power supply, door lock, radio

3 AN Right turn signal control

4 RN Right brake light (versions with Check Panel)

5 A Left turn signal control

6 A Left turn signal control

7 A Left turn signal warning light

8 AN Right turn signal control

9 RV Brake light control (versions with

Check Panel)

10 MN Mirror demister control

CONNECTOR J

N.

No.

Wiring colour Circuit involved

1 RG Left brake light (versions with check

panel)

2 AG Alarm and instrument panel power

supply (to December 2000)

3 GN Side light warning light, switch panel lighting, automatic transmission control lighting

4 BC Rear window control

5 R Power supply, radio

6 LB Main beam warning light

7 RV Radio phone power supply

8 -N.C.

9 R Radio power supply

10 GN Radio lighting

11 GN Instrument lighting dimmer

12 GN Cigar lighter lighting

6 Publication no. 506. 763/24

Page 137 of 330

Marea-Marea Weekend Electrical system

2000 range @ Junction unit

55.

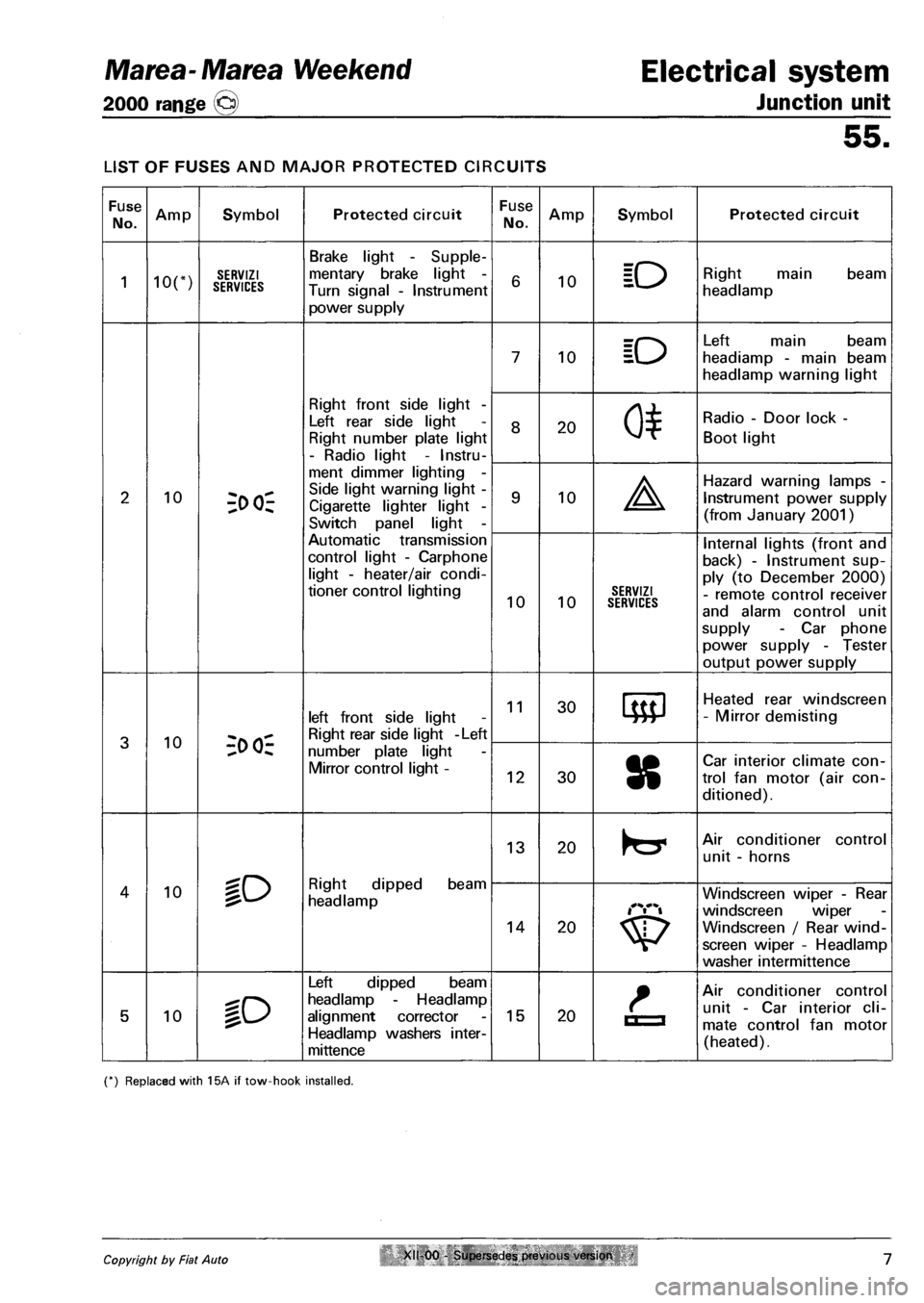

LIST OF FUSES AND MAJOR PROTECTED CIRCUITS

Fuse

No. Amp Symbol Protected circuit Fuse

No. Amp Symbol Protected circuit

1 ion SERVIZI SERVICES

Brake light - Supple

mentary brake light -

Turn signal - Instrument

power supply

6 10 ID Right main beam

headlamp

7 10 ID

Left main beam

headiamp - main beam

headlamp warning light

Right front side light -

Left rear side light

Right number plate light

- Radio light - Instru

8 20 0*

Radio - Door lock -

Boot light

2 10 3>

Side light warning light -

Cigarette lighter light -

Switch panel light -

9 10 A

Hazard warning lamps -

Instrument power supply

(from January 2001)

Automatic transmission

control light - Carphone

light - heater/air condi

tioner control lighting 10 10 SERVIZI SERVICES

Internal lights (front and

back) - Instrument sup

ply (to December 2000)

- remote control receiver

and alarm control unit

supply - Car phone

power supply - Tester

output power supply

3 10 -;o oi-

left front side light

Right rear side light -Left

11 30 Heated rear windscreen

- Mirror demisting

3 10 -;o oi-number plate light

Mirror control light -12 30 8

Car interior climate con

trol fan motor (air con

ditioned).

lO Right dipped beam

headlamp

13 20 Air conditioner control

unit - horns

4 10 lO Right dipped beam

headlamp

14 20

Windscreen wiper - Rear

windscreen wiper

Windscreen / Rear wind

screen wiper - Headlamp

washer intermittence

5 10 %o

Left dipped beam

headlamp - Headlamp

alignment corrector

Headlamp washers inter-

mittence

15 20 La

Air conditioner control

unit - Car interior cli

mate control fan motor

(heated).

(*) Replaced with 15A if tow-hook installed.

Copyright by Fiat Auto XII 00 - Supersedes previous version 7

Page 143 of 330

Marea- Marea Weekend

2000 range ©

Electrical equipment

Control module

55.

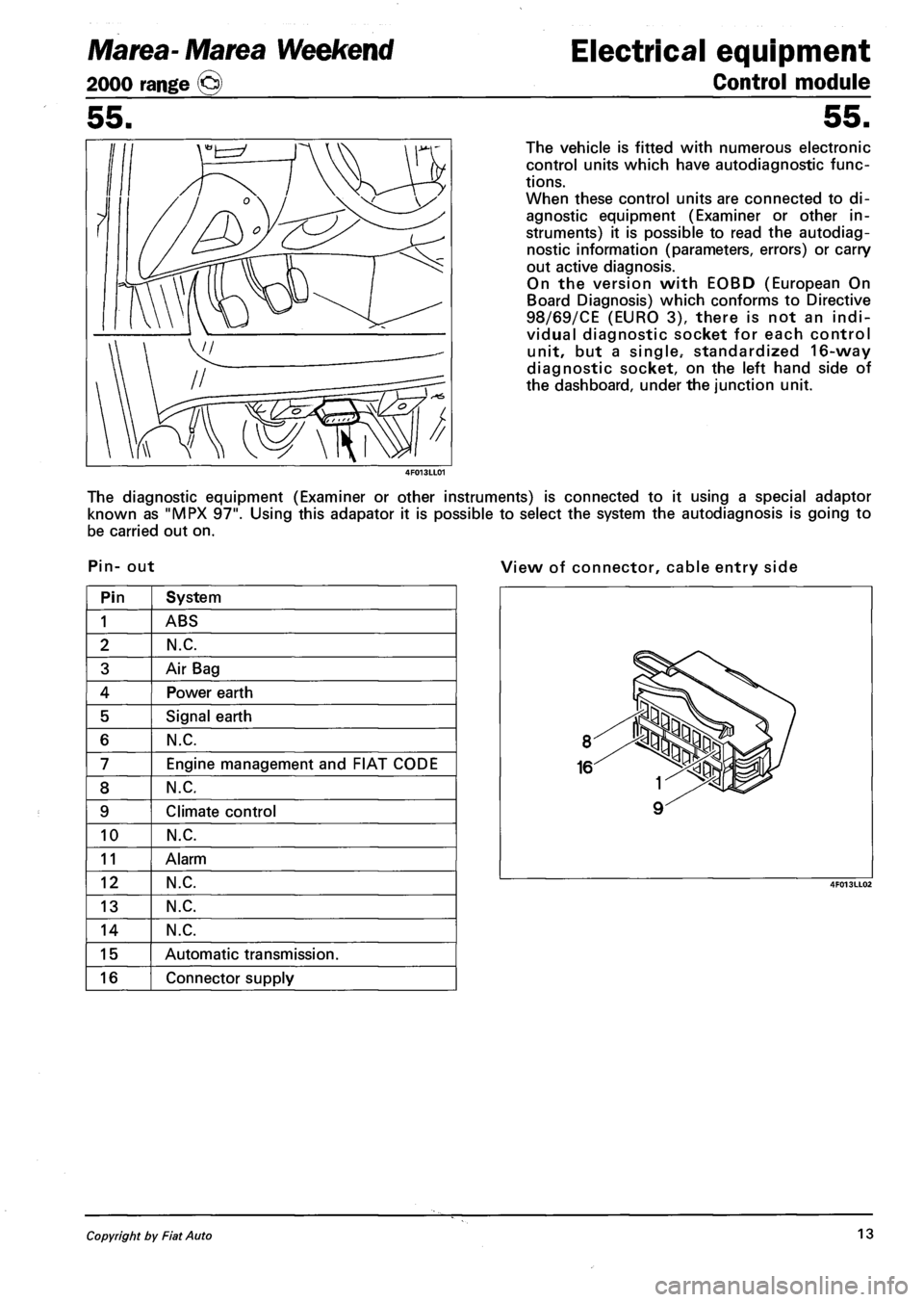

The vehicle is fitted with numerous electronic

control units which have autodiagnostic func

tions.

When these control units are connected to di

agnostic equipment (Examiner or other in

struments) it is possible to read the autodiag

nostic information (parameters, errors) or carry

out active diagnosis.

On the version with EOBD (European On

Board Diagnosis) which conforms to Directive

98/69/CE (EURO 3), there is not an indi

vidual diagnostic socket for each control

unit, but a single.- standardized 16-way

diagnostic socket, on the left hand side of

the dashboard, under the junction unit.

The diagnostic equipment (Examiner or other instruments) is connected to it using a special adaptor

known as "MPX 97". Using this adapator it is possible to select the system the autodiagnosis is going to

be carried out on.

Pin- out View of connector, cable entry side

Pin System

1 ABS

2 N.C.

3 Air Bag

4 Power earth

5 Signal earth

6 N.C.

7 Engine management and FIAT CODE

8 N.C.

9 Climate control

10 N.C.

11 Alarm

12 N.C.

13 N.C.

14 N.C.

15 Automatic transmission.

16 Connector supply

Copyright by Fiat Auto 13

Page 144 of 330

Electrical equipment

Instrument panel

Marea-Marea Weekend

2000 range ©

55.

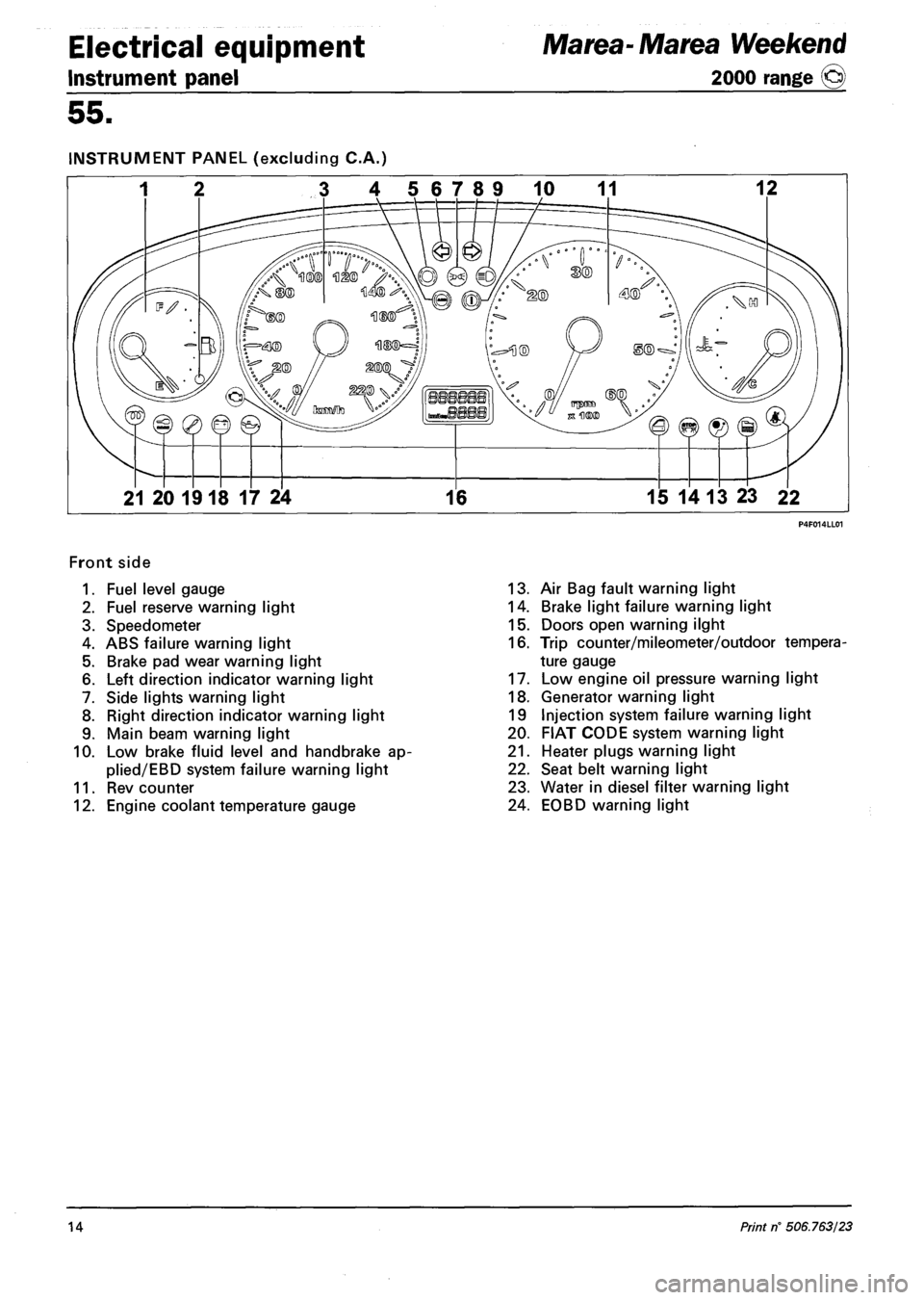

INSTRUMENT PANEL (excluding C.A.)

3 4 56789 10 11 12

21 20 1918 17 24 16 15 14 13 23 22

Front side

1. Fuel level gauge

2. Fuel reserve warning light

3. Speedometer

4. ABS failure warning light

5. Brake pad wear warning light

6. Left direction indicator warning light

7. Side lights warning light

8. Right direction indicator warning light

9. Main beam warning light

10. Low brake fluid level and handbrake ap-

plied/EBD system failure warning light

11. Rev counter

12. Engine coolant temperature gauge

13. Air Bag fault warning light

14. Brake light failure warning light

15. Doors open warning ilght

16. Trip counter/mileometer/outdoor tempera

ture gauge

17. Low engine oil pressure warning light

18. Generator warning light

19 Injection system failure warning light

20. FIAT CODE system warning light

21. Heater plugs warning light

22. Seat belt warning light

23. Water in diesel filter warning light

24. EOBD warning light

14 Print rf 506.763/23