diagram FIAT MAREA 2000 1.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2000, Model line: MAREA, Model: FIAT MAREA 2000 1.GPages: 330

Page 126 of 330

Marea- Marea Weekend

2000 range ©

Auxiliary Units

Climate control

50

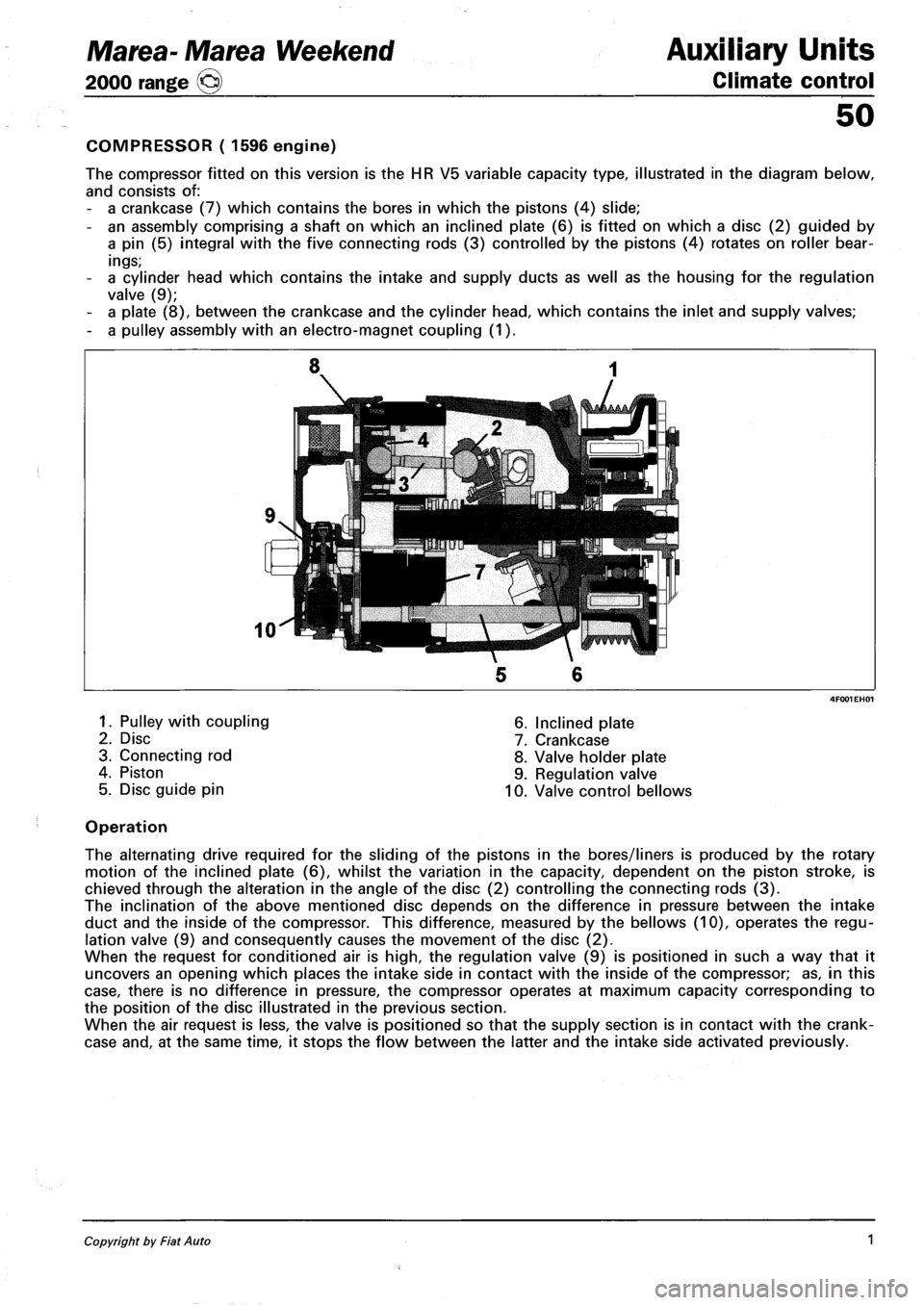

COMPRESSOR ( 1596 engine)

The compressor fitted on this version is the HR V5 variable capacity type, illustrated in the diagram below,

and consists of:

- a crankcase (7) which contains the bores in which the pistons (4) slide;

- an assembly comprising a shaft on which an inclined plate (6) is fitted on which a disc (2) guided by

a pin (5) integral with the five connecting rods (3) controlled by the pistons (4) rotates on roller bear

ings;

- a cylinder head which contains the intake and supply ducts as well as the housing for the regulation

valve (9);

- a plate (8), between the crankcase and the cylinder head, which contains the inlet and supply valves;

- a pulley assembly with an electro-magnet coupling (1).

1. Pulley with coupling

2. Disc

3. Connecting rod

4. Piston

5. Disc guide pin

6. Inclined plate

7. Crankcase

8. Valve holder plate

9. Regulation valve

10. Valve control bellows

Operation

The alternating drive required for the sliding of the pistons in the bores/liners is produced by the rotary

motion of the inclined plate (6), whilst the variation in the capacity, dependent on the piston stroke, is

chieved through the alteration in the angle of the disc (2) controlling the connecting rods (3).

The inclination of the above mentioned disc depends on the difference in pressure between the intake

duct and the inside of the compressor. This difference, measured by the bellows (10), operates the regu

lation valve (9) and consequently causes the movement of the disc (2).

When the request for conditioned air is high, the regulation valve (9) is positioned in such a way that it

uncovers an opening which places the intake side in contact with the inside of the compressor; as, in this

case, there is no difference in pressure, the compressor operates at maximum capacity corresponding to

the position of the disc illustrated in the previous section.

When the air request is less, the valve is positioned so that the supply section is in contact with the crank

case and, at the same time, it stops the flow between the latter and the intake side activated previously.

Copyright by Fiat Auto 1

Page 127 of 330

Auxiliary Units

Climate control

Marea-Marea Weekend

2000 range O

50

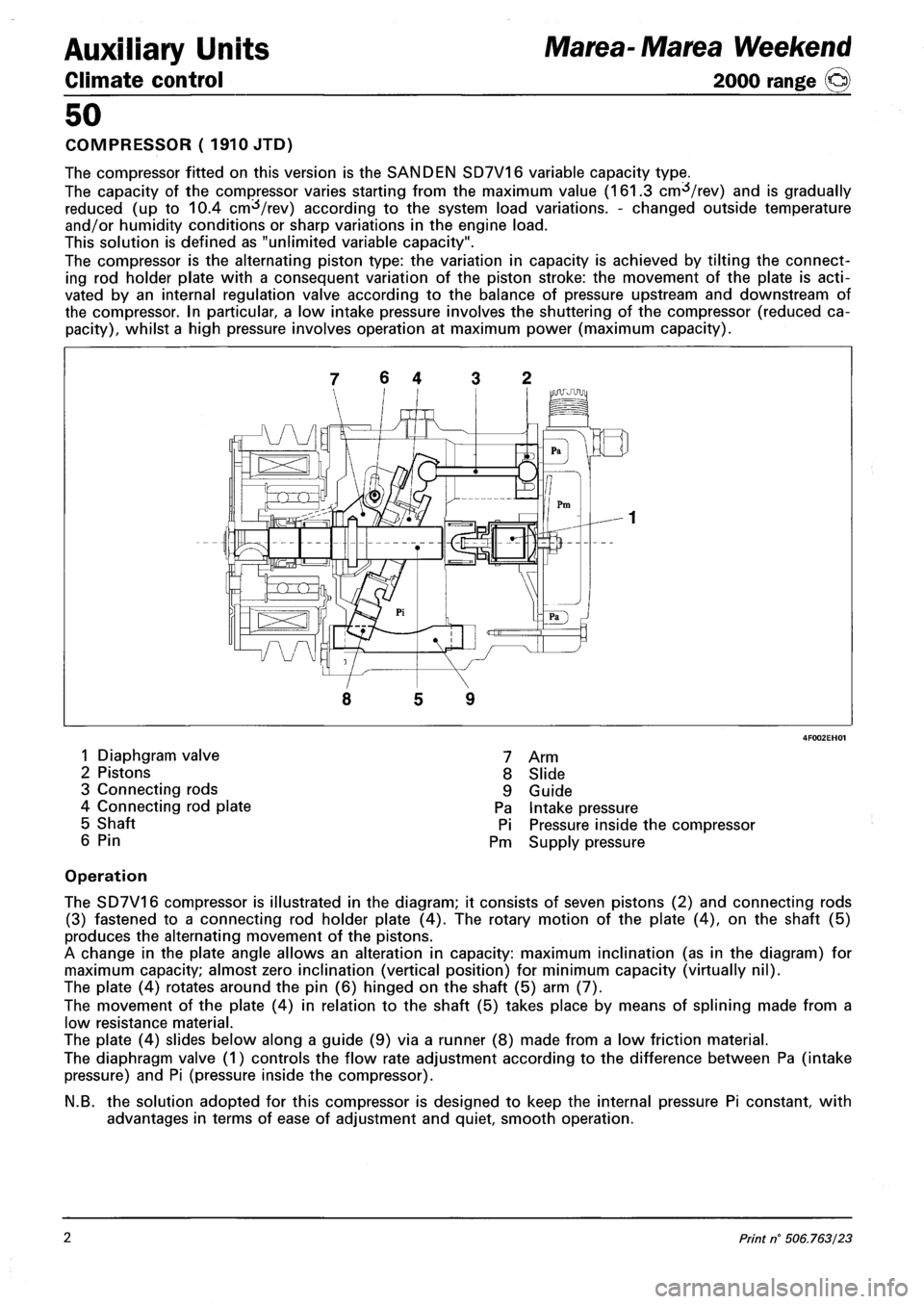

COMPRESSOR (1910 JTD)

The compressor fitted on this version is the SANDEN SD7V16 variable capacity type.

The capacity of the compressor varies starting from the maximum value (161.3 cm^/rev) and is gradually

reduced (up to 10.4 cm^/rev) according to the system load variations. - changed outside temperature

and/or humidity conditions or sharp variations in the engine load.

This solution is defined as "unlimited variable capacity".

The compressor is the alternating piston type: the variation in capacity is achieved by tilting the connect

ing rod holder plate with a consequent variation of the piston stroke: the movement of the plate is acti

vated by an internal regulation valve according to the balance of pressure upstream and downstream of

the compressor. In particular, a low intake pressure involves the shuttering of the compressor (reduced ca

pacity), whilst a high pressure involves operation at maximum power (maximum capacity).

7 6 4 3 2

5 9

1 Diaphgram valve

2 Pistons

3 Connecting rods

4 Connecting rod plate

5 Shaft

6 Pin

7 Arm

8 Slide

9 Guide

Pa Intake pressure

Pi Pressure inside the compressor

Pm Supply pressure

Operation

The SD7V16 compressor is illustrated in the diagram; it consists of seven pistons (2) and connecting rods

(3) fastened to a connecting rod holder plate (4). The rotary motion of the plate (4), on the shaft (5)

produces the alternating movement of the pistons.

A change in the plate angle allows an alteration in capacity: maximum inclination (as in the diagram) for

maximum capacity; almost zero inclination (vertical position) for minimum capacity (virtually nil).

The plate (4) rotates around the pin (6) hinged on the shaft (5) arm (7).

The movement of the plate (4) in relation to the shaft (5) takes place by means of splining made from a

low resistance material.

The plate (4) slides below along a guide (9) via a runner (8) made from a low friction material.

The diaphragm valve (1) controls the flow rate adjustment according to the difference between Pa (intake

pressure) and Pi (pressure inside the compressor).

N.B. the solution adopted for this compressor is designed to keep the internal pressure Pi constant, with

advantages in terms of ease of adjustment and quiet, smooth operation.

2 Print n° 506.763/23

Page 132 of 330

Electrical equipment

Protection and safety devices

Marea- Marea Weekend

2000 range ©)

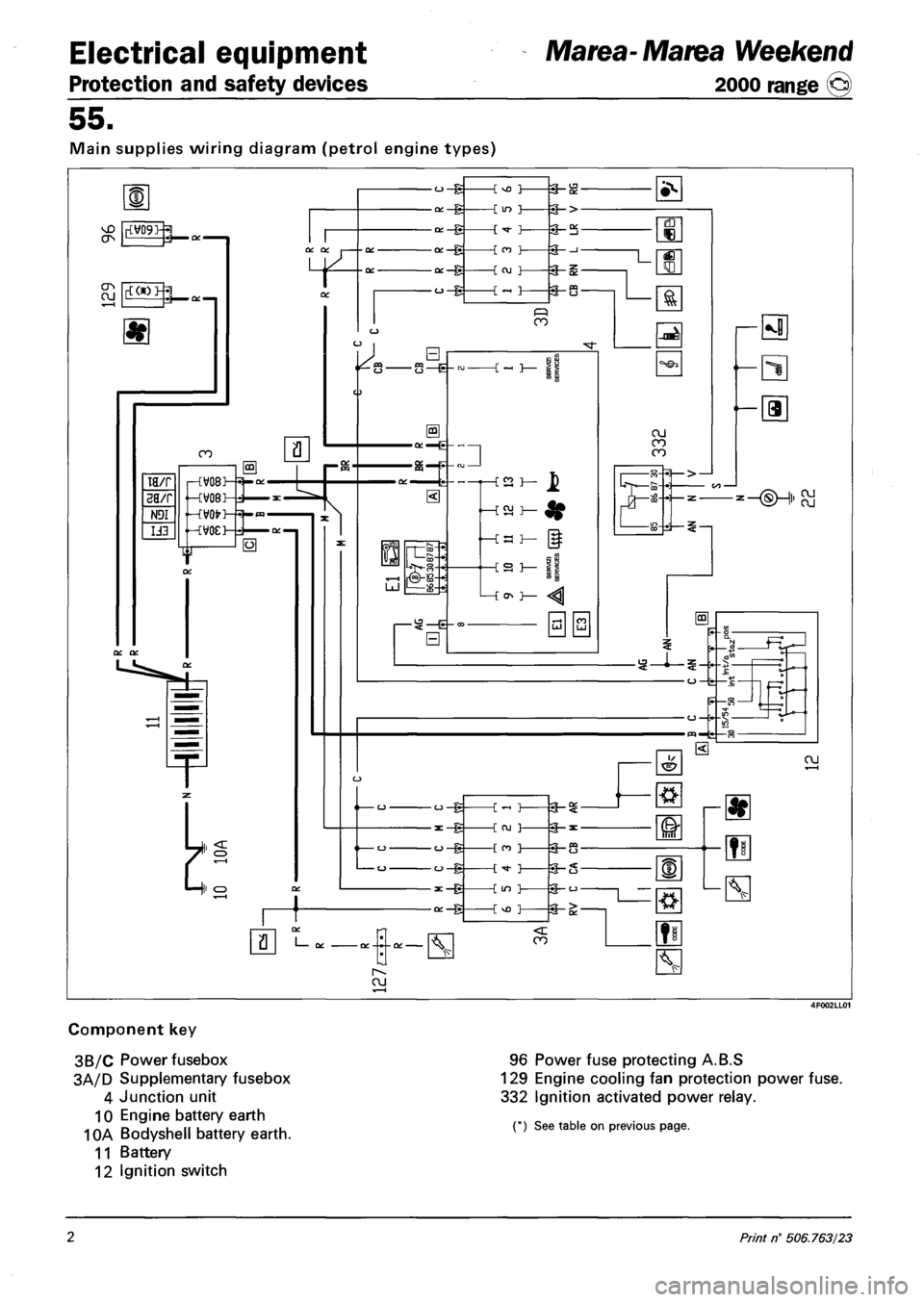

55.

Main supplies wiring diagram (petrol engine types)

Component key

3B/C Power fusebox

3A/D Supplementary fusebox

4 Junction unit

10 Engine battery earth

10A Bodyshell battery earth.

11 Battery

12 Ignition switch

96 Power fuse protecting A.B.S

129 Engine cooling fan protection power fuse.

332 Ignition activated power relay.

(*) See table on previous page.

2 Print n° 506.763/23

Page 133 of 330

Marea- Marea Weekend

2000 range ©)

Electrical equipment

Protection and safety devices

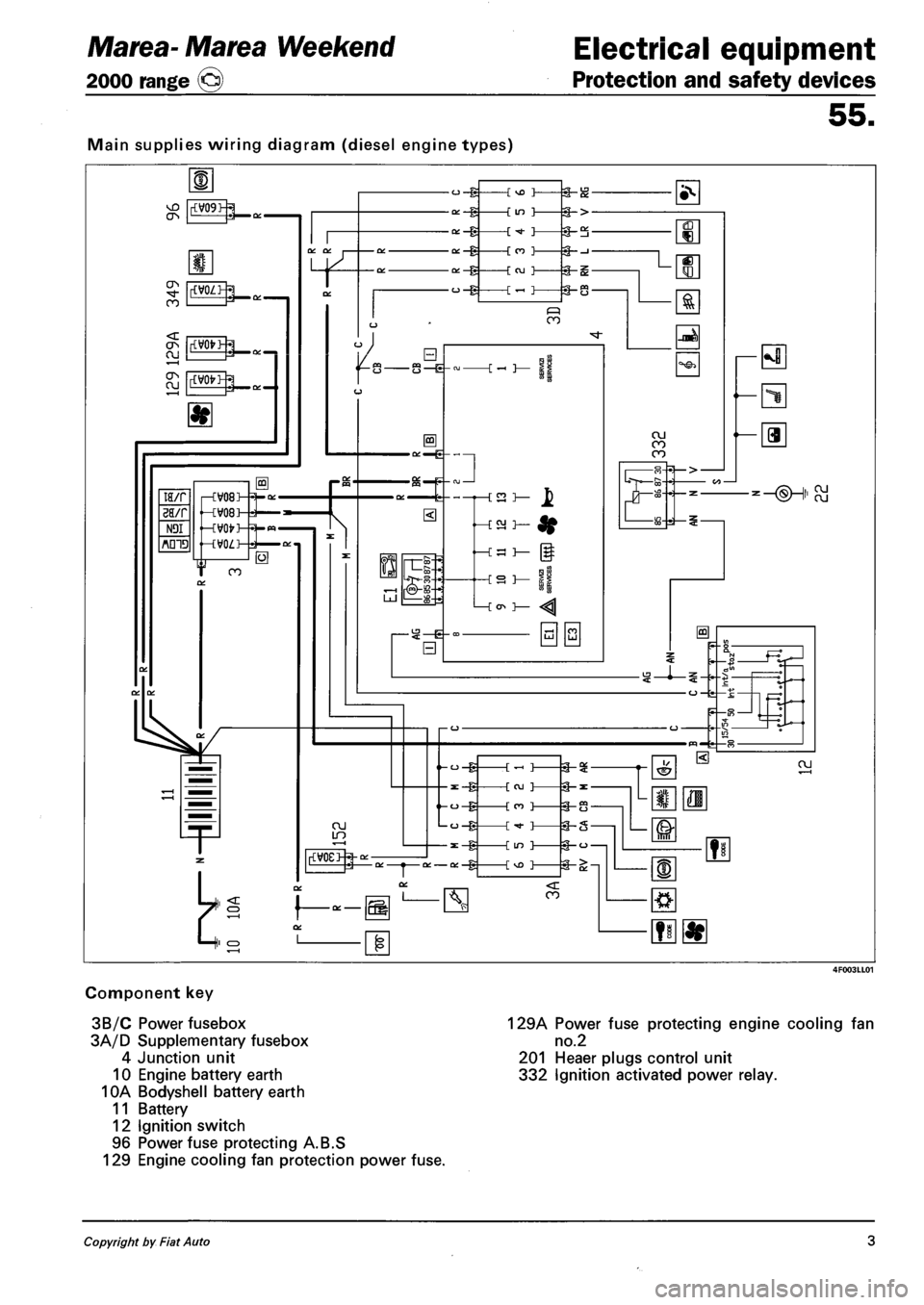

55.

Main supplies wiring diagram (diesel engine types)

Component key

3B/C Power fusebox

3A/D Supplementary fusebox

4 Junction unit

10 Engine battery earth

10A Bodyshell battery earth

11 Battery

12 Ignition switch

96 Power fuse protecting A.B.S

129 Engine cooling fan protection power fuse.

129A Power fuse protecting engine cooling fan

no.2

201 Heaer plugs control unit

332 Ignition activated power relay.

Copyright by Fiat Auto 3

Page 134 of 330

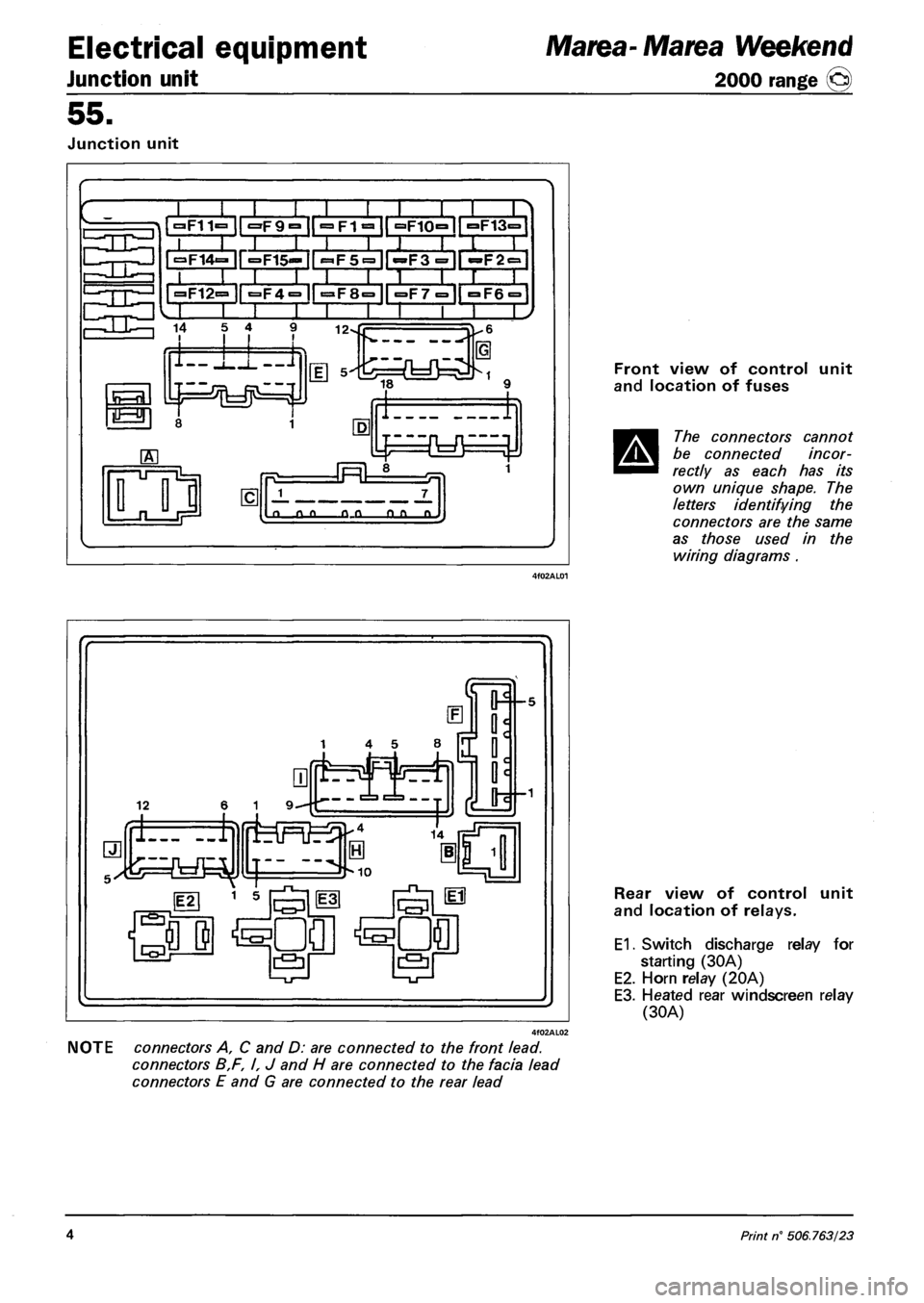

Electrical equipment

Junction unit

Marea-Marea Weekend

2000 range ©

55.

Junction unit

»F11=

~T~ II l;

•F9° |["^FT^1| °F10°ir°F13=

| ^14=- ir=F15«=- II

»F12=

SLHHItHia r i i i •

3F4= ir^F8=1l =F7="|| °F6 = 1

I I I I I 1 I '

14 5 4 12-

lor

1-11-J

I 1

J 7_

a o_o o_o OLD n.

Front view of control unit

and location of fuses

The connectors cannot

be connected incor

rectly as each has its

own unique shape. The

letters identifying the

connectors are the same

as those used in the

wiring diagrams .

NOTE connectors A, C and D: are connected to the front lead.

connectors B,F, I, J and H are connected to the facia lead

connectors E and G are connected to the rear lead

Rear view of control unit

and location of relays.

E1. Switch discharge relay for

starting (30A)

E2. Horn relay (20A)

E3. Heated rear windscreen relay

(30A)

4 Print n° 506.763/23

Page 145 of 330

Marea- Marea Weekend

2000 range ©

Electrical equipment

Control module

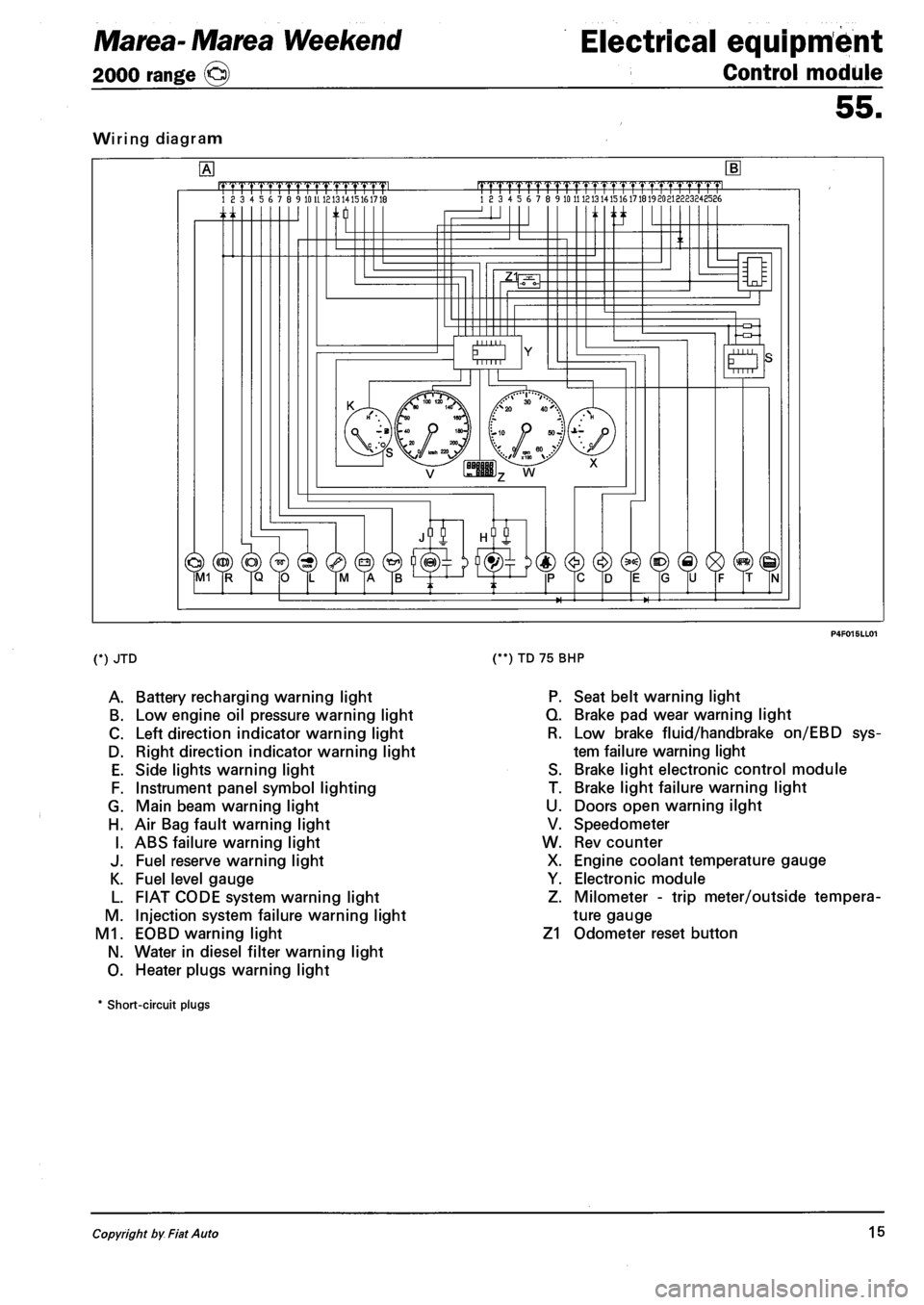

55.

Wiring diagram

.mrmmmL 18 3 4 5 6 7 8 9 10 U 1213 1415161718 |TTTTrTrrrrTTTTT1.TTTTT1pmL 18 3 4 5 6 7 8 9 10 11 121314151617181920213223248586

n ti

O Mill

(*) JTD

A. Battery recharging warning light

B. Low engine oil pressure warning light

C. Left direction indicator warning light

D. Right direction indicator warning light

E. Side lights warning light

F. Instrument panel symbol lighting

G. Main beam warning light

H. Air Bag fault warning light

I. ABS failure warning light

J. Fuel reserve warning light

K. Fuel level gauge

L. FIAT CODE system warning light

M. Injection system failure warning light

M1. EOBD warning light

N. Water in diesel filter warning light

O. Heater plugs warning light

(**) TD 75 BHP

P. Seat belt warning light

Q. Brake pad wear warning light

R. Low brake fluid/handbrake on/EBD sys

tem failure warning light

S. Brake light electronic control module

T. Brake light failure warning light

U. Doors open warning ilght

V. Speedometer

W. Rev counter

X. Engine coolant temperature gauge

Y. Electronic module

Z. Milometer - trip meter/outside tempera

ture gauge

Z1 Odometer reset button

* Short-circuit plugs

Copyright by Fiat Auto 15

Page 183 of 330

Marea-Marea Weekend

2000 range ©

Electrical equipment

Index

Electrical symbols

Explanation for reading wiring diagram

Wiring diagrams

Connector block

Key

55.

page

1

4

5

82

141

Copyright by Fiat Auto

Page 184 of 330

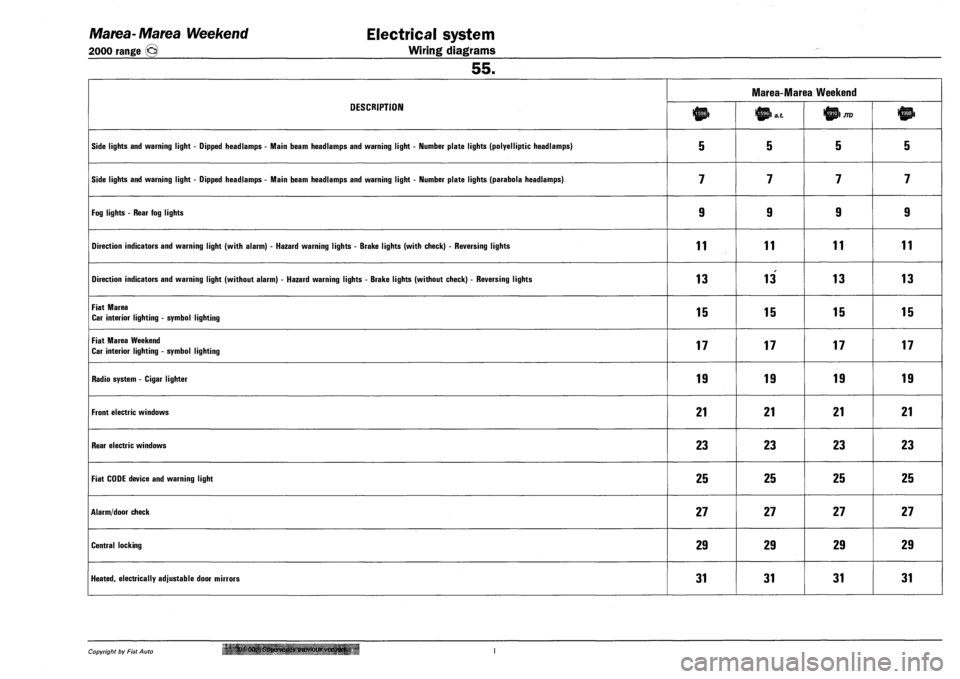

Marea-Marea Weekend Electrical system

2000 range ©> Wiring diagrams

55.

DESCRIPTION

Marea-Marea Weekend

DESCRIPTION JTD

SIDE LIGHTS AND WARNING LIGHT - DIPPED HEADLAMPS - MAIN BEAM HEADLAMPS AND WARNING LIGHT - NUMBER PLATE LIGHTS (POLYELLIPTIC HEADLAMPS) 5 5 5 5

SIDE LIGHTS AND WARNING LIGHT - DIPPED HEADLAMPS - MAIN BEAM HEADLAMPS AND WARNING LIGHT - NUMBER PLATE LIGHTS (PARABOLA HEADLAMPS) 7 7 7 7

FOG LIGHTS - REAR FOG LIGHTS 9 9 9 9

DIRECTION INDICATORS AND WARNING LIGHT (WITH ALARM) - HAZARD WARNING LIGHTS - BRAKE LIGHTS (WITH CHECK) - REVERSING LIGHTS 11 11 11 11

DIRECTION INDICATORS AND WARNING LIGHT (WITHOUT ALARM) - HAZARD WARNING LIGHTS - BRAKE LIGHTS (WITHOUT CHECK) - REVERSING LIGHTS 13 13 13 13

FIAT MAREA

CAR INTERIOR LIGHTING - SYMBOL LIGHTING 15 15 15 15

FIAT MAREA WEEKEND

CAR INTERIOR LIGHTING - SYMBOL LIGHTING 17 17 17 17

RADIO SYSTEM - CIGAR LIGHTER 19 19 19 19

FRONT ELECTRIC WINDOWS 21 21 21 21

REAR ELECTRIC WINDOWS 23 23 23 23

FIAT CODE DEVICE AND WARNING LIGHT 25 25 25 25

ALARM/DOOR CHECK 27 27 27 27

CENTRAL LOCKING 29 29 29 29

HEATED, ELECTRICALLY ADJUSTABLE DOOR MIRRORS 31 31 31 31

Copyright by Fiat Auto '' XI Supersedes previous verster*.

Page 185 of 330

Electrical system Marea-Marea Weekend

Wiring diagrams 2000 range (jcj)

55.

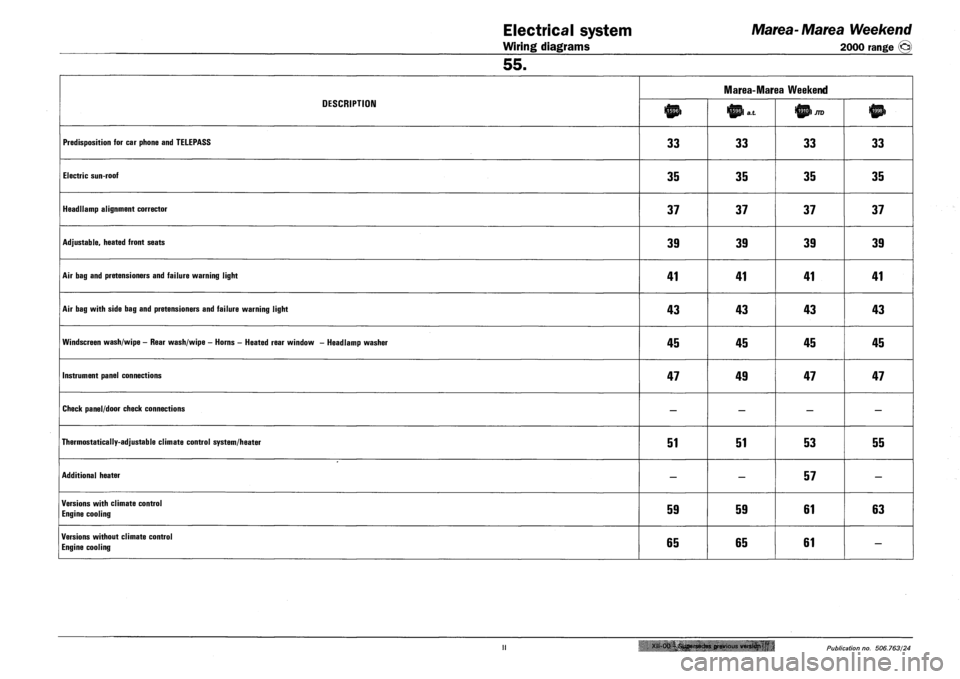

DESCRIPTION

Marea-Marea Weekend

DESCRIPTION lnp> Ittpl a.t

PREDISPOSITION FOR CAR PHONE AND TELEPASS 33 33 33 33

ELECTRIC SUN-ROOF 35 35 35 35

HEADLLAMP ALIGNMENT CORRECTOR 37 37 37 37

ADJUSTABLE, HEATED FRONT SEATS 39 39 39 39

AIR BAG AND PRETENSIONERS AND FAILURE WARNING LIGHT 41 41 41 41

AIR BAG WITH SIDE BAG AND PRETENSIONERS AND FAILURE WARNING LIGHT 43 43 43 43

WINDSCREEN WASH/WIPE - REAR WASH/WIPE - HORNS - HEATED REAR WINDOW - HEADLAMP WASHER 45 45 45 45

INSTRUMENT PANEL CONNECTIONS 47 49 47 47

CHECK PANEL/DOOR CHECK CONNECTIONS — — — —

THERMOSTATICALLY-ADJUSTABLE CLIMATE CONTROL SYSTEM/HEATER 51 51 53 55

ADDITIONAL HEATER — — 57 —

VERSIONS WITH CLIMATE CONTROL

ENGINE COOLING 59 59 61 63

VERSIONS WITHOUT CLIMATE CONTROL

ENGINE COOLING 65 65 61 —

Xll-Oa-i.Supersedes previous version 'u • Publication no. 506.763/24

Page 186 of 330

Marea-Marea Weekend Electrical equipment

2000 range (§) Wiring diagrams

55.

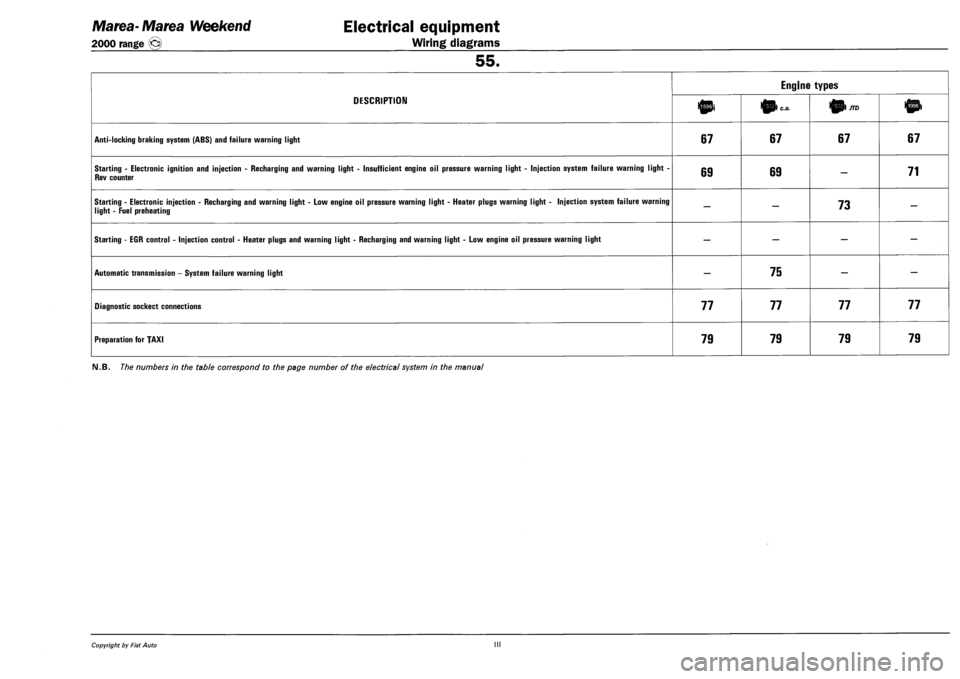

DESCRIPTION

Engine types

DESCRIPTION 10i 0) c.a. 01/70

ANTI-LOCKING BRAKING SYSTEM (ABS) AND FAILURE WARNING LIGHT 67 67 67 67

STARTING - ELECTRONIC IGNITION AND INJECTION - RECHARGING AND WARNING LIGHT - INSUFFICIENT ENGINE OIL PRESSURE WARNING LIGHT - INJECTION SYSTEM FAILURE WARNING LIGHT -

REV COUNTER 69 69 — 71

STARTING - ELECTRONIC INJECTION - RECHARGING AND WARNING LIGHT - LOW ENGINE OIL PRESSURE WARNING LIGHT - HEATER PLUGS WARNING LIGHT - INJECTION SYSTEM FAILURE WARNING

LIGHT - FUEL PREHEATING — — 73 —

STARTING - EGR CONTROL - INJECTION CONTROL - HEATER PLUGS AND WARNING LIGHT - RECHARGING AND WARNING LIGHT - LOW ENGINE OIL PRESSURE WARNING LIGHT — — — —

AUTOMATIC TRANSMISSION - SYSTEM FAILURE WARNING LIGHT — 75 — —

DIAGNOSTIC SOCKECT CONNECTIONS 77 77 77 77

PREPARATION FOR TAXI 79 79 79 79

FM.B. The numbers in the table correspond to the page number of the electrical system in the manual

Copyright by Fiat Auto III